Foreword

Thank you for choosing Powtran PI500 Series Frequency Inverter. This

product made by Powtran is based on years of experience in professional

production and sale, and designed for variety of industrial machinery, fan and

water pump drive unit and IF heavy-duty grinding unit.

This manual provides user the relevant precautions on installation,

operational parameter setting, abnormal diagnosis, routine maintenance and

safe use. In order to ensure correct installation and operation of the frequency

converter, please carefully read this manual before installing it.

For any problem when using this product, please contact your local dealer

authorized by this company or directly contact this company, our professionals

are happy to serve you.

The end-users should hold this manual, and keep it well for future

maintenance & care, and other application occasions. For any problem within

the warranty period, please fill out the warranty card and fax it to the our

authorized dealer.

The contents of this manual are subject to change without prior notice. To

obtain the latest information, please visit our website.

For more product information, please visit: http:// www.powtran.com.

Powtran

March , 2018

Contents

Chapter 1.Inspection and safety precautions .................................................................... 1

1-1. Inspection after unpacking ............................................................................ 1

1-1-1. Instructions on nameplate .................................................................. 1

1-1-2. Model designation ............................................................................. 1

1-2. Safety precautions ......................................................................................... 2

1-3. Precautions .................................................................................................... 3

1-4. Scope of applications ................................................................ .................... 5

Chapter 2 Standard specifications .................................................................................... 6

2-1. Technical specifications ................................................................ ................ 6

2-2. Standard specifications ................................................................................. 8

Chapter 3 Keyboard ....................................................................................................... 12

3-1. Keyboard description .................................................................................. 12

3-2. Keyboard Indicators .................................................................................... 12

3-3. Description of operation panel keys ............................................................ 13

3-4. Keyboard display letters and numbers correspondence table ...................... 13

3-5. Examples of parameter settings .................................................................. 14

3-5-1. Instructions on viewing and modifying function code ..................... 14

3-5-2. The way to read parameters in various status .................................. 15

3-5-3. Password settings ............................................................................. 15

3-5-4. Motor parameter auto turning .......................................................... 15

Chapter 4 Installation and commissioning ..................................................................... 16

4-1. Installation direction and space ................................................................... 16

4-2. Wiring Diagram .......................................................................................... 17

4-2-1. Wiring diagram ................................................................................ 18

4-3. Main circuit terminal .................................................................................. 19

4-3-1. Main circuit terminal arrangement ................................................... 19

4-3-2. Function description of main circuit terminal .................................. 22

4-4. Control circuit terminals ............................................................................. 22

4-4-1. Control circuit terminals arrangement ............................................. 22

4-4-2. Description of control circuit terminals ........................................... 22

4-5. Wiring Precautions ..................................................................................... 25

4-6. Spare Circuit ............................................................................................... 26

4-7. Commissioning ........................................................................................... 26

Chapter 5 Function parameter ........................................................................................ 28

5-1. Menu grouping ............................................................................................ 28

Chapter 6 Troubleshooting ............................................................................................. 61

6-1. Fault alarm and countermeasures ................................................................ 61

6-2. EMC (Electromagnetic Compatibility) ....................................................... 65

6-2-1. Definition ......................................................................................... 65

6-2-2. EMC standard.................................................................................. 65

6-3. EMC directive ............................................................................................ 65

6-3-1. Harmonic effect ............................................................................... 65

6-3-2. Electromagnetic interference and installation precautions .............. 65

6-3-3. Remedies for the interference from the surrounding electromagnetic

equipment to the inverter ............................................................... 66

6-3-4. Remedies for the interference from the inverter to the surrounding

electromagnetic equipment ............................................................ 66

6-3-5. Remedies for leakage current .......................................................... 66

6-3-6. Precautions on installing EMC input filter at the input end of power

supply ............................................................................................. 67

Chapter 7 Dimension ..................................................................................................... 68

7-1. Dimension .................................................................................................. 68

7-1-1. Product outside drawing, installation size ....................................... 68

7-1-2. PI500 series ..................................................................................... 68

7-1-3. PI500 series (With DC reactor base) ................................ ............... 73

7-1-4. Keypad dimension drawing ............................................................. 76

Chapter 8 Maintenance and repair ................................................................................. 78

8-1. Inspection and maintenance........................................................................ 78

8-2. Parts for regular replacement ...................................................................... 78

8-3. Storage........................................................................................................ 79

8-4. Capacitor .................................................................................................... 79

8-4-1. Capacitor rebuilt .............................................................................. 79

8-5. Measuring and readings .............................................................................. 80

Chapter 9 Options .......................................................................................................... 81

Chapter 10 Warranty ................................................................................................ ...... 83

Appendix I RS485 Communication protocol ................................................................ 84

I-1 Communication protocol ........................................................................... 84

I-1-1 Communication content ................................................................. 84

I-1-2 Protocol description ....................................................................... 85

I-3 Definition of communication parameter address .......................................... 88

Appendix II How to use universal encoder expansion card ........................................... 93

III-2 Description of mechanical installation and control terminals

function .................................................................................................... 93

Appendix III CAN bus communication card use description ........................................ 95

IV-1.Overview ................................................................................................... 95

IV2.Mechanical installation and terminal functions .......................................... 95

Appendix IV: Instruction of Profitbus –DP communication card .................................. 96

IV-1.Outline ....................................................................................................... 96

IV-2 Terminal function ...................................................................................... 96

Appendix V product application case ............................................................................ 98

3

V-1. Single pump constant pressure water supply parameter setting ................. 98

V-2 terminal block control motor forward and reverse ...................................... 99

V-3 external frequency table and ammeter......................................................... 99

V-4 Terminal block control forward /reverse running jog ............................... 100

V-5 Multi-speed running .................................................................................. 101

V-6 External potentiometer speed .................................................................... 102

V-7 Keyboard potentiometer speed .................................................................. 103

V-8. Rise / Fall Control Speed ......................................................................... 103

V-9. External analog speed control (external 0 ~ 10V voltage signal

given) ..................................................................................................... 104

V-10. External analog speed control (external 0 ~ 20mA current signal

given) ..................................................................................................... 104

V-11. Air compressor constant pressure control (sensor for two-wire

pressure transmitter) ............................................................................... 105

V-12.frequency reference mode(external potentiometer, keyboard

encoder) switching ................................................................................. 107

第

十

Chapter 1

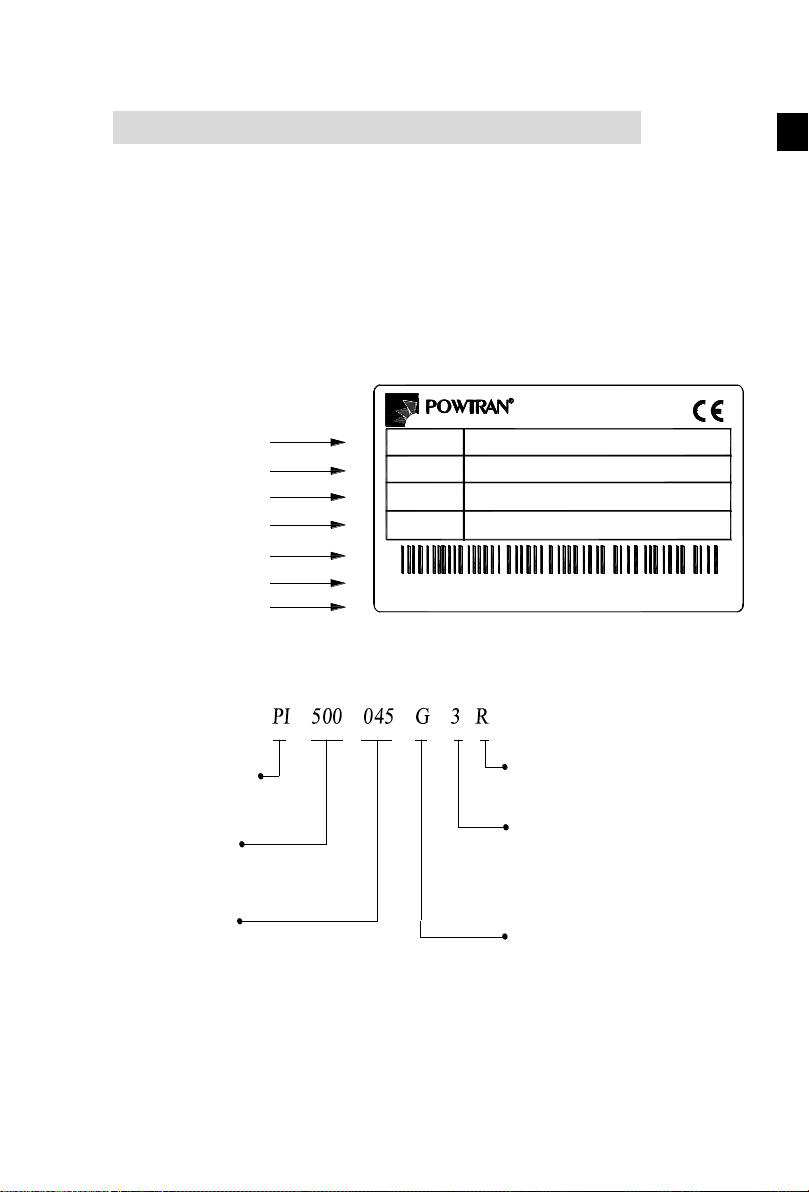

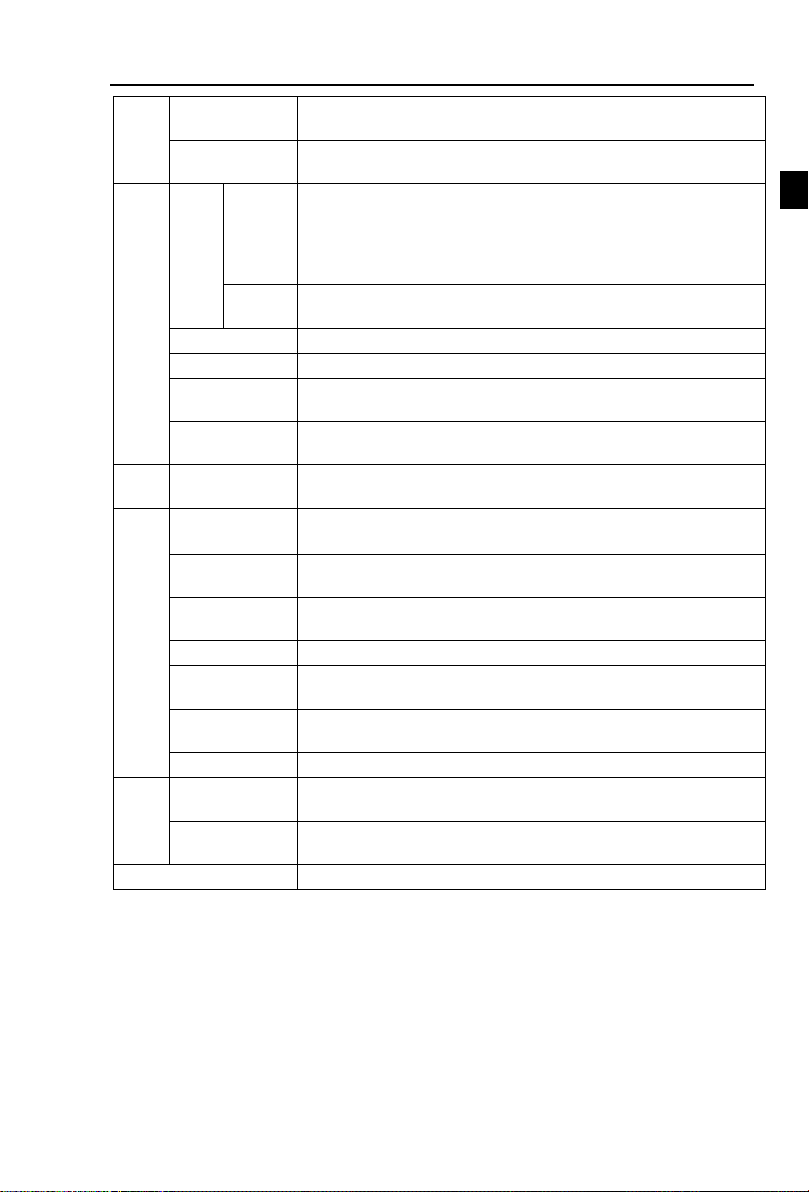

*Input Source Spec.

*Output Power Spec.

*Production Sequence

Number

*POWTRAN

Inverter model

POWER

INPUT

OUTPUT

DALIAN POWTRAN TECHNOLOGY CO.,LTD.

MODEL

45kW

AC 3PH 380V(-15%) ~440V(+10%) 50Hz/60Hz

AC 3PH 0V~Vin 90A 0~400Hz

PI500 045G3

ZPB1A8888888

*Output Spec.

*Bar code

*Production Address

POWTRAN Inverter

Rated output capacity

045: 45kW

132: 132kW

Series Code

PI500 Series

Input Voltage Level

1: Single-phase 220V

2: Three-phase 220V

3: Three-phase 380V

4: Three-phase 480V

6: Three-phase 690V

Code with DC reactance

R: with DC reactor

(don't write without DC reactance)

Function code

F: Light load

G: Standard load

Chapter 1.Inspection and safety precautions

Powtran

purchasing, please check if its package is damaged due to careless transportation, and if the

specifications and model of the product are consistent with your order requirements. For any

problem, please contact your local authorized

1-1.Inspection after unpacking

※ Check if that packing container contains this unit, one manual and one warranty card.

※ Check the nameplate on the side of the frequency inverter to ensure that the product you

1-1-1.Instructions on nameplate

frequency inverters have been tested and inspected before leaving factory. After

Powtran

dealer or directly contact this company.

have received is right the one you ordered.

Figure 1-1:Nameplate Description

1-1-2.Model designation

Figure 1-2:Model Description

1

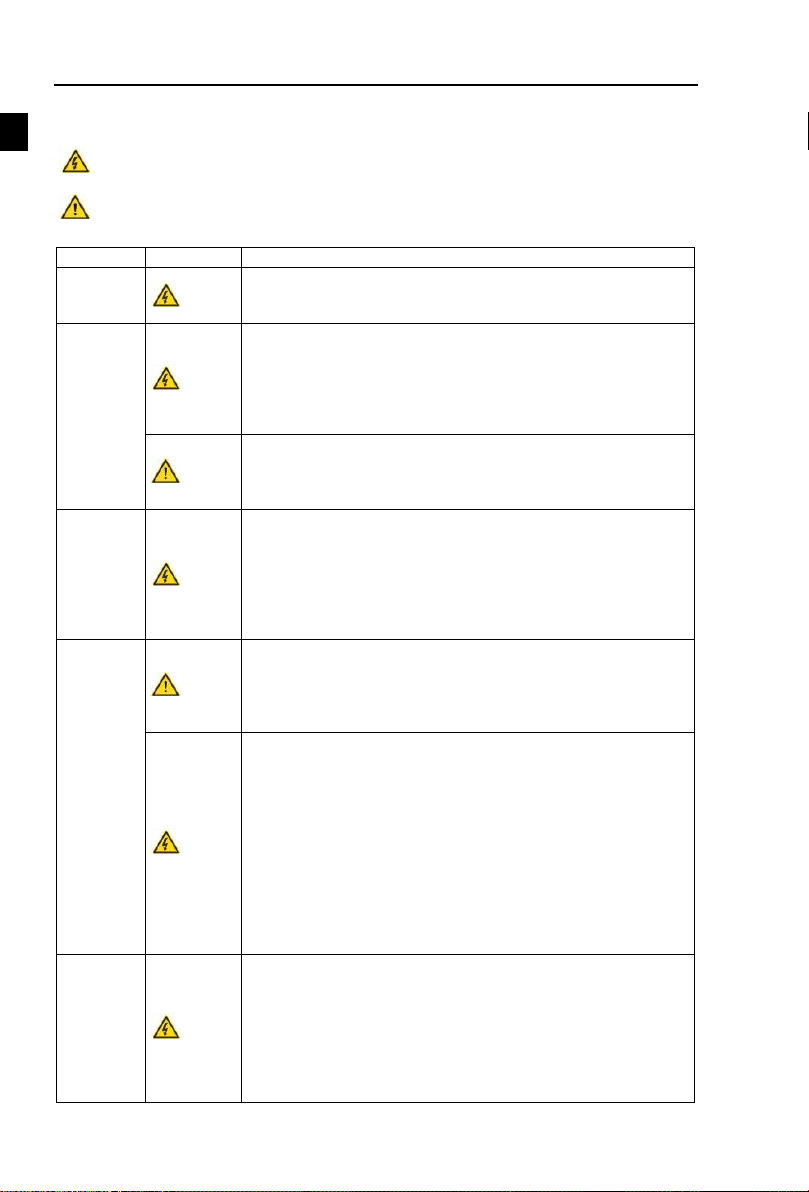

Chapter 1.Inspection and safety precautions

Chapter 1

Process

Type

Explanation

Before

installation

Danger

●When unpacking, if control system with water, parts missed or

component damaged are found, do not install!

