Page 1

INSTALLER’S INSTRUCTIONS

IMPORTANT

It is advisable to check the following before turning on the boiler for the first time:

– Check that there are no liquids or flammable materials in the immediate vicinity of the boiler.

– Check that electrical connections have been made correctly and that the ground wire is connected to a proper

grounding system.

– Open the gas cock and check the seal on connections, including the burner connection.

– Check that the boiler is set up to run on the type of gas available.

– Check that the flue through which the products of combustion are eliminated is free.

– Check that gate valves are open, if there are any.

– Check that the heating system has been filled with water and air has been bled out of it.

– Turn on the circulation pump, unless it is commanded by an aut omatic sy stem.

– Bleed air out of the gas pipe using the pressure intake bleed valve located on the gas valve inlet.

– Check that none of the regulation, control and safety devices have been tampered with.

NOTE: When turning the generator back on, or if the boiler has not been used for some time, it is advisable to

bleed gas pipes for air. If this is not done, burner ignition may be delayed, possibly causing the boiler to shut

down. Wait at least 20 seconds from the time the indicator light comes on before releasing it.

If there is no voltage, the burner will shut down immediately. When the voltage is restored, the boiler will start

functioning again automatically. If gas pressure is insufficient, the device will shut down immediately, and the

signal for shutting down the equipment and the red gas pressure indicator light will come on.

If this occurs, the boiler cannot be started up using the device’s release button, for safety reasons. The boiler

will be ignited automatically when the pressure returns to the minimum pressure setting on the gas pressure

switch (10 mbar).

ENGLISH

CONTENTS

1 DESCRIPTION OF THE BOILER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pag. 58

2 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pag. 60

3 FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pag. 67

4 USE AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pag. 69

Page 2

58

1.1 INTRODUCTION

“RS Mk.II” boilers are hot water gene-

rators for mid to high power heating

systems. They consist of 7 to 14 cast

iron elements grouped in sets covering

the thermal power produced by 129,0

kW to 279.1 kW.

They are designed and built in accordance with European directives

90/396/CEE,89/336/CEE,

73/23/CEE, and 92/42/CEE and

European standard EN 656. They can

run on natural gas (methane), butane

(G30) or propane (G31).

Follow the instructions provided in this

manual to ensure correct installation

and perfect functioning of the boiler.

