Powrmatic VPC Series, VPC52, VPC30, VPC110, VPC80 User, Installation & Servicing Manual

...Page 1

VPC Gas Cabinet Heater Range

Industrial & Commercial Heating Systems

Doc Ref: M202 Issue 5.5 Aug 2018

User, Installation

& Servicing Manual

www.powrmatic.co.uk

+44 (0) 1460 53535

info@powrmatic.co.uk

Page 2

Certificate of Guarantee

Dear Customer

This is to certify that this heater is guaranteed for two years parts and one year labour from the date

of original commissioning. The heater must be commissioned within 4 weeks of installation.

To make a claim

In the first instance you must contact your appliance supplier, or installer and provide:-

1. The appliance type and serial number.

2. The original commissioning documentation. As much detail as possible on the fault.

3. Your supplier, or installer, will then contact Powrmatic to make a guarantee claim on your behalf.

Conditions of Guarantee

1. The heater must have been installed by a competent recognised installer, and in

accordance with the manufacturer’s instructions, building regulations and local regulations.

2. The heater has been professionally commissioned, within 4 weeks of installation, and a copy of

the commissioning sheet returned to Powrmatic.

3. The heater has been maintained on a yearly basis by a competent servicing company.

4. The heater has been used in accordance with the manufacturer’s instructions.

5. The correct specification fuel has been used.

6. No unauthorised repairs of modifications have been made. Powrmatic ‘General Conditions of

Sales’ have been observed.

7. Except for the obligation of Powrmatic Ltd to perform warranty repairs during the guarantee

period Powrmatic will not be liable in respect of any claim for direct or indirect consequential

losses, including loss of profits or increased cost arising from loss of use of the heater, or any

event arising there from.

Exclusions

Consumables such as gaskets, ignition electrodes, flame rectification electrodes, drive belts, fusible

links, control batteries are all excluded from guarantee.

----------------------------------------------------

Powrmatic Ltd, Hort Bridge, Ilminster, Somerset, TA19 9PS

Tel: 01460 53535 Fax: 01460 52341

Web: www.powrmatic.co.uk e-mail: warranty@powrmatic.co.uk

Important: This certicate

must be kept with the appliance

Failure to provide a copy of the commissioning sheet invalidates the heater warranty

Installer

Date:________________Signed: _____________________________________Installer

Commissioned

Date:________________Signed:_______________________Commissioning Engineer

page no. 2 of 40

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

Page 3

Dear Customer - thank you for choosing Powrmatic.

We appreciate you buying one of our high quality products and know that you have made the best

choice. By choosing Powrmatic, you are investing in UK manufacturing & its workforce. We pride

ourselves by manufacturing products that provide clean, comfortable and safe working environments

worldwide together with the personal & professional service and back-up you deserve. If you have

any questions or concerns regarding this product, please contact our Technical Support Team by

calling 01460 53535.

Users, Installation and Servicing Instructions

CONTENTS

Title Section Contents Page

User Instructions 4

Pre Installation

1.1 Introduction 5

Duties 6

Dimensions 7

Accessories 8

1.2 Technical data 9

1.3 General Requirements 11

1.4 Ventilation Air Requirements 13

Installation

2.1 Fitting the unit 14

2.2 Flue/Combustion Air Duct System 16

2.3 General Identification of Electrical Items 18

2.4 Electrical Cable Installation 19

2.5 Wiring Diagrams 20

2.6 Commissioning and Testing 26

2.7 Servicing 30

Additional Documents

3.1 Fault Finding Flow Chart 33

3.2 Short List of Parts 34

3.3 Gas Conversion 36

Appendices

Information required for ecodesign (ErP) Directive 2009/125 38

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

page no. 3 of 40

Page 4

User Instructions

If the heater has not been left operational

proceed as follows.

A) Checks before lighting the Air Heater

The following preliminary checks should be made before

lighting the heater(s)

a) Ensure that the ELECTRICAL supply to the heater is

switched OFF.

b) Check that all warm air delivery outlets are open.

c) Check that the thermostat is set at MAX.

d) Check that the clock control is set to an ON period.

e) Check that any other controls are calling for heat.

B) Lighting the Air Heater

1. Switch on the electrical supply at the isolator

2. If the Limit indicator light comes on press the limit

interlock reset switch inside the heater.

3. The startup sequence will commence. After a short

delay the burners will light.

4. If the burners fail to light the control box will

automatically restart the ignition sequence. If after 5

attempts at ignition the burners have still failed to light the

control box will go to lockout and the amber lockout light

inside the heater (or on the low level remote reset, MC200

or Powrtrol RR if fitted) will be illuminated. To restart the

ignition sequence depress the reset button on the low

level reset for about 1-2 seconds.

D) Description of Operation

Important: The heater must NOT be

controlled by switching ON and OFF the

main electrical supply to it.

1) Standard Units

The ignition sequence commences each time the external

controls e.g. Time clock, room thermostat etc. call for

heat. The internal exhaust fan will run and, when sufficient

combustion airflow is proved by the air pressure switch, the

ignition spark will be generated, the main gas valve opens

and the burners light. The heater fan will automatically

start approximately 2 minutes after the burners light.

When the external controls are satisfied the burners will be

turned off and approximately 2 - 3 minutes later the heater

fan will be automatically stopped. If the burners fail to light

the control box will make another four attempts at ignition.

2) High / Lo & Modulating Units

When the burners are alight, the heat output will be

controlled either to high fire or low fire or, in the case of

modulating units, to any point between high and low fire;

depending on the requirements of the space being heated

and the controls system.

3) Summer / Winter Modes

Certain types of external controls will provide for two

modes of operation i.e.

Summer: The heater fan alone will run at the dictate of the

external controls to provide air movement.

Winter: The heater will operate normally.

WARNING: If it is not possible to light the

heater after several attempts, contact the

installer or local service company.

C) To Shut Down the Air Heater

1) For Short Periods:

Turn the room thermostat to the OFF, or set to it’s lowest

setting.

2) For Long Periods:

Complete step 1 above. Wait for 5 minutes and then turn

OFF the electrical supply at the isolator.

page no. 4 of 40

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

4) Fan and Limit Control

The fan and limit controls are mounted towards the top of

the air heater inner bulkhead and are accessed via the front

door.

i) Main Air Fan MAN / Auto

When the white button is pushed in the fan will run

continuously i.e. not controlled by any external controls

e.g. Time clock. When the white button is pulled out the

fan will start and stop automatically in conjunction with

the burner.

ii) Limit Thermostat

This operates if high temperatures within the heater are

detected, the burners are turned off and a red indicator

light inside the heater is illuminated. The fault condition

must be identified and rectified and the thermostat

manually reset.

When the unit has cooled push the reset switch on the

front of the heater to reset the limit thermostat interlock

relay, the red indicator light will go out and the unit is

operational again.

Page 5

Note: The limit thermostat(s) can only be reset

once the unit has cooled down.

Unless the cause of the fault condition is

readily obvious, for example a power cut whilst

the heater was operating, a service engineer should be

contacted.

All Powrmatic heaters use gas and electricity

to power them, they may also contain moving

parts such as pulleys and belts. It would be

hazardous to tamper with or attempt to

service unless you are a competent person in the field of

Gas and Electrical work.

E) Maintenance

To maintain efficient, reliable and safe operation of the

heater it must serviced by a qualified person at least

annually and preferably at the end of the heating season.

IMPORTANT

Free access must be maintained to and around

the heater for servicing purposes and the air

supply to the heater must not be restricted

in any way. Combustible materials must not be stored

adjacent to the heater.

If at any time a gas leak is suspected, turn OFF the gas

supply at the meter and contact the local gas undertaking

immediately.

1.1 Introduction

The VPC range are highly efficient gas fired, fanned

circulation floor standing air heaters that cover heat

outputs of 30kW to 130kW. The units have a single closed

flue system that can be either vertical or horizontal and

feature a single burner assembly which as standard is ON/

OFF but can also be supplied in High/Low or Modulating

formats. High/Low or Modulating formats give a turn down

facility of approximately 2:1. The heaters are certified for

use on Natural Gas, Group H - G20, and Propane - G31 only.

Appliance Categories are Cat II2H3P (GB, IE).

The heaters intended primarily for heating commercial

or industrial premises. They must not be used where the

atmosphere inside the premises could be contaminated

e.g. Dust, oil mist etc. or in areas classified as hazardous as

defined in BS 5345: Part 2. They are not suitable for siting

externally.

VPC heaters feature a closed combustion circuit and have

an internal exhaust fan, mounted downstream of the

heat exchanger, to evacuate the products of combustion

and draw in air for combustion. The air heater must be

connected to a flue system that is approved by Powrmatic

Ltd.

They may be used where the atmosphere inside the

premises could be contaminated e.g. Dust, oil mist etc. but

the heaters are not airtight and therefore may not be used

in areas classified as hazardous as defined in BS 5345: Part 2

or areas subjected to significant negative pressures due to

extract systems.

If you have any safety questions reference the servicing

and installation of any of our heaters please do not hesitate

to contact our head office for expert advice. Your safety is

paramount to us.

Gas Safety (Installation & Use) (Amendment)

Regulations

It is law that all gas appliances are

installed, adjusted and, if necessary,

converted by qualied persons* in

accordance with the current issue of the

above regulations. Failure to install appliances

correctly can lead to prosecution. It is in your own

interests and that of safety to ensure that the law is

complied with.

* An approved class of person listed on the gas safe

register.

VPC heaters have a centrifugal fan assembly fitted at the

base of the heater to circulate the air being heated past the

formed tube heat exchanger.

Heaters are fitted as standard with inshot burners, a fully

automatic control for ignition, flame sensing, gas supply

control and safety functions, an internal exhaust fan, main

air fan and fan/limit thermostat.

Options include High/Low or Modulating burner controls,

inlet duct connection, outlet duct connection, 90° outlet

bend and a full range of modular duct components.

