Page 1

OUH Suspended Oil Unit Heater

Industrial & Commercial Heating Systems.

Issue 5.1 September 2015

Users, Installaon and

Servicing Instrucons

WARNING: THIS APPLIANCE MUST BE EARTHED

H E A T I N G / / V E N T I L A T I O N / / A I R C O N D I T I O N I N G

Page 2

powrmatic

Certificate of Guarantee

Dear Customer

This is to certify that this heater is guaranteed for two years parts and one year labour

from the date of original commissioning. The heater must be commissioned within 4

weeks of installation.

To make a claim

In the first instance you must contact your appliance supplier, or installer and provide:-

1. The appliance type and serial number.

2. The original commissioning documentat

ion.

3. As much detail as possible on the fault.

Your supplier, of installer, will then contact Powrmatic to make a guarantee claim on

your behalf.

Conditions of Guarantee

1. The heater must have been installed by a competent regognised instraller, and in

accordance with the manufactures instructions, building regulations and local

regulations.

2. The heater has been professionally commissioned

, within 4 weeks of installation,

and a copy of the Commissioning Sheet returned to Powrmatic.

3. The heater has been maintained on a yearly basis by a competent servicing

company.

4. The heater has been used in accordance with the manufactures instructions.

5. The correct specification fuel has been used.

6. No unauthorised repairs of modifications have been made.

7. Powrmatic ‘General Conditi

ons of Sales’ have been observed.

8. Except for the obligation of Powrmatic Ltd to perform warranty repairs during the

guarantee period Powrmatic will not be liable in repect of any claim for direct or

indirect consequential losses, including loss of profits or increased cost arising from

loss of use of the heater, or any event arising there from.

Exclusions

1. Gaskets and fan belts are not included in the guarantee.

----------------------------------------------------

Powrmatic Ltd, Hort Bridge, Ilminster, Somerset, TA19 9PS

Tel:01460 53535 Fax: 01460 52341

Web: www.powrmatic.co.uk e-mail service@powrmatic.co.uk

Important: This certificate must

be kept with the appliance

Failure to provide a copy of the commissioning sheet invalidates the heater waranty

Installer

Date :_____________ Signed ____________________________________________Installer

Commissioned

Date :_____________ Signed _______________________________Commissioning Engineer

Page 2 OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015

Page 3

OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015 Page 3

Dear Customer - thank you for choosing Powrmac.

We appreciate you buying one of our high quality products and know that you have made the best

choice. By choosing Powrmac, you are invesng in UK manufacturing & its workforce. We pride

ourselves by manufacturing products that provide clean, comfortable and safe working environments worldwide together with the personal & professional service and back-up you deserve. If you

have any quesons or concerns regarding this product, please contact our Technical Support Team by

calling 01460 53535.

Users, Installaon and Servicing Instrucons

CONTENTS

Title Secon Contents Page

User Instrucons 4

Pre Installaon 1.1 Introducon 5

1.2 Technical Data - Size Data 6

1.3 General Requirements 8

Installaon 2.1 Fing the unit 11

2.2 Air Distribuon 12

2.3 Commissioning and Tesng 13

Servicing 3.1 Servicing 14

Data 4.1 Short List of Parts 15

Figure Title Page

1. Limit Thermostat 15

Table Title ` Page

1. Dimensions 7

2. Specications 7

3. Electrical Loadings 1ph 8

4. Burner Settings - 35sec Oil 8

Page 4

Page 4 OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015

A) Checks before lighting the Air

Heater

The following preliminary checks should be made before

lighting the heater(s)

a) Ensure that the ELECTRICAL supply to the heater is

switched OFF.

b) Check that all warm air delivery outlets are open.

c) Check that the thermostat is set at MAX.

d) Check that the clock control is set to an ON period.

e) Check that any other controls are calling for heat.

f) Ensure that the Summer/Winter switch is in the Winter

position.

g) Check that the overheat reset button has not operated.

B) Lighting the Air Heater

NOTE: If it is not possible to light the heater after

2/3 attempts contact your installer.

1. Switch on the electrical supply at the isolator.

2. Press the limit interlock reset switch on the control box

of the heater. (Note: This step is not performed again

unless there is an interruption in the electrical supply to

the heater).

3. The burner air fan will run and after a pre purge period

of approximately 30 seconds the ignition spark will be

generated and the oil valve opened.

The main burner will then start.

NOTE: If the main burner fails to light the burner

will go to lockout and the lockout indicator / reset

button on the burner control box will be illuminated. To restart the burner push the lockout reset

button. Additional, more easily accessible,

controls may be fitted that mimic the lockout

indicator and reset button functions.

If the unit will not light after four or five attempts

then shut down the unit and call in a service engineer.

C) To Shut Down the Air Heater

1. For Short Periods:

Turn the room thermostat to the OFF or lowest setting.

2. For Long Periods:

Turn the room thermostat to the OFF or lowest setting.

Wait approximately 4-5 minutes for the main air fan of the

heater to stop running and the turn off the oil supplies and

electric supplies to the heater.

