2 3

IMPORTANT SAFETY INSTRUCTIONS

Recommendation:

For the installation of the equipment, it is important that the specialized installer follow all instructions given in this TECHNICAL MANUAL

and USER MANUAL.

With the USER MANUAL, the installer must provide all the information, and uses the user equipment safety items.

Before using the GIRO SOCIAL DOOR OPERATOR, read and follow

all instructions contained in this manual carefully.

- Before installing the operator system, make sure that the local electrical network is compatible with the one required on the equipment

identification label. Connect the power cord only into outlets connected to the ground network;

- Do not connect the mains until installation / maintenance is complete. Make the electrical connections of the board always turning off

the electrical network;

- After installation, make sure that the door parts do not extend

through the roads and public walkway;

- Under no circumstances, remove the grounding pin from the power

plug. Do not use adapters that eliminate this ground connection. It is

mandatory to use the ground pin.

INDEX

Important Safety Instructions ...............................................................................................3

Tools needed for installation .................................................................................................4

Electrical installation .............................................................................................................4

Care with electrical installation .............................................................................................5

Technical characteristics ......................................................................................................6

Installing and fixing the operator ..........................................................................................7

Arm fixing ..................................................................................................................7

Fixing the operator to the wall ...................................................................................7

Fixing the guide to the door ......................................................................................9

Radar ........................................................................................................................9

Photocell .................................................................................................................13

Closing the operator cover .....................................................................................14

Maintenance .......................................................................................................................15

Defects, Probable causes, and Corrections ...........................................................15

Inverter command to the board ..........................................................................................16

Board inverter installation .......................................................................................16

First drive of the inverter after being installed on the door

automatic (memorization) .......................................................................................16

From the second drive on .......................................................................................17

Quick guide for programming the frequency inverter.............................................17

Photocell incorporated ............................................................................................21

Encoder Test ...........................................................................................................21

STS Jumper .............................................................................................................22

Event and fault signaling .........................................................................................22

Decimal point functions of the inverter displays when the

Operator is operating ..............................................................................................22

Possible errors and defects ....................................................................................23

4 5

TOOLS NEEDED FOR INSTALLATION

Here are some tools needed to install the operator:

