Powtran PR5200 5R5G3, PR5200 7R5G3, PR5200 018G3, PR5200 022G3, PR5200 030G3 User Manual

...

Foreword

Thank you very much for purchasing PR5200 soft starter.

This User’s Manual provides the users with the instructions on the installation, parameter

setting, error diagnosis, remote control software instruction, routine maintenance and necessary

precautions. Please read the Manual carefully before the installation of the product in order to

ensure that it can be correctly installed and operated.

Please contact Powtran's dealers or directly contact with the company if you have difficult

questions during the use of the soft starter , our professional staff is willing to serve for you.

Please leave this manual to the end user and keep it in good condition for the future

maintenance and other application occasions . Please fill in the warranty card then fax to the

distributor or fax to Powtran if there is quality problem during the warranty period.

During this product updating period, some details may be changed without prior notice. If you

want to get the latest information, please visit our website.

For other products’ information, Please visit our homepage:http://www.powtran.com.

Contents

Precaution .................................................................................................................... 4

Section I The introduction of PR5200 soft starter ................................................... 1

1-1. The feature of the PR5200 soft starter ............................................. 1

1-2. The main function of the PR5200 soft starter .................................. 1

1-3. The main features of the PR5200 soft starter ................................... 1

Section II Product model description and open package inspection ........................ 3

2-1. The steps of open package inspection .............................................. 3

Section III The Conditions of use and installation requirements ............................. 4

3-1. The Conditions of use of the soft starter .......................................... 4

3-2. The installation requirements of the soft starter ............................... 4

3-3. The appearance and installation dimension of the soft starter ......... 5

Section IV Main circuit and terminal wiring ........................................................... 7

4-1. The basic wiring diagram of the soft starter ..................................... 7

4-2. Instruction of soft starter terminal wiring. ....................................... 8

Section V Control panel and operation ................................................................. 10

5-1 Keyboard operational approach ..................................................... 10

5-2 Function parameters setting and description .................................. 12

5-3 Programmable relay output functions ............................................ 13

5-4 Automatic restart function ............................................................. 14

5-5 Other settings Description ............................................................. 15

5-6 .Help and instructions .................................................................... 16

Section Ⅵ Protection and description ...................................................................... 17

6-1 Protection functions and their parameters ...................................... 17

6-2 Protection level setting description ................................................ 18

Section VII Test runing and application ................................................................ 20

7-1. Power test running ......................................................................... 20

7-2. PR5200 Series soft starter starting mode and application ........... 21

7-3. PR5200 series soft starter's stop mode and application .................. 23

7-4. Special application ......................................................................... 24

7-5. Application examples .................................................................... 24

Section VIII RS485 communication ..................................................................... 26

Section IX Fault causes and treatment ....................................................................... 27

Section X Soft-start model specifications and options ............................................... 29

Section XI Quality Assurance .................................................................................... 30

POWTRAN Technology Product Warranty Card ..................................................- 31 -

Product information feedback ................................................................................- 34 -

Precaution

thanks for selecting intelligent motor soft starter products from Powtran technology Co.,

LTD., we will with excellent performance in return for your attention!

Please pay attention to the following matters during the soft starter installation, operation

and maintenance process

please be sure to read the operating instructions before installation

Must by professional technicians to install the soft starter

The specifications of the motor must match with the soft starter

Prohibit to connect the capacitors in soft starter output terminal (U, V, W)

the bare terminals must be wrapped by insulating tape after installation

Soft starter or related equipment should be reliable grounding

Input power must be cut off when equipment maintenance

Do not disassemble , modify, maintenance of this product personally.

Only trained people are allowed to operate this device, please read this manual

about the safety, installation, operation, and maintenance section before use of the

items. The safe application of this equipment depends on the correct transportation,

installation,operation and maintenance.

1

第

十

Section I

Section I The introduction of PR5200 soft starter

1-1. The feature of the PR5200 soft starter

PR5200 series intelligent motor soft starter incorporates the latest motor control

theory and proprietary motor protection technology and advanced software technology

of new equipment, it is an ideal replacement of startup products which early used start

method of “Star to Triangle conversion”, “autoformer step-down voltage” and

“magnetic control step-down voltage” ; At present market ,Its performance is more

superior than other ordinary soft starter without using intelligent control technology.

1-2. The main function of the PR5200 soft starter

First: to reduce the motor starting current and reduce power distribution capacity,

avoid investment of expansion of power capacity.

The second: to reduce the starting stress of the motor and the load of the

equipment ; Extend lifespan of the motor and related equipments.

Third: Its soft stop function can effectively solve the problem of parking vibration

of the inertial system,which is unable to realize by traditional starting equipment.

Fourth: to have six unique start-up modes adapts to the complex conditions of

motor and load, to perfect start effect.

Fifth: has the perfect and reliable protection function; Effectively protect the

motor and the related production equipment use safety.

Sixth: motor soft starter intelligence, and network technology application makes

motor control technology to adapt to the rapid development of the electric power

automation technology in higher requirements.

1-3. The main features of the PR5200 soft starter

● perfect human nature design:

beautiful shape and reasonable structure

perfect function and easy operation

sturdy and reliable and compact structure

industrial product excellence in the design of art.

● Reliable quality assurance:

using the computer simulation design.

SMT placement production process.

excellent electromagnetism compatibility.

The whole machine of aging, vibration test in high temperature before they

leave the factory

● perfect and reliable protection function:

Voltage lose, lower voltage and over-voltage protection.

soft starter motor overheating, lower load, too long starting time protection.

input phase lose, output phase lose, three-phase unbalance protection.

Startup current, overload, short circuit protection.

Section I The introduction of PR5200 soft starter

2

Section I

● proprietary intellectual property products:

appearance design patent.

independent software copyright.

proprietary motor starting and protection technology.

unique testing debugging equipment and process.

● swift thoughtful after-sales service:

reliable performance and lay the foundation of quality service quality.

provide excellent perfect supporting design scheme.

timely and thoughtful use consultation.

Continuously improve product performance according to user opinion

3

第

十

Section II

Section II Product model description and open package inspection

Each PR5200 series soft starter is under strict inspection and testing before they

leave the factory. Users received the products and unpacked, please follow the

inspection steps , if found, please contact the supplier promptly

2-1. The steps of open - package inspection

Confirm the soft starter without any damage in transport process (machine body

damage or gap).

Check with the machine, the instruction manual,the warranty card

Check the product of the specifications of the enclosure panels, ensure that the

received goods match with you ordered products

SOURCE:

OUTPUT:

TYPE:

Z01001A00001

5.5Kw 11A

3φ 380V 50-60Hz

POWTRAN TECHNOLOGY CO.,LTD.

PR5200 5R5G3

Soft starter model

Serial NO.

Output spec

Input spec

Powtran soft starter

PR 520 0 a 011 G 3

Model specification

Rated Power:

7R5 7.5KW

011 11KW

Class code:

0:normal configuration

1:special 1 configuration

2:special 2 configuration

Machine code:

a:General

Function code:

G Gerneral

Output configuration

0:General configuration

4

第

十

Section III

Section III The Conditions of use and installation

requirements

PR5200 series soft starter should comply with the following conditions of use and

installation requirements; Otherwise, the performance will not guarantee, it can shorten

life of soft starter even damage.

3-1. The Conditions of use of the soft starter

3-1-1. Power supplies: the utility, self-power station, diesel generating sets three-

phase AC 380 V or 660 V plus or minus 15%, frequency 50 Hz or 60 Hz, the

power supply capacity must meet soft starter motor starting to the requirement

3-1-2. Applicable motor: mouse cage type three-phase asynchronous motor,

electrical power rating should with soft starter rated power match.

3-1-3. Start frequency: no demands, depending on the specific number load up.

3-1-4. Cooling way: air cooling.

3-1-5. The protective level: IP20.

3-1-6. Environmental conditions: elevation 3000 meters, the environment

temperature-25 ℃ ~ + 40 ℃ between, relative humidity below 90% RH, no

dewing, no inflammable, no explosive, no corrosive gas easily, have no

electrical conductivity dust, indoor and ventilated good, vibration is less than

0.5 G place.

We can offer under special conditions of use products, such as the explosion

proof type, low temperature, high pressure type type soft starter, its use

conditions will need further instructions.