D) Description of Operation

Important: All heaters must be controlled by the

fitted external controls and not by use of the main

switch in the electrical supply to the heater.

The burner start up sequence will commence when the

controls

e.g. Timeclock, room thermostat etc. call for heat. The

burner air fan will run and after a pre purge period the

burner will light.

Approximately 2/3 minutes after the burner lights the

heater fan will automatically start. When the external

controls are satisfied the burner will be turned off and

approximately 4/5 minutes later the heater fan will automatically stop.

D.1) Summer / Winter Modes

Certain types of external controls will provide for two

modes of operation i.e.

Summer: The heater fan alone will run at the dictate of the

external controls to provide air movement.

Winter: The heater will operate normally.

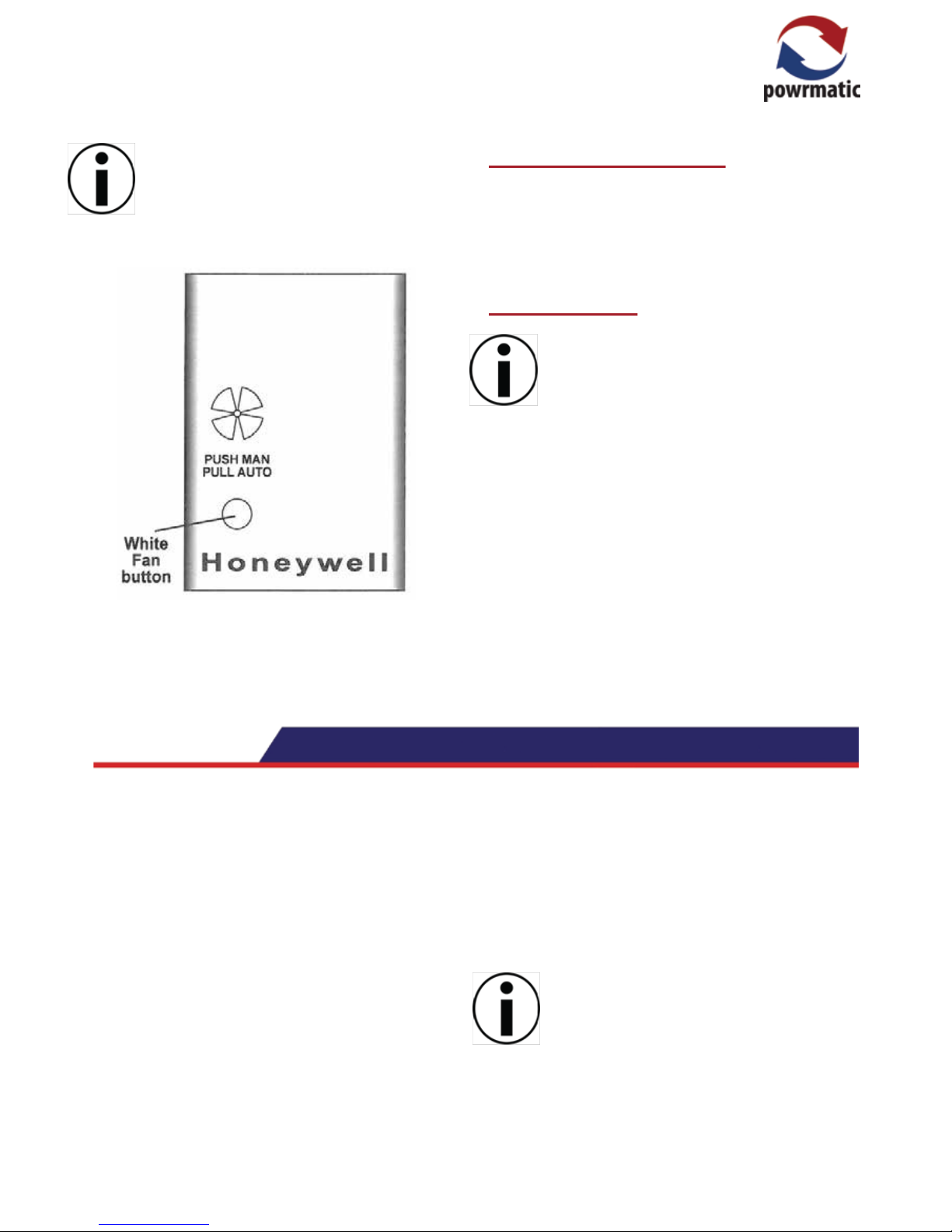

E) Fan and Limit Control

The fan and limit controls are mounted on the top of the

air heater.

1. Main Air Fan MAN / Auto

When the white button (Refer to Figure following) is

pushed in the fan will run continuously i.e not controlled

by any external controls e.g. Timeclock. When the white

button is pulled out the fan will start and stop automatically in conjunction with the burner. See Section 2.

2. Limit Thermostat

This operates if high temperatures within the heater are

detected, the burners are turned off and a red indicator

light on the front of the heater is illuminated. The fault

condition must be identified and rectified and the thermostat manually reset.

