Powrmatic PG Series G 03, PG Series G 04, PG Series G 05, PG Series G 06, PG Series G 07 Installation, Operation & Maintenance Manual

r

Cast iron

Triple - Pass Design

G 03 - G 07 ( 28,5 kW to 65,7 kW )

PG Series Range Of Floor Standing Oil / Gas Fired Boile

PG SERIES BOILER

Contents :

3

Certification 3

Symbols 5

Introduction 4

Guarantee Terms 5

General Warnings 5

General Characteristics of PG Series Boiler 7

Delivery Conditions 7

PG Series Cast Iron Boiler-Technical Data 8

PG Series Cast Iron Boiler-Dimension 9

Recommended Minimum Distance for Installation 10

Plumbing Instructions 11

PG Series Cast Iron Boiler,Cabin Part 12

PG Series Cast Iron Boiler Spare Parts List 13

Instructions For Connecting The Fuel Tank 14

Boiler Standard Control Panel - Electrical Diagram 15

Cast Iron Sections with High Efficiency Three Draught Design 16

Operating Instructions 17Operating Instructions 17

Loading and Unloading Boiler Water 17

Water Circulation 18

Gas Side Resistance , Exit Flue Gas Temperature 19

Important Instructions About Boiler Room 20

Boiler Room Ventilation 21

Instructions For Product Disposal 22

Positioning the Boiler 22

Checkings And Starting The Boiler 23

Failure First Control 24

Checking the Safety Temperature Limiter 24

Care Instructions 25

Cleaning The Boiler 26

Burner Door And Burner Connection 27

Burner Connection Flange Size 28

Transportation and Storage 29

2

Certifications

PG Series boilers are in compliance with the ;

EC Directives

(90/396/EEC) Gas Appliances Directive

(73/23/EEC) Low Voltage Directive

(89/336/EEC) Electromagnetic Compability Directive

92/42/EEC Efficiency Directive

Ref Standards :

EN 303-1

EN 303-2

EN 304

EN 60.335.1

EN 50165

EN 550114-1

EN 550114-2

EN 61000-6-3

EN 61000-3-2

EN 61000-3-2

EN 61000-3-3

PG Series Boiler CE approved , No: CE - 1015BR0259

Symbols

Caution danger

Important

Info

3

Introduction

First of all we'd like to thank you for choosing cast iron boilers.

In this manual you will find the instructions for our three pass cast iron boilers suitable for both gas and liquid

fuel. PG series hot water boilers and related information for installation, operation and maintenance of the boiler.

For high efficiency and proper working conditions please read this manual carefully.For more information please

check the product catalog or get in touch with technical services.

Please do not touch or remove any parts of the boiler for starting, adjusting or repairing the boiler except the

processes written in this manual.

Please call our services and technical officials for installing the boiler.

Our licensed frenchisers and services will give you instructions about working principals, conditions and care

instructions after installing and starting the boiler.

And our professionals will be glad to answer all your questions at any time.

Licensed services are in your service all kind of problems and questions. You may find the contact

informations in the licensed services manual which will be given to you with the boiler.

4

Guarantee Items

� In the terms of obeying the instructions,warnings, points in this manual and the standards in charge (EN norms

and directives must be applied if mentioned standards are not in use.) cast body is under 5 (five) and other parts

are under 2 (two) years guarantee.

� Guarantee Document must be filled by the frenchiser that you have bought the boiler and must be send to

us.

� Assembling and installing faults and problems, problems that will be occured because of wrong upkeeping

and working are not under guarantee. Problems related to lime coating or/and any other materials coating and

corrosion on the heat transfer units of the boiler are not under guarantee conditions.

� Minimum life of these kind of products is mentioned as fifteen years by the minister of industry and commerce

Manufacturer and sales companies are to suplly all spare parts and services to the

clients in this period.

� The problems happened by the following mentioned issues are out of guarantee conditions

� Boiler without guarantee document

� Boiler fixed,repaired or adjusted by unauthorized services

� Boilers with wrong type selection, wrong installing and assembling, boilers used wrong conditions and out of aim.

� Problems occured while transportation, stocking or problems occured under atmospheric conditions.

� The problems occured by physical or chemical effects.

� Wrong fuel selection and the problems occured by fuel conditions,

� Wrong installation or connection to the boiler to water and other plumbing systems.

� Weak flue (gas output) system

� Weak flue (gas output) system

� The problems occured by scratching,touching to control and safety systems of the boiler.

