PPA FACILITY CONNECT Technical Manual

NOTE: If is a Digital limit switch System, after

programming the “Default Settings” topic, it is

necessary to memorize the route. Otherwise, the

board will operate with a minimum of 100 pulses.

IMPORTANT

• Once the board has been installed in the operator

system, it is necessary to memorize the path for

correct operation.

• In case of limit switch, whenever the power is

switched on (first command after power failure),

the motor will be activated (pulsing torque

mode) until the mechanical closing stop is found.

If this is done, the operation will be normal.

• In case of limit switch, whenever it is necessary to

reverse the motor rotation (black and red wires),

the boardmust be switched off. After the first

command after reconnecting it, the operating

procedure will be identical to the previous topic.

It is not necessary to reverse the position of the

encoder because the board corrects the position

automatically. Reversing the direction of rotation

of the motor is necessary to adjust the operation

of the board to the position of the gate. Failure

to observe this item may result in improper

operation of the operator by reversing the logic

operating for controls and photocell.

• In case of limit switch, when storing the course or

near the limit switch, the engine will be running

in pulsating torque mode, ie the engine will be

on and off continuously.

• The maximum pause time is 4 minutes.

• In case of limit switch, in equipment with little

force to learn the course, we must abort the

process and enter the programming to increase

the pulsating torque force in the memorization

(simultaneously press the 2 buttons of the

transmitter for 8 Times).

• To perform any of the programming steps on the

board, there is no need to record the 2 buttons

on the transmitter. With just one of the recorded

keys, we can access all the functions of the

electronics.

• When the PROG jumper is open, the GRV button

functions as the gate open / close command.

3. TRANSMITTER RECORD

The board can record up to 160 different and

independent buttons.

For transmitter record:

1. The gate must be stopped and not be timed for for

automatic closing.

1. Close the jumper PROG. The green SN led must be

dim.

2. Press and hold the transmitter button. The green SN

led should flash.

3. Press and release the GRV button, and check the

SN led:

- If the SN led flashes 1 time: Recorded the

transmitter button.

- If the SN led flashes 2 times: The transmitter

button is already recorded.

- If the SN led flashes 3 times: The memory

is full.

4. Release transmitter button.

5. To record other transmitter buttons, continue from

step 3.

6. To end the operation, open the jumper PROG.

NOTE: In User Mode (open PROG jumper), the

transmitter commands are only for gate opening /

closing operation. In this mode, the control panel

will not accept a command when the 2 transmitter

buttons are pressed simultaneously.

4. SELECTING DIGITAL OR ANALOGUE COURSE

SYSTEM

1. The gate must be stopped and not timed for

automatic closing.

2. Manage the PROG jumper open.

3. Select the limit switch option via the FC jumper:

FC Open: Limit switch Analog.

FC Closed: Limit switch Digital.

4. After selecting the limit switch system, it will be

necessary to memorize the automatic route.

Otherwise, if Digital limit switchis selected, the

board will operate with a minimum of 100 pulses

or, if Analog limit switch is selected, the opening /

closing time will be 120 sec.

5. AUTOMATIC BOARD PROGRAMMING

(COMPLETE CYCLE)

1. The gate must be open.

2. Close the PROG jumper. The green SN led must be on.

3. Simultaneously press and release the 2 transmitter

buttons (recorded) once. The SN led will flash when

the buttons are released. After 5 seconds, the board

will enter the automatic programming mode.

4. The gate will close until the mechanical stop FCF

(Closing limit switch) or the two buttons of the

transmitter are pressed simultaneously. After 1

second, the gate will open by memorizing the route

until you find the mechanical stop FCA (Opening

limit switch) or if the two buttons on the transmitter

are pressed simultaneously.

NOTE: In the case of Digital limit switch, in the

course of Memorizing the engine will operate in

Pulsating Torque mode.

5. The SN led will begin to flash as a clock every

1 second and wait for the programming of the

Automatic or Semi-Automatic Mode.

NOTE: If both buttons of the transmitter are

pressed simultaneously, the Pause setting will be

canceled and you will go to the next step, leaving

the last setting recorded.

Automatic Mode: In this mode, after it is

opened, the gate will close automatically after a

programmed pause time.

When the SN led:

• Slow flashing 1 time (2 sec.): Force minimum.