IMPORTANT

Service and Maintenance Engineers shall

ensure that replacement items are tted,

adjusted and set in accordance with the

data and detail set out in these instructions. If in doubt

consult Powrmatic Technical Department.

Gas Safety (Installation & Use) Regulations 1998

It is law that all gas appliances are

installed, adjusted and, if necessary,

converted by qualied persons* in

accordance with the current issue of the

above regulations. Failure to install appliances

correctly can lead to prosecution. It is in your own

interests and that of safety to ensure that the law is

complied with.

* An approved class of person listed on the gas safe

register.

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

page no. 5 of 40

Page 6

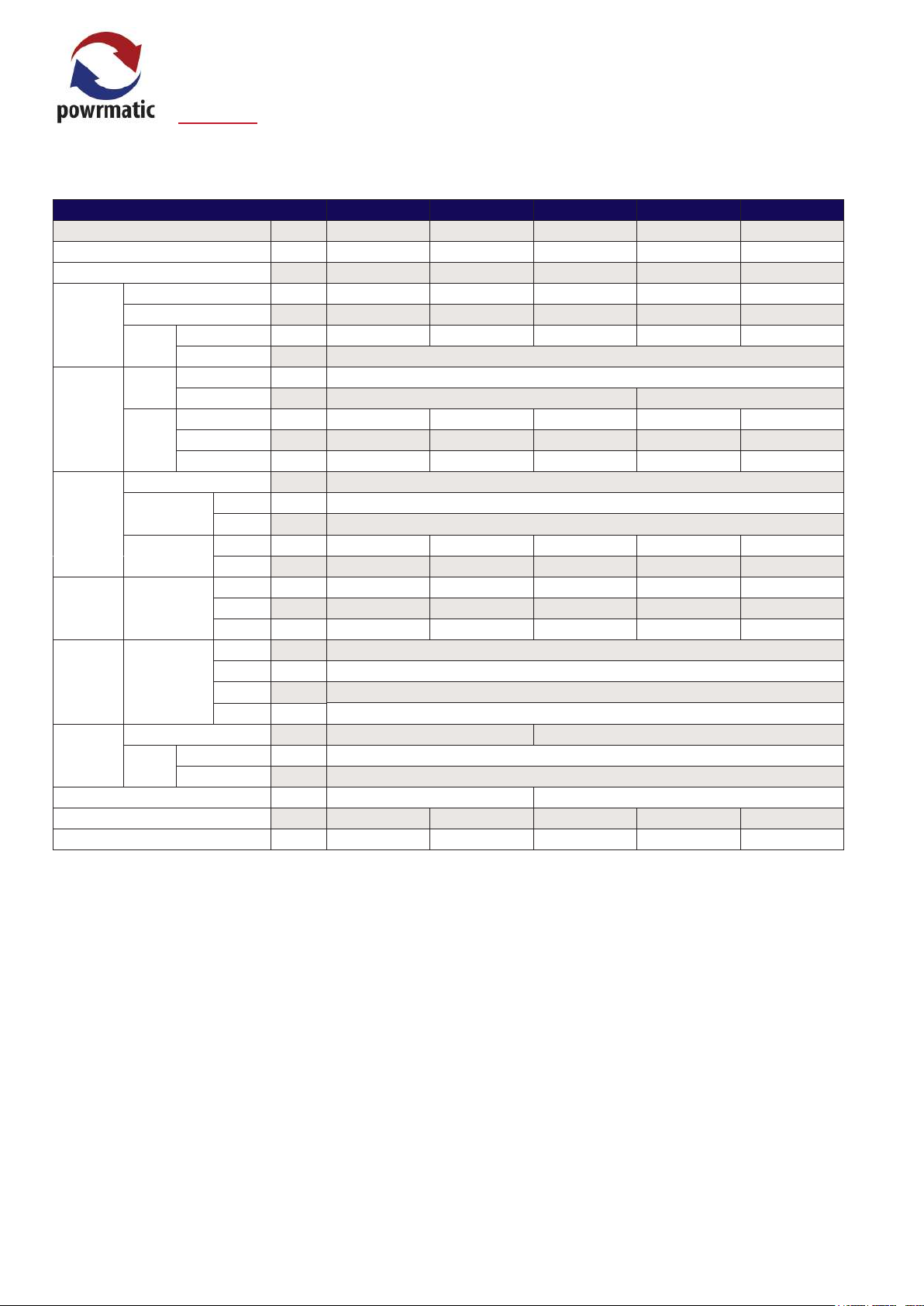

VPC UF / VPC UD

Duties

Model

Output kW 30 52 80 110 130

Input (nett CV) kW 32.6 56.5 87.0 119.5 141.3

Volume m3/s 0.87 1.59 2.34 2.96 3.63

Heads m 3 3 4 4 4

Airflow

Electrics

Fuel

Overall

Dims

Install

Clearance

Flue

Combustion Air Spigot mm Ø 100 130

Noise Levels dB(A) 60 68 76 72 74

Nett Weight kg 178 248 305 362 410

Throw m 12.0 22.0 21.0 26.0 27.0

Fan

Static

Supply

Std

Fan

Connection BSP/Rc ¾”

Minimum Inlet

Pressure

Consumption

UF Upright

Freeblow

UF Upright

Freeblow

Diameter mm Ø 100 130

Max

Length

Standard Pa 150 200 225 150 200

Uprated (Refer to Powrmatic)

Standard V/ph/Hz 230/1/50

Optional V/ph/Hz n/a 400/3/50

Motor kW 0.55 1.1 1.4 1 x 1.5 1 x 2.2

Start amp 6.5 8.3 19 28 40

Run amp 4.2 4.2 9.5 9.3 10.7

Nat Gas mbar 17.5

LPG mbar

Nat Gas m3/h 3.45 5.98 9.19 12.64 14.94

LPG m3/h 1.33 2.31 3.55 4.89 5.78

Height mm 2272 2713 2804 2715 2998

Width mm 750 750 750 750 750

Depth mm 1108 1108 1412 1767 1767

Front mm 1000

Blank mm 150

Louvred mm 500

Read mm 500

Flue Only m 12

Room Sealed m 6

30 52 80 110 130

37.0

Notes -

• Fuel consumption and output figures based upon nett calorific values as follows

-Natural gas (G20) nett CV 34.02 MJ/m³

-Propane (G31) nett CV 88.00 MJ/m³

• Heaters have efficiency levels which meet with the minimum heater efficiency requirements of UK Part L Building Regulations

• Air handling data is assessed at room ambient conditions

• Throw figures provide the distance to the point where the terminal velocity degrades to 0.25 m/s

• Overall vertical heater height include heads or extended heads where appropriate

• Standard height heads can be specified where site height is restricted

• Blank and louvred lower side panels are interchangeable

• Noise levels are applicable to standard UF models and are measured 5m from appliance and in free field conditions

• Motor kW, run and start amps apply to standard electrical supply as stated. For optional data contact sales office

• Connection of combustion air duct is not required for ‘flue only’ applications

• It is the responsibility of the installing contractor to ensure that ductwork is correctly sized and balanced when installing ducted units

