Powrmatic NVx10, NVx25, NVx15, NVx20, NVx30 User, Installation And Servicing Instructions

...

Users, Installation and Servicing

Instructions

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: Reset from Lockout is by a switched Neutral

CE

NVx Range Users, Installation & Servicing Instructions Issue 1.9 March 2012

The NVx Range

(Brahma Control)

Dear Customer

This is to certify that this heater is guaranteed for two years parts and one year

labour from the date of original commissioning. The heater must be

commissioned within 4 weeks of installation.

The heat exchanger, where fitted, is guaranteed (parts only) for a further eight

years, chargeable on a sliding scale basis, price relative to age.

To make a claim

In the first instance you must contact your appliance supplier, or installer and

provide:-

1. The appliance type and serial number.

2. The original commissioning documentation.

3. As much detail as possible on the fault.

Your supplier, or installer, will then contact Powrmatic to make a guarantee

claim on your behalf.

Conditions of Guarantee

1. The heater must have been installed by a competent recognised installer, and

in accordance with the manufacturers instructions, building regulations and

local regulations.

2. The heater has been professionally commissioned, within 4 weeks of

installation, and a copy of the Commissioning Sheet returned to Powrmatic.

3. The heater has been maintained on a yearly basis by a competent servicing

company.

4. The heater has been used in accordance with the manufacturers instructions.

5. The correct specification fuel has been used

6. No unauthorised repairs or modifications have been made.

7. Powrmatic ‘General Conditions of Sale’ have been observed.

8. Except for the obligation of Powrmatic Ltd to perform warranty repairs during

the guarantee period, Powrmatic will not be liable in respect of any claim for

direct or indirect consequential losses, including loss of profits or increased

costs arising from loss of use of the heater, or any event arising there from.

Exclusions

1. Gaskets and fan belts are not included in the guarantee

Important: This certificate must

be kept with the appliance

Certificate of Guarantee

Powrmatic Ltd, Hort Bridge, Ilminster, Somerset, TA19 9PS

tel: 01460 53535 fax: 01460 52341

web: www.powrmatic.co.uk e-mail: service@powrmatic.co.uk

Installed

Date: ___________ Signed______________________________________ Installer

Commissioned

Date: ___________ Signed________________________ Commissioning Engineer

Failure to provide a copy of the Commissioning Sheet invalidates the heater warranty

1. Checks before lighting the Air Heater

The following preliminary checks should be made before lighting

the heater(s)

a) Ensure that the ELECTRICAL supply to the heater is

switched OFF.

b) Check that all warm air delivery outlets are open.

c) Check that the thermostat is set at MAX.

d) Check that the clock control is set to an ON period.

e) Check that any other controls are calling for heat.

2. Lighting the Air Heater

NOTE:

On initial lighting of the heater(s), it may take some time to

purge the internal pipe work of air. If it is not possible to light

the heater after several attempts contact the local service

company.

1. Switch on the electrical supply at the isolator and the start up

sequence will commence.

Note: Check that the red overheat indicator on the front of the

unit is not alight. If it is refer to Section 4.4

After a short delay the burners will light and the green ‘ON’

indicator on the front of the heater will be illuminated.

2. If the burners fail to light the control box will automatically

restart the ignition sequence. If after 5 attempts at ignition the

burners have still failed to light the control box will go to lockout

and the lockout light on the low level remote reset (or MC200

or Powrtrol RR if fitted) will be illuminated. To restart the

ignition sequence depress the reset button on the low level reset

for about 1-2 seconds.

If the heater will not light after two or three attempts shut down

the heater and contact a service engineer.

3. To Shut Down the Air Heater

3.1 For Short Periods: Turn the room thermostat to the OFF

or lowest setting.

3.2 For Long Periods: Complete step 3.1 above. Wait for 5

minutes and then turn OFF the

electrical supply at the isolator.

4. Description of Operation

Important: All heaters must be controlled by the fitted external

controls and not by use of the main switch in the electrical

supply to the heater.

4.1 Standard Units

The ignition sequence will commence each time that the external

controls e.g. Time clock, room thermostat etc. call for heat. The

internal exhaust fan will run and when sufficient combustion

airflow is proved by the air pressure switch the ignition spark

will be generated, the main gas valves opened and the burners

lit. The green ‘ON’ indicator will be illuminated. The heater fan

will automatically start approximately 2 minutes after the burners

light. When the external controls are satisfied the burners will

be turned off and approximately 2 - 3 minutes later the heater

fan will be automatically stopped.