●If packing list does not match the real name, do not install!

When

installing

Danger

● Gently carry with care, otherwise there is the risk of damage to

equipment!

●Please do not use the damaged driver or the frequency inverter

with missed pieces, otherwise there is the risk of injury!

●Do not use your hand to touch the control system components,

otherwise there is the risk of electrostatic damage!

Note

● Please install the unit on the metal or flame retardant objects;

away from combustible material. Failure to do so may cause a fire!

● Never twist the mounting bolts of the equipment components,

especially the bolt with the red mark!

When

wiring

Danger

● Do not let the lead wires or screws fall into the driver. Otherwise

which may cause damage to the driver!

● Keep the driver installed in the place where less vibration, avoid

direct sunlight.

● When two or more converters are installed in a cabinet, please

pay attention to the installation location, ensure the good heat

dissipation effect.

Before

energizing

Note

● Must comply with this manual's guidance, any construction shall

be performed by a professional electrician, otherwise there would

be the unexpected risk !

● A circuit breaker must be set between the inverter and the power

supply to separate them, otherwise it may cause a fire!

Danger

● Verify if power is a zero-energy status before wiring, otherwise

there is a risk of electric shock!

● The inverter shall be grounded correctly according to standard

specifications, otherwise there is a danger of electrical shock!

● Ensure that the distribution line meets the regional safety

standards of EMC requirements. The diameter of used wire shall

refer to the recommendations of this manual. Otherwise it may

cause an accident!

● Never directly connect braking resistor to the DC bus P(+) and

P(-) terminals. Otherwise it may cause a fire!

● Encoder must use the shielded wire, and the shielding layer must

ensure the single-ended grounded!

After

energizing

Danger

● Please confirm whether the input power voltage is same as the

inverter rated voltage; wiring positions of power input terminals(R,

S, T) and output terminals(U, V, W) are correct or not; and note

that if there is a short circuit in the peripheral circuit connected to

driver, if the connected lines are tight, otherwise it may cause

damage to the driver!

● Do not need to perform withstand voltage test for any part of the

inverter, this product has been tested before leaving factory.

1-2.Safety precautions

Safety precautions in this manual are divided into the following two categories:

Danger: the dangers caused by failure to perform required operation, may result in serious

injury or even death;

Caution:the dangers caused by failure to perform required operation, may result in moderate

injury or minor injury, and equipment damage;

2

Chapter 1.Inspection and safety precautions

Chapter 1

Otherwise it may cause an accident!

During

operation

Danger

● The inverter's cover plate must be closed before power on.

Otherwise it may cause an electric shock!

● Wiring of all external accessories must comply with the guidance

of this manual, please correctly wiring in accordance with the

circuit connection methods described in this manual. Otherwise it

may cause an accident!

Note

● Do not open cover plate after energizing. Otherwise there is a

risk of electric shock!

● Do not touch the driver and peripheral circuits with wet hands.

Otherwise there is a risk of electric shock!

● Do not touch any input and output terminals of the inverter.

Otherwise there is a risk of electric shock!

● The inverter automatically perform the safety testing for the

external strong electrical circuit in the early stages of energizing,

therefore never touch the driver terminals(U, V, W) or motor

terminals, otherwise there is a risk of electric shock!

● If you need to identify the parameters, please pay attention to the

danger of injury during motor rotation. Otherwise it may cause an

accident!

● Please do not change the inverter manufacturer parameters.

Otherwise it may cause damage to this unit!

When

maintaining

Danger

● Do not touch the cooling fan and the discharge resistor to feel the

temperature. Otherwise it may cause burns!

● Non-professional personnel is not allowed to detect signal when

operating. Doing so may cause personal injury or damage to this

unit!

● When the inverter is operating, you should avoid that objects fall

into this unit.Otherwise cause damage to this unit!

● Do not start/stop the driver by switching on/off contactor.

Otherwise cause damage to this unit!

● Do not perform repairs and maintenance for the live electrical

equipment. Otherwise there is a risk of electric shock!

● The repairs and maintenance task can be performed only when

the inverter bus voltage is lower than 36V,Otherwise, the residual

charge from capacitor would cause personal injury!

● Non-well-trained professional personnel is not allowed to

perform repairs and maintenance of inverter. Doing this may cause

personal injury or damage to this unit!

● After replacing the inverter, parameter settings must be redone,

all pluggable plugs can be operated only in the case of powering

off!

No.

Type

Explanation

1

Motor insulation

inspection

Please perform motor insulation inspection for the first time use,

re-use after leaving unused for a long time as well as regular

check, in order to prevent damage to the inverter because of the

motor's winding insulation failure. Wiring between motor and

inverter shall be disconnected, it is recommended that the 500V

voltage type megger should be adopted and insulation resistance

shall be not less than 5MΩ.

2

Motor thermal

protection

If the rated capacity of the selected motor does not match the

inverter, especially when the inverter rated power is greater than

1-3.Precautions

3

Chapter 1.Inspection and safety precautions

Chapter 1

the motor rated power, be sure to adjust the motor protection

parameter values inside inverter or install thermal relay in the front

of motor for motor protection.

3

Run over power

frequency

The inverter output frequency rang is 0Hz to 3200Hz(Max.vector

control only supports 300Hz). If the user is required to run at 50Hz

or more, please consider the endurance of your mechanical

devices.

4

Vibrations of

mechanical device

Inverter output frequency may be encountered mechanical

resonance point of the load device, you can set jump frequency

parameter inside inverter to avoid the case.

5

Motor heat and

noise

The inverter output voltage is PWM wave that contains a certain

amount of harmonics, so the temperature rise, noise and vibration

of motor show a slight higher than frequency power frequency

operation.

6

Output side with

piezoresistor or

capacitor for proving

power factor

The inverter output is PWM wave, if the piezoresistor for lightning

protection or the capacitor for improving power factor is installed

in the output side, which easily cause the inverter instantaneous

overcurrent or even cause damage to the inverter. Please do not

use.

7

Contactor or switch

used in the inverter

input/output

terminals

If contactor is installed between power supply and inverter, the

contactor is not allowed to start/stop the inverter. Necessarily need

to use the contactor to control the inverter start/stop, the interval

should not be less than one hour. Frequent charging and

discharging may reduce the service life of the inverter capacitor. If

the contactor or switch is equipped between output terminals and

motor, the inverter should be turned on/off without output status,

otherwise which easily lead to damage to the inverter module.

8

Use other than the

ratedvoltage

PI series inverter is not suitable for use beyond the allowable

operating voltage described in this manual, which easily cause

damage to the parts inside inverter. If necessary, please use the

corresponding transformer to change voltage.

9

Never change 3phase input to 2phase input

Never change PI series 3-phase inverter to 2-phase one for

application. Otherwise it will lead to malfunction or damage to the

inverter.

10

Lightning surge

protection

The series inverter is equipped with lightning overcurrent

protection device, so it has the ability of self-protection to

lightning induction. For the area where lightning is frequent, user

should also install the extra protection in the front of the inverter.

11

High altitude and

derating application

When the inverter is used in areas over 1000m altitude, it is

required to reduce frequency because the thin air will decrease the

cooling effect of inverter. Please consult our technician for details

on the application.

12

Special use

If the user need to use methods other than the suggested wiring

diagram provided in this manual, such as common DC bus, please

consult our technician.

13

Precautions for scrap

disposal of the

inverter

When electrolytic capacitors on the main circuit and printed circuit

board as well as plastic parts are burned, it may produce toxic

gases.Please disposing as industrial waste.

14

Adaptive motor

1) Standard adaptive motor shall be four-pole asynchronous

squirrel-cage induction motor or permanent magnet synchronous

motor. Apart from the said motors, please select the inverter

according to the motor rated current.

2) The cooling fan and the rotor shaft for non-inverter motor are

coaxially connected, the fan cooling effect is reduced when the

4

Chapter 1.Inspection and safety precautions

Chapter 1

rotational speed is reduced, therefore, when the motor works in

overheating occasions, a strong exhaust fan should be retrofitted or

replace non-inverter motor with the inverter motor.

3) The inverter has built-in the adaptive motor standard

parameters, according to the actual situation, please identify motor

parameters or accordingly modify the default values to try to meet

the actual value, otherwise it will operation affect and protection

performance;

4) When short-circuit of cable or motor internal will activate the

inverter alarm, even bombing. Therefore, firstly perform insulation

short-circuit test for the initial installation of the motor and cable,

routine maintenance often also need to perform such test. Note that

the parts to be tested and the inverter shall be disconnected

completely when testing.

15

Others

1)We need to fix cover and lock before power on, so as to avoid the

harm to personal safety that is caused by internal injuries of bad

capacitors and other components.

2)Do not touch internal circuit board and any parts after powering

off and within five minutes after keyboard indicator lamp goes out,

you must use the instrument to confirm that internal capacitor has

been discharged fully, otherwise there is a danger of electric shock.

3)Body static electricity will seriously damage the internal MOS

field-effect transistors, etc., if there are not anti-static measures, do

not touch the printed circuit board and IGBT internal device with

hand, otherwise it may cause a malfunction.

4)The ground terminal of the inverter(E or ) shall be earthed

firmly according to the provisions of the National Electrical Safety

and other relevant standards. Do not shut down(power off) by

pulling switch, and only cut off the power until the motor stopping

operation.

5)It is required to add the optional input filter attachment so as to

meet CE standards.

Only the well-trained personnel can be allowed to operate this unit, please carefully

read the instre1tions on safety, installation, operation and maintenance before use.

The safe operation of this unit depends on proper transport, installation, operation

and maintenance!

1-4.Scope of applications

※ This inverter is suitable for three-phase AC asynchronous motor and permanent magnet

synchronous motor.

※ This inverter can only be used in those occasions recognized by this company, an

unapproved use may result in fire, electric shock, explosion and other accidents.

※ If the inverter is used in such equipment (e.g: equipment for lifting persons, aviation systems,

safety equipment, etc.) and its malfunction may result in personal injury or even death. In

this case, please consult the manufacturer for your application.

