Powtran PI76007800, PI7600, PI7800 User Manual

Foreword

CONTENTS

Thank you very much for purchasing PI7800,PI7600 Family Frequency

Inverters. This family is designed based on the experience of

POWTRAN Company in the professional manufacture and sale of the

products, and suitable for general-purpose machine, fan/pump drive,

high frequency drive and heavy load machine.

This User’s Manual provides the users with the instructions on the

installation, parameter setting, fault diagnosis, routine maintenance and

necessary precautions. Please read the Manual carefully before the

installation of the product in order to ensure that it can be correctly

installed and operated.

This User’s Manual includes PI7800,PI7600, the general purpose

control and special purpose control . The general purpose control ha

F,G ,M and H; The special purpose control has S,T and Z:

F: FLOW LOAD

G:GENERAL LOAD

M: MEIDDLE LOAD

H: HEAVY LOAD.

S: TEXDRIVE.

T: WINDLASS.

Z: JETDRIVE.

Please contact the local dealers or directly contact our company.

Please keep this user’s manual in good condition, for it will be helpful to

the repair, maintenance, and applications in the future.

For information about other product, please visit our website:

http://www.powtran.com.

Section I. Inspection and Safety Precautions.........................1

Section II. Installation & Standby Circuit................................3

Section III. Operating keyboard..........................................14

Section IV. Test running....................................................19

Section V. Function parameter table...................................21

Section VI. Function Parameter Description..........................34

Section VII. Fault Diagnosis and Solutions.............................88

Section VIII. Standard Specifications.....................................90

Section IX. Maintenance.................................................103

Section X. Options........................................................105

Appendix 1. PI7000 RS485 communication protocol...............109

Appendix 2. PG Instruction...............................................120

Appendix 3. Converter water supply controller instruction ........123

SECTION I. INSPECTION AND SAFETY PRECAUTIONS

Section I. Inspection and Safety Precautions

POWTRAN PI7800/7600 frequency inverters have been tested and inspected

before leaving the manufacturer. Before unpacking the product, please check if

its package is damaged due to careless transportation, and if the specifications

and type of the product complies with the order. Please contact the supplier of

POWTRAN products if any problems are found.

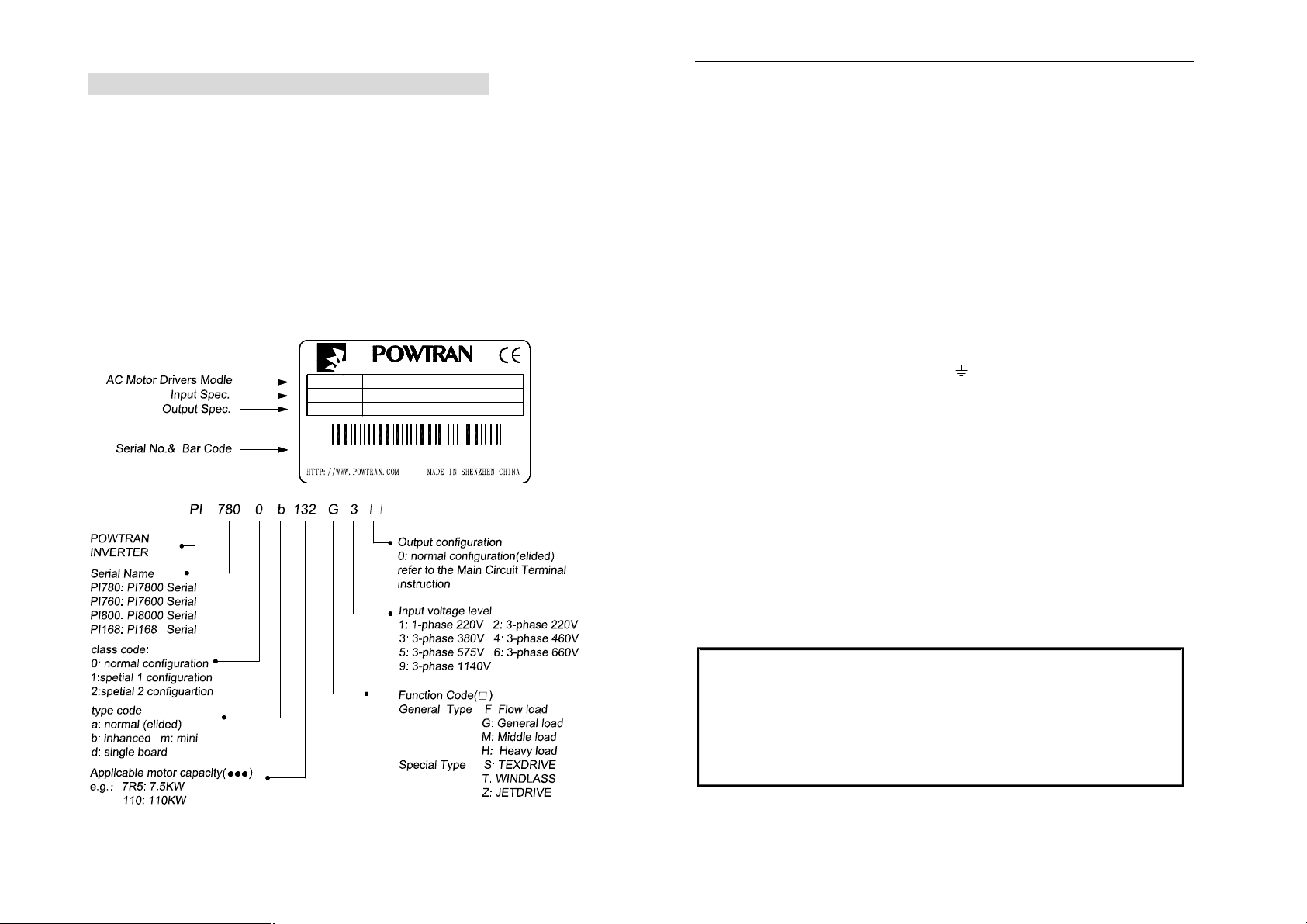

1-1. Inspection after Unpacking

※ Inspect that the contents are complete (one PI7000/7100 frequency

inverter, one Operation Manual).

※ Check the nameplate on the side of the frequency inverter to ensure that

the product you have received is right the one you ordered.

Instructions on name plate: (giving 132kW/380V as example)

TYPE:

SOURCE:

OUTPUT:

POWTRAN TECHNOLOGY CO.,LTD.

Model designation:

PI7800 132G3

3φ 380V 50-60Hz

132KW 250A 0.00-800.0Hz

Z0501A00001

the frequency inverter.

※ Fix and lock the panel before supplying power so as to avoid the danger

caused by the poor capacity or other components inside the inverter.

※ After the power supply is switched on, do not perform wiring or check, etc.

※ Don’t touch the circuit boards or its parts or components in the inverter

when it is powered, so as to avoid danger of electric shock.

※ If the power supply is switched off, do not touch the PCB or other parts

inside the inverter within 5 minutes after the keyboard indicator lamp goes

off, and you must check by using the instrument that the inverter has

completely discharged all its capacity before you start to work inside the

inverter. Otherwise, there will be the danger of electric shock.

※ The static electricity in human body will cause serious damage to the MOS

field effect transistor in the inverter. Please keep your hands away from the

PCB, IGBT and other internal parts before taking actions to prevent static

electricity. Otherwise, faults may be caused.

※ In use, the earthing terminal (E or ) of the frequency inverter must be

grounded to the earthing connections correctly and securely according to

the national electrical safety specifications and other applicable standards.

※ Please don’t shut off the unit by turning off the power supply. Turn off the

power supply after the motor has stopped its operation.

※ Meet CE standard with EMI filter.

1-3. Application

※ Powtran inverter is generally applied to 3 phase AC asynchronism motors.

※ Powtran inverter is applied to the admisive occasion, the occasion where is

not admissive may lead to fire, electric shock, explosion and so on.

※ If the inverter seizes up when it is applied to the equipment which may lead

danger (e.g. lift tools of transportation, aviation system, saftety equipment,

etc), it should be managed carefully. Do inquire the factory when it

happens.

1-2. Safety Precautions

※ Never connect the A.C. power supply to the output terminals (U, V, W) of

1

Only the well-trained personnel are allowed to use this

unit, and such personnel must read through the parts of this

manual relating to the safety, installation, operation and

maintenance before using the unit. The safe operation of this

unit depends on correct transport, installation, operation and

maintenance!

2

SECTION II. INSTALLATION & STANDBY CIRCUIT

Section II. Installation & Standby Circuit

2-1. Conditions for Use

1) Ambient temperature -10℃~40℃.

2) Avoid electromagnetic interference and keep the unit away from the

interference source.

3) Prevent dropping water, steam, dust, powder, cotton fiber or fine metal

powder from entering it.

4) Prevent oil, salt and corrosive gas from entering it.

5) Avoid vibration.

6) Avoid high temperature and moisture and avoid being wetted due to raining,

with the humidity below 90%RH (not dewing).

7) Prohibit the use in the dangerous environment where inflammable or

combustible or explosive gas, liquid or solid exists.

2-2. Installation

The frequency inverter must be installed by wall hooking in the indoor room with

adequate ventilation, with enough space left between it and the adjacent

objects or damper (walls) surrounding it, as shown in the below figure:

150MM

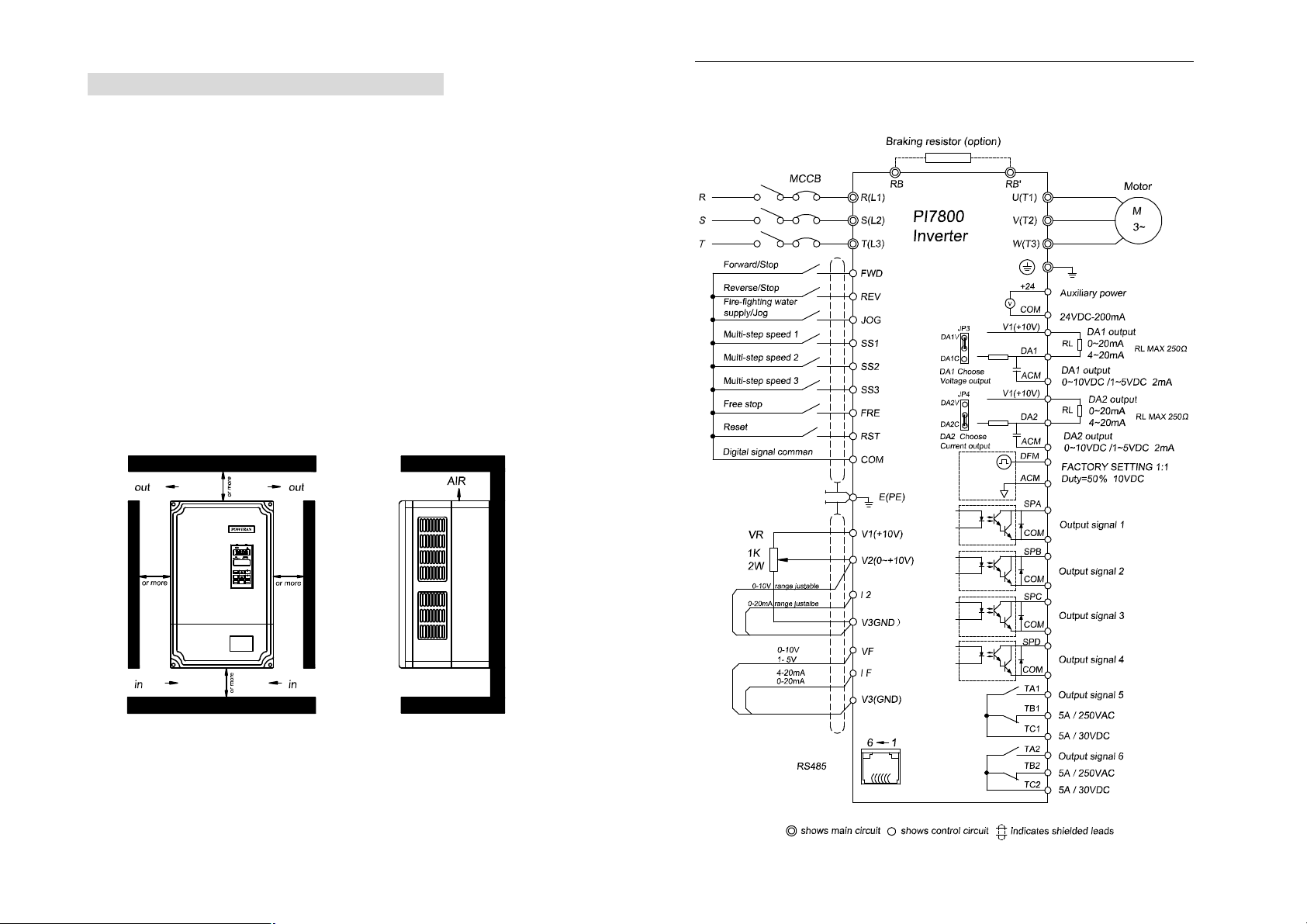

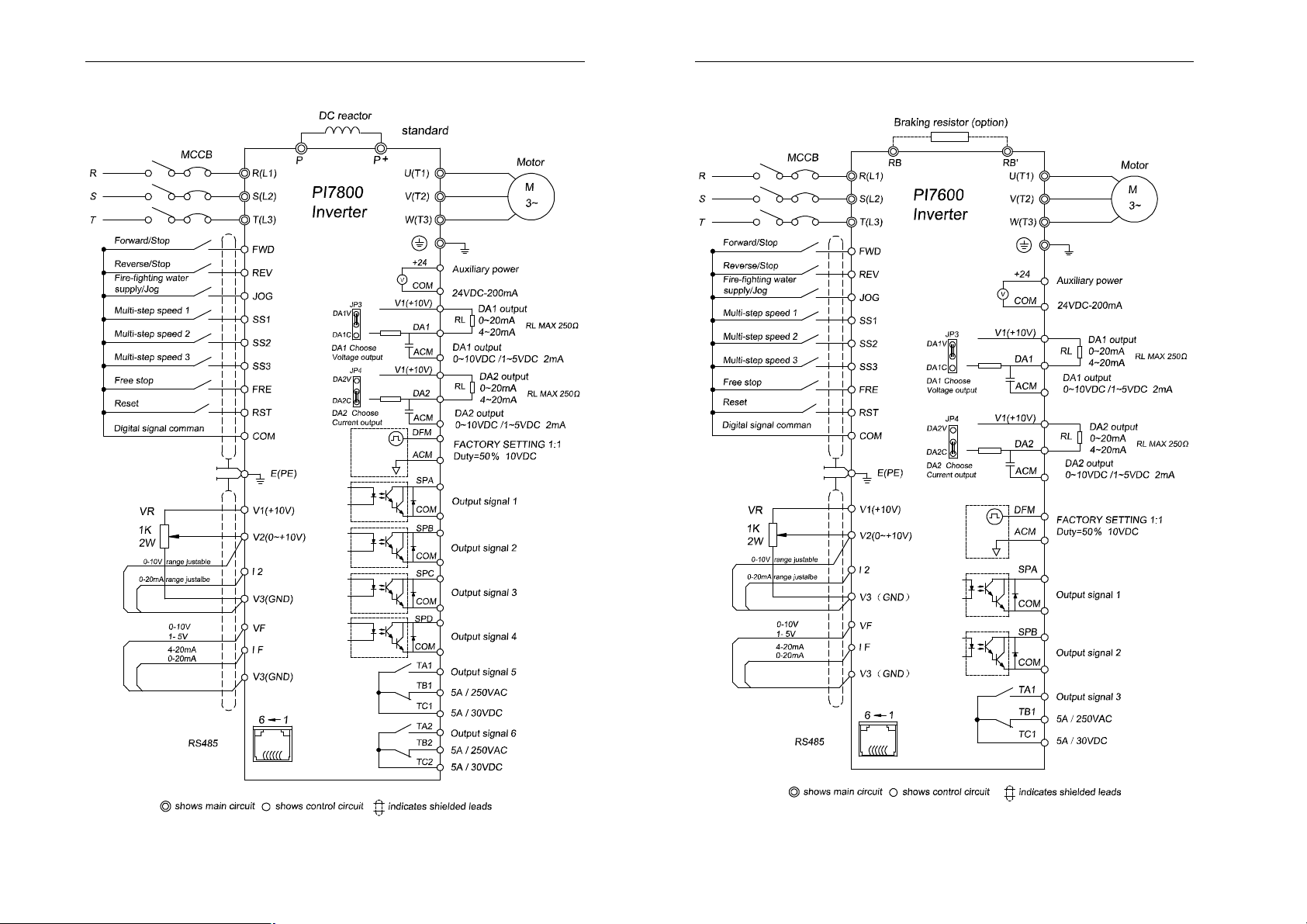

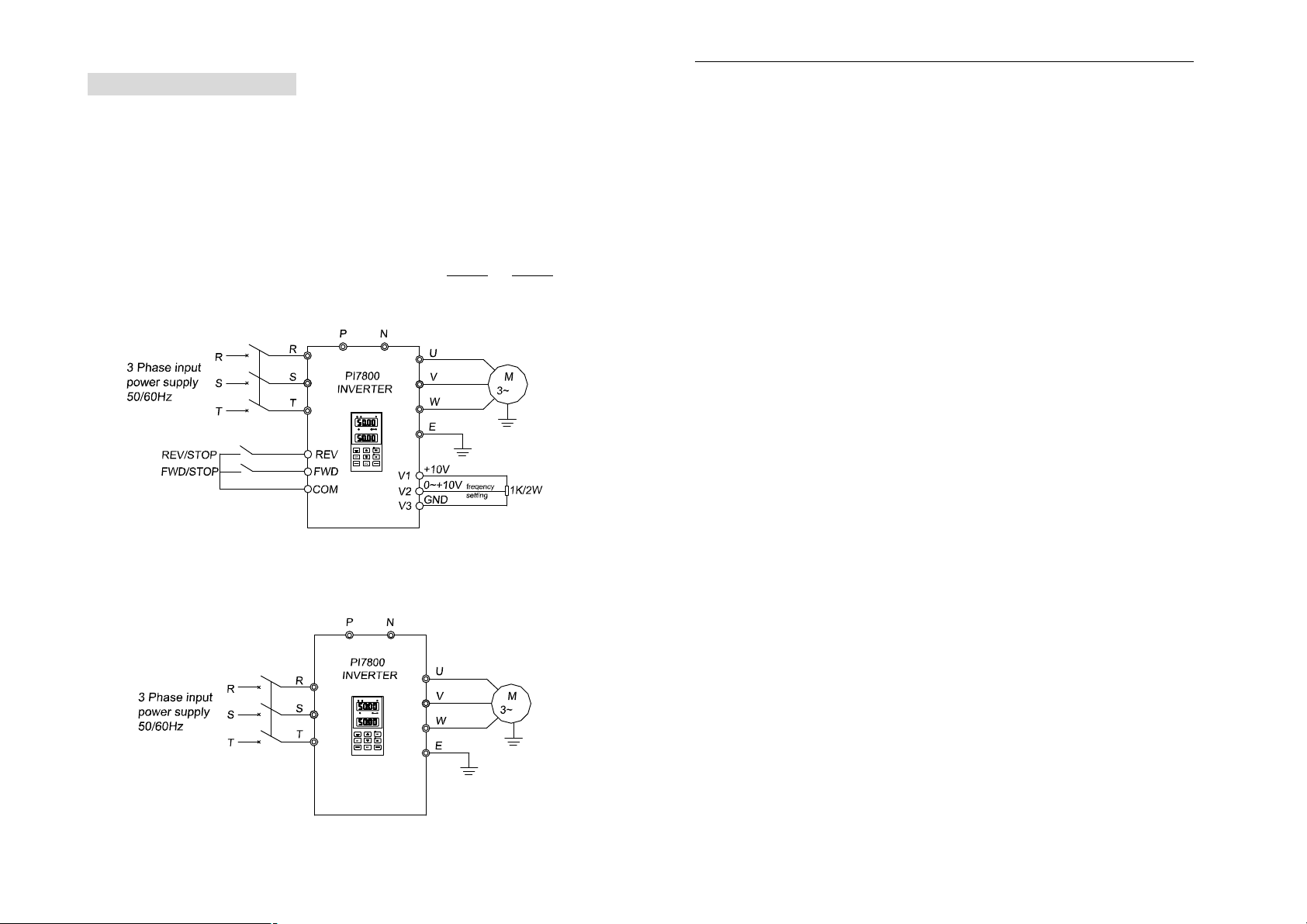

2-3-1. PI7800 Diagram

1. Wiring diagram 7.5KW~15KW and below

+ -

PRG

FWD

50MM50MM

REV

SET

STOP

ESC

JOG

RESET

DISPL

150MM

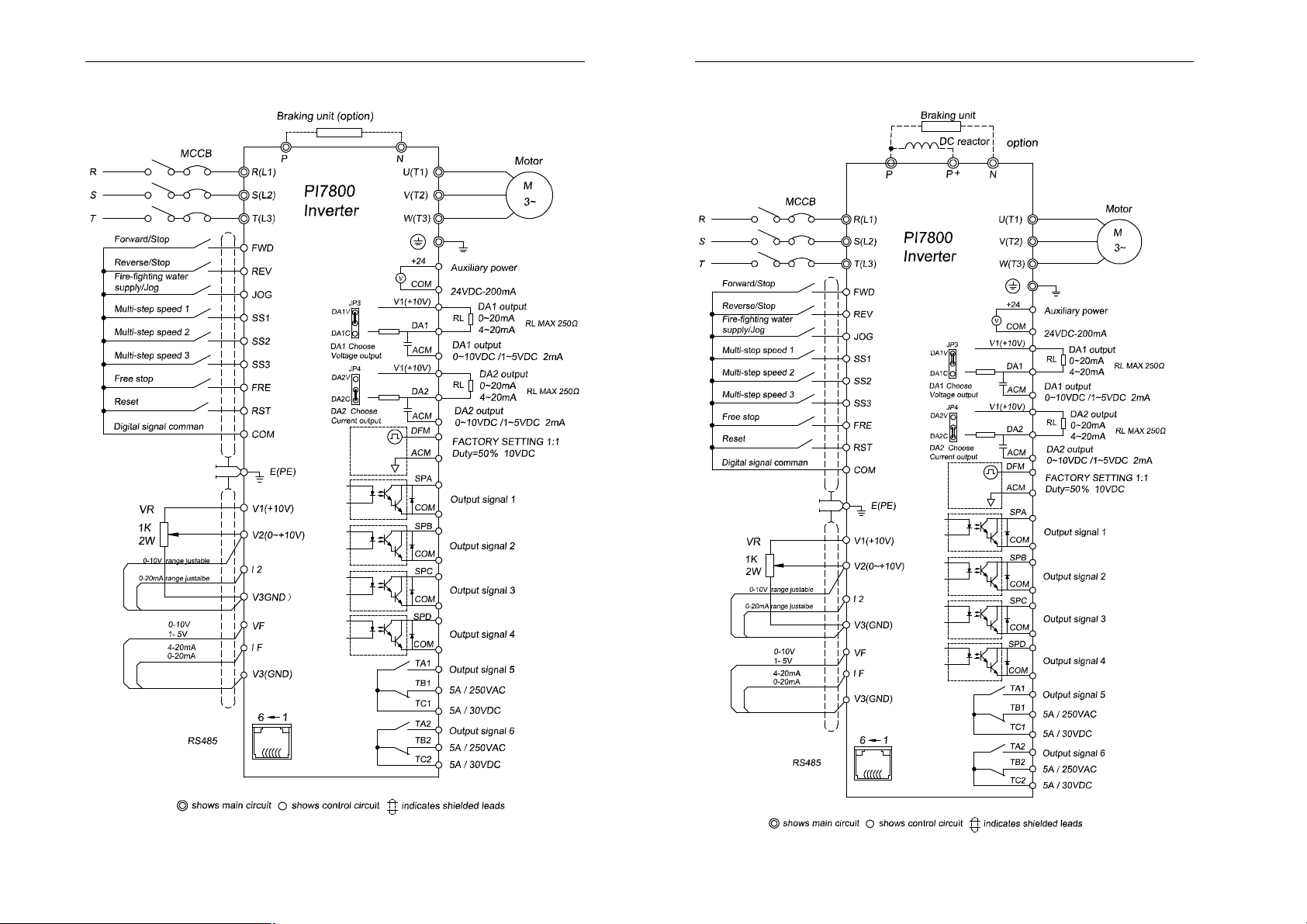

2-3. Wiring

The wiring of frequency inverter includes two parts: main circuit and control

circuit. The user must ensure correct connections according to the following

connection diagram.

3

4

SECTION II. INSTALLATION & STANDBY CIRCUIT

SECTION II. INSTALLATION & STANDBY CIRCUIT

2. Wiring diagram 18.5KW~22KW

3. Wiring diagram 30~160KW

5

6

SECTION II. INSTALLATION & STANDBY CIRCUIT

SECTION II. INSTALLATION & STANDBY CIRCUIT

4. Wiring diagram1187~355KW

2-3-2. PI7600 Wiring diagram

1. Wiring diagram 7.5KW and below

7

8

SECTION II. INSTALLATION & STANDBY CIRCUIT

SECTION II. INSTALLATION & STANDBY CIRCUIT

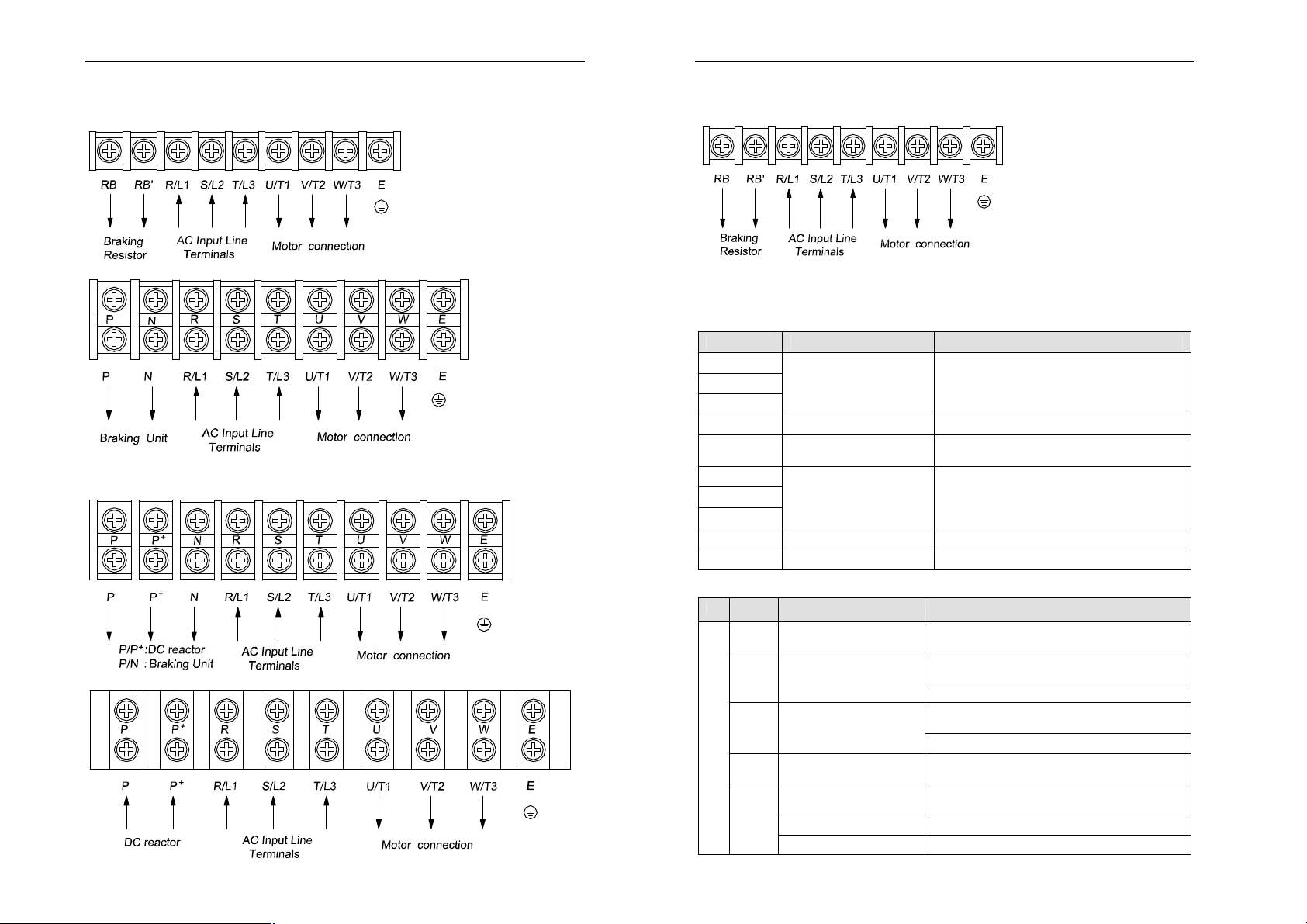

2-4. Main Circuit Terminals:

2-4-1. PI7800 Main Circuit Terminals

1. 7.5KW~15KW (380V) Main Circuit Terminal

2. 18.5~22KW (380V) Main Circuit Terminal

3. 30~160kW (380V) Main Circuit Terminal

Note: P/P+ Standard setting is short circuit; if it is with external reactance, please

disconnect and then connect it.

2-4-2. PI7600 Main Circuit Terminal

1. 7.5KW and below (380V) Main Circuit Termial

For 4N2B and 4N3B panel, “E” is on the steel panel.

Note: The above KW categaries are for G type inverter.

2-4-3. Terminal Function

Terminal Description Functions

R/L1

S/L2

T/L3

E/PE Grounding point Grounded to the earth

RB, RB′

U/T1

V/T2

W/T3

P+, N DC Bus output Connect the brake unit

P, P+ DC reactance Connect DC reactance

Power input for

frequency inverter

Connection point for

braking resistance

Connected to 3-phase power

(Single input connected to R ,T)

Connect brake resistance

3 Phase Output Connected to 3-phase motor

2-5. Control Circuit Terminals

Class Terminal

COM

4.187KW~355KW and above (380V) Main Circuit Terminal (132~160KW optional)

FWD Forward rotation command

REV Reverse rotation command

Control signal

JOG Jog command

SS1

9

Description Function

Common point for control

commands

Multi-step speed/acceleration

Rising/Falling control F04=4,for rising control

Frequency mode switch Switch the frequency setting mode with SS2

F05=1, Edge triggers(F62=0),and runs forward in falling

edge, stops in rising edge

F05=3, Level triggers(F62=0/1/2)

F05=1, Edge triggers (F62=0), and runs reverse in falling

edge, stops in rising edge.