1 DESCRIPTION OF THE BOILER

L

P

D

G

S

C

M

R

880

14 0

485

1365

110

825

F

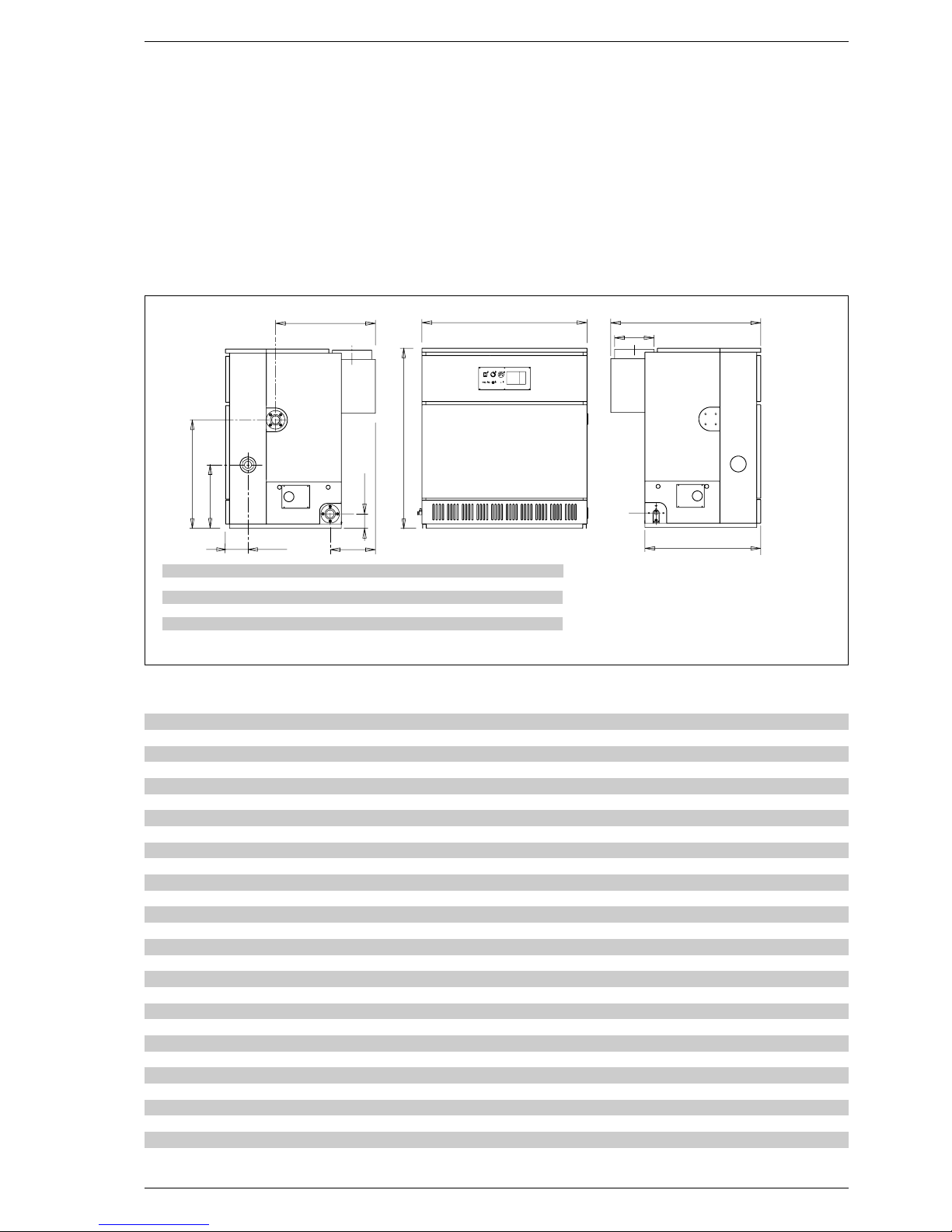

1.2 DIMENSIONS

129 151 172 194 215 237 258 279

L mm 810 920 1030 1145 1255 1370 1480 1580

P m m 1110 111 0 111 0 114 0 114 0 119 0 119 0 119 0

C mm 730 730 730 760 760 810 810 810

F mm 315 315 315 345 345 395 395 395

D ø mm 250 250 250 300 300 350 350 350

Fig. 1

R Return from heating system 2”

M Delivery to heating system 2”

G Gas 1

1

/

2

”

S Boiler drain 3/4”

1.3 TECHNICAL DATA

129 151 172 194 215 237 258 279

Thermal power kW 129,0 150,6 172,2 193,7 215,2 236,5 257,8 279,1

Thermal capacity kW 145,9 170,0 194,2 218,2 242,1 266,0 290,0 313,6

Electric power absorbed W 50 50 808080808080

Degree of electrical insulation IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20

Heating elements n° 7 8 9 10 11 12 13 14

Water content l 67,5 77,0 86,5 96,0 105,5 115,0 124,5 134,0

Max. operating pressure bar 5 5 5 5 5 5 5 5

Category II

2H3+ II2H3+ II2H3+ II2H3+ II2H3+ II2H3+ II2H3+ II2H3+

Type B11

B11 B11 B11 B11 B11 B11 B11

Maximum temperature °C 95 95 95 95 95 95 95 95

Main nozzles

Quantity n° 6 7 8 9 10 11 12 13

Methane gas ø mm 4,30 4,30 4,30 4,30 4,30 4,30 4,30 4,30

G30 - G31 ø mm 2,50 2,50 2,50 2,50 2,50 2,50 2,50 2,50

Gas rate of flow

Methane gas m

3

/h 15,44 17,99 20,55 23,10 25,63 28,16 30,70 33,20

Butane (G30) kg/h 11,50 13,41 15,32 17,21 19,10 20,98 22,88 24,74

Propane (G31) kg/h 11,32 13,19 15,07 16,93 18,79 20,64 22,50 24,34

Gas pressure at burners

Methane gas mbar 9,7 9,7 9,7 9,7 9,7 9,7 9,7 9,7

Butane (G30) mbar 28 28 28 28 28 28 28 28

Propane (G31) mbar 35 35 35 35 35 35 35 35

Gas supply pressure

Methane mbar 20 20 20 20 20 20 20 20

Butane (G30) mbar 30 30 30 30 30 30 30 30

Propane (G31) mbar 37 37 37 37 37 37 37 37

Weight kg 542 612 682 757 829 904 974 1044

Page 3

59

1.4 SHIPPING

“RS Mk.II” thermal units are supplied

in three separate packs:

PACK N. 1

Cast iron body strapped onto pallet,

complete with:

– n° 2 flanges with 2” collar for hea-

ting system delivery and return

– n° 1 blind flange

– n° 1 flange with 3/4” connection for

drain cock

– n° 2 combustion chamber doors

with cast iron indicator door

– n° 2 sheaths for thermostats and

thermometer

– n° 1 water distributor located in the

boiler return manifold, supplied in

two different lengths:

L = 406 mm vers. “129÷194”

L = 851 mm vers. “215÷279”.

PACK N. 2

Wooden crate containing:

– flue gas chamber to be assembled

– cardboard box containing skirt

– main burners, one for each element

in the body minus one

– burner manifold

– plastic bag containing:

•

n° 13 tornillos M5 x 8 screws for

anchoring burners to manifold

•

n° 32 self-tapping 12E x 1/2”

screws for fastening various parts

of the flue gas chamber and skirt

•

n° 4 M8x30 screws with plate, flat

washer and M8 nut for anchoring

flue gas chamber to boiler body

•

n° 1 3/4” drain cock with cap.

PAQUETE n° 3

Cardboard box containing:

– Gas assembly, comprising:

•

main gas valve with coil unit

•

gas pressure switch

•

pressure intake

•

second gas solenoid valve

– Electric control panel, consisting of:

•

BRAHMA SM 191.1 control device

•

interference filter

•

ignition and detection electrodes

•

sockets for connection with control panel

•

anchoring screws

– Control panel consisting of:

•

two-step control thermostat

•

manually reset safety thermostat

•

thermometer

•

gas pressure indicator light

•

device shutdown indicator light

•

illuminated main switch

•

anchoring screws.