When the unit has cooled push the reset switch on the

front of the heater to reset the limit thermostat interlock

relay, the red indicator light will go out and the unit is operational again.

Note: The limit thermostat(s) can only be reset

once the unit has cooled down.

Unless the cause of the fault condition is readily

obvious, for example a power cut whilst the

heater was operating, a service engineer should

be contacted.

Users Instructions

Page 5

1.1 Introduction

The Powrmatic OUH Range is a range of oil fired forced

draught, closed flue, fanned circulation air heaters having

an output range of 20kW to 60kW .

The heaters are designed for suspension from suitable

roof points, or alternatively mounted on purpose designed

wall brackets, and are intended for heating commercial or

industrial premises.

The OUH-F has an axial type fan assembly fitted at the

rear of each heater to circulate the air being heated

across the combined combustion chamber/ heat

exchanger. A centrifugal fan variation is presented in the

OUH-C range for ducted applications. The OUH-D range,

in having no fan fitted, allows for ducted use where the air

moving unit is remote from the heater.

All units are fired with a forced draught packaged oil

burner complete with all necessary safety controls. Each

air heater must be connected to an individual closed flue

system only.

Fuel Types

All units are supplied as standard for use with 35sec fuel

and can be supplied for use with 28sec fuel as an option.

In accordance with guidelines from our burner supplier,

Riello, the burners fitted to Powrmatic oil-fired heaters are

suitable for fuels with a bio content of up to 10% only.

For fuels with a bio content of more than 10%, please

consult our Technical Department.

IMPORTANT

Service and Maintenance Engineers shall ensure

that replacement items are fitted, adjusted and

set in accordance with the data and detail set out

in these instructions. If in doubt consult P o w r matic Technical Department.

OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015 Page 5

Note: The limit thermostat interlock relay will

require resetting after loss of the electrical supply

to the heater regardless of whether the limit

thermostat has operated.

Limit Thermostat

F) Fan and Limit Control

Regular servicing is essential to maintain efficient, reliable

and safe operation of the heater. Users are strongly

recommended to have the heater serviced by a qualified

person at least annually and preferably at the end of the

heating season.

G) IMPORTANT

Free access must be maintained to and around

the heater for servicing purposes and the air

supply to the heater must not be restricted in any

way. Combustible materials must not be stored

adjacent to the heater.

All Powrmatic OUH heaters use oil and electricity

to power them, they may also contain moving

parts such as pulley belts.

It would be hazardous to tamper with or attempt

to service unless you are a competent person in

the field of Oil and Electrical work.

If you have any safety questions reference the

servicing and installation of any of our heaters

please do not hesitate to contact our head office

for expert advice.

Your safety is paramount to us.

Page 6

Page 6 OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015

1.2 Technical Data

OUH20/F

OUH20/C

OUH30, 45 & 60/F

Rear View

EF F

D

A K

Side View

B

C

M

Front View

Rear View

L50mm

Side View

J

H

G

Front View

Rear View

E F

D

A K

Side View

B

C

M

Front View

Page 7

OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015 Page 7

OUH30, 45 & 60/C

Table 1. Dimensions

Note: D is the norminal flue diameter.

Table 2. - Specifications

Rear View

50mm L

Side View

J

H

G

Front View

Model

OUH 20

555 610 100 465 101 549

410

370340

85

OUH 30

270

Type

668

N/A N/A

780 847 125 490 276 490

494

270975

636 418

131

N/A N/A

N/A

N/A

N/A

N/A

F

F

C

C

A

B

C

D

E

F

G

H

J

K

L

M

MAXIMUM

DUCT

RESISTANCE

MODEL

INPUT

(Net)

OUTPUT

kg

kW m³/s Pa kW

OUH20

21.92 20.0 0.5758

OUH 30

32.15 30.0 0.6847

OUH 45

49.40 45.0 1.0814

OUH 60

65.57 60.0 1.4072

N/A 0.040 53

140

0.373

91.5

N/A

0.130

126

187 1.100 142

N/A 0.300 126

100 1.100 142

N/A 0.760 126

50 1.100 142

F

C

F

C

F

C

F

C

HIGH FIRE

AIR

VOLUME

FAN

MOTOR

WEIGHT

NOISE

LEVEL

dB(A) @ 3m

N/A

N/A

N/A

N/A

46

54

52

53

THROW

8.5

16.1

25.3

34.1

N/A

N/A

N/A

N/A

lt/h

2.17

3.19

4.89

6.51

FUEL

INPUT

OUH 45 780 847 125 490 276 490

494

270975

636 418

143

N/A N/A N/A

N/A

F

C

OUH 60 780 847 125 490 276 490

494

270975

636 418

165

N/A N/A N/A

N/A

F

C

Page 8

Page 8 OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015

Table 3 - Electrical Loadings 1ph

Table 4 - Burner Settings - 35sec Oil - Net CV (i) = 42.69 Mj/kg

1.3 General Requirements

1.3.1. Related Documents

Installation of air heaters must be in accordance with the

relevant requirements of:

BS 5410: Part 2: 1978 Code of Practice for Oil Firing

Installations of 45kW and Above

The Building Regulations

The I.E.E. Regulations

It should also be in accordance with relevant requirements of the local authority and fire authority, in addition

the following British Standard Codes of Practice must be

observed CP.3 Ch IV Precautions Against Fire Part 2

Shops and Departmental Stores Part 3 Office Buildings.

