Powrmatic NVx15CCF, NVx20CCF, NVx25CCF, NVx30CCF, NVx40CCF User, Installation & Servicing Manual

...

NVx Suspended Gas Unit Heater

Industrial & Commercial Heating Systems

Issue 6.4 Aug 2017

User, Installation

& Servicing Manual

www.powmatic.co.uk

+44 (0) 1460 53535

info@powrmatic.co.uk

powrmatic

ertificate of Guarantee

C

Dear Customer

This is to certify that this heater is guaranteed for two years parts and one year labour

from the date of original commissioning. The heater must be commissioned within 4

weeks of installation.

To make a claim

In the first instance you must contact your appliance supplier, or installer and provide:-

1. The appliance type and serial number.

2. The original commissioning documentation.

3. As much detail as possible on the fault.

Your supplier, or installer, will then contact Powrmatic to make a guarantee claim on

your behalf.

Conditions of Guarantee

1. The heater must have been installed by a competent recognised installer, and in

accordance with the manufacturers instructions, building regulations and local

regulations.

2. The heater has been professionally commissioned, within 4 weeks of installation,

and a copy of the commissioning sheet returned to Powrmatic.

3. The heater has been maintained on a yearly basis by a competent servicing

company.

4. The heater has been used in accordance with the manufacturers instructions.

5. The correct specification fuel has been used.

6. No unauthorised repairs of modifications have been made.

7. Powrmatic ‘General Conditions of Sales’ have been observed.

8.

Except for the obligation of Powrmatic Ltd to perform warranty repairs during the

guarantee period Powrmatic will not be liable in repect of any claim for direct or

indirect consequential losses, including loss of profits or increased cost arising from

loss of use of the heater, or any event arising there from.

Exclusions

1. Gaskets and fan belts are not included in the guarantee.

----------------------------------------------------

Powrmatic Ltd, Hort Bridge, Ilminster, Somerset, TA19 9PS

Tel:01460 53535 Fax: 01460 52341

Web: www.powrmatic.co.uk e-mail service@powrmatic.co.uk

Important: This certificate must

Installer

Date :_____________ Signed ____________________________________________Installer

Commissioned

Date :_____________ Signed _______________________________Commissioning Engineer

page no. 2 of 44

be kept with the appliance

Failure to provide a copy of the commissioning sheet invalidates the heater waranty

NVx Range Users, Installation & Servicing Instructions issue 6.4 Aug 2017.

Dear Customer - thank you for choosing Powrmatic.

We appreciate you buying one of our high quality products and know that you have made the best

choice. By choosing Powrmatic, you are investing in UK manufacturing & its workforce. We pride

ourselves by manufacturing products that provide clean, comfortable and safe working environments

worldwide together with the personal & professional service and back-up you deserve. If you have

any questions or concerns regarding this product, please contact our Technical Support Team by

calling 01460 53535.

Users, Installation and Servicing Instructions

CONTENTS

Title Section Contents Page

User Instructions 4

Pre Installation

1.1 Introduction 5

Duties 6

Dimensions 7

Accessories 12

1.2 Technical data 14

1.3 General Requirements 16

Installation

2.1 Fitting the unit 20

2.2 Flue/Combustion Air Duct System 22

2.3 General Identication of Electrical Items 24

2.4 Electrical Cable Installation 25

2.5 Wiring Diagrams 27

2.6 Commissioning and Testing 32

2.7 Servicing 36

Additional Documents

3.1 Fault Finding Flow Chart 40

3.2 Short List of Parts 42

NVx Range Users, Installation & Servicing Instructions issue 6.4 Aug 2017.

page no. 3 of 44

User Instructions

If the heater has not been left operational

proceed as follows.

A) Checks before lighting the Air Heater

The following preliminary checks should be made before

lighting the heater(s)

a) Ensure that the ELECTRICAL supply to the heater is

switched OFF.

b) Check that all warm air delivery outlets are open.

c) Check that the thermostat is set at MAX.

d) Check that the clock control is set to an ON period.

e) Check that any other controls are calling for heat.

B) Lighting the Air Heater

1. Switch on the electrical supply at the isolator

2. If the Limit indicator light comes on press the limit

interlock reset switch inside the heater.

3. The startup sequence will commence. After a short

delay the burners will light and the green ‘ON’ indicator on

the front of the heater will be illuminated.

D) Description of Operation

Important: The heater must NOT be

controlled by switching ON and OFF the

main electrical supply to it.

1) Standard Units

The ignition sequence commences each time the external

controls e.g. Time clock, room thermostat etc. call for

heat. The internal exhaust fan will run and, when sucient

combustion airow is proved by the air pressure switch,

the ignition spark will be generated, the main gas valve

opens and the burners light. The green ‘ON’ indicator

will be illuminated. The heater fan will automatically start

approximately 2 minutes after the burners light. When the

external controls are satised the burners will be turned

o and approximately 2 - 3 minutes later the heater fan will

be automatically stopped. If the burners fail to light the

control box will make another four attempts at ignition.

2) High / Lo & Modulating Units

When the burners are alight, the heat output will be

controlled either to high re or low re or, in the case of

modulating units, to any point between high and low re;

depending on the requirements of the space being heated

and the external controls tted.

4. If the burners fail to light the control box will

automatically restart the ignition sequence. If after 5

attempts at ignition the burners have still failed to light

the control box will go to lockout and the Amber lockout

light on the front of the heater (or on the low level remote

reset, MC200 or Powrtrol RR if tted) will be illuminated. To

restart the ignition sequence depress the reset button on

the low level reset for about 1-2 seconds.

WARNING: If it is not possible to light the

heater after several attempts, contact the

installer or local service company.

C) To Shut Down the Air Heater

1) For Short Periods:

Turn the room thermostat to the OFF, or set to it’s lowest

setting.

2) For Long Periods:

Complete step 1 above. Wait for 5 minutes and then turn

OFF the electrical supply at the isolator.

3) Summer / Winter Modes

Certain types of external controls will provide for two

modes of operation i.e.

Summer: The heater fan alone will run at the dictate of the

external controls to provide air movement.

Winter: The heater will operate normally.

4) Overheat Thermostat

This operates if high temperatures within the heater are

detected, the burners are turned o and a Red indicator

switch light on the front panel is illuminated. NVx15 - 75

units have the thermostat located inside the controls

section. NVx90SF - 140SF units have an additional

thermostat on the side of the unit at the opposite end to

the controls (either thermostat can go to limit and shut o

the burners). The fault condition must be identied and

rectied and the thermostat manually reset via the red

high limit reset switch. When the unit has cooled, push the

Red indicator switch inside the front panel to reset the limit

thermostat interlock relay, the red indicator light will go

out and the unit is operational again.

Note: The limit thermostat(s) can only be reset

once the unit has cooled down.

Unless the cause of the fault condition is

readily obvious, for example a power cut whilst

page no. 4 of 44

NVx Range Users, Installation & Servicing Instructions issue 6.4 Aug 2017.

the heater was operating, a service engineer should be

contacted.

and belts. It would be hazardous to tamper with or attempt

to service unless you are a competent person in the eld of

Gas and Electrical work.

E) Maintenance

To maintain ecient, reliable and safe operation of the

heater it must serviced by a qualied person at least

annually and preferably at the end of the heating season.

F) IMPORTANT

Free access must be maintained to and around the heater

for servicing purposes and the air supply to the heater

must not be restricted in any way. Combustible materials

must not be stored adjacent to the heater.

If at any time a gas leak is suspected, turn OFF the gas

supply at the meter and contact the local gas undertaking

immediately.

All Powrmatic heaters use gas and electricity to power

them, they may also contain moving parts such as pulleys

1.1 Introduction

The NVx range are highly ecient, gas red, fanned

circulation air heaters that cover heat outputs of 15kW to

140kW, have a closed combustion circuit and are supplied

complete with a ue system. They are certied for use

on Natural Gas, Group H - G20, and Propane - G31 only.

Appliance Categories are Cat II2H3P (GB, IE).

The heaters are designed to be suspended from suitable

roof points or alternatively to be mounted on purpose

designed brackets and are intended primarily for heating

commercial or industrial premises. All variants, with the

exception of NVx/EA units, are for internal use only.