3-2. The installation requirements of the soft starter

Installation direction and distance: in order to ensure that the soft starter in use

with good ventilation and cooling conditions, soft starter should be installed

vertically, and in the equipment with sufficient heat dissipation space all round,

as shown in chart 3.2 3.1, in the photo, to allow the minimum distance.

Soft starter install inside ark, in addition to the above requirements outside,

still must choose, under ventilated cabinet put oneself in another's position, as

shown in chart 3.3.

OUT

OUT

IN

IN

AIR

50mm

50mm

150mm

150mm

Section III The Conditions of use and installation requirements

5

Section III

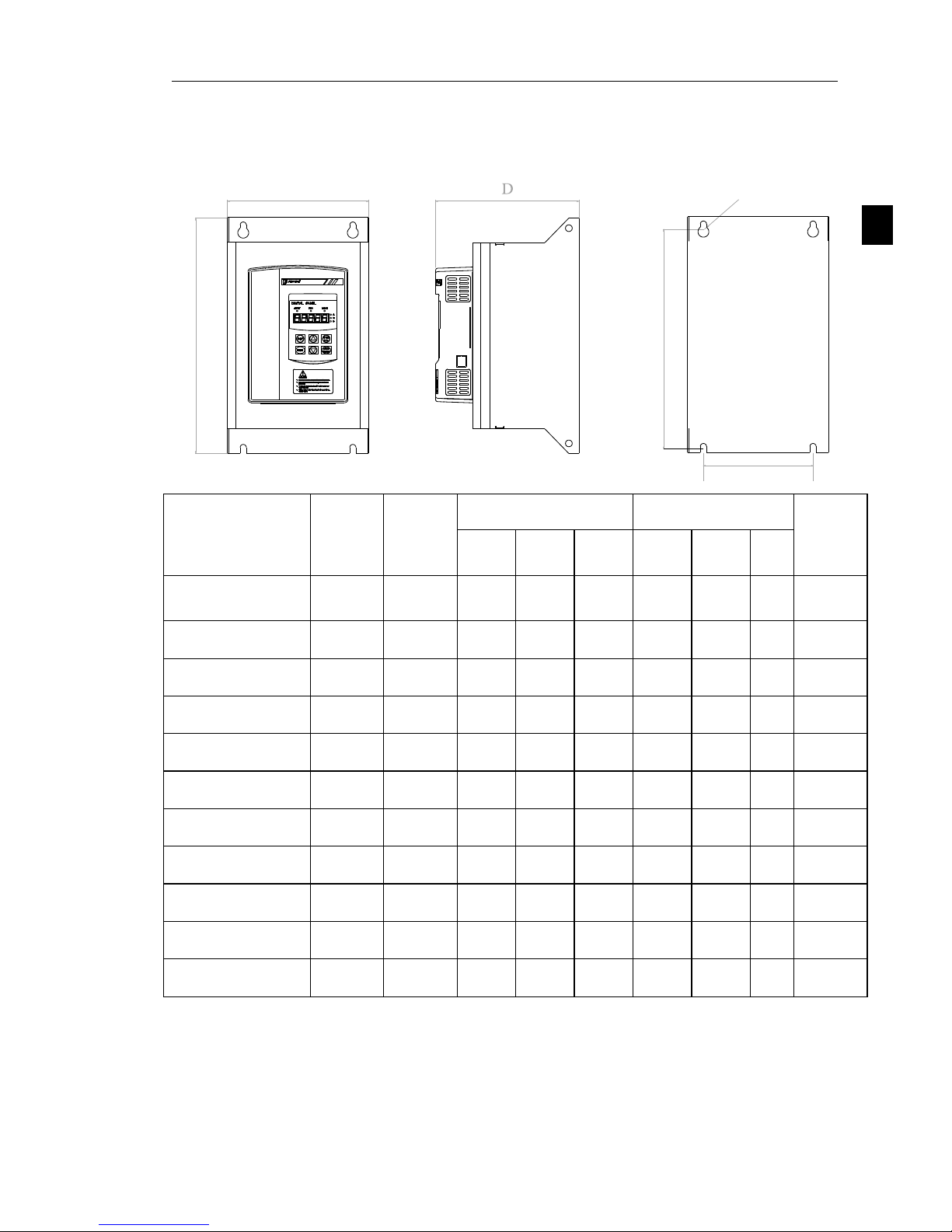

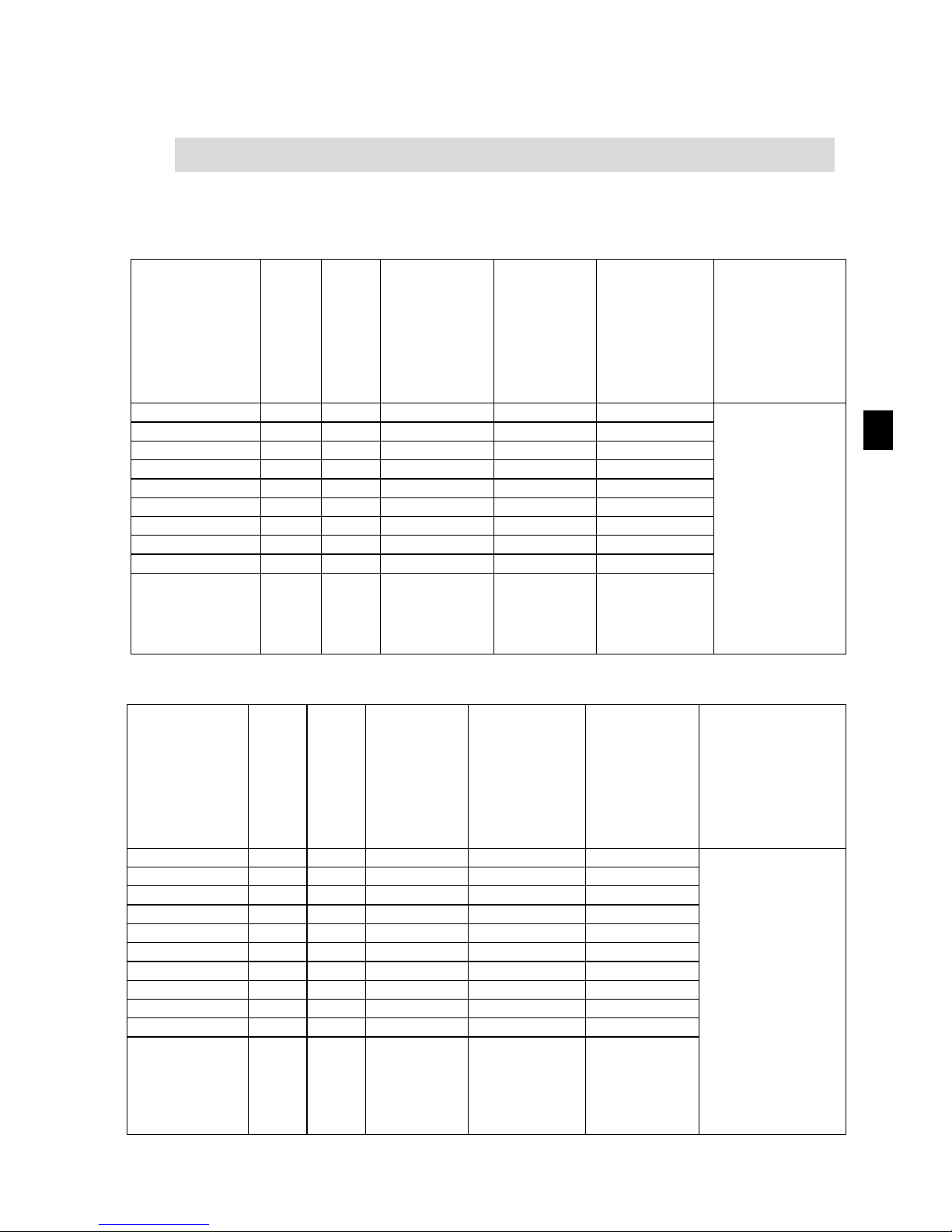

3-3. The appearance and installation dimension of the soft starter

3-3-1. The appearance and installation dimension of the 5.5KW-55KW soft

starter. chart3.1

W1

H1

d

W2

H2

Model

Rated

Power

(KW)

Rated

current

(A)

Dimension

Installation

Net(

kg)

H1

W1 D H2

W2 d PR5200 5R5G3

5.5

11

288

146

159

270

115

Ø8

<3.5

PR5200 7R5G3

7.5

15

288

146

159

270

115

Ø8

<3.5

PR5200 011G3

011

22

288

146

159

270

115

Ø8

<3.5

PR5200 015G3

015

30

288

146

159

270

115

Ø8

<3.5

PR5200 018G3

18.5

37

288

146

159

270

115

Ø8

<3.5

PR5200 022G3

022

44

288

146

159

270

115

Ø8

<3.5

PR5200 030G3

030

60

288

146

159

270

115

Ø8

<3.5

PR5200 037G3

037

74

288

146

159

270

115

Ø8

<3.5

PR5200 045G3

045

90

288

146

159

270

115

Ø8

<3.5

PR5200 055G3

055

110

288

146

159

270

115

Ø8

<3.5

3-3-2. The rated power and rated current is max rated value of soft starter. Usually,

matching the corresponding parameter of motor shall not be more than this

value.