• Fast flashing: Strength adjustment between the

minimum and maximum.

• Slow flashing 1 time (2 sec.): Maximum force.

To go back and select new setting (step 6):

Simultaneously press and release the 2 buttons on the

transmitter.

To end programming: Simultaneously press and

release the 2 transmitter buttons or open the PROG

jumper.

9.ADJUSTING THE OPENING/ CLOSING

POSITION OF THE LIMIT SWITCH

This type of adjustment allows you to gradually

advance or rewind the limit switch, independent of

the opening and closing stop.

1. The gate must be stopped and not timed for

automatic closing.

2. Selected Digital limit switch (FC jumper closed).

3. The gate path must be memorized. Otherwise, the

function will be canceled.

4. Close the PROG jumper. The green SN led must

be dim.

5. Simultaneously press and release the 2 buttons

on the transmitter (recorded) 6 times. The SN

led will flash each time the buttons are released.

Waint 5 seconds.

6. Next, the SN led will go off and the board will wait

for the limit switch position programmed.

7. To adjust the position of the closing limit switch,

press and release the GVR button. The SN ledwill

flash once.

NOTE: If the REC button is not pressed, the

adjustment of the limit switch position will be

opening.

8. Adjusting the position of the limit switch (setting up

to 10 pulses)

1 pulse back off of the limit switch position:

Press the left button of the transmitter until find

the desired setting.

Advance 1 pulse of the limit switch position:

Pulse the right button on the transmitter until

find the desired setting.

To go back and select new setting (step 6):

Simultaneously press and release the 2 buttons on the

transmitter.

End programming: Simultaneously press and release

the 2 transmitter buttons or open the PROG jumper.

10.ADJUSTING THE OPENING/ CLOSING

INDEPENDENT LIMIT SWITCH

The limit switch is the distance that is missing to

reach the mechanical stop. The board will continuosly

monitor the position of the gate and when it reaches

this limit, the pulsating torque mode is turned on to

slow down and to smoothly stop. .

1. The gate must be stopped and not timed for

automatic closing.

2. Selected Digital limit switch (FC jumper closed).

3. The gate path must be memorized. Otherwise, the

function will be canceled.

4. Close the PROG jumper. The green SN led must be

dim.

5. Simultaneously press and release the 2 buttons on

the transmitter (recorded) 7 times. The SN led will

flash each time the buttons are released. Wait 5

seconds.

6. Next, the SN led will turn off and the board will wait

for the limit switch programmed.

7. Adjusting the limit and check the SN led. The

function has up to 5 adjustment levels:

8. To adjust the position of the closing limit switch,

press and release the GRV button. The SN led wil

flash once.

NOTE: If the GRV button is not pressed, the li mit

switch setting will be adjusted for the opening.

Decrease limit switch distance: Press the left button

of the transmitter until the desired setting is reached.

Increasing the limit switch distance: Press the right

button of the transmitter until you find the desired

setting.

End programming: Simultaneously press and release

the 2 transmitter buttons or open PROG jumper.

When the LED SN:

• SN led slow flashing 1 time (2 sec): minimum

limit.

• SN led flashes fast: between minimum and

maximum limit.

• SN ledflashes slow 1 time (2 sec): maximum limit.

Divider adjustment index (5 levels): 04, 08, 16, 32

and 64

Exemplo:

• Memorized course by the board = 1000 pulses.

• Limit switch selected = Divider 04.

• Calculation: 1000 pulses / 04 = 250 pulses remaining.

• Then, when 250 pulses are missing to reach the

mechanical stop, the board will reduce the speed

in pulsating torque so that the gate gently touches

the stop.

NOTE: The higher the divider, the lower the speed

reduction distance, the gate will be closer to the

mechanical stop of the limit switch.

11. AJUSTING OF THE TORQUE FORCE

PULSING INDEPENDENT FOR OPENING AND

CLOSING MEMORIZED OF THE COURSE.

To set the pause time, press and hold the right

button of the transmitter and count the seconds

through the clock or SN led. After counting

the pause time, the transmitter button must be

released.

Semi-Automatic Mode: In this mode, after

opening the gate, a new command is required

for closing.

To program, press and release the left button of

the transmitter.