NVx heaters feature a closed combustion circuit and have

an internal exhaust fan, mounted downstream of the

heat exchanger, to evacuate the products of combustion

and draw in air for combustion. The air heater must be

connected to a ue system that is approved by Powrmatic

Ltd.

They may be used where the atmosphere inside the

premises could be contaminated e.g. Dust, oil mist etc. but

the heaters are not airtight and therefore may not be used

in areas classied as hazardous as dened in BS 5345: Part 2

or areas subjected to signicant negative pressures due to

extract systems.

NVx/F heaters have an axial fan assembly tted at the

rear to circulate the air being heated through the formed

tube heat exchanger. NVx/CCF units are supplied with

a centrifugal fan and NVx/D units for use with ducted

systems where the air moving fan is by others or a

If you have any safety questions reference the servicing

and installation of any of our heaters please do not hesitate

to contact our head oce for expert advice. Your safety is

paramount to us.

Gas Safety (Installation & Use) (Amendment)

Regulations

It is law that all gas appliances are

installed, adjusted and, if necessary,

converted by qualied persons* in

accordance with the current issue of the

above regulations. Failure to install appliances

correctly can lead to prosecution. It is in your own

interests and that of safety to ensure that the law is

complied with.

* An approved class of person listed on the gas safe

register.

centrifugal fan section is used adjacent to or remote from

the heater. NVx/DH units are for use in air handling units

and NVx/EA units are for siting externally.

Heaters are tted as standard with inshot burners, a fully

automatic control for ignition, ame sensing, gas supply

control and safety functions, an internal exhaust fan, main

air fan (/F and /C models), and fan/limit thermostat.

Options include High/Low or Modulating burner controls,

inlet duct connection, outlet duct connection, 30°, 45°

head, 90° outlet bend, vertical/horizontal outlet louvre

assembly and a full range of modular duct components.

IMPORTANT

Service and Maintenance Engineers shall

ensure that replacement items are tted,

adjusted and set in accordance with the

data and detail set out in these instructions. If in doubt

consult Powrmatic Technical Department.

Gas Safety (Installation & Use) Regulations 1998

It is law that all gas appliances are

installed, adjusted and, if necessary,

converted by qualied persons* in

accordance with the current issue of the

above regulations. Failure to install appliances

correctly can lead to prosecution. It is in your own

interests and that of safety to ensure that the law is

complied with.

* An approved class of person listed on the gas safe

register.

NVx Range Users, Installation & Servicing Instructions issue 6.4 Aug 2017.

page no. 5 of 44

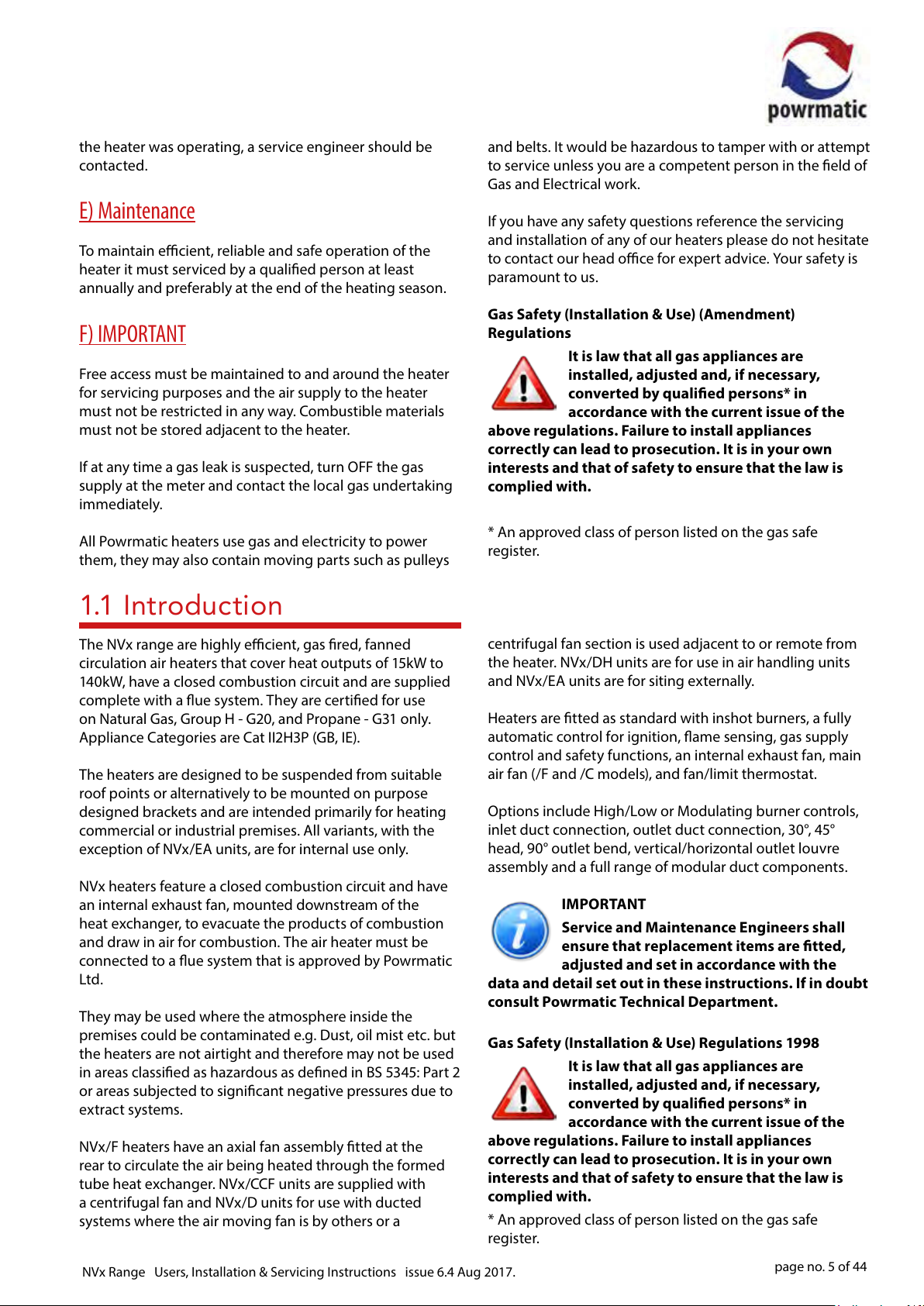

Duties

Model 15 20 25 30 40 50 60 75 SF90 SF120 SF140

Output kW 15 20 25 30 40 50 60 75 90 120 140

Input (nett CV) kW 16.4 21.9 27.3 32.9 43.5 54.2 65.5 80.6 97.4 128.5 148.9

NVx F / C / V m

Airflow

Volume

Throw

Airflow

Fan

Static

Supply

NVx F

Electrics

Duo m

D

Min m

Max m

NVx

NVx F m 10.0 14.0 20.0 24.0 28.0 30.0 30.0 32.0 34.0 36.0 38.0

NVx Duo m N/A N/A N/A N/A N/A N/A N/A N/A 60.0 60.0 64.0

NVx C Pa 220 320 220 220 150 250 250 250 180 290 250

Standard V/ph/Hz 230/1/50

Optional* V/ph/Hz 400/3/50 *on Centrifugal Unit Only. 3ph units shown in brackets ()

Motor kW 0.12 0.13 0.18 0.18 0.27 0.39 0.66 0.66

Run amp 0.50 0.53 0.56 1.0 1.0 1.7 2.6 2.6 3.40 5.2 5.2

Motor kW 0.25 0.42 0.42 0.55 0.55 1.10 1.40 1.40

NVx C

Start amp 5.0 8.5 13.3 13.3 18.0 26.3 29(16.5) (18.0) 31.0 40(14.9)44(16.8)

Run amp 2.0 3.1 4.2 4.3 5.8 7.6 10(4.8) (5.3) 12.8 17(4.6) 20(4.9)

Connection BSP/Rc ½” ¾”

