PPA Eurus Custom Technician Manual

COMFORT whit SECURITY

COMFORT whit SECURITY

www.ppa.com.br

PPA - Portas e Portões Automáticos Ltda.

Av. Labieno da Costa Machado n-7 3526 - Distrito Industrial

CEP: 17.400-000 - Tel: (0**) 14 3407-1000

Garça/SP - Brasil

COMFORT whit SECURITY

COMFORT whit SECURITY

Technician’s Manual

Gate operator with micro-processed digital control for gates up to 300 Kg

Installation Manual

EURUS CUSTOM

Contents

* Installation Procedure .......................................................................... 2

* Tools .................................................................................................... 2

* Preparation of the gate before automation ........................................... 3

* Technical Characteristics .................................................................... 3

* Installing the rack ................................................................................ 4

* Releasing System ............................................................................... 6

* Main Characteristics............................................................................ 6

* Control unit Logical Function ............................................................... 7

* Access Buttons Memorization............................................................. 7

* Electronic Lock Transmitter Memorization .......................................... 8

* Turning on Electronic Lock .................................................................. 8

* Turning off Electronic Lock .................................................................. 9

* Turning off Buttons............................................................................... 9

* Blow out image .................................................................................... 10 e 11

* Parts List ............................................................................................ 12

* Memorizing Adjustments of Trimpots and Virtual Fuse ........................ 13

* Types of Virtual Fuse Protection .......................................................... 13

* Adjusting Trimpots ............................................................................... 14

* Configuring Jumpers ............................................................................ 15

* Auto light timer (LG) ............................................................................ 16

* Functions of Signaling Led .................................................................. 16

* Smoth Start ......................................................................................... 17

* Photocell ............................................................................................. 17

* Electrical Connections Scheme .......................................................... 18

*Warranty Terms .................................................................................... 19

CÓD. P14433 FORM. 150 REV.: 0

INSTALLATION PROCEDURE

Introduction: The perfect operation of this equipment and warranty depend

on the instructions included in this manual.

Here are some of the necessary tools for the assembly and installation of the

equipment:

TOOLS:

Cannon handle socket

wrench

Hack saw arc

Screwdriver

Setsquare

Sander

Pliers

Double open ended

spanners

Pencil

Welder

Drill

Level

Tape measure

Page 02

Drill

COMFORT whit SECURITY

COMFORT whit SECURITY

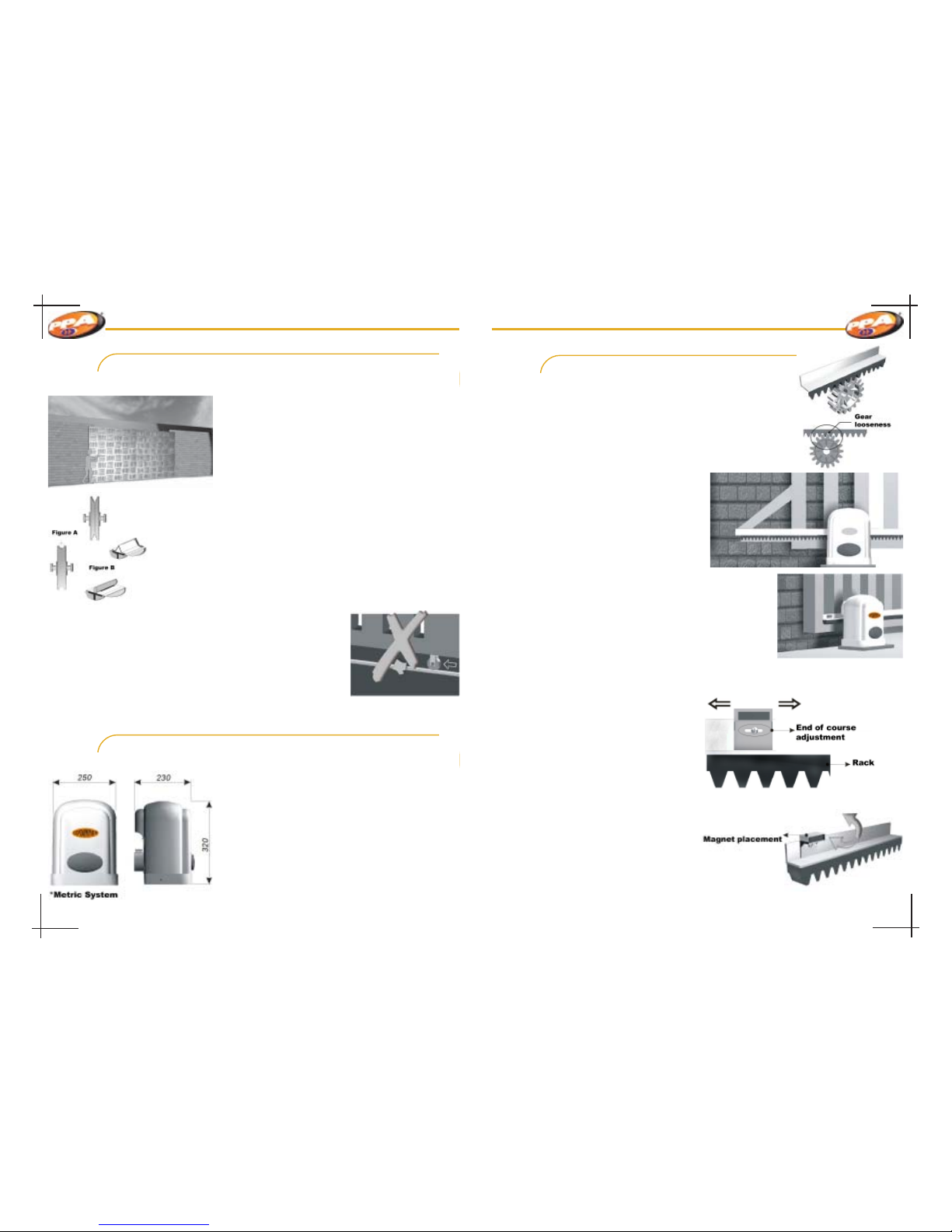

PREPARATION OF THE GATE BEFORE AUTOMATION

Before installation of the machine, check rolling, following the instructions

below:

1º Step: Move gate leaf manually and see the required

effort. Gate should move with ease.

2º Step: Move leaf back manually and check whether

the effort required was the same as the previous

operation.

Gate should have a strong structure and as

much as possible straight.

Pulleys should be of a diameter according to

gate dimensions. They also should be in rolling

perfect conditions and assembled in a way that the gate leaf has

stability during its trajectory. We recommend pulleys have at least

120mm of diameter.

Figures beside represent two types of tracks and pulleys used.

The system that uses straight section (figure A – angle iron) shows

more resistance, therefore, more wear. On the other hand, the system

that uses round section (figure B) allows a better gate movement

and less resistance to the gate operator.

3º Step: Check if gate leaf does not stop during opening and closing

trajectory.

Gate rolling track should be perfectly straight and

occasionally cleaned from any element or dirt that

complicates pulleys sliding, as it is showed on picture

beside:

Observation: The information above is very important

because it can be prejudicial for gate operator

performance.

TECHNICAL CHARACTERISTICS

Equipment Dimensions

Source: ........................... 110/220V

Frequency: ..................... 50/60Hz

Rotation: ......................... 1450(50Hz)/ 1750(60Hz)

Reduction: ...................... 30:1

Protection: ...................... IP 44

Capacitor: ....................... 8uFx400V/ 20uF x 250V

Isolation: ......................... F

Packing dimensions: ...... 260 x 240 x 317 mm

Gate operator weight: ..... 9Kg

Max. gate weight : .......... 300Kg

INSTALLING THE RACK

1º Step: Set the machine on manual mode (see page 6),

open gate completely, and place rack on gear in a way

that it has 2mm between teeth. Make the fixation on leaf

every 30 or 40 cm using a welder or screw in the entire

extension of the gate leaf.

Observation:

In case the gate leaf is crooked,

provide shimes to assure rack

alignment. In certain cases, the rack will

exceed the leaf length. If that is the case,

provide an L-bracket so it does not jump

the track during the machine start.

2º Step: Feed control unit with 220v,

according to equipment voltage, to

record remote controls as it is

explained in this manual.

-With the gate on manual mode, place leaf in

the middle of course and switch equipment to

automatic mode.

-Turn power off temporarily and turn it on again;

activate remote control and check if gate opens

obeying the command. If gate opens, it will show that

rotation direction is correct. In case situation described

previously is not occurring, switch motor’s Red and

Black wire.

3º Step: Magnets Installation – with the

gate closed, place magnet support

facing the REED, open gate

completely and place the other

magnet facing the REED. Turn motor on and do the final test,

observing if REEDs are turning off

correctly. If it is necessary switch

plate connector.

After installing magnets

support, do fine adjustments and if

necessary use the opening situated

on magnet support to move the

magnet position, according to

illustration beside.

L-bracket detail

Page 03 Page 04

Loading...

Loading...