6. The gate will start to cycle in a continuous close and

open and wait for the programming of the Motor

Force (Electronic Clutch). This force must be checked

by trying to hold the gate. To reduce or increase the

force exerted by the motor, proceed as follows:

Decrease Strength: Press and release the left

button of the transmitter and check the force

again. If necessary, you can press and release

the left button slowly until you find the desired

setting.

Increase Strength: Press and release the right

button of the transmitter and check the force

again. If necessary, you can press and release

the right button momentarily until you find the

desired setting.

NOTE: At this stage, the gate will not reach the

mechanical stop (opening / closing), but until the

point of the course where there will be the change

from high speed to low. This transition point is

programmable (see “Limit switch Adjustment”).

7. When the desired force is chosen, the 2

transmitter buttons must be pressed and released

simultaneously, and then the motor will be turned

off and the selected force will be recorded in the

memory.

NOTE: At this stage, if the PROG jumper is opened,

the motor will shut down and will not record the

force setting, keeping the previous record.

8. To complete the Automatic Programming (Full

Cycle), open the PROG jumper.

NOTE: Automatic Programming (Full Cycle) can be

terminated at any time in the plant configuration

cycle, just by opening the PROG jumper.

During the programming process, only the

transmitter recorded in memory and started

programming can interfere with or change

the configuration parameters. To change the

programming of the control panel with another

recorded transmitter, you must restart the entire

programming process.

6. AUTOMATIC PROGRAMMING OF BOARD

(FROM PAUSE ADJUSTMENT)

1. Close the PROG jumper. The green led SN should

be dim.

2. Simultaneously press and release the 2 buttons

on the transmitter (recorded) 2 times. The LED SN

flashes each time the buttons are released. After

5 seconds, the board will enter the automatic

programming mode (see from step 5 of the previous

topic - Automatic plant programming [full cycle]).

7. DELETE ALL THE TRANSMITTER MEMORY.

1. The gate must be stopped and not timed for

automatic closing.

2. Close the PROG jumper. The green led SN should

be dim.

3. Simultaneously press and release the two buttons

on the transmitter (recorded) 3 times. The SN led

will blink every time the buttons are released.

Wait 5 seconds.

4. Next, the SN led will be on awaiting confirmation

for the exclusion of the transmitters or the

cancellation of the operation.

To cancel operation: Press and release the left

button of the transmitter. The SN led will be

weak again.

Deleting all transmitters: Press and release the

right button on the transmitter. The SN led will

flash 3 times indicating that you have cleared all

transmitters.

5. Open the PROG jumper.

8. SETTING TORQUE FORCE PULSATING

INDEPENDENT FOR OPENING AND CLOSING

The board will be pulsing the motor, ie it will be turned

off and turned on quickly so that it has low speed force.

Depending on the weight of the gate, the torquemust

be adjusted to move it.

1. The gate must be stopped and not timed for

automatic closing.

2. Selected Digital limit switch (FC jumper closed).

3. The gate path must be memorized. Otherwise, the

function will be canceled.

4. Close the PROG jumper. The green SN led must

be dim.

5. Simultaneously press and release the 2 buttons

on the transmitter (recorded) 5 times. The SN led

will flash each time the buttons are released. Wait

5 second.

6. Next, the SN led will turn off and the board will

wait for the setting of the pulsating torque force

setting.

7. To adjust the pulsing torque fosse in the

clsingcycle, must press GRV.The SN led will flash

1 time.

NOTE: If the GRV button is not pressed, the force

setting of the pulsating torque will be for the

opening cycle.

8. Adjust the force and check the SN led. The function

has up to 32 adjustment levels:

Decrease the force of the pulsating torque:

Press the left button of the transmitter until the

desired setting is reached.

Increase the force of the pulsating torque:

Press the right button of the transmitter until

you find the desired setting.

IMPORTANT

Please read this manual carefully for proper use and

to ensure proper installation of the automation. All

data referenced in this manual is for information

only. Any technical changes to the product are

reserved without prior notice.