3-3-3. PR5200 series 75 kW-400 kW soft starter appearance and installation

dimensions are shown in chart 3.2, the standard factory configuration is

three input and six out.

Section III The Conditions of use and installation requirements

6

Section III

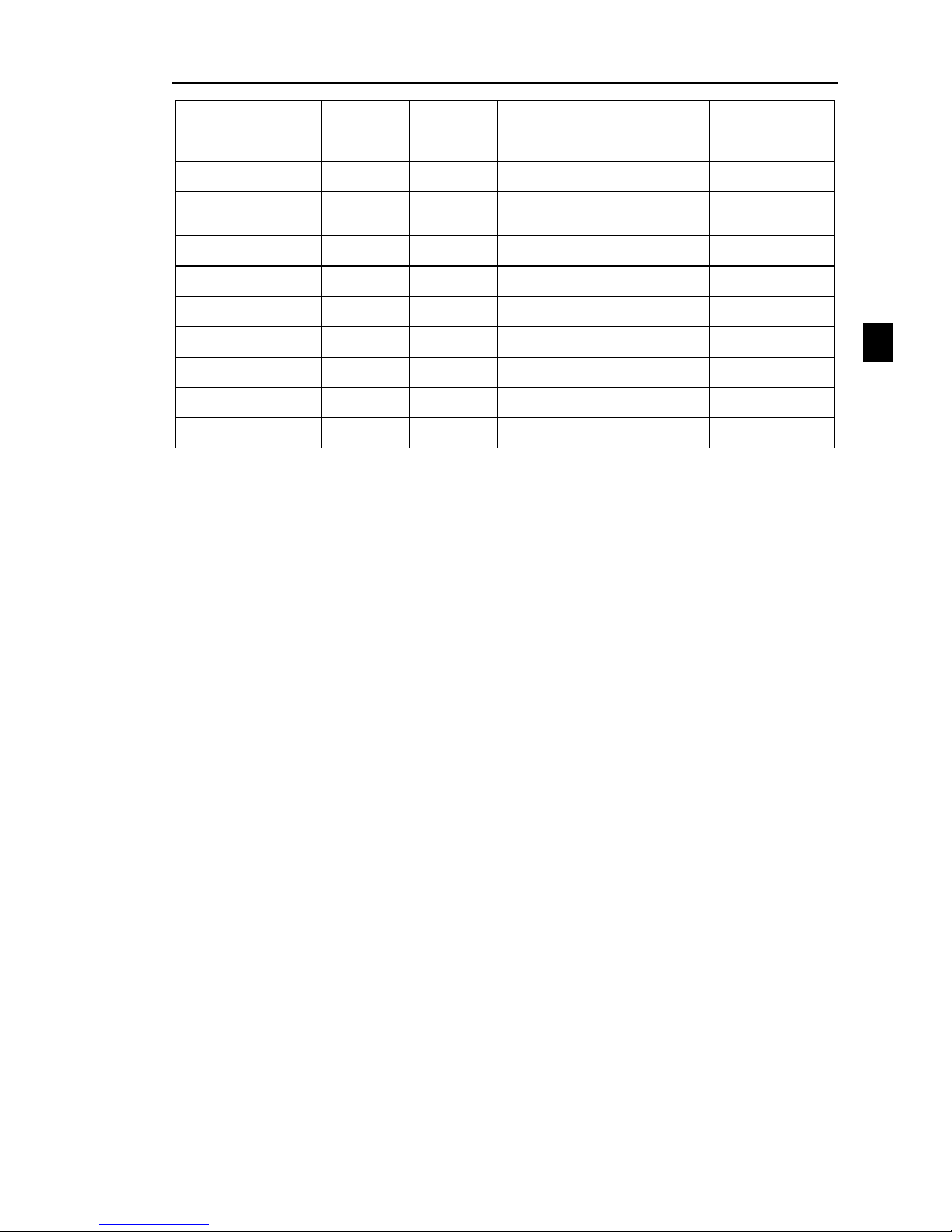

Rated

Power

(KW)

Rated

Current

(A)

Dimension

Installation

Net

(kg)

H1

W1 D H2

W2

d

075

150

350

206

210

330

160

Ø9

<20

090

180

350

206

210

330

160

Ø9

<20

115

230

350

206

210

330

160

Ø9

<20

132

264

420

256

250

400

210

Ø9

<23

160

320

420

256

250

400

210

Ø9

<23

185

370

420

256

250

400

210

Ø9

<23

200

400

420

256

250

400

210

Ø9

<23

250

500

490

360

290

465

290

Ø9

<31

280

560

490

360

290

465

290

Ø9

<31

320

640

490

360

290

465

290

Ø9

<31

400

800

490

360

290

465

290

Ø9

<31

W1

H1

d

W2

H2

7

第

十

Section IV

Section IV Main circuit and terminal wiring

PR5200 series soft starter has three kinds of wiring:

The main circuit wiring: three phase power input and output to the motor wiring

and coil in line circuit breaker, bypass contactor wiring.

External terminal wiring: by 12 small terminals derivation, including input, output

control lines and analog output signal lines.

Communication wiring: a standard RJ-45 network line socket and a DB9 socket

which are used to connect computers or computer network

4-1. The basic wiring diagram of the soft starter

PR5200 Series

Soft Starter

3phase power input

Keyboard

control

M

3phase asynchronous mouse cage motor

Braker(QF)

chart

4.1

Connector(KM)

Note:six copper bar, below 3 for motor,upper 3 for contactor

Section IV Main circuit and terminal wiring

8

Section IV

7

8

9

10

Transient

stop

stop

start

common

3lines way

7

8

9

10

Transient

stop

stop

start

common

2lines way:close K start

open K stop

K

4-2. Instruction of soft starter terminal wiring.

Output terminal like chart 4.2 illustration

:

1

2

3

4

5

6

7

8

9

10

11

12

-

+

bypass output

program output

error output

Transientstop

stop

start

common

DC0~20mAoutput

图4.2

4-2-1.Terminal 1、2 is bypass output which is used to control bypass contactor.

Normally open terminalwill close. The terminal capacity is AC250V/5A.

4-2-2.Terminal 3、4 is programable relay output, output model and function set by

“PJ”parameter. This terminal is normally open passsive pot. Capacity is

AC250V/5A.

4-2-3.Terminal 5、6 is error output: which will colse when soft starter error or

power lose, Capacity is AC250V/5A.

4-2-4.Terminal 7 is transient stop input. This terminal must connect with Terminal

10 when soft starter normally work. If Terminal 7 disconnect with terminal

10, softstart will transient stop and show error. This terminal can be

controled by normal close output terminal of outside protection device, Set

PC to 0 (primary protection),this terminal funtion is prohibited.

4-2-5.Terminal 8、9、10 is for wiring of outside control start,stop button. There

are two type wiring way( 3lines and 2 lines) To choose proper way according

to demand. As chart 4.3.

4-2-6.Terminal 11、12 is 0~20mA DC anolog output. Which is used to inspect

the motor current. The max 20mA indicates motor current is 4 times of soft

starter rated current. Which can be viewed by extra 0-20mA current meter.