F05=3, Level triggers(F62=0/1/2)

Level triggers, and executes JOG command in a lower

level, stops in a high level

F63=1/2,Short-circuited to COM to compose 7-step speed

and acceleration, level triggers, effective in a lower level

10

SECTION II. INSTALLATION & STANDBY CIRCUIT

SECTION II. INSTALLATION & STANDBY CIRCUIT

Multi-step speed/acceleration

SS2

Rising/Falling control F04=4,for falling control

Frequency mode switch Switch the frequency setting mode with SS1

Multi-step speed/acceleration

JOG control

SS3

Three-line running control F63=1/2,F62=2 Three-line terminal running for details

Program running restart For selecting the program running restart mode

FRE Free Run

RST Restore Level triggers, executes restore command in falling edge.

TA1

TB1

Output signal 5

TC1

TA2

TB2

Output signal 6

TC2

SPA/COM Output signal 1

Output signal

SPB/COM Output signal 2

SPC/COM Output signal 3

SPD/COM Output signal 4

V1,V3 Power Supply +10V, GND

V2 Voltage Input signal Range is adjustable in 0~10V

I2 Current Input signal Range is adjustable in 0~20mA

VF Voltage feedback input signal 0~10V/1~5V

IF Current feedback input signal 0~20mA/4~20mA

Common terminal of DA1 and

ACM

DA2

Power Supply of DA1 and

V1

DA2

Multi-function analog signal

DA1

Analog Input and output signal

Power

Auxiliary

Signal

Communication

output 1

Multi-function analog signal

DA2

output 2

DFM DFM multiple adjustment Factory setting 1:1, duty=50%, 10VDC

24V Power Positive terminal

COM Common point

SG+,

SG-,

SH

Communication positive/

negative signal, Screen signal

F63=1/2,Short-circuited to COM to compose 7-step speed

and acceleration, level triggers, effective in a lower level

Short-circuited to COM to compose 7-step speed and

acceleration, level triggers, effective in a lower level

F63=3 COM is short-circuited to SS3 to execute JOG

reverse command, to JOG to execute JOG forward

command, and the previous JOG direction is invalid.

Level triggers, and executes free stop command in a lower

level

TA1-TC1 is open and

TB1-TC1 is closed ( programmable)

TA2-TC2 is open and

TB2-TC2 is closed (programmable)

Output open collector signal (24VDC-50mA)

Used for common terminal when DA1/DA2 selects voltage

output

Used for Power Supply when DA1/DA2 selects current

output

0~10/1~5VDC

0~20/4~20mA

0~10/1~5VDC

0~20/4~20mA

Maximal output 24V/200mA

RS485 communication(refer to Appendix 1)

2-5-2 Control circuit terminal

1) 7KLCB.V4 Control circuit terminal

2) 7KSCB.V1 Control circuit terminal

2-6. Connection Precautions

※ Don’t install power factor capacitance or resistance-capacitance absorbing

device between the output terminals U, V, W of the frequency inverter.

※ To disassemble or replace the motor, the input power supply must be

turned off for the frequency inverter.

※ The motor or power supply can be switched on/off only after the inverter

stops its output.

※ In order to minimize the effect of electromagnetic interference, a surge

absorbing device should be installed if used electromagnetic contactor and

relay, etc. is near to the frequency inverter.

※ For external control of frequency inverter, a isolation device should be used

for the control lines or screened cable should be used.

※ A screened cable should be used as the signal connection line for input

command and must be routed separately as well, and it had better be

installed far from the main circuit.

※ When the carrier frequency is less than 3kHz, the distance between the

frequency inverter and motor must not be greater than 50 meters

(maximum). When it is above 4kHz, this distance should be reduced. The

cable for this connection had better be laid in metal conduit.

※ If the frequency inverter is equipped with peripheral devices (such as filter,

reactor), first measure its insulation resistance to the earth with 1000V

megohm meter, and ensure the resistance value is not below 4MΩ.

※ If the frequency inverter must be started frequently, don’t switch off its

power supply, and the operator must start or stop the inverter by using the

COM/FWD of the control terminal or Keyboard or RS485, in order to avoid

damage to the bridge rectifier.

11

12

SECTION II. INSTALLATION & STANDBY CIRCUIT

※ Don’t connect A.C. input power to the output terminals U, V, W of the

frequency inverter.

※ In order to prevent unexpected accidents, earthing terminal E or must

be grounded to the earth securely (the grounding resistance should be

below 100Ω). The cable size should be greater than half of belowmentioned corresponding cable size; otherwise current leakage will happen

possibly.

※ For wiring of main circuit, please refer to national rule.

※ Capacity of the motor should be equal to or smaller than that of the inverter.

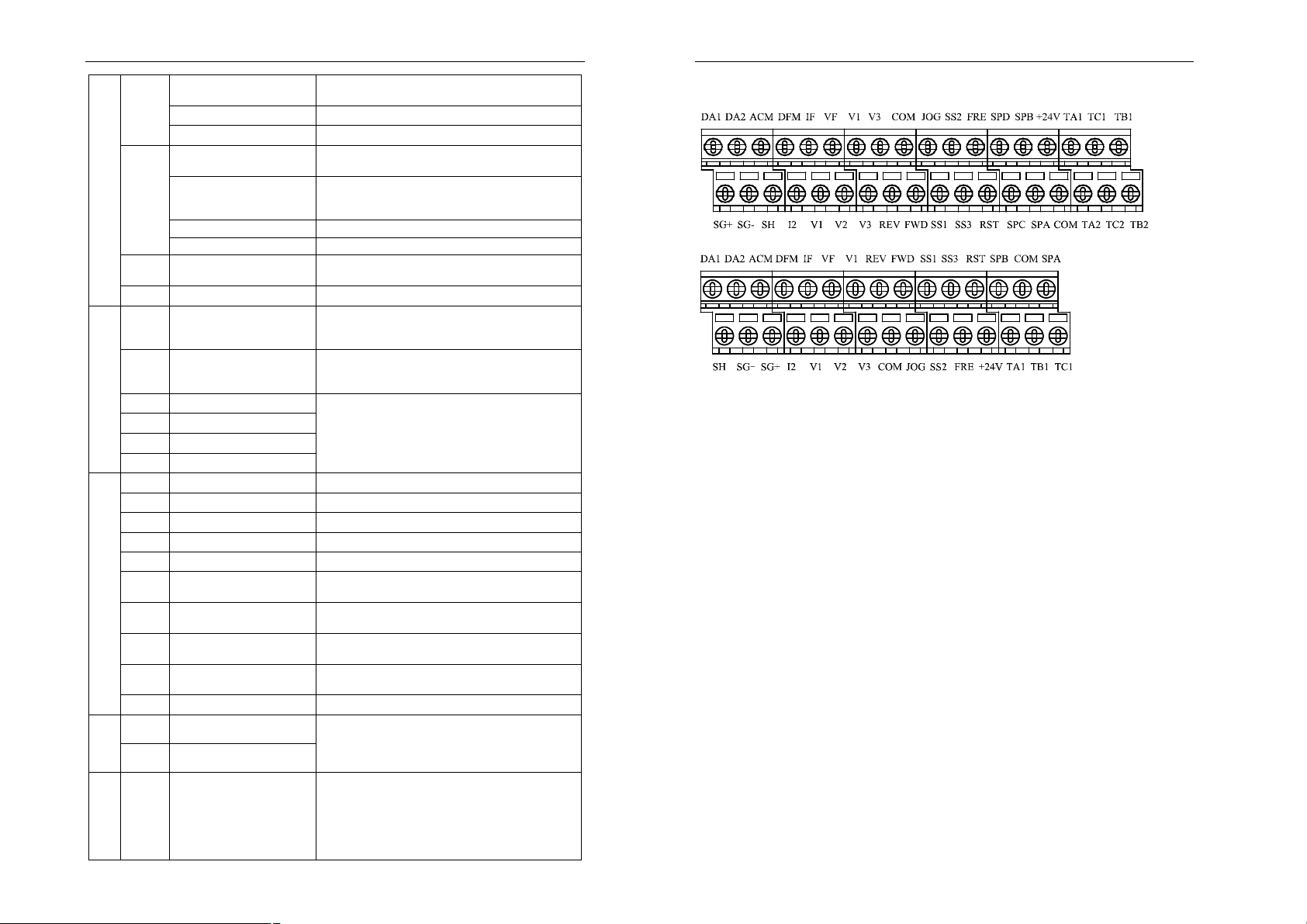

2-7. Standby circuit

When the fault or trip of the inverter may cause great loss or accident, please

add the standby circuit.

Note: confirm and test the running characteristic of the standby circuit, in order

to ensure the industrial phase and the converter phase are in the same direction.

I

nterlock relay

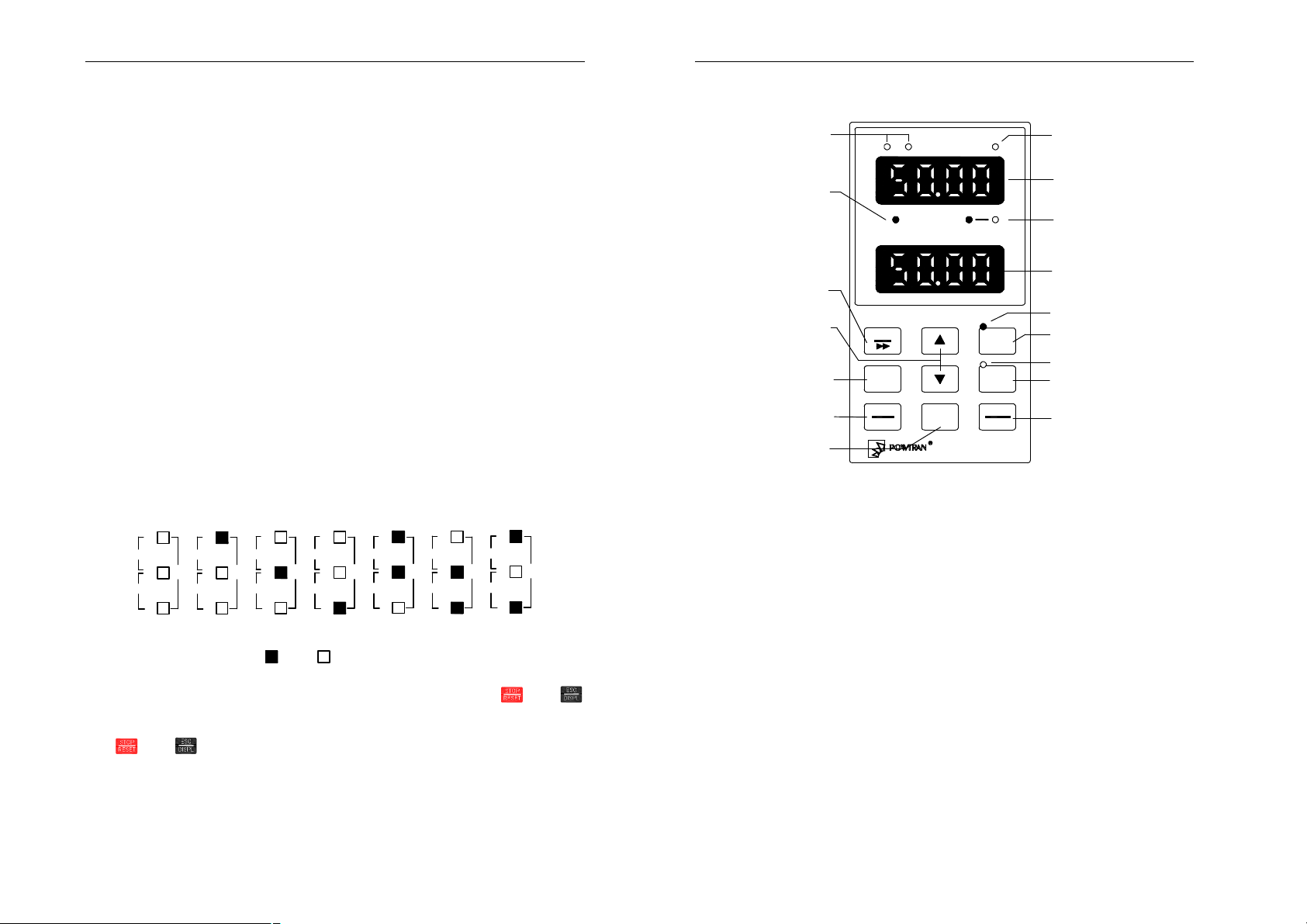

Section III. Operating keyboard

3-1. Operating keyboard

☆ JP3E7000 keyboard

Specification and function description

Run Indication Light

Alarm Indication Light

Paramiter

setting/shift key

RUN VAHZ

DIGITAL OPERATOR

PRG

ALARM

% S

℃

Acc. selection/

Parameter setting

SET

RUN

Escape/Display

ESC

DISPL

JOG

Jog key

The detailed function description is in the following text (JP5E7000).

*JP3E7000 Keyboard is optional for PI7800, PI76000 Family inverter.

STOP

RESET

JP-01

Data unit Prompt Light

LED main display area

Potentiometer

Parameter Alternation

Key (acc/reduction key)

Run key

Stop/Reset key

13

☆ JP5E7000 Keyboard

Specification and function description

Alarm Indication Light

Reverse command light

Forward command light

Run key

DIGITAL OPERATOR

RUN

Parameter Alternation

Key (acc/reduction key)

Paramiter

setting/shift key

PRG

SET

Acc. selection/

Parameter setting

REV

ALARMFWD VA

STOP

RESET

14

H

Z

℃

% S

JOG

ESC

DISPL

Data unit Prompt Light

LED main display area

Stop/Reset key

Potentiometer

Jog key

Escape/Display

JP-08

SECTION III. OPERATING KEYBOARD

SECTION III. OPERATING KEYBOARD

Function description

Run key:

² drive forward.

Stop/Reset key:

² Drive stops, resets after abnormity and confirms fault.

Acc. Selection /Parameter setting:

² When select parameter, press the SET key and add/reduction key,

parameter code add/reduce 10

² Restore modified value

² alternate the monitor object and monitor

Escape/display

² Escape modifying the data of function parameters

² Escape of submenu or running into menu of status display from function

menu

² Escape of fault status.

Jog key

² On: jog

² Off: stop

LED main display area

² Anterior 3 digits display the function code

² Latter 4 digits display the value as per the function code

Data unit prompt Light:

² It is formed up by 3 instruction light on the right upside of the keyboard,

different status indicates different unit of the current parameter displayed in

the LED. The units for the parameters as blow:

UNIT

Hz

%

A

S

V

none

UNIT

Hz

%

A

° C

S

V

Hz

UNIT

Hz

%

A

° C

S

V

UNIT

Hz

%

A

° C

S

V

OFFON

UNIT

Hz

%

A

° C

S

V

%VA

UNIT

Hz

%

A

° C

S

V

S

UNIT

Hz

%

A

° C

° C

S

V

° C

*JP5E7000 is the standard keyboard for PI7800, PI7600 Family inverter.

u For the 4 keypads, when the keypad is unlocked, press the and

simultaneously for 3 seconds, the keypad is locked, LED displays normally

after displaying “LoC” for 2 seconds; when the keypad is locked, press the

and simultaneously for 3 seconds, the keypad is unlocked, LED

displays normally after displaying “ULoC” for 2 seconds.