6

7

4

2

3

1

5

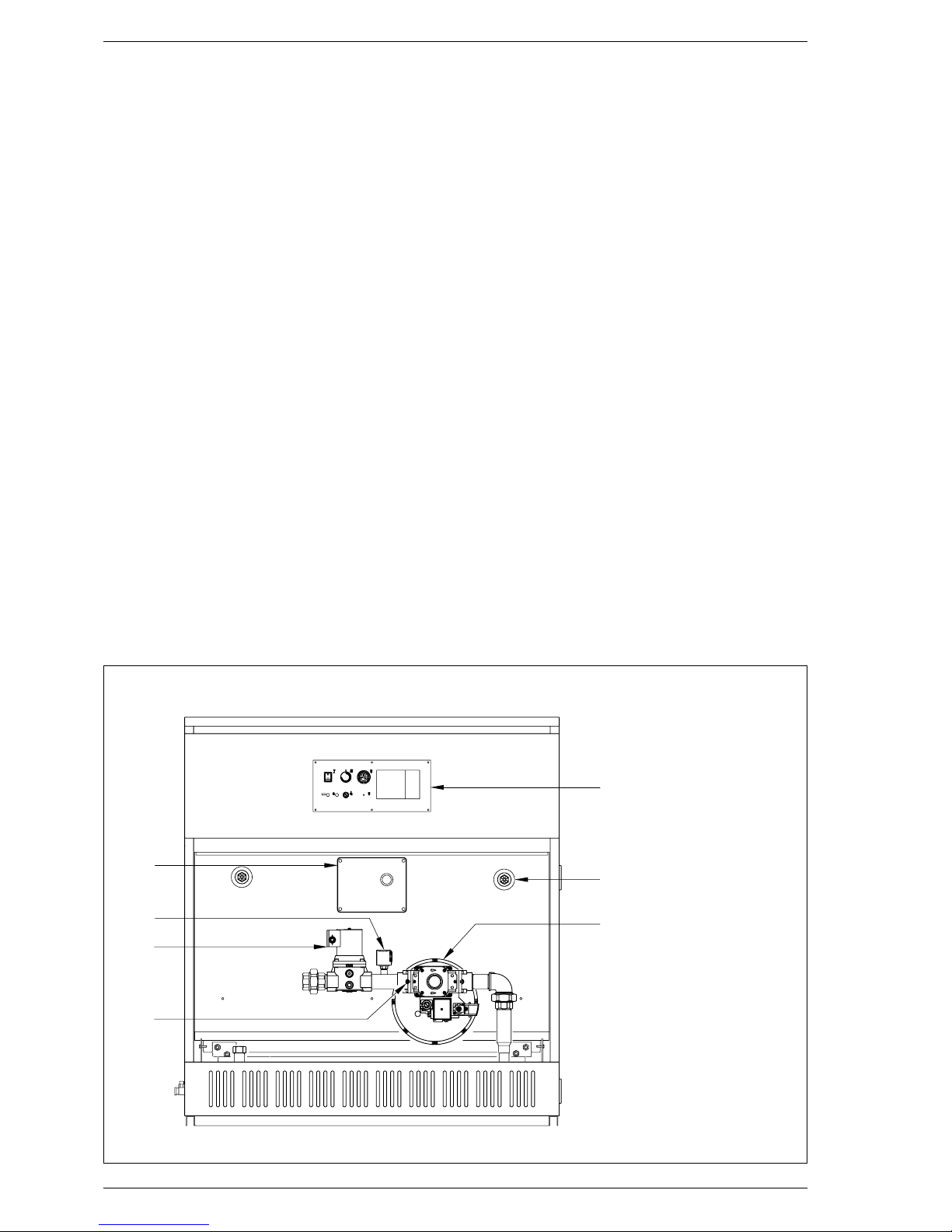

Fig. 2

1.5 FRONT INSIDE VIEW

KEY

1 Electrical control panel

2 Gas pressure switch

3 Second gas solenoid valve

4 Pressure intake

5 Control panel

6 Bulb housing sheath

7 Gas valve

Page 4

60

The boiler must be installed in a fixed

location and only by specialized and

qualified firms in compliance with all

instructions contained in this manual.

Furthermore, the installation must be

in accordance with current standards

and regulations.

2.1 BOILER ROOM

AND VENTILATION

The “RS Mk.II” boilers with a rating of

more than 35 kW must be equipped

with a technical room whose dimensions and requirements correspond to

the current safety standards. The minimum height of the boiler room must

comply with what is indicated in fig. 3 in

relation to the overall thermal capacity.

The minimum distance between the

walls of the room and the outer points

on the boiler (right and left sides and

rear) must be no less than 0.60 m. It is

possible to place a number of apparatus next to each other, on condition

that all the safety and control devices

can be easily reached. In addition, to

circulate air in the room, air vents

must be made on the outside walls for

which the surface area must never be

less than 3,000 cm

2

and 5,000 cm

2

for gas with a density greater than 0.8.

The distance between the boiler and

any fuels stored in the area must be

sufficient to prevent the fuels from reaching a hazardous temperature, and in

no case less than 4 metres.

2.2 CONNECTION WITH

HEATING SYSTEM

Connections with the heating system

should be easy to disconnect, made

with rotating pipe unions. It is always

advisable to assemble suitable gate

valves on the heating system delivery

and return pipes.

WARNING: In order to ensure proper

distribution of water in the cast iron

body, the heating system delivery

and return pipes must be connected

to the same side of the boiler. The

boiler is supplied with connections on

the right side, though they may be

moved to the left side by moving the

flanges and their collars and the corresponding water distributor.

It is advisable to ensure that the temperature dif ference between the heating system delivery and return pipes

does not exceed 20°C; installation of a

mixer valve with an anti-condensation

pump is advisable for this purpose.

WARNING: The heating system’s circulation pump(s) must be turned on

when the boiler is on. An automatic

precedence system is recommended

for this purpose.

The gas connection must be made

with seamless galvanised steel pipes

(such as Mannesmann pipes), with

threaded, sealed joints, excluding

three-piece unions except for the start

and end connections.

Pipes must pass through walls in a

sealed sheath. In determining the size

of the gas pipe from the meter to the

boiler, take into account both rate of

flow in volume (consumption) in m3/c

and the density of the gas in question.

The section of pipes in the heating

system must be sufficient to ensure

that the gas supply fulfils maximum

demand, limiting pressure drop from

the meter to any utility to no more than:

– 1,0 mbar in the case of gases in the

second family (methane gas)

– 2,0 mbar in the case of gases in the

third family (G30-G31).

On the inside of the skirt is an adhesive plate bearing technical data identifying the boiler and the type of gas

which it is set up to burn.