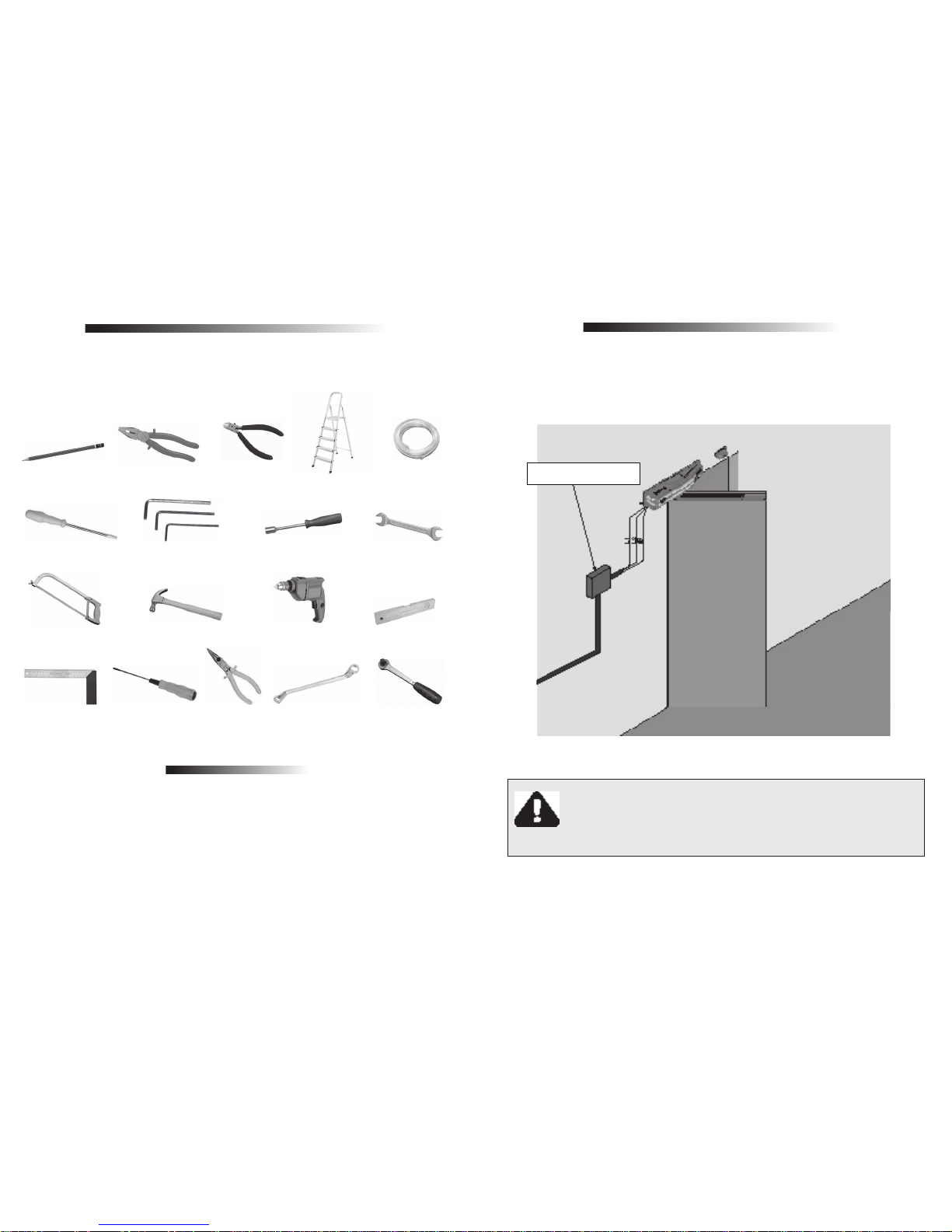

ELECTRICAL INSTALLATION

For electrical installation, the network shall contain the following characteristics:

- Electric network 127V or 220V;

- Have 5A circuit breakers in the electrical distribution box;

- 3/4 "diameter conduit between the electrical distribution box and the total disconnect device;

- 3/4 "diameter conduit between the total turn off device and the operator connection point;

- Conduits 1/2 "in diameter and optional external buttonhole;

- 1/2 "diameter conduit for safety photocells (required).

PENCIL

SCREWDRIVER

SAWING BOW

FRAME

UNIVERSAL

PLIERS

ALLEN KEY

3, 4 e 6mm

HAMMER

PHILIPS KEY

CUTTING

PLIERS

HAMMER

SOCKET WRENCH

10mm

DRILL

SCREWDRIVE STAR

NEEDLE-

NOSED PLIERS

NUT WRENCH 10,

13, 22 e 28mm

COMMON LEVEL

HOSE LEVEL

LADDER

RATCHET SCREWDRIVER

CARE WITH THE ELECTRICAL INSTALLATION

To avoid damage to the wiring, it is important that all conductors be properly fixed

to the operator. Wiring must be done through conduits, passing internally through

the base of the floor, ensuring that none of the wiring conductors are trapped and

damaged.

IMPORTANT

The device must be powered by a residual current (DR) device with a

rated residual current of more than 30 mA

.

TURN OFF MEANS

6 7

INSTALLING AND FIXING THE OPERATOR

ARM FIXING

Fixed the articulated arm to the gear motor shaft and, using an Allen wrench, secure with the screw that comes with the kit.

FIXING THE OPERATOR TO THE WALL

Secure the operator so that the steel base is aligned with the door hinge.