4.2 High / Lo & Modulating Units

When the burners are alight the heat output will be controlled

either to high fire or low fire or, in the case of modulating units,

to any point between high and low fire; depending on the

requirements of the space being heated and the external controls

fitted.

4.3 Summer / Winter Modes

Certain types of external controls will provide for two modes

of operation i.e.

Summer: The heater fan alone will run at the dictate of the

external controls to provide air movement.

Winter: The heater will operate normally.

4.4 Overheat Thermostat

This operates if high temperatures within the heater are detected,

the burners are turned off and a red indicator light on the front

panel is illuminated. NVx10 - 75 units have the thermostat

located inside the controls section. NVx90 - 140 units have an

additional thermostat on the side of the unit at the opposite end

to the controls (either thermostat can go to limit and shut off

the burners). The fault condition must be identified and rectified

and the thermostat manually reset.

Isolate the electrical supply to the heater and open the controls

section door. Push in the red button on the fan/limit thermostat

(located towards the top of the compartment) to reset. On NVx90

- 140 units also reset the second limit thermostat.

Note: The thermostat can only be reset once the unit has cooled

down.

Unless the cause of the fault condition is readily obvious, for

example a power cut whilst the heater was operating, a service

engineer should be contacted.

5. Maintenance

To maintain efficient, reliable and safe operation of the heater

it must serviced by a qualified person at least annually and

preferably at the end of the heating season.

6. IMPORTANT

Free access must be maintained to and around the heater for

servicing purposes and the air supply to the heater must not be

restricted in any way. Combustible materials must not be stored

adjacent to the heater.

If at any time a gas leak is suspected turn OFF the gas supply

- DO NOT USE A NAKED FLAME - and contact the local gas

undertaking immediately.

All Powrmatic heaters use gas and electricity to power them,

they may also contain moving parts such as pulleys and belts.

It would be hazardous to tamper with or attempt to service unless

you are a competent person in the field of Gas and Electrical

work.

If you have any safety questions reference the servicing and

installation of any of our heaters please do not hesitate to contact

our head office for expert advice. Your safety is paramount to us.

Gas Safety (Installation & Use) (Amendment) Regulations

It is law that all gas appliances are installed, adjusted and, if

necessary, converted by qualified persons* in accordance with

the current issue of the above regulations. Failure to install

appliances correctly can lead to prosecution. It is in your own

interests and that of safety to ensure that the law is complied

with.

* An approved class of person listed on the gas register.

Users Instructions

CONTENTS

Section Title Page

1.

Introduction 1

2. Technical Data 2

3. General Requirements 6

4. Installation 7

5. Air Distribution System 10

6. Commissioning & Testing 10

7. Servicing 12

8. Functional Flow Diagram 15

9. Connections to External Controls 17

10. Fault Finding Flow Chart 19

11. Short List of Parts 20

Tables Title Page

1. Dimensions 3

2. Specifications 3

3. Electrical Loadings 1ph 4

3.1 Injector Sizes & Burner Pressures

Natural Gas - Group H - G20 5

3.2 Injector Sizes & Burner Pressures

Propane - G31 5

Figure Title Page

1a. Exhaust only system - horizontal 8

1b. Exhaust only system - vertical 8

2a. Individual system - horizontal 9

2b. Individual system - vertical 9

3. General Controls Layout 10

4. Governor adjustment (Honeywell VR425A) 11

5. Governor adjustment (Honeywell VR4605A) 11

6. High/Lo Regulator 11

7. Modulating Regulator 12

8. Flame Current Measurement 12

9. Ignition Electrode Spark Gap 13

10. Thermostat Fan / Limit - Honeywell L4064N 13

Installation & Servicing Instructions

1. INTRODUCTION

The NVx range are highly efficient gas fired, fanned circulation

air heaters that cover heat outputs of 10kW to 140kW, have a

closed combustion circuit and are supplied complete with a flue

system. They are certified for use on Natural Gas, Group H G20, and Propane - G31 only.

Appliance Categories are Cat II2H3P (GB, IE).

The heaters are designed to be suspended from suitable roof

points or alternatively to be mounted on purpose designed

brackets and are intended primarily for heating commercial or

industrial premises.

NVx heaters feature a closed combustion circuit and have an

internal exhaust fan, mounted downstream of the heat exchanger,

to evacuate the products of combustion and draw in air for

combustion. The air heater must be connected to the flue system

that is provided by Powrmatic Ltd.