5

第

十

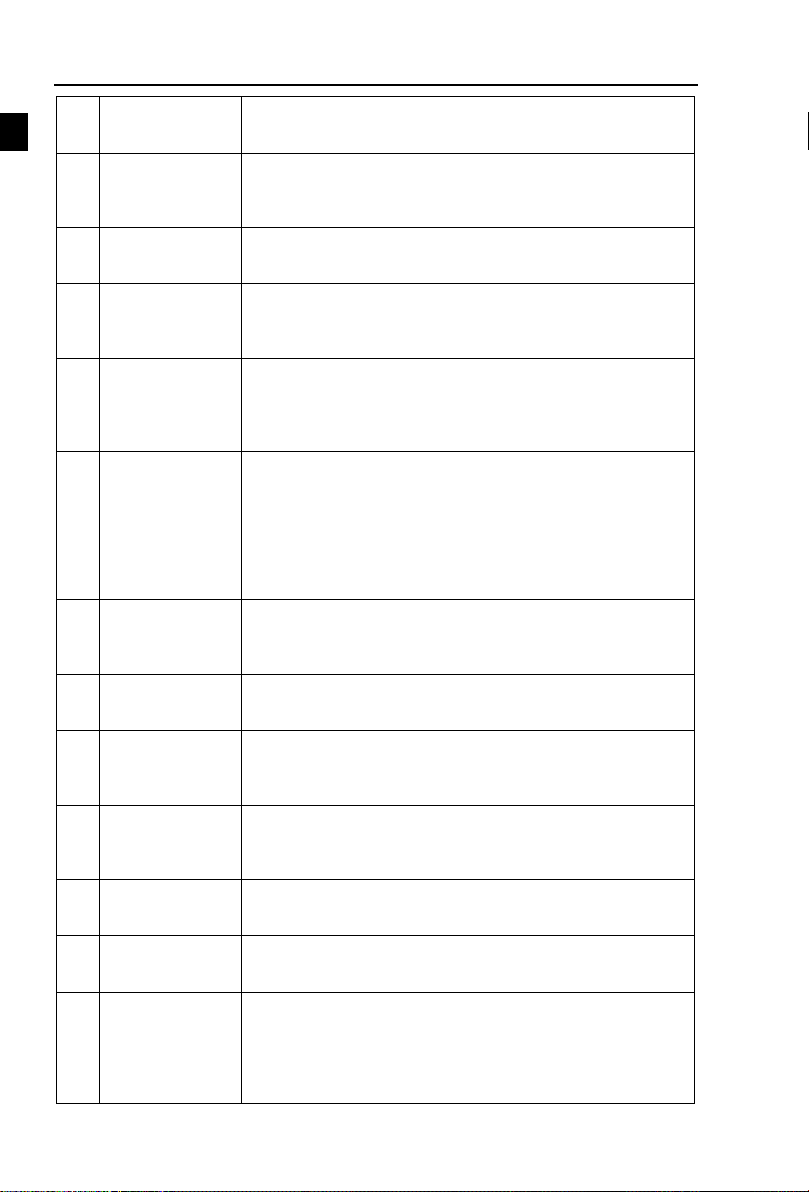

Chapter 2

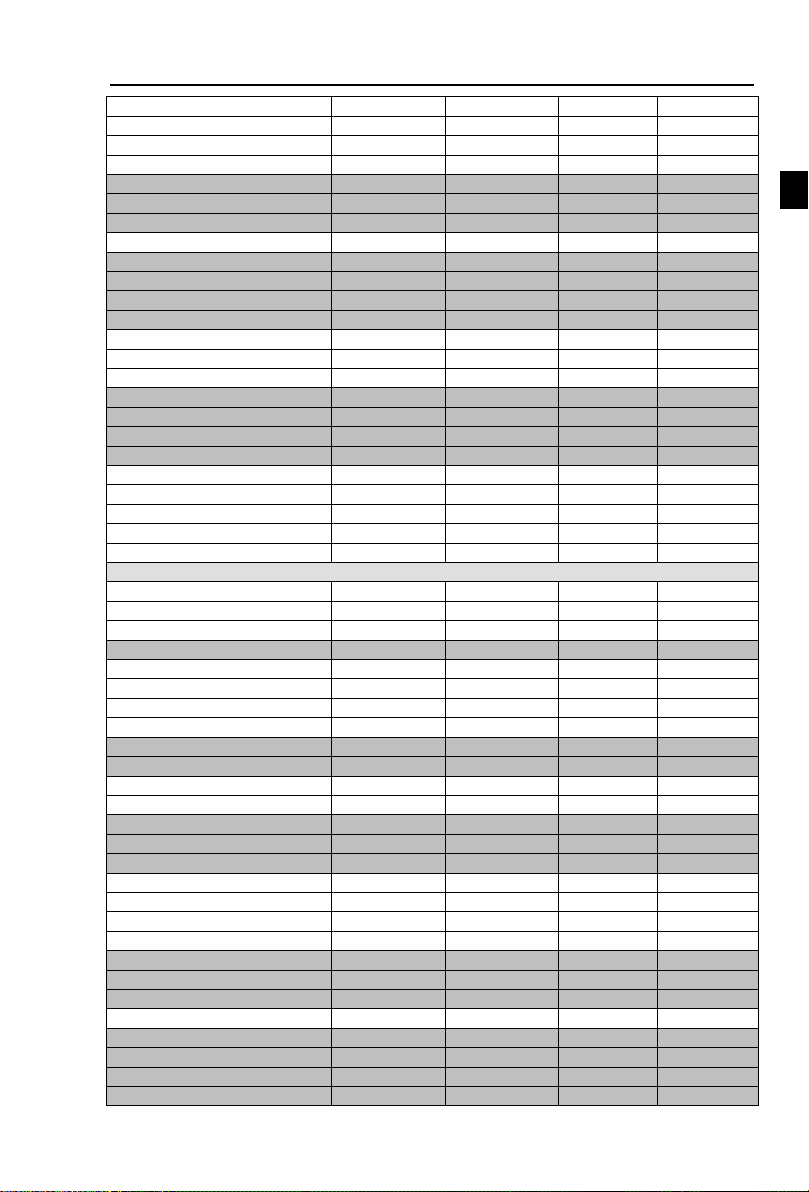

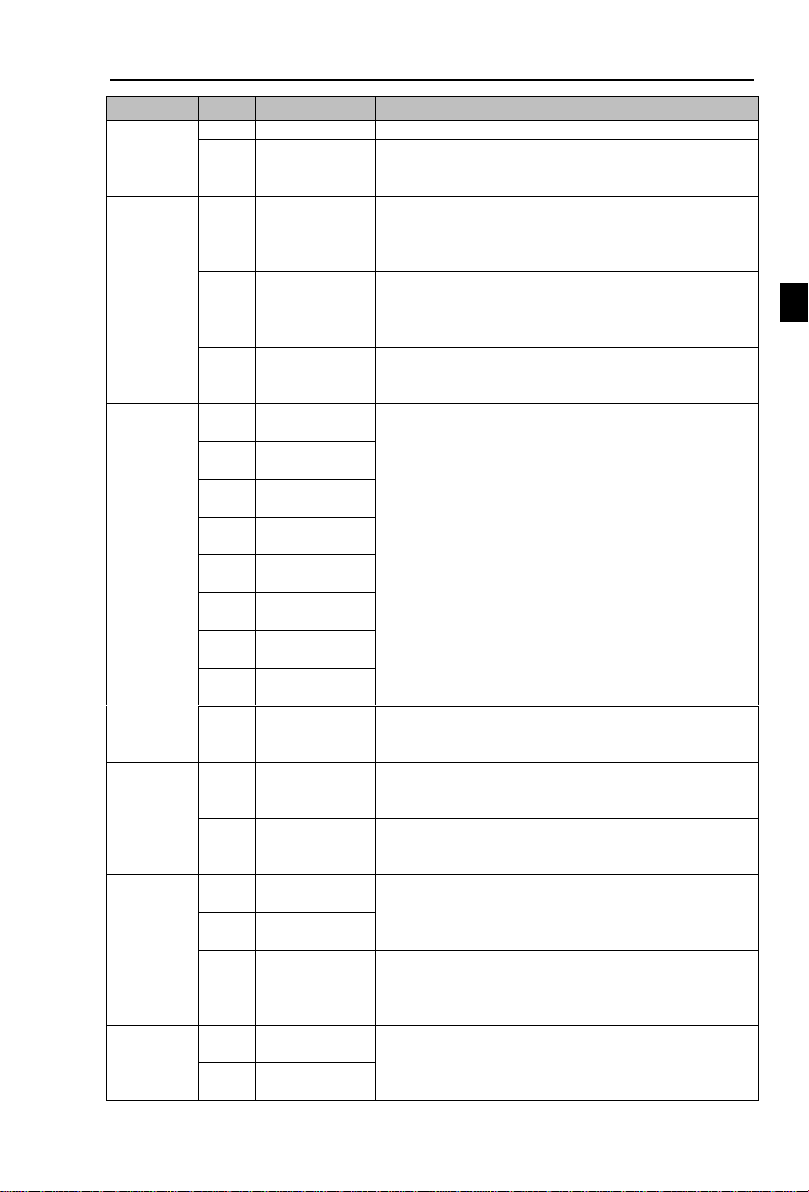

Model

Rated output

power(kW)

Rated input

current(A)

Rated

output

current(A)

Adaptive

motor(kW)

AC 1PH 220V(-15%)~240V(+10%)

PI500 0R4G1

0.4

5.4

2.5

0.4

PI500 0R7G1

0.75

8.2 4 0.75

PI500 1R5G1

1.5

14 7 1.5

PI500 2R2G1

2.2

23

10

2.2

PI500 004G1

4.0

35

16

4.0

PI500 5R5G1

5.5

50

25

5.5

AC 3PH 220V(-15%)~240V(+10%)

PI500 0R4G2

0.4

4.1

2.5

0.4

PI500 0R7G2

0.75

5.3 4 0.75

PI500 1R5G2

1.5

8.0 7 1.5

PI500 2R2G2

2.2

11.8

10

2.2

PI500 004G2

4.0

18.1

16 4 PI500 5R5G2

5.5

28

25

5.5

PI500 7R5G2

7.5

37.1

32

7.5

PI500 011G2

11

49.8

45

11

PI500 015G2

15.0

65.4

60

15.0

PI500 018G2

18.5

81.6

75

18.5

PI500 022G2

22.0

97.7

90

22.0

PI500 030G2

30.0

122.1

110

30.0

PI500 037G2

37.0

157.4

152

37.0

PI500 045G2

45.0

185.3

176

45.0

PI500 055G2

55.0

214

210

55.0

PI500 075G2

75

307

304

75

PI500 093G2

93

383

380

93

PI500 110G2

110

428

426

110

PI500 132G2

132

467

465

132

PI500 160G2

160

522

520

160

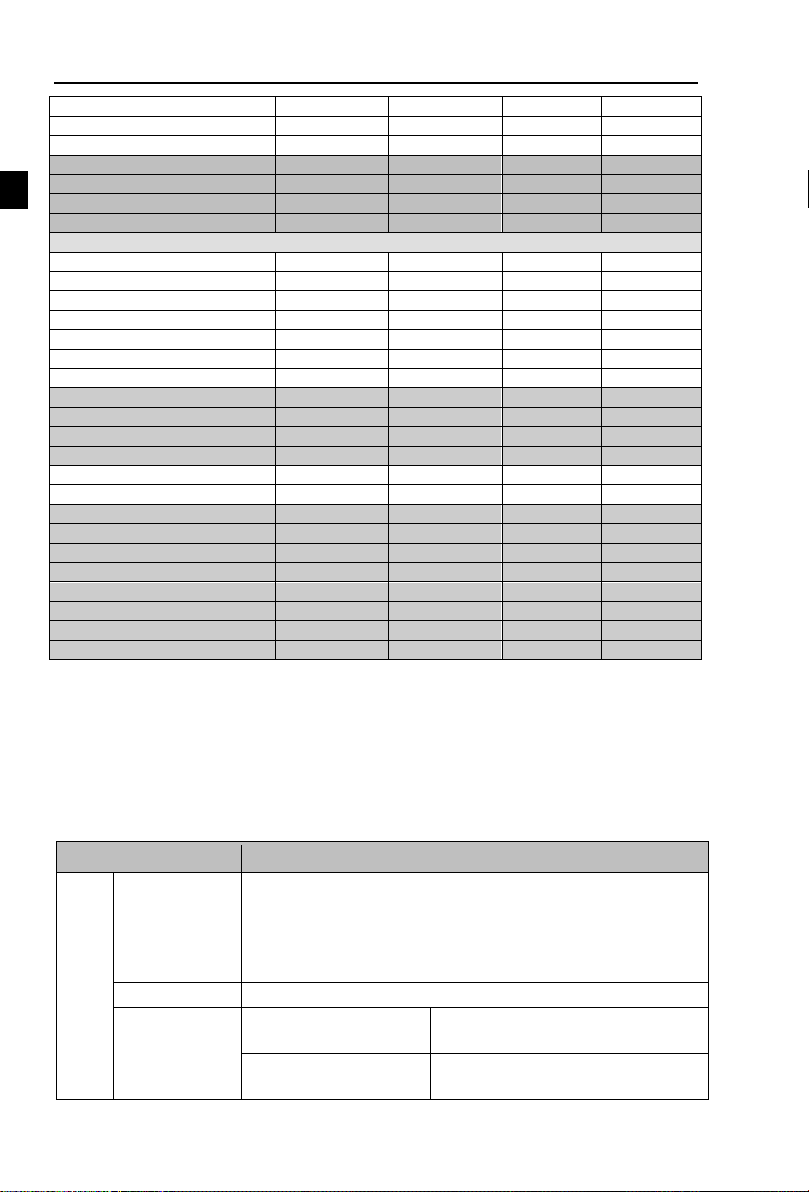

AC 3PH 380V(-15%)~440V(+10%)

