PPA DZ IND. 1.0, DZ IND. 1.5, DZ 2.0 Technical Manual

www.ppa.com.br

+55 (14) 3407-1000

callcenter@ppa.com.br

DZ IND. 1.0 BRUSHLESS DC

DZ IND. 1.5 BRUSHLESS DC

DZ 2.0 ROBUST BRUSHLESS DC

Technical Manual

Av. Dr. Labieno da Costa Machado, 3526 - Distrito Industrial - CEP 17400-000 - Garça - SP - Brasil

MOTOPPAR INDÚSTRIA E COMÉRCIO DE AUTOMATIZADORES LTDA.

WARNING:

Do not use the product

without rst reading the

instruction manual.

EU DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINERY

Identication Number: PPA CE 001 (Revision: 01)

Manufacturer:

Company Name: MOTOPPAR INDÚSTRIA E COMÉRCIO DE AUTOMATIZADORES LTDA.

Address: AV. DR LABIENO DA COSTA MACHADO, 3526

GARÇA, SÃO PAULO, 17400000 - BRASIL

Authorized Representative / Person authorized to compile the Technical File:

Company Name: PERES & SELLANI S.L.

Address: CARRER SALVADOR DALI, 3-1-1

SANT CUGAT DEL VALLÈS, 08173, BARCELONA - ESPAÑA

This declaration of conformity is issued under the sole responsibility of the manufacturer, which declares that:

The following partly completed machinery is the object of this declaration:

Product Type: AUTOMATIC GATE OPERATOR FOR SLIDING GATES

Models: DZ IND 2.0, DZ IND 1.5, DZ IND 1.0, DZ RIO 800, DZ RIO 500

The object of the declaration described above is in conformity with the following essential requirements of Directive

2006/42/EC on machinery:

1.1.1, 1.1.2, 1.1.3, 1.1.5, 1.2.1, 1.2.3, 1.2.4.1, 1.2.4.2, 1.2.4.3, 1.2.6, 1.5.1, 1.5.14, 1.5.5, 1.5.6, 1.6.1, 1.6.3, 1.7

The object of the declaration described above is in conformity with the relevant Community harmonization legislation:

DIRECTIVE 2014/30/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 26 February 2014 on the

harmonisation of the laws of the Member States relating to electromagnetic compatibility

DIRECTIVE 2011/65/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 8 June 2011 on the

restriction of the use of certain hazardous substances in electrical and electronic equipment

The relevant harmonised standards considered for compliance are:

Machinery Directive (2006/42/EC):

IEC 60335-1:2010+AMD1:2013 CSV/COR1:2014, IEC 60335-2-103:2015, ISO 12100:2010

EMC Directive (2014/30/EU):

IEC 61000-4-2, IEC 61000-4-3, IEC 61000-4-4, IEC 61000-4-5, IEC 61000-4-6, IEC 61000-4-11, IEC 610004-13

RoHS Directive (2011/65/EU):

EN 50581:2012

The relevant technical documentation is compiled in accordance with Annex VII, part B of Directive 2006/42/EC;

In response to a reasoned request by the national authorities, the relevant information will be transmitted;

The partly completed machinery must not be put into service until the nal machinery into which it is to be incorporated has

been declared in conformity with the provisions of the Machinery Directive (2006/42/EC)

GARÇA, 01/02/2019

INdEX

IMPORTANT SAFETY INSTRUCTIONS ........................................................................................ 4

TECHNICAL CHARACTERISTICS .................................................................................................. 5

TOOLS REQUIRED FOR INSTALLATION ..................................................................................... 6

TYPICAL INSTALLATION OVERVIEW .......................................................................................... 6

ELECTRICAL INSTALLATION ......................................................................................................... 7

CARE WITH ELECTRICAL INSTALLATION .................................................................................. 7

CARE WITH THE GATE BEFORE THE AUTOMATION ..............................................................8

INSTALLATION OF THE OPERATOR ............................................................................................ 9

INSTALLATION ANALOG LIMIT SWITCHES ............................................................................14

TRIFLEX CONNECT BRUSHLESS BOARD.................................................................................17

LOGICAL FUNCTION OF THE SYSTEM FOR GATES ......................................................22

PARAMETERS PROGRAMMING .......................................................................................... 22

ERASE THE RECOGNIZED GATE TRAVEL .........................................................................28

APPLY FACTORY DEFAULTS .................................................................................................28