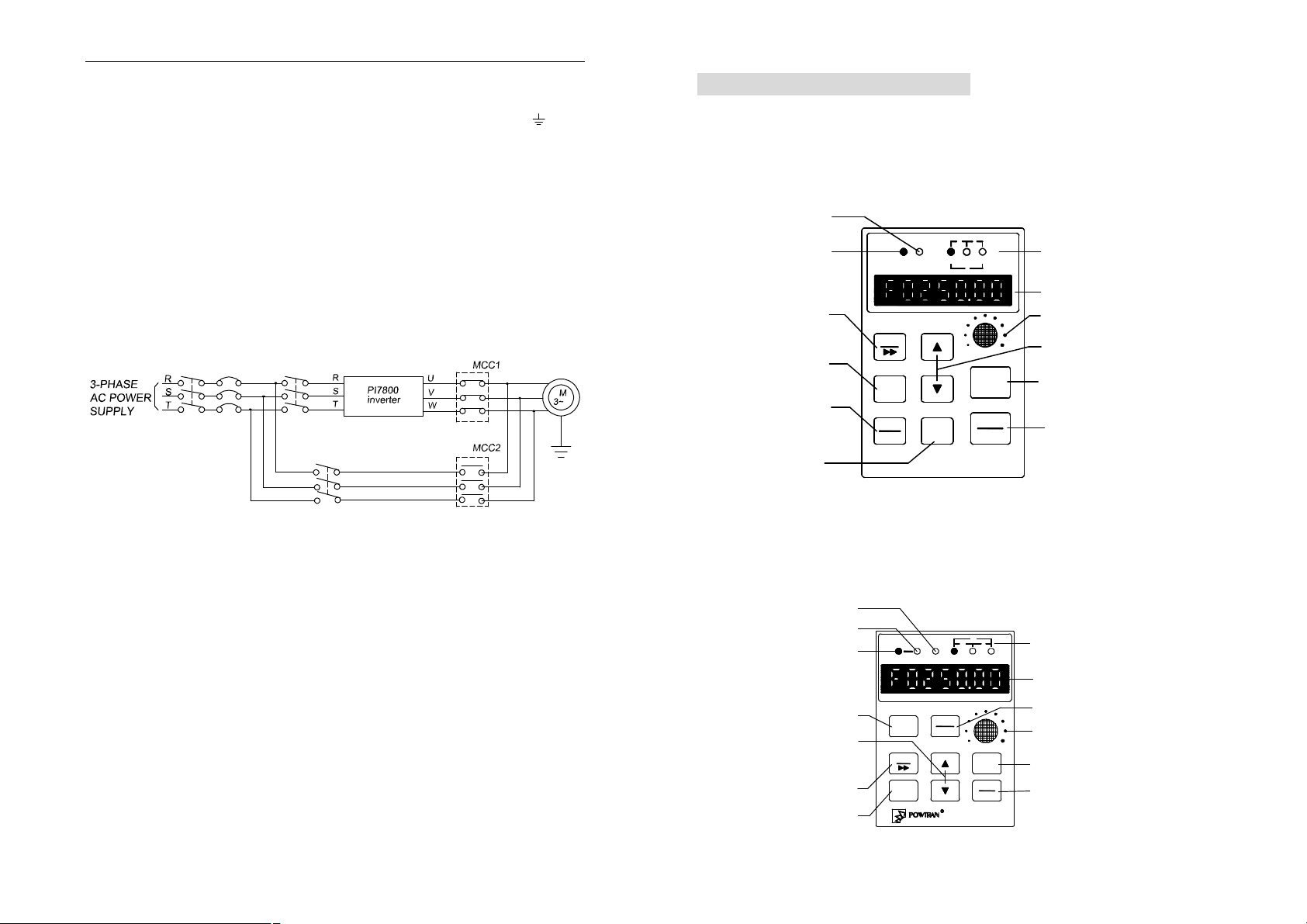

☆ JP6E7000, JP6C7000 keyboard

Specification and function description

Positive/Negative

Value indication light

Speed Status light

* Display of running status

Off:Stop status

Flash:Acc/dec status

On:Even Speed status

Paramiter

setting/shift key

Parameter Alternation

Key (acc/reduction key)

Acc. selection/

Parameter setting

Escape/Display

Jog key

+

-

SPEED-STATUS REV

DIGITAL OPERATOR

PRG

FWD

SET

ESC

DISPL

JOG

ALARM

FWD

REV

STOP

RESET

JP-07

Alarm Indication Light

LED main display area

FWS/REV Indication light

LED main display area

Forward command light

Forward key

Reverse command light

Reverse key

Stop/Reset key

function description

Forward key:

² Drive forward.

Reverse key:

² Drive reverse.

Stop/Reset key:

² Drive stops, resets after abnormity and confirms fault.

Acc. Selection /Parameter setting:

² When select parameter, press the SET key and add/reduction key,

parameter code add/reduce 10

² Restore modified value

² alternate the monitor object and monitor

Escape/display

² Escape modifying the data of function parameters

² Escape of submenu or running into menu of status display from function

menu

² Escape of fault status.

Jog key

² On: jog

² Off: stop

The upper LED main display area

² Display frequency, current, voltage, etc. Also display fuult code, password

15

16

SECTION III. OPERATING KEYBOARD

SECTION III. OPERATING KEYBOARD

right

FWD/REV Indication light

² Display motor’s running state: forward or reverse.

The nether LED main display area

² Display function code

² Display set frequency during running

JP6E7000 is standard keyboard for PI7800, PI7600 Family inverter.

JP6C7000 keyboard has the same structure and instruction with those of

JP6E7000. The difference is that the lower LED display is changed into LCD

display which displays the state and parameters in English. JP6C7000 is the

optional keyboard for PI7800, PI7600.

The second

monitor select

F65=4 output voltage

200 16.0

9 PID set Value%

The third

monitor select

F66=2 motor actual current

LCD main display area

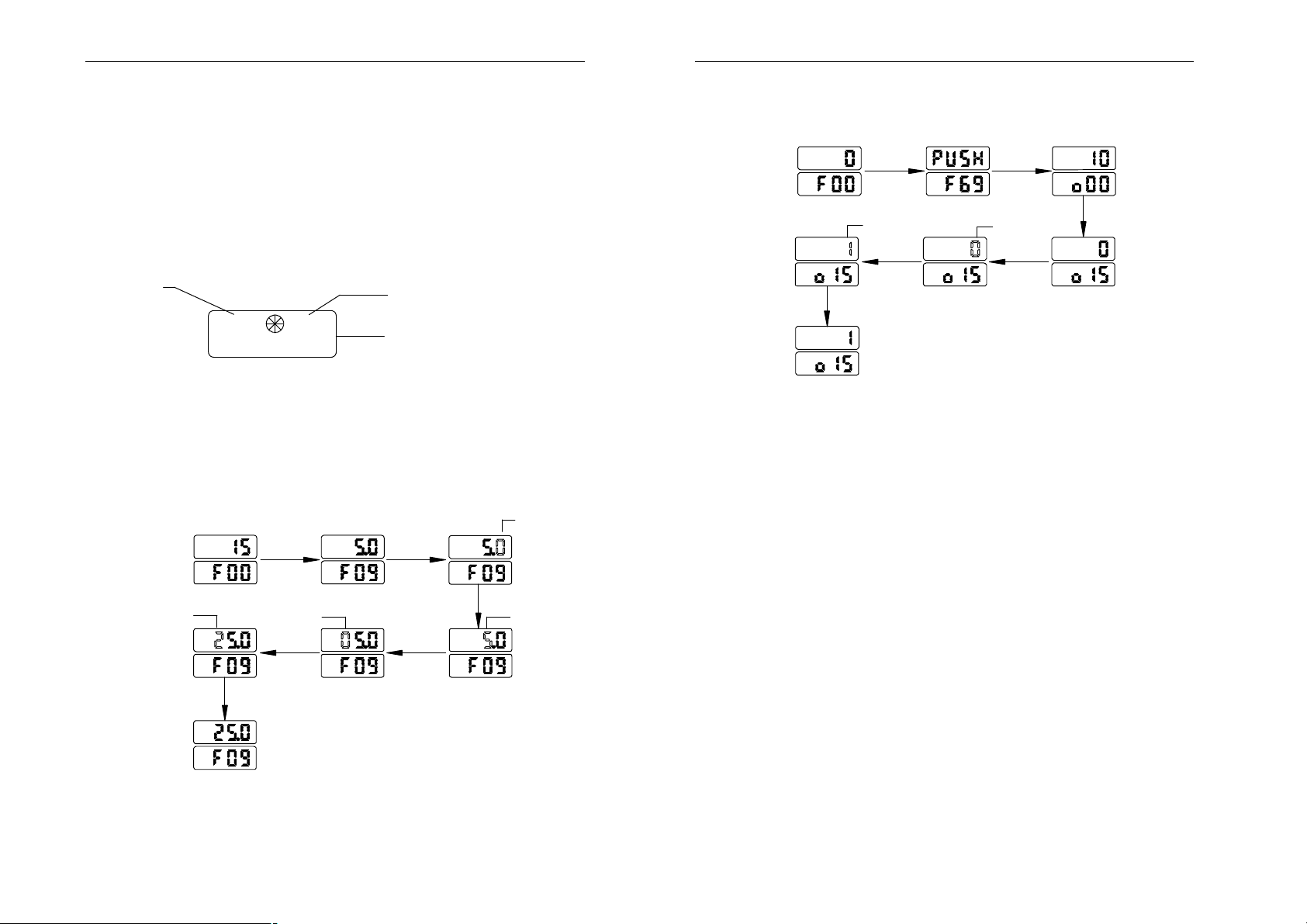

3-2. Parameters set mode

e.g. 1 Modify acceleration time F09=5.0 to F09=25.0:v

1. With F00 mode, press ▲ selecting F09, upper LED displays 5.0.

2. Press PRG for 3 times, upper LED ten digits “0” flashes.

3. Press ▲ for twice, upper LED ten digits displays “2”.

4. Press SET confirming value modification.

glitter

up LED

down LED

press

▲ key

press

PRG key

once

4. Press PRG once modifying o15.

5. Press ▲ once, upper LED flashes “1”.

6. Press SET confirming value modification.

up LED

down LED

press SET key

press

▼ key

glitter

press

▲ key

once

to affirm

press

PRG key

once

glitter

press

PRG key

once

press ▼ key

glitter

press SET key

to affirm

glitter

press

▲ key

twice

e.g. 2 Modify o15=0 to o15=1

1. With F00, press ▼ selecting F69.

2. Press PRG entering I/O group parameters menu.

3. Press ▼ selecting o15.

17

press PRG key

press

PRG key

once

once

glitter

18

SECTION IV. TEST RUNNING

Section IV. Test running

u Before connecting the power supply with the frequency converter, confirm

that the input voltage of AC power is within the rated input voltage of the

frequency converter.

u Connect the power supply with the R, S and T terminals of frequency

converter (connect with R and S terminals for single-phase input).

u Select the proper operation control method.

e.g.: analog voltage input + keyboard /terminal operating (Pr.F04=1, Pr.F05=1).

The frequency command is controlled by terminal V2, and the operation is

controlled by the keyboard and terminal FWD、REV.

ALARM

FWD

REVSPEED-STATUS

DIGITAL OPERATOR

PRG

STOP

ESC

RESET

DISPL

JP-07

※ Check JOG control.

※ Confirm the acceleration and deceleration time.

※ Connect with the motor.

※ Run the motor at low speed and check its rotation direction.

Check if all the displays and outputs during the operation are correct.

e.g.: keyboard adjust speed + keyboard operating (Pr.F04=0, Pr.F05=0)

The frequency command is controlled by the key , and operation is controlled by

the key FWD、REV controlling the forward and reverse.

ALARM

FWD

REVSPEED-STATUS

DIGITAL OPERATOR

PRG

STOP

ESC

RESET

DISPL

JP-07

※ Running the unit without load, regulate the speed and check.

※ Confirm the min. and max values of the set output frequency.