page no. 6 of 40

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

Page 7

Dimensions

J 1

COMBUSTION

AIR INLET

M

J

EXHAUST

AIR OUTLET

Ø D

J 1

ALTERNATIVE FLUE

& COMBUSTION AIR

POSITIONS

G

G

J

K

H

L

M

E

50

H

L

M

C

GAS ENTRY

F

BAB

Model A B C D E F G H J J1 K L M

30 1108 750 1676 100 265 1378 142 237 255 596 207 657 650 2

52 1108 750 2132 100 265 1832 142 237 286 581 256 657 650 2

80 1412 750 2132 130 265 1756 220 237 340 672 308 960 650 3

110 1767 750 2043 130 265 1667 220 237 340 672 308 1315 650 4

130 1767 750 2209 130 265 1835 220 237 400 788 358 1315 650 3

Head

Plan

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

page no. 7 of 40

Page 8

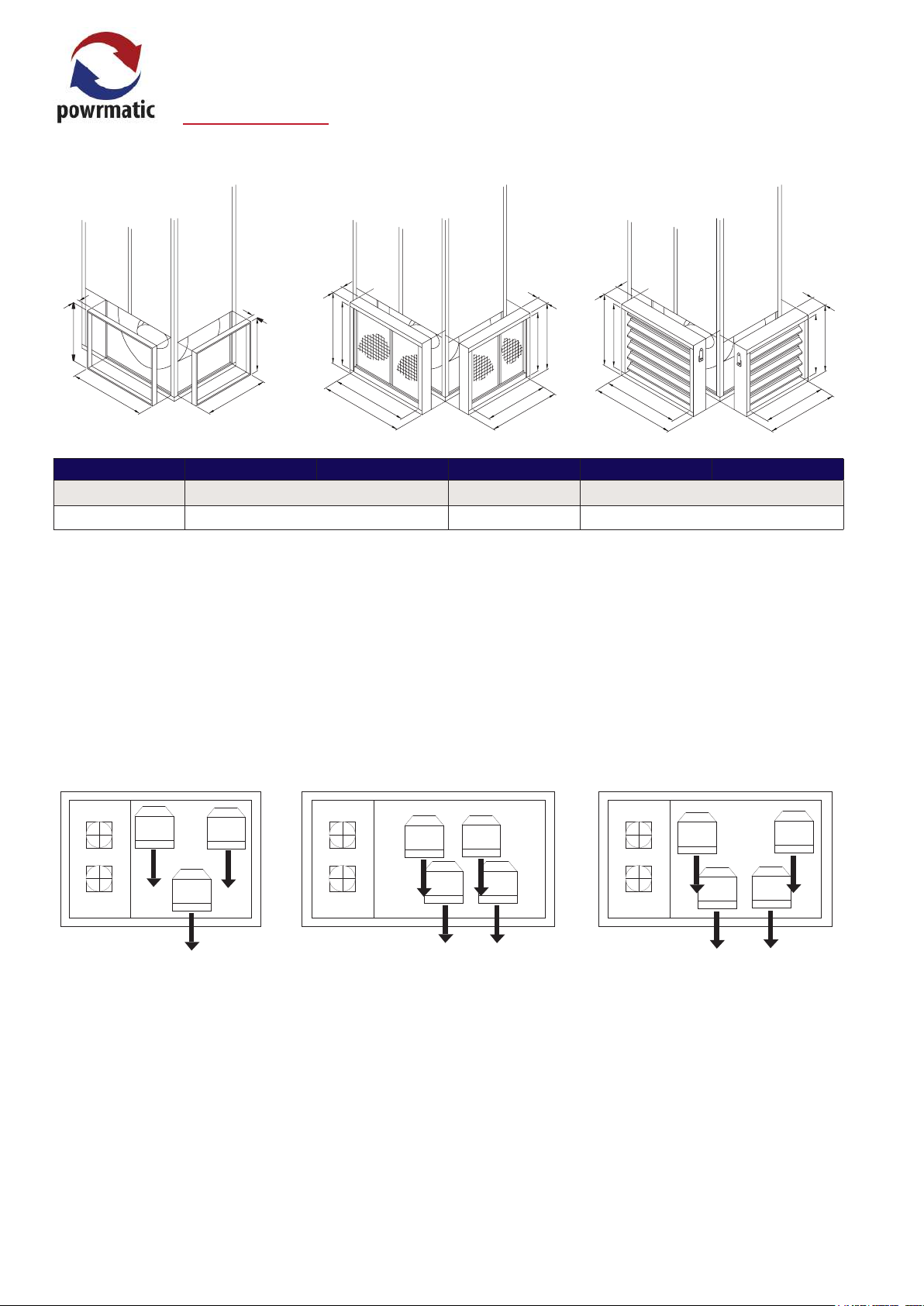

Accessories

Side/Rear Inlet Spigot Side/Rear Filters

660

L

SIDE REAR

50

660

650

50

760

136

660

N

Model 30 52 80 110 130

L 657 960 1315

N 757 1060 1415

Notes -

• All dimensions are outside dimensions

• Vertical units shown.

• Standard filter specification is 10ppi

• Higher specification filters available on request - contact our sales team for more information

• Standard dampers are manual operation - motorised options available

L

SIDE REAR

650

750

660

136

760

760

Side/Rear Dampers

185

660

L

N

SIDE REAR

650

750

660

185

760

Head Plans

Head Plan 2 Head Plan 3Head Plan 1

page no. 8 of 40

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

Page 9

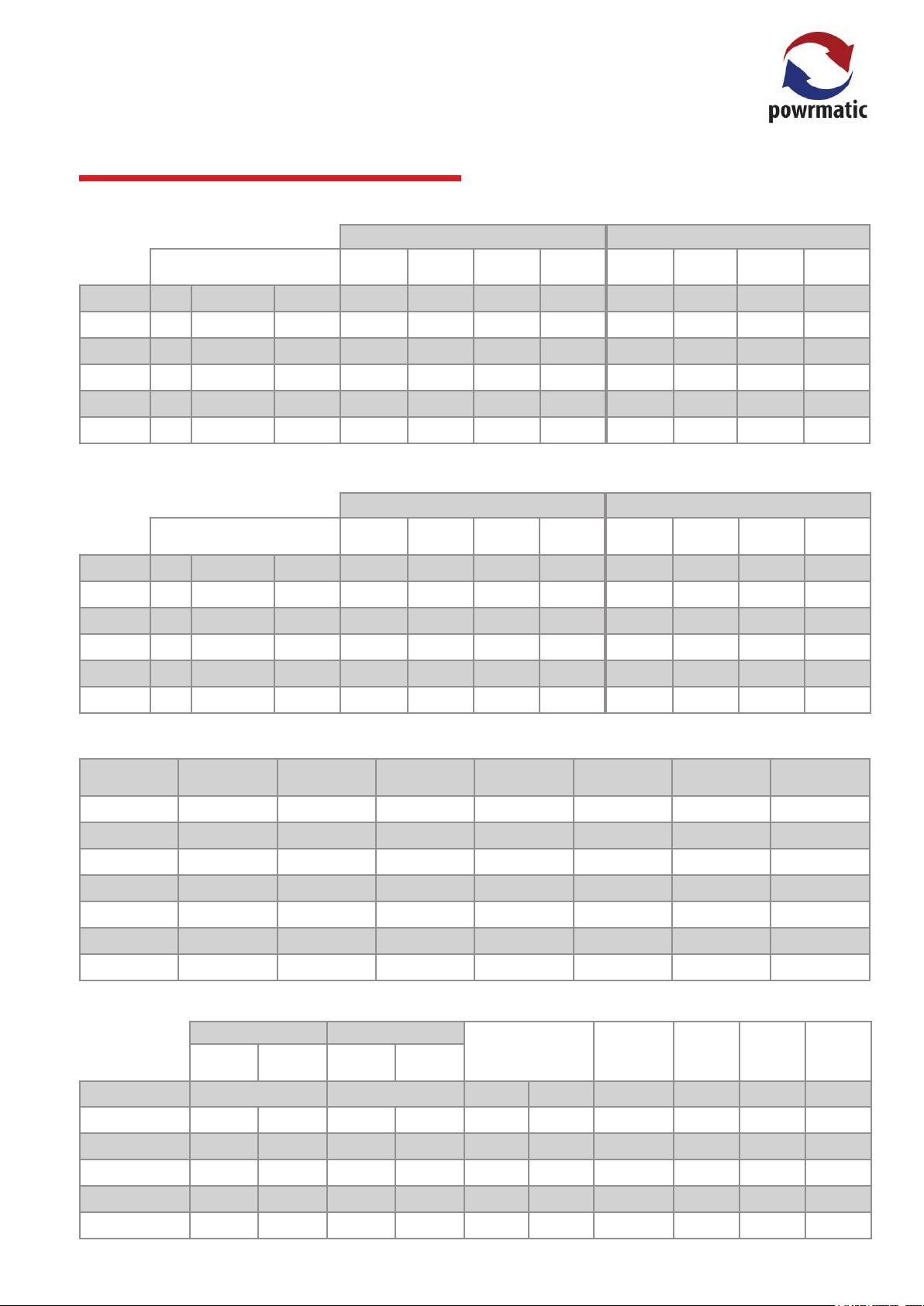

1.2 Technical Data

Injector Sizes & Burner Pressures - Natural Gas - Group H - G20 Net CV (Hi = 34.02MJ/m³).

Minimum Inlet Pressure = 17.5mbar

Injectors

MODEL No. Size (mm)

Marked mbar m/h % °C mbar m/h % °C

Burner

Pressure

VPC30 6 1.94 194 13.8 3.45 8.6 171 4.6 1.90 3.7 125

VPC52 12 1.94 194 10.4 5.98 8.2 17 2 3.0 3.22 3.1 117

VPC80 12 2.54 254 8.1 9.19 8.0 146 2.1 4.44 2.7 91

VPC110 10 3.00 300 10.2 12.64 9.0 180 3.2 6.50 3.2 114

VPC130 12 3.00 300 10.0 14.94 7.2 180 3.6 8.26 3.4 113

Injector Sizes & Burner Pressures - Propane G31 Net CV (Hi = 88.00MJ/m³).

Minimum Inlet Pressure = 37mbar

Injectors

MODEL No. Size (mm)

Marked mbar m/h % °C mbar m/h % °C

VPC30 6 1.36 136 21.7 1.33 11.0 170 7. 0 0.74 4.6 125

Burner

Pressure

High Fire Low Fire

Gas

Rate

Gas

Rate

Nominal

CO

High Fire Low Fire

Nominal

CO

Nett Flue

Tem p

Nett Flue

Tem p

Burner

Pressure

Burner

Pressure

Gas

Rate

Gas

Rate

Nominal

CO

Nominal

CO

Nett Flue

Nett Flue

Tem p

Tem p

VPC52 12 1.25 125 27. 0 2.31 8.9 170 8.0 1.24 4.0 118

VPC80 12 1.55 155 24.1 3.55 9.4 151 6.0 1.72 3.4 99

VPC110 10 1.94 194 26.5 4.89 10.4 192 7.0 2.51 4.0 121

VPC130 12 1.94 194 25.0 5.78 9.0 181 7.9 3.19 3.6 114

Electrical Loadings - 1Pha

Electrical

MODEL

Supply

VPC30 230V 1N 0.55 940 4.3 6.5 4.4 7

VPC52 230V 1N 1.1 940 4.2 8.3 4.5 7

VPC80 230V 1N 1.4 940 10.0 19.0 9.4 15

VPC110 230V 1N 1.5 1500 6.7 28.0 9.3 15

VPC130 230V 1N 2.2 1500 9.4 40.0 10.7 15

VPC110 400V 3N 1.5 1500 3.5 17. 5 3.4 5

VPC130 400V 3N 2.2 1500 4.8 25.1 4.5 7

Motor

kW

Nominal

Motor R.P.M.