The max resistor of output load is 300Ω.

4-2-7.The outside terminal should be correct connection, otherwise which will

damage this softstarter.

4-2-8.PR5200series soft starter main circuit diagram.

Section IV Main circuit and terminal wiring

9

Section IV

L1

L2

L3

1

3 5

braker

(QF)

L1

L2

L3

1

3

5

A2

A4

A6

1

3

5

KH

bypass

electromagnetic

contactor

2

4

6

T1

T2

T3

2

4

6

07

08

09

10

10

11

12

G

01

02

03

04

05

06

M

A

-

+

anolog output

(DC 0~20mA)

KH/transient stop

stop

start common

KM

N或L1

A1

A2

bypass

output

PR5200 series soft stater

Delay

output

error

output

FU

(KM)

10

第

十

Section V

ampere

percentage

second

Error light

bypass light

colon blankready light

three

digitals

two

position

function

code

parameterchange/plus or minus key.

*set parameter and change

program(to set

parameter)

rapid select/confirm

parameter setting.

running key

stop/reset(stop

running,error reset

and error

confirmation)

Section V Control panel and operation

★PR5200series soft starter has five kinds working state:ready,running,error,start

and stop. Ready、running、error has corresponding state light.Startup indicates××××,

softstop indicates —ЧЧЧ ,and ЧЧЧЧЧindicates motor current.

5-1 Keyboard operational approach

5-1-1. startup state: when the indication ready light display 5200 or READY,then

softstater can start. The displaying 5200 means POWTRAN 5200 series

softstarter. And ready means ready to start.

5-1-2. Delay state: ready or error state indication light flash means interval, display

dE××× and count down means startup delay.

5-1-3. Start and stop key:in the process of soft startup,the screen display ×××× to

indicates motor current, and only Stop key is valid, and can not enter menu

to set parameter, and ready,running,error lights black out.In the process of soft

stop, the screen display×××× to indicates motor current,and only RUN key is

valid, and can not enter menu to set parameter, and ready, running, error lights

black out, Meanwhile the stop key has reset function.

5-1-4. PRG Key , in the non-help mode, press the PRG Key to enter the setup

menu,display PX: XXX,then press PRG key again, colon flashes, that means

can modify the parameters after colon.Press the Set key when the colon

flashes, if the data has been modified, it will display good and twice ring,

indicating that new data has been saved, and then exit. If you do not want to

save the new data, press the PRG key, colon will stop flashing and restoring

the original data, then press Set key or Stop key to exit.

5-1-5. Set Key, in the non-setting state, press the Set key to enter the Help menu,

Section V Control panel and operation

11

Section V

display HX: XXX, press the Set key or Stop key to exit. In setting state, press

the Set key to save the new setting of data and to exit the setting state.

5-1-6. Acceleration,deceleration key, in the setting menu, when the colon does not

flash ,press the acceleration or deceleration key to change the function number;

when colon flashes, press the acceleration or deceleration key to change the

data, press on the acceleration or deceleration key for more than 1 second, the

data will be increased or decreased continuously and quickly .In the help

menu, press the acceleration or deceleration key to change the function

number and the corresponding message.When the indicator light of bypass

operation is on, and did not enter the setting and help menu, display AXXXX,

that means the motor running current, then press the acceleration or

deceleration key to select display PXXXX or HXXXX.PXXXX indicates

motor apparent power;HXXXX indicates motor overloaded heat balance

coefficient. When indication value of HXXXX is more than 100%,soft starter

will be overload protection and display Err08.

5-1-7. When the data is more than 999, the last decimal point is bright, indicates the

mantissa + 0.

5-1-8. If the key operating is effective,there will be a voice tip, or this key does not

work in this state.

5-1-9. When the external control terminal connected to a 3-wire mode, the external

control start button and stop button have the equivalent function with start and

stop keys on the control panel.

5-1-10. The control panel with super anti-jamming design,and the outside connection

distance is allow to be more than 3 m.

5-1-11. Keyboard digital display illustration

Display

letter

relative

letter

Display

letter

relative

letter

Display

letter

relative

letter

0 1 2 3 4 5 6 7 8

9 或 g

A 或 R

B

C

d 或 D

E F H J L N

U 或 V

o P r Y

RUN

Ver

READY

good

Err

Section V Control panel and operation

12

Section V

5-2 Function parameters setting and description

Function parameters code in the following table

Code Setting Description

Code

Name

Range

of set

value

Factory

setting

Explanation

P0

Starting voltage

30-

70%

30%

Voltage slope model is

effective, the starting voltage

of current mode is 40%.

P1

Soft starting time

2-60S

16S

Limiting current mode does

not work.

P2

Soft stop time

0-60S

0S

Setting 0 means free stopping,

please set 0 for one with two

connections .

P3

Start delay

0-

999S

0S

With a countdown delay, set to

0 without delay, starting

immediately.

P4

Programming

delay

0-

999S

0S

For programmable relay

output.

P5

Interval delay

0-

999S

0S

Delay When overheated is

released, indicator blinks to

warn of the delay period.

P6

Starting to confine

current

50-

500%

280%

Limiting mode is effective, the

maximum current limit value

of Voltage slope model is

400%.

P7

Maximum operating

current

50-

200%

100%

Parameters input of P6, P7 is

decided by P8 .

P8

Enter the display

method

0-3

1

See note 5.5 Other Settings

Description

P9

Under voltage

protection

40-

90%

80%

Protection when below the

setted value .

PA

Overvoltage

protection

100-

140%

120%

Protection when higher than

the set value

Section V Control panel and operation

13

Section V

PB

Start mode

0-5

1

0 limit current,1voltage, 2

sudden sudden stop + limit

current, 3 sudden stop +

voltage, 4 current ramp, 5

pairs of closed-loop.

PC

Output protection

allowed

0-4

4

0 Primary, 1 light load, 2

standard, 3 overloaded, 4

senior

PD

Operation control

mode

0-7

0

Set 7 indicates banning

starting or stopping operation ,

see note 5.5 other settings.

PE

Re-starting enable

0-13

0

See note 5.4 auto restart

function.

PF

Parameters modified

allowed

0-3

1

See note 5.5 Other settings.

PH

Communication

address

0-64

0

For many sets of soft starter and

PC computer communication

PJ

Programming output

0-19

7

See note 5.3 programmable

relay output.

PL

Soft stop the

current limit

20-

100%

80%

See note 7.3.1 soft stop mode.

PP

Motor rated current

Rating

Used to input motor nominal

is rated current

PU

Motor under load

protection

Ban

See note 5.5 Other settings.

Note, 1, The maximum current of P7 is based on PP calculated sustainable

operation of the maximum current according to the light and heavy of the

load,More than this value will do inverse time thermal protection.

2, It will automatically exit the setting mode,if no key operation is more than 2

minutes during setting state.

3, Can not set parameters in the soft start and soft stop process , but other states

are no problem.

4, Pressing the Set key (PRG) when is powered on, can set the parameters (PJ

excluded) to restore the factory values.

5-3 Programmable relay output functions

There are two programmable relay output function, programmable timing output

Section V Control panel and operation

14

Section V

way and programmable state output way.

5-3-1. PJ set from 0 to 4 items (10 ~ 14), programmable output work is timing output

way, the setting of output starting time as tabled below.

PJ setting

value

0(10)

1(11)

2(12)

3(13)

4(14)

Programming

output time

Initiate

action

command

Starting at

the

beginning

Bypass

operation

Stop

action

command

Stopping is

complete

5-3-1-1. This way of working contains a 999 seconds timer which setted by the

setting item P4. If P4 is not 0, the start timing is according to the initial

setting time setted by PJ , when the time is up changing the output state, if

P4 is 0, changing the output state immediately. The output of the reset time is

to sustain 1 seconds after finishing the time delay setted by P4 and in the

state of readiness.

5-3-1-2. The control cycle of Programmable output timing is according to one

starting process, if re-start the motor , the last programming output process is

automatically stopped and re-started the programming process.