PARAMETER AND TECHNICAL CHARACTERISTICS

OPERATOR TYPE PIVOTING PIVOTING

RATED VOLTAGE 220 V 220 V

NOMINAL FREQUENCY 60 Hz 50 Hz

RATED POWER 150 W 150 W

MOTOR ROTATION 3492 rpm 2910 rpm

NOMINAL CHAIN 1,2 A 1,2 A

REDUCTION 1:111,5 1:111,5

LINEAR SPEED 1,2 m/minute 1,2 m/minute

OPERATIONS 240 Continuous cycles 240 Continuous

cycles

DEGREE OF PROTECTION IPX 0 IPX 0

RAIL Aluminum Aluminum

TEMPERATURE RANGE

-5°C

+50 °C

-5°C

+50 °C

GEARMOTOR SHAFT

TECHNICAL CHARACTERISTICS

ARTICULATED ARM

ALIGNED

FIXING SCREW

ARTICULATED ARM

8 9

If the door is an internal opening, secure the operator so that the drive arm is

slightly above the top of the door leaf.

If the door is an external opening, secure the operator so that the drive arm is

below the top of the door leaf.

FIXING THE GUIDE TO THE DOOR

After fixing the operator to the drive arm, secure the aluminum guide to the door so

that the drive arm does not extend beyond the limit and do not move off the guide

(fixe the aluminum guide in the center of the door).

NOTE: Check manually whether the door opens and closes properly without friction.

RADAR

Radar is a sensor that drives the automatic door when an object approaches its

detection radius.

Technical specifications

- Supply voltage: 12 to 24 VDC / 12 to 18 VAC

- Voltage and current in the relay contacts: 200 V / 0.5 A

- Frequency emitted: 24,125 GHz

- Maximum installation height: approximately 3.5 m

- Adjustment angles: 0 to 90º vertical and -45 to 45º horizontal

THE DRIVE ARM MUST BE

ABOVE THE TOP OF THE LEAF.

ALUMINUM GUIDE

THE DRIVE ARM MUST BE BELOW

THE TOP OF THE LEAF.

10 11

- Detection area: - long - narrow

Knowing the board

Installation mode

1. Fix the radar in the desired place and connect the power cord (red and brown

are power supply and yellow and orange are the contacts of the relay).

2. Adjust the sensitivity through the P1 trimpot.

3. Adjust the direction of the detection area through the mechanical positioning of

the antenna. For wide detection area, install the antenna upright (connector up).

For narrow detection area, install the antenna in the horizontal position (connector

to the right).

Connector up = long detection Connector to the right = narrow detectio

NOTE

To reverse the position of the antenna, push

the locks in opposite direction from each other,

remove the board and fit it back into the desired

position (figure on the side). Pay attention to the

correct position of the connector. The side with

the arrow should always be facing the outside of

the board (figure on the side).

Dip switch setting

Key 1 sets the state of the relay: ON = NF and OFF = NA.

Key 2 sets the pulse time retention shot: ON = 2 seconds and OFF = 0,5 seconds.

Key 3 sets the mode of immunity: ON = high immunity and OFF = normal immunity.

NOTE

Set up with high immunity in environments where rain or other light movement may

occur in front of the sensor to prevent false shots. This setting makes the sensor

"slower".

Observations:

- Do not touch the surface area of the antenna, as it is sensitive to small electrostatic

discharges.

- Do not install the sensor in places where plant movements or other objects may

occur.

- Do not install the sensor near fluorescent bulbs as they may cause interference.

- Do not install in places where vibration may occur.

- Ensure good sensor fixing to prevent false shots.

Dip Switch setting /

Trimpot P1 for sen-

sitivity adjustment

/ In this connector,

the side with the arrow should face up.

/ Detection Antenna.

Antenna locking

latches

This side out

12 13

Wiring diagram in the Command Board - Radar

PHOTOCELL

Fixing and connecting the photocell

1. Pass a 4-way cable going from the TX to the board, passing through the rail and

fastened with cable ties.