RECORD A RADIO FREQUENCY TRANSMITTER (RF) ...................................................29

SELECTION OF RF RECEPTION PROTOCOL (CF / CR) ..................................................29

DELETE ALL RF TRANSMITTERS RECORDED .................................................................29

ANTI-CRUSHING SYSTEM ....................................................................................................29

ENCODER OPERATION TEST ...............................................................................................30

EVENTS AND FAILURES INDICATIONS .............................................................................30

MAINTENANCE AND TROUBLESHOOTING ...........................................................................31

EXPLODED VIEW DZ IND 1.0 BRUSHLESS DC. ......................................................................34

EXPLODED VIEW DZ IND 1.5 BRUSHLESS DC. ......................................................................36

EXPLODED VIEW DZ 2.0 ROBUST BRUSHLESS DC .............................................................. 38

Samuel Peres

MOTOPPAR INDÚSTRIA E COMÉRCIO DE AUTOMATIZADORES LTDA.

CEO

3

IMPORTANT SAFETY INSTRUCTIONS

THE FULL AUTOMATION MUST COMPLY WITH THE CURRENT EUROPEAN MACHINERY

DIRECTIVE, IN PARTICULAR WITH THE STANDARDS: EN 13241-1, EN 12635, EN 602041, EN 12445, EN 12453, EN 12978

• Installation shall be carried out by qualifed personnel only, who can issue the

Certifcate of Compliance concerning the whole installation (Machine Directive

2006/42/CE).

• Before installing the equipment, it is important that the specialist installer follow

all instructions given in this technical manual and in the user manual.

• Never let children operate or play with door controls. Keep the remote control

away from children. With the help of the user manual, the installer must present

all information, uses and safety items of the equipment to the end user.

• Before installing the operator, make sure that the local power supply is compatible

with that required on the equipment identifcation label;

• The electrical installation must be provided with a device (eg. circuit breaker) to

ensure the complete disconnect of the equipment from the power supply, as well

a proper cabling, grounding and residual current devices for users protection.

• The product must be installed in an environment that suits the IP rating (IPX4) of

the product.

• Ensure that entrapment between the gate and the surrounding xed parts due to

the movement of the gate is avoided, according to harmonized standars (i.e. DIN

EN 349, ISO EN 14120)

• The opening and closing forces should be measured and tested in accordance

with BS EN 12445 (Test method) using an appropriate tool.

• Protective devices installed must comply with EN 12978 (Safety devices).

• Check the automation periodically, with special attention to cables, springs and

mechanic parts for wear and tear, damages and unbalancing. Do not use the

opener when service or adjustment work is required. Have a qualifed service

person to make repairs to gate hardware.

• Only carry out electrical connections once the electricity supply to the system has

been switched o. Disconnect any buer batteries or Nobreaks present.

• Use the manual release only when the gate is not moving.

• Save these instructions for later reference. The original instructions are in

Portuguese.