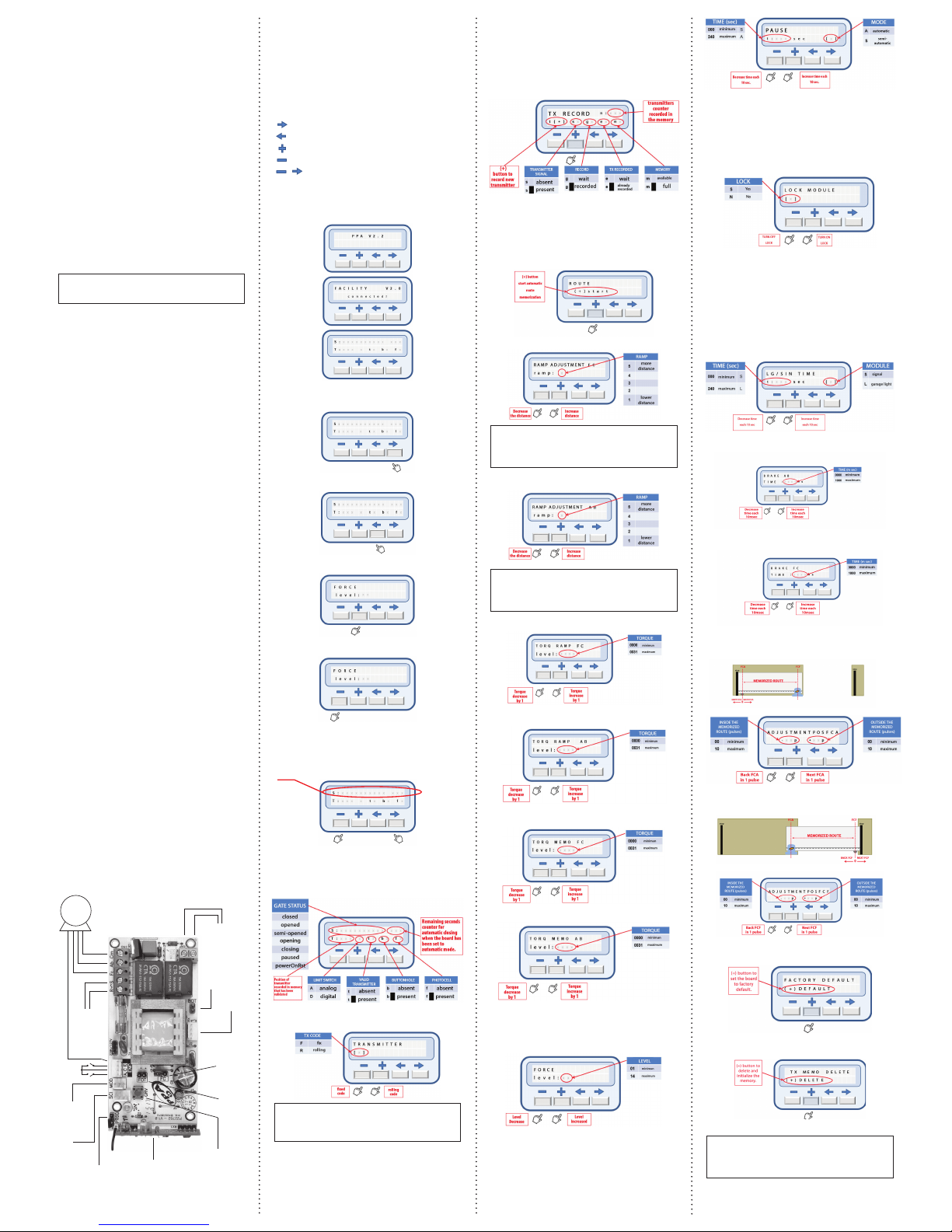

QUICK REFERENCE GUIDE TO

PROGRAMMING INDEXES

Simultaneously press the 2 buttons on the

transmitter (the number of times indicated below).

At least one of the buttons must be recorded:

1 time: Automatic board Programming (full cycle).

2 times: Automatic programming of the board

starting with the Pause setting.

3

times

: Deleting all transmitters from memory.

4 times: Factory default settings (Reset).

5 times: Adjusting the pulsating torque (opening /

closing).

6 times: Adjustment of the limit position (opening

/ closing).

7 times: Limit switch setting (opening / closing).

8 times: Setting the pulsating torque in the memory

(opening / closing).

9 times: Setting the brake operating time.

10 times: Select transmitter code type (fixed /

moving).

11 times: Select relay module type (latch, garage

or signal light).

1. MAIN CHARACTERISTICS

• Digital / Analog End-of-Course System.