2.2.1 Filter on gas pipe

To prevent poor val ve functioning or, in

some cases, exclusion of the safety

devices provided, assemble an adequate filter on the gas pipe inlet.

2.3 CHARACTERISTICS

OF WATER SUPPLY

TREATMENT OF WATER USED IN THE

HEATING SYSTEM IS ABSOLUTELY

INDISPENSABLE UNDER THE FOLLOWING CONDITIONS:

– Very large heating systems (with

large water content)

– Frequent topping up of water in the

system

– When the system must be partially

or totally emptied.

2.4 FILLING THE

HEATING SYSTEM

It is a good idea to circulate water in

the pipes before connecting up the boiler in order to eliminate any foreign

matter which could affect boiler functioning. Fill the heating system slowly to

permit air bubbles to come out through

the outlets on the heating system. The

pressure at which the heating system

is filled with cold water and the preinflation pressure of the expansion tank

must correspond to, and in no case be

less than, the height of the static

column on the heating system (for

example, in the case of a static column

of 5 metres, tank pre-filling pressure

and filling pressure must at least correspond to a minimum of 0.5 bar).

2.5 FLUE

The flue for evacuation of the products

of combustion of natural draught boilers into the atmosphere must meet

the following requirements:

2 INSTALLATION

Fig. 3

H on the basis of total thermal capacity:

– no more than 116 kW: 2.00 m

– from 116 to 350 kW: 2.30 m

– from 350 to 580 kW: 2.60 m

Page 5

–

sealed against products of combustion, waterproof and heat insulated;

– made of materials which can resist

normal mechanical stress, heat and

the action of products of combustion and condensation produced by

them over time;

– ver tically oriented and free of

choking throughout its length;

– adequately insulated to prevent con-

densation or cooling of flue gases,

especially if located outside the building or in unheated premises;

– separated from combustible or

highly flammable materials by an air

space or appropriate insulation;

– provided with a chamber at least

500 mm high for collection of solid

materials and condensation underneath the entrance to the first

channel.

This chamber must be accessible

through an opening with a metal

door which does not let air in;

– circular, square or rectangular inter-

nal section; if square or rectangular,

corners must be rounded off with a

radium of no less than 20 mm;

hydraulically equivalent sections are

also permitted;

– fitted with a chimneypot at its top,

the outlet of which must be outside

of the so-called reflux area to prevent formation of counter-pressure

preventing the products of combustion from being freely released into

the atmosphere.

The minimum heights shown in fig. 4

must be complied with;

– without mechanical intake devices

at the top of the flue;

– if the flue passes through or adja-

cent to inhabited rooms, there must

be no over-pressure.

2.5.1 Flue size

The correct sizing of the flue is an

essential condition for efficient boiler

operation.

The main factors to be taken into consideration for calculating the section

are the heat input of the boiler, the type

of fuel, the percentage of CO

2

, the

mass flow of smoke at nominal load,

the temperature of the smoke, the roughness of the internal wall, and the

effect of gravity on the draught pressure, which must take into account the

external temperature and the altitude.

Table 1 shows specific parameters

pertaining to “RS Mk.II” boilers.

2.6 BOILER BODY

The cast iron body is supplied ready

assembled; if it cannot enter the boiler

room assembled, it may be supplied

dismantled.

Follow the instructions below to

assemble the body:

61

Tetto piano

0,50 m

0,50 m

Volume

tecnico

> 5 m

≤ 5m

Colmo

> 1,50 m

≤ 1,50 m

Zona di reflusso

1,50 m

2 m min.

0,50 m

oltre il colmo

45°

Tetto a 45°

Colmo

> 1,30 m

≤ 1,30 m

Zona di reflusso

0,80 m

1,20 m min.

0,50 m

oltre il colmo

30°

Tetto a 30 °

Fig. 4

TABLE 1

Thermal capacity Flue gas temperature Flue gas rate of flow

kW °C gr/s

RS 129 Mk.II 145,9 154 109,4

RS 151 Mk.II 170,0 170 111,7

RS 172 Mk.II 194,2 173 118,6

RS 194 Mk.II 218,2 153 160,8

RS 215 Mk.II 242,1 160 164,2

RS 237 Mk.II 266,0 143 206,9

RS 258 Mk.II 290,0 148 213,6

RS 279 Mk.II 313,6 154 212,5

Flat roof

30° roof

45° roof

Page 6

62

– Prepare components by cleaning

the housings of the conical nipples

with thinner.