19

20

optimized space vector

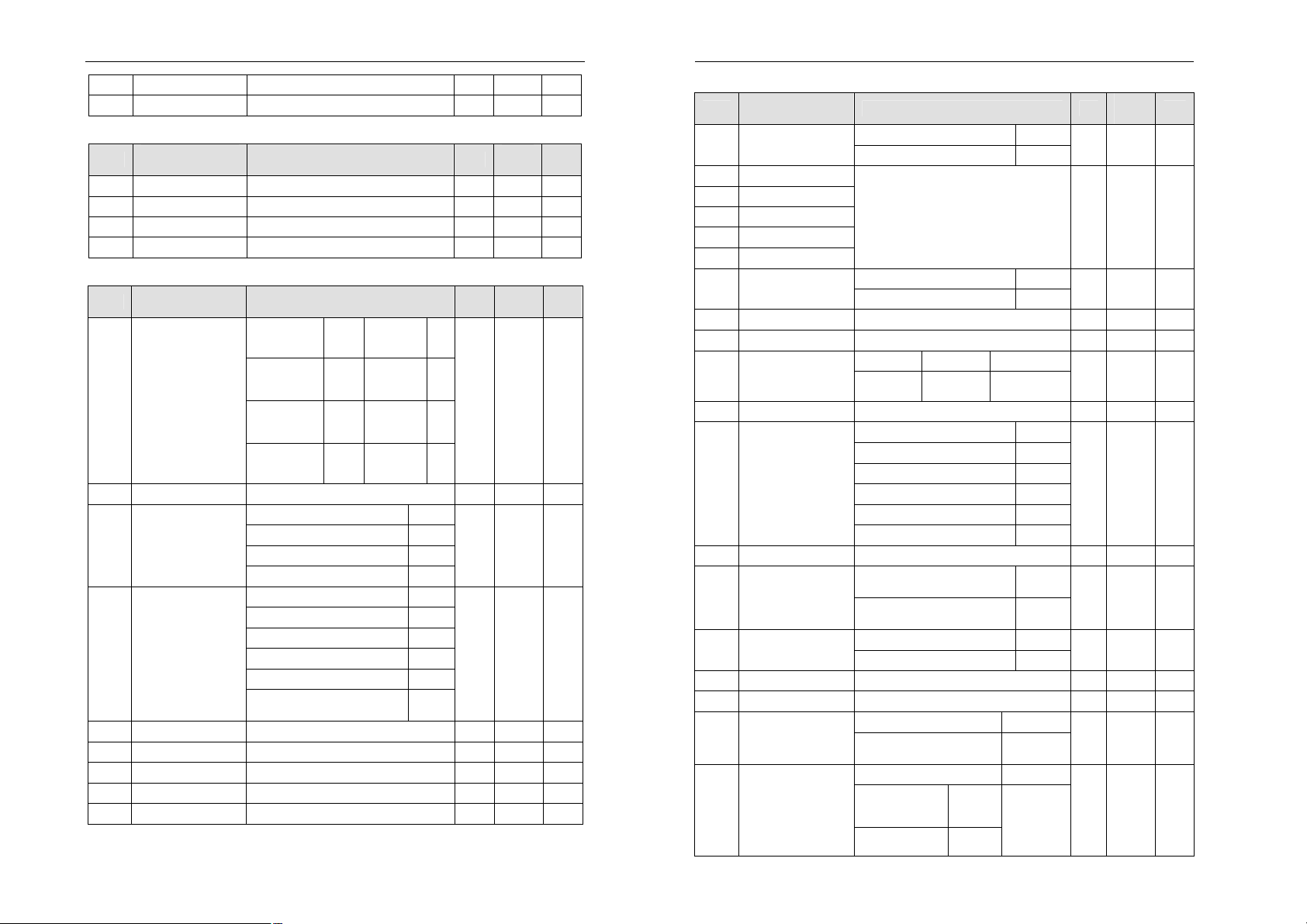

SECTION V. FUNCTION PARAMETER TABLE

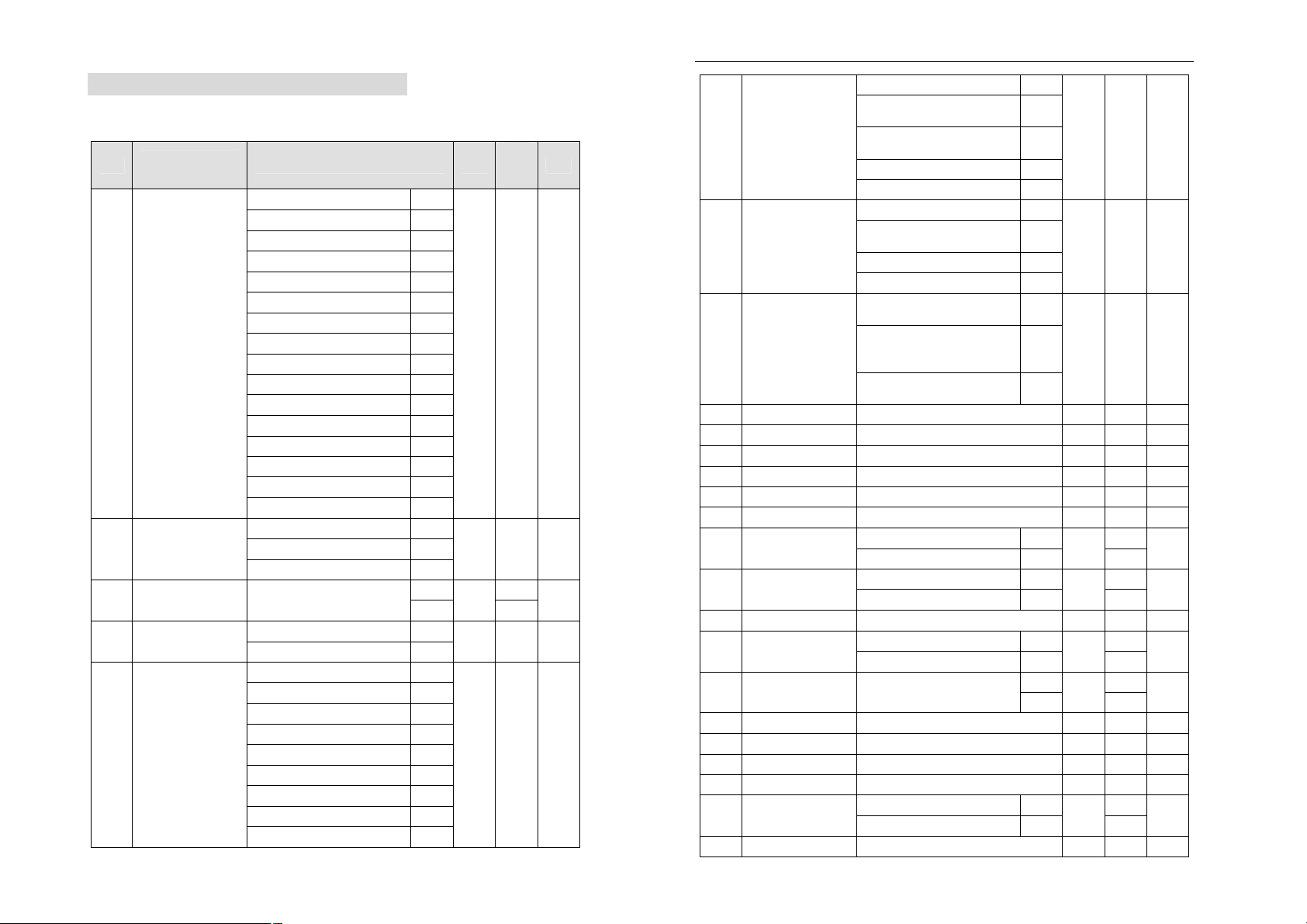

Section V. Function parameter table

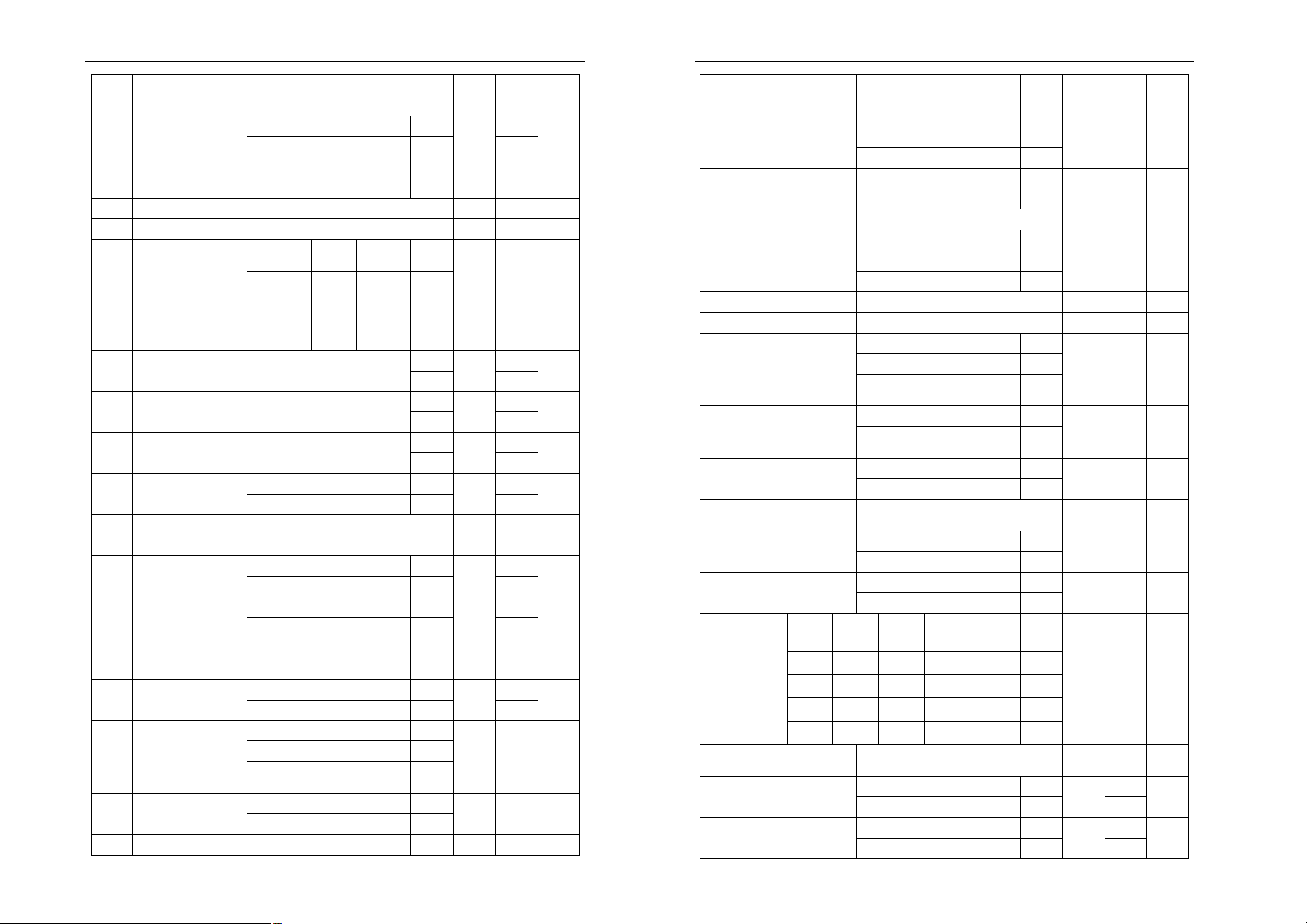

5-1. Basic Parameters

Ref

F00

F02

F03 fre. multiple set

F04

LCD keyboard

explanation

monitor select

set frequency

fre. set mode

Range of set value Unit

Set frequency 0

Actual frequency 1

Motor actual current 2

Actual current percent 3

DC Bus voltage 4

Actual output voltage 5

Actual motor speed 6

Total running time 7

IGBT temperature 8

PID set value 9

PID feedback value 10

Motor output power 11

Excitation heft set value 12

Excitation heft actual value 13

Torque heft set value 14

Torque heft actual value 15

No PG V/F control 0

PG V/F control 1 F01 control methods

PG vector control 2

Lower frequency~Upper

frequency

×1 0

×10 1

Keypad 0

V2 1

I2 2

V2+I2 3

Ascend/Descend control 1 4

Program running 5

Traverse running 6

PID control 7

Keypad potentionmeter set 8

F03=0

F03=1

Factor

y

setting

- 0 Y

- 0 N

50.00

Hz

500.0

- 0 N

- 0 N

Y/N

Y

V2 Forward/Reverse set 9

Keypad potentionmeter

FWD/REV set

V2 proportional linkage

adjustment

10

11

I2 proportional linkage 12

Ascend/Descend control 2 13

Keypad+RS485/CAN 0

F05 run control mode

Keypad +

terminal+RS485/CAN

1

- 0 Y

RS485/CAN 2

terminal 3

Asynchronous space vector

PWM

0

Stepless & subsection

F06 waveform mode

synchronous space vector

1

- 1 N

PWM

2 phase

PWM

F07 auto.torque boost

0~10 % 0 Y

F08 V/F boost mode 0~61

F09 accelerate time 0.1~3200.0

F10 decelerate time 0.1~3200.0

2

-

2 N

s

10.0 Y

s

10.0 Y

F11 slip compensate 0~10 % 0 N

F12 O.P. voltage ratio

F13 max. frequency

F14 basic frequency

50~110 % 100 N

10.00~300.00 F03=0

100.0~800.0 F03=1

5.00~ F13 F03=0

50.0~ F13 F03=1

Hz

Hz

50.00

500.0

50.00

500.0

F15 carrier frequency 1.0~16.0 kHz ★ Y

F16 Lower frequency

0.00~ F17 F03=0

0.0~ F17 F03=1

F17 upper frequency F16~F13

F18 S curve acc. start

0.0~50.0 % 0.0 Y

F03=0

F03=1

Hz

Hz

0.00

0.0

50.00

500.0

F19 S curve acc. stop 0.0~50.0 % 0.0 Y

F20 S curve dec. start

F21 S curve dec. stop

F22 min. running fre.

0.0~50.0 % 0.0 Y

0.0~50.0 % 0.0 Y

0.00~ F13 F03=0

0.0~ F13 F03=1

Hz

0.00

0.0

F23 DC brake current 0~135 % 100 Y

N

N

N

N

N

21

22

SECTION V. FUNCTION PARAMETER TABLE

N

SECTION V. FUNCTION PARAMETER TABLE

F24 start brake time 0.0~60.0 s 0.0 N

F25 stop brake time 0.0~60.0 s 0.0 N

F26 brake start fre.

F27 stopping mode

F28

F29

jog acc. time 0.1~3200.0 s 1.0 N

jog dec. time 0.1~3200.0 s 1.0 N

F30 Jog function set

JOG stop

Reset to

the state

before JOG

0.00~F13 F03=0

0.0~F13 F03=1

Deceleration stop 0

Free stop 1

Ten’s

mode

Stop

running

place

0 Forward 0

1 Reverse 1

F31 jog frequency set F16~F17

F32

F33

F34 traverse differ.

traverse fre. 1 F33~F17

traverse fre. 2 F16~F32

0.00~5.00 F03=0

0.0~50.0 F03=1

direction digit

F03=0

F03=1

F03=0

F03=1

F03=0

F03=1

0.00

Hz

0.0

- 0 N

- 0 N

6.00

Hz

60.0

40.00

Hz

400.0

20.00

Hz

200.0

2.00

Hz

20.0

F35 traverse time 1 0.0~3200.0 s 2.0 Y

F36 traverse time 2 0.0~3200.0 s 2.0 Y

F37 skip frequency 1

F38 skip frequency 2

F39 skip frequency 3

F40 skip frequency range

0.00~F13 F03=0

0.0~F13 F03=1

0.00~F13 F03=0

0.0~F13 F03=1

0.00~F13 F03=0

0.0~F13 F03=1

0.00~5.00 F03=0

0.0~50.0 F03=1

Hz

Hz

Hz

Hz

0.00

0.0

0.00

0.0

0.00

0.0

0.00

0.0

Invalid 0

F41

auto. Voltage

regulation

F42 OU stall protect

F43

current limit

Valid 1

Valid but useless when

decelerating

Invalid 0

Valid 1

Invalid 0

- 0 Y

2

- 1 Y

- 0 Y

Valid 1

Invalid 0

Y

Pick up mode when power

down

1 F44 rate track select

- 0 N

Pick up mode when start 2

F45 elec. o.h. protect

F46

protect level 120~250 % ★ N

Invalid 0

Valid 1

- 1 Y

Invalid 0

F47 consumed brake

Safe mode 1

- 0 Y

General mode 2

F48 Fault reset times 0~10 - 0 N

F49 Fault reset time 0.5~20.0 s 1.0 N

Single circulation 0

Program running

Y

F50

mode

Y

F51

Restart mode

Y

F52 RST input signal

Y

F53

Fan start temp.