2. Pass a 4-way cable going from RX to the board, passing through the rail and

fastened with cable ties.

The command for the activation of the photocell must be made by an NF (Normally

Closed) contact, that is, for the board to receive a photocell command, the

connection between PHOTO and GND of the CN6 connector.

Precautions

-Do not install the receiver directly facing the sun;

- Make sure that the side that has the output of the wires is positioned downwards;

Fixing the radar on the cover

Fit and fix the radar stand near the Giro operator.

PHOTO / RADAR / EXTERNAL RADAR / INTERNAL RADAR /

Internal (polarized) connector / Gray Cable

RADAR

14 15

Photocell connection

CLOSING THE OPERATOR COVER

After all connections and adjustments have been made, fit the board cover,

close the operator cover and fixed it with 2 screws M5 x 10 .

MAINTENANCE

Before any Maintenance, remove the power cord from the electrical

network.

DEFECTS, POSSIBLE CAUSES AND CORRECTIONS

It will mention some DEFECTS, PROBABLE CAUSES AND CORRECTIONS, which

may occur in your operator, in case you need to occur Maintenance.

INVERTER COMMAND TO THE BOARD

DEFECTS PROVáVEIS CAUSAS CORREçõES

Door opening and closing

alone

-Dirt in the rail.

-Dirt in the door guide.

-Radar unregulated, is

picking up the movement

of the leaf.

-Clean the rail.

-Clean the door guide.

--Regular sensitivity of the

radar.

Door slowly opening - Lack of electricity.

--Drive the radar on and

wait for the door to open

and close slowly.

Door opened and did not

close

Blocked photocell. -Unblocked the photocell.

TRANSMITTER

PHOTOCELL

RECEIVING

PHOTOCELL

SCREW M5 X 10

16 17

INVERTER BOARD INSTALLATION

The electrical connections of the board must be made according to the diagram

contained in this manual.

When the automatic door has an electromagnetic lock, or garage light, a relay

module must be connected to "LOCK" and / or "LIGHT" (optional, separate sale).

To adapt a single receiver, simply connect it to "RECEIVER" (optional). The motor

is connected to the "MOTOR" terminal.

The mains voltage is connected to the "NETWORK" terminal and must be either

127Vac or 220Vac according to the "CH1" voltage selection switch and the

frequency according to the requested transformer in the inverter (60Hz or 50Hz).

The CN4 has a 15V (450mA) power supply to power the radars and the photocell

as well as the input for radar command and photocell command. The radar

command is a normally open contact, that is, for the board to receive a command,

you must connect RADAR1 or RADAR2 to the GND.

The photocell PHOTO command on the CN4 connector must be a normally closed

command, that is, for the board to receive a photocell command, the PHOTO of

the GND must be disconnected.

FIRST DRIVE OF THE INVERTER AFTER BEING INSTALLED ON THE

AUTOMATIC DOOR (MEMORIZATION)

WARNING: Before any drive, make sure that the door model selected in the

inverting unit is the same port that is installed (F9 function, see Table 2).

The photocell PHOTO command on the CN4 connector must be a normally closed

command, ie for the board to receive a photocell command; the PHOTO of the

GND must be disconnected. If no photocell is used, a jumper between PHOTO

and GND must be connected. (Optional / replacement).

After the inverter is energized for the first time, start the motor by pressing the OK

button or by a command on RADAR1 or RADAR2 or RECEIVER. The door should

initiate an opening movement, for better visualization of the movement leave it in

the middle of the opening path. If the door starts a closing movement, remove the

F / R jumper, wait two seconds (2s), and then start the engine again. Note that the

board will change the direction of the motor. The door should start the opening

movement.

After this condition, leave the door open until it stops at the opening stop. Then it

will reverse the direction to close, let it lean against the closing stop. The automatic

door is now ready to operate.

Note: During closing in the storage period, only one photocell command can

revert the door.