They may be used where the atmosphere inside the premises

could be contaminated e.g. Dust, oil mist etc. but the heaters

are not airtight and therefore may not be used in areas classified

as hazardous as defined in BS 5345: Part 2 or areas subjected

to significant negative pressures due to extract systems.

NVx/F heaters have an axial fan assembly fitted at the rear to

circulate the air being heated through the folded tube heat

exchanger. NVx/C units are supplied with a centrifugal fan and

NVx/D units for use with ducted systems where the air moving

fan is by others or a centrifugal fan section is used adjacent to

or remote from the heater. NVx/DH units are for use in air

handling units and NVx/EA units are for siting externally.

Heaters are fitted as standard with inshot burners, a fully

automatic control for ignition, flame sensing, gas supply control

and safety functions, an internal exhaust fan, main air fan (/F

and /C models), and fan/limit thermostat.

Options include High/Low or Modulating burner controls, inlet

duct connection, outlet duct connection, 45° head, 90° outlet

bend, vertical/horizontal outlet louvre assembly and a full range

of modular duct components.

IMPORTANT

Service and Maintenance Engineers shall ensure that replacement

items are fitted, adjusted and set in accordance with the data

and detail set out in these instructions. If in doubt consult

Powrmatic Technical Department.

Gas Safety (Installation & Use) Regulations 1998

It is law that all gas appliances are installed, adjusted and, if

necessary, converted by qualified persons* in accordance with

the current issue of the above regulations. Failure to install

appliances correctly can lead to prosecution. It is in your own

interests and that of safety to ensure that the law is complied

with.

* An approved class of person listed on the gas register.