PI500 0R7G3

0.75

4.3

2.5

0.75

PI500 1R5G3

1.5

5.0

3.8

1.5

PI500 2R2G3

2.2

5.8

5.1

2.2

PI500 004G3

4.0

10.5 9 4.0

PI500 5R5G3

5.5

14.6

13

5.5

PI500 7R5G3

7.5

20.5

17

7.5

PI500 011F3

11

26

25

11

PI500 011G3

11

26

25

11

PI500 015F3

15

35

32

15

PI500 015G3/PI500 018F3

15/18.5

35/38.5

32/37

15/18.5

PI500 018G3/PI500 022F3

18.5/22

38.5/46.5

37/45

18.5/22

PI500 022G3/PI500 030F3

22/30

46.5/62

45/60

22/30

PI500 030G3/PI500 037F3

30/37

62/76

60/75

30/37

PI500 037G3/PI500 045F3

37/45

76/91

75/90

37/45

PI500 045G3N

45

91

90

45

Chapter 2 Standard specifications

2-1.Technical specifications

6

Chapter 2 Standard specifications

Chapter 2

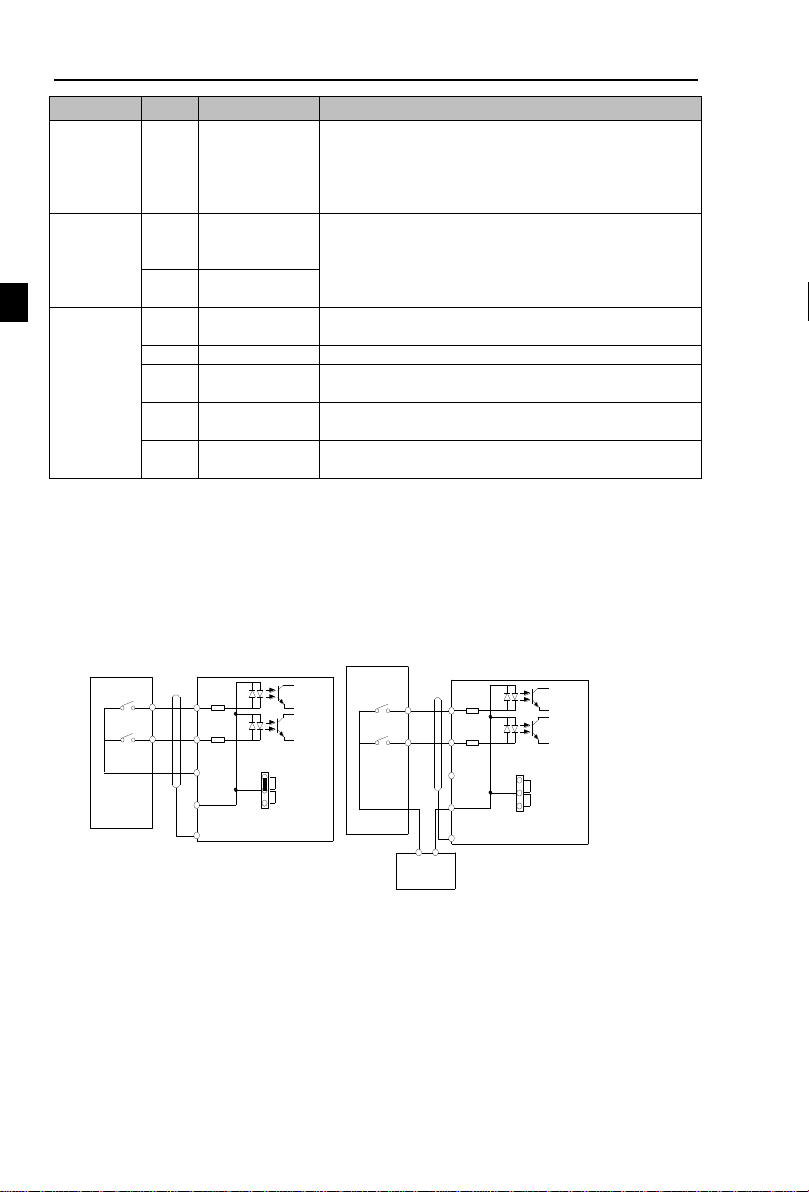

PI500 045G3/PI500 055F3

45/55

91/112

90/110

45/55

PI500 055G3

55

112

110

55

PI500 075F3

75

157

150

75

PI500 075G3

75

157

150

75

PI500 093F3

93

180

176

93

PI500 093G3/PI500 110F3

93/110

180/214

176/210

93/110

PI500 110G3/PI500 132F3

110/132

214/256

210/253

110/132

PI500 132G3/PI500 160F3

132/160

256/307

253/304

132/160

PI500 160G3/PI500 187F3

160/187

307/345

304/340

160/187

PI500 187G3/PI500 200F3

187/200

345/385

340/380

187/200

PI500 200G3/PI500 220F3

200/220

385/430

380/426

200/220

PI500 220G3

220

430

426

220

PI500 250F3

250

468

465

250

PI500 250G3/PI500 280F3

250/280

468/525

465/520

250/280

PI500 280G3

280

525

520

280

PI500 315F3

315

590

585

315

PI500 315G3/PI500 355F3

315/355

590/665

585/650

315/355

PI500 355G3/PI500 400F3

355/400

665/785

650/725

355/400

PI500 400G3

400

785

725

400

PI500 450F3R

450

883

820

450

PI500 450G3R/PI500 500F3R

450/500

883/920

820/860

450/500

PI500 500G3R/PI500 560F3R

500/560

920/1010

860/950

500/560

PI500 560G3R/PI500 630F3R

560/630

1010/1160

950/1100

560/630

PI500 630G3R/PI500 700F3R

630/700

1160/1310

1100/1250

630/700

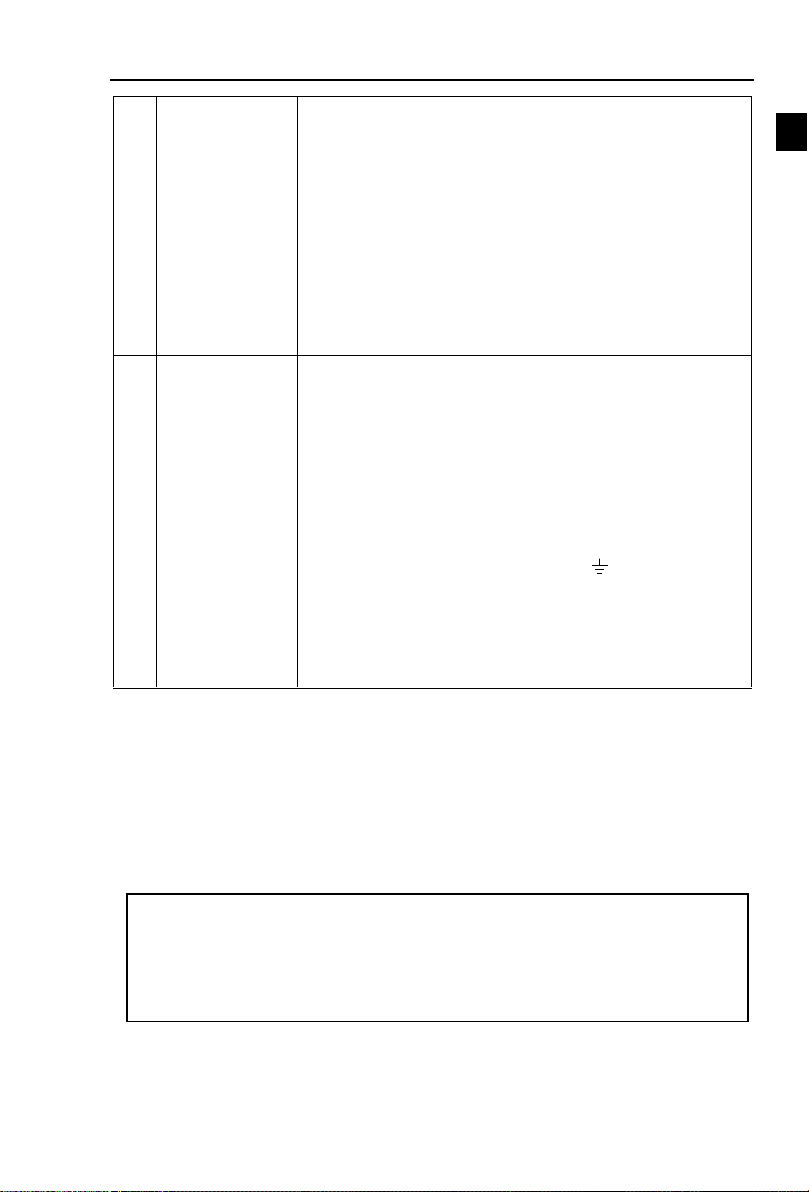

AC 3PH 480V±10%

PI500 0R7G4

0.75

4.1

2.5

0.75

PI500 1R5G4

1.5

4.9

3.7

1.5

PI500 2R2G4

2.2

5.7

5.0

2.2

PI500 004G4

4.0

9.4 8 4.0

PI500 5R5G4

5.5

12.5

11

5.5

PI500 7R5G4

7.5

18.3

15

7.5

PI500 011F4

11

23.1

22

11

PI500 011G4

11

23.1

22

11

PI500 015F4

15

29.8

27

15

PI500 015G4/PI500 018F4

15/18.5

29.8/35.7

27/34

15/18.5

PI500 018G4/PI500 022F4

18.5/22

35.7/41.7

34/40

18.5/22

PI500 022G4/PI500 030F4

22/30

41.7/57.4

40/55

22/30

PI500 030G4/PI500 037F4

30/37

57.4/66.5

55/65

30/37

PI500 037G4/PI500 045F4

37/45

66.5/81.7

65/80

37/45

PI500 045G4N

45

81.7

80

45

PI500 045G4/PI500 055F4

45/55

81.7/101.9

80/100

45/55

PI500 055G4

55

101.9

100

55

PI500 075F4

75

137.4

130

75

PI500 075G4

75

137.4

130

75

PI500 093F4

93

151.8

147

93

PI500 093G4/PI500 110F4

93/110

151.8/185.3

147/180

93/110

PI500 110G4/PI500 132F4

110/132

185.3/220.7

180/216

110/132

PI500 132G4/PI500 160F4

132/160

220.7/264.2

216/259

132/160

PI500 160G4/PI500 187F4

160/187

264.2/309.4

259/300

160/187

PI500 187G4/PI500 200F4

187/200

309.4/334.4

300/328

187/200

PI500 200G4/PI500 220F4

200/220

334.4/363.9

328/358

200/220

PI500 220G4

220

363.9

358

220

7

Chapter 2 Standard specifications

Chapter 2

PI500 250F4

250

407.9

400

250

PI500 250G4/PI500 280F4

250/280

407.9/457.4

400/449

250/280

PI500 280G4

280

457.4

449

280

PI500 315F4

315

533.2

516

315

PI500 315G4/PI500 355F4

315/355

533.2/623.3

516/570

315/355

PI500 355G4/PI500 400F4

355/400

623.3/706.9

570/650

355/400

PI500 400G4

400

706.9

650

400

AC 3PH 690V±10%

PI500 011G6/ PI500 015F6

11/15

15/20

12/15

11/15

PI500 015G6/ PI500 018F6

15/18.5

20/30

15/20

15/18.5

PI500 018G6/ PI500 022F6

18.5/22

30/35

20/24

18.5/22

PI500 022G6/ PI500 030F6

22/30

35/45

24/33

22/30

PI500 030G6/ PI500 037F6

30/37

45/55

33/41

30/37

PI500 037G6/ PI500 045F6

37/45

55/65

41/50

37/45

PI500 045G6/ PI500 055F6

45/55

65/70

50/62

45/55

PI500 055G6/ PI500 075F6

55/75

70/90

62/85

55/75

PI500 075G6/ PI500 093F6

75/93

90/105

85/102

75/93

PI500 093G6/ PI500 110F6

93/110

105/130

102/125

93/110

PI500 110G6/ PI500 132F6

110/132

130/170

125/150

110/132

PI500 132G6/ PI500 160F6

132/160

170/200

150/175

132/160

PI500 160G6/ PI500 187F6

160/187

200/210

175/198

160/187

PI500 187G6/ PI500 200F6

187/200

210/235

198/215

187/200

PI500 200G6/ PI500 220F6

200/220

235/247

215/245

200/220

PI500 220G6/ PI500 250F6

220/250

247/265

245/260

220/250

PI500 250G6/ PI500 280F6

250/280

265/305

260/299

250/280

PI500 280G6/ PI500 315F6

280/315

305/350

299/330

280/315

PI500 315G6/ PI500 355F6

315/355

350/382

330/374

315/355

PI500 355G6/ PI500 400F6

355/400

382/435

374/410

355/400

PI500 400G6/ PI500 450F6

400/450

435/490

410/465

400/450

Items

Specifications

Power Input

Rated voltage

AC 1PH 220V(-15%)~240V(+10%)

AC 3PH 220V(-15%)~240V(+10%)

AC 3PH 380V(-15%)~440V(+10%)

AC 3PH 480V(-10%)~480V(+10%)

AC 3PH 690V(-10%)~690V(+10%)

Input frequency

50Hz/60Hz

Allowing

fluctuations

Voltage continued

volatility:±10%

Less than 3% of voltage unbalance rate

3%;

Input frequency

fluctuation:±5%;

Distortion satisfy IEC61800-2 standard

Note:

(1)PI500 inverter PI500 132G3/PI500 160F3 to PI500 630G3R/PI500 700F3R with "R"

indicating a DC reactor, such as PI500-160G3R, PI500 160G4R.

(2) The correct frequency converter selection method is: inverter rated output current is more

than or equal to the rated current of motor. The difference between the frequency inverter and the

rated power of the motor generally recommends no more than two power segments;Large

frequency inverter with small motor, must accurately input motor parameters, can avoid motor

overload and damage.

2-2.Standard specifications

8

Chapter 2 Standard specifications

Chapter 2

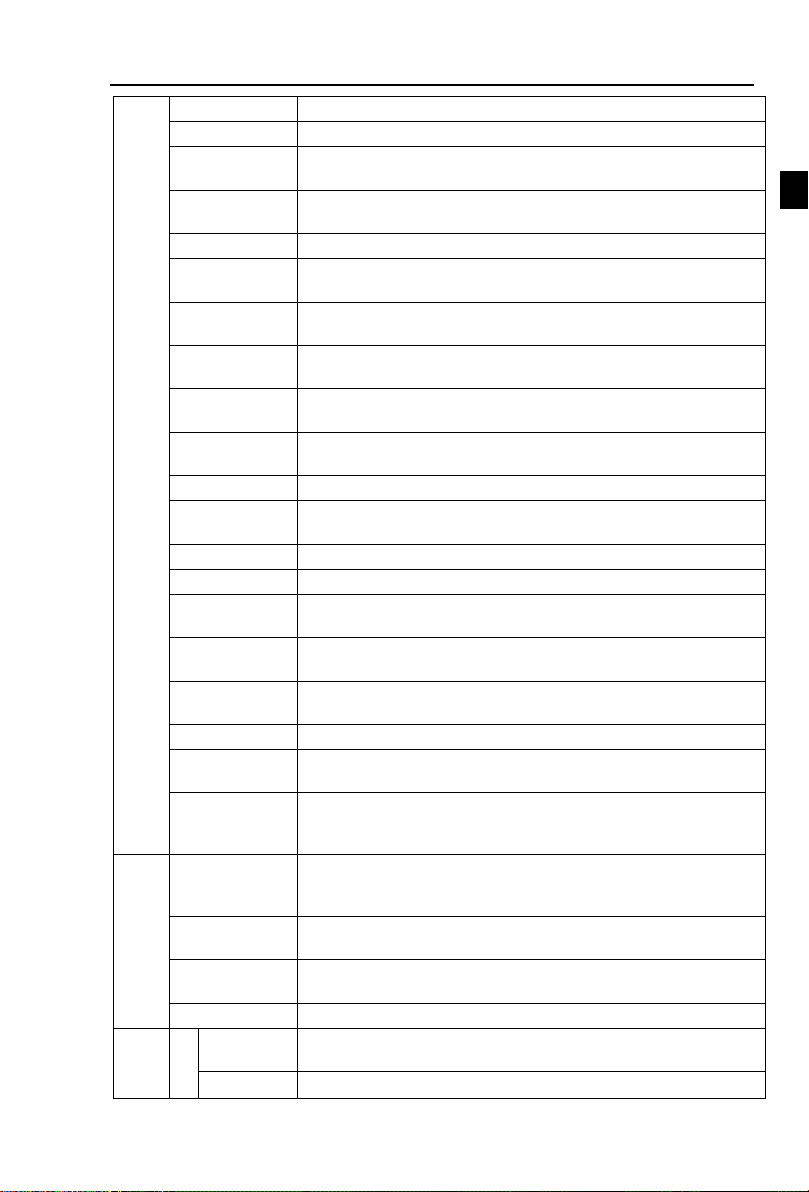

Control system

Control system

High performance vector control inverter based on DSP

Control method

V/F control, vector control W/O PG, vector control W/ PG

Automatic torque

boost function

Realize low frequency (1Hz) and large output torque control under the

V/F control mode.

Acceleration/decel

eration control

Straight or S-curve mode. Four times available and time range is 0.0 to

6500.0s.

V/F curve mode

Linear, square root/m-th power, custom V/F curve

Over load

capability

G type:rated current 150% - 1 minute, rated current 180% - 2 seconds

F type:rated current 120% - 1 minute, rated current 150% - 2 seconds

Maximum

frequency

1、Vector control:0 to 300Hz; 2、V/F control:0 to 3200Hz

Carrier Frequency

0.5 to 16kHz; automatically adjust carrier frequency according to the

load characteristics.

Input frequency

resolution

Digital setting: 0.01Hz minimum analog: 0.01Hz.

Start torque

G type: 0.5Hz/150% (vector control W/O PG)

F type: 0.5Hz/100% (vector control W/O PG)

Speed range

1:100 (vector control W/O PG) 1:1000 (vector control W/ PG)

Steady-speed

precision

Vector control W/O PG: ≤ ± 0.5% (rated synchronous speed)

Vector control W/ PG: ≤ ± 0.02% (rated synchronous speed)

Torque response

≤ 40ms (vector control W/O PG)

Torque boost

Automatic torque boost; manual torque boost(0.1% to 30.0%)

DC braking

DC braking frequency: 0.0Hz to max. frequency, braking time:

0.0 to 100.0 seconds, braking current value: 0.0% to 100.0%

Jogging control

Jog Frequency Range: 0.00Hz to max. frequency;

Jog Ac/deceleration time: 0.0 to 6500.0s

Multi-speed

operation

Achieve up to 16-speed operation through the control terminal

Built-in PID

Easy to realize closed-loop control system for the process control.

Automatic voltage

regulation(AVR)

Automatically maintain a constant output voltage when the voltage of

electricity grid changes

Torque limit and

control

"Excavator" feature - torque is automatically limited during the

operation to prevent frequent overcurrent trip; the closed-loop vector

mode is used to control torque.

Personalization function

Self-inspection of

peripherals after

power-on

After powering on, peripheral equipment will perform safety testing,

such as ground, short circuit, etc.

Common DC bus

function

Multiple inverter can use a common DC bus.

Quick current

limiting

The current limiting algorithm is used to reduce the inverter over

current probability, and improve whole unit anti-interference capability.

Timing control

Timing control function: time setting range(0m to 6500m)

Running

Input

signal

Running

method

Keyboard/terminal/communication

Frequency

10 frequency settings available, including adjustable DC(0~10V/-10~

9

Chapter 2 Standard specifications

Chapter 2

setting

+10V), adjustable DC(0 to 20mA), panel potentiometer, etc.

Start signal

Rotate forward/reverse

Multi-speed

At most 16-speed can be set(run by using the multi-function terminals

or

program

)

Emergency

stop

Interrupt

controller output

Wobbulate run

Process

control run

Fault reset

When the protection function is active, you can automatically or

manually

reset the fault condition.

PID feedback

signal

Including

DC(0 to 10V), DC(0 to 20mA)

Output Signal

Running status

Motor

status

display, stop, ac/deceleration, constant speed, program

running status.

Fault output

Contact capacity :normally closed contact 3A/AC 250V,normally

open

contact5A

/AC 250V,1A/DC 30V.

Analog output

Two-way analog output, 16 signals can be selected such as frequency,

current

, voltage and other, output signal range (0 to 10V / 0 to 20mA).

Output signal

At most 4-way output, there are 40 signals each way

Run function

Limit frequency, jump frequency, frequency compensation, auto-tuning,

PID control

DC current

braking

Built-in PID regulates braking current to ensure sufficient braking

torque under no overcurrent condition.

Running

command channel

Three channels: operation panel, control terminals and serial

communication port. They can be switched through a variety of ways.

Frequency source

Total 10 frequency sources: digital, analog voltage, analog current,

multi-speed and serial port. They can be switched through a variety of

ways.

Input terminals

8 digital input terminals, compatible with active PNP or NPN input

mode, one of them can be for high-speed pulse input(0 to 100 kHz

square wave); 3 analog input terminals for voltage or current input.

Output terminals

2 digital output terminals, one of them can be for high-speed pulse

output(0 to 100kHz square wave); one relay output terminal; 2 analog

output terminals respectively for optional range (0 to 20mA or 0 to

10V), they can be used to set frequency, output frequency, speed and

other physical parameters.

Protection function

Inverter protection

Overvoltage protection, undervoltage protection, overcurrent

protection, overload protection, overheat protection, overcurrent stall

protection, overvoltage stall protection, losting-phase protection

(optional), communication error, PID feedback signal abnormalities,

PG failure and short circuit to ground protection.

IGBT temperature

display

Displays current temperature IGBT

Inverter fan control

Can be set

Instantaneous

power-down restart

Less than 15 milliseconds: continuous operation.

More than 15 milliseconds: automatic detection of motor speed,

instantaneous power-down restart.

10

Chapter 2 Standard specifications

Chapter 2

Speed start tracking

method

The inverter automatically tracks motor speed after it starts

Parameter

protection function

Protect inverter parameters by setting administrator Password and

decoding

Display

LED/O

LED

display

keyboa

rd

Running

informatio

n

Monitoring objects including: running frequency, set frequency, bus

voltage, output voltage, output current, output power, output torque,

input terminal status, output terminal status, analog AI1 value, analog

AI2 value, motor Actual running speed,PID set value percentage, PID

feedback value percentage.

Error

message

At most save three error message, and the time, type, voltage, current,

frequency and work status can be queried when the failure is occurred.

LED display

Display parameters

OLED display

Optional, prompts operation content in Chinese/English text.

Copy parameter

Can upload and download function code information of frequency

converter, rapid replication parameters.

Key lock and

function selection

Lock part or all of keys, define the function scope of some keys to

prevent misuse.

Com

muni

catio

n

RS485

The optional completely isolated RS485 communication module can

communicate with the host computer.

Environment

Product standard

Environment

temperature

-10to 40℃ (The environment temperature in 40 ~ 50 ℃, please

derating use)

Storage

temperature

-20 to 65 ℃

Environment

humidity

Less than 90% R.H, no condensation.

Vibration

Below 5.9m/s² (= 0.6g)

Application sites

Indoor where no sunlight or corrosive, explosive gas and water vapor,

dust, flammable gas,oil mist, water vapor, drip or salt, etc.

Altitude

No need derating below 1000m, please derating 1% every 100 m when

the altitude is above 3000m

Protection level

IP20

Product

standard

Product adopts

safety standards.