FROM THE SECOND DRIVE ON

After memorizing, the door need not record the route again. On a new power-up,

it will simply open slowly until it stops at the opening stop. Ready! The door is now

ready to operate.

QUICK GUIDE FOR FREQUENCY INVERTER PROGRAMMING

The inverter already comes with factory-set parameters, but the user can modify

them if he deems it necessary. To do this, press and hold the SHIFT key (+) until

the display shows F01, you can now release the key. Ready, the user has already

entered the programming mode. The programming menu has twenty-six functions

(26) functions described in the table below:

CODE

PRINTED

ON

DISPLAY

FUNCTION

F01 Semi-automatic mode or pause time in automatic mode.

F02 Operation with lock or without lock.

F03 Time the garage light stays on after the door is closed.

F04 Reset recorded route.

F05 Opening speed.

F06 Closing speed.

F07 Opening limit switch.

18 19

CODE

PRINTED

ON DISPLAY

FUNCTION

F08 Closing limit switch.

F09 Door model (Bona, Flash, Tore, Avanti, Replacement and Pivoting).

F10 Sensibility of anti-smashing at closing (force at closing).

F11 Enables or disables Anti Panic.

F12 Function to choose whether the door should stop when there is na anti panic signal

or if should open at a slower speed.

F13 Filter time for photocell command input and “Radar 1”.

F14 Limit switch speed.

F15 Applies the factory settings.

F16 Deceleration at closing.

F17 Reserved.

F18 Anti panic opening speed.

F19 Forçe during opening.

F20 Closing limit switch force (closing ensure).

F21 Enables or disables “Anti-wind” function (more used in the pivoting model).

F22 Acceleration / deceleration at opening.

F23 On/Off Pulse on the closing lock.

F24 Enable inver ted pause.

F25 Wait time to start the engine after the lock has been activated.

F26 On/Off automatic opening when the door is manually moved in the opening

direction

Out Exit the programming menu.

To navigate through the programming menu, simply press the SHIFT (+) button

to incremented or (-) button to decrease until find the desired function, and then

press OK to enter the function. Each function has own specific settings that can

be changed by the SHIFT (+) button or (-) button.

When finish changing, press OK again and then the value is saved and the menu

returns to the functions and can navigate through again.

See the table below for the meaning of each existing configuration for the functions.

FUNCTION

EXISTING CONFIGURATION

FOR THIS FUNCTION

MEANING OF CONFIGURATION

F01 Sau/t00 to t99

Semi-automatic mode (SA) or pause time in seconds

[s].

F02 tof or t01 to t99

Disables the operation of electromagnetic lock (tof) or

enable locking and the activation time of it (t01 to t99)

in milliseconds, t01 = 0,1s.

F03 t00 to t99

Time the garage light comes on after the door is

closed (time in seconds [s]).

F04 rst or nrt Delete the route (rst) or do not delete the route (nrt).

F05

001 to 060 for Tore and

Replacement models, up to

090 for the Flash and Bona

models.

Opening speed, 001 to 090 [Hz].

F06 001 to 090 Closing speed 001 to 090 [Hz].

F07 001 to 099

Openign limit switch, 001 (minor), 099 (higher limit

switch).

F08 001 to 099

Closing limit switch, 01 (minor), 99 (higher limit

switch).

F09

FLA, bon, tor, rEP, AuA or PIu

Door model: Flash (FLA: larger motor with encoder

hall), Bona (bon: smaller motor with encoder

hall), Tore (tor: smaller motor with hall encoder),

Replacement (rEP: smaller motor with optical

encoder), Avanti AuA: medium motor with Hall

encoder) and Pivot (PIu).

F10 A10 to A50

Sensitivity of the anti-smash in the closing, the smaller

the value, the smaller the force. Higher the value, the

greater the force.

F11 dAP or EAP

Enable (EAP) or disable (dAP) anti-panic.

ATTENTION: This function should only be enabled if

the door is the mechanical anti panic system.