5-3-2. PJ is from 5 to 9 (15 ~ 19), the programmable output work is state output

mode, the setting of the working state output as tabled below:

PJ set value

5(15)

6(16)

7(17)

8(18)

9(19)

state of output

indication

Motor fault

conditions

Running

Readiness

Start state

Bypass state

5-3-2-1Programmable state output to indicate the working state of the soft starter, the

time setted by P4 is invalid in this mode. The factory setting of PJ is 7,

which indicates the preparation state of soft starter, can start the motor in this

state; programmable output is in the failure state, which indicates the fault of

the motor(Err05, Err06, Err07, Err08, Err12, Err15 ), which is different from

the function of ⑤, ⑥ fault output terminals; running state refers to non

preparation or fault condition, which includes 3 process of start, bypass, softstop.

5-3-2-2When PJ> 9, the reset state of the programmable output (③, ④ No. external

pin) changed from normally open to closed, that is inverted output. Flexible

using the function of programmable relay output, which can effectively

simplify the external control logic circuit。

5-4 Automatic restart function

5-4-1. When setting PE from 1 to 9 , it will allow the automatic restart function. This

function is only valid for outside control line 2 way , and is not controlled by

the outside allowed setting of PD. According to two-line wiring way and in

the put off start state:

5-4-2. After power is on ,delay of 60 seconds, then automatically start 。

Section V Control panel and operation

15

Section V

5-4-3. After stop, automatically restart after delaying 60 seconds, but if the time

setting of P5 more than 60 seconds, the delay time is according to P5. During

delay time the state indicator flashes。

5-4-4. The total automatically start times can be N, Including power-on start and

restart after a failure. N is the setting value of PE. Auto-start mode must be

again on electricity then take effective , and it is effective again after the

power is on for every time。

5-4-5. When PE is set to 10, banned the function of losing electric protection . When

the power is on, if the outside control terminal is in a closed state, then

automatic starter motor, which means allows the electric start-up.

5-4-6. When PE is set to 11, it can re-start after failure: When the external control of

instantaneous stop terminal ⑦ is not prohibited ( PC> 0), or occurred the fault

of instantaneous stop, overheating, overvoltage, under voltage and then

recovery, can start the motor again without reset.

5-4-7. When PE is set to12, banned the function of losing electric protection and

restart after fault。

5-4-8. When PE is set to 13, running the function of memory recovery. During the

running of bypass state , the power is off and then is on, the soft starter will

auto-start recovery bypass operation。

5-4-9. Warning: The soft starter with the function of voltage-absent protection ,

when the power is off and then on, no matter the external control terminals in

what position,it won't self-starting, so as to avoid injuries. But when the

automatic restart function allows, banned the function of losing electric

protection , allowing the memory running resume function, the function of

losing electric protection will fail!

5-5 Other settings Description

5-5-1 P8 set used to select input and display the way, as followed table:

P8 set value 0 1 2 3

P6, P7 input

Current value

Percentage

Current value

Percentage

Operation

display

Current value

Current value

Percentage

Percentage

When the input mode of P6, P7 as a percentage, it is indicates the percentage of

motor current value setted by PP.

5-5-2 PD used to select the motor start control mode, as followed table:

Value

0 1 2 3 4 5 6

7

Keyboard

1 1 0 0 1 1 0 0 External control

0 1 1 1 1 0 0 0 Communicate

0 0 0 1 1 1 1

0

⑴ In table 1 indicates allowed, 0 indicates prohibited. For example, if the

accident is not allowed to stop after starting, or not allow accidental starting

during the maintain-ance, you can set it to 7, then ban all the operation of

Section V Control panel and operation

16

Section V

starting and stopping

⑵ When the external control allows, the external control terminal ⑧, ⑩ must be

connected by a normally closed switch or shorted , or can not start the motor.

5-5-3 PF is the selection of allowing to modify parameter, there are three options:

⑴ PF is setted to 0, it is prohibited to modify any parameter in addition to PF.

⑵ PF is setted to 1, it is prohibited to modify P4, P7, P8, PE, PH, PJ, PL, PU

parameters。

⑶ PF is setted to 2, it is allowed to modify all the parameters.

5-5-4 PU is used to set the motor under load protection。

5-5-4-1 PU <10, the motor under load protection is prohibited.

5-5-4-2 The range of low load current protection is 10% to 90% of the motor

rated current, it is decided by the ten digits of PU.

5-5-4-3 The delay time of low load is ranging from 5 to 90 seconds, it is setted

by 10 times of PU digit. If the PU digit is 0, the protection operation

delays 5 seconds. For example,PU = 42, indicates the low load current is

40% , the delay time of protection action is 20 seconds。

5-6 .Help and instructions

Help information as following table:

Display

Explanation

AC:XXX

Three digital voltmeter, to monitor three-phase AC power supply

voltage.

022-3

the specifications of soft starter is 22KW-380/50Hz

H1:E05

last occurred fault information Err05.

H2:E01

There had been a fault information Err01.

H3:E06

There had been a fault information Err06.

H9:E00

There was no fault information.

Uer3.0

the software version of this product is Ver3.0. With the software

upgrade, version with the increase.

LXXXX

Total number of successful starting.

RUNXX

The spending time (seconds) of last soft starting (starting

successfully) .

Note: H1 ~ H9 with recursive way to storage newly happened nine fault information.

⑴ In the non-soft start and non-soft stop state, and did not enter the setting mode,

press the Set key, can enter the Help menu, and then press the acceleration or

deceleration key to select message。

⑵ In the help state, press the Set key or Stop button to exit help state。

17

第

十

Chapter Ⅵ

Section Ⅵ Protection and description

PR5200 series soft starter with complete protection to protect the safety of soft

starter and motor. During the application, appropriate protection parameters and level

should be setted based on different situation.

6-1 Protection functions and their parameters

6-1-1. Soft starter over-temperature protection: the temperature rose to 80 ℃ ± 5 ℃

over-temperature protection, when the temperature dropped to 55 ℃ (the

lowest), no over-temperature protection。

6-1-2. Input phase protection lag time : <3 seconds。

6-1-3. Three-phase unbalance protection lag time: <3 seconds.

6-1-4. Three-phase unbalance protection lag time: <3 seconds.It is based on the

deviation of all phase current greater than 50% ± 10% . When the load

current is lower than 30% of the nominal rating of soft starter, the benchmark

deviation will increase.

6-1-5. Starting time of over current protection: continuous 5 times greater than the

maximum operating current of the protection time setted byP7 in Table 6.1。

6-1-6. Time of running overload protection, it is based on the maximum operating

current of P7 and doing the inverse thermal protection, trip protection time

curve shows on Chart 6.1.

6-1-7. The protection lag time of much too low supply voltage, when the power

supply voltage is lower than the 40% of limit, the protection time <0.5

seconds, or the protection time <3 seconds if it is lower than the setting value.

6-1-8. The protection lag time of much too high supply voltage : when the power

supply voltage is lower than the 140% of limit, the protection time <0.5

seconds, or the protection time <3 seconds if it is higher than the setting

value.

6-1-9. The protection delay time of load short-circuit : <0.1 seconds, the current is

10 times more than soft starter nominal rated current. This protection can not

replace fuse short-circuit protection device.

6-1-10. Motor under load protection, the current range is 10% to 90% of motor rated

current, the protection action delay from 5 to 90 seconds。

These time parameters are from tested effective signal to a tripping protection

instructions, and the parameters just for reference. All the protection functions of

Section Ⅵ Protection and description

18

Chapter Ⅵ

PR5200 series soft starter can be verified through the actual or simulation method. If it

can't meet the user's requirements, special protection device should be added to ensure

safety。

6-2 Protection level setting description

6-2-1. In order to adapt to different applications, PR5200 series soft starter has five

protection level, there are 0: primary, 1: light load, 2: Standard 3: heavy, 4:

Advanced, it setted by PC setting. Among them,

6-2-1-1. Primary protection is against to the function of external terminal

instantaneous stop, meanwhile only remains the overheating, short circuit

and main circuit fault protection, it can be applied to needed emergency

start in unconditional occasion, such as fire systems, etc.

6-2-1-2. The three protection level of light load, standard load and overload have

the complete protection function. The difference is the time curves of

motor overloaded thermal protection are not the same. The time

parameters of motor thermal protection are as Table 6.1 and Chart 6.1.