IEC61800-5-1:2007

Product adopts

EMC standards.

IEC61800-3:2005

Cooling method

Forced air cooling

11

第

十

Chapter 3

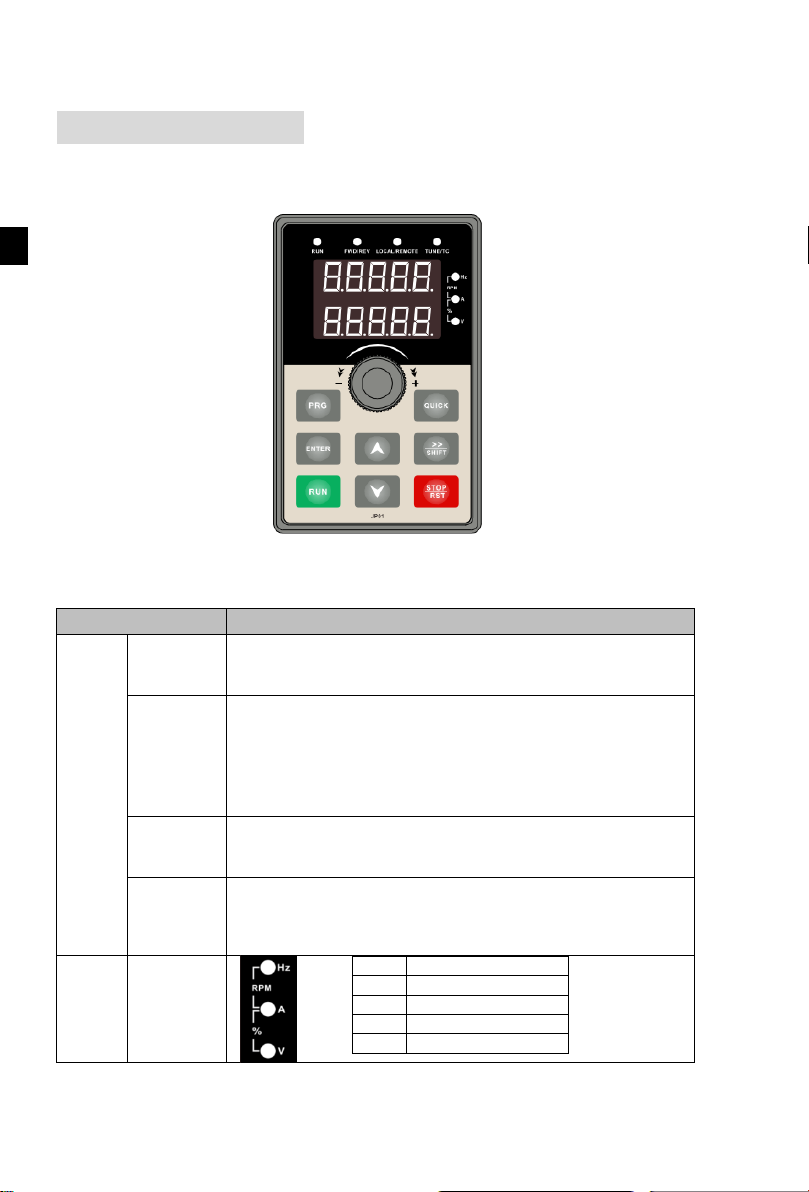

Indicator

flag

Name

Status lamp

RUN

Running indicator light

* ON: the inverter is working

* OFF: the inverter stops

LOCAL/R

EMOTE

Command indicator light

That is the indicator for keyboard operation, terminal operation and

remote operation (communication control)

* ON: terminal control working status

* OFF: keyboard control working status

* Flashing: remote control working status

FWD/REV

Forward/reverse running light

* ON: in forward status

* OFF: in reversal status

TUNE/TC

Motor self-learning/Torque control/Fault indicator

* ON: in torque control mode

* Slow flashing: in the motor tunning status

* Quick flashing: in the fault status

Units

combinatio

n indicator

HzAV

Hz

frequency unit

A

current unit

V

voltage unit

RPM

speed unit

%

percentage

Chapter 3 Keyboard

3-1.Keyboard description

Figure 3-1:Operation panel display

3-2.Keyboard Indicators

12

Chapter 3

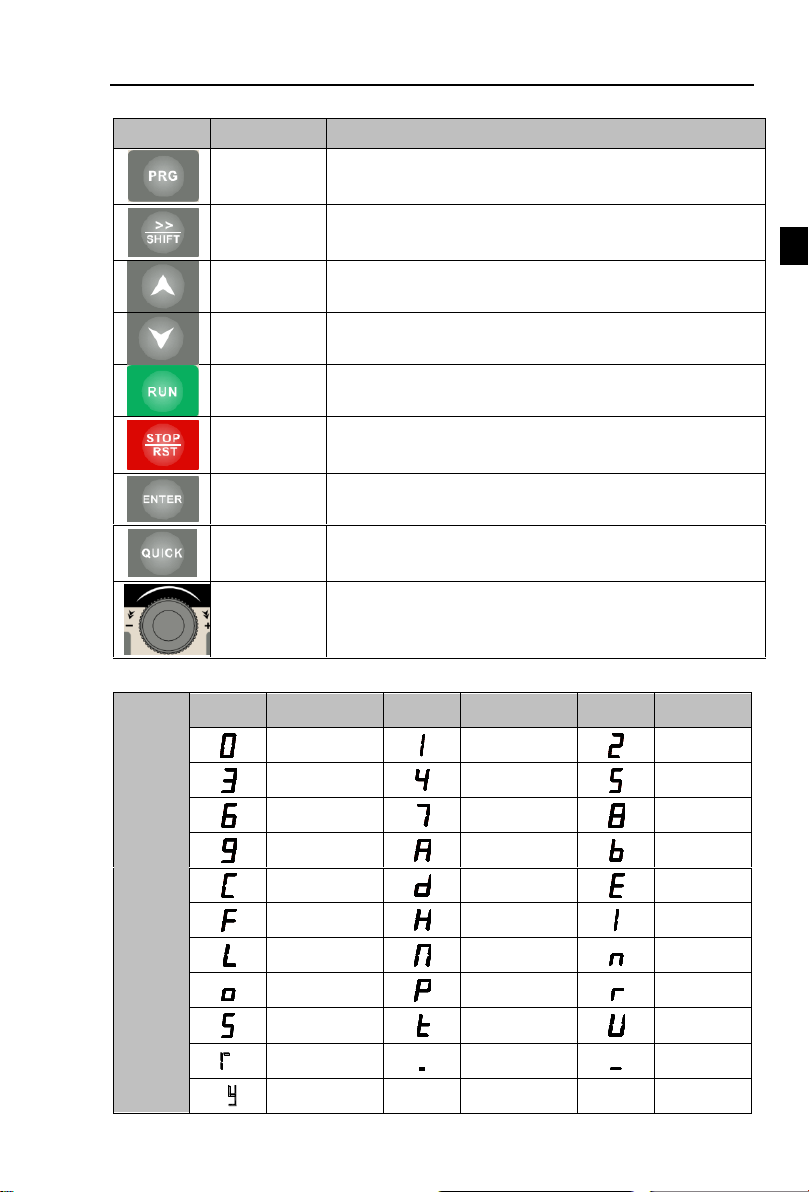

3-3.Description of operation panel keys

Sign

Name

Function

Parameter

Setting/Esc

Key

* Enter into the modified status of main menu

* Esc from functional parameter modification

* Esc submenu or functional menu to status menu

Shift Key

*Choose displayed parameter circularly under running or stop

interface; choose parameter’s modified position when modify

parameter

Increasing Key

Parameter or function number increasing,set by parameter F6.18.

Decreasing

key

Parameter or function number decreasing, set by parameter

F6.19.

Running key

For starting running in the mode of keyboard control status

Stop/Reset

Key

*For stopping running in the running status; for resetting the

operation in fault alarm status. The function of the key is subject

to F6.00

Enter key

Enter into levels of menu screen confirm setting

Quick

multifunction

key

This key function is determined by the function code F6.21.

Keyboard

encoder

* In query

status

, function parameter increasing or decreasing

* In modified status, the function parameter or modified

position

increasing or decreasing.

* In monitoring status, frequency setting increasing or decreasing

Digital

display

area

Display

letters

Corresponding

letters

Display

letters

Corresponding

letters

Display

letters

Correspondi

ng letters

0 1 2 3 4 5 6 7 8 9 A B

C d E

F H I L

N n o P r S t U T . -

y

Chapter 3 Keyboard

3-4.Keyboard display letters and numbers correspondence table

13

Chapter 3 Keyboard

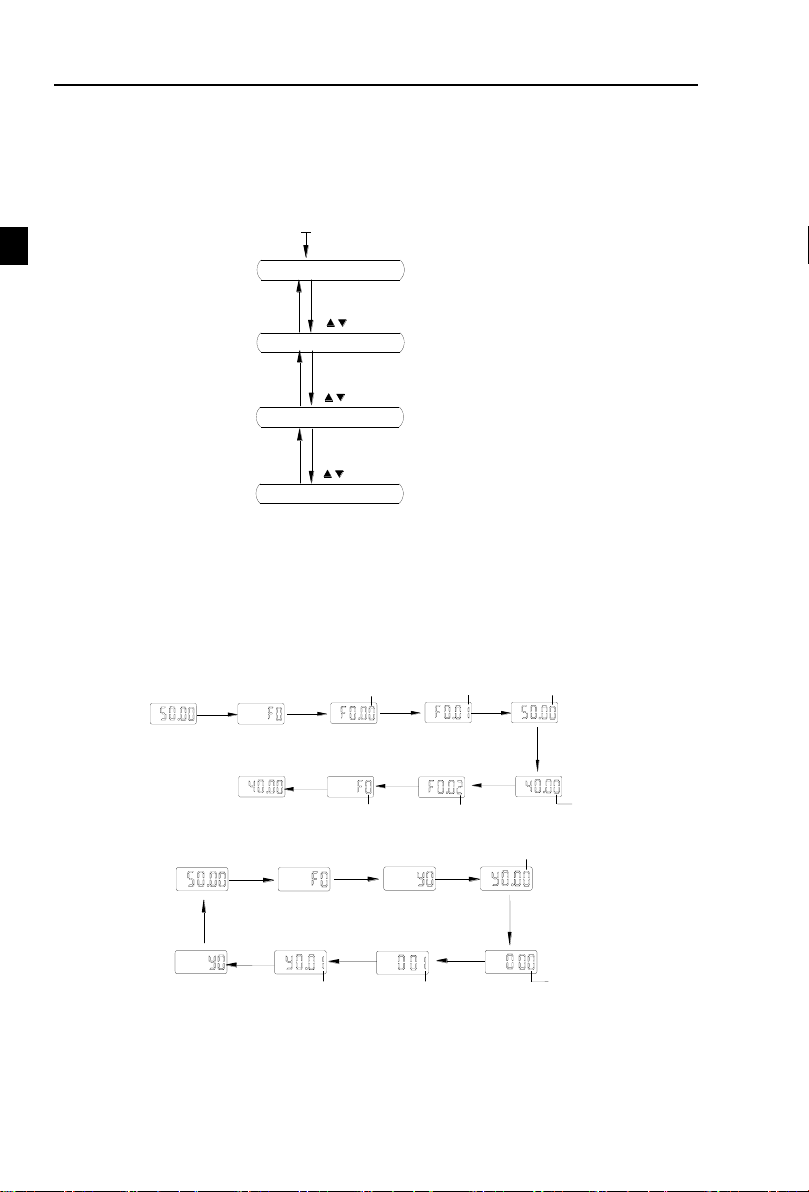

Chapter 3

Shutdown parameter display

PRG

Change parameter group

PRG

First-level menu display

ENTER

Change function parameter selection

PRG

ENTER

Change function parameter value

PRG

ENTER

Power-on

Second-level menu display

Third-level menu display

Press PRG

Press ENTER

Press ▲

Press ▼

Press ENTER

Press PRG

Press PRG

Press ENTER

Flicker

Flicker

Flicker

Flicker

Flicker

Flicker

Press ▲

Press PRG

Press ENTER

Flicker

Flicker

Flicker

Flicker

Press PRG

Press ENTER

Press ▲

Press ENTER

Press PRG

3-5.Examples of parameter settings

3-5-1.Instructions on viewing and modifying function code

PI500 inverter’s operation pane is three levels menu for parameter setting etc.Three levels:

function parameter group (Level 1)→function code(level 2)→function code setting(level 3). The

operation is as following:

Description: Back to the level 2 menu from level 3 menu by PRG key or ENTER key in the

level 3 operation status. The differences between the two keys : ENTER will be back to the level 2

menu and save parameter setting before back, and transfer to the next function code automatically;

PRG will be back to the level 2 menu directly, not save parameter setting, then back to current

function code.

Example 1 Frequency setting to modify parameters

Set F0.01 from 50.00Hz to 40.00Hz

Figure 3-2:Operation processes

Example 2 :Restore factory settings

Without twinkling parameter position, the function code can not be modified in the level 3

menu. The reason maybe as following:

1) The function code can not be modified itself, eg: actual detecting parameters, running

record parameters.

2) The function code can not be modified in the running status. It must be modified in the stop

status.

14

Chapter 3 Keyboard

Chapter 3

Motor Selection

Parameters

Motor

b0.00: motor type selection b0.01: motor rated power

b0.02: motor rated voltage b0.03: motor rated current

b0.04: motor rated frequency b0.05: motor rated speed

Motor Selection

Parameters

Motor

b0.06:asynchronous motor stator resistance b0.07:asynchronous motor rotor

resistance

b0.08:asynchronous motor leakage inductance b0.09: asynchronous motor

mutual inductance

b0.10: asynchronous motor no-load current

SHIFT

3-5-2.The way to read parameters in various status

In stop or run status, operate shift key to display a variety of status parameters

respectively. Parameter display selection depends on function code F6.01 (run parameter 1), F6.02

(run parameter 2) and F6.03 (stop parameter 3).

In stop status, there are total 16 stop status parameters that can be set to display/not display:

set frequency, bus voltage, DI input status, DO output status, analog input AI1 voltage, analog

input AI2 voltage, panel potentiometer input voltage, Actual count value, Actual length value, PLC

running step number, Actual speed display, PID settings, high-speed pulse input frequency and

reserve, switch and display the selected parameter by pressing key orderly.

In running status, there are 5 running-status parameters:running frequency,setting

frequency,bus voltage,output voltage, output current default display, and other display parameters:

output power, output torque, DI input status, DO output status, analog input AI1 voltage, analog

input AI2 voltage, panel potentiometer input voltage, Actual count value, Actual length value,

linear speed, PID settings and PID feedback, etc, their display depends on function code F6.01 and

F6.02 switch and display the selected parameter by pressing key orderly.

Inverter powers off and then powers on again, the displayed parameters are the selected

parameters before power-off.

3-5-3.Password settings

The inverter has password protection. When y0.01 become not zero, it is the password and

will be work after exit from function code modified status. Press PRG key again, will display”----”.

One must input the correct password to go to regular menu, otherwise, inaccessible.

To cancel the password protection function, firstly enter correct password to access and then

set y0.01 to 0.

3-5-4.Motor parameter auto turning

Choose vector control, one must input the motor’s parameters in the nameplate accurately

before running the inverter. PI500 series frequency inverter will match the motor’s standard

parameters according to its nameplate. The vector control is highly depend on motor’s parameters.

The parameters of the controlled motor must be inputted accurately for the good control

performance.

Motor parameter auto tunning steps are as follows:

Firstly select command source (F0.11=0) as the comment channel for operation panel, then

input the following parameters according to the actual motor parameters (selection is based on the

current motor):

asynchronous

For

If the motor can NOT completely disengage its load, please select 1 (asynchronous motor

parameter static auto turning) for b0.27, and then press the RUN key on the keyboard panel.