– Introduce the plaster seam into the

groove provided for the flue gas

seal, pressing gently (fig. 5).

–

Prepare one of the two intermediate

heating elements with a 1/2” perforated stud, lubricating the conical nipples with boiled linseed oil before

introducing them (fig. 5/a).

– Prepare the head, following the same

procedure, and bring it into position

adjacent to the intermediate element.

Add only one element at a time.

– Assemble the heating elements

using the pair of tie rods supplied

assembled with their accessories,

code 6050900 (fig. 6), exerting

pressure on the upper hub and on

the lower hub simultaneously. In the

event that the elements should not

move forward in parallel during this

operation, introduce the chisel into

the tighter part and force the two

parts to be joined into parallel. The

two elements are properly joined

when their outer edges come into

contact.

– Introduce the plaster seam into the

groove in the element just mounted

and proceed to join the other elements until the body is complete.

NOTE: Before making the connection

with the heating system, test the cast

iron body at a pressure of 7.5 bar.

2.7 ASSEMBLING THE FLUE

GAS CHAMBER

The flue gas chamber is supplied in

four pieces to be joined with screws

supplied (fig. 7). It is assembled by

anchoring the right side panel (2) to

the upper panel (1) with nine self-tapping TE 12E x 1/2” screws.

The same operation must be performed on the left side panel (3). Lastly,

anchor the cleaning panel in place (4).

When assembly is complete, position

the flue gas chamber above the cast

iron body. Anchor the flue gas chamber to the body using the four plates

and the four TE M8 x 30 screws supplied (fig. 7/a).

2.8 ASSEMBLING THE WATER

DISTRIBUTOR

The water distributor on the return

line coming in from the heating

system is located on the right side of

Fig. 5

Fig. 5/a

KEY

1 Plug

2 Flange ø 35/87

3 Two-way cone

4 Tie rod L. 900 + tie rod L. 980

5 Flange ø 50/87

6 Pipe segment

7 Thrust bearing

8 Nut

9 Tightening key

Fig. 6

KEY

1 Upper panel

2 Right side panel

3 Left side panel

4 Cleaning panel

Fig. 7

Fig. 7/a

KEY

1 TE M8 x 30 screw

2 Plate

3 Washer ø 8,4

4 Nut M8

Page 7

63

the generator. If it is necessary to

move it to the left side, check that the

two rows of holes in the distributor

are directed upwards and toward the

front of the boiler (fig. 8).

2.9 ASSEMBLING THE BURNER

MANIFOLD

To assemble the burner manifold,

screw in the four TE M8 x 16 screws

on the threaded nibs of the two heads

of the boiler body (fig. 9).

2.10 ASSEMBLING THE BURNERS

Once the burner manifold has been

assembled, insert the burners in the

combustion chamber one at a time,

ensuring that the slits in the burner

are turned upward.

Push so that the burner suppor t goes

into the hole in the cast iron wall and

divides the elements (fig. 10). Anchor

the burner to the manifold with a TCB

M5 x 8 screw.

2.11 ASSEMBLING THE SKIRT

Proceed as follows to assemble the

skirt (fig. 11):

– Position the front and back supports

of the skirt base (1) between the

feet on the two heads.

– Anchor the side supports (2) and (3)

to the front and back of the skirt

base (1) with the M6 nuts supplied.

– Anchor panel (4) to panel (5) and

panel (7) to panel (8) using the connecting pins.

– and panels (7-8) to panel (9) using

connecting pins, anchoring them

together with two 7SP x 1/2” selftapping screws.

– Assemble panels (4) and (6) on the

base (3) , anchoring them on connecting pins. Proceed in the same

way to anchor panels (7) and (9) to

the base (2).

Fig. 10

KEY

1 Boiler body

2 Burner

3 Burner manifold

4 TCB M5 x 8

screw

5 Aluminium

washer ø 14

6 Burner nozzle

KEY

1 Boiler body

2 M12 x 60 stud bolt

3 Seal ø 65/95 x 2

4 Distributor pipe

5 DN50 2” collar flange

6 Nut M12

Fig. 8

Fig. 9

KEY

1 Front and rear skirt base support

2 Right skirt base support

3 Left skirt base support

4 Lower left side rear panel

5 Upper right side rear panel

6 Front left side panel

7 Rear lower right side panel

8 Rear upper right side panel

9 Front right side panel

10 Cover

11 Lower front wall

12 Upper front wall (cleaning plate)

13 Rear wall

14 Baseboard

15 Door

16 Upper front panel

Fig. 11

NOTE: The position of rings (6) and (9) may be inverted, though the

ring with the slit must always be positioned on the side where the gas

assembly exits.