Nat Gas mbar 20.0

LPG mbar 37.0

Nat Gas m

LPG m

Min m 2.5 3.00

Max m 3.0 5.00

Min m 3.00 4.00 4.00 5.00 6.00 6.00

Max m 5.00 6.00 7.00 8.00 10.00 12.00

Fuel

Mounting

Height

Nominal Inlet

Pressure

Consumption

NVx F/Duo

Crossflow

NVx V

Downflow

Height mm 540 540 540 760 760 912 760 912 831 975 1140

Overall

Dims

NVx F

Width mm 1000 1000 1000 1000 1000 1000 1325 1325 1950 1950 1950

Depth mm 892 925 925 925 905 925 941 941 925 941 941

To p mm 200

Install

Clearance

NVx F

LH Side mm 200

RH Side mm 1000

Rear mm 400

Diameter mm Ø 80 80 80 100 100 100 130 130 130 130 130

Flue

Max

Length

Flue Only m 12

Room Sealed m 6

Combustion Air Spigot mm Ø 80 80 80 100 100 100 130 130 130 130 130

Noise Levels

eight

Nett W

Notes:

Fuel Consumption and input figures based upon nett calorific values as follows:

- Natural Gas (G20) nett CV 34.02 MJ/m

- Propane (G31) nett CV 88.00 MJ/m

• Heaters have efficiency levels which meet with the minimum heater efficiency requirements of UK Part L Building Regulations

• Air handling data is assessed at room ambient conditions

• Throw figures provide the distance to the point where the terminal velocity degrades to 0.25m/s

Dimensions and clearance data in the table above refer to NVx F units only - for NVx C and NVx D data refer to the dimensions p

•

• Noise levels are applicable to standard NVx F models and are measured 5m from appliance in a typical installation situation.

• Motor kW, run and start amps apply to standard electrical supply as stated. For optional data contact sales office

• Optional 3 phase direct drive centrifugal blowers shown in italics within brackets()

• Connection of combustion air duct is not required for ‘flue only’ applications

• The NVx Duo throw dimension is the effective combined throw measurement

• It is the responsibility of the installing contractor to ensure that ductwork is correctly sized and balanced when installing NVx Centrifugal units

NVx F dB(A) 54 52 53 54 58 61 62 62 66 67 67

NVx V dB(A) 64 62 63 64 68 71 72 72 76 77 77

NVx F kg 71.5 71.5 72.5 75.5 115 133.5 135.5 157 202 238 286

NVx C kg 106.5 120.5 126.5 166.5 168.5 183 213 234 329 363.5 430

3

/s 0.42 0.56 0.78 1.06 1.18 1.51 1.86 2.56 2.81 3.56 3.75

3

/s N/A N/A N/A N/A N/A N/A N/A N/A 2.34 3.12 3.64

3

/s 0.42 0.56 0.78 1.06 1.18 1.51 1.83 2.56 2.81 3.56 3.75

3

/s 0.46 0.62 0.86 1.16 1.30 1.67 2.02 2.81 3.09 3.91 4.13

2 x

0.39

2 x

1.10

3

/h 1.69 2.31 2.89 3.45 4.60 5.73 6.93 8.59 10.29 13.73 15.74

3

/h 0.65 0.90 1.13 1.33 1.78 2.21 2.68 3.33 4.01 5.44 6.20

3

3

age and/or the installation instructions

2 x

0.66

2 x

1.40

2 x

0.66

2 x

1.40

page no. 6 of 44

NVx Range Users, Installation & Servicing Instructions issue 6.4 Aug 2017.

Dimensions

NVx F - Axial Fan Crossow Units

122

228

CTRS

228

CTRS

122

C

NVx 40 F

K

PLAN FOR NVx F 15-75

A

FRONT VIEW

J CTRS

SUSPENSION POINTS M10

M

E

G

H

NVx SF90

L

G

F

35

R/H SIDE VIEW

122

228

CTRS

228

CTRS

122

B

K

Q

J CTRS J CTRS

PLAN FOR NVx F 90-140

ØD

P

N

GAS ENTRY POINT

ELEC ENTRY

REAR VIEW

M

E

G

H

Model 15 20 25 30 40 50 60 75 SF90 SF120 SF140

A mm 1000 1000 1000 1000 1000 1000 1325 1325 1950 1950 1950

B mm 700 700 700 700 700 700 700 700 700 700 700

C mm 540 540 540 760 760 912 760 912 831 975 1140

DØ mm 80 80 80 100 100 100 130 130 130 130 130

E mm 248 248 248 233.5 233.5 233.5 235.5 235.5 235.5 235.5 235.5

F mm 308 308 308 492 492 644 416 568 487 631 796

G mm 120 120 120 142 142 142 220 220 220 220 220

H mm 317 317 317 317 317 317 347 347 347 347 347

J mm 450 450 450 450 450 450 700 700 2 x 662.5 2 x 662.5 2 x 662.5

K mm 218 232.5 232.5 232.5 232.5 232.5 278 278 278 278 278

L mm 892 925 925 925 925 922 939 985 922 941 941

M mm 216 216 216 206 206 206 236 236 246 246 246

N mm 114 114 114 114 114 114 145 145 88 88 88

P mm 194 194 225.5 297 297 374 297 374 326 398 481

Q mm 157 190 190 190 170 190 204 250 188 207 207

NVx Range Users, Installation & Servicing Instructions issue 6.4 Aug 2017.