Max Fan

Amps (A)

Start Amps

(A)

Run Amps

(A)

Fuse Rating

(A)

Heater Specications

High Fire Low Fire

Air Volume

MODEL

Input

(Nett)

Output

kW kW m/s m/h Pa kW dB(A) kg

Input

(Nett)

Output

VPC30 32.6 30 18.0 15.7 0.8664 3119 150 0.55 68 178

Maximum

Duct

Resistance

Fan

Motor

Noise

Level

Weight

VPC52 56.5 52 30.4 26.1 1.5884 5718 200 1.10 68 248

VPC80 87.0 80 42.0 36.8 2.3372 8414 225 1.40 76 305

VPC110 119 . 5 110 61.5 53.3 2.9568 10645 150 1.50 72 362

VPC130 141.3 130 78.1 69.0 3.6288 13064 200 2.20 74 410

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

page no. 9 of 40

Page 10

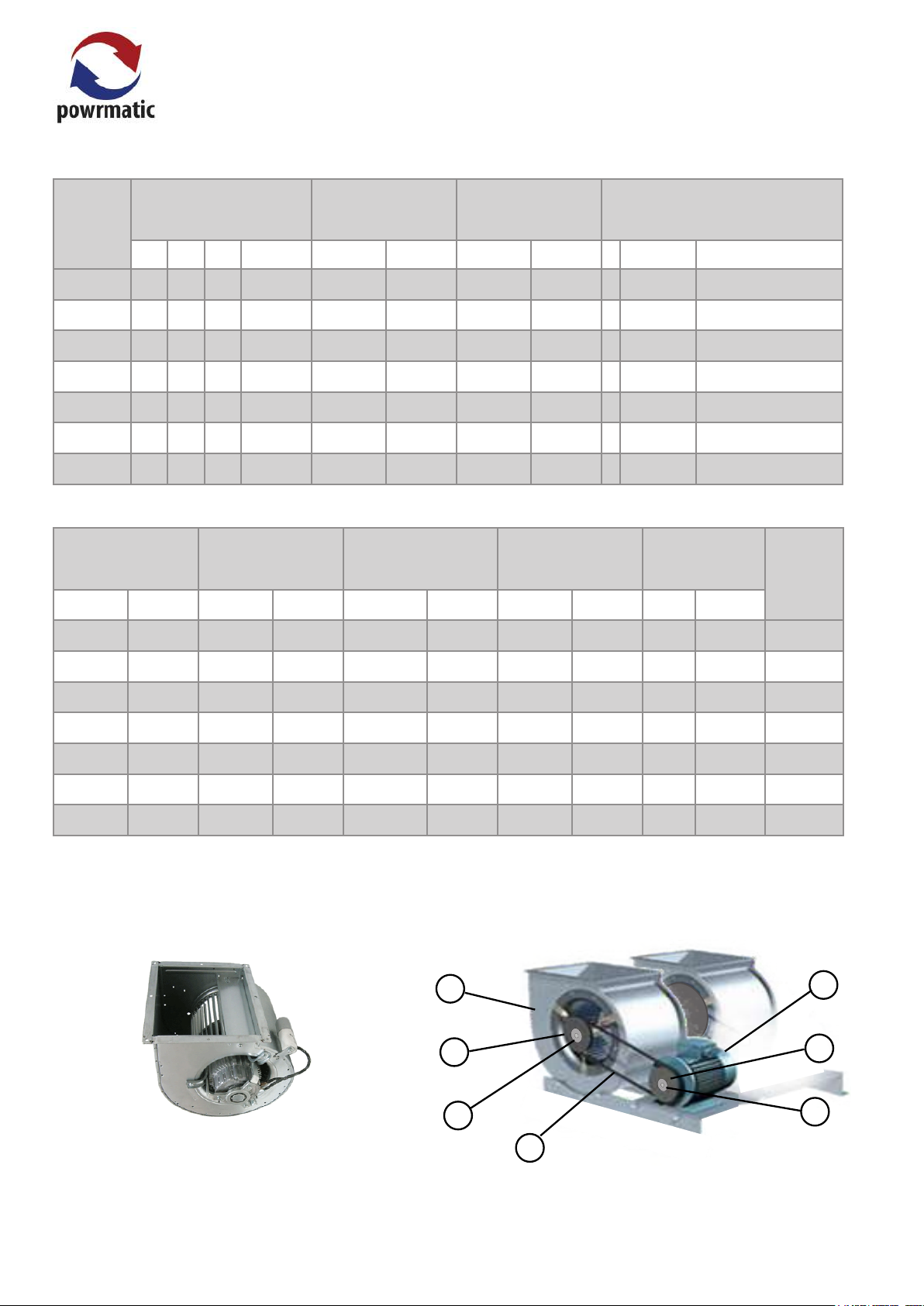

Drive Data - Standard Motor

Motor (a) Motor Pulley (b)

kW Pha RPM Pt no. Size Pt no.

VPC30

VPC52

VPC80

VPC110

VPC130

VPC110

VPC130

Fan Pulley (e)

Size Pt no.

n/a n/a n/a n/a n/a n/a 5.5kW AC3 143000601 7-11A 143000801

0.55 1 940 n/a n/a n/a n/a n/a 1 321 x 321 1402CFAN280/T/15

1.1 1 940 n/a n/a n/a n/a n/a 1 321 x 321 1402CFAN210/T/15

1.4 1 940 n/a n/a n/a n/a n/a 1 381 x 381 1402CFAN580/T/15

1.5 1 1500 140001908 95x1SPA 142000602 1210-24 142003350 2 321 x 321 1402CFAN240/T/2DECK

2.2 1 150 0 140001998 100x1SPA 142000601 1610-28 142161028 2 321 x 321 1402CFAN240/T/2DECK

1.5 3 1500 140001915 95x1SPA 142000602 1210-24 142003350 2 321 x 321 1402CFAN240/T/2DECK

2.2 3 150 0 140002000 100x1SPA 142000601 1610-28 142161028 2 321 x 321 1402CFAN240/T/2DECK

Fan Pulley

TaperLock (f)

Size

Pt no. Size Pt no. Typ e Pt no. Type Pt no.

Belt(s) (g) Contactor/Relay Overload

Motor Pulley

TaperLock (c)

Size

Pt no.

Centrifugal Fan (d)

Size Pt no.

type

VPC30

n/a n/a n/a n/a n/a n/a 5.5kW AC3 143000601 7-11A 143000801

n/a n/a n/a n/a n/a n/a 7.5kW A C3 143000600 7-11A 143000801

170 x1SPA 142001689 1610 -25 142003370 A990/38 142109801 7. 5kW AC3 143000600 7-11A 143000801

180x1SPA 142001675 1610 -25 142003370 A105 0/4 0 142110 507 7.5kW AC3 143000600 12-18A 142000800

160x1SPA 142001619 1610 -25 142003370 A990/38 142109801 7. 5kW AC3 143000600 7-11A 143000801

180x1SPA 142001675 1610 -25 142003370 A105 0/4 0 142110 507 7.5kW AC3 143000600 5-8A 142000802

d

e

f

VPC52

VPC80

VPC110

VPC130

VPC110

VPC130

a

b

c

page no. 10 of 40

g

Fan type 2Fan type 1

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

Page 11

1.3 General Requirements

1.3.1. Related Documents

All VPC heaters comply with the following European

Directives:

Energy Related Product Directive: 2009/125/EC*

Gas Appliance Directive: 2009/142/EC

Electromagnetic Compatibility Directive: 2004/108/EC

Low Voltage Directive: 2006/95/EC

Machinery Directive: 2006/42/EC

Air heater(s) must be installed in accordance with BS6230

and BS5440 plus any relevant requirements of local and

national building codes. * where appropriate

1.3.2 Location

The location chosen for the air heater must permit:

- the provision of a satisfactory flue system and an

adequate air supply.

- adequate space for servicing and air circulation around

the air heater.

The heater(s) must not be installed in conditions for which

it is not specifically designed e.g. where the atmosphere

is corrosive or salty. Standard units are not suitable for

outdoor location.

1.3.4 Gas Supply

1.3.4.1 Service Pipes

The local gas undertaking should be consulted at the

installation planning stage in order to establish the

availability of an adequate supply of gas. An existing

service pipe must not be used without prior consultation

with the local gas undertaking. The inlet gas pressure

under running conditions must not be less than 17.5mb.

1.3.4.2 Meters

An existing meter should be checked, preferably by the gas

undertaking, to ensure that the meter is adequate to deal

with the total rate of gas supply required by all connected

equipment.

1.3.4.3. Installation Pipes

Installation pipes should be fitted in accordance with IGE/

UP/2. Pipe work from the meter to the air heater must be

of adequate size. Do not use pipes of a smaller size than

the inlet gas connection of the heater. The complete

installation must be tested for soundness as described in

the above Code.

Where the location of the air heater is such that it might

suffer external mechanical damage e.g. from overhead

cranes, fork lift trucks, it must be suitably protected.

VPC units are designed to operate within an ambient

temperature range of -10 to 25°C.

1.3.3 Electrical Supply

Wiring external to the air heater must be installed in

accordance with the I.E.E. Regulations for Electrical

Installations and any local regulations which apply.

All standard heaters are supplied by 230V - 1ph, 50Hz. The

method of connection to the main electricity supply must:-

- facilitate the complete electrical isolation of the unit(s)

- be in a readily accessible position adjacent to the unit(s)

- serve only the unit(s)

- have a contact separation of at least 3mm in all poles. See

the accompanying wiring diagram for the heater electrical

connections

1.3.4.4. Boosted Supplies

Where it is necessary to employ a gas pressure booster the

controls must include a low pressure cut off switch at the

booster inlet. The local gas undertaking must be consulted

before a gas pressure booster is fitted.

1.3.5 Flue System

VPC units must be used with a closed flue system and have

an internal exhaust fan, mounted downstream of the heat

exchanger, to both assist the evacuation of the products of

combustion and to draw in air for combustion.

The flue must terminate in a freely exposed position and

be sited to prevent the products of combustion entering

any opening in a building in such concentration as to be

prejudicial to health or a nuisance.

1.3.6 Air Distribution System

VPC units used in buildings having a low heat loss i.e.

where single units are required to cover a large floor area,

and in buildings with high roof or ceiling heights Calecon

thermal economiser units should be fitted to ensure even

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

page no. 11 of 40

Page 12

heat distribution and minimise stratification.

Care should be taken to avoid impeding the air throw with

racking, partitions, plant or machinery etc.