6-2-1-3. High level of protection standards is stringent at start. Other protection

features parameters keep the same with standard protection set.

6-2-2. Protection level and thermal protection time according to PC setting is as the

diagram below:

Diagram 6.1

PC setting

0(Primary)

1(Light load)

2(standard)

3(heavy load)

4(high

grade)

Description

Running overload

Level of

protection

no

2 level

10 level

20 level

10 level

According to

IEC60947

-4-2 Standard

Start over-current

Protection time

no

3 seconds

15 seconds

30 seconds

15 seconds

Starting current for

more than F7setting

5times calculation

Overload trip time

running list

Current

multiple

(I/Ie)

3 4 5 3 4 5 3 4 5 3 4

5

Typical values

for the table

Trip time

(seconds)

4.5

2.3

1.5

23

12

7.5

46

23

15

23

12

7.5

Setting item PP should be according to the value of motor rated input current,

Otherwise, when the setting item P6, P7 as a percentage of the input mode (Set by the

setting item P8)Starting current and protect the current will be with high deviation.

The motor current set by item PP can not be less than 20% of the soft starter

nominal current. When the motor current set by PP is small, tripping action for

protecting the sensitivity of the error will increase.

6-2-3. According to IEC60947-4-2 standard curve of the motor thermal protection

Chapter Ⅵ Protection and description

19

Chapter Ⅵ

tripping time is as follows:

Chart 6.1

Protection tripping time curve (thermal state)

20

第

十

Section VII

Section VII Test runing and application

Double-check before power running according to the following terms:

Whether the soft starter power match with the motor rated power.

Whether the motor insulation satisfy the requirements.

Whether the Input and output main circuit wiring is correct.

Whether all the terminal screws are tightened.

7-1. Power test running

Test running

Make sure the supplying power voltage is

in the rated input voltage range of soft

starter

Follow 4-1 wiring diagram of soft starter, make

sure phase sequence connection of the bypass

contactor is correct, then power is on.

Setting PP according to the input rated current

of the motor plate

Press the Run Key to starting motor

The direction of motor rotation

is correct.

To stop the machine immediately, and cut off

the input power and changing the reversing

wiring of the main loop.

Stop for ending the test running.

N

Y

Section VII Test runing and application

21

Section VII

7-1-1. If the motor starter status is not satisfactory, Refer to 7.2 of the soft starter

starting mode and application to select appropriate starting model.

7-1-2. If the motor starting torque is not enough, you can change the starting voltage

(voltage mode) or current-limiting value (current mode), to improve the motor

starting torque.

7-1-3. When soft starter power on, do not open the cover, to avoid electric shock.

7-1-4. In the power test of running, if appearing unusual phenomena, such as

abnormal noise, smoke or odor, etc., should be quickly cut off the power and

make further investigation.

7-1-5. If power on or when starting, appearing failure light and display ErrXX, you

can find the reason according to the displayed fault code and the

corresponding chapter of the cause.Press the stop button or external stop

button to reset the fault status.

Note:

⑴ When the ambient temperature is below -10 ℃, should power on for more

than 30 minutes to warm-up before starting.

⑵ When the soft starter drive the motor successfully, the operation status

indicator on the middle panel lights, that proves the bypass is in running status.

If at this time, the motor stop by bypass contactor without actuation,y ou

should check the bypass contactor and associated wiring connection.

7-2. PR5200 Series soft starter starting mode and application

PR5200 series soft starter has six models to suit a variety of complex starter motor

and load conditions, the user can choose it as different application.

7-2-1 Current limit starting mode

When setting PB to 0, Set the start mode

for this mode.

Chart 7.1 shows the current limit mode

of the motor starting current waveform

changes. I1 is starting current limit by

setting, when the motor starts, the output

voltage rapidly increases, Till the motor

current reaches the current limit value I1, and maintain the motor current is not higher

than this value, then gradually as the output voltage increased, gradually accelerate

the motor, when the motor reaches the rated speed, the bypass contactor make

actuation, output current rapidly dropped to or below the motor rated current Ie,

starting process is complete.

When the motor is lightly loaded or setingt the current limit highly, the

maximum starting current may not reach the set limit value is normal.

Section VII Test runing and application

22

Section VII

Current limit starting mode is generally used for a strictly limited starting

current requirements of the occasion.

7-2-2 Voltage ramp start model

When PB setting item is 1, Start

mode is for this mode.

Chart 7.2 shows the output

voltage waveform as voltage ramp

start voltage waveform. U 1 is the

initial starting voltage of starting,

when the motor start, the motor

current does not exceed 400% of

rated range, the output voltage of soft starter quickly rise to U1, then the output

voltage gradually increase by the start parameters setting, the motor is in smooth

acceleration according to voltage continuously rise, when the voltage reach the rated

voltage Ue, the rated motor speed, bypass contactor act, starting process is complete.

Starting time t is based on standard load obtained in the standard experimental

conditions, control parameters, PR5200 series soft starter is based on this parameter

benchmark, by controlling the output voltage, make the motor speed up in a smooth

start-up process, not a mechanical control, regardless of time t. Acceleration is

smooth. In view of this, when the load is light, set the start time often less than the

starting time, as long as a smooth start is normal.

In general, the voltage ramp start mode is suit to not strict starting current

requirement and strict demanding of a

smooth start of the occasion.

7-2-3 Kickstart mode

PB setting item set to 2 or 3, starter

model is for this mode.

Chart 7.3 and Chart 7.4 shows the

kickstart mode waveform of the output. In

some heavy load situations, due to

mechanical effects of static friction, when

it can not start the motor, you can use this

start mode. At the start, imposing a high

fixed voltage to the motor first and last for

a limited period of time, to

Section VII Test runing and application

23

Section VII

Before using this model, start motor with non-sudden jump model, if the motor

can not move due to static friction, then use this model; otherwise avoid to start this

mode to reduce the unnecessary high current impact.

7-2-4 Current ramp start mode

PB items set 4, start mode is for this mode.