(options)

F54 Motor run direction

Y

F55

Motor reverse

forbidden

Y

dec. time

Y

Y

Time

unit

F56

setting

% in energy saving

F57

F58

F59

×1s 0 ×1s 0

×30s 1 ×30s 1

×600s 2 ×600s 2

×3600s 3 ×3600s 3

energy

FDT fre. set 1

FDT fre. set 2

Continuous circulation 1

Single circulation command

running

Runs at step 1 0

Runs at the step before

stopping

Reset 0

External fault/Reset 1

0.0~60.0 ℃ 0.0 Y

FWD command,motor forwards 0

FWD command,motor reverses 1

Reverse allowable 0

Reverse forbidden 1

hundred'

s place

Acc. time

tens

place

reserved digit

30~100 % 100 N

F59~ F13 F03=0

F59~ F13 F03=1

0.00~ F58 F03=0

0.0~ F58 F03=1

2

1

- 0 N

- 0 N

- 0 Y

- 0 N

- 0 N

- 0

0.00

Hz

0.0

0.00

Hz

0.0

Y

Y

23

24

SECTION V. FUNCTION PARAMETER TABLE

Hz

Hz

Hz

Hz

Hz

Hz

SECTION V. FUNCTION PARAMETER TABLE

F60

F61

F62

F63

F64

F65

F66

Fre. Inspection

range

Load type

Terminal control

modes

MSS terminal

function selection

Polarity of input

terminal

Monitor Subject

Reserved

0.00~5.00 F03=0

0.0~50.0 F03=1

General 0

Water Pump 1

Blower fan 2

Plastic jetting mould machine 3

Braiding machine 4

Hoister 5

Pumping jack 6

Belt conveyor 7

Electromagnetic stirring power

supply

Standard running control 0

2-point running control 1

3-point running control 2

Invalid 0

MSS multi-step speed control 1

MSS multi-step acceleration

control

JOG forward/ reverse control 3

Frequency setting mode switch 4

Upper torque shifted 5

MSS time running 6

Control mode shifted 7

Reset program running

segment

0~255 - 0 N

Set frequency 0

Actual frequency 1

Motor actual current 2

Actual current percent 3

DC Bus voltage 4

Actual output voltage 5

Actual motor speed 6

Total running time 7

IGBT temperature 8

PID set value 9

PID feedback value 10

Motor output power 11

8

2

8

0.00

Hz

0.0

0 N

- 0 N

- 0 N

-

1

-

2

Y

Excitation heft set value 12

Excitation heft actual value 13

Torque heft set value 14

Torque heft actual value 15

F67

V/F curve set

F68 MSS speed control

F69 I/O group select

F70 CUR group select

F71 SPD group select

Useless

Press

[PROG/ENT]

- Y

F72 PID group select

F73 SYS group select

F74 MOT group select

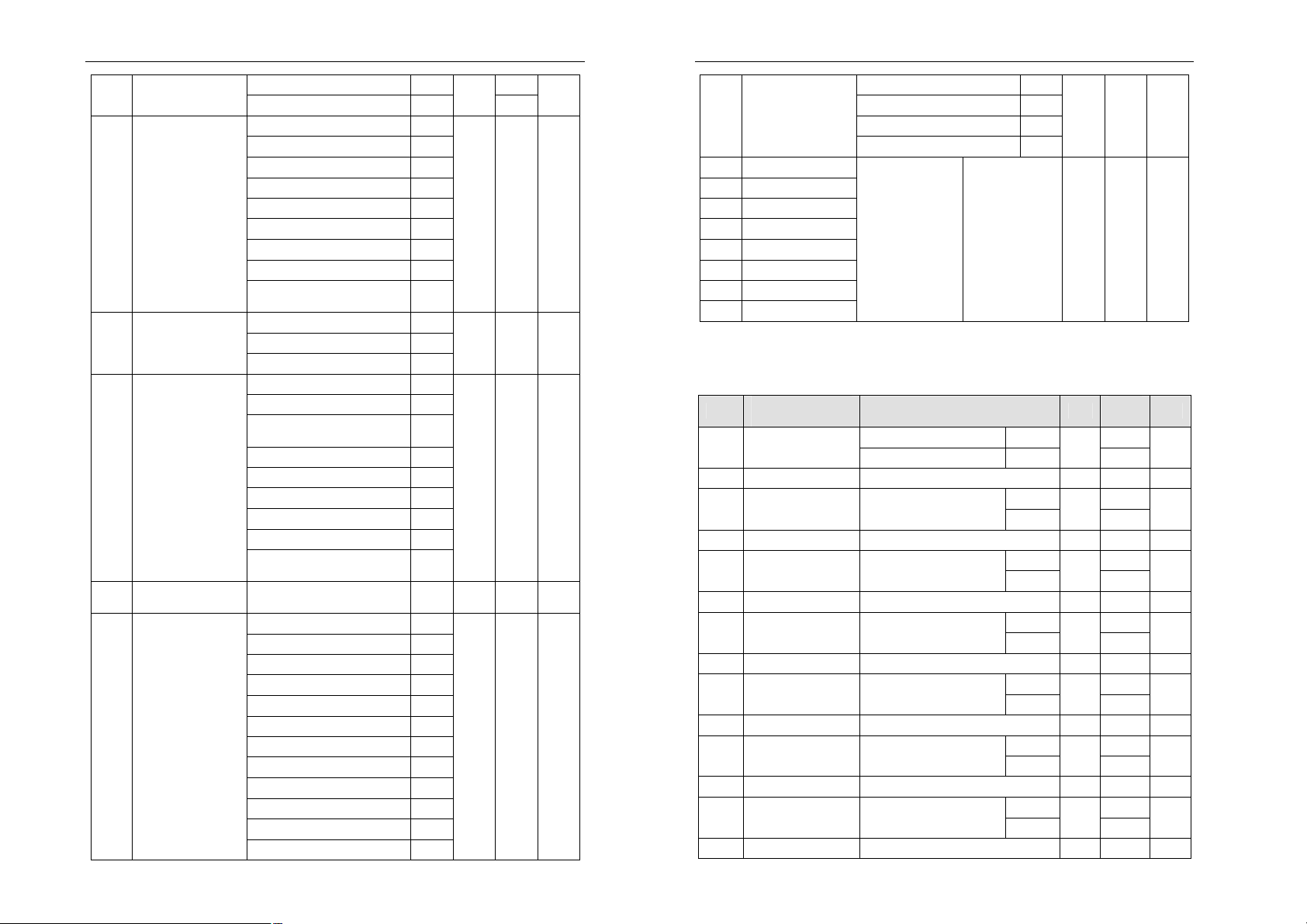

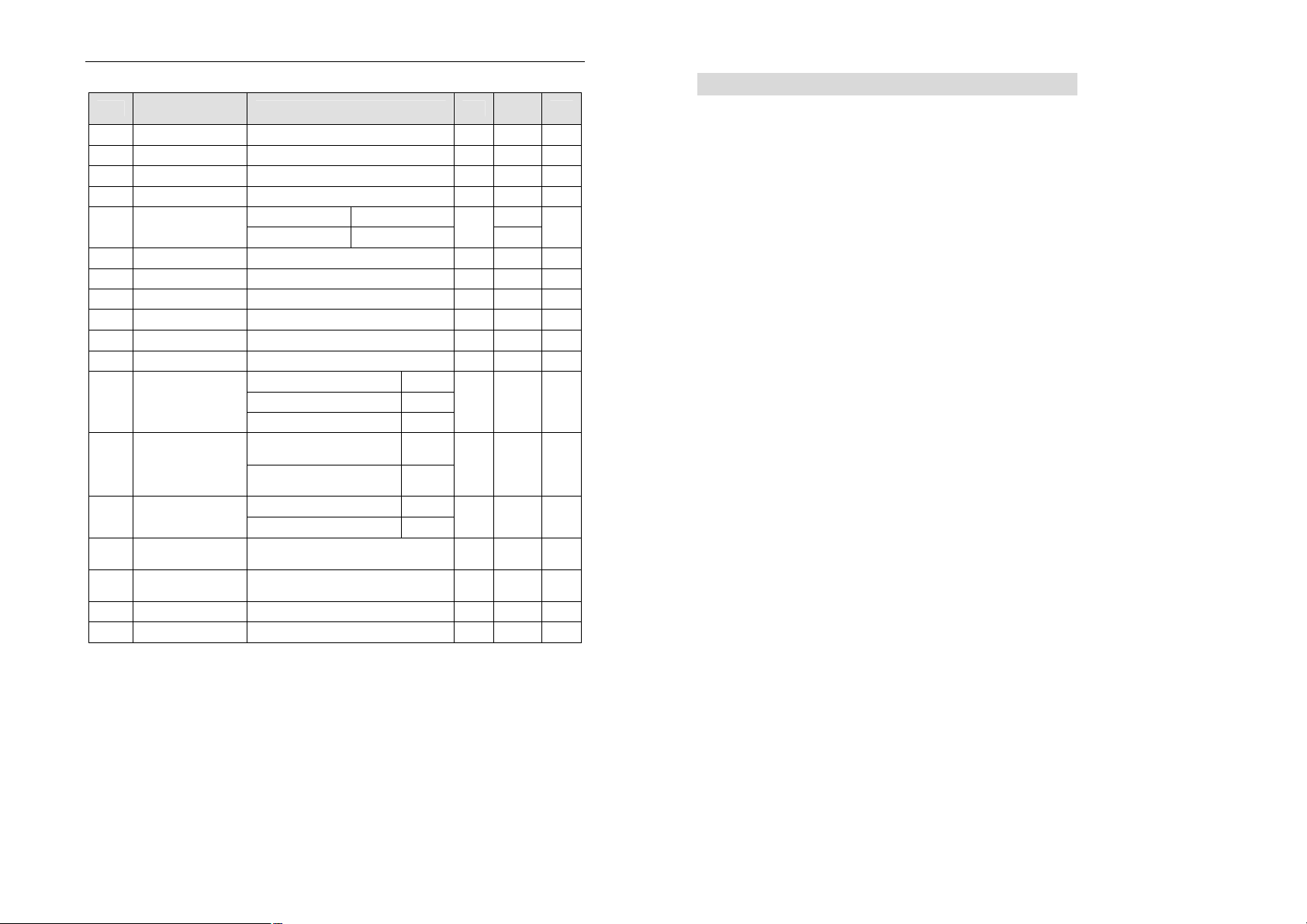

5-2. Other Parameters

5-2-1. F67 V/F curve [V/F]

Ref

U00

LCD keyboard

explanation

V/F set fre 1

Range of set value Unit

0.00~U02 F03=0

0.0~U02 F03=1

U01 V/F set voltage 1 0~U03 % 5 N

U02

V/F set fre. 2 U00~U04

F03=0

F03=1

U03 V/F set voltage 2 U01~U05 % 10 N

U04

V/F set fre. 3 U02~U06

F03=0

F03=1

U05 V/F set voltage 3 U03~U07 % 15 N

N

U06

V/F set fre. 4 U04~U08

N

F03=0

F03=1

U07 V/F set voltage 4 U05~U09 % 20 N

U08

V/F set fre. 5 U06~U10

F03=0

F03=1

U09 V/F set voltage 5 U07~ U11 % 25 N

U10

V/F set fre. 6 U08~U12

F03=0

F03=1

U11 V/F set voltage 6 U09~U13 % 30 N

U12

V/F set fre. 7 U10~U14

F03=0

F03=1

U13 V/F set voltage 7 U11~U15 % 35 N

Hz

Factory

setting

5.00

50.0

10.00

100.0

15.00

150.0

20.00

200.0

25.00

250.0

30.00

300.0

35.00

350.0

Y/N

N

N

N

N

N

N

N

25

26

SECTION V. FUNCTION PARAMETER TABLE

Factory

Y

Y

Y

Y

Y

Y

Y

step

step

step

step

step

step

step

SECTION V. FUNCTION PARAMETER TABLE

U14

V/F set fre. 8 U12~F13

F03=0

F03=1

Hz

40.00

400.0

U15 V/F set voltage 8 U13~100 % 40 N

5-2-2. F68 MSS group [MSS]

Ref

H00

H01

H02

H03

H04

H05

H06

H07

H08

H09

H10

H11

H12

H13

H14

H15

H16

H17

H18

H19

H20

H21

H22

H23

LCD keyboard

explanation

1 step speed 1X F16~F17

2 step speed 2X F16~F17

3 step speed 3X F16~F17

4 step speed 4X F16~F17

5 step speed 5X F16~F17

6 step speed 6X F16~F17

7 step speed 7X F16~F17

Range of set value Unit

F03=0 5.00

F03=1

F03=0 30.00

F03=1

F03=0 20.00

F03=1

F03=0 30.00

F03=1

F03=0 40.00

F03=1

F03=0 45.00

F03=1

F03=0 50.00

F03=1

Hz

Hz

Hz

Hz

Hz

Hz

Hz

setting

300.0

200.0

300.0

400.0

450.0

500.0

1 step time T1 0.0~3200.0 s 2.0 Y

2 step time T2 0.0~3200.0 s 2.0 Y

3 step time T3 0.0~3200.0 s 2.0 Y

4 step time T4 0.0~3200.0 s 2.0 Y

5 step time T5 0.0~3200.0 s 2.0 Y

6 step time T6 0.0~3200.0 s 2.0 Y

7 step time T7 0.0~3200.0 s 2.0 Y

acc. time at1 0.1~3200.0 s 10.0 Y

dec. time dt1 0.1~3200.0 s 10.0 Y

acc. time at2 0.1~3200.0 s 10.0 Y

dec. time dt2 0.1~3200.0 s 10.0 Y

acc. time at3 0.1~3200.0 s 10.0 Y

dec. time dt3 0.1~3200.0 s 10.0 Y

acc. time at4 0.1~3200.0 s 10.0 Y

dec. time dt4 0.1~3200.0 s 10.0 Y

acc. time at5 0.1~3200.0 s 10.0 Y

dec. time dt5 0.1~3200.0 s 10.0 Y

27

50.0

N

H24

H25

H26

H27

Y/N

H28

H29

H30

H31

H32

H33

H34

acc. time at6 0.1~3200.0 s 10.0 Y

dec. time dt6 0.1~3200.0 s 10.0 Y

acc. time at7 0.1~3200.0 s 10.0 Y

dec. time dt7 0.1~3200.0 s 10.0 Y

Multi-

speed 1

running

direction

Multi-

speed 1

running

direction

Multi-

speed 1

running

direction

Multi-

speed 1

running

direction

Multi-

speed 1

running

direction

Multi-

speed 1

running

direction

Multi-

speed 1

dec.

time

×1s 0 ×1s 0 ×1s 0

×30s 1 ×30s 1 ×10s 1

×600s 2 ×600s 2 ×100s 2

×3600s 3 ×3600s 3 ×1000s 3

dec.

time

×1s 0 ×1s 0 ×1s 0

×30s 1 ×30s 1 ×10s 1

×600s 2 ×600s 2 ×100s 2

×3600s 3 ×3600s 3 ×1000s 3

dec.

time

×1s 0 ×1s 0 ×1s 0

×30s 1 ×30s 1 ×10s 1

×600s 2 ×600s 2 ×100s 2

×3600s 3 ×3600s 3 ×1000s 3

dec.

time

×1s 0 ×1s 0 ×1s 0

×30s 1 ×30s 1 ×10s 1

×600s 2 ×600s 2 ×100s 2

×3600s 3 ×3600s 3 ×1000s 3

dec.

time

×1s 0 ×1s 0 ×1s 0

×30s 1 ×30s 1 ×10s 1

×600s 2 ×600s 2 ×100s 2

×3600s 3 ×3600s 3 ×1000s 3

dec.

time

×1s 0 ×1s 0 ×1s 0

×30s 1 ×30s 1 ×10s 1

×600s 2 ×600s 2 ×100s 2

×3600s 3 ×3600s 3 ×1000s 3

dec.

time

×1s 0 ×1s 0 ×1s 0 forward 0

kilobit

kilobit

kilobit

kilobit

kilobit

kilobit

kilobit

Acc.

time

Acc.

time

Acc.

time

Acc.

time

Acc.

time

Acc.

time

Acc.