1

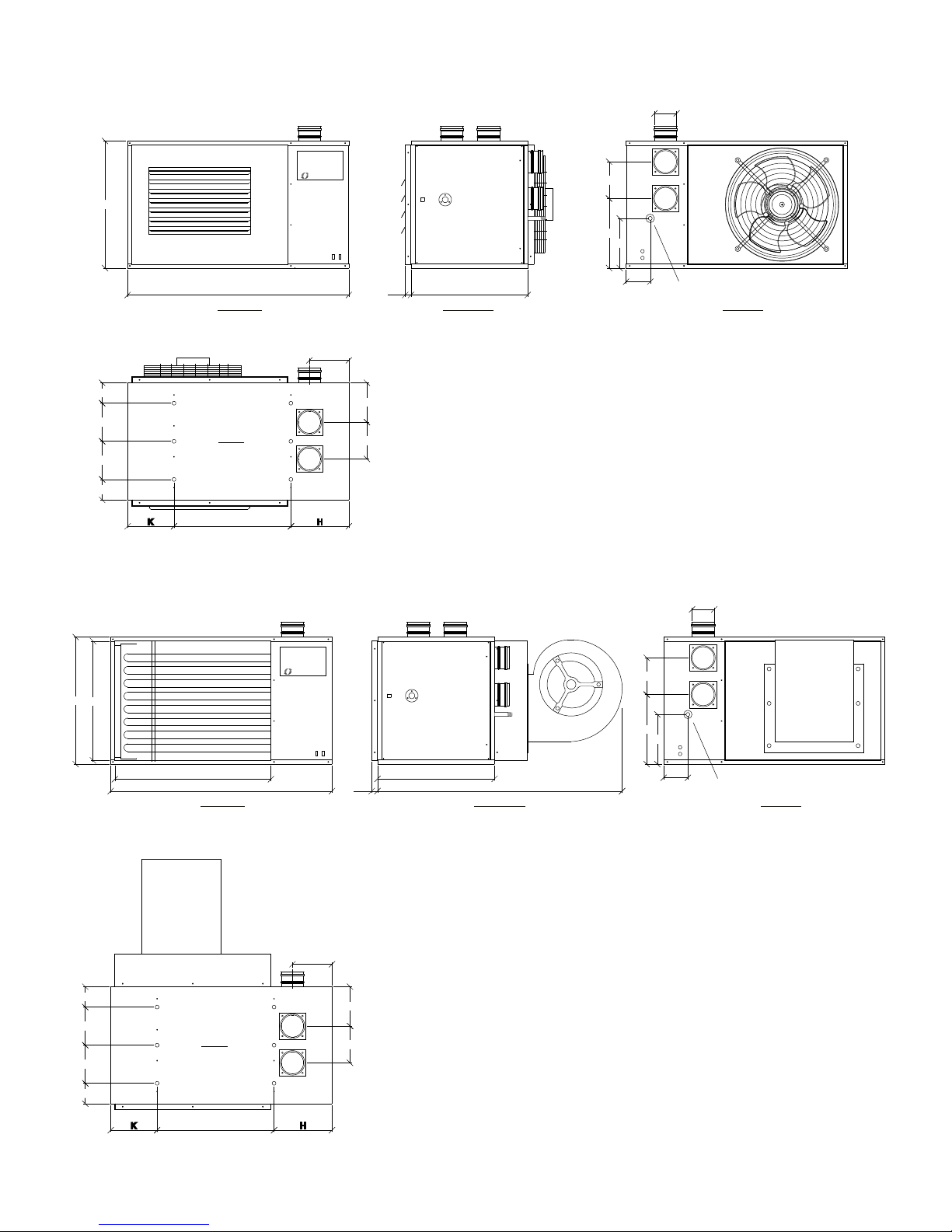

2. TECHNICAL DATA

2

R/H SIDE VIEW

A B

REAR VIEW

PLAN

FRONT VIEW

GAS ENTRY POINT

N

P

F

G

E

G

M

H

J CTRS

K

228 CTRS

228 CTRS

122

122

C

ø D

35

NOTE: For dimensioning purposes both top and rear

flue and combustion air connections are shown

R/H SIDE VIEW

A

REAR VIEW

PLAN

FRONT VIEW

N

P

F

G

E

G

M

H

J CTRS

K

228 CTRS

228 CTRS

122

122

C

ø D

35

NOTE: For dimensioning purposes both top and rear

flue and combustion air connections are shown

L

B

T

S

NVx

POWRMATIC

NVx

POWRMATIC

GAS ENTRY POINT

NOTE: For dimensioning purposes both top and rear

flue and combustion air connections are shown

33.733.7

T

S

R/H SIDE VIEW

A

S

REAR VIEW

PLAN

FRONT VIEW

N

P

F

G

E

G

M

H

J CTRS

K

B

228 CTRS

228 CTRS

122

122

C T

ø D

NVx

POWRMATIC

GAS ENTRY POINT

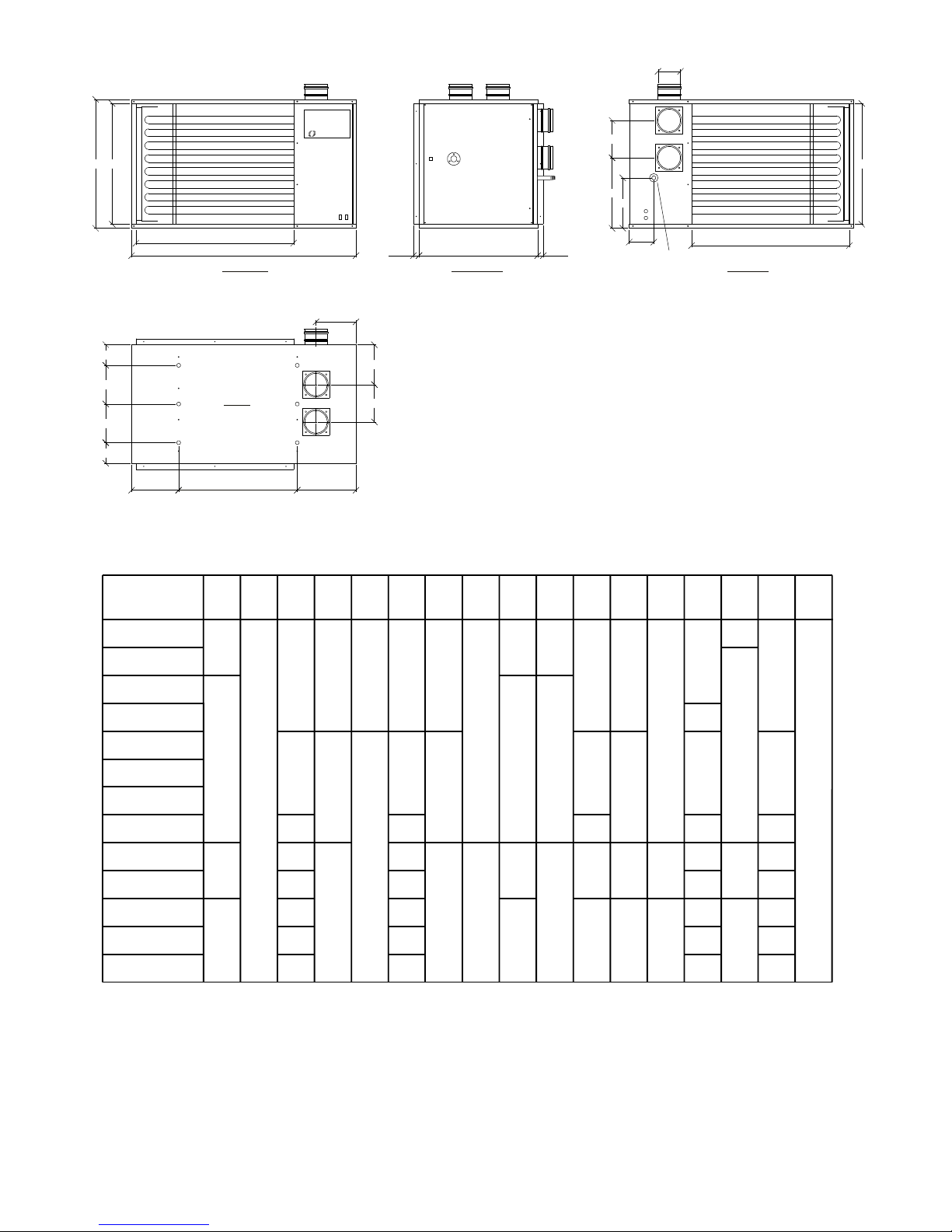

Table 1. Dimensions

3

NVx

15

NVx

25

NVx

30

NVx

50

NVx

60

NVx

75

NVx

90

NVx

120

NVx

140

NVx

35

Model

NVx10

B

700

A

1000

1325

2325

785

C

540

760

912

912

700

760

831

975

422

637

932

1932

492

712

864

864

652

712

783

927

ØD E

233.5

24880

100

130

F

492

644

416

568

321

487

631

308

G

142

220

120

H

347

317

J

450

700

850

250

M

236

246

206

216

L

524

752

904

752

904

639

804

969

K

218

232.5

278