F12

oPE to Sto

Set the anti-panic function to open the door (ope)

or stop the door (sto) when receiving an anti-panic

signal.

F13

t01 or t99

Waiting time to recognize that there is no photocell

command and "radar 1", this function is used when

the door is commanded by access control by cards,

time x 100ms (one hundred milliseconds) [ms].

F14 001 to 015 Limit switch speed [Hz].

F15 ndE or dEF Applies factory values (dF) or does not apply (nd).

F16 001 or 099

Deceleration at closing [Hz / s], the lower the

smoother the motion and the greater the closing limit

switch.

F17 Reserved.

20 21

FUNCTION

EXISTING CONFIGURATION

FOR THIS FUNCTION

MEANING OF CONFIGURATION

F18 001 or 025

Opening speed [Hz] when there anti panic signal, if

the door is configured to open in this situation.

F19 10 to A50

Opening force. WARNING: If the value is too low, the

operator can have little force to open, slowing.

F20 000 or 015

Force in the final closing region, used to ensure

closing.

F21

dAu or LAu

Enables (dAu) or disables (LAu) anti-wind function.

This function is most commonly used in pivoting

doors, forming the set closing again if the door open

due to an external factor and not by an electric

command.

F22

001 to 099

Acceleration / Deceleration at aperture [Hz / s]. As

the value of this function decreases, the opening

movement of the door will be smoother and the open

limit switch should be increased as the door will

require more braking space

F23 dPt or LPt

Turn on closing lock pulse (LPt) or turn off closing

pulse lock (dPt).

F24

PnI or PIn

Non-inverted pause (PnI) starts counting when the

door is fully open. Pause inverted (PIn), the pause

starts counting when there is no more radar, photocell

or buttonhole signal. If any command is restarted

during the pause, the count is restarted.

F25 tof or t01 to t99

Disables the wait to start the engine after tof the tof

or enables the time to start the engine (t01 to t99) in

milliseconds, t01 = 0.1s.

F26 LAA or dAA

Turn on automatic open when the door is moved in

the open direction (LAA) or Turn off automatic when

the door is moved in the opening direction (dAA).

Out Exit of the menu. Exits the programming menu.

Important: At the end of the configuration of the operating parameters, navigate

the menu to the Out function and press OK. If the card is turned off without this

operation, the settings will return to the previous.

ATTENTION: It is mandatory (a) to use photocells to prevent accidents.

INCORPORATED PHOTOCELL

In this board there is a incorporated photocell, ie it is only necessary to connect

the light transmitter and the infrared light receiver to the "TXFOT" and "RXFOT"

connectors respectively.

Operation can be checked by the first display point from left to right. When the

point is lit, the photocell is obstructed. When the point is off, the light receiver is

receiving the signal from the light transmitter.

When the photocell is disconnected or has any change of connection or operation,

the door remains open until the correction is applied.

ENCODER TEST

It is possible to test the encoder operator by simply plugging it into the board

and starting the motor, press the SHIFT button once and the display will show the

encoder pulses in real time. There is a sequence of pulses that must be obeyed:

First sequence: the display shows 0 1 3 2 ...

Second sequence: the display shows 0 2 3 1 ...

Any sequence is valid, but if the encoder is working correctly all numbers should

appear, without exception!

Pressing the SHIFT button a second time, the route of the door will be shown in

hexadecimal format, eg the number 0200h corresponds to the zero point (door

open).

Ao pressionar o botão SHIFT pela segunda vez, o percurso da porta será mostrado

no formato hexadecimal, exemplo: o número 0200h corresponde ao ponto zero

(porta aberta).

ATTENTION: To check that the motor encoder is in perfect condition, open and

close the door several times by pressing the OK or RADAR button, then open it

and leave it open, then press the SHIFT button twice and write down the number

(it should be 0200h). Whenever the door is open, the display should mark the

position 0200h or close to it, for example: 0201h or 0202h. If the number changes

beyond 0200h, the encoder may be experiencing problems.