page no. 7 of 44

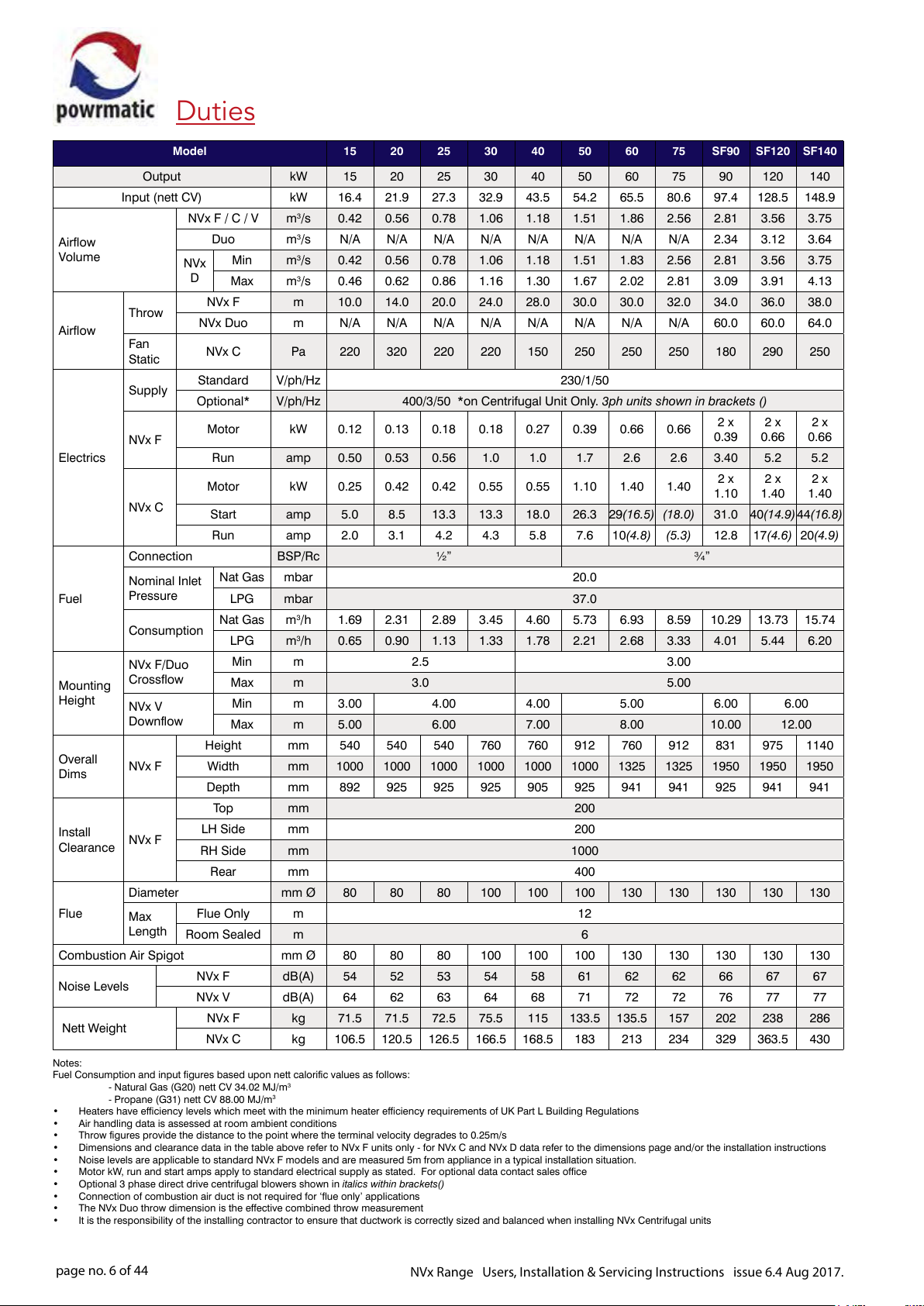

NVx Duo - Axial Fan Bi-Directional Units

NVx SF90 Duo

C

L

A

FRONT VIEW

122

G

F

P

GAS ENTRY POINT

N

ELEC ENTRY

REAR VIEW

122

228

CTRS

228

CTRS

B

R/H SIDE VIEW

K

Q

SUSPENSION POINTS M10

PLAN

J CTRS J CTRS

Model SF90 SF120 SF140

A mm 1950 1950 1950

B mm 700 700 700

C mm 831 975 1140

DØ mm 130 130 130

E mm 235.5 235.5 235.5

F mm 487 631 798

G mm 220 220 220

H mm 347 347 347

J mm 2 x 662.5 2 x 662.5 2 x 662.5

K mm 278 278 278

L mm 1287 1350 1350

M mm 246 246 246

N mm 88 88 88

P mm 326 398 481

Q mm 188 207 207

M

E

G

H

page no. 8 of 44

NVx Range Users, Installation & Servicing Instructions issue 6.4 Aug 2017.

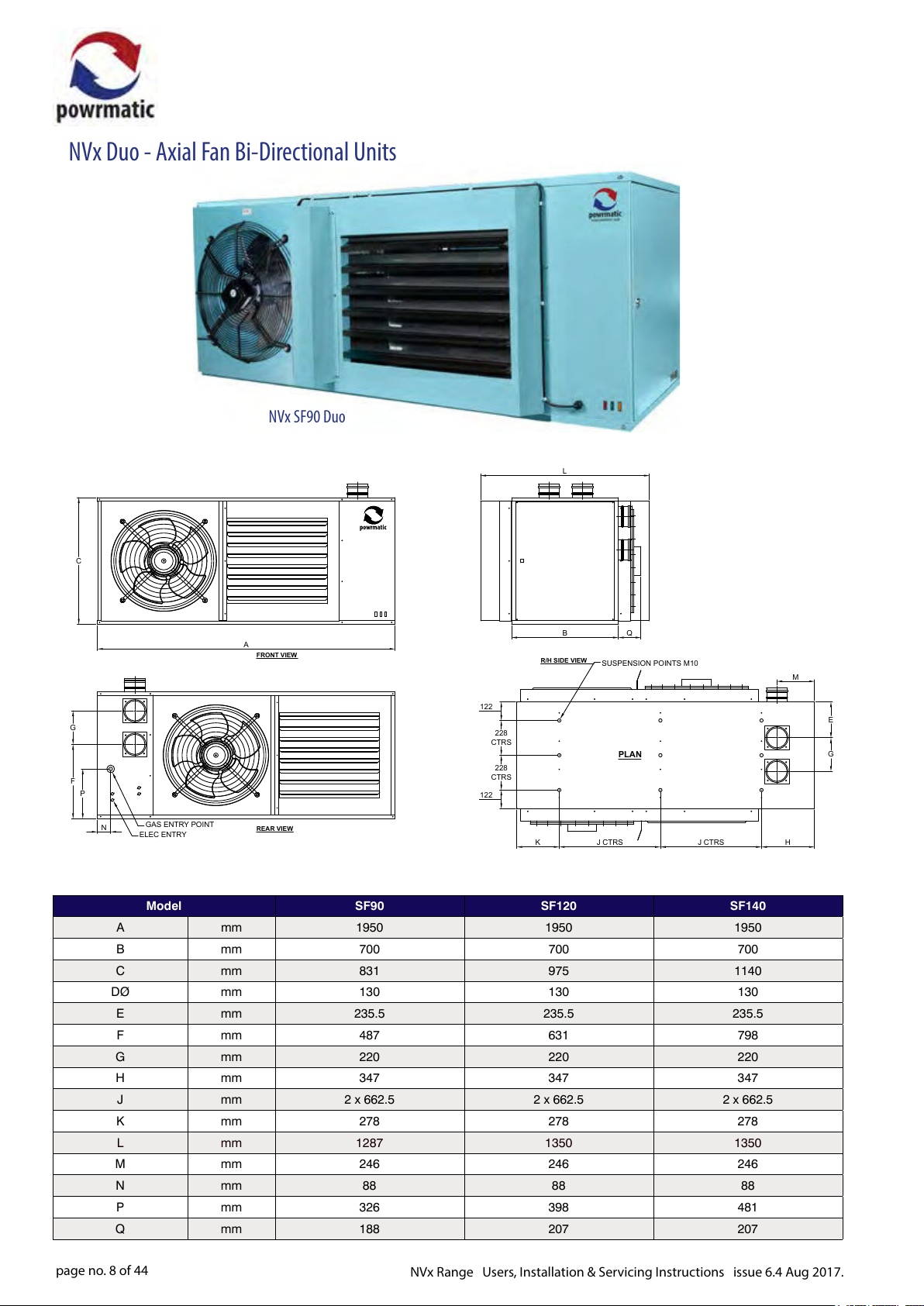

NVx V - Axial Fan Downow Units

C+30mm

NVx 60 V

1325

FRONT

J CTRS J CTRS

K H

PLAN FOR NVx D 10-75

E

G

SUSPENSION POINTS M10

N

ELEC ENTRY

P

F

G

ØD

DROP ROD

GAS ENTRY POINT

L

B+70mm

C

R/H SIDE VIEW

J CTRS J CTRS J CTRS

K H

C+30mm

PLAN FOR NVx D 90-140

NVx 60 V

M

A

REAR

N

ELEC ENTRY

P

F

G

GAS ENTRY POINT

Model 15 20 25 30 40 50 60 75 SF90 SF120 SF140

A mm 1000 1000 1000 1000 1000 1000 1325 1325 1950 1950 1950

B mm 700 700 700 700 700 700 700 700 700 700 700

C mm 540 540 540 760 760 912 760 912 831 975 1140

DØ mm 80 80 80 100 100 100 130 130 130 130 130

E mm 248 248 248 233.5 233.5 233.5 235.5 235.5 235.5 235.5 235.5

F mm 308 308 308 492 492 644 416 568 487 631 796

G mm 120 120 120 142 142 142 220 220 220 220 220

H mm 283 283 304 283 283 283 312 312 319 319 319

J mm 260 260 260 260 260 260 385 385 460 460 460

K mm 197 197 197 197 197 197 243 243 251 251 251

L mm 892 925 925 925 925 925 939 985 986 986 986

M mm 216 216 216 206 206 206 236 236 246 246 246

N mm 114 114 114 114 114 114 145 145 88 88 88

P mm 194 194 225.5 297 297 374 297 374 326 398 481

NVx Range Users, Installation & Servicing Instructions issue 6.4 Aug 2017.