TECHNICAL CHARACTERISTICS

OPERATOR TYPE Slider Slider Slider

MODEL

RATED VOLTAGE 230 V 230 V 230 V

NOMINAL FREQUENCY 50 Hz 50 Hz 50 Hz

RATED POWER 350 W 400 W 450 W

MOTOR ROTATION 4500 rpm 4500 rpm 4500 rpm

MOTOR CURRENT 3A 3A 3,2 A

MOTOR REDUCTION 1:40 1:40 1:40

LINEAR SPEED

PERFORMANCE 60 cycles/h 60 cycles/h 60 cycles/h

PROTECTION DEGREE IPX4 IPX4 IPX4

TEMPERATURE RANGE -20 ºC / +50°C -20 ºC / +50°C -20 ºC / +50°C

ISOLATION TYPE Class B, 130°C Class B, 130°C Class B, 130°C

LIMIT SWITCH Hybrid Hybrid Hybrid

MAXIMUM GATE LEAF WEIGHT 1000 Kg 1500 Kg 2000 Kg

MAXIMUM GATE DIMENSIONS

NOMINAL LOAD 450 N 580 N 850 N

DZ IND. 1.0

BRUSHLESS DC

Z12 = 0,42 m/s

Z17 = 0,60 m/s

Height: 2,5m

Length: 10m

DZ IND. 1.5

BRUSHLESS DC

Z12 = 0,42 m/s

Z17 = 0,60 m/s

Height: 2,5m

Length: 10m

DZ 2.0 ROBUST

BRUSHLESS DC

Z12 = 0,42 m/s

Z17 = 0,60 m/s

Height: 2,5m

Length: 10m

WARNING: Important safety instructions. Follow all instructions

in this manual. Incorrect installation can lead to serious injury.

4 5

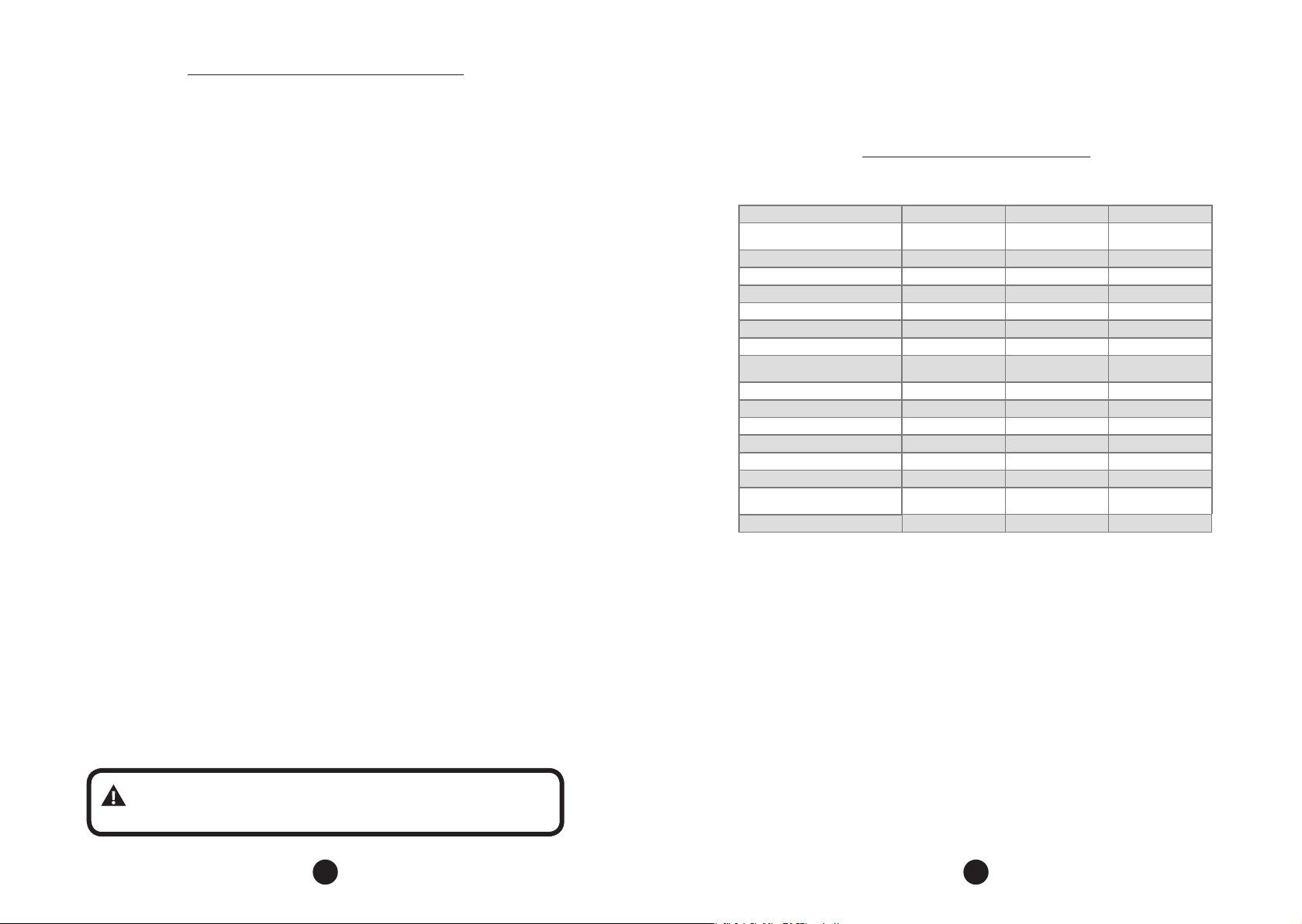

TOOLS REQUIREd FOR INSTALLATION

ELECTRICAL INSTALLATION

Here are some tools required to install the operator:

PLIERS SAWING BOW SOCKET WRENCH SCREWDRIVER NUT WRENCH

LADDER

WELDING MACHINE HAMMER LEVEL TAPE MEASURE

FRAME DRILL PENCIL SANDER

TYPICAL INSTALLATION OVERVIEW

For electrical installation, the network shall contain the following characteristics:

- 230V-50Hz power supply;

The passage of the wiring must be made through conduits between:

- the electrical distribution box and the total disconnect device

- the total disconnect device and the operator supply terminals;

- the control board and the (optional) external pushbutton;

- the control board and the photocells;

The wires used must comply with the local standards. The recommended cable

sizes are listed below:

DZ IND 1.0 BRUSHLESS DC

DZ IND 1.5 BRUSHLESS DC

DZ 2.0 ROBUST BRUSHLESS DC

Power supply 230V 3 x 1,5 mm² 50 m

Photocells 2 x 0,5 mm² 10 m

Safety Edges 2 x 0,5 mm² 10 m

Pushbutton 2 x 0,5 mm² 5 m*

Flashing light 2 x 1 mm² 20 m

*For further distances, please contact technical support.

Cable Section Maximum Lenght

CARE WITH ELECTRICAL INSTALLATION

To avoid damage to the wiring, it is important that all conductors are properly

attached to the operator. Wiring must be done through conduits, passing internally

through the base of the oor, ensuring that none of the wiring conductors are

trapped and damaged.

ITEM DESCRIPTION

1 Gate Operator

2 Rack

3 Photocells

4 Safety Edges

5 Pushbutton

6 Flashing light

7 Power supply 230V

6 7

It is mandatory that the

Z12 = 117

Z17 = 132

Z12 = 117

Z17 = 132

ground terminal is connected

to the grounding cable

network.