If the motor can

comprehensive auto turning) for b0.27, and then press the RUN key on the keyboard panel, the

inverter will automatically calculate the motor’s following parameters:

Complete

motor parameter auto turning

motors

completely

disengage its load, please select 2 (asynchronous motor parameter

15

第

十

Chapter 4

AA

B B B

Cool wind

Hot wind

Mounted

vertically

upwards

Power rating

Dimension requirement

0.75~11kW

A≥100mm;B≥10mm

15~22kW

A≥200mm;B≥10mm

30~75kW

A≥200mm;B≥50mm

93~400kW

A≥300mm;B≥50mm

Chapter 4 Installation and commissioning

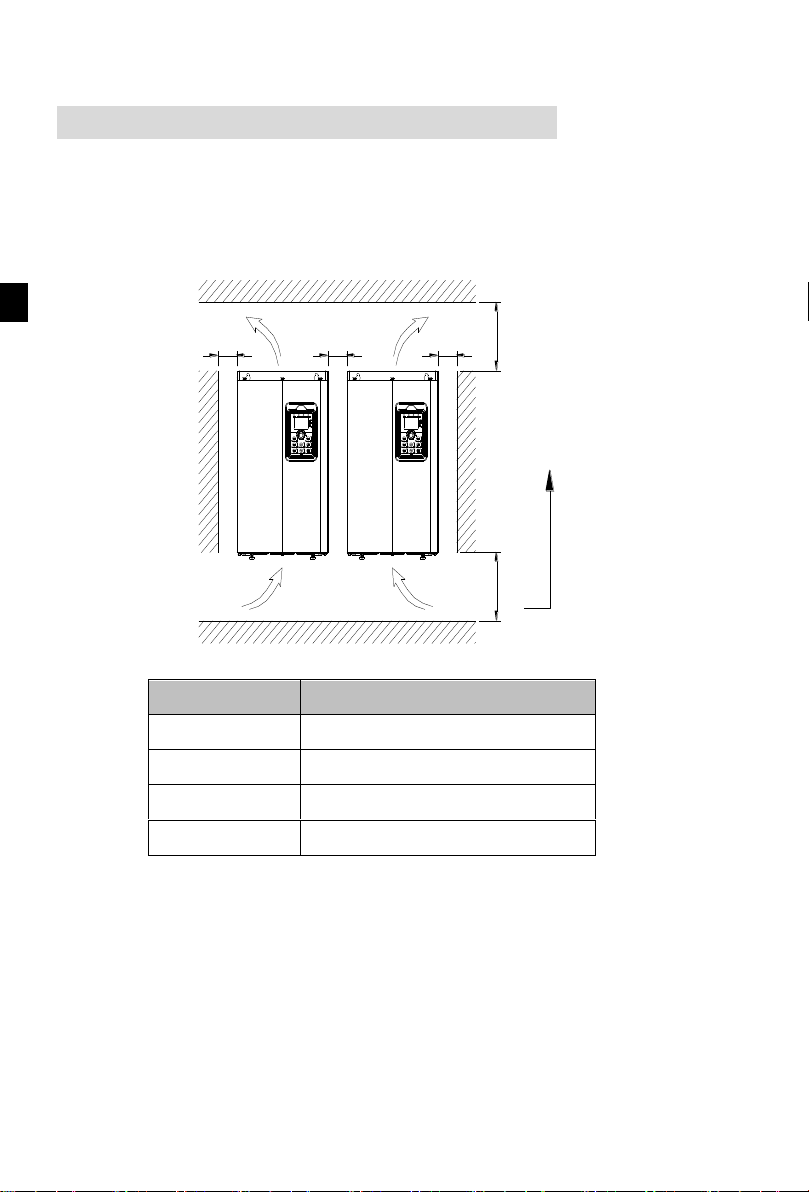

4-1.Installation direction and space

PI500 series inverter according to different power rating, the requirements of around

installation reserve space is different, specifically as shown below:

PI500 Series frequency inverter heat radiator circulated from bottom to top, when more than

one inverter work together, usually mounted side by side. In the case of the need to install them by

upper and lower rows, due to the heat of the lower inverters rising to the upper equipment, fault

maybe caused, heat insulation deflector and other objects to be installed.

Figure 4-1:PI500 Series Each power level installation space requirement

16

Chapter 4 Installation and commissioning

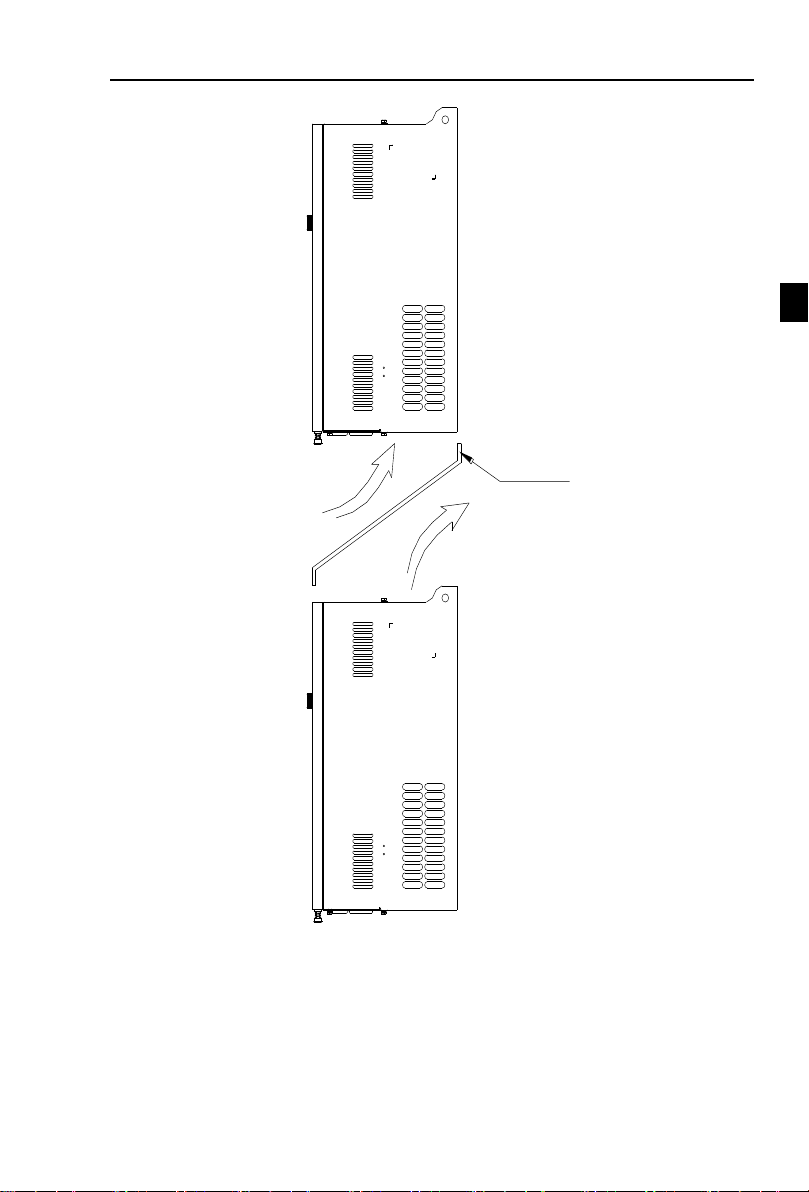

Chapter 4

Deflector

Cool wind

Hot wind

Figure 4-2:Heat insulation deflector up and down installation diagram

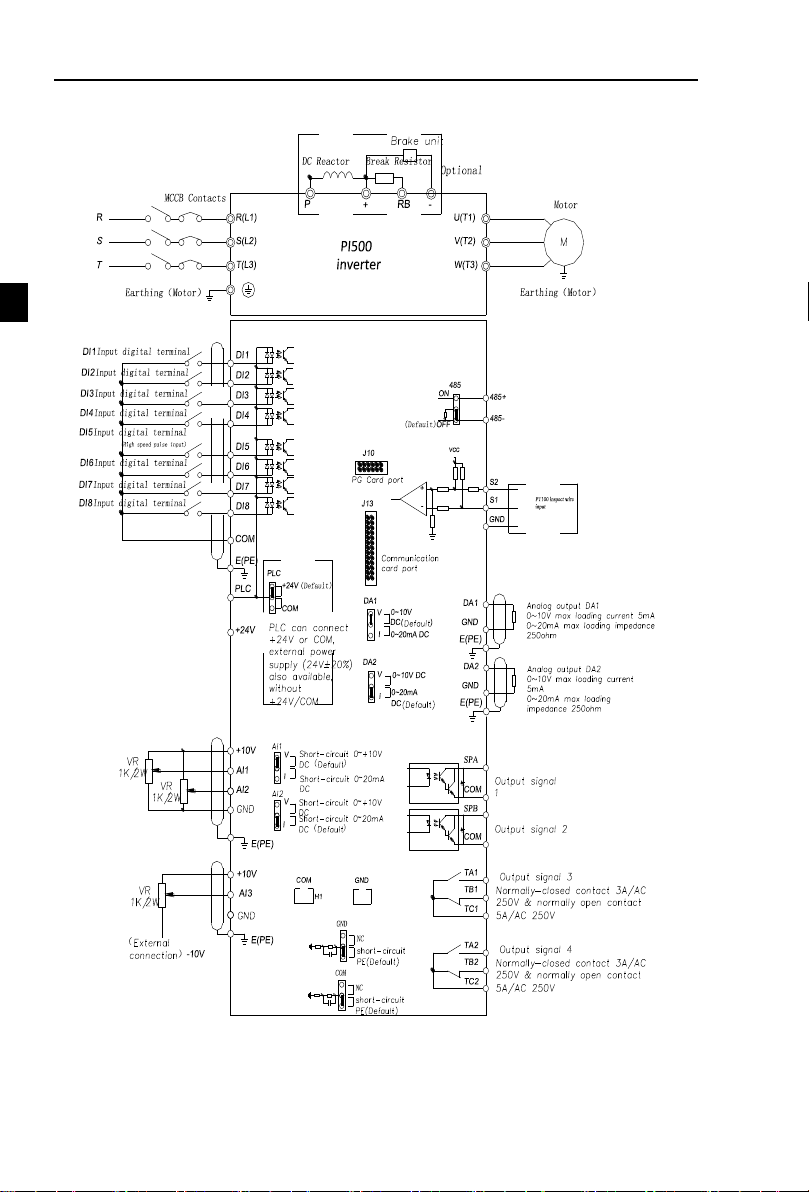

4-2.Wiring Diagram

Frequency inverter wiring is divided by main circuit and control circuit. Users must properly

connect frequency inverter in accordance with the wiring connection diagram showing below.

17

Chapter 4 Installation and commissioning

Chapter 4

Main circuit

Control circuit

4-2-1.Wiring diagram

Figure 4-3:Wiring diagram

18

Chapter 4 Installation and commissioning

Chapter 4

R S T + RB - U V W

R S T+RB

-

U V WP

4-3.Main circuit terminal

4-3-1.Main circuit terminal arrangement

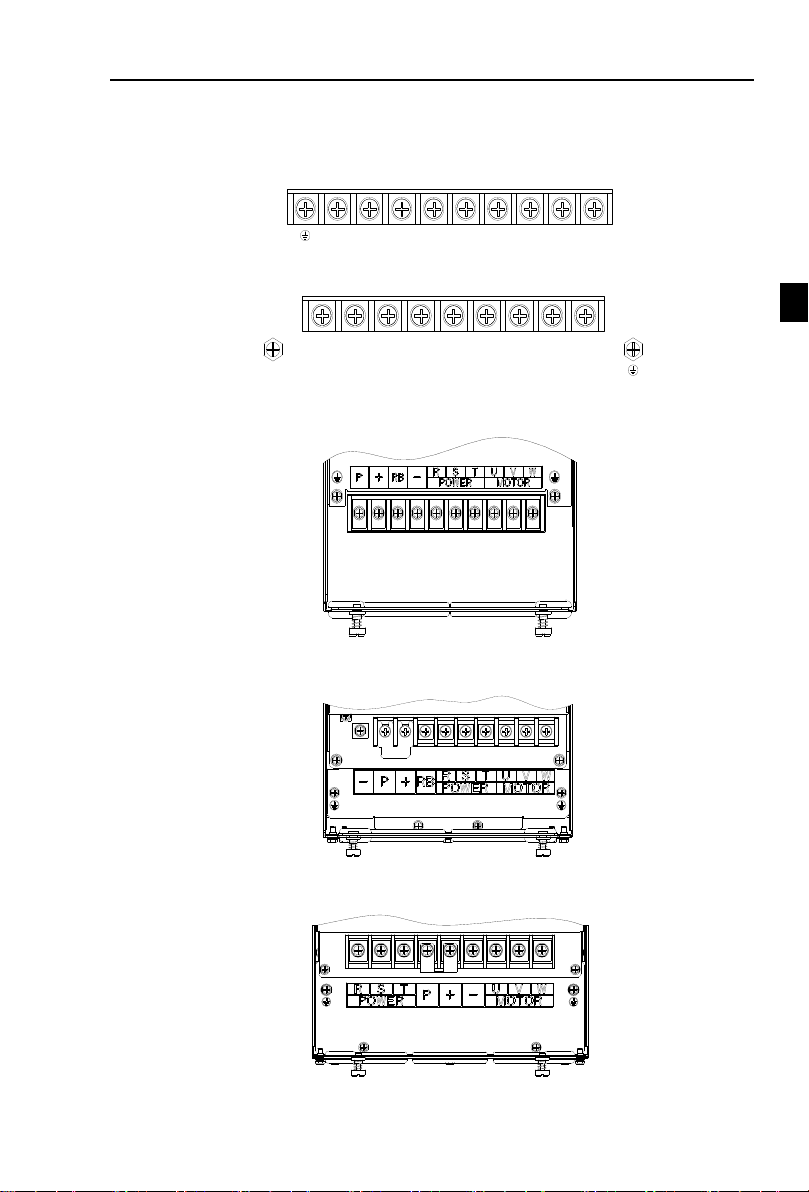

1.0.75~4kW G3 main circuit terminal

Figure 4-4:0.75~4kW G3 main circuit terminal

2.5.5~11kW G3 main circuit terminal

Figure 4-5:5.5~11kW G3 main circuit terminal

3.15kW G3 main circuit terminal

Figure 4-6:11~15kW G3 main circuit terminal

4.18.5~22kW G3 main circuit terminal

5.30~37kW G3 main circuit terminal

Figure 4-7:18.5~22kW G3 main circuit terminal

Figure 4-8:30~37kW G3 main circuit terminal

19

Chapter 4 Installation and commissioning

Chapter 4

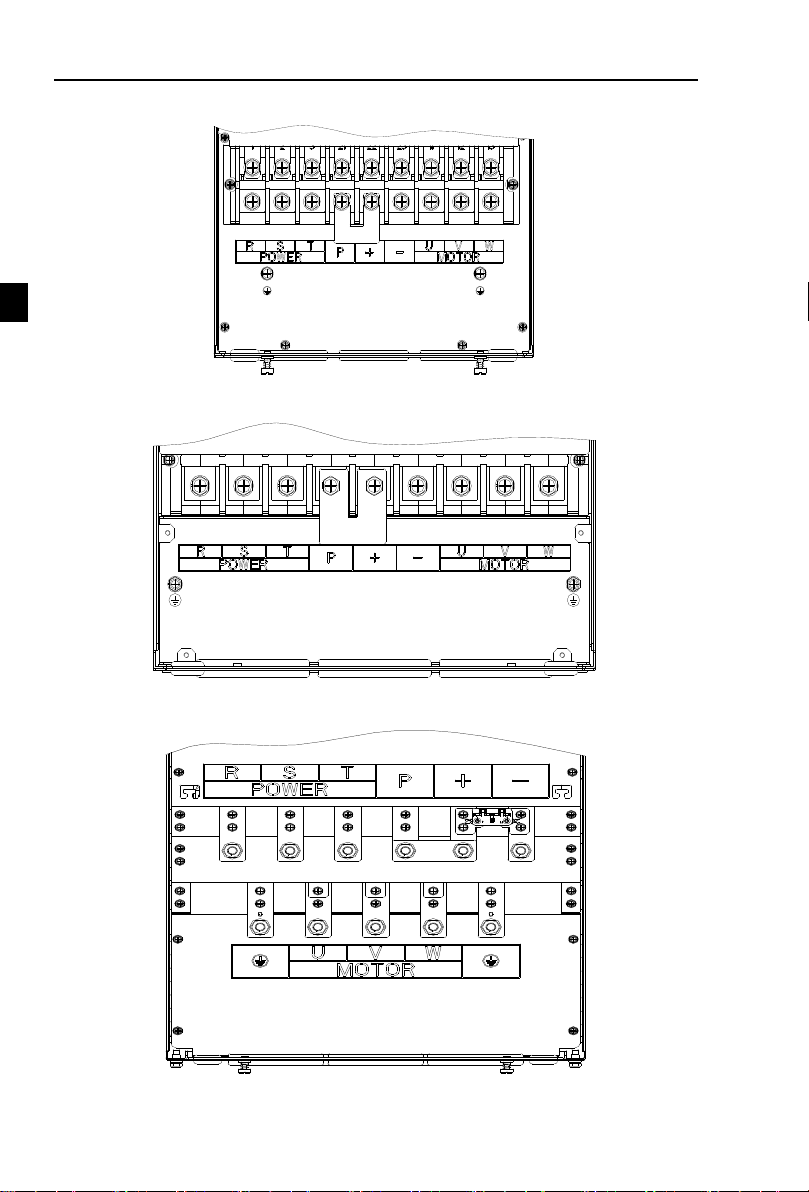

132G3/160F3

6.45~75kW G3 main circuit terminal

Figure 4-9:45~75kW G3 main circuit terminal

7.93~110kW G3 main circuit terminal

8.132kW main circuit terminal

Figure 4-10:93~110kW G3

Figure 4-11:132kW G3 main circuit terminal

20

Chapter 4

9.160~220kW G3 main circuit terminal

Chapter 4 Installation and commissioning

Figure 4-12:160~220kW G3 main circuit terminal

10.250~400kW G3 main circuit terminal

Figure 4-13:250~400kW G3 main circuit terminal

11.450~630kW G3 main circuit terminal

Note: P/+ standard is circuit standard configuration is for the shorted state; if external DC reactor

is connected, firstly disconnect and then reconnect.