When you press the SHIFT button for the third time, the bus capacitor voltage will

be displayed (V).

After the button is pressed, the display will automatically delete in 255s.

22 23

TST JUMPER

When removing the TST jumper, the OK button is used to slowly rotate the motor

in a certain direction while the button is pressed, and the SHIFT button is used to

turn the motor in the opposite direction of the OK button while it is pressed. When

the TST jumper is replaced, the inverter returns to normal operation.

EVENTS AND FAULTS SIGNING

The main function of the OSC LED is to indicate that the microcontroller of the

board is operational (the same flashes, with fixed frequency (~ 1Hz), as long as

the power is on).

The BUS LED indicates that there is load on the capacitors of the DC bus.

ATTENTION: Do not touch the power region (capacitor region) of the board while

this LED is lit even after the inverter is disconnected from the electrical network!

The FAULT LED indicates the alignment between the emitter and the receiver of

the internal photocell. The higher the light intensity of the LED, the greater the

alignment accuracy of the TX / RX photocell.

The activated panic indication (unlocked ports) is signaled on the seven segment

displays (DSP1, DSP2 and DSP3) by means of the "APA" description (display

format source).

NOTE: The signaling connections of the activated panic system are carried out by

means of the ANTPA and ANTPB connectors.

FUNCTIONS OF THE DECIMAL POINTS OF THE INVERTER

DISPLACES WHEN THE OPERATOR IS OPERATING

There are some functions for the decimal points of the displays when the operator is

operating, these functions facilitate the verification of the operation and installation

errors:

1. The point of the unit (the first point from the right to the left) represents commands

for opening, ie when there is a receiver command or buttonhole, the point will be

lit. When there is no signal, the point remains off.

2. The point of the tenth (the second point from the right to the left) represents a

photocell signal, if the photo is drive or absent or still faulted the point will be lit and

the door will remain open.

3. The hundredth point (the third point from right to left) represents whether there

is a signal from the incorporated photocell. Lit point: photocell blocked, missing or

connection failure; the door will remain open until clearing / correction.

POSSIBLE ERRORS AND DEFECTS

Errors

1.E00, E01 and E02: Signals that the power part of the inverter is faulty. Cause:

Problems with power or weld defect. Solution: A qualified technician should

evaluate the equipment.

2. E03: There is no encoder signal. Cause: Encoder disconnected or defective.

Solution: Connect encoder to the board and check encoder.

3. E04: Indicates that the route recorded during memorization is too small. Cause:

The encoder cable is missing and the door is locked. Solution: Check the encoder

cable, check if the door slides all the way, in case the error persists.

4. E06: The port is not reaching the zero point (aperture). Cause: Encoder may be

broken, or lack of force at the end of stroke. Solution: Check the encoder. Increase

the limit switch speed (see "Encoder Test").

5. E09: Possibility of loss of synchronism of the belt with the toothed pulley. Cause:

Belt loose or improper to pulley.

ATTENTION: When the new inverter is to replace one of the old model (optical

encoder), the two wires in the middle of the encoder harness must be crossed:

- Old sequence: Black, White, Red, Yellow.

- New sequence: Black, Red, White, Yellow.

- For the optical encoder extender that has two ends, cross only one of them:

- Old sequence: Brown, Red, Orange, Yellow.

- Sequence and mapping are as follows: Brown, Orange, Red, Yellow.

24 25

DEFECT

DEFECT CAUSE SOLCTION

The door does not

match the installed

location route (brakes

before closing stop or

hits closing).

There is a different route

recorded the route from

the local installed.

Enter the function menu

and function 4 (F4),

change from nrt to rSt,

exit the menu via out,

and allow to memorize

the course.

Door remains open

and when it receives

commands to open, it

closes.

The memorization was

performed erroneously.

See item: First drive of

the inverter after being

installed in the operator

(memorization).

Loading...

Loading...