OFTEC Technical Book 3: Domestic & Commercial

requirements for oil storage and supply equipment.

OFTEC Technical Book 4: Oil fired appliances & system

installation requirements.

OFTEC Easy Guides to non domestic oil feed pipes and

oil storage.

1.3.2 Location

The location chosen for the air heater must permit the

provision of a satisfactory flue system and an adequate air

supply. The location must also facilitate ease of servicing

and satisfactory air circulation around the heater.

The air heater must be installed strictly in accordance with

any fire regulations or insurance company's requirements

appertaining to the area in which the heater is located,

particularly where special risks are involved such as areas

where petrol vehicles are housed, cellulose spraying

areas, and wood working departments etc.

The air heater must be installed either:

(a) suspended by chains or straps of adequate strength to

safely carry the weight of the unit and ancillary equipment

or

(b) On specifically designed cantilever brackets from a

non-combustible wall or

(c) On a level non-combustible surface which is capable

of adequately supporting the weight of the air heater and

any ancillary equipment.

The heater must not be installed in conditions for which it

is not specifically designed e.g. highly corrosive atmospheres, vitiated atmospheres, or where adverse wind

conditions may be experienced. Where the location of the

heater is such that it might suffer external mechanical

damage e.g. from overhead cranes, fork lift trucks etc. it

must be suitably protected. Any ducting should be kept as

short and direct as possible having regard to the distribution of the heated air.

/F Models /C Models

MODEL

PLATE

AMPS

(A)

START

AMPS

(A)

RUN

AMPS

(A)

FUSE

RATING

(A)

OUH 20

2

OUH 30

0.18 0.34 0.16 3.3 6.5 4.2

1.05 0.33 9.8 18.0 7.2

OUH 45

2.40 1.20 9.8 18.0 7.2

5

NOMINAL

MOTOR

R.P.M.

PLATE

AMPS

(A)

START

AMPS

(A)

RUN

AMPS

(A)

FUSE

RATING

(A)

OUH 60

5.90 3.00

0.60

3.30

1.25

9.8 18.0 7.2

900

1230

10

900

Riello Burners

Nozzle Pump Head Setting Combustion Nominal

Model Type Make Size Angle Type Pressure No. Postion Air Setting CO

2

%

US Gal ° bar

OUH 20 3GB Danfoss 0.50 60 S 9.5 N/A Fixed 2.0 12.5

OUH 30 G10 Danfoss 0.60 45 S 14.3 1.0 N/A 1.5 12.8

OUH 45 G10 Danfoss 1.00 45 S 12.2 3.0 N/A 2.0 12.0

OUH 60 G10 Danfoss 1.25 45 S 15.6 3.0 N/A 5.0 12.0

950

910

1370

NOMINAL

MOTOR

R.P.M.

5

3

Page 9

OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015 Page 9

Any combustible material adjacent to the heater and flue

systems must be so placed as to ensure that its temperature does not exceed 65°C (150°F).

1.3.3 Main Storage Tank and fittings

Construction and installation should be in accordance

with:

(a) BS 5410 Part 2 Section 6

(b) BS 799 Part 5

(c) BS 1563

The latter three standards apply to cast iron sectional,

mild steel sectional, and mild steel welded tanks respectively and therefore must be applied appropriately.

1.3.4 Service Tanks and fittings

1.3.4.1 Construction

These should be designed and constructed in accordance with BS 799 Part 5

1.3.4.2. Installation

The installation should be in accordance with:- BS 5410

Part 2.

In addition the service tank installation must comply with

local regulations and by-laws and with the requirements

of insurance companies

1.3.5 One Pipe System (Storage to

burner)

1.3.5.1 General

Refer also to the detail provided in the burner handbook

regarding pipe sizing. These must be generally in accordance with B S 799 Part 3 and BS 5410 Part 2.

Particular attention is drawn to the following:

a) Pipe jointing compounds must be capable of withstanding the solvent action of the fuel oil under all operating

temperatures and pressures. Jointing compounds

containing oil shall not be used. Hemp and other fibrous

materials shall not be used as packing for screwed joints.

b) Soft solder copper tube fittings and galvanised pipes

and fittings must not be used.

c) Oil lines must be completely air-tight.

d) The pump suction must not exceed a maximum of 0.4

bar (30cm Hg). Beyond this limit gas may be released

from the oil.