Figure 4-14:450~630kW G3 main circuit terminal

21

Chapter 4 Installation and commissioning

Chapter 4

Terminal

Name

Explain

R

Inverter input terminals

Connect to three-phase power supply, single-phase

connects to R, T

S

T

Ground terminals

Connect to ground

P, RB

Braking resistor terminals

Connect to braking resistor

U

Output terminals

Connect to three-phase motor(Please do not connect single

phase motor)

V

W

+, -

DC bus output terminals

Connect to braking unit

P, +

DC reactor terminals

Connect to DC reactor(remove the shorting block)

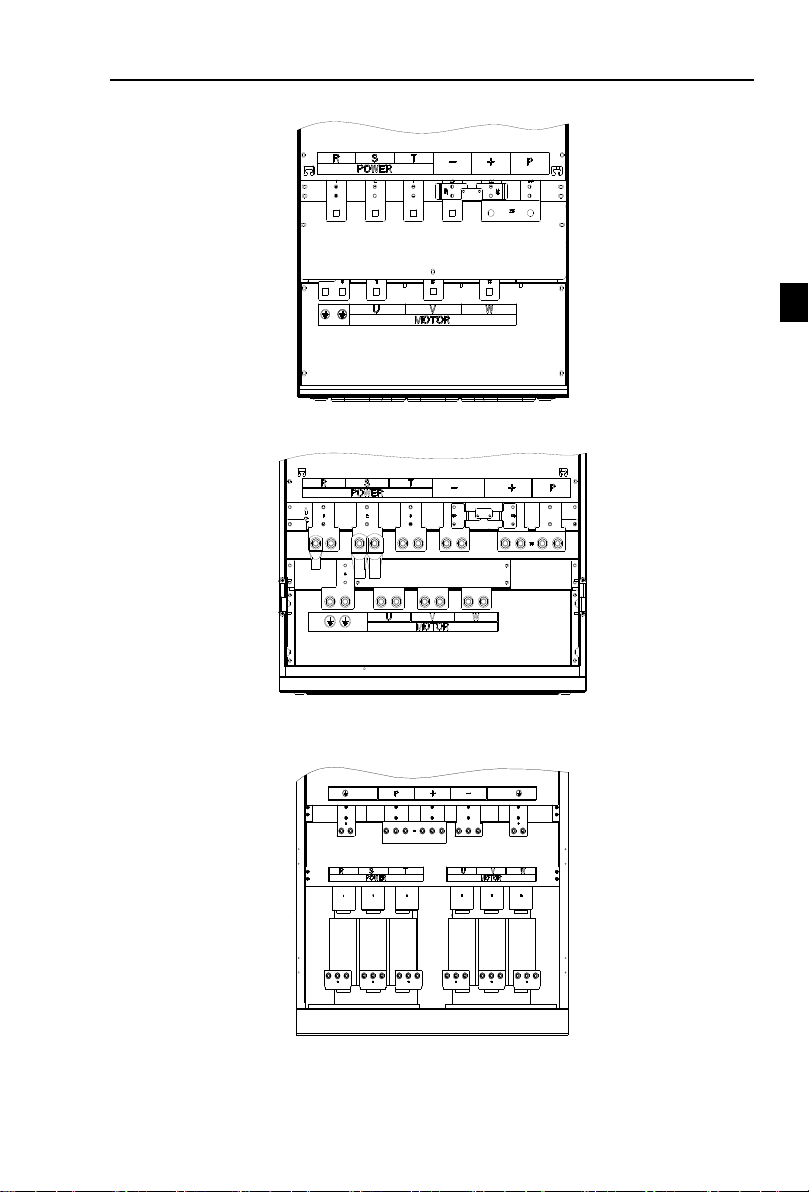

Category

Symbol

Name

Function

Power

supply

+10VGND

+10V power

supply

Output +10V power supply, maximum output current:

10mA

Generally it is used as power supply of external

potentiometer, potentiometer resistance range: 1 to 5kΩ

+24VCOM

+24V power

supply

Output +24V power supply, generally it is used as power

supply of digital input and output terminals and external

sensor.

4-3-2.Function description of main circuit terminal

4-4.Control circuit terminals

4-4-1.Control circuit terminals arrangement

1. Control panel control circuit terminals

Figure 4-15:Control panel control circuit terminals

4-4-2.Description of control circuit terminals

22

Chapter 4 Installation and commissioning

Chapter 4

Category

Symbol

Name

Function

Maximum output current: 200mA

PLC

External power

input terminal

The use of external signal when driving, PLC to be

connected with an external power supply, please unplug

the PLC jumper. Factory default and +24V connection..

Analog

input

AI1GND

Analog input

terminal 1

1.Input range:(DC 0 to 10V/0 to 20mA), depends on the

selected AI1 jumper on control panel.

2.Input impedance: 20kΩ with voltage input,

500

Ω with

current input.

AI2GND

Analog input

terminal 2

1.Input range:(DC 0 to 10V/0to 20mA), depends on the

selected AI2 jumper on control panel.

2.Input impedance: 20kΩ with voltage input,

500

Ω with

current input.

AI3

Analog input

terminal 3

1, Input range:DC-10~+10V

2, Voltage input impedance:20kΩ;

3.AI3 reference potential can be GND or -10V.

Digital

input

DI1

Multi-function

digital input 1

1.Optocoupler, compatible bipolar input, determined by

the choice of the jumper PLC;

2.Input impedance: 3.3kΩ

3.Level input voltage range is 19.2~28.8V.

Note: DI5 input impedance is 1.65k.

DI2

Multi-function

digital input 2

DI3

Multi-function

digital input 3

DI4

Multi-function

digital input 4

DI5

Multi-function

digital input 5

DI6

Multi-function

digital input 6

DI7

Multi-function

digital input 7

DI8

Multi-function

digital input 8

DI5

High-speed

pulse input

terminals

Except the function of DI1 to DI4,DI6 to DI8,DI5 can

also be used as high-speed pulse input channels.

Maximum input frequency: 100kHz

Analog

output

DA1GND

Analog output 1

The selected DA1 jumper on control panel determines

voltage or current output. Output voltage range: 0 to

10V , output current range: 0 to 20mA

DA2GND

Analog output 2

The selected DA2 jumper on control panel determines

voltage or current output. Output voltage range: 0 to

10V , output current range: 0 to 20mA

Digital

output

SPACOM

Digital output 1

Opto-coupler isolation, bipolar open collector output

Output voltage range: 0 to 24V , output current range: 0

to 50mA

SPBCOM

Digital output 2

SPBCOM

High-speed

pulse output

Subject to function code(F2.00)"SPB terminal output

mode selection"

As a high-speed pulse output, the highest frequency up to

100kHz;

Relay

output

TA1TC1

Normally open

terminals

Contactor drive capacity: normally closed contact 3A/AC

250V,normally open contact 5 A/AC 250V, COSø = 0.4.

TB1TC1

Normally closed

terminals

23

Chapter 4 Installation and commissioning

Chapter 4

Category

Symbol

Name

Function

Motor

temperature

inspection

input

S1S2GND

PT100 inspect

wire input

PT100 temperature senso. Note: such as PT100 three

detection line, with a universal table test, to find two of

the detection line is 0Ω after the one received S2

terminal, the other received a GND; the remaining one

received S1 terminal.

Built-in

RS485

485+

485 differential

signal +

terminal

485 communication interface, 485 differential signal

terminal, use twisted-pair or shielded wire connect to the

standard 485 communication interface

485 jump line in the control panel to decide whether to

connect the terminal resistance

485-

485 differential

signal - terminal

Auxiliary

interface

J13

communication

interface

CAN card, 26-pin terminal

J10

PG card interface

12-pin terminal

GND

GND ground

interface

GND jump line decide whether to connect PE, improve

the inverter anti-interference

COM

COM ground

interface

COM jump line decide whether to connect PE, improve

the inverter anti-interference

H1

COM Terminal

interface

Consistent with the COM function on the terminal line。

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Shielded

cable

External

contactor

Inverter

Inner power supply with main connect

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Shielded

cable

External

contactor

Inverter

External power supply with main connection

External power

supply

+

-

Signal input terminal circuit

Switch input and output signal transmission, generally use the shielded cable and wiring short

distance as far as possible, good grounding and shielding layer on the inverter side, try not to over 20

m transmission distance. Drive in active way, elected to the power of crosstalk necessary filtering

measures are taken, generally recommend that choose dry contact control mode.

Wiring control cable should be kept with the main circuit and high voltage lines (such as the

power cord, motor connecting line, relay or contactor) more than 20 cm distance, and to avoid high

voltage lines parallel to and can't be avoided and the high voltage lines cross, the proposal USES

vertical wiring way, in order to prevent the misoperation caused by disturbance frequency converter

Dry contact mode:

Note: using an external power supply, PLC and 24 v jumper cap must be removed, otherwise it

Figure 4-16:Signal input terminal circuit- dry contact mode

will damage the product.

Open collector NPN connect wire:

When the input signal from the NPN transistor, according to the use of power supply, please

according to the figure + 24 v and PLC jumper cap.

24

Chapter 4 Installation and commissioning

Chapter 4

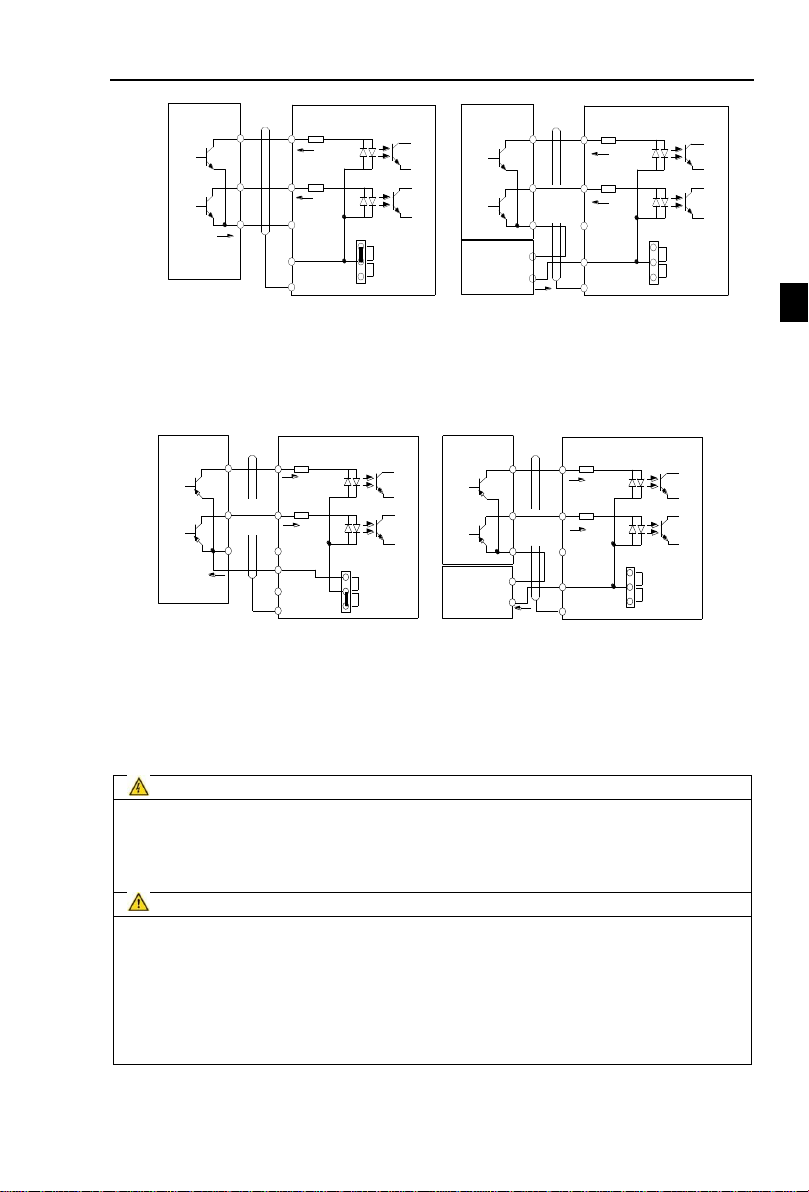

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Shielded

cable

Inverter

Inner power NPN connect mode

External

contactor

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Shielded

cable

Inverter

External power supply NPN connect mode

External

contactor

External

power supply

+

-

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Inverter

Inner power PNP connect mode

External

contactor

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Shielded

cable

Inverter

External power supply PNP

connect mode

External

contactor

External

power supply

+

-

+24V

Danger

Make sure that the power switch is in the OFF state before wiring operation, or electrical shock

may occur!

Wiring must be performed by a professional trained personnel, or this may cause damage to the

equipment and personal injury!

Must be grounded firmly, otherwise there is a danger of electric shock or fire hazard !

Note

Make sure that the input power is consistent with the rated value of inverter, otherwise which

may cause damage to the inverter!

Make sure that the motor matches the inverter, otherwise which may cause damage to the

motor or activate the inverter protection!

Do not connect power supply to U, V, W terminals, otherwise which may cause damage to the

inverter!

Do not directly connect braking resistor to DC bus (P), (+) terminals, otherwise which may

cause a fire!

Figure 4-17:Signal input terminal wiring diagram, open collector NPN connection mode

Note: using an external power supply, PLC and 24 v jumper cap must be removed, otherwise

it will damage the product.

Open collector PNP connection mode:

Figure 4-18:Signal input terminal wiring diagram, open collector PNP connection mode

Note: using an external power supply, PLC and 24 v jumper cap must be removed, otherwise

it will damage the product.