page no. 9 of 44

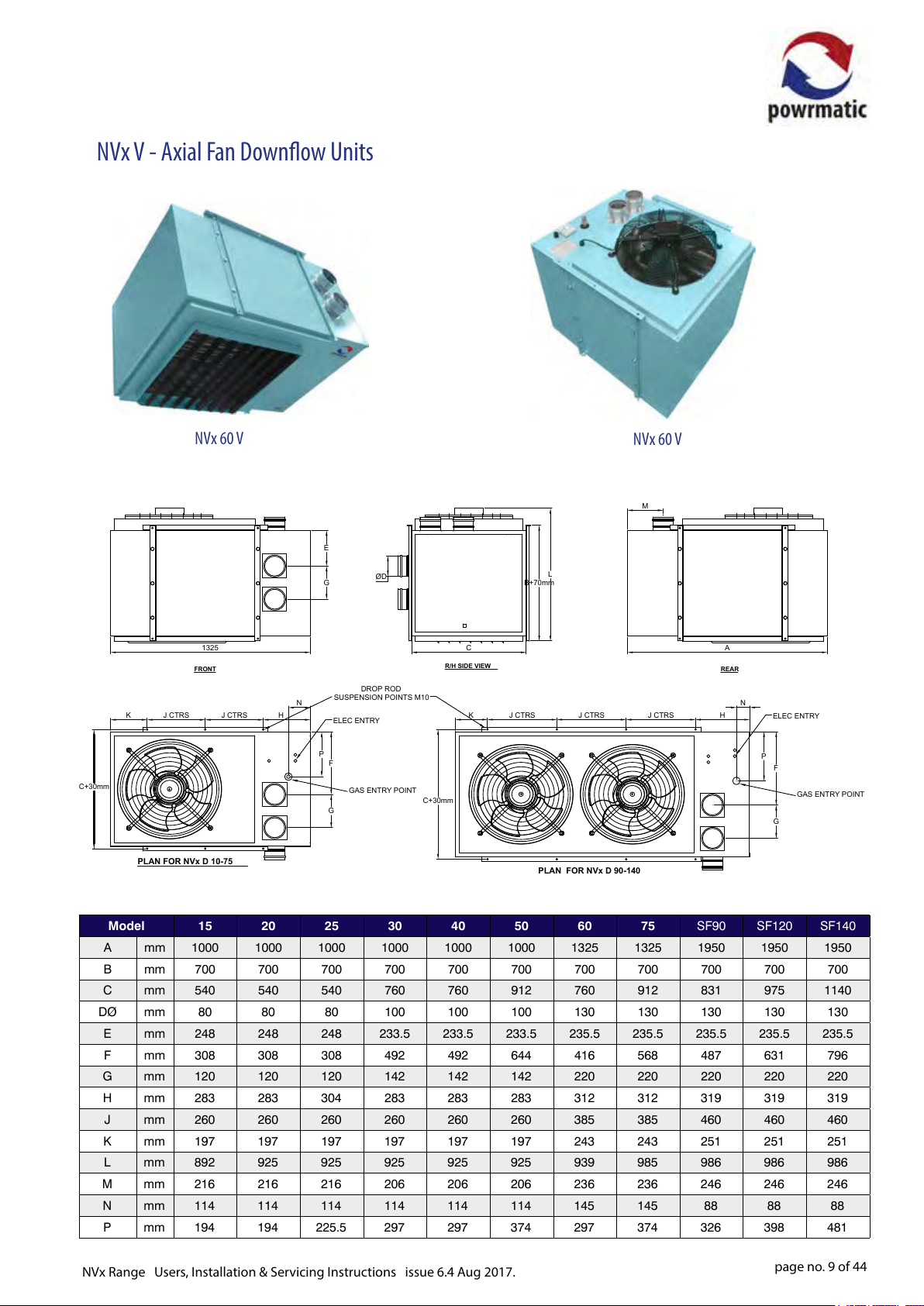

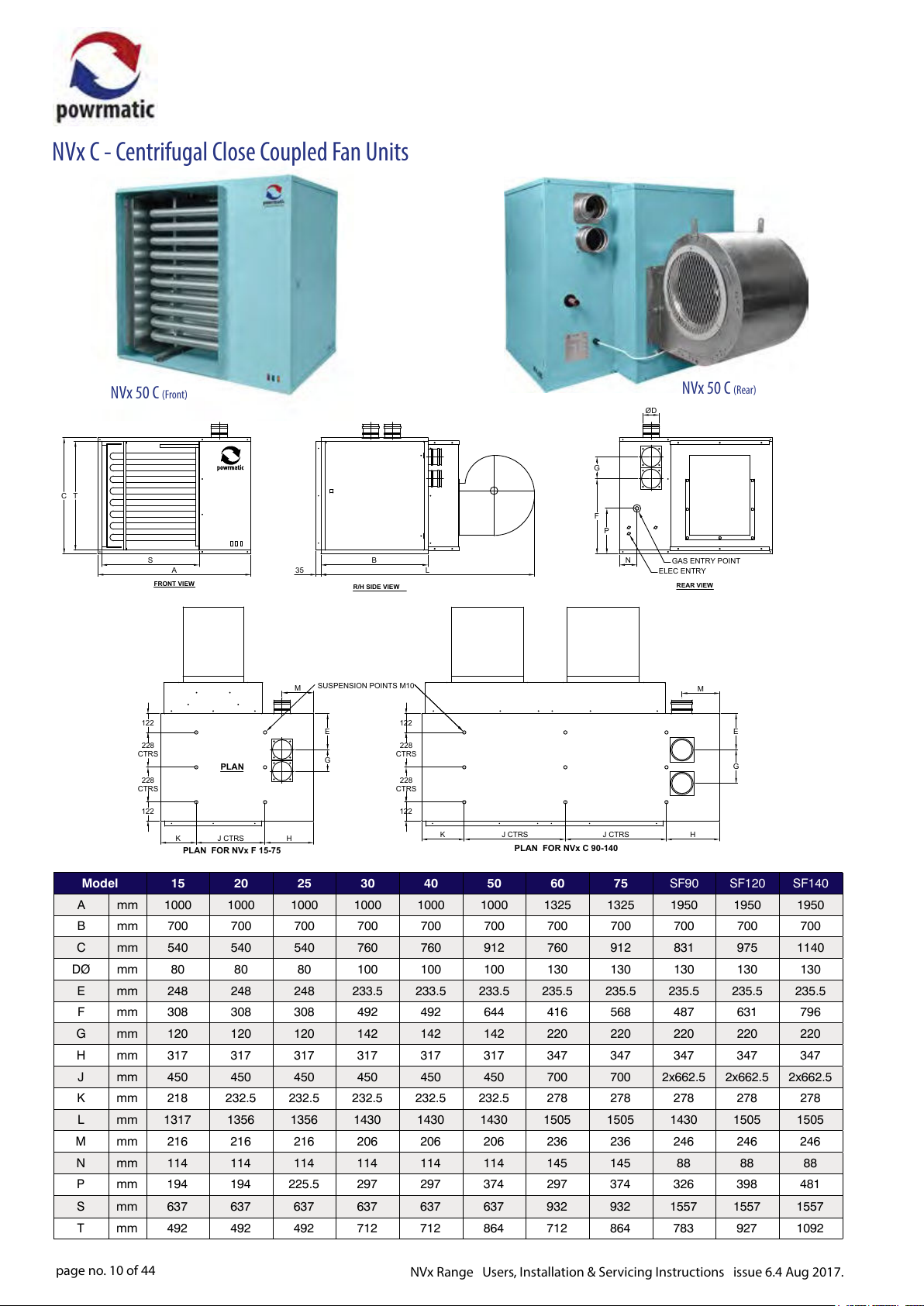

NVx C - Centrifugal Close Coupled Fan Units

TC

NVx 50 C (Front)

S

A

FRONT VIEW

122

228

CTRS

228

CTRS

122

PLAN

J CTRS

K

PLAN FOR NVx F 15-75

35

SUSPENSION POINTS M10

M

E

G

H

B

R/H SIDE VIEW

122

228

CTRS

228

CTRS

122

NVx 50 C (Rear)

ØD

G

F

P

N

L

K

J CTRS J CTRS

PLAN FOR NVx C 90-140

GAS ENTRY POINT

ELEC ENTRY

REAR VIEW

M

H

E

G

Model 15 20 25 30 40 50 60 75 SF90 SF120 SF140

A mm 1000 1000 1000 1000 1000 1000 1325 1325 1950 1950 1950

B mm 700 700 700 700 700 700 700 700 700 700 700

C mm 540 540 540 760 760 912 760 912 831 975 1140

DØ mm 80 80 80 100 100 100 130 130 130 130 130

E mm 248 248 248 233.5 233.5 233.5 235.5 235.5 235.5 235.5 235.5

F mm 308 308 308 492 492 644 416 568 487 631 796

G mm 120 120 120 142 142 142 220 220 220 220 220

H mm 317 317 317 317 317 317 347 347 347 347 347

J mm 450 450 450 450 450 450 700 700 2x662.5 2x662.5 2x662.5

K mm 218 232.5 232.5 232.5 232.5 232.5 278 278 278 278 278

L mm 1317 1356 1356 1430 1430 1430 1505 1505 1430 1505 1505

M mm 216 216 216 206 206 206 236 236 246 246 246

N mm 114 114 114 114 114 114 145 145 88 88 88

P mm 194 194 225.5 297 297 374 297 374 326 398 481

S mm 637 637 637 637 637 637 932 932 1557 1557 1557

T mm 492 492 492 712 712 864 712 864 783 927 1092

page no. 10 of 44

NVx Range Users, Installation & Servicing Instructions issue 6.4 Aug 2017.