• RF receiver module 433.92 MHz.

• Rolling Code up to 160 different and independent or

fixed code transmitters button rolling.

• Automatic memory of the course.

• Selecting the automatic or semiautomatic mode via

the transmitter.

• Setting the pause time for automatic closing via the

transmitter (maximum = 4.0 min).

• Adjusting the electronic clutch (force) through the

transmitter.

• Command to delete all transmitters through the

transmitter.

• Command to configure the board (factory default)

via the transmitter.

• Output for relay module, Garage Light, Signal or Lock.

• Input for external device selector as programmer or

bluetooth for access and also programmer.

• Photocell input.

• RF receiver socket.

• Pushbutton input.

• Input for external device selector as programmer or

bluetooth for access and also programmer.

2. DEFAULT SETTINGS (FACTORY DEFAULT)

• Strength = Maximum.

• Closing = Semiautomatic.

• Pulse torque (aperture) = Level 8.

• Pulsing torque (closing) = Level 5.

• Pulse force in the memorization (opening)= Level 11.

• Pulse torque in memory (closing) = Level 7.

• Limiter system = Depends on the FC jumper setting:

- If jumper FC open = Analog limit switch, then:

* Brake time (opening / closing) = 200 msec.

* Time A / F = 120sec.

- If jumper FC closed End of digital course, then:

*Brake time (open / close) = Off.

*Track = 0.

• Limit switch = Course / 16

• Retraction FCA = 2 pulses.

• Recall FCF = 0 pulses.

• Relay module output = Latch.

To return to the factory default settings:

1. The gate must be stopped and not be timed for

automatic closing.

2. In the FC jumper, select the limit switch: Analog (FC

open) or Digital (FC closed).

3. Close the PROG jumper. The green led SN should

be dimly lit.

4. Press and release, simultaneously the 2 transmitter

button (recorded) 4 times. The LED SN flashes each

time the buttons are released. Wait 5 seconds.

5. The LED SNflashes 4 timesconfirming the reset of the

board.

6. Open the jumper PROG.

BOARD

FACILITY

CONNECT

TECHNICAL

MANUAL

WARNING

Do not opera te the equi pment

without f irst rea ding the

instructions manual.

P0464 0 - Rev. 0

of flash on the led. Each flash represents 10

seconds for the garage light.

5. Open jumper PROG.

15. PROGRAMMER

It has the purpose of executing the programming of

internal functions independently and faster.

Button Function:

= Advance function;

= Back in function;

= Increase the value of the function.

= Decrementar o valor da função.

= Both buttons pressed simultaneously to

start motor.

Board to be connected, the programmer displays the

messages of Figures 1, 2 and 3 in sequence.

ADVANCE FUNCTION

BACK FUNCTION

INCREASE THE VALUE OF THE FUNCTION

DECREASE VALUE OF THE FUNCTION

COMMAND TO OPEN OR CLOSE THE GATE

Press and release both buttons simultaneously and

slowly to start the engine and observe the status of

the gate.

SCREEN INFORMATION

Displays the gate status information, sensors, and

transmitter position that released gate access.

TRANSMITTER

NOTE: : In attempt to program the type of transmitter

with the gate in moviment, the function will be

canceled and an audible alarm will be activated.

RECORD TRANSMITTER

1. It is not necessary to close the panel’s PROG

jumper.

2. Press and hold the transmitter button.

3. The indicator s on the screen will signal the

presence of the transmitter.

This type of adjustment is identical to “Independent

Piston Torque Adjustment for Opening and Closing”,

but it is valid only in the event of course.

For this setting, you must simultaneously press and

release the 2 buttons on the transmitter (recorded) 8

times.

12.TRIGGER TIME OF THE BRAKE

INDEPENDENT FOR OPENING AND CLOSING

This type of adjustment allows the electronic brake to

be turned off.

1. The gate must be stopped and not timed for

automatic closing.

2. Close the PROG jumper. The green SN led must

be dim.

3. Press and release simultaneously the 2 buttons on

the transmitter (recorded) 9 times. The SN led will

flash each time the buttons are released. Wait 5

seconds.

4. Then the SN led will turn off and wait for the limit

switch position to be programmed.

5. To select the brake adjustment at closing, press

and release the GRV button. The SN led will flash

once.