� Cold water load while the boiler is hot

� Starting the boiler without water or required water in it.

General Warnings

� PG series cast iron boilers are designed for working with hot water heating and/or hot water plumbing and

produced with the proper technology and materials suitable to this design.This design is restricted to use out

of it's aim of use.

� PG series boilers are delivered completely assembled.

Removing or re-assembling of the boiler should also be made by licensed Rima services, if not the risk of

damage is high.

� In the assembling of the boiler; there must be a proper and safe concrete platform for to put the boiler on.

� In the assembling of the boiler, an empty space must be left from sides for safety requirements and for future

repairing operations.

� Starting and first operation of the boiler must be made by authorized Rima technicians.

� Do not add or pump water to the boiler or plumbing system as it is working and hot. For adding water to the

boiler or to the system please wait for water temperature to reach 40 ºC. Circulation pump must surely be

started while adding water to the system.If not,the sections may crack.

5

If the boiler will be kept off for a long time the electric system must be shut down from the main fuse. The

electric must be cut off from the main shelter/fuse as the boiler is in repair,service or cleaning.

In summer months, when the boiler is off for a long term, for preventing probable problems with circulation

pumps, must be started 1 -2 times per month for 5 minutes. (The water with chalk can cause problems if the

pump is not used for long time period.)

The periodical controls of the boiler and the burner must be done. If not, the boiler can lose efficiency and the

fuel amount used can increase.

The capacity choice of the boiler must be made according to the projects that prepared properly in the terms

of related standards.If not the efficiency will be low.

PG series boilers are produced for heating only. For heating the sanitary water another equipment such as

water heater or heat exchanger is needed. And for proper efficiency in this operation,correct water heater or heat

exchanger must be selected.

PG series boilers are delivered without burners. For suitable burner selection please get in touch with Rima

technicians. Suitable burners must be selected for taking high efficiency.

If the boiler is stopped automatically because of overheating do not add cold water to the boiler for restarting.

In this case wait for the boiler to cool down and try- restarting.If it does not start please get in contact with

technical services.

In cleaning, repair and other care operations the original spare parts which approved and manufactured by Rima

must be used.

The periodical and yearly controls of the boiler must be done properly and on time.Natural gas is a clean fuel and

doesn't make a lot of dirt in the boiler.But the boilers that liquid fuels are used as fuels are much more easily ge

doesn t make a lot of dirt in the boiler.But the boilers that liquid fuels are used as fuels are much more easily ge

dirt. Controls and care operations of the boiler is needed for keeping high efficiency and long life of the boiler.

Repairing and periodical controls of G series boilers require profession. In this manual the responsibilities and

required information for users of the boiler is declared. Besides these declared operations, boiler must not be

started by a person rather than the user or one our technicians. Please do not try to make adjustment or do not

touch any parts of the boilers.

The electric of the burner and the boiler is supplied by city electric network.In this case the elecric and lighting

systems of the boiler room, burner and boiler electrical connections, grounding line of control panel and boiler

must be made by professionals under the required and related standards.

In this manual you will find informations only for the boilers. Please do not forget to get the instruction manual

of the burner that you purchase from the manufacturer of it. Burner is not delivered with the boiler. In this case

we do not give any guarantee for the burner that you purchase. Please get the quarantee certificate for the

burner from your supplier.

Please be sure that the front door ( burner door) for the boiler is strictly closed and burner connections are

properly made as the boiler is working.

�

Do not touch hot water connections or the flue outlet when the boiler is operating.

6

General Characteristics of PG series Boilers

PG series boilers are, blowing burner, cast iron sectioned, between the capacities 28,5 – 65,7 kW with proper

burner connection, works with gas or liquid fuel in 5 different ( 3 – 7 sections ) type.

PG series boilers operating pressure is 3 bar maximum, and working temperature is 90 °C maximum.

In PG series boilers, heat transfer surface areas are increased by the special wings in the burning room and

chimney ways.This increases the high heat transfer ability of cast iron boiler to the maximum level.

PG series boilers are cast iron sectioned boilers. This brings easy assembling and easy capacity increasing by

adding sections to the boiler. The transportation and set up of the boiler is easy because boiler is assembled

in boiler rooms It is easily to carry or shift position without breaking walls etc.

PG series boilers are casted with special alloy, which is durable for thermal expansions and changes, EN GJL 200.

They are long life boilers according to this special cast iron alloy.

With the help of vertical and three pass specially designed sections burning gases pass three times in the

boiler and transmits burning energy to the water inside the sections at high level.