1.3.5.2 Single Pipe System - Gravity

Feed

Warning: The burners are supplied adjusted for a single

pipe system. If the burner is to be used on a twin pipe

system the Internal bypass plug of the burner oil pump

must be fitted. Refer to the burner instruction booklet.

Ideally the return pipe should terminate within the oil tank

at the same level as the suction line, both being below the

minimum oil level.

1.3.6 Fire Valve

It is recommended that the fire valves should be installed

as follows:

1. Main storage to service tank supply (if applicable)

2. Main storage to burner supply

3. Service tank to burner supply (if applicable)

Fire valves should be installed generally in accordance

with the requirements of BS 799: Part 5. The fire valve

should be situated in an easily accessible position as near

the tank as possible and where practicable within the

boundary of the tank chamber or catchpit retaining wall.

1.3.7 Flue System

The flue system should generally be in accordance with

BS 5410 Part 2.

Materials used for the flue system should be mechanically

robust, resistant to internal and external corrosion,

non-combustible and durable under the conditions to

which they are likely to be subjected. Prevention of

condensation within the flue should be an important factor

in the design of the flue system. In order to minimise

condensation the use of double walled flue pipe or insulation is recommended.

Where condensation in the flue is unavoidable, or rain

ingress is possible, provision must be made for a condensate drain connected to a suitable drain or gully. The

condensation pipe from the flue to the disposal point

should be of non-corrodible material of not less than

22mm (¾ in) size.

Facilities should be provided for disconnecting the flue

pipe from the air heater for inspection and servicing

purposes. Bends with removable covers should be fitted

for inspection and cleaning purposes where considered

appropriate.

The flue should terminate in a freely exposed position and

must be situated such that products of combustion do not

enter any opening in a building in such concentration as

Page 10

Page 10 OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015

to constitute a health hazard.

1.3.8 Combustion & Ventilation Air

Supply

Where the air heater is to be installed in the space to be

heated it requires the space containing it to have a permanent air vent direct to outside air. The air vent should have

negligible resistance and must not be sited in any position

where it is likely to be easily blocked or flooded, neither

should it be positioned adjacent to an extraction system

carrying flammable vapour.

The air supply requirement that follows is related to the

maximum rated heat input of the heater, or heaters if more

than one is installed in the same space.

Total Input Rating Air Vent Area

of Air Heaters (Air direct-from outside)

Up to 60kW 4.5 cm²/kW in excess of 7kW

From 60kW up to 730kW 4.5 cm²/kW

Where the air heater is to be installed in a plant room, the

heater requires the plant room housing it to have permanent air vents communicating directly with the outside air,

at high and low level. Where communication with the

outside air is possible only by means of high level air

vents, ducting down to floor level for the lower vents

should be used. Air vents should have negligible resistance and must not be sited in any position where they are

likely to be easily blocked or flooded, neither should they

be positioned adjacent to any extraction system carrying

flammable vapour.

Grilles or louvers should be so designed that high velocity

air streams do not occur within the plant room.

The air supply requirements stated below are related to

the maximum rated heat input of the air heater(s). The

minimum free area requirements of the air vents is given

below.

Total Input Rating Position of Air Vent Areas

of Air Heater(s) Vents (Air direct from

outside)

Up to 730kW High Level 4.5cm²/kW

Low Level 9.0 cm²/kW

1.3.9 Air Distribution System

Where single OUH units are required to cover a large floor

area, and in buildings with high roof or ceiling heights

Calecon thermal economiser units should be fitted to

ensure even heat distribution and minimise stratification.

Care should be taken to avoid impeding the air throw with

racking, partitions, plant or machinery etc. Various outlet

configurations are available as optional extras to modify

the air throw pattern to suit particular site conditions.

For ducted units all delivery and return air ducts, including

air filters, jointing and any insulation or lining must be

constructed entirely of materials which will not contribute

to a fire, are of adequate strength and dimensionally

stable for the maximum internal and external temperatures to which they are to be exposed during commissioning and normal operation.

Where inter-joist spaces are used as duct routes they

should be suitably lined with a fire-resisting material.

A full and unobstructed return air path to the air heater(s)

must be provided.

If the air heater(s) is installed in a plant room the return air

intake(s) and the warm air outlet(s) from the heater(s)

must be fully ducted, into and out of the plant room to

avoid interference with the operation of the heater.

The openings in the structure of the plant room through

which the ducting passes must be fire stopped.

Care must be taken to ensure that return-air intakes are

kept clear of sources of smells and fumes, and where

there is any possibility of pollution of the air by dust, shavings etc., precautions must be taken to prevent contamination.

If necessary suitable barrier rails should be provided to

prevent any combustible material being placed within

900mm of the outlets.

1.3.10 Electrical Supply

Wiring external to the air heater must be installed in accordance with the I.E.E. Regulations for Electrical Installations and any local regulations which apply.

All standard heaters are supplied by 230V - 1ph, 50Hz.

The method of connection to the main electricity supply

must:-

- facilitate the complete electrical isolation of the unit(s)

- be in a readily accessible position adjacent to the unit(s)

- serve only the unit(s)

- have a contact separation of at least 3mm in all poles.