Care must be taken to ensure that return-air intakes are

kept clear of sources of smells and fumes, and where there

is any possibility of pollution of the air by dust, shavings

etc., precautions must be taken to prevent contamination.

If necessary suitable barrier rails should be provided to

prevent any combustible material being placed within

900mm of the warm air outlets.

page no. 12 of 40

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

Page 13

1.4 Ventilation Air Requirements

Type B ued installations.

Where VPC heaters are installed within the heated space

(ie not in a plant room or an enclosure) and having

a building design air change rate of greater than 0.5/h,

additional provision for ventilation is not required.

If the building design air change rate is less than 0.5/h,

additional provision for natural or mechanical ventilation

is required. These being:

Natural Ventilation:

Grilles having a free area of at least 2cm² per kW of rated

heat input shall be provided at low level i.e. below the level

of the heater flue connection.

Mechanical Ventilation:

Must ensure that the space air change rate is at least 0.5/h,

must be of the ‘input’ type and interlocked to ensure the

heaters cannot work if the input system is not working.

Type B ued installations.

Where VPC heaters are installed in a plant room

or an enclosure (ie not within the heated space)

having combustion air drawn directly from the room

and connected to a flue that evacuates the products of

combustion directly from the room additional provision for

natural or mechanical ventilation is required. These being:

Natural Ventilation:

There must be permanent air vents communicating

directly with the outside air, at high level and at low level.

Plant Rooms

Low level (inlet) 4cm²/kw of total rated net heat input

High level (outlet) 2cm²/kw of total rated net heat input

Enclosures

Low level (inlet) 10cm²/kw of total rated net heat input

High level (outlet) 5cm²/kw of total rated net heat input

Mechanical Ventilation:

The minimum flow rate of ventilation shall be 4.14m³/h per

kilowatt of total rated heat input.

Type C ued installations.

Where VPC heaters are Installed within the heated

space (ie not in a plant room or an enclosure) having

combustion air ducted to the appliance and combustion

products ducted to the outside air, NO additional

provision for the supply of either combustion air or for

combustion products dilution or additional provision

for the supply of air is necessary.

Type C ued installations.

Where VPC heaters are Installed in a plant room or

an enclosure (ie not within the heated space) having

combustion air ducted to the appliance and combustion

products ducted to the outside, air vents shall be provided

and be permanently open.

To room or internal space

Low level (inlet) 10cm²/kw of total rated net heat input

High level (outlet) 10cm²/kw of total rated net heat input

Direct to outside air

Low level (inlet) 5cm²/kw of total rated net heat input

High level (outlet) 5cm²/kw of total rated net heat input.

Type B22 Installation (these refer to section 2.2 of these

instructions)

Air vents shall be permanently open.

In all cases gures are per heater installed.

For multi heater installations the appropriate values for each heater

must be added together

In the

heated

VPC

30 32.6 65.2 130.0 65.2 326.0 163.0 n/a 326.0 326.0 163.0 163.0

52 56.5 113 .0 226.0 113.0 565.0 283.0 n/a 565.0 565.0 283.0 283.0

80 87.0 174.0 348.0 174.0 870.0 435.0 n/a 870.0 870.0 435.0 435.0

110 119.5 239.0 478.0 239.0 1195.0 598.0 n/a 1195.0 1195.0 598.0 598.0

130 141.3 283.0 565.0 283.0 1413.0 707.0 n/a 1413.0 1413.0 707.0 707.0

Input

kW

space

Low level

grille. Free

area cm²

In a plant room,

ventilation to

outside

Low level

grille. Free

area cm²

High level

grille. Free

area cm²

In an enclosure,

ventilation to

outside

Low level

grille. Free

area cm²

High level

grille. Free

area cm²

Type C12 or C32 Installation (these refer to section 2.2

of these instructions)

Air vents shall be permanently open.

Figures are for heaters in plant rooms or enclosures ONLY

In all cases gures are per heater installed.

For multi heater installations the appropriate values for each heater

must be added together.

In the

heated

space

Free area

grille cm²

Ventilation is to a

room or internal

space

Low level

grille. Free

area cm²

High level

grille. Free

area cm²

Ventilation is to a

outside air

Low level

grille. Free

area cm²

High level

grille. Free

area cm²

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

page no. 13 of 40

Page 14

2.1 Fitting the Unit

Minimum Clearance Distance

C

D*

Model 30 52 80 110 130

A Front mm 1000 1000 1000 1000 1000

B Rear mm 500

C Above mm 1000

D Side (Blank panel)* mm 150

E Side (Louvred)* mm 500

To the front of the heater to nearest wall 1.0m

To the rear of the heater to nearest wall 0.5m

To the side having louvred lower panels* 0.5m

To the side having blank lower panels (see below)* 0.15m

Above the heater 1.0m

AE* B

* Side panels are interchangeable to ease with installation against walls etc.

Therefore D can = 1.0m if E = 0.15m OR E can = 0.15m if D = 1.0m

page no. 14 of 40

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

Page 15

Before installation, check that the local distribution

conditions, nature of gas and pressure, and adjustment of

the appliance are compatible.

The air heater must be installed in accordance with

the rules in force and the relevant requirements of any

fire regulations or insurance company's requirements

appertaining to the area in which the heater is located,

particularly where special risks are involved such as areas

where petrol vehicles are housed, where cellulose spraying

is carried out, in wood working departments etc.

2.1.4 Minimum Clearances

The minimum clearances for installation and servicing

shown opposite must be observed.

Any combustible material adjacent to the air heater and

the flue system must be so placed or shielded as to ensure

that its temperature does not exceed 65 °C.

If the method of mounting allows for any movement of

the heater it is essential that all gas, duct, and electrical

connections to the heater are made with flexible

connections to maintain continuity of connection.

2.1.3 Gas Connection

To facilitate servicing a servicing valve and downstream

union must be fitted at the inlet to the air heater. The gas

supply to the air heater must be completed in solid pipe

work and be adequately supported. Heaters suspended by

drop rods, straps or chains must have a flexible connection

as the final link between the gas supply pipe work and the

heater. Sufficient slack must be left in the connection to

take account of normal movement of the heater.

WARNING: When completing the nal gas

connection to the heater do not place undue

strain on the gas pipe work of the heater.

IMPORTANT:

1. Heaters shall not be installed in:a) Those parts of spaces within buildings that have been

classified as hazardous areas as defined in BS 5345 : Part 2.

b) Where there is a foreseeable risk of flammable particles

or gases or corrosion inducing gases or vapours being

drawn into either the heated air stream or the air for

combustion.

c) In areas subjected to significant negative pressures due

to extract systems.

2.1.2 Fitting the Unit

If necessary consideration should be given to mounting

the heater on resilient pads, or equivalent, to minimise

transfer of noise and vibration to the structure of the

building.

Floor mounted heaters must be installed on a level

noncombustible surface.

Heaters mounted at high level must be supported

on a purpose designed platform or framework that is

suspended from vertical drop rods, chains or straps or

mounted on specifically designed cantilever brackets

from a non-combustible wall. The method of installation

support must be capable of adequately supporting the

weight of the unit (See section 1.2) and any ancillary

equipment. Before installing the heater the existing

structure must be inspected to ensure it is suitable. All

supports should be protected against the effects of rust or

corrosion.

Any combustible material adjacent to the air heater and

the flue system must be so placed or shielded as to ensure

that its temperature does not exceed 65 °C.

2.1.4 Air Distribution System General

VPC heaters, if required, can be used with duct work either

to more precisely define the point of air delivery, and /

or provide ducted return air or ducted fresh air inlet. The

system should be checked to ensure that the installation

work has been carried out in accordance with the design

requirements. Particular attention should be given to the

correct arrangement of delivery ducts and registers, return

air ducts and grills and general adequacy of return air

paths. Ensure that the total duct system resistance does

not exceed the available air pressure of the equipment

supplied refer to section 1.2. If the duct system resistance

is less than the available air pressure of the equipment

supplied additional resistance must be introduced e.g.

by adjustment of duct outlet nozzles and balancing of

the duct system. Conversely if the duct system resistance

is greater than the available air pressure of the heater

supplied the system resistance must be reduced.

2.1.4 Room Thermostat Siting

The room thermostat should be fitted at a point which

will be generally representative of the heated area as

far as temperature is concerned. Draughty areas, areas

subjected to direct heat e.g. from the sun, and areas where

the air movement is relatively stagnant e.g. in recesses,

should be avoided. The thermostat should be mounted

approximately 1.5m from the floor.

Any room thermostat, frost thermostat, time clock etc.

must be suitable for switching 230V, 5A and must be of the

'snap action' type to minimise contact bounce.

For electrical connections of external controls see section

2.5 or the accompanying wiring diagram.

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

page no. 15 of 40

Page 16

2.2 Flue/Combustion Air Duct System

The minimum distance between surfaces of the flue pipe

and any surfaces made from combustible materials is

300mm. If it is necessary for the flue pipe to pass through a

structure made from combustible materials a metal sleeve

must be used so that the minimum clearance of 300mm is

maintained.

The flue and combustion air ducts supplied with the heater

are capable of withstanding their own weight over the

allowable flue lengths. Wall bands and bracing brackets,

or equivalent, must be used to provide lateral stability and

should be used at centres not exceeding 2.5 metres.

All models are supplied as standard with a top flue outlet

and the flue outlet and combustion air sockets temporarily

fitted.

2.2.1 Conversion to Side Flue Outlet

1. Remove the two blanking plates from the flue /

combustion air openings at the side of the unit.

2. Disconnect the flexible pipe from the exhaust spigot.

All outer joints must be finished with the provided locking

bands. A smear of silicon grease to the inside of sockets

will assist in fitting components together. All flue and

combustion air ducts must be supported independently

of the air heater. The flue or flue/combustion air terminal

must not be installed so as to be less than:

- 300mm below an opening e.g. window, air brick

etc.