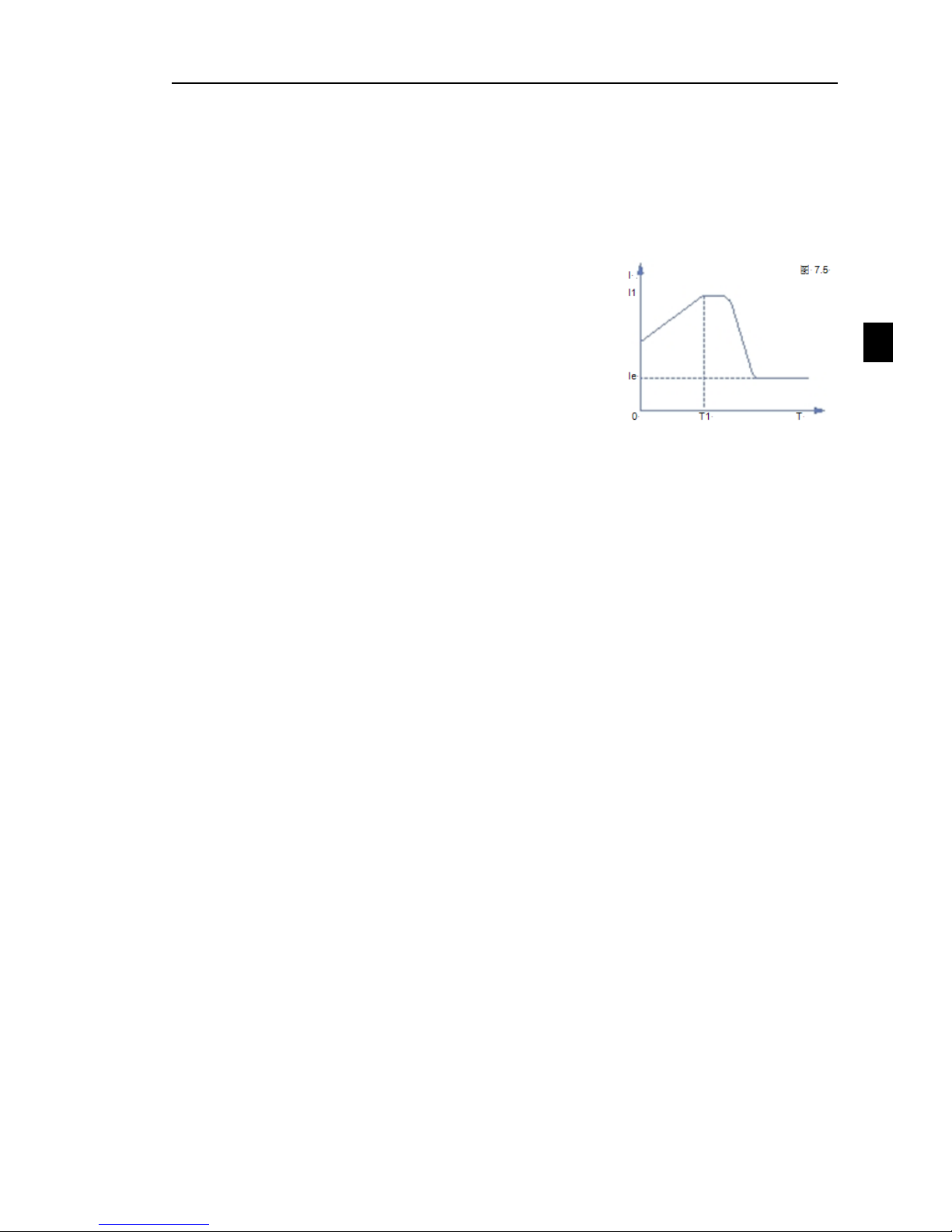

Chart 7.5 shows the Current Ramp start mode

output current waveform, which I1 is the current limit

set P6, T1 value is the time set by P1.

Current ramp start mode has a strong

acceleration ability, for bipolar motors, can also

shorten the start-up time within a certain range.

7-2-5 The voltage limiting double loop start mode

PB Set PB as 5 to set start mode for this mode.

Double loop starting voltage limiting mode adopt voltage ramp and current limit

dual closed-loop control model, is both stable requires and strict current limiting

demanding, the integrated starter-limiting mode, it uses the prediction algorithm to

estimate the work status of the motor.

In this start mode, output voltage waveform will be based on the motor and load

conditions vary.

7-3. PR5200 series soft starter's stop mode and application

PR5200 series soft starters, there are two stop modes, soft-stop mode and free

stop mode.

7-3-1 Soft stop mode

When Setting item P2 is not zero, set the stop mode for this mode.

In this stop mode, the motor power start from the bypass contactor and switch to

the output of soft starter thyristor, soft starter output voltage decrease steadily from

the total pressure, reducing the motor speed steady in order to avoid mechanical

shock, till the motor stops running. Soft stop output cut-off voltage equal to the initial

voltage of starting.

Soft stop mode can reduce and eliminate the surge of pump type load.

Soft stop mode can use setting item PL to set the soft stop current limit, in soft

stop, reduce the impact of high current, pay attention that, this soft start current limit

is a percentage calculated on the basis of starting current limit value.

7-3-2 Free stop mode

Item P2 is set to 0, set stop mode for this mode.

In this stop mode, when the soft starter receive the stop command, immediately

disconnect the bypass contactor and ban soft starter thyristors voltage output, motor

gradually stop as load inertia. In the situation of one drive two(more) wiring, should

set soft starter stop mode as this, in order to avoid of the phase fault reporting when

Section VII Test runing and application

24

Section VII

output switching.

Under normal circumstances, if not necessary soft stop, stop mode should be

free stop model, to extend the life of the soft starter.

As stop model completely ban the instantaneous output, can avoid an

instantaneous high-current impact in special applications.

7-4. Special application

7-4-1 .Motors in parallel Start:

If not exceed the rated power limit of the soft starter, the motor can be connected

in parallel (motors sum current can not exceed the power of soft starter, the type

selected depending on the application rated current), but at this time should provide

additional thermal protection devices for each motor.

7-4-2 Two-speed motor start:

PR5200 series soft starter can start with two-speed motor, before changing from

low speed to high speed, must be solved by delayed magnetic period, to avoid a very

large reverse current between the line and the motor.

7-4-3 Long cable:

As the resistance of the cable causes, a very long motor cables could cause

voltage landing, if the voltage drop is very obvious, it will affect the current

consumption and starting torque, when choosing motor and soft starter, must consider

this.

7-4-4 soft starters parallelled with the same one power line:

If in a power line, installed several soft starters, should install the input reactor

between the wiring of the soft starter and transformer, to the middle of the line should

be . Reactor should be installed between each feeder circuit breaker and soft starter.

7-4-5 Surge Protection Device (SPD) application:

In the applications which may suffer from lightning or other causes that lead to

overvoltage, overcurrent, surge interference, should consider installing a surge

protector, detailed application methods instructions, refer to POWTRAN company

"surge protector (SPD)" Product Sample or other relevant data.

7-5. Application examples

Under different load conditions, parameter settings for example shown in Table

7.2. Data in the table is only for reference, should be adjusted according to actual

situation

Table 7.2

Type of load

Start time

(seconds)

The initial

voltage

Voltage starting

(maximum current limit)

Limit Start

Ball

30

60% 4 4.5

Section VII Test runing and application

25

Section VII

Fans

26

30% 4 3.5

Centrifugal pump

16

40% 4 2.5

Piston compressor

16

40% 4 3

Enhance the

mechanical

16

60% 4 3.5

Mixer

16

50% 4 3

Crusher

16

50% 4 3.5

Screw compressor

16

40% 4 3

Screw conveyor

20

40% 4 2

Light load motor

16

30% 4 3

Belt conveyors

20

40% 4 2.5

Heat pump

16

40% 4 3

26

第十第

十

第

十

Section VIII

Section VIII RS485 communication

POWTRAN PR5200 series soft starters through the built-in RS485 standard

interface can be connected with the personal computer and PLC for serial

communication.

Controlled by the host command to run the soft starter / stop, monitor the

operational status of the soft starter and modify its function data, etc.

This communication details, please refer to RS485 operating instructions.

Soft starter can be used for RS485 communications for remote operation by

computer, run the command input, run the state administration, more than one soft

starter function code data one time input to achieve such a write function code input

effort.

8-1. Main functions:

A. Running stop command input .

B. Health monitoring.

C. Real-time tracking (the table shows operating information).

D. Function code to one time read, write, save to the documentation.

E. Communications software, please separate agreement with the our company.

27

第

十

Section IX

Section IX Fault causes and treatment

Fault codes and treatment as following table:

Display

Description

Problems and treatment methods

Err00

Failure has been

solved

Just happened undervoltage, overvoltage or

overheating, instantaneous stop terminals are open,

such failures, now has been normal, this time to

prepare lights, reset to start the motor.

Err01

External terminal

momentary

Open circuit

Short-circuit connection with the external

Instantaneous stop terminal⑦and public terminal

⑩ , or connecting to other protective devices

normally closed contact.

Err02

Soft starter

overheating

Start too often or the motor power do not match

with the soft starter.

Err03

Starting times

too longer than

60 seconds

Starting parameter settings is inadequate or the load

is too heavy, the power capacity is not enough,

etc.

Err04

Input phase lost

Check the input or main circuit failure, whether the

bypass contactor is stuck in the closed position and

whether the SCR is in open circuit and so on.

Err05

Output phase

lost

Check the input or main circuit failure, whether the

bypass contactor is stuck in the closed position and

whether the SCR is in open circuit and so on.

Err06

Three-phase

unbalanced

Check whther the input three-phase power supply

and the load motor is normal.

Err07

Start over-

current

Whether the load is too heavy or motor power does

not match with soft starter.

Err08

Running

overload

protection

Whether the load is too heavy or setting items P7,

PP parameters set incorrectly.

Err09

Supply voltage

is too low

Check the input voltage or setting item P9

parameter set incorrectly.

Err10

Supply voltage

is too high

Check the input voltage or setting item PA

parameter set incorrectly.

Err11

Set the

parameters

error

Modify the settings, or pressing the Enter key on

power to restore the factory values.

Err12

Load short-

circuit

Check whether overloading or thyristor short

circuit.

Err13

Automatic re-start

wiring error

Check whether the outside the control start and stop

terminal is connected to 2-wire mode.