See the accompanying wiring diagram for the heater

electrical connections

OUH units can also be supplied for 400V 3N, 50Hz.

Page 11

OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015 Page 11

2.1 Fitting the Unit

2.1.1 General

The air heater will be delivered to site pallet mounted and

protected by plastic sheeting.

Whichever method of mounting the air heater is used the

following minimum clearances for installation and servicing must be observed:

Right-hand side (looking at front of heater) 0.5m

Left-hand side (looking at front of heater) 0.5m

Top of burner to ceiling 1.0m

Rear of heater to nearest wall 0.4m

In order to achieve the desired performance levels it is

recommended that the installation height (floor level to

base of unit) for OUH20 and OUH30 is between 2.5m

and 3.0m, and OUH45 and OUH60 is between 3.0m and

5.0m.

If the heater is to be base mounted it may be stood directly on the platform, provided it is of a suitable non-combustible material and does not extend past the front edge of

the heater.

For multi-heater installations the following minimum

distances between units must be observed.

Between units, side to side 3.0m

Between units, back to back 3.0m

2.1.2 Fitting the Air Heater

The air heater may be installed either:

(a) Suspended by steel chains, rods or straps.

(b) On specifically designed cantilever brackets from a

non-combustible wall.

(c) On a level non-combustible surface providing the

platform does not extend past the front edge of the heater.

Whatever method of installation is used it must be capable of adequately supporting the weight of the unit (See

Table 2) and allowance must be made for any ancillary

equipment. Before installing the heater any existing trusses, walls brackets etc. must be inspected to ensure they

are suitable. All supports should be protected against

corrosion.

If noise levels are of particular importance, the heater

should be isolated from the structure of the building by

installing it on suitable anti-vibration mountings.

In all such cases, and in addition, when the heater is

suspended it is essential that all oil, duct, electrical and

flue connections to the heater are made with flexible

connections to maintain continuity of connection. In the

case of the flue connection single wall stainless steel flue

is deemed to flex sufficiently to meet the requirements.

2.1.3 Connection of Air Heater(s) to

Flue System

The flue system connects directly into the flue socket on

the top (OUH20) or rear (OUH30 - 60) of the heater. The

socket is sized to accept standard sheet metal flue that is

secured in place using suitable fasteners.

The flue system must be fabricated with sockets facing

upwards and sound joints must be achieved by either:

(a) a close tolerance mechanical fit between sections, or

(b) the use of a suitable caulking string and cold caulking

compound.

2.1.3.1. General Requirements

In all cases the flue outlet socket must be connected via

an approved flue system to outside air. . If an offset is

required two sets of 45° bends may be used each set

being equivalent to 0.5m of flue length. The minimum flue

length (end of flue terminal to top of heater) shall not be

less than 2.0m.

All flue ducts must be supported independently of the air

heater.

The flue terminal must not be installed so as to be less

than:

- 300mm below an opening e.g. window, air brick etc.

- 200mm below eaves or gutter.

- 300mm from an internal or external corner.

- 1200mm from a surface facing the terminal.

- 1500mm vertically from another terminal on the same

wall.

- 300mm horizontally from another terminal on the same

wall.

- 2000mm from ground level.

2.1.4 Condensate Drainage

The design of the flue system should minimise the formation of condensation and long external runs should be

completed in twin wall insulated flue. Where condensate

and/or rain water ingress is envisaged to be a problem a

flue drain length or condensate drain tee that drains into a

gulley must be fitted.

Page 12

Page 12 OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015

2.1.5 Oil Connection

The oil pipework length and diameter should be in accordance with the information given in the burner instruction

booklet.

The pump suction should not exceed 0.4 bar.

The oil line must terminate not more than 450mm from the

burner with the final connection by the flexible hoses

supplied with the burner.

Because the burner is at high level it is recommended that

a non-return valve is fitted adjacent to the burner to

prevent oil draining back when the burner is not operating.

2.1.6 Electrical Connections

All units are fully prewired and only require final connection of the incoming mains supply and completion of the

control circuit (230V) via a room thermostat, time clock

etc.

All units must be earthed. The electrical supply must be

run to a point adjacent to the heater and be suitably terminated to provide an isolation point that will prevent remote

activation of the unit during servicing. See Table 3 (Page

3) to ascertain the electrical loading of the unit(s) so that

cables of adequate cross-sectional area are used for the

electrical installation. The length of the conductors

between the cord anchorage and the terminals must be

such that the current carrying conductors become taut

before the earth conductor if the cable or cord slips out of

the cord anchorage. All external controls must be of an

approved type.

See the wiring diagram in Section 8.

OUH/D models supplied less fan must be electrically

interlocked to the air movement system so that this is

started in the same manner as the air heater fan would be

viz. A connection from the heater terminal marked “Live

Main Fan” must be made to one side of the fan motor

contactor coil, the other side of the coil being connected to

Neutral. The fan motor electrical supply must be direct

and not taken from the internal wiring of the OUH heater.