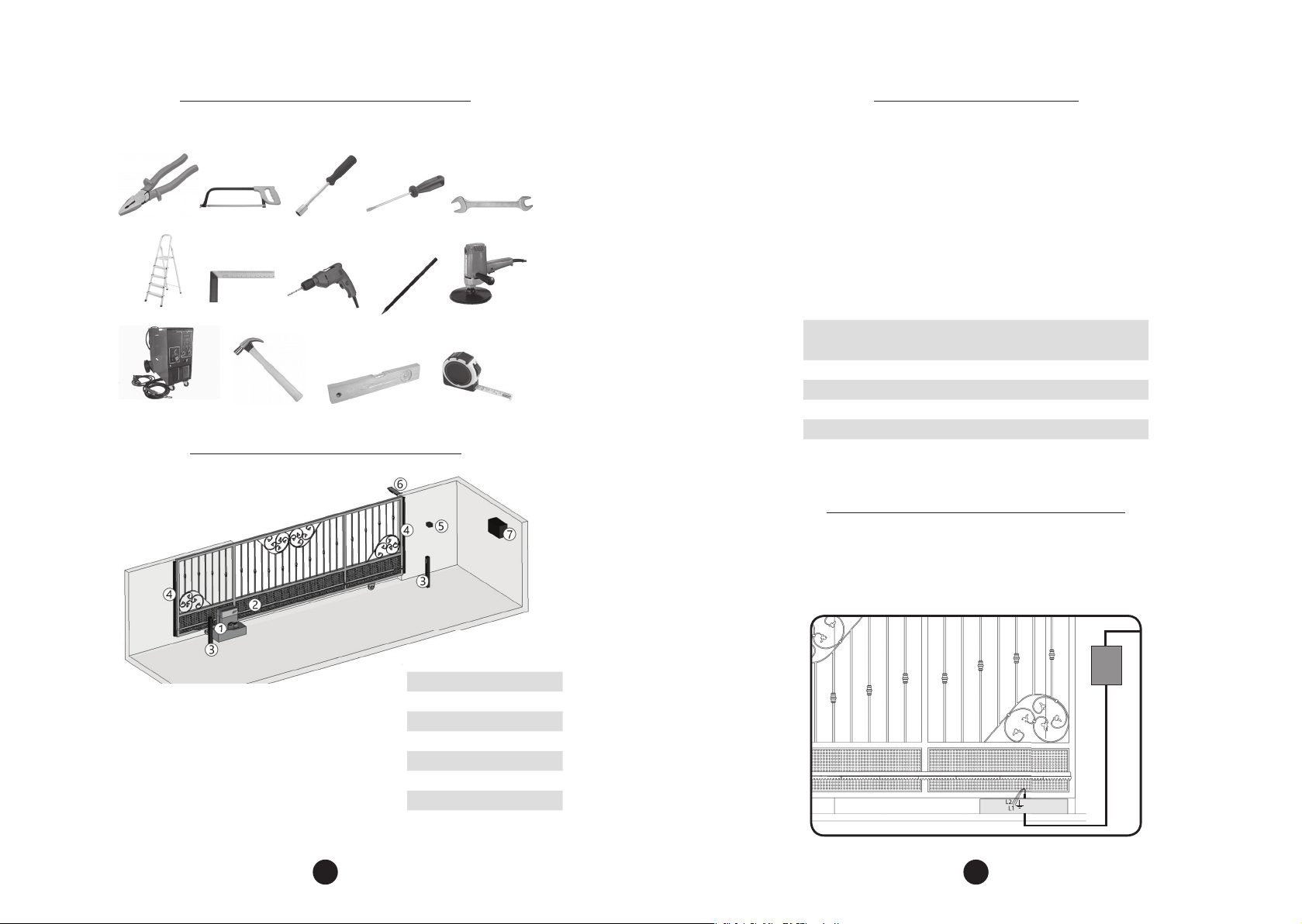

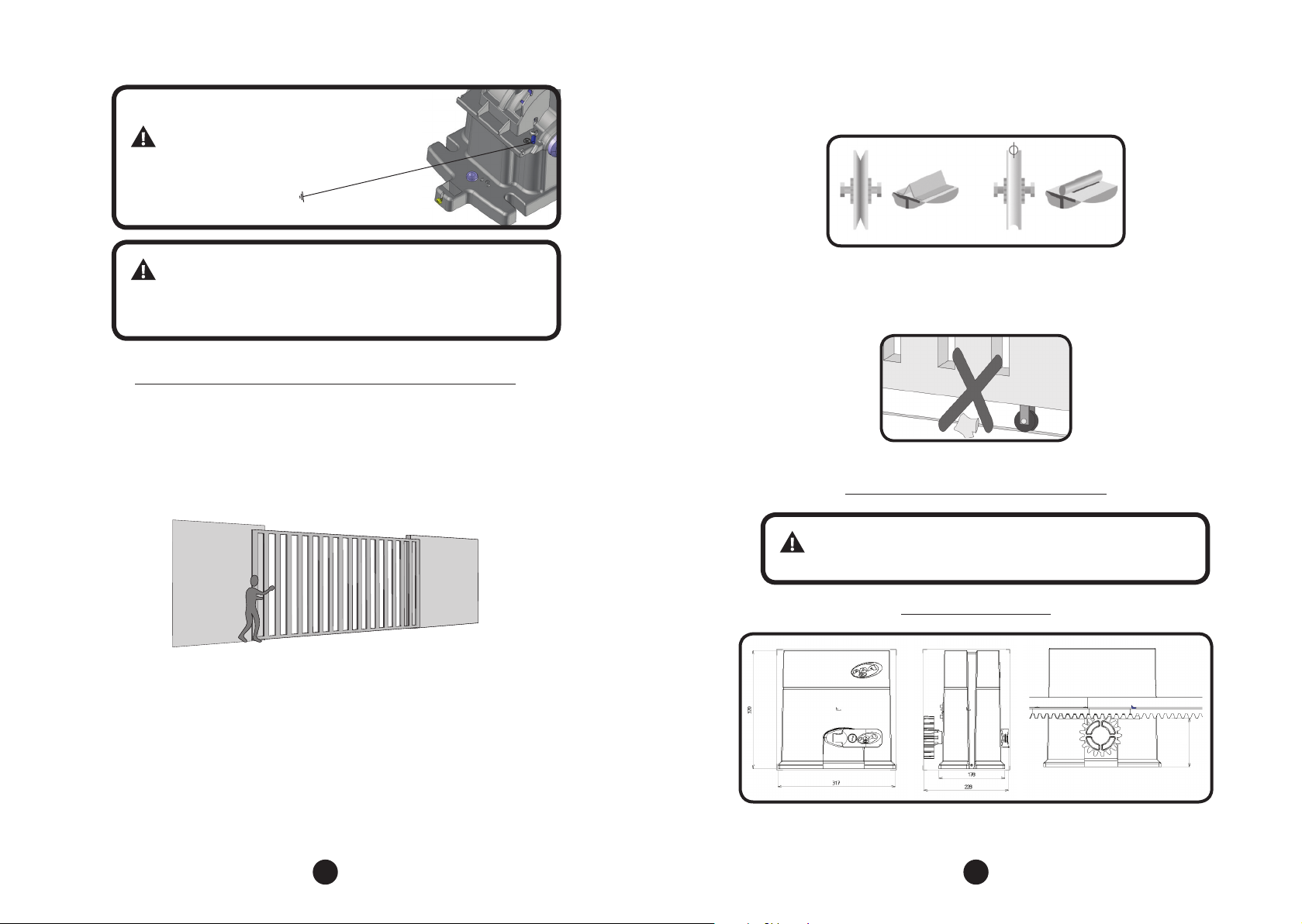

and consequently greater wear. The circular section (Figure B) allows a better

displacement of the gate and less friction for the operator.

FIGURE A FIGURE B

IMPORTANT

The electrical installation must have a residual current (RCD)

device with a rated residual current of 30 mA.

CARE WITH THE GATE bEFORE THE AUTOMATION

Before adapting the machine to the gate, check the gate movement by following

the instructions below:

Step 1: Before installing the operator, check if the gate is in good mechanical

condition, ie opening and closing properly. Open the gate manually and observe

the required e ort. This e ort should be minimal for the entire length of the rail.

Step 2: Close the gate manually and check whether the e ort was the same as the

previous operation.

The gate shall have a sturdy and, as far as possible, non-deformable structure. The

pulleys shall have a diameter suitable to the dimensions of the gate, shall be in

perfect running condition and shall be mounted in such a way that the gate leaf

has stability along all its displacement. We recommend pulleys with a diameter of

at least 120 mm.

The gures below represent the two types of rails and pulleys used. The system

that uses straight section (Figure A - angle bracket) exhibits greater friction

Step 3: Check wether the gate leaf does not jam in the opening and closing

movement. The slide rail of the gate must be perfectly rectilinear, undercut, and clear

of any element or dirt that makes it di cult to slide the pulleys in their entire length.

INSTALLATION OF THE OPERATOR

Before installing the operator, remove all unnecessary cables and

disable any equipment or system connected to the mains.

EQUIPMENT DIMENSIONS

Z12 = 117

Z17 = 132

NOTE: All measurements are in milimeters.

8 9

The correct operation of this equipment depends on the instructions in this

manual. To secure the equipment, proceed as follows:

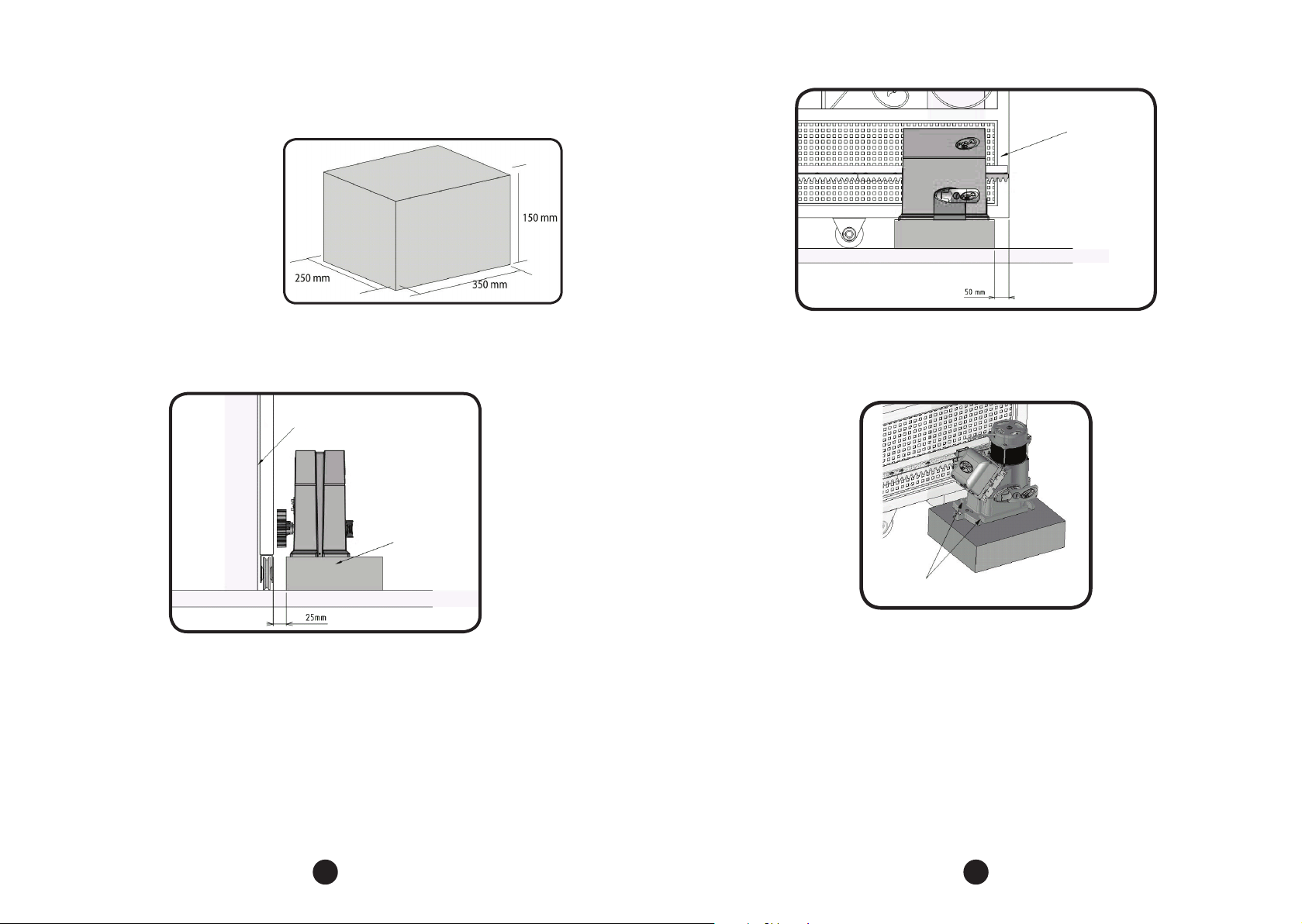

Step 1: Make sure the oor

is rm enough so that the

equipment can be screwed on

a level. If it does not comply

with the requirement, provide

a concrete base, following the

guidelines in the right image:

GATE LEAF

Step 2: The dimensions of the base should be appropriate for the dimensions of

the operator. The concrete base should be at a distance of approximately 25 mm

from the face of the gate leaf.

GATE LEAF

SIDE VIEW

CONCRETE BASE

Step 3: When the conditions are fullled, open the gate and position the operator

near the face of the gate leaf, obeying the 50 mm measurement between the leaf

end and the operator.

Step 4: Pre-align the operator with the gate, positioning the rack over the gear

and pushing the assembly to the gate. Then mark the xing holes in the oor or

concrete base.

MARK THE FIXING HOLES

ON THE FLOOR

Step 5: Drill the holes for fastening. Place the operator aligned to the gate and

insert the 3/8” x 3.3/4” bolts without tightening them. Move the gate, making sure

that it does not lean against the operation during the during its travel. If this occurs,

pull back the operator.

10 11

Loading...

Loading...