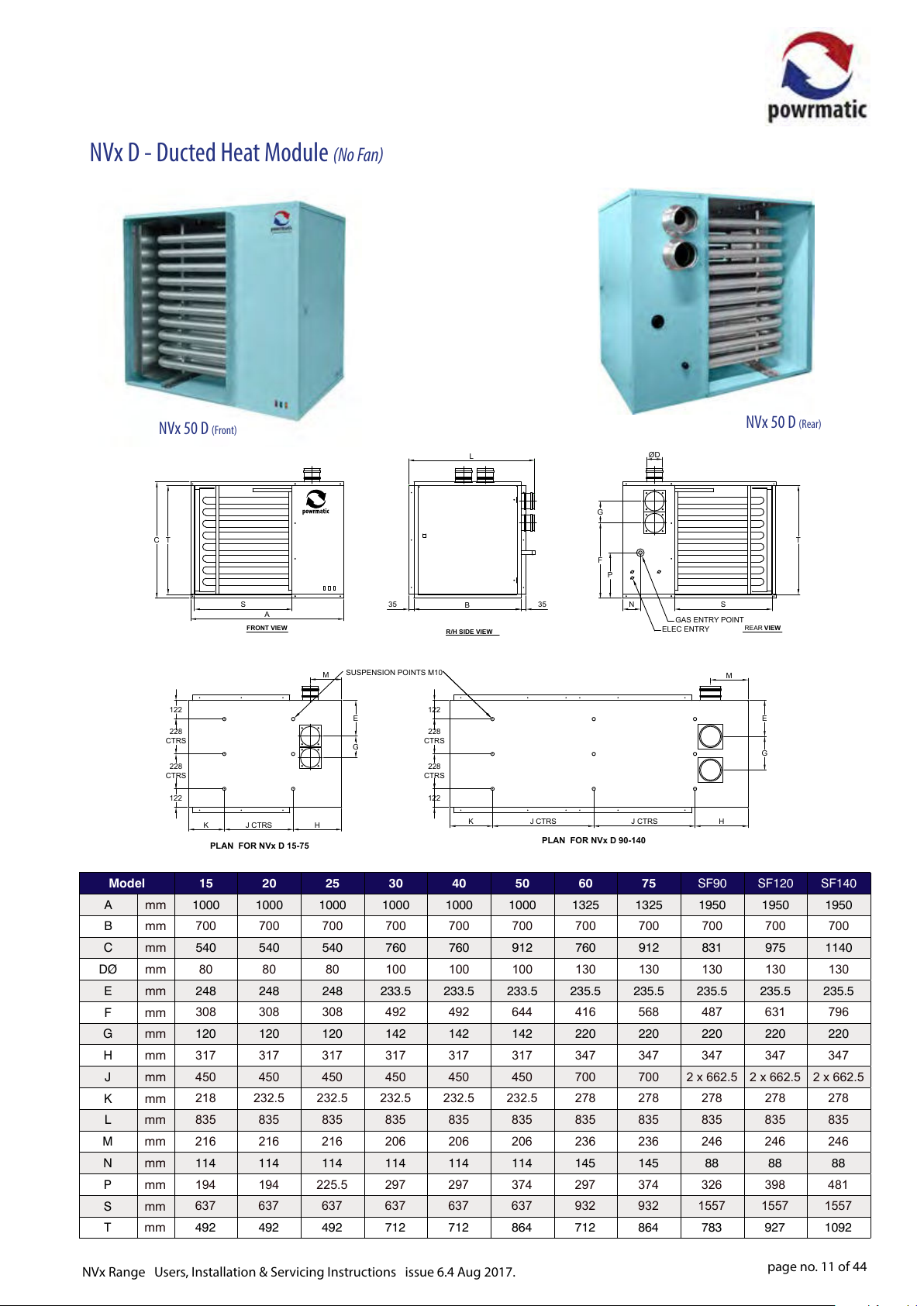

NVx D - Ducted Heat Module (No Fan)

NVx 50 D (Front)

TC

122

228

CTRS

228

CTRS

122

K

PLAN FOR NVx D 15-75

S

A

FRONT VIEW

J CTRS

SUSPENSION POINTS M10

M

E

G

H

NVx 50 D (Rear)

L

G

F

35

122

228

CTRS

228

CTRS

122

B

R/H SIDE VIEW

K

35

J CTRS J CTRS

PLAN FOR NVx D 90-140

ØD

T

P

N

ELEC ENTRY

S

GAS ENTRY POINT

M

H

REAR VIEW

E

G

Model 15 20 25 30 40 50 60 75 SF90 SF120 SF140

A mm 1000 1000 1000 1000 1000 1000 1325 1325 1950 1950 1950

B mm

700 700 700 700 700 700 700 700 700 700 700

C mm 540 540 540 760 760 912 760 912 831 975 1140

DØ mm

80 80 80 100 100 100 130 130 130 130 130

E mm 248 248 248 233.5 233.5 233.5 235.5 235.5 235.5 235.5 235.5

F mm

308 308 308 492 492 644 416 568 487 631 796

G mm 120 120 120 142 142 142 220 220 220 220 220

H mm

J mm

K mm

L mm

M mm

317 317 317 317 317 317 347 347 347 347 347

450 450 450 450 450 450 700 700 2 x 662.5 2 x 662.5 2 x 662.5

218 232.5 232.5 232.5 232.5 232.5 278 278 278 278 278

835 835 835 835 835 835 835 835 835 835 835

216 216 216 206 206 206 236 236 246 246 246

N mm 114 114 114 114 114 114 145 145 88 88 88

P mm

S mm

194 194 225.5 297 297 374 297 374 326 398 481

637 637 637 637 637 637 932 932 1557 1557 1557

T mm 492 492 492 712 712 864 712 864 783 927 1092

NVx Range Users, Installation & Servicing Instructions issue 6.4 Aug 2017.