Section IX Fault causes and treatment

28

Section IX

Err14

External Stop

terminal wiring

error

When you allow external control mode, the external

control stop terminal is in the open state, which can

not start the motor.

Err15

Motor

underload

Check the motor shaft and load faults.

Note: Some fault phenomena are interrelated, as the report Err02, may be

related with soft starter overheating or load short current, so when checking fails,

consideration should be comprehensive, accurately determine the point of failure.

29

第

十

Section X

Section X Soft-start model specifications and options

10-1 PR5200 Series soft starter (5.5KW-55KW) list of the external parts of the

specification reference:

Soft starter model

Rated

Power

(KW)

Rated

current

(A)

Supporting

circuit breaker

model (QF)

Supporting

the bypass

contactor

model

pporting the

bypass

contactor

type (KM)

A line size

Remarks

PR5200 5R5G3

5.5

11

CM1-63L/16

CJ20-25

2.5mm2 Cable

55KW and below,

the wiring for the

three-in & six-out,

usually in the

bypass contactor

circuit, do not

require heating or

motor protection

devices, have line

protection.

Rated power and

rated current is the

maximum rating of

the soft starter.

PR5200 7R5G3

7.5

15

CM1-63L/20

CJ20-25

4mm2 Cable

PR5200 011G3

011

22

CM1-63L/32

CJ20-40

6mm2 Cable

PR5200 015G3

015

30

CM1-63L/40

CJ20-63

10mm2 Cable

PR5200 018G3

018

37

CM1-63L/50

CJ20-63

10mm2 Cable

PR5200 022G3

022

44

CM1-63L/63

CJ20-63

16mm2 Cable

PR5200 030G3

030

60

CM1-63L/80

CJ20-100

25mm2 Cable

PR5200 037G3

037

74

CM1-63L/100

CJ20-160

35mm2 Cable

PR5200 045-3

045

90

CM1-63L/125

CJ20-160

35mm2 Cable

PR5200 055G3

055

110

CM1-63L/160

CJ20-160

35mm2 Cable

10-2 PR5200 Series soft starter (75KW-400KW) list of external accessories

specifications reference:

Soft starter model

Rated

Power

(KW)

Rated

current

(A)

Supporting

circuit breaker

model (QF)

Supporting the

bypass

contactor

model

pporting the

bypass

contactor type

(KM)

A line size

Remarks

PR5200 075G3

075

150

CM1-225L/180

CJ20-250

30*3mm2 Cable

75KW and below, the

wiring for the three-in

& six-out, when the

bypass contactor is

closed position with

line protection, no

need external motor

protection device.

Rated power and rated

current is the

maximum rating of the

soft starter, matching

circuit breaker and the

bypass contactor

should match the size

of motor specification.

PR5200 090G3

090

180

CM1-225L/225

CJ20-250

30*3mm2 Cable

PR5200 115G3

115

230

CM1-225L/315

CJ20-400

30*3mm2 Cable

PR5200 132G3

132

260

CM1-400L/315

CJ20-400

30*4mm2 Cable

PR5200 160G3

160

320

CM1-400L/350

CJ20-630

30*4mm2 Cable

PR5200 185G3

185

370

CM1-400L/400

CJ20-630

40*4mm2 Cable

PR5200 200G3

200

400

CM1-400L/500

CJ20-630

40*4mm2 Cable

PR5200 250G3

250

500

CM1-630L/630

CJ20-630

40*4mm2 Cable

PR5200 280G3

280

560

CM1-630L/630

CJ29-1000A

40*4mm2 Cable

PR5200 320G3

320

640

CM1-630L/700

CJ29-1000A

40*4mm2 Cable

PR5200 400G3

400

800

CW1-1000/3

CJ29-1000A

40*4mm2 Cable

30

第

十

章

Section XI

Section XI Quality Assurance

This product quality assurance is in accordance with the following provisions:

1. Indeed the responsibility of the manufacturer, quality assurance details:

1-1. When used in the China (to the date of shipment)

※ Within one month after shipping, refund, replacement,

※ Within three months after shipment, replacement, repair.

※ Within 15 months after delivery, repair.

1-2. Export to overseas (excluding demestic), the ship within six months after

purchase, be responsible for repair.

2. No matter when and where, use of our brand's products, enjoy the paid services

for all life.

3. The Company's sales throughout the country, production, all agents can provide

service to this product, their service conditions:

3-1 Location of the unit to "3" inspection services (including troubleshooting).

3-2 Be in accordance with these companies and distribution agents in relation to

service, the contract responsibility standards.

3-3 Can be paid to the general mass of the distribution agent, the request for after-

sales service (whether or not the warranty).

4. Quality of the product or products appear responsible for the accident, up to 1-1 or

1-2 terms only assume the responsibility, if you need more liability guarantee,

prior to your own property insurance in insurance companies.

5. This product is warranted for one year from the date of shipment.

6. In the case of the following causes of failure, even during the warranty period is

also a paid repair:

6-1 Incorrect operation (according to manual date), or caused by modified without

permission to repair the problems.

6-2 Beyond the standard specification requires, problems caused by the use of the

the soft starter.

6-3 After purchasing, loss or damage caused by improper handling.

6-4 The device poor or failure caused by environmental aging.

6-5 Due to earthquake, fire, wind and flood damage, lightning, abnormal voltage or

accompanied by other natural disasters damage.

6-6 Damage during transport (Note: The mode of transport specified by the client .

Our company assist on behalf of the procedures for transfer of goods).

6-7 Manufacturer's brand label, trademark, serial number, nameplate and other

damaged or unreadable.

6-8 Purchase agreement is not paid in money.

6-9 For installation, wiring, operation, maintenance or other use of objective reality

can not be described to the Company's service units.

7. For refund, replacement, repair services, goods shall be returned to the company,

confirmed the attribution of responsibility, before be returned or repai

POWTRAN Technology Product Warranty Card

Thank you very much for purchasing POWTRAN product.

The product has passed the strict quality inspection by POWTRAN technology.

According to the guarantee card, in the warranty period, if he product has quality

problem caused by the hardware malfunction during the normal using condition, the

company will be responsible for free maintenance.

Product type: Producing number:

Warranty Period:

Purchasing date: _____ Day _____ Month _____ Year

Invoice No.:

Customer Name:

(Or Company Name)

Address:

Postcode: Tel: Fax:

Dealers Name:

Address:

Postcode: Tel: Fax:

Dealers Seal

Customer feedback form of soft starter fault

Dear customer: In order to provide our best service to you ,please fill in the table

below

Applicatio

n

Motor

KW pole type

When

happens

Continuous operation Acceleration slow down power supply

others( )

What

displays

Alarm display( )with or without keyboard display( )

output voltage(YES NO)

Running

after rest

Yes No Resetting way Keyboard Panel Terminal Power

Others( )

The control

terminal

01,02 03,04 05,06 07 08 09 10 11,12

Others( )

Working

hours

frequency

Installatio

n place

Whether

the power

is off

Yes

No

Whether the

machine is

abnormal

YES

No

Whether it

has fault

before

Yes( Times)

No

The following table is filled in by service agencies

Maintenance Record:

The first

time

Maintenance

Agency Name

Tel

Address

Postcode

Maintenance bill

number

Maintenance

staff sign

The

second

time

Maintenance

Agency Name

Tel

Address

Postcode

Maintenance bill

number

Maintenance

staff sign

The

third

time

Maintenance

Agency Name

Tel

Address

Postcode

Maintenance bill

number

Maintenance

staff sign

Product information feedback

Dear users:

Thank you for your attention and purchasing POWTRAN technology products! In order to

serve you better, we hope to get your personal general information about using POWTRAN

technology products, your now and future demand on POWTRAN technology products, gain for

your valuable feedback. To facilitate as early as possible when you need our services, please visit

the company website POWTRAN technology Http://www.powtran.com "technologies and

services" and "Downloads" section for information feedback.

1) Download and update you product manual

2) Access to products, technical information, such as instructions, size characteristics, and

frequently asked questions

3) Application Case Share.

4) Technical consulting, on-line feedback

5) Feedback by the form of e-mail on product information and user needs information

6) For the latest products, access to all kinds of additional services and extended warran

Loading...

Loading...