2.2 Air Distribution System

2.2.1 General

OUH/C and OUH/D models are designed for use with duct

work to more precisely define the point of air delivery, and

/or provide ducted return air or ducted fresh air inlet. All

ducting must be independently supported of the air

heater.

Joints and seams of supply ducts and fittings must be

securely fastened and made airtight. If required the

ductwork should be insulated to reduce heat loss.

2.2.2 Noise Reduction

Ducting should be connected to the heater spigots via an

airtight flexible coupling of non-combustible material.

Before fitting the coupling it must be ensured that a

minimum clearance of approximately 15mm will be maintained between the ends of the ducting and the heater

spigots.

Sound attenuators may be fitted in inlet and outlet ducts to

reduce airborne fan noise. Materials used in outlet sound

attenuators must be capable of withstanding 100°C air

temperature without any deterioration.

2.2.3 Room Thermostat Siting

The room thermostat should be fitted at a point which will

be generally representative of the heated area as far as

temperature is concerned. Draughty areas, areas subjected to direct heat e.g. from the sun, and areas where the

air movement is relatively stagnant e.g. in recesses, are

all positions to be avoided.

The thermostat should be mounted about 1.5m from the

floor.

Any room thermostat, frost thermostat, time clock etc.

must be suitable for switching 230V, 5A and must be of the

'snap action' type to minimise contact bounce.

For electrical connections of external controls see the

wiring diagrams in Section 4.2.

Page 13

OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015 Page 13

2.3 Commissioning & Testing

2.3.1 Electrical Installation

Checks to ensure electrical safety must be carried out by

a qualified person.

2.3.2 Oil Installation

This should be commissioned generally in accordance

with BS 5410 Part 2 Section 59 Paragraphs 59.1.1.1 to

59.1.1.6

2.3.3 Air Distribution System

The system should be checked to ensure that the installation work has been carried out in accordance with the

design requirements.

Particular attention should be given to the correct arrangement of delivery ducts and registers, return air ducts and

grills and general adequacy of return air paths.

For OUH/C and OUH/D units ensure that the ductwork is

balanced so that the specified motor running currents are

achieved.

2.3.4 Checks before lighting the Air

Heater

This should generally be in accordance with BS 541 Part

2 Section 59.2.1.1 to 59.2.1.5 inclusive. In addition check

that:

a) The ELECTRICAL supply to the heater is switched

OFF.

b) That all warm air delivery outlets are open.

c) That the thermostat is set at MAX.

d) That the clock control is set to an ON period.

e) That any other controls are calling for heat.

f) If a Powrtrol or MC200 is being used that the Winter

mode is selected.

2.3.5 Lighting the Air Heater

Refer also to the burner instruction booklet.

1. Remove the burner cover after releasing the three

retaining screws.

2. Fit pressure gauge, complete with vent tee to oil pump.

3. Check oil supply valve is open.

4. Switch on electricity supply

5. Press the limit interlock reset switch on the control box

of the heater. (Note: This step is not performed again

unless there is an interruption in the electrical supply to

the heater).

6. The burner fan should start to run. If it does not, check

the red lock out button on the control box. If this is illuminated depress once to re-set.

7. During the pre-purge period bleed the air from the pump

and pipework through the bleed plug on the pressure

gauge vent tee, until air free oil is obtained.

N.B.: Depending upon the length of pipework it may be

necessary to repeat this operation more than once. If this

is the case it should be noted that the burner will go to

lockout and therefore the lock-out button must be pressed

to restart the burner.

8. Once air free oil is flowing from the bleed plug close the

gauge vent plug. If necessary restart the ignition

sequence.

2.3.6 Adjustments

2.3.6.1 Oil Pressure

Leave the appliance to run for 15 minutes and then cheek

that the oil pressure is as specified in Table 4 Section 1. If

not adjust the pump pressure accordingly. (See burner

instruction booklet.)

2.3.6.2 Combustion

1. Complete a flue gas analysis. The Carbon Dioxide

content should be within ± 0.5% of the following values, if

not adjust combustion air accordingly, (See burner

instruction booklet.) and re-check the flue gas analysis.

OUH 20 12.5%

OUH 30 12.8%

OUH 45 & 60 12.0%

2. Turn the room thermostat to MIN to turn OFF the

burner.

Remove the pressure gauge, refit the sealing plug into the

pump.

3. Refire the burner and ensure that there are no oil leaks.

Replace the burner cover.

2.3.7 Handing over the Air Heater

Hand these instructions to the user or purchaser for retention and instruct in the efficient and safe operation of the

air heater and associated controls.

Adjust the automatic controls to those values required by

the User.

Page 14

Page 14 OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015

Finally, advise the user or purchaser that, for continued

efficient and safe operation of the air heater, it is important

that servicing is carried out annually.

In the event that the premises are not yet occupied turn off

the oil and electricity supplies and leave instructional

literature on site.