time

hundred'

s place

hundred'

s place

hundred'

s place

hundred'

s place

hundred'

s place

hundred'

s place

hundred'

s place

Running

time

Running

time

Running

time

Running

time

Running

time

Running

time

Running

time

tens

place

tens

place

tens

place

tens

place

tens

place

tens

place

tens

place

Running

direction

forward 0

reverse 1

Running

direction

forward 0

reverse 1

Running

direction

forward 0

reverse 1

Running

direction

forward 0

reverse 1

Running

direction

forward 0

reverse 1

Running

direction

forward 0

reverse 1

Running

direction

digit

digit

digit

digit

digit

digit

digit

- 0 Y

- 0 Y

- 0 Y

- 0 Y

- 0 Y

- 0 Y

- 0 Y

28

SECTION V. FUNCTION PARAMETER TABLE

SECTION V. FUNCTION PARAMETER TABLE

running

direction

×30s 1 ×30s 1 ×10s 1

×600s 2 ×600s 2 ×100s 2

×3600s 3 ×3600s 3 ×1000s 3

reverse 1

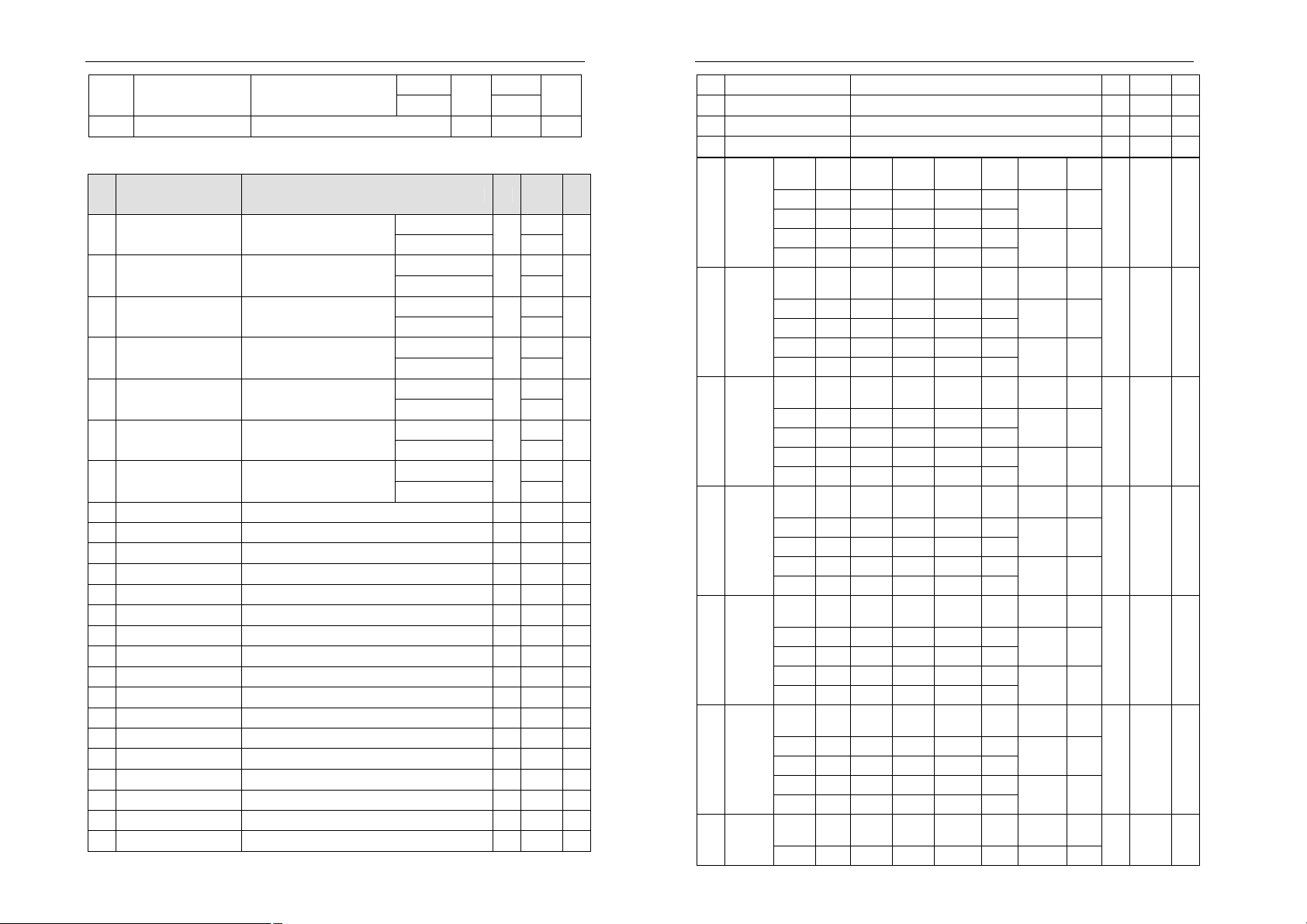

5-2-3. F69 I/O group [I/O]

Ref

LCD keyboard

explanation

Range of set value Unit

o00 V2 input filter time 2~200 ms

o01 V2 min. input voltage

o02 V2 max. input voltage

0.00~o02 V 0.00 Y

o01~10.00 V 10.00 Y

Factory

setting

10 Y

o03 I input filter time 2~200 ms 10 Y

o04 I input min. current

o05 I input max. current

0.00~o05 mA 0.00 Y

o04~20.00 mA 20.00 Y

No Function 0

Set frequency 1

Actual frequency 2

Actual current 3

o06

o07

DA1 Ouput

DA2 Output

Output voltage 4

Bus voltage 5

-

0

-

0

IGBT temperature 6

Output power 7

Output speed 8

Actual torque 9

DA1 output lower

o08

o09

o10

o11

o12

o13

o14

o15

o16

o17

o18

adjustment

DA1 output upper

adjustment

DA2 output lower

adjustment

DA2 output upper

adjustment

DFM multiple 1~20 - 1 Y

O.P. signal sel. 1

O.P. signal sel. 2

O.P. signal sel. 3

O.P. signal sel. 4

O.P. signal sel. 5

O.P. signal sel. 6

Over current inspection 2

Over load inspection 3

Over voltage inspection 4

0~o09 % 0.0 Y

o08~100.0 % 100.0 Y

0~ o11 % 0.0 Y

o10~100.0 % 100.0 Y

No function 0

Fault alarm 1

-

-

-

-

-

-

0

0

0

0

1

8

Lack voltage inspection 5

Low load inspection 6

Over heat inspection 7

Running state with command 8

Y/N

Y

Y

Y

Y

Y

Y

Y

Y

PID feedback signal abnormity

9

Motor reverse 10

Set frequency arrival 11

Upper limit frequency 12

Lower limit frequency 13

FDT frequency 1 arrival 14

FDT frequency level inspection 15

0 speed running 16

Position arrival 17

PG fault 18

Program running 1 cycle

finished

Speed pursue mode inspection

Running state without

command

19

20

21

Inverter reverse command 22

Deceleration running 23

Acceleration running 24

High pressure arrival 25

Low pressure arrival 26

Inverter’s rated current arrival

27

Motor’s rated current arrival 28

Set fre. arrives lower fre. 29

FDT frequency set 2 arrives 30

o19

o20

Minimum input

frequency

Maximum input

frequency

Fault code output

(o13~o16 valid)

Digits of frequency

output (o13~o16 valid)

0.00~F13 F03=0 0.00

0.0~F13 F03=1

0.00~F13 F03=0 50.00

0.0~F13 F03=1

31

32

-

0.0

-

500.0

5-2-4. F70 CUR group [CUR]

Ref

LCD keyboard

explanation

Range of set value Unit

Factory

setting

C00 detect filter time 2~200 ms 10 Y

C01

C02

C03

re. filter time 2~200 ms 10 Y

integral time of

current loop

0~9999 ms 500 Y

proportion gain 0~1000 % 100 Y

Y

Y

Y/N

29

30

SECTION V. FUNCTION PARAMETER TABLE

Adjustment

password or Input

SECTION V. FUNCTION PARAMETER TABLE

C04

torque setting 0.0~100.0 % 80.0 Y

C05 excitation setting 0.0~100.0 % 60.0 Y

5-2-5. F71 SPD group [SPD]

Ref

d00

d01

LCD keyboard

explanation

Range of set value Unit

filter time 2~200 ms 10 Y

integral time 0.01~100.00 s 0.25 Y

Factory

setting

d02 differential time 0.000~1.000 s 0.000 Y

d03

proportion gain 0~1000 % 100 Y

5-2-6.F72 PID group [PID]

Ref

LCD keyboard

explanation

P00 PID regulate mode

P01

O.P. fre. limit 0~110 % 100 N

Range of set value Unit

Abnormity

management

Warning

Continuous

running

Warning

Decelerating

running

Warning Free

stop

Tens

digit

1

2

mode

Negative

action

Positive

action

3

Unit

0

1

Factory

setting

- 10 N

External terminal IF:0~20mA 0

P02

Feedback signal

select

External terminal IF:4~20mA 1

External terminal VF:0~10V 2

- 2 N

External terminal VF:1~5V 3

External terminal I2:0~20mA 0

External terminal I2:4~20mA 1

External terminal V2:0~10V 2

P03 set signal select

Keyboard input 3

- 3 N

RS485 input 4

P04

P05

Setting by keypad

potentionmeter

key set signal 0.0~100.0 % 50.0 Y

integral time 0.01~100.00 s 0.25 Y

5

P06 differential time 0.000~1.000 s 0.000 Y

P07 proportion gain 0~1000 % 100 Y

P08 fault detect time 0.0~3200.0 s 300.0 Y

Y/N

Y/N

5-2-7. SYS group [SYS]

Ref

y00

y01

y02

y03

y04

y05

LCD keyboard

explanation

Restore factory

setting

fault record 1

fault record 2

fault record 3

fault record 4

fault record 5

y06 Fault record reset

y07 rated O.P. current

Range of set value Unit

No reset 0

Instant reset 1

Press [PRG] and [▲], the frequency,

current and running state of fault time can

be known.

No activity 0

Reset 1

0.1~1000.0 A ★ N

Factory

setting

- 0 N

- - N

- 0 Y

y08 rated I.P. voltage 100~1140 V ★ N

70 0 3

y09

product series

Family serial

Function

code

Input voltage

level

- ★ N

y10 software version - - - N

Baud rate 1200 0

Baud rate 2400 1

y11 baud rate

Baud rate 4800 2

Baud rate 9600 3

- 3 N

Baud rate 19200 4

Baud rate 38400 5

y12 communi. address

y13

y14

total time set

total time unit

y15 Manufacture date

y16 making month/day

Clear automatically after

Continuous accumulation after

1~128 - 8 N

starting

starting

Hour 0

Day 1

0

- 1 Y

1

- 0 Y

YYYY - - N

MMDD - - N

0~9999 set range

y17

decode input

Record of times of wrong

decode

display

content

- - Y

0~9999 set range

No setting

y18 password input

decode correct

Parameters

locked

deco

code

display

content

- - Y

Y/N

31

32

SECTION V. FUNCTION PARAMETER TABLE

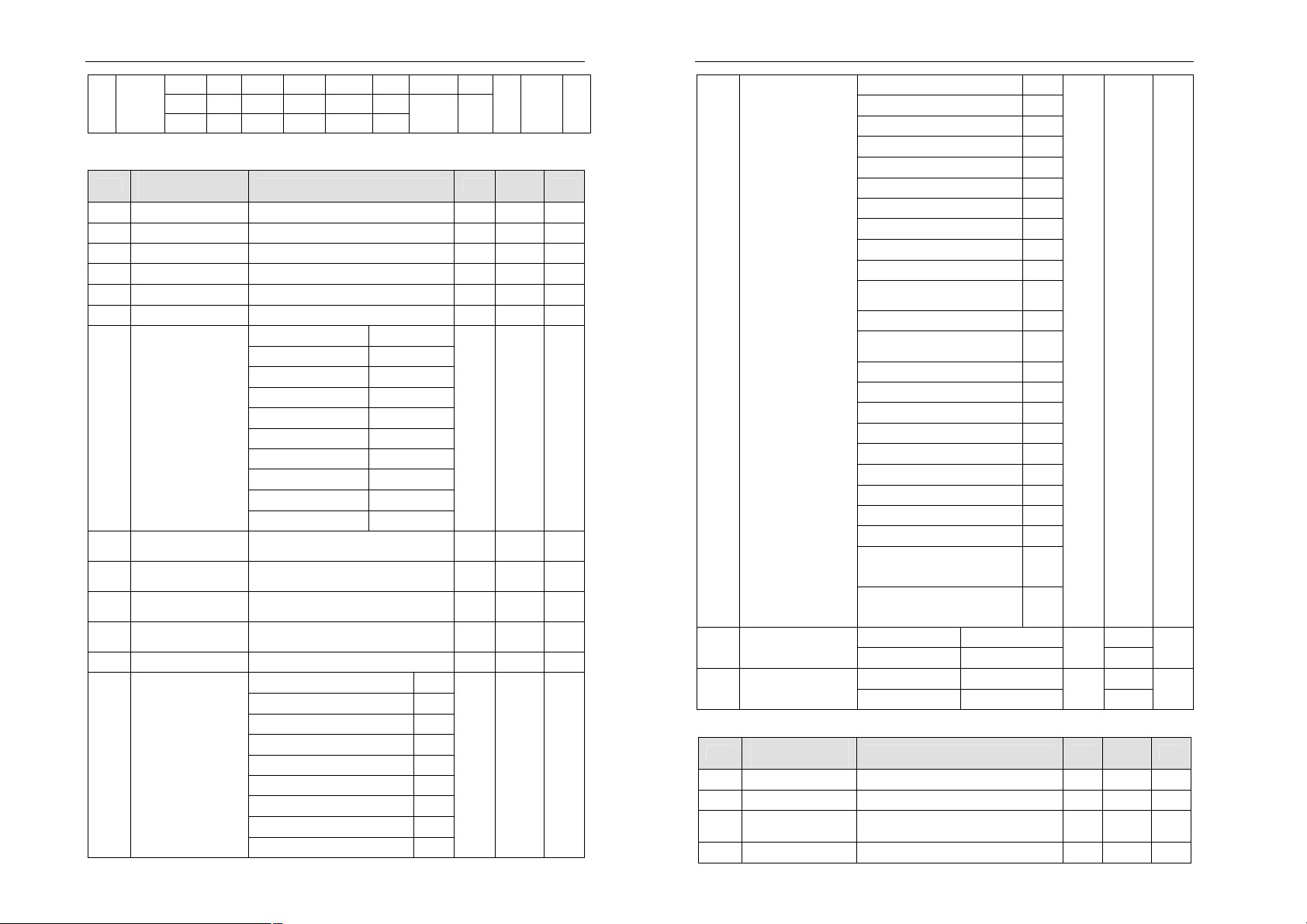

5-2-8. MOT group [MOT]

Ref

b00

b01 motor rated cur. y07×(30%~120%) A ★ N

b02 motor rated vol. 100~1140 V ★ N

b03 motor rated speed

b04

b05 Motor un-load cur.

b06

b07

b08

b09 mutual inductance

b10

b12 PG rotate direct.

b13

b14

b15

b16

b17

NOTE:

1) Y/N means the parameter is adjustable or not during running, Y means it is

2) ★ means the parameter’s factory setting is affected by the power and type.

LCD keyboard

explanation

motor poles 1~8 - 2 N

motor rated

frequency

stator resistor 0.000~30.000 ohm 0.000 N

rotor resistor 0.000~30.000 ohm 0.000 N

leakage inductance 0.0~3200.0 mH

PG pulse 300~9999 - 2048 N

PG cut action

Motor parameter

measure

Rotate speed display

plus

Percentage linkage

modulus

reserved 0 - 0 N

reserved 0 - 0 N

adjustable, N means it is not.

Alarm & decelerate to stop 1 b11

Phase A is foregoing when

Phase B is foregoing when

Range of set value Unit

500~5000 rpm 1500 N

0.00~F13 F03=0 50.00

0.0~F13 F03=0

0~b01 A ★ N

0.0~3200.0 mH 0.0 N

Continue running 0

Alarm and stop freely 2

motor forwards

motor forwards

No measurement 0

Measured before running

0.1~2000.0 % 100.0 Y

0.10~10.00 - 1.00 Y

33

0

1

1

Factory

setting

%

500.0

0.0 N

- 0 N

- 0 N

- 0 N

Y/N

N

Section VI. Function Parameter Description

6-1. Basic parameter:

F00: Monitor selection factory setting: 0

The value range is 0~15 monitoring 0~15 different objects under running.

Monitor objects under running

0: Set frequency

Set frequency under frequency setting mode.

1: Actual frequency

Current output frequency.

2: Motor actual current

Detected value of motor’s current.

3: Actual current percentage

Percentage of motor’s actual current and rated current.

4: DC bus voltage

Detected voltage of DC bus.

5: Output voltage

Actual output voltage of inverter.