4-5.Wiring Precautions

※ The U,V,W output end of inverter can not install phase advancing capacitor or RC absorbing

device. The inverter input power must be cut off when replacing the motor

25

Chapter 4 Installation and commissioning

Chapter 4

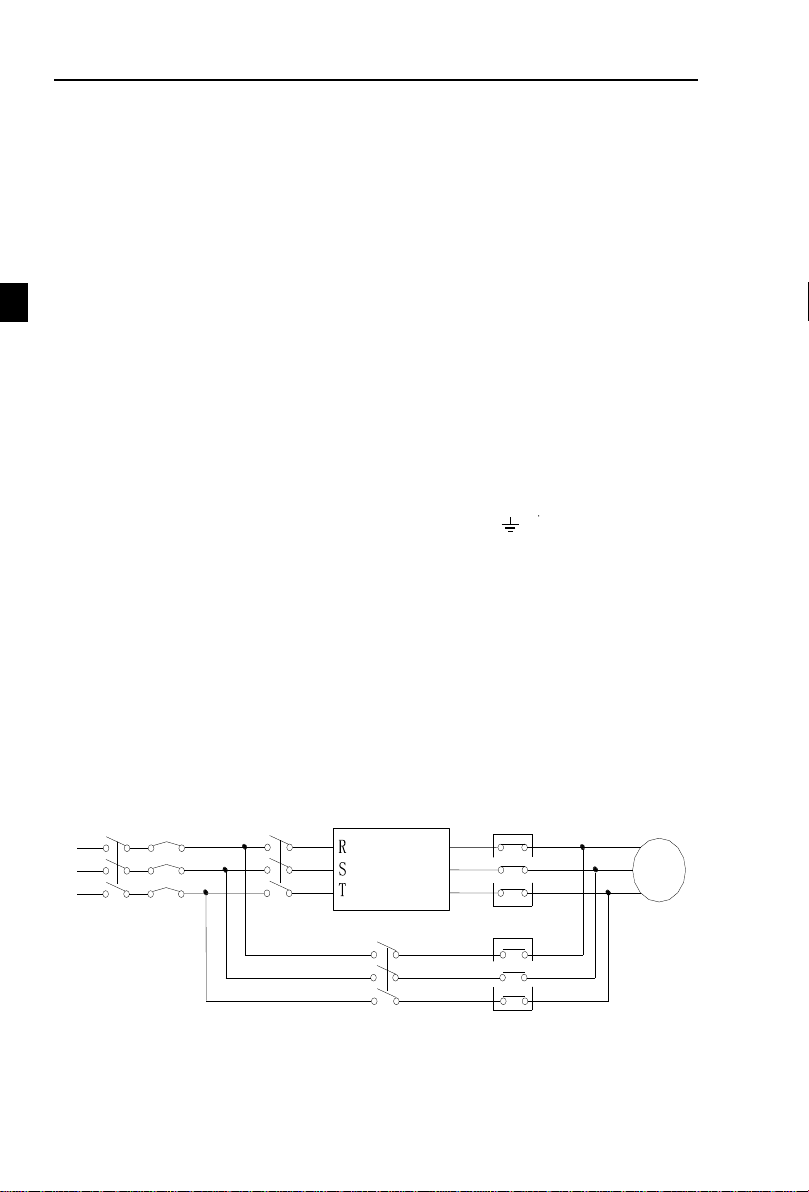

PI500

inverter

M

3

~

R

S

T

U

V

W

K1

K2

K3

MCC1

MCC2

MCC1 & MCC2 interlock ac contactor

※ Do not let metal chips or wire ends into inside the inverter when wiring, otherwise which may

cause malfunction to the inverter.

※ Disconnect motor or switch power-frequency power supply only when the inverter stops

output

※ In order to minimize the effects of electromagnetic interference, it is recommended that a

surge absorption device shall be installed additionally when electromagnetic contactor and

relay is closer from the inverter.

※ External control lines of inverter shall adopt isolation device or shielded wire.

※ In addition to shielding, the wiring of input command signal should also be aligned

separately, it is best to stay away from the main circuit wiring.

※ If the carrier frequency is less than 3KHz, the maximum distance between the inverter and

the motor should be within 50 meters; if the carrier frequency is greater than 4KHz, the

distance should be reduced appropriately, it is best to lay the wiring inside metal tube.

※ When the inverter is additionally equipped with peripherals (filter, reactor, etc.), firstly

measure its insulation resistance to ground by using 1000 volt megger, so as to ensure the

measured value is no less than 4 megohms.

※ When the inverter need to be started frequently, do not directly turn power off, only the

control terminal or keyboard or RS485 operation command can be used to control the

start/stop operation, in order to avoid damage to the rectifier bridge.

※ To prevent the occurrence of an accident, the ground terminal( )must be earthed

firmly(grounding impedance should be less than 10 ohms), otherwise the leakage current

will occur.

※ The specifications on wires used by the main circuit wiring shall comply with the relevant

provisions of the National Electrical Code.

※ The motor's capacity should be equal to or less than the inverter's capacity.

4-6.Spare Circuit

When the inverter occurs the fault or trip, which will cause a larger loss of downtime or other

unexpected faults. In order to avoid this case from happening, please additionally install spare circuit

to ensure safety.

Note: Electrical diagram MCC1 and MCC2 interlock ac contactor; Spare circuit must be

confirmed in advance and test running characteristics, make sure that the power frequency and

frequency conversion phase sequence

4-7.Commissioning

26

Figure 4-19:Spare Circuit electrical diagram

Chapter 4

F0.00=?

Correctly set motor and

encoder parameters

Vector control W/PG

V/F

1

2

Select command source

Select suitable frequency

source

Start motor to run,observe the

phenomenon,if abnormal,please

refer to the troubleshooting

End

Select motor start-up mode

Control

NO

YES

Achieve the required

control effect?

0

Vector control W/O PG

Select motor stop mode

Correctly motor parameters

Motor parameter self-learning

Commission ing

Select control manner

(setting F0.00)

(Set b0.00-b0.05,b0.28,etc)

(Set b0.00-b0.05)

Select appropriate

ac/deceleration time

(Set F0.13,F0.14)

Select appropriate

ac/deceleration time

(Set F0.13,F0.14)

(Set b0.27)

Motor parameter self-learning

(Set b0.27)

(Set F0.11)

(Set F0.03,F0.04,F0.07,etc)

(Set F3.00)

Select appropriate

ac/deceleration time

(Set F0.13,F0.14)

(Set F3.07)

Chapter 4 Installation and commissioning

● Firstly confirm that AC input power supply voltage shall be within inverter rated input

● Connect power supply to the R, S and T terminals of the inverter.

● Select the appropriate operation control method.

voltage range before connecting power supply to the inverter.

Figure 4-20:Commissioning

27

第

十

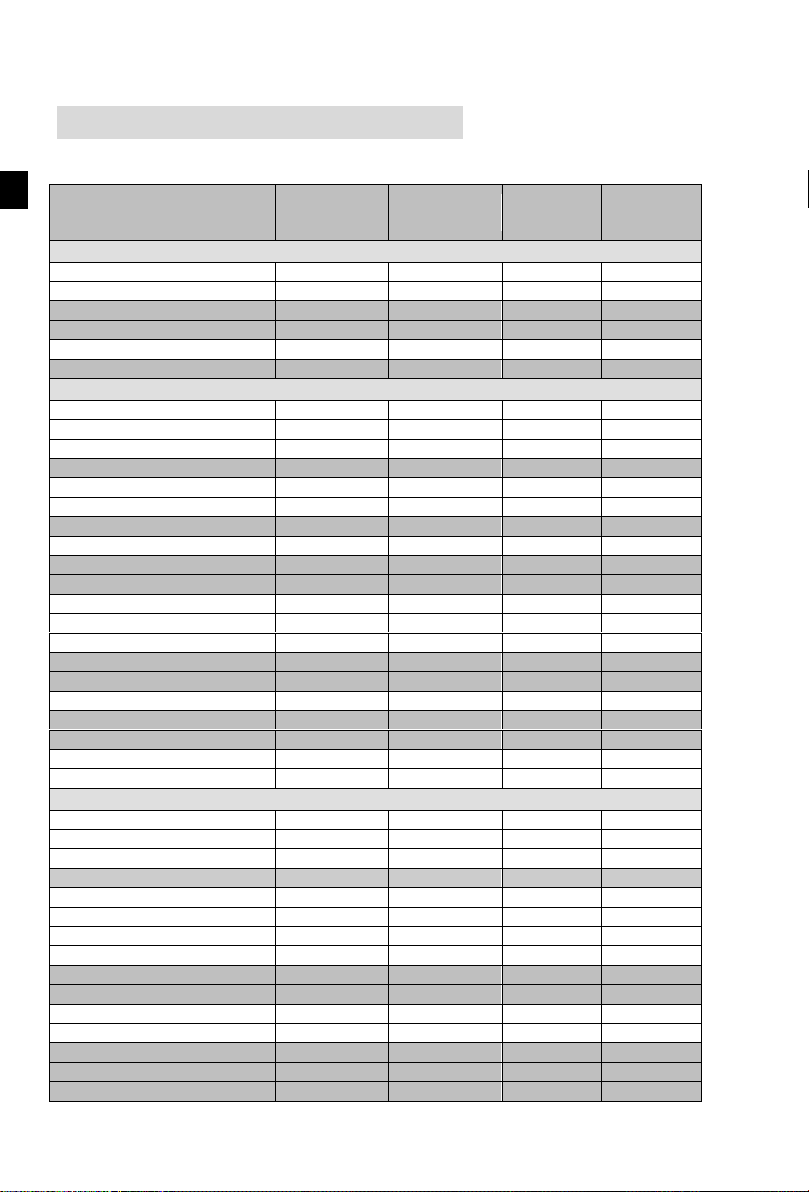

Chapter 5

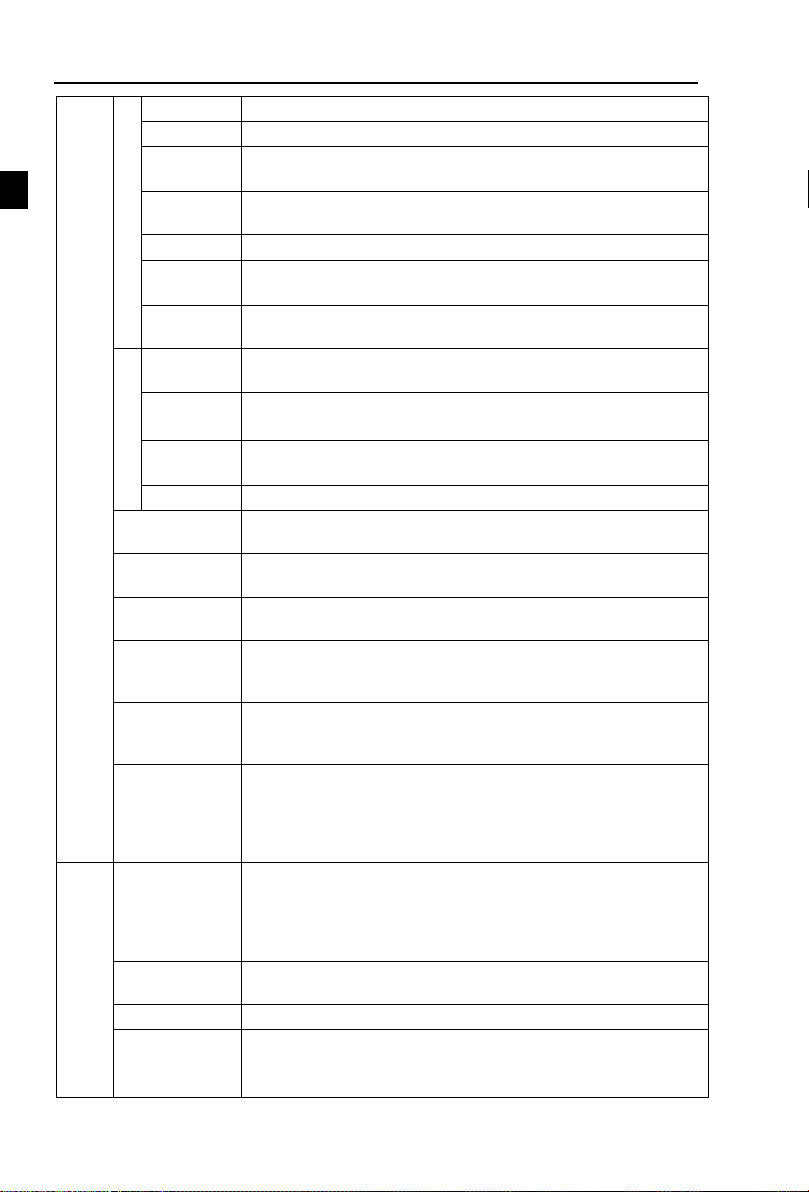

Code

Parameter name

Functional Description

d0

Monitoring function group

Monitoring frequency, current, etc

F0

Basic function group

Frequency setting, control mode, acceleration and

deceleration time

F1

Input terminals group

Analog and digital input functions

F2

Output terminals group

Analog and digital output functions

F3

Start and stop control group

Start and stop control parameters

F4

V/F control parameters

V/F control parameters

F5

Vector control parameters

Vector control parameters

F6

Keyboard and display

To set key and display function parameters

F7

Auxiliary function group

To set Jog, jump frequency and other auxiliary function

parameters

F8

Fault and protection

To set fault and protection parameters

F9

Communication parameter group

To set MODBUS communication function

FA

Torque control parameters

To set parameters under torque control mode

Fb

Control optimization parameters

To set parameters of optimizing the control performance

FC

Extend parameters group

specialapplicationparameterssetting

E0

Wobbulate, fixed-length and

counting

To set Wobbulate, fixed-length and counting function

parameters

E1

Multi-stage command, simple PLC

Multi-speed setting, PLC operation

E2

PID function group

To set Built-in PID parameters

E3

Virtual DI, Virtual DO

Virtual I/O parameter setting

b0

Motor parameters

To set motor parameter

y0

Function code management

To set password, parameter initialization and parameter

group display

Chapter 5 Function parameter

5-1.Menu grouping

Note:

“★”: In running status, can not modify the parameter setting

“●”: The actual testing data, can not be modified

“☆”: In stop and run statuses, both can be changed;

“▲”: “Factory parameter”, no change about it.

“_” means the factory parameter is related to power or model. Please check the details in the

involved parameter introduction.

Note:“Italic ³”means software version is C3.00 and the keyboard just like the above with

MCU can do the functions.

Change limit refers to whether the parameters are adjustable.

y0.01 is used for parameters protection password. Parameter menu can be enter into only after

inputting the right password in the function parameter mode or user change parameter mode. When

the y0.01 set to 0, the password is canceled.

Parameter menu is not protected by password under user customized parameters mode.

F group is the basic function parameters,E group is to enhance function parameters, b group is

a function of motor parameters,d group is the monitoring function parameters.

28

Chapter 5

y1

Fault query

Fault message query

5-1-1.d0Group - Monitoring function group

No.

Code

Parameter name

Setting range

Factory

setting

1

d0.00

Running frequency

Frequency converter theory

0.01Hz

2

d0.01

Set frequency

Actual set frequency

0.01Hz

3

d0.02

DC bus voltage

Detected value for DC bus voltage

0.1V

4

d0.03

output voltage

Actual output voltage

1V

5

d0.04

output current

Effective value for Actual motor current

0.01A

6

d0.05

output power

Calculated value for motor output power

0.1kW

7

d0.06

output torque

Motor output torque percentage

0.1%

8

d0.07

DI input status

DI input status

- 9 d0.08

DO output status

DO output status

-

10

d0.09

AI1 voltage (V)

AI1 input voltage value

0.01V

11

d0.10

AI2 voltage (V)

AI2 input voltage value

0.01V

12

d0.11

AI3 voltage (V)

AI3 input voltage value

0.01V

13

d0.12

Count value

Actual pulse count value in counting function

-

14

d0.13

Length value

Actual length in fixed length function

-

15

d0.14

Actual operating speed

Motor actual running speed

-

16

d0.15

PID setting

Reference value percentage when PID runs

%

17

d0.16

PID feedback

Feedback value percentage when PID runs

%

18

d0.17

PLC stage

Stage display when PLC runs

-

19

d0.18

High-speed pulse input

frequency

High-speed pulse input frequency display,

unit: 0.01Khz

0.01kHz

20

d0.19

Feedback

speed(unit:0.1Hz)

Actual output frequency of converter

0.01Hz

21

d0.20

Remaining run time

Remaining run time display, it is for timing

run control

0.1Min

22

d0.21

Linear speed

Show the line speed of DI5 high speed pulse

sampling, according to the actual sample

pulse number per minute and E0.07, calculate

the line speed value.

1m/Min

23

d0.22