- 200mm below eaves or gutter.

- 300mm from an internal or external corner.

- 1200mm from a surface facing the terminal.

- 1500mm vertically from another terminal on the same

wall.

- 300mm horizontally from another terminal on the same

wall.

- 2000mm from ground level.

2.2.3. Installation of Flue System

Note: A terminal guard, as supplied by

Powrmatic Ltd, must be fitted to horizontal flue

terminals.

3. Remove the four screws securing the exhaust spigot and

reposition the spigot to the side of the heater using the top

position. Refit the flexible pipe

4. Remove the four screws securing the combustion air

spigot and reposition spigot to the side of the heater.

5. Refit the blanking plates to cover the holes in the top of

the heater.

2.2.1.2 Internal Combustion Air

1. If ducted combustion air is not required (see Section 1.4)

fit the mesh inlet plate (supplied loose) behind the unused

combustion air inlet hole.

2.2.2. General Requirements

See Figures 1a to 2b for the different types of flue

installation. In all cases the flue outlet socket must be

connected via the provided flue system to outside air. The

maximum permitted length of flue system is 6m, or 12m if

the flue outlet only is used. If an offset is required two sets

of 45° bends should be used each set being equivalent to

0.5m of flue length. 90° bends may be used but each set

will be equivalent to 1.0m of flue length.

The minimum flue length (end of flue terminal to side or

top of heater) shall not be less than 1.3m.

2.2.3.1. Vertical System - Top Outlet

1. Locate the position of the flue terminal cut a hole in the

roof to suit.

2. Fit the flashing and the flue terminal so that the lower

edge of the outer case is over the top of the flashing.

Weather with silicon sealant or equivalent. Fit a condensate

drain length into the flue socket on the heater and an

equivalent straight length onto the combustion air socket.

3. Fit the twin to concentric adaptor to the terminal section

and then extend down to the heater using straight lengths.

Fit adjustable lengths as the final connection pieces, to

facilitate flue disconnection for servicing.

Extend the adjustable lengths to make the final connection

but do not exceed the maximum extended length so as to

maintain joint integrity.

Extend the drainage off take of the condensate drainage

length to a suitable gully or drain.

4. Ensure that internal silicon sealing rings are in place and

that all tubes are pushed fully home.

Secure concentric lengths with the locking bands provided.

page no. 16 of 40

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

Page 17

Fig 1a Exhaust only system - vertical

Type C32 installation

Fig 1b Exhaust only system - horizontal

Type C12 installation

Terminal

Flashing

Single to twin

adaptor

6m maximum

Lengths

Combustion air

socket

Adjustable

lengths

Condensate drain

length

Flue socket

2.2.3.2. Horizontal System - Side Outlet

1. Locate the position of the flue terminal, allowing for

a slight gradient running down from the heater to the

terminal of 2° - 3° and cut a hole in the building wall to suit.

Flue socket

Lengths

Adjustable

length

Combustion

air socket

6m maximum

Single to twin

adaptor

Combustion

air duct

Terminal

2.2.3.3. Internal Combustion Air System

1. Complete the run of flue sections from the terminal

spigot to the flue outlet socket of the heater generally as

described in 2.2.3.1. and 2.2.3.2., ensuring that the internal

silicon sealing rings are in place.

2. It is recommended that both air inlets are utilized and

that both are fitted with the mesh inlet plates supplied.

Fig 2a Individual system - vertical

Type B22 installation

Terminal

2. Fit the flue terminal, securing via the wall plate and

weather with silicon sealant or similar.

3. Fit the twin to concentric adaptor to the terminal section

and extend the flue and combustion air ducts to the heater

using straight lengths. Fit an adjustable length prior to the

unit, to facilitate flue disconnection for servicing. Extend

the adjustable lengths to make the final connection to the

appropriate heater inlet/outlet spigots.

4. Ensure that internal silicon sealing rings are in place and

that all tubes are pushed fully home. Secure concentric

lengths with the locking bands provided.

Notes for all systems.

i) Final overall length of adjustable disconnection

piece must be between 360 - 415mm.

ii) 45° offsets may be used if required. Each set is

equivalent to 0.5m of flue length.

iii) Where VPC heaters are used in clean environments it is

permissible to take the combustion air directly from the

heated space. The supplied mesh intake plate, must be

fitted to the combustion air inlet on the rear of the heater.

Lengths

OPTION 1

Combustion air entry

(fitted with inlet grille)

Flashing

12m maximum

Adjustable

length

Condensate drain

length

Flue

socket

OPTION 2

Combustion air entry

(fitted with inlet grille)

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

page no. 17 of 40

Page 18

Fig 2b Individual system - horizontal

Type B22 installation

Flue

outlet

Adjustable

length

OPTION 2

Combustion air entry

(fitted with inlet grille)

Lengths

12m maximum

Terminal

2.2.4. Condense Length

VPC gas fired heaters (with on/off burner)

A VPC heater fitted with an on/off burner, an approved flue

terminal & vertical flue run that’s predominantly internal,

will typically not require an inline condense drain as flue

gas temperatures are higher than the dew point, which is

approximately 60°C.

VPC gas fired heater (with high/low & modulating burners)

A VPC heater fitted with high/low or modulating burner

may require an inline condense flue drain if vertically flued,

due to the lower flue gas temperatures experienced when

the heater is operating at low firing rates.

Exceptions may occur if the installation requires significant

length of the flue which may cause chilling, or if heater

may be exposed to high winds and heavy rain, which may

ingress the flue. We would always recommend fitting the

inline condense drain even if the drain point is capped,

should the drain be required in the future. Any clarification

can be achieved by consulting with Powrmatic’s Technical

Department.

2.3 General Identication of Electrical Items

FAN / LIMIT THERMOSTAT

EXHAUST FAN

PRESSURE SWITCH

GAS VALVE

HIGH LIMIT RESET

MANUAL OVERRIDE SWITCH

BURNER RESET

page no. 18 of 40

CONTACTOR

OVERLOAD

MC200 CAB

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

Page 19

2.4 Electrical Cable Installation

Electrical Connections

Warning: THIS APPLIANCE MUST BE

EARTHED.

Warning: Lockout reset is by a switched

Neutral to the controls in the heater.

Warning: Wiring external to the unit must

be carried out by an appropriately

qualied person to current IEE regulations

for Electrical Installations and any local regulations

which apply.

The local electrical supply must be run to a point adjacent

to the heater and be suitably terminated to provide an

isolation point that will prevent remote activation of the

unit during servicing.

The local electrical supply conditions must be compatible

with the electrical data given on the appliance data plate.

Reference must be made to the table below to ascertain

the electrical loading of the unit(s) being installed so that

cables of adequate cross-sectional area are used for the

electrical installation.

C= Screened 2 core (MC200 models only)*

* (screen must be grounded only at the MC200, See

instructions supplied with controller for wiring sizing,

Max. 100m)All units are fully prewired and only require

final connections for the incoming mains supply and

completion of the control circuit (230V).

The wiring terminals are located behind the front panel

which has to be removed.

The mains supply ( single or three phase) connections are

via a Hylec terminal block. Control Circuitry connections

are via a 30A numbered terminal strip. They are:

terminal 1 Heat on

terminal 2 Fan only

terminal 3* 0-10V (modulating) OR 230V High

Fire

terminal 4* 0V (modulating negative)

terminal 5 Lockout indication

terminal 6 Burner reset

* Used where required

Model Phase

30 1

52 1

80 1

110 1

130 1

110 3

130 3

The length of the conductors between the cord anchorage

and the terminals must be such that the current carrying

conductors become taut before the earth conductor if the

cable or cord slips out of the cord anchorage.

All external controls must be of an approved type.

Initial Wiring Instalation

Key

A = 2 core and earth

B = MC200 Hi/Lo = 7 core and earth

MC200 Mod = 8 core and earth

Running

Amps (A)

4.4

4.5

9.4

9.3

10.7

3.4

4.5

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

page no. 19 of 40

Page 20

Mains Input: 230v 50Hz 1ph Supply.

For input power refer to Installation instructions.

Warning: High voltages present at the ignition

electrode when the unit attemps to light.

POWRTROL RR

NVx Terminal Numbers

2.5 Wiring Diagrams

VPC 30-80 On/O Gas Cabinet 1Pha

Model specific

Model specific

Model specific

Model specific

143100603

147600101

Model specific

142423003

143000526

142403600/2

143070274

143000816

143100663

MC200BL

POWRTROL/RR

Model specific

Model specific

145030844

143000306

143070274

A. Brahma Control DMN32

B. Honeywell Fan/Limit Thermostat

C. Limit Indicator / Res et Button

D. Air Pressure Switch

E. Main Gas Valve

F. Exhaust / Combustion Fan

G. Main fan

H. Hylec Terminal Block 3 Way

I. NVx Ver 2 Wiring Loom

J. Ignition Electrode

K. Rectification Probe

L. Fuse Holder 3.15A

M. High Limit Interface B oard

N. Internal Lockout Reset Button

COMPONENT LIST Powrmatic part #

O. Jox Relay

143000816

P. Engineers Override S witch

Q. MC200 Fuel Saver

R. Powrtrol Remote Reset

S. Ktec Contactor

T. Otec Overload

U. Jox Relay

5

.

1

B

r

5

.

1

B

r

4

1

3

1

T

3

L

3

T

2

L

2

T

1

L

NOTES

1

A

A

1

2

S

Mains Input: 230v 50Hz 1ph Supply.

For input power refer to Installation instructions.

Warning: High voltages present at the ignition

electrode when the unit attemps to light.

T

3

T

2

T

1

5

9

6

9

T

3 Core

Cable

r

1

.

5

B

l

B

u

1

.

5

e

l

1

.