PG series boilers are high efficiency boilers. ( According to the fuel bottom heating value % 91 – 93 ). With this

high efficiency and perfect isolation more energy is gained with less fuel. Heat loses are minimized on G series

boilers.

By appropriate burning room, heat transfer surface, turbulator, collector and isolation high heat transfer and optimum flue gas emition results are provided.

Delivery Condition

s

Boiler sections are delivered as assembled or not assembled according to the boiler room specifications and

dimensions. In not assembled deliveries, sections and assembling aparats are delivered on a pallet, cabins,

isolation and other elements are delivered in a box. Rima technicians make the assembling of the boiler.

7

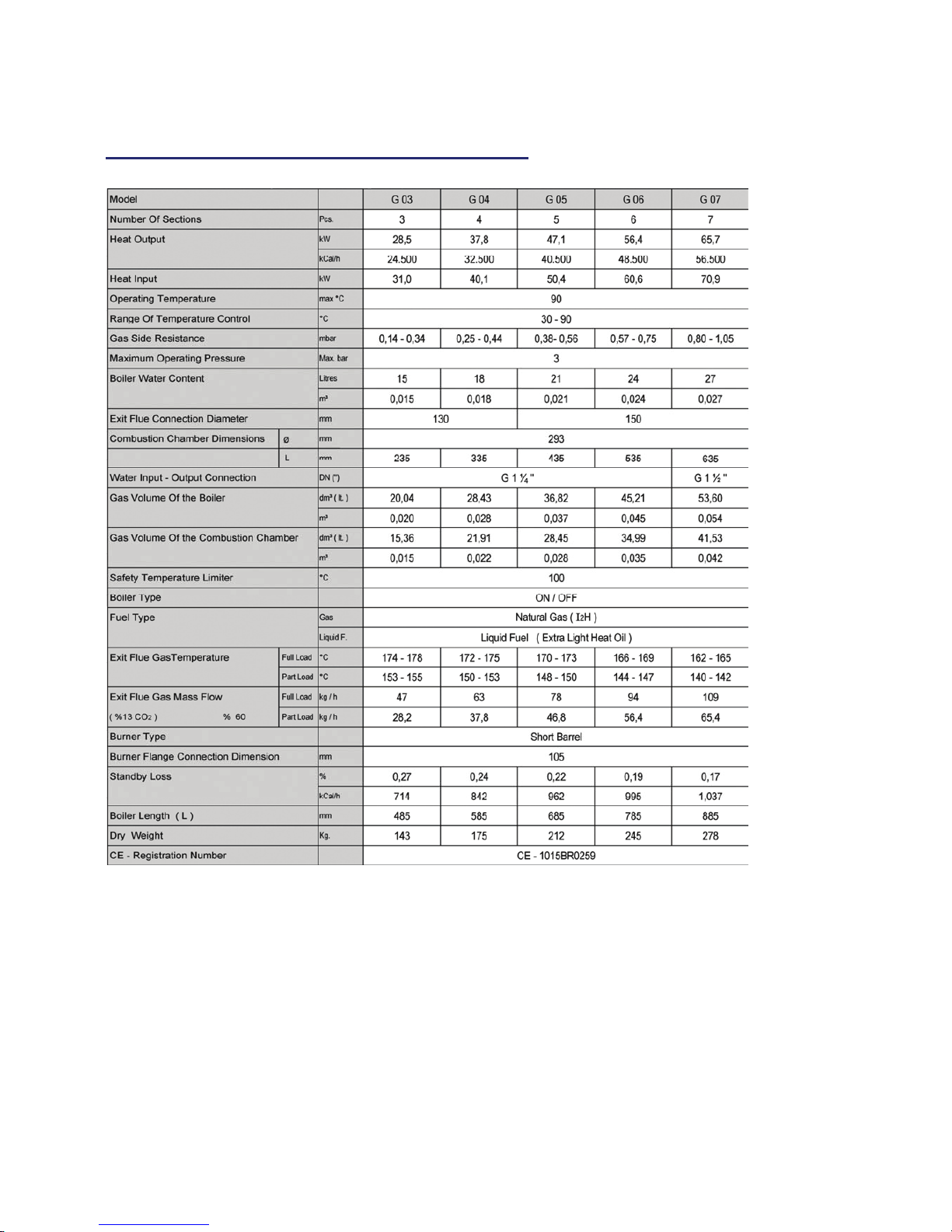

PG Series Cast Iron Boiler - Technical Data

8

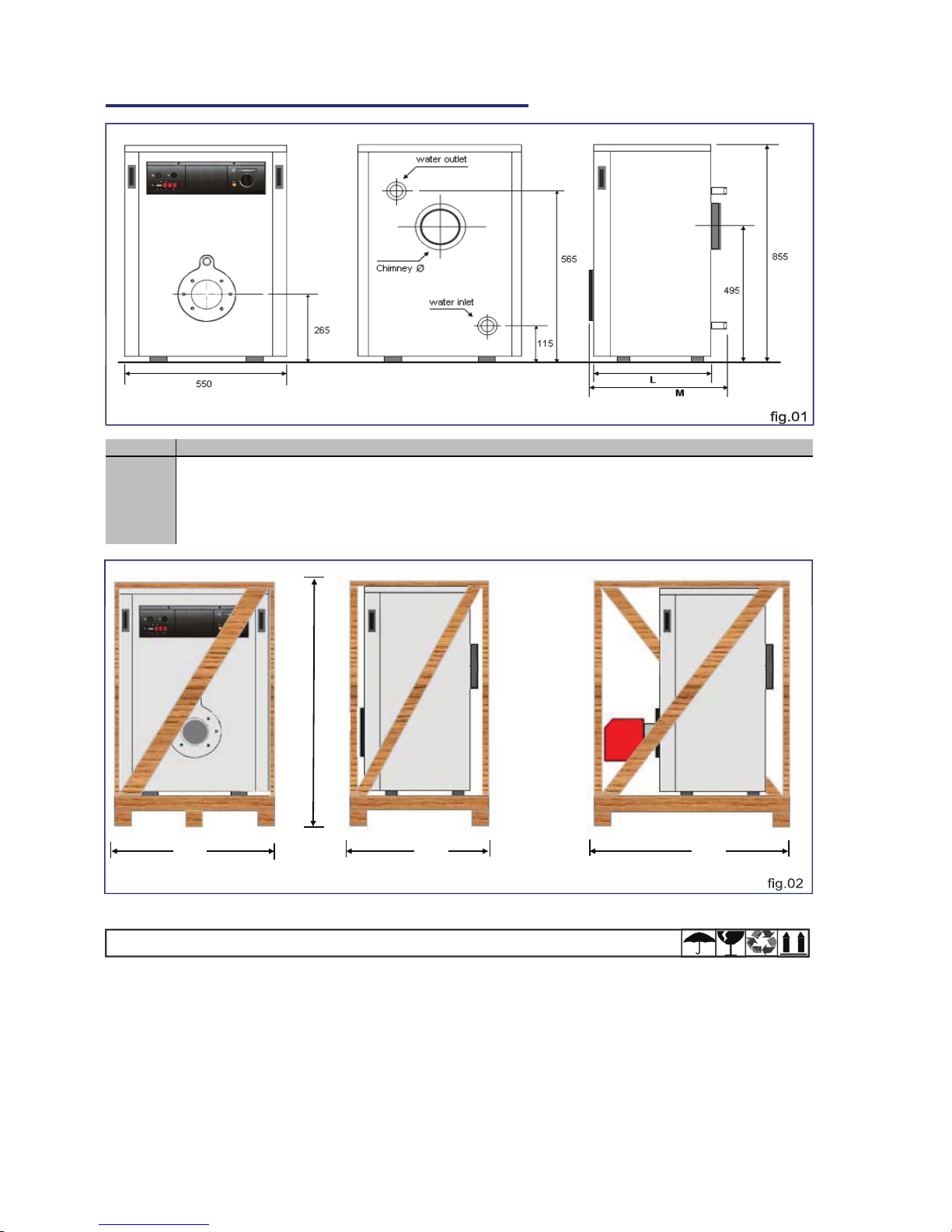

PG Series Cast Iron Boiler - Dimensions

Serie

L (

mm) M (mm) A (mm) B (mm) C (mm) D (mm)

PG 03..

400 485 600 1.055 550 850

PG 04 500 585 600 1.055 650 950

PG 05 600 685 600 1.055 750 1.050

PG 06 700 785 600 1.055 850 1.150

PG 07 800 885 600 1.055 950 1.250

Notice: Please obey to the meanings of the symbols on packaging for healty care.

Rima PG series boilers are delivered as mounted on a wooden pallet with bubble nylon protection surrounded and

in wooden cross case.

A

B

C

D

9

Loading...

Loading...