page no. 11 of 44

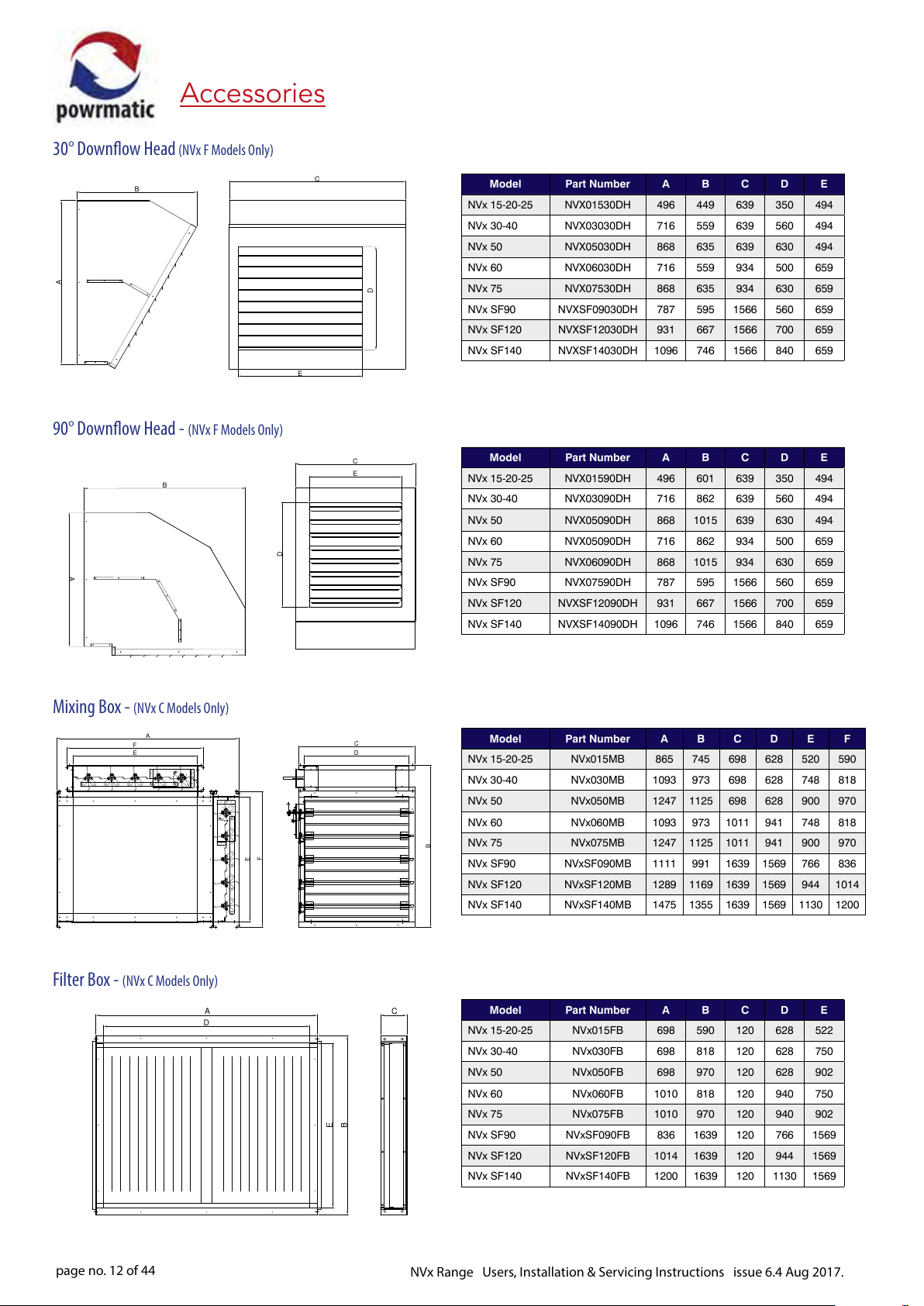

Accessories

C

A

E

30° Downow Head (NVx F Models Only)

B

90° Downow Head - (NVx F Models Only)

B

A

Model Part Number A B C D E

NVx 15-20-25 NVX01530DH 496 449 639 350 494

NVx 30-40 NVX03030DH 716 559 639 560 494

NVx 50 NVX05030DH 868 635 639 630 494

NVx 60 NVX06030DH 716 559 934 500 659

D

NVx 75 NVX07530DH 868 635 934 630 659

NVx SF90 NVXSF09030DH 787 595 1566 560 659

NVx SF120 NVXSF12030DH 931 667 1566 700 659

NVx SF140 NVXSF14030DH 1096 746 1566 840 659

C

E

Model Part Number A B C D E

NVx 15-20-25 NVX01590DH 496 601 639 350 494

NVx 30-40 NVX03090DH 716 862 639 560 494

NVx 50 NVX05090DH 868 1015 639 630 494

D

NVx 60 NVX05090DH 716 862 934 500 659

NVx 75 NVX06090DH 868 1015 934 630 659

NVx SF90 NVX07590DH 787 595 1566 560 659

NVx SF120 NVXSF12090DH 931 667 1566 700 659

NVx SF140 NVXSF14090DH 1096 746 1566 840 659

Mixing Box - (NVx C Models Only)

A

F

E

Filter Box - (NVx C Models Only)

A C

D

C

D

Model Part Number A B C D E F

NVx 15-20-25 NVx015MB 865 745 698 628 520 590

NVx 30-40 NVx030MB 1093 973 698 628 748 818

NVx 50 NVx050MB 1247 1125 698 628 900 970

NVx 60 NVx060MB 1093 973 1011 941 748 818

NVx 75 NVx075MB 1247 1125 1011 941 900 970

F

E

B

NVx SF90 NVxSF090MB 1111 991 1639 1569 766 836

NVx SF120 NVxSF120MB 1289 1169 1639 1569 944 1014

NVx SF140 NVxSF140MB 1475 1355 1639 1569 1130 1200

Model Part Number A B C D E

NVx 15-20-25 NVx015FB 698 590 120 628 522

NVx 30-40 NVx030FB 698 818 120 628 750

NVx 50 NVx050FB 698 970 120 628 902

B

E

NVx 60 NVx060FB 1010 818 120 940 750

NVx 75 NVx075FB 1010 970 120 940 902

NVx SF90 NVxSF090FB 836 1639 120 766 1569

NVx SF120 NVxSF120FB 1014 1639 120 944 1569

NVx SF140 NVxSF140FB 1200 1639 120 1130 1569

page no. 12 of 44

NVx Range Users, Installation & Servicing Instructions issue 6.4 Aug 2017.

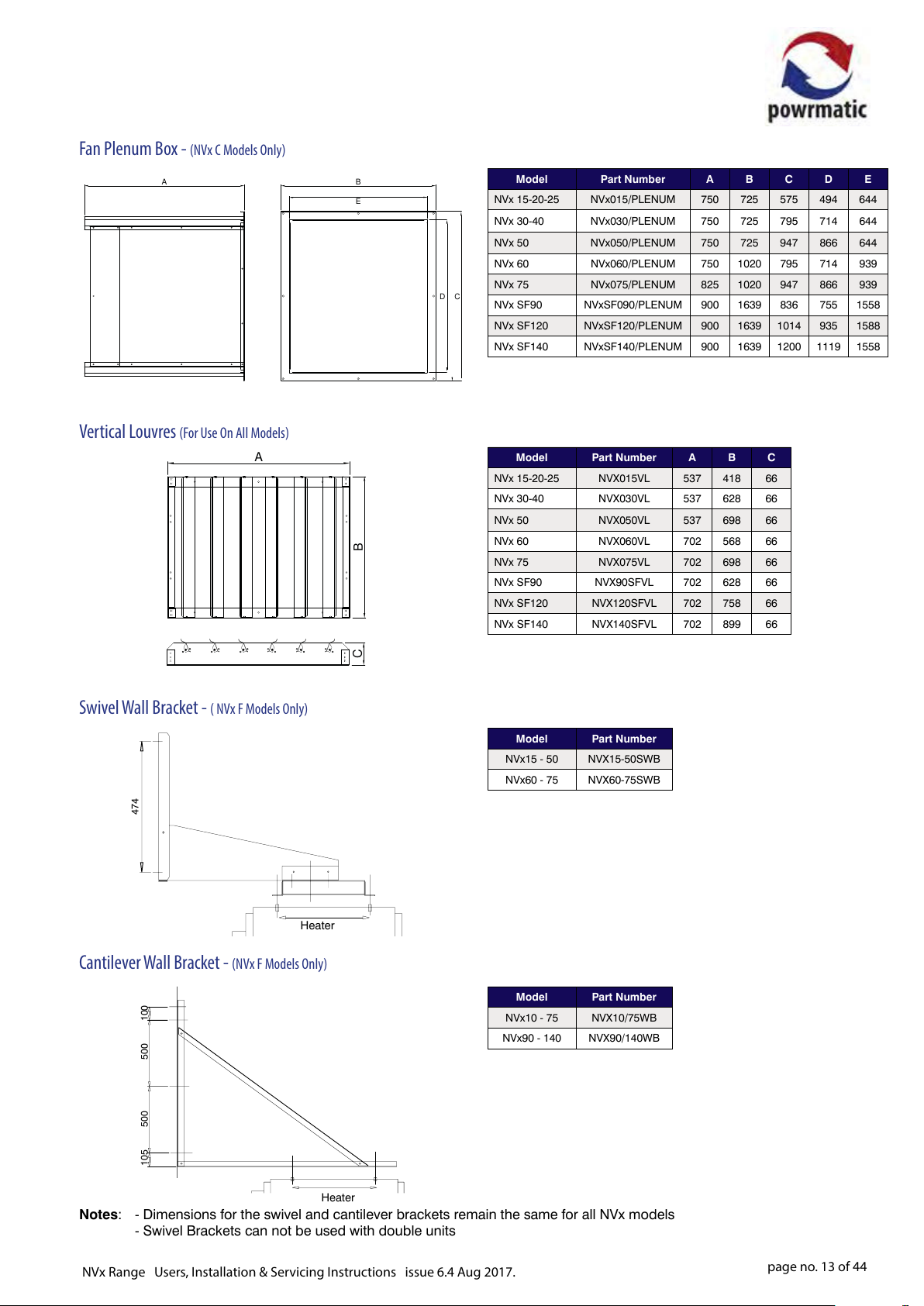

Fan Plenum Box - (NVx C Models Only)