5

r

G

/

Y

G

E

Br 0.5

Blk 1.0

Blu 1.0

Gry 1.0

F

Br 0.5

Blu 0.5

Blu 0.5

C

Br 1.0

0

.

5

18

18

0

.

5

19

19

0

.

5

20

20

0

.

5

21

21

NOTES

K

B

C

°

C

°

N

A

F

ºc

IT

IM

(143000307)

alternative stat

231

NO

COM

654

3

2

5

6

4

0

A

1617181913141

L

7

7

8

8

9

10

11

12

13

14

15

16

17

Note:

Remove Mode Link 'B'

NC

8

9

1

0

1

1

1

N

M

p

e

D

y

E

D

3

7

O

M

H

A

R

2

T

C

B

E

S

U

F

4

A

1234567

Or 0.5

Blk 0.5

Wh 0.5

Blu 0.5

5 Core

Cable

White Rodgers

Br 1.0

Gry 1.0

r

B

l

B

k

l

B

u

y

r

G

Yel 1.0

Blk 1.0

5

l

B

u

0

.

Br 0.5

9

10

N

L

M

R/S

87

TRP

11

5

J

J

6

J

1

T

J

2

T

0

5

A

N

J

15

Br 1.5

Blk 1.5

Blu 1.5

Gr/Yel 1.5

8

Note:

Fan Stat - Right Hand Side

Limit Stat - Left Hand Side

16

4 Core

Cable

MAINS SUPPLY

LIVE

EARTH

NEUTRAL

H

NO

NC

U

COM

7

7

8

8

0

.

5

r

B

9

10

11

12

13

14

15

16

17

Or 0.5

0

.

5

ENN

E

EE

N1

l

B

u

0

.

5

5

.

5

r

B

N

l

B

u

0

0

.

r

B

L LL

L

6

6

5

5

4

4

3

3

2

2

W

h

0

.

5

1

I

Or 0.5

Q

L

D

NCNOC

Br 0.5

Br 0.5

Br 0.5

Or 0.5

Yel 0.5

Wh 0.5

Blu 0.5

Or 0.5

Blu 0.5

Blu 0.5

Wh 0.5

Blk 0.5

MC200 fuelsaver

L

Or 0.5

E

N

t

u

O

L

t

u

a

O

F

n

a

In

F

n

t

u

O

o

e

a

t L

H

In

o

e

a

t L

H

t

u

O

i

e

a

t H

H

In

i

e

a

t H

H

t

c

o

k

u

L

o

e

s

e

t

R

0

v

-

-1

0

0

v

+

0

-1

2

IN

M

O

C

1

N

E

S

R

T

N

E

V

T

N

E

V

e

s

e

t

R

/O

L

P

M

A

L

/O

L

/P

O

K

C

O

L

C

IN

T

A

E

H

T

U

O

T

A

E

H

L

N

Connections

External Controls

Lockout Reset - Neutral Switch

Lockout Indicator 230v Output

Main Fan Only 230V Input

Heat Demand 230V Input

LN2156

NVx Terminal Numbers

65 21

N L

page no. 20 of 40

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

Page 21

VPC 30-80 Hi/Low Gas Cabinet 1Pha

Connections made by Control board Assembler

Connections made by Final Assembler

Note: When the valve

is de-energized the

heater operates in

low fire.

NVx Terminal Numbers

145030844

143000306

143070274

Model specific

Model specific

Model specific

Model specific

143100603

147600101

Model specific

142423003

143000526

142403600/3

143070274

142466402

143100663

MC200BL

Powrtrol/RR

Model specific

Model specific

143000816

A. Brahma Control DMN32

B. Honeywell Fan/Limit Thermostat

C. Limit Indicator / Res et Button

D. Air Pressure Switch

E. Main Gas Valve

F. Exhaust / Combustion Fan

G. Main fan

H. Hylec Terminal Block 3 Way

I. NVx Ver 2 Wiring Loom

J. Ignition Electrode

K. Rectification Probe

L. Fuse Holder 3.15A

M. High Limit Interface B oard

N. Internal Lockout Reset Button

O. Hi-Lo Gas Valve Head

P. Engineers Override S witch

Q. MC200 Fuel Saver

R. Powrtrol Remote Res et

S. Ktec Contactor

T. Otec Overload

COMPONENT LIST Powrmatic part #

U. Jox Relay

5

.

1

B

r

5

.

1

B

r

4

1

3

1

T

3

L

3

T

2

L

NOTES

2

T

1

L

1

A

A

1

2

S

Mains Input: 230v 50Hz 1ph Supply.

For input power refer to Installation instructions.

Warning: High voltages present at the ignition

electrode when the unit attemps to light.

T

3

T

2

T

1

5

9

6

9

T

3 Core

Cable

r

1

.

5

B

l

B

u

1

.

5

e

l

1

.

5

r

G

/

Y

G

E

Br 0.5

Blk 1.0

Blu 1.0

Gry 1.0

F

Br 0.5

Blu 0.5

Blu 0.5

C

Br 1.0

0

.

5

18

18

0

.

5

19

19

0

.

5

20

20

y

0

.

5

21

21

B

C

°

C

°

5 Core

Cable

Br 1.0

Gry 1.0

r

B

l

B

k

l

B

u

r

G

Yel 1.0

Blk 1.0

l

B

u

0

.

5

Br 0.5

9

10

N

L

M

231

R/S

87

NO

TRP

11

5

J

J

6

J

1

T

J

2

T

0

0

N

A

F

ºc

I

L

IT

M

(143000307)

White Rodgers

alternative stat

7

7

7

7

8

8

8

8

0

.

5

r

B

9

9

l

B

u

0

.

5

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

Or 0.5

Note:

Remove Mode Link 'B'

NC

COM

654

3

2

N

M

p

e

D

y

T

E

D

3

7

5

O

6

4

C

A

M

H

A

R

B

E

S

U

4

A

D

NCNOC

8

Yel 0.5

Wh 0.5

9

1

0

1

1

1

2

F

8

Note:

Fan Stat - Right Hand Side

16 15

Br 0.5

Or 0.5

Blu 0.5

Limit Stat - Left Hand Side

NO

NC

U

COM

Br 0.5

Br 0.5

Or 0.5

Blu 0.5

Blu 0.5

L

Br 1.5

Blk 1.5

Blu 1.5

Gr/Yel 1.5

4 Core

Cable

.

5

l

B

u

0

r

B

0

.

5

W

h

0

.

5

r

0

.

5

O

Br 0.5

Q

Blu 0.5

Wh 0.5

Blk 0.5

MC200 fuelsaver

ENN

EE

N

L LL

6

5

4

3

2

1

MAINS SUPPLY

Connections

External Controls

LIVE

EARTH

NEUTRAL

H

E

N

L

6

5

4

3

2

1

Main Fan Only 230V Input

Lockout Reset - Neutral Switch

Lockout Indicator 230v Output

Heat Hi Demand 230V Input

Heat Lo Demand 230V Input

I

L

E

N

t

u

O

L

t

u

a

O

F

n

a

In

n

F

t

u

O

o

e

a

t L

H

In

o

e

a

t L

H

t

u

O

i

e

a

t H

H

In

i

e

a

t H

H

t

c

o

k

u

L

o

e

s

e

t

R

0

v

-

0

-1

0

v

+

0

-1

2

IN

M

O

C

1

N

E

S

LN2156

5

Wiring Legend

A

Connections made by Installer

K

J

1617181913141

Wh 0.5

Blu 0.5

N

1234567

Or 0.5

Blk 0.5

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

Or 0.5

7

8

O

R

T

N

E

V

T

N

E

V

e

s

e

t

R

/O

POWRTROL RR

L

P

M

A

L

/O

L

/P

O

K

C

O

L

C

IN

T

A

E

H

T

U

O

T

A

E

H

L

N

65 21

NVx Terminal Numbers

N L

page no. 21 of 40

Page 22

VPC 30-80 Modulating Gas Cabinet 1Pha

Model specific

Model specific

Model specific

Model specific

143100603

147600101

Model specific

142423003

143000526

142403600/3

143100663

MC200BL

Powrtrol/RR

Model specific

Model specific

142400305

142466403

145030844

143000306

143070274

A. Brahma Control DMN32

B. Honeywell Fan/Limit Thermostat

C. Limit Indicator / Reset B utton

D. Air Pressure Switch

E. Main Gas Valve

F. Exhaust / Combustion Fan

G. Main fan

H. Hylec Terminal Block 3 W ay

I. NVx Ver 2 Wiring Loom

J. Ignition Electrode

K. Rectification Probe

L. Fuse Holder 3.15A

M. High Limit Interface Boa rd N.O.

P. Engineers Override Sw itch

COMPONENT LIST Powrmatic part #

E

F

Q. MC200 Fuel Saver

C

°

143000816

R. Powrtrol Remote Reset

S. Ktec Contactor

T. Otec Overload

U. Modulating Driver Board

V. Modulating Driver Head

W Jox Relay

B

C

°

5 Core

Cable

5

.

1

B

r

5

.

1

B

r

4

1

3

1

T

3

L

3

T

2

L

2

T

1

L

NOTES

1

A

A

1

2

S

Mains Input: 230v 50Hz 1ph Supply.

For input power refer to Installation instructions.

Warning: High voltages present at the ignition

electrode when the unit attemps to light.

N

A

F

ºc

IT

IM

L

(143000307)

White Rodgers

alternative stat

8

Note:

16 15

T

3

T

2

T

1

5

9

6

9

T

Br 1.5

Blk 1.5

Blu 1.5

Gr/Yel 1.5

Fan Stat - Right Hand Side

Limit Stat - Left Hand Side

4 Core

Cable

3 Core

Cable

r

1

.

5

B

l

B

u

1

.

5

e

l

1

.