3.1 Servicing

WARNING: Always switch off and disconnect the

electrical supply to the heater and any seperate

electrical supply to external controls. Close the

gas service valve or turn off the oil supply before

carrying out any servicing work or replacement of

failed components. (Refer also to the burner

instruction booklet.)

3.1.1 General

Full maintenance should be undertaken not less than

once per year. After any servicing work has been complete or any component replaced the air heater(s) must be

fully commissioned and tested for fuel tightness as

described in Section 6.

In addition the following should be completed.

a) Check and clean any oil filters

b) Check the correct operation of any fire valves

3.1.2 Burner Servicing/Maintenance

Refer to the burner instruction booklet supplied with the

heater and complete the servicing/maintenance instructions therein.

3.1.3 Main Burner Assembly Removal

1. Ensure that the oil valve is turned OFF and then disconnect the oil supply pipe from the burner.

2. Disconnect the electrical connections to the burner.

3. Remove the nuts securing the burner to the heater.

4. reassemble in reverse order.

3.1.4 Heat Exchanger

Whilst the main burner assembly is removed from the unit

check that the inside of the heat exchanger is clean. If

necessary clean out deposits using a stiff brush and

vacuum cleaner.

3.1.5 Main Fan Assembly

3.1.5.1 OUH/F Models

1. Inspect the fan blades to see that they are not damaged

and that there is no excessive build up of deposits that

could give rise to an imbalance. Should it be necessary to

remove the assembly for cleaning proceed as follows.

2. Slacken the cable gland on the heater casing through

which the fan electrical cable passes.

3. Disconnect the fan leads from the electrical terminals.

4. Withdraw cable through entry grommet.

5. Remove the fan and motor assembly complete by

removing the four hexagon headed bolts that secure the

fan to the rear panel.

6. Reassemble in reverse order.

3.1.5.2 OUH/C Models

1. Inspect the fan blades to see that they are not damaged

and that there is no build up of excessive deposits that

could give rise to an imbalance. Should it be necessary to

remove the assembly for cleaning proceed as follows.

2. Slacken the cable gland on the casing through which

the fan electrical cable passes.

3. Disconnect the fan leads from the electrical terminals in

the contactor enclosure.

4. Withdraw cable through entry grommet.

5. Remove the complete fan assembly by removing the

fixings securing the fan to the rear panel of the heater.

6. Reassemble in reverse order.

3.1.6 Replacement of Faulty

Components

3.1.6.1 Fan/Limit Thermostat

- Honeywell L4064B

1. Squeeze the sides of the cover and remove cover by

pulling forward.

2. Release wiring from clamp terminals by pushing a small

screwdriver into the clamp release holes adjacent to the

clamps.

3. Remove the 2 screws securing the thermostat to the

heater panel and withdraw thermostat.

4. Reassemble new unit in reverse order referring to the

heater wiring diagram to ensure correct wiring location.

Important: A replacement fan/limit thermostat may have a

brass link between the bottom fan terminal and the bottom

limit terminal (situated in the slot between the two terminals). This MUST be removed, by breaking the link off

using a pair of thin nose pliers, before the replacement

thermostat is installed.

5. Ensure that the fan and limit settings are as follows:Fan ON - 122°F (50°C), Fan OFF - 86°F (30°C)

Limit OUH20 239°F (115°C)

OUH30-60 194°F (90°C)

Page 15

OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015 Page 15

Note: The new L4064B may be supplied with the

limit temperature mechanically limited to less

than the setting required. To release the mechanical limit push a pointed object into the small hole

at the top of the dial. At the same time prevent the

dial from rotating and push the limit temperature

adjuster around to the required setting.

4.1 Short List of Parts

Only originally specified parts may be fitted as service replacements.

Please refer to Powrmatic Ltd for any parts not detailed in the listing below.

ITEM USAGE PART #

Fan & Limit Thermostat All 143000306

Fig 1 Limit Thermostat

CAUTION

DO NOT ROT ATE - HOLD

DIAL WHEN SETTING POINTERS

5

0

1

0

0

1

5

0

2

0

0

2

5

0

F

A

N

L

I

M

I

T

O

F

F

O

N

O

F

F

Limit Set point

Adjustment

Fan Circuit

OUT

Limit Circuit

OUT

Fan ON

Override

Set Point Dial

Brass Link Location

Fan OFF Set point

Adjustment

NOTE: Temperature points on the dial are in Fahrenheit

Limit Circuit

IN

Fan Circuit

IN

Fan ON Set point

Adjustment

Page 16

Page 16 OUH Range Users, Instrucons & Service Instrucons Issue 5.1 September 2015

HEATING DIVISION

Hort Bridge

Ilminster, Somerset TA19 9PS

Tel: 01460 53535 Fax: 01460 52341

Every effort is made to ensure accuracy at time of going to press. However as part of our continued product improvement, we reserve the right to alter spcification without notice.

More information is available from our web site on:-

http://www.powrmatic.co.uk/products/heating/browse/view/product/ouh-oil-unit-heaters/

Loading...

Loading...