A

Vertical Louvres (For Use On All Models)

A

B

E

CD

B

Model Part Number A B C D E

NVx 15-20-25 NVx015/PLENUM 750 725 575 494 644

NVx 30-40 NVx030/PLENUM 750 725 795 714 644

NVx 50 NVx050/PLENUM 750 725 947 866 644

NVx 60 NVx060/PLENUM 750 1020 795 714 939

NVx 75 NVx075/PLENUM 825 1020 947 866 939

NVx SF90 NVxSF090/PLENUM 900 1639 836 755 1558

NVx SF120 NVxSF120/PLENUM 900 1639 1014 935 1588

NVx SF140 NVxSF140/PLENUM 900 1639 1200 1119 1558

Model Part Number A B C

NVx 15-20-25 NVX015VL 537 418 66

NVx 30-40 NVX030VL 537 628 66

NVx 50 NVX050VL 537 698 66

NVx 60 NVX060VL 702 568 66

NVx 75 NVX075VL 702 698 66

NVx SF90 NVX90SFVL 702 628 66

NVx SF120 NVX120SFVL 702 758 66

NVx SF140 NVX140SFVL 702 899 66

Swivel Wall Bracket - ( NVx F Models Only)

474

Heater

Cantilever Wall Bracket - (NVx F Models Only)

100500500105

C

Model Part Number

NVx15 - 50 NVX15-50SWB

NVx60 - 75 NVX60-75SWB

Model Part Number

NVx10 - 75 NVX10/75WB

NVx90 - 140 NVX90/140WB

Heater

Notes: - Dimensions for the swivel and cantilever brackets remain the same for all NVx models

- Swivel Brackets can not be used with double units

NVx Range Users, Installation & Servicing Instructions issue 6.4 Aug 2017.

page no. 13 of 44

1.2 Technical Data

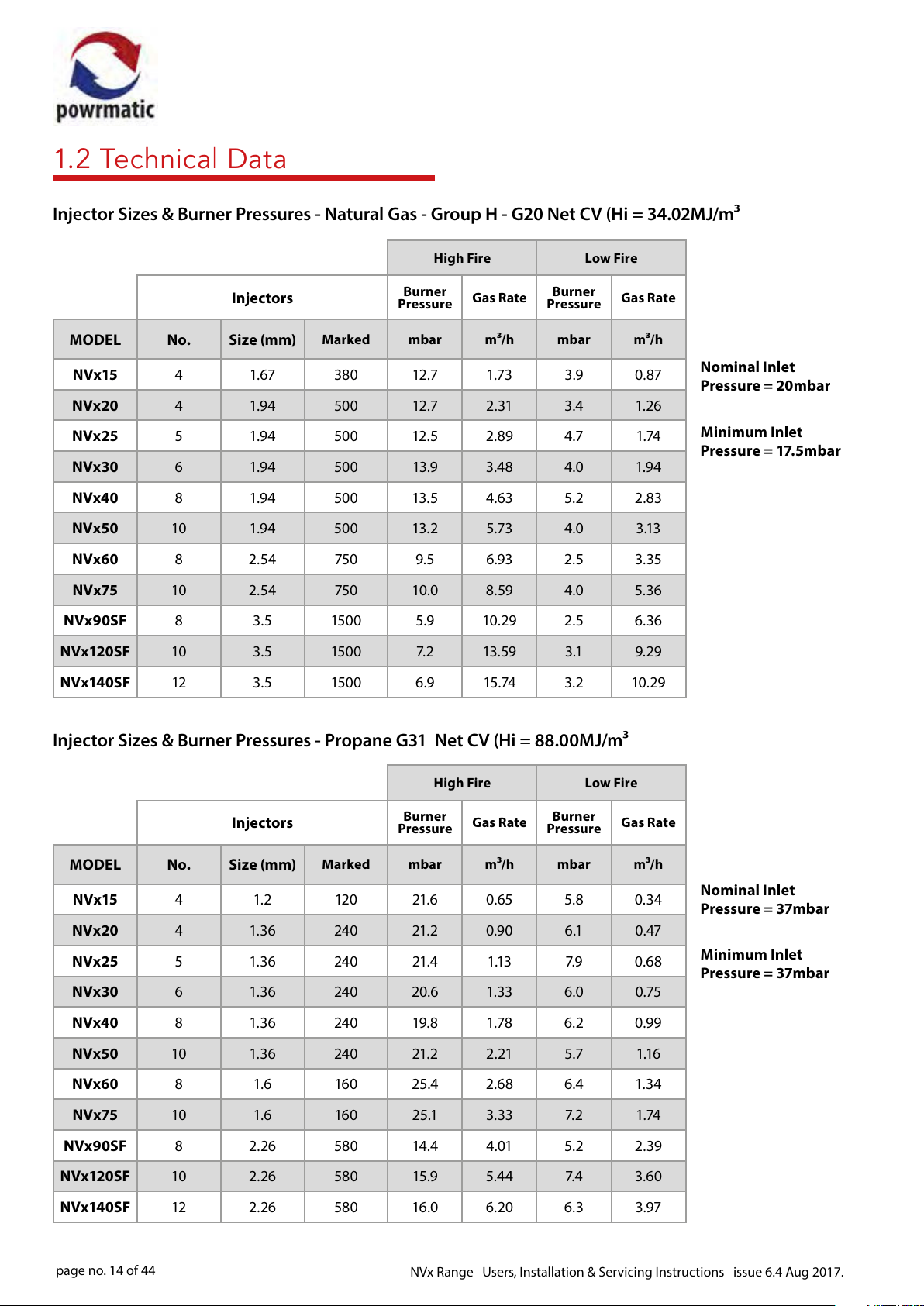

Injector Sizes & Burner Pressures - Natural Gas - Group H - G20 Net CV (Hi = 34.02MJ/m³

High Fire Low Fire

Injectors

MODEL No. Size (mm)

Burner

Pressure

Marked mbar m ³/h mbar m³/h

Gas Rate

Burner

Pressure

Gas Rate

NVx15 4 1.67 380 12.7 1.73 3.9 0.87

NVx20 4 1.94 500 12 .7 2 .31 3.4 1.26

NVx25 5 1.94 500 12 .5 2.89 4.7 1.74

NVx30 6 1.94 500 13.9 3.48 4.0 1.94

NVx40 8 1.94 500 13 .5 4.63 5.2 2.83

NVx50 10 1.94 500 13. 2 5.73 4.0 3.13

NVx60 8 2.54 750 9.5 6.93 2.5 3.35

NVx75 10 2.54 750 10.0 8.59 4.0 5.36

NVx90SF 8 3.5 1500 5.9 10.29 2.5 6.36

NVx120SF 10 3.5 150 0 7. 2 13 .59 3 .1 9.29

NVx140SF 12 3.5 150 0 6.9 15.74 3.2 10.29

Nominal Inlet

Pressure = 20mbar

Minimum Inlet

Pressure = 17.5mbar

Injector Sizes & Burner Pressures - Propane G31 Net CV (Hi = 88.00MJ/m³

High Fire Low Fire

Injectors

MODEL No. Size (mm)

Burner

Pressure

Marked mbar m ³/h mbar m³/h

Gas Rate

NVx15 4 1.2 120 21. 6 0.65 5.8 0.34

NVx20 4 1. 36 240 21. 2 0.90 6 .1 0.47

NVx25 5 1. 36 240 21.4 1.13 7. 9 0.68

NVx30 6 1.3 6 240 20.6 1.33 6.0 0.75

NVx40 8 1.36 240 19 .8 1. 78 6.2 0.99

NVx50 10 1. 36 240 21. 2 2.21 5.7 1.16

NVx60 8 1.6 160 25.4 2.68 6.4 1. 34

NVx75 10 1.6 16 0 25.1 3.33 7. 2 1. 74

NVx90SF 8 2.26 580 14. 4 4.01 5.2 2.39

NVx120SF 10 2.26 580 15.9 5.44 7. 4 3.60

Burner

Pressure

Gas Rate

Nominal Inlet

Pressure = 37mbar

Minimum Inlet

Pressure = 37mbar

NVx140SF 12 2.26 580 16.0 6.20 6.3 3.97

page no. 14 of 44

NVx Range Users, Installation & Servicing Instructions issue 6.4 Aug 2017.

Loading...

Loading...