5

r

G

/

Y

MAINS SUPPLY

LIVE

EARTH

NEUTRAL

G

Connections

External Controls

W

NO

Br 0.5

C

Blk 0.75

Blu 0.75

Gry 0.75

Wiring Legend

Connections made by Control board Assembler

Connections made by Final Assembler

Br 0.5

Blu 0.5

Blu 0.5

Br 0.75

18

19

20

21

Br 1.0

Gry 1.0

r

B

0

.

5

18

l

B

k

0

.

5

19

l

B

u

0

.

5

20

r

G

y

0

.

5

21

Connections made by Installer

K

J

Yel 1.0

Blk 1.0

Br 0.5

7

7

7

7

8

8

8

8

0

.

5

r

B

9

9

l

B

u

0

.

5

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

l

B

u

0

.

5

Br 0.5

9

10

N

L

M

R/S

87

TRP

11

5

J

J

6

J

1

T

J

2

T

5

A

Or 0.5

231

NO

2

4

0

0

Note:

Remove Mode Link 'B'

NC

COM

654

3

N

M

p

e

D

y

T

E

D

3

7

O

5

6

C

A

M

H

A

R

B

1617181913141

Blk 0.5

Wh 0.5

Blu 0.5

17

D

NCNOC

8

Yel 0.5

Wh 0.5

9

1

0

1

1

1

2

E

S

U

F

4

A

1234567

Or 0.5

C

Br 0.5

Blu 0.5

ON

1 2 3 5 6

U

COM

Br 0.5

Br 0.5

Or 0.5

Blu 0.5

Blu 0.5

L

Or 0.5

2

1

61 62 63 64 65 66

P

NC

.

5

0

.

5

Br 0.5

H

ENN

E

EE

N

N

l

B

u

r

B

0

L LL

L

6

6

5

5

4

4

3

3

2

2

W

h

0

.

5

1

1

Lockout Reset - Neutral Switch

Lockout Indicator 230v Output

Modulating Signal 0v

Modulating Signal 0-10v

Main Fan Only 230V Input

Heat Demand 230V Input

I

Or 0.5

Q

L

E

N

t

u

O

Br 0.5

Or 0.5

Blu 0.5

Blu 0.5

Or 0.5

Yel 0.5

Wh 0.5

Blk 0.5

MC200 fuelsaver

L

t

u

O

a

n

F

In

a

n

F

t

u

O

o

e

a

t L

H

In

o

e

a

t L

H

t

u

O

i

e

a

t H

H

In

i

e

a

t H

H

t

c

u

k

o

o

L

e

s

e

t

R

0

v

-

0

-1

0

v

+

0

-1

2

IN

M

O

C

1

N

E

S

LN2156

NVx Terminal Numbers

43

R

T

N

E

V

T

N

E

V

e

s

e

t

R

/O

L

P

M

A

L

/O

L

/P

O

K

C

O

L

C

IN

T

A

E

H

T

U

O

T

A

E

H

L

N

POWRTROL RR

Or 0.5

Yel 0.5

7

8

V

65 21

NVx Terminal Numbers

N L

page no. 22 of 40

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

Page 23

VPC 110-130 On/O Gas Cabinet 3Pha

Connections made by Control board Assembler

Connections made by Final Assembler

Connections made by Installer

POWRTROL RR

NVx Terminal Numbe rs

Model specific

Model specific

Model specific

Model specific

143100603

147600101

Model specific

142423003

143000526

142403600/3

143070274

143100663

MC200BL

POWRTROL/RR

Model specific

Model specific

145030844

143000306

143070274

143000816

5

.

1

B

r

5

.

1

B

r

3

1

4

1

L

3

T

3

L

2

T

2

L

1

T

NOTES

1

A

A

1

2

T

3

T

2

T

1

6

9

5

9

3 Core

Cable

LN

r

B

1

.

5

l

B

u

1

.

5

r

/

G

e

l

Y

1

.

5

G

M

COMPONENT LIST Powrmatic part #

A. Brahma Control DMN32

B. Honeywell Fan/Limit Therm ostat

C. Limit Indicator / Reset Button

D. Air Pressure Switch

E. Main Gas Va lve

F. Exhaust / Co mbustion Fan

G. Main fan moto r

H. Hylec Terminal Block 3 Way

I. NVx Ver 2 Wir ing Loom

J. Ignition Electrode

K. Rectification Probe

L. Fuse Holder 3.15A

M. High Limit Interface Board

N. Internal Lockout Reset Button

P. Engineers Override Switch

Q. MC200 Fuel Saver

R. Powrtrol Remote Reset

S. Ktec Contactor

T. Otec Overload

U. Jox Relay

E

Br 0.5

Blk 1.0

Blu 1.0

Gry 1.0

F

Blu 0.5

C

Br 0.5

Blu 0.5

Br 1.0

r

0

.

5

18

18

l

k

0

.

5

19

19

l

u

0

.

5

20

20

r

y

0

.

5

21

21

B

C

°

C

°

5 Core

Br 1.0

Gry 1.0

B

B

B

G

Yel 1.0

Blk 1.0

l

B

u

0

.

5

Br 0.5

9

10

N

L

M

R/S

87

TRP

11

5

J

J

6

1

J

T

2

J

T

5

Wiring Legend

A

Cable

White Rodgers

alternative stat

231

NO

COM

654

3

2

6

4

0

0

1617181913141

Mains Input: 230v 50Hz 1ph Supply.

For input power refer to Instal lation instruct ions.

Warning: High voltages present at the ignition

electrode when the unit attemps to light.

N

A

F

ºc

IT

IM

L

(143000307)

7

7

7

7

8

8

8

8

r

0

.

5

9

9

u

0

.

5

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

Or 0.5

Note:

Remove Mode Link 'B'

NC

NCNOC

8

Yel 0.5

9

0

1

1

1

1

2

N

M

y

T

p

e

D

3

7

5

E

D

O

C

M

A

H

A

R

B

E

S

U

F

4

A

1234567

Or 0.5

Blk 0.5

Wh 0.5

Blu 0.5

N

K

J

VPC Range Users, Installation & Servicing Instructions Doc Ref M202 issue 5.5 Aug 2018.

S

8

Note:

16 15

T

MAINS SUPPLY

Br 1.5

Blk 1.5

Blu 1.5

Gr/Yel 1.5

Fan Stat - Right Ha nd Side

Limit Stat - Left Ha nd Side

4 Core

Cable

LIVE

EARTH

NEUTRAL

Connections

External Controls

U

NO

NC

COM

u

0

.

5

r

0

.

5

r

0

.

B

l

B

5

0

.

5

.

5

P

Q

Or 0.5

Br 0.5

Br 0.5

Br 0.5

Or 0.5

Wh 0.5

Blu 0.5

Blu 0.5

Blu 0.5

Wh 0.5

Blk 0.5

L

Or 0.5

R

l

r

0

B

B

B

h

MC200 fuelsaver

H

ENN

E

EE

N

N

L LL

L

B

6

6

5

5

4

4

3

3

2

2

W

1

1

I

L

E

N

t

u

O

L

t

u

a

O

F

n

a

In

F

n

t

u

O

e

o

a

t

H

L

In

e

o

a

t

H

L

t

u

O

i

e

a

t

H

H

In

i

e

a

t

H

H

t

c

o

k

L

u

o

e

s

e

t

R

0

-

1

0

v

-

1

0

v

+

0

-

2

IN

M

O

C

1

N

E

S

T

N

E

V

T

N

E

V

e

s

e

t

R

/O

L

P

M

A

L

/O

L

/P

O

K

C

O

L

C

IN

T

A

E

H

T

U

O

T

A

E

H

L

N

Lockout Reset - Neu tral Switch

Lockout Indicator 230v Output

Main Fan Only 230V Input

Heat Demand 230V Input

LN2156

NVx Terminal Numbe rs

65 21

N L

page no. 23 of 40

Page 24

VPC 110-130 Hi/Low Gas Cabinet 3Pha

Connections made by Control board Assembler

Connections made by Final Assembler

Note: When the valve

is de-energized the

heater operates in

low fire.

NVx Terminal Numbe rs

145030844

143000306

143070274

Model specific

Model specific

Model specific

Model specific

143100603

147600101

Model specific

142423003

143000526

142403600/3

143070274

142466402

COMPONENT LIST Powrmatic part #

A. Brahma Control DMN32

B. Honeywell Fan/Limit Thermost at

C. Limit Indicator / Reset Button

D. Air Pressure Switch

E. Main Gas Valv e

F. Exhaust / Co mbustion Fan

G. Main fan moto r

H. Hylec Terminal Block 3 Way

I. NVx Ver 2 Wir ing Loom

J. Ignition Electrode

K. Rectification Probe

L. Fuse Holder 3.15A

M. High Limit Interface Board

N. Internal Lockout Reset Button

O. Hi-Lo Gas Valve Head

143100663

MC200BL

P. Engineers Override Switch

Q. MC200 Fuel Saver

143000816

Powrtrol/RR

Model specific

Model specific

NOTES

R. Powrtrol Remote Reset

S. Ktec Contactor

T. Otec Overload

U. Jox Relay

Mains Input: 230v 50Hz 1ph Supply.

For input power refer to Install ation instructi ons.

5

.

1

B

r

5

.

1

B

r

3

1

4

1

L

3

T

3

L

2

T

2

L

1

T

1

A

A

1

2

S

Warning: High voltages present at the ignition

electrode when the unit attemps to light.

T

3

T

2

T

1

6

9

5

9

T

3 Core

Cable

LN

r

B

1

.

5

l

B

u

1

.

5

r

/

G

e

l

Y

1

.

5

M

G

E

F

B

N

A

C

°

C

°

White Rodgers

5 Core

Cable

F

ºc

IT

IM

L

(143000307)

alternative stat

8

Note:

Fan Stat - Right Hand Side

16 15

Limit Stat - Left Hand Side

Br 1.5

Blk 1.5

Blu 1.5

Gr/Yel 1.5

4 Core

Cable

MAINS SUPPLY