KEY

1 Burner manifold

2 TE M8 x 16 screws

3 Right head

Page 8

64

– Position the lower front wall (11) by

fitting it in between the screws on

the burner manifold support

brackets and the cast iron body;

anchor the walls to panels (6) and

(9) with two 7SP x 1/2” self-tapping

screws.

– Position the upper front wall (12) by

anchoring it to panels (5-8) and to

wall (11) using four 7SP x 1/2” selftapping screws.

– Anchor the rear wall (13) to panels

(4-5) and (7-8) using the eight 7SP x

1/2” self-tapping screws supplied.

– Assemble the baseboard (14),

anchoring it to panels (6) and (9)

using connecting pins.

– Proceed in the same way to anchor

the upper front panel (16) in place.

– Assemble the cover (10) and the

door (15).

2.12 ASSEMBLING THE GAS

ASSEMBLY

Connect the gas assembly to the burner manifold as shown in fig. 12. The

gas assembly may be assembled on

the right or left side of the manifold.

WARNING: in case of the gas assembly is mounted on the left side of the

manifold, remove and rotate the gas

valve of 180° to get access frontally

at the regulations.

2.13 ASSEMBLING THE CONTROL

PANEL (fig. 12/a)

Remove the control panel’s protective

cover and inser t the wiring guard on

the front upper panel, anchoring it in

place with the screws provided. Replace the cover. Proceed to assemble the

instrument panel, anchoring it in place

with the screws provided. Insert the

instrument bulbs in their sheaths: first

insert the control thermostat bulb,

pushing it in until it touches the bottom of the sheath.

WARNING: To ensure correct temperature control in the boiler, the

bulbs of the control and safety devices must be inserted in the sheath

from the side corresponding to the

heating system delivery and return

connections. If the heating system

delivery and return connections are

on the left side of the generator, the

gas assembly must also be assembled on the left side to permit this

arrangement.

2.14 ASSEMBLING THE

ELECTRICAL PANEL

(fig. 12/b)

Remove the cover of the electrical

panel and anchor the control panel to

the lower front wall using the screws

provided. Connect the two sockets to

the plugs from the control panel. Complete the electrical panel by hooking up

the gas valve, the second gas solenoid

valve, the gas pressure switch and the

coil. Unwind the cables of the ignition

and detection electrodes emerging

from the electrical panel. Insert the

ignition electrode in the hole between

the head and the intermediate on the

gas assembly side, anchoring it to the

two stud bolts (fig. 12/c).

Perform the same operation on the

detection electrode, which will go in

the hole provided between the head

and the intermediary at the other end

of the body.

1

2

3

KEY

1 Burner manifold

2 Gas assembly

3 Bulb sheath

Fig. 12

KEY

1 Protective cover

2 Wiring guard

3 Front upper panel

4 Instrument panel

5 Instrument bulbs

6 Sheath

7 5 pole plug

8 7 pole plug

Fig. 12/a

KEY

1Cover

2 Electrical panel

3 Lower front panel

4 5 pole plug

5 7 pole plug

6

Second gas solenoid valve cable

7 Gas pressure switch cable

8 Gas valve cable

9 Coil cable

10 Detection electrode

11 Ignition electrode

Fig. 12/b

Page 9

NOTE: When assembling the two

electrodes, be very careful not to

break their ceramic coating; they

must be replaced immediately if it

is broken. All gas connections

must be tested for seal after

assembly using soapy water or

products manufactured specifically for the purpose, without using

open flame.

2.15 ELECTRICAL CONNECTION

The electrical power supply must be

connected to terminals L and N and

to the panel complying with all phase

and neutral positions as shown in

the diagram. If they are not connected properly, the flame detection circuit will not work and the boiler will

be shut down. The boiler must be con-

nected up to a single phase 230V50Hz power supply through a main

switch protected by fuses with at least

3 mm between contacts (fig. 13).

NOTE: The device must be connected to an efficient grounding

system. SIME shall not accept any

liability for damage or injury resulting from failure to ground the boiler. Turn off the power supply before

performing any operations on the

electrical panel.