NOTE: In Case of the GRV button not pressed, the

adjustment of the brake will be open.

6. Adjusting the brake. The function has up to 11

adjustment levels.

Decrease the brake time (SN LED flashes

quickly) or off (SN LED flashes slow): Press

the left button of the transmitter until you find

the desired setting.

Increase the brake time (SN LED flashes

quickly): Press the right of the transmitter until

find the desired setting.

End of programmer: Open PROG jumper.

13. SELECT THE TYPE OF TRANSMITTER FIXE

CODE OR ROLING

1. The gate must be stopped and not timed por

automatic closing.

2. Close the PROG jumper. The green SN led must

be dim.

3. Simultaneously press and release the two buttons

on the transmitter (recorded) 10 times. The SN led

will flash each time the buttons are released. Wait

5 seconds.

4. Next, the led SN will be on waiting for the

configuration of the type of transmitter.

To transmitter fixed code: Press and release

the left button of the transmitter.

For rolling code transmitter: Press and release

the right button of the transmitter.

5. Open the PROG jumper.

End programming: Simultaneously press and release

the 2 transmitter buttons or open the PROG jumper.

After the transmitter type is selected, the memory will

be deleted.

14. SELECTING THE RELAY MODULE FUNCTION

1. The gate must be stopped and not timed for

automatic closing.Fechar o jumper PROG.

2. Close the PROG jumper. The green led SN should

be dim.

3. Simultaneously press and release the two buttons

on the transmitter (recorded) 11 times. The SN led

will flash each time the buttons are released. Wait

5 seconds.

4. Next, the SN LED will flash in the clock mode and

wait for the configuration of the relay module

function.

To lock: Press and release the right and left

buttons of the transmitter simultaneously.

For signalman: Press and release the left button

of the transmitter.

For garage light: Press and hold the right

button on the transmitter and count the number

4. Press and release the + button, and the g

indicator on the screen will indicate that you have

recorded.

5. The transmitter counter recorded n: on the screen

will be updated.

6. Remove transmitter button, and the s indicator on

the screen will be erased.

To record other buttons, repeat from item 2.

MEMORY COURSE

The board will enter the closing cycle until the limit

switch is found, and after 1 sec., Initializes the opening

cycle, storing the encoder time or pulses until the limit

switch is opened.

CLOSING RAMP

NOTE: : In attempt to program the closing ramp

with the gate in moviment, the function will be

canceled and an audible alarm will be activated.

OPENING RAMP

NOTE: In attempt to program the opening ramp

with the gate in moviment, the function will be

canceled and an audible alarm will be activated.

CLOSING RAMP TORQUE

OPENING RAMP TORQUE

CLOSING MEMORIZED TORQUE

OPENING MEMORIZED TORQUE

FORCE

Adjust the electronic clutch with the gate moving or

stopped, up to 14 levels.

PAUSE

Time adjustment for automatic closing when the gate

find the FCA opening limit switch.

LOCK

At the opening cycle command, if the lock is enabled

[S] and the module connected, it will be activated and

after 1 sec. The board will start the engine and after 2

sec. The lock will be turned off.

GARAGE LIGHT / TRAFFIC LIGHT

• For garage light, set time in xxx seconds, and when

the board finds the limit switch sensor FCF, it will

timer for shutdown.

• For traffic light, set the time to 000 seconds, and

when theboard finds the limit switch sensor FCF, it

will shut down.

• To activate the garage light or traffic light

functions, disable the lock module [N].

OPENING BRAKE TIME

CLOSING BRAKE TIME

OPENING ADJUST LIMIT SWITCH POSITION

CLOSING ADJUST LIMIT SWITCH POSITION

RESTORE FACTORY DEFAULT

DELETE TRANSMITTER

NOTE: In attempt to program the type of

transmitter with the gate in movimente, the function

will be canceled and an audible alarm will be

activated.

127 or 220V

(50 / 60 Hz)

FCA

FCF

Capacitor

starting motor

Separated

Receiver

Buttonhole

Optional

Module

Light, Signal,

Lock

Analog

Limit

Switch

Digital Limit Switch

RF Receiver 433,92 MHz

Button for TX

recording and

ajusting some

functions

Photocell

Limit switch

selection jumper

Programming

Jumper

Motor

Yellow

Red/Black

Black/Red

Loading...

Loading...