6: Actual motor speed rpm

During running, the display of the adjusted motor’s actual rotate speed=60 ×

Actual output frequency × Rotate speed display plus/Motor poles

e.g. Actual output frequency50.00Hz, Rotate speed display plus b14=100.0%,

Motor poles b00=2, the display of the adjusted motor’s actual rotate

speed=1500rpm.

During stopping state, checking the motor speed according to residual stress,

renewed speed 500ms.

The display of the adjusted motor’s actual rotate speed=60 × residual stress

frequency × rotate speed display plus/Motor poles

7: Total running time

This parameter indicates the total running time, and the unit is hour or day.

e.g. If led display value is 10.31, y14 is 0, the actual running time of the

machine is 10 hours,18 minutes and 36 seconds; if led display value is 20.03

and y14 is 1, the actual running time of the machine is 20 days,43 minutes and

12 seconds.

8: IGBT temperature

Detected IGBT temperature inside inverter.

9: PID set value

Set value percentage when running under PID adjustment.

10: PID feedback value

11: Motor output power

Motor actual output power percentage.

12: Excitation heft set value

Motor’s set excitation heft percentage.

13: Excitation heft actual value

Motor’s actual excitation heft percentage.

14: Torque heft set value

Motor set torque percentage.

34

SECTION VI. FUNCTION PARAMETER DESCRIPTION

SECTION VI. FUNCTION PARAMETER DESCRIPTION

15: Torque heft actual value

Motor actual torque hefts percentage.

F01: Control mode factory setting: 0

This parameter value range is 0~2.

0: Without PG V/F control. V/F space voltage vector control.

1: With PG V/F control. V/F space voltage vector control + speed sensor.

2: With PG vector control .vector control + speed sensor

F02: Set frequency factory setting: 50.00/500.0Hz

Setting running frequency can be from lower frequency to upper frequency.

F03: Frequency multiple setting factory setting: 0

0: Set frequency display accuracy is 0.01Hz. With this accuracy, F13 maximum

frequency range is 10.00~300.00Hz.

1: Set frequency display accuracy is 0.1Hz. With this accuracy, F13 maximum

frequency range is 100.0~800.0Hz.

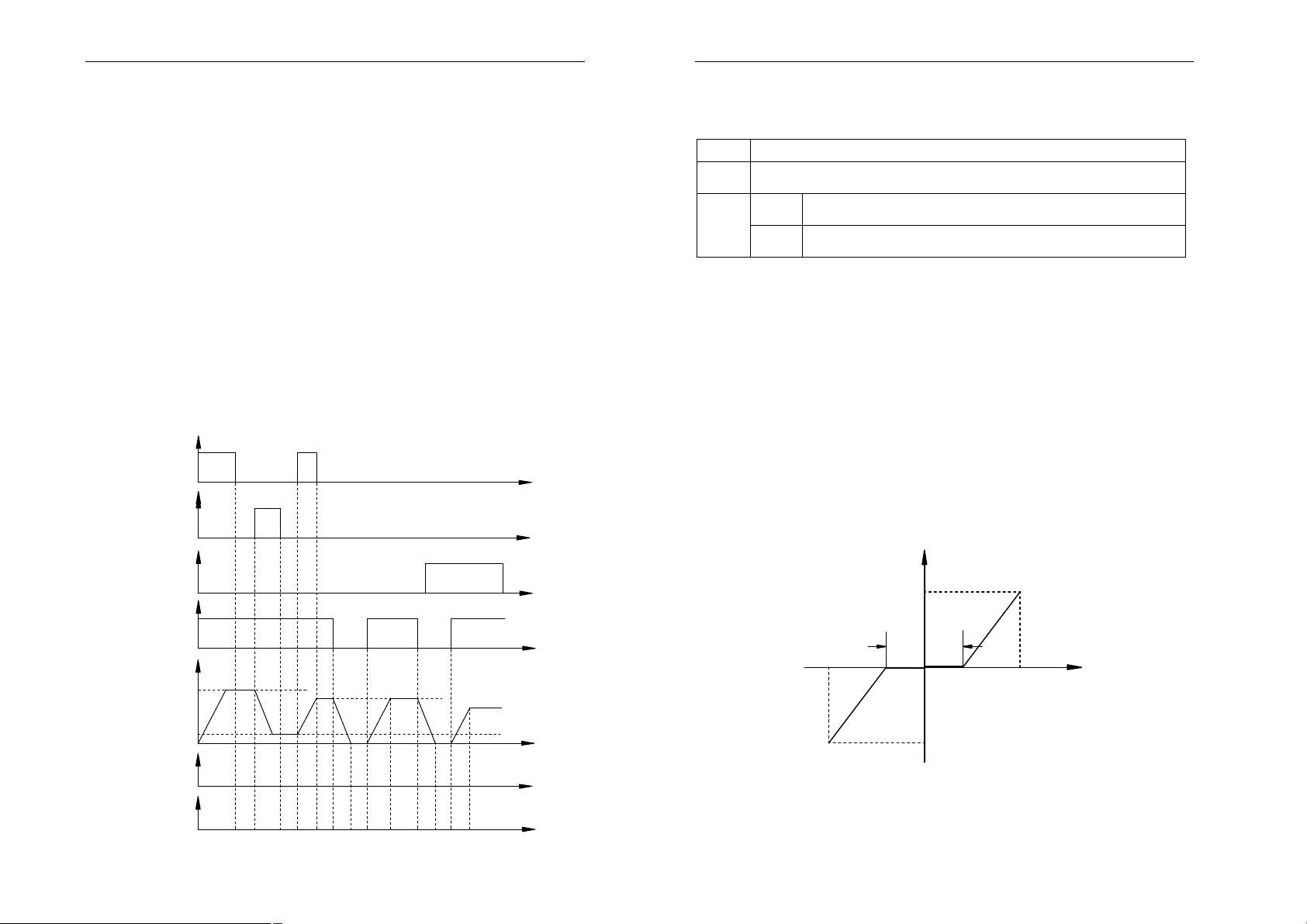

F04: Frequency setting mode factory setting: 0

Frequency setting modes can be set by the value 0~10, as following:

0: Keypad or RS485 set

1: Set frequency by analog input V2

2: Set frequency by analog input I2

3: By analog input V2 and I2 simultaneity

4: Ascend/Descend control:

SS1

SS2

SS3

RUN

STOP

output

frequency

upper limit

frequency

lower limit

frequency

up/down control mode 1

up/down control mode 2

F04=4

acc./dec. time

F04=13

acc./dec. time

ON

OFF

F28

OFF

ON

F09F09

F28

OFF

OFF

F10F10

F10

ON

F29

SS1,SS2 valid in high level

target frequency=

frequency before stop

F10

F09F09

F09 F09

F10

time

time

ON

time

time

target frequency=F31

setting JOG frequency

time

time

time

This function is to control ascend/descend and target frequency with the

terminals SS1, SS2, SS3.

It is OFF when SS1, SS2, SS3 are disconnected with COM, ON when they are

short circuited.

SS1

SS2

SS3

Ascend control is to change the frequency increased

Descend control is to change the frequency reduced, has

precedence over SS1

During stopping state, change the frequency caused by

ON

SS1/SS2 and turn it to F31 jog frequency

OFF

During stopping state, keep the frequency caused by

SS1/SS2

The Ascend/Descend control time in Ascend/Descend control 1 is set by

modifying F09/ F10.

The Ascend/Descend time in Ascend/Descend control 2 mode is setted by

modifing F28/F29.

5: Program Running

No limitation of the reverse forbidden. Setting value of H28~H34 and terminal

FWD/REV decide the running direction

6: Traverse running

Running by setting traverse.

7: PID adjustment running

Applicable for pressure, current close loop control.

8: Keypad potentiometer set

Frequency set by the potentiometer on the keypad.

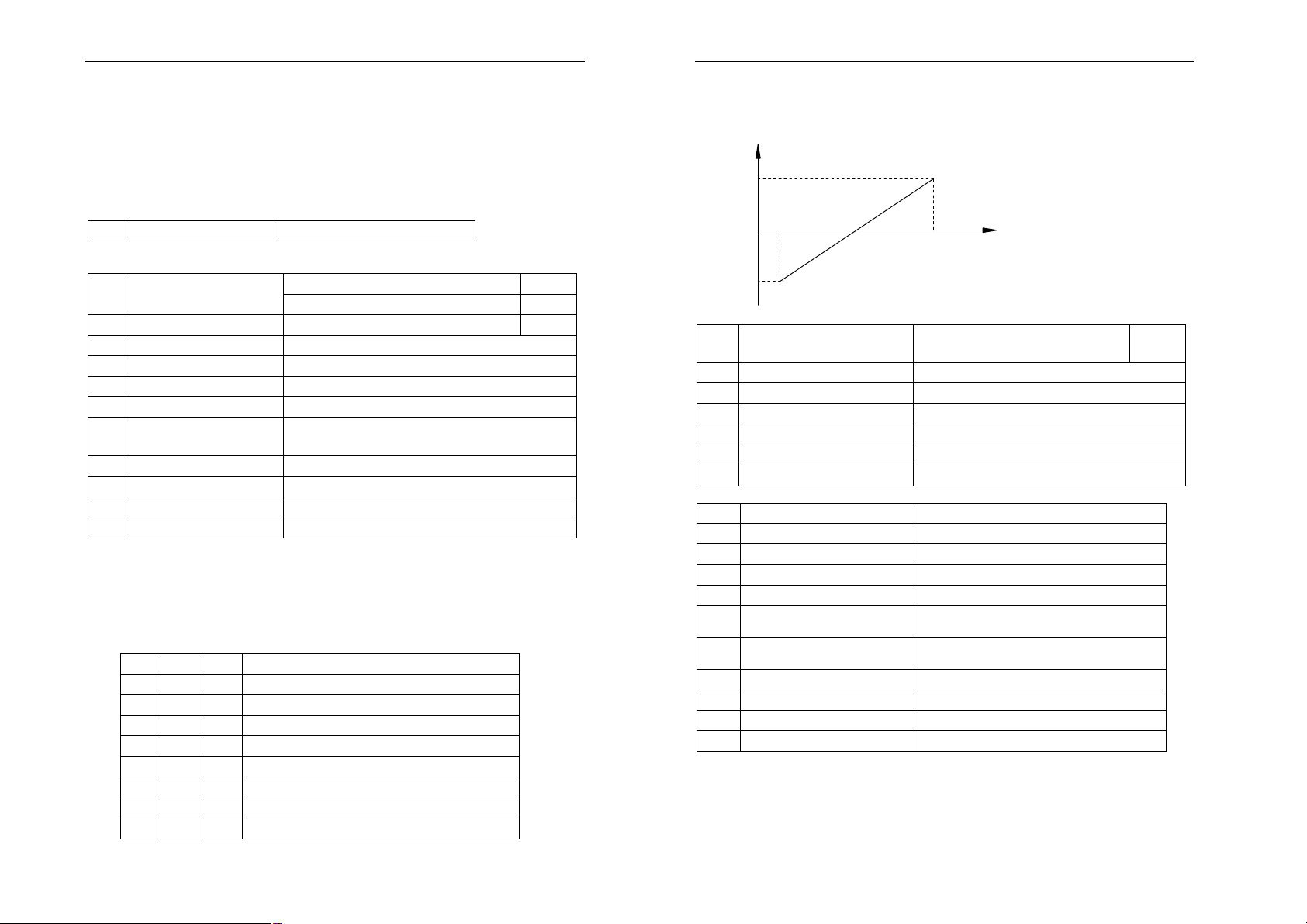

9. V2 Forward/Reverse set

Anolog input signal V2 is to the signal to forward/reverse frequency, when V2

is larger than o01 (V2 minimum input voltage), it is the signal to forward

frequency;when V2 is smaller than o01, it is the signal to reverse frequency.

Set frequency

maximum frequency

forward

STOPSTOP

o01+0.5V

0V

o01-0.5V

reverse

o01

Maximum reverse

frequency

10. Keypad potentionmeter FWD/REV set

o02

Voltage

11: V2 proportion linkage tiny adjust

12: I2 proportion linkage tiny adjust

13: Ascend/Descend control 2

F05: Running control mode factory setting: 0

35

36

SECTION VI. FUNCTION PARAMETER DESCRIPTION

SECTION VI. FUNCTION PARAMETER DESCRIPTION

0: Keypad+RS485/CAN control

1: Keypad + terminal control+RS485/CAN control

To terminal control, edge triggers. Execute FOR/REV command in falling edge

and execute STOP command in rising edge.

Note: F62=0 is valid.

2: RS485/CAN

3: Terminal, level triggers. F62=0/1/2 is valid.

4.Proportional linkage function (improved)

For this function, the host computer should be set with the following parameters:

y12 Communication add.

128

For this function, the slave computer should be set with the following

parameters:

F04 Fre. Set mode

V2 proportional linkage adjustment 11

I2 proportional linkage adjustment 12

F05 Run control mode proportional linkage control 4

F13 Max. frequency Max. output frequency of inverter

F22 Min. running fre. Min. output frequency of inverter

y12 Communi. address 0~127

y11 Baud rate The same with that of host inverter

Proportional linkage

b15

factor

0.10~10.00

o01 V2 min. input voltage Adjustment range min. voltage

o02 V2 max. input voltage Adjustment range max voltage

o19 Min. input frequency 0.00

o20 Max. input frequency Adjustment range

υ Set 128, the inverter is the host inverter among the proportional linkage.

There is only one host inverter in one proportional linkage.

υ The F04 and F05 parameters of the host inverter can be any settings. The

running states of the slave inverters follow the host inverter.

υ If the host inverter F04=11/12, setting proportional linkage adjustment, then

F63=1 automatically, the frequency of the host inverter controlled by MSS

multi-step speed SS1/SS2/SS3.

SS3 SS2 SS1

0 0 0 Potentiometer adjustment

0 0 1 1 step speed + Potentiometer adjustment

0 1 0 2 step speed + Potentiometer adjustment

0 1 1 3 step speed + Potentiometer adjustment

1 0 0 4 step speed + Potentiometer adjustment

1 0 1 5 step speed + Potentiometer adjustment

1 1 0 6 step speed + Potentiometer adjustment

1 1 1 7 step speed + Potentiometer adjustment

The host inverter frequency

υ The host inverter controls the slave inverter’s running state.

υ The inverter set frequency=proportional linkage factor × host inverter

frequency + value adjusted by the potentiometer.

υ The range of inverter’s set frequency: F22 min. running frequency~F13

max. frequency.

o20/2

-o20/2

0

o01

(o01+o02)/2

o02

Voltage

E.g. Host inverter set:

F04 Fre. Set mode

V2 proportional linkage

adjustment

11

y12 Communi. address 128

y11 Baud rate 3

o01 V2 min. input voltage 2V

o02 V2 max. input voltage 10V

o19 Min. input frequency 0.00Hz

o20 Max. input frequency 20.00Hz

Slave inverter set:

F04 Fre. Set mode 11:V2 proportional linkage adjustment

F05 Run control mode 4

F13 Max. frequency 50.00Hz

F22 Min. running fre. 0.00Hz

y12 Communi. address 8

y11 Baud rate

Proportional linkage

b15

factor

The same with that of the host

inverter

1.00

o01 V2 min. input voltage 2V

o02 V2 max. input voltage 10V

o19 Min. input frequency 0.00Hz

o20 Max. input frequency 20.00Hz

Potentiometer adjustment range 20.00Hz

2V -10Hz

6V 0Hz

10V +10Hz

The proportional linkage wiring:

37

38

Loading...

Loading...