65

KEY

SB Boiler shutdown indicator light

PG Gas pressure switch

EVG Main gas valve

F T 4 fuse

ER Detection electrode

E Ignition electrode

TC Step control thermostat

IG Main switch

SG Gas pressure indicator light

TS Safety thermostat

A SM 191.1 device

P Water pressure switch (not supplied)

B Coil

EVS Second gas solenoid valve

F Interference filter

TF Flue gas thermometer (Poland only)

UA Type Q 70 room thermometer (optional)

SE Outdoor temperature probe (optional)

SC Type Q Z21 boiler immersion probe (optional)

SS Type Q Z21 boiler immersion probe (optional)

PI Heating system pump (not supplied)

PB Boiler pump (not supplied)

C Control unit connectors (black - red - brown)

T Climate control

TI Insulation transformer (Belgium only)

F1 Fuse F800 mA (Belgium only)

SF Flue gas gate (not supplied)

NOTE: When connecting up the RVA 43.222 unit,

remove jumpers 12 - 13 and 15 - 16. When connecting up the flue gas gate (SF) remove the jumper

between terminals 22 - 23.

Fig. 13

KEY

1 Ignition electrode

2 M5 x 15 stud bolt

3 Washer ø 5.3

4 Nut M5 OT

5 Right head

6 Intermediate element

with nib

Fig. 12/c

Page 10

2.16 RVA43.222

CONTROL UNIT

(optional)

All boiler functions can be controlled

by the optional control unit code

8096303, supplied with an outdoor

temperature probe (SE) and boiler

immersion probe (SC) (fig. 14). Use of

the control unit requires connection of

an additional series of low voltage connectors for connection of probes and

the room temperature control unit

(the connectors are supplied in a bag

in the control panel). The bulb of the

sensor of the external D.H.W. tank

(SS), optional code 6277110, must

be inserted in the hot water sheath

and the boiler probe (SC) in the boiler

sheath. To assemble the outdoor temperature probe (SE), follow the instructions provided on its packaging. Refer

to the wiring diagram in fig. 13 for

electrical connections.

WARNING: to grant the correct

operation of the plant set the boiler thermostat at the maximum

value.

2.16.1 Features and functions

“RVA 43.222” is realized as regulator

of one boiler mono or bi-stadium or

regulator of cascade connections to

manage 16 boilers maximum.

Economical operation

– Heat production may be turned on

or off in the presence of integration

with accumulation.

– Boiler temperature control on the

basis of climate, permitting environmental compensation.

– Direct heating circuit management

(with pump) for each controller.

– Automatic adaptation to climatic

curve on the basis of the building’s

thermal inertia and the presence of

“free heat” sources (with environmental compensation).

– On/off optimisation (accelerated

heating and early off feature).

– Daily economy function calculated

on the basis of the dynamic characteristics of the building.

– Automatic summer/winter switch.

Protective functions

– Minimum and maximum delivery

temperature settings.

– Differentiated anti-freeze protection

for boiler, hot water tank and heating system.

– Boiler overheating protection.

– Pump seizing up protection.

– Burner protection with minimum

operating temperature.

Operative functions

– Simplified start-up.

– All calibration operations are per for-

med on control unit.

– Standard weekly programming.

– All calibration operations and opera-

ting settings can be read on leds

and display.

– Relay and probe tests.

Hot water production

– Daily scheduling.

–

Minimum hot water delivery temperatu-

re may be set for reduced time period.

–

Control of hot water tank filling pump.

–

Selectable priority of hot water circuit.

Other technical features

– Easy connection with digital environ-

mental unit (QAA 70).

2.16.2 Electrical connection

The electrical circuit includes a series

of connectors for installation of an

optional control unit, marked with dif ferent colours: black, red and brown (fig.

14/a). Connectors are polarised so

that order cannot be inverted.

To install the control unit, connect these

connectors and remove jumpers 13 14 and 16 - 17 from the terminal board

(fig. 13). The control unit also permits

use of room temperature control units

and probes; polarised, coloured connectors for these are located in a bag inside the control panel.

66

12

Fig. 14

KEY

1 Plastic hole cover

2 Optional control unit

12 3

Fig. 14/a

KEY

1 Control unit connectors (black - red - brown)

2 Fuse (T 4 )

3 Terminal boar d

Loading...

Loading...