NVx

20

NVx

40

N

114

145

88

P

¾'’

194

225.5

297

374

374

260

326

398

297

S T

Gas

inlet

Ø

Table 3

Electrical Loadings 1ph

NVx

90

NVx

120

7.81 4.22

9.57 5.13

NVx

140

9.64 4.98

/F Models /C Models

MODEL

PLATE

AMPS

(A)

START

AMPS

(A)

RUN

AMPS

(A)

FUSE

RATING

(A)

NVx

10

2

NVx

15

0.18 0.34 0.16

870

2.8 4.2 2.10

1.39 0.51 4.0 8.1 2.60

NVx

20

0.38 0.28 4.0 7.8 3.20

3

NVx

30

1.83 0.61 14.7 4.50

7

NVx

40

1.30

2.56

1.35 8.4

14.5 5.00

NVx

50

1.40 4.01 1.96 3 16.0 6.40

NVx

60

4.70 2.44

NVx

75

4.78 2.51

2 x 1.40

NOMINAL

MOTOR

R.P.M.

PLATE

AMPS

(A)

START

AMPS

(A)

RUN

AMPS

(A)

FUSE

RATING

(A)

NVx

25

1.89 0.62

0.54

0.89

2.50

2 x 2.50

0.31

7

5

NOMINAL

MOTOR

R.P.M.

4.0 8.2 2.90

28.4 11.6

25

900

1400

775

910

820

900

11.1

2 x 8.4

2 x 11.1

24.5 10.6

42.5 21.5

24.5 12.3

16

NVx

35

Note: 3ph Data is

supplied separately with

units ordered to this

specification.

14.0

39.8

5.30

25.2

5

Table 2 - Specifications

4

Note: /D data refers to Powrmatic supplied centrifugal/silencer duct section

MODEL

INPUT

(Nett)

OUTPUT

INPUT

(Nett)

OUTPUT

kg

kW kW m³/s m³/h Pa kW

NVx10

10.79 10.0 6.57 5.90 0.2601

NVx15

16.00 15.0 8.22 7.50 0.3902

NVx20

21.85 20.0 11.58 9.92 0.5203

NVx25

27.32 25.0 16.50 14.30 0.6503

NVx30

32.60 30.0 18.34 16.30 0.7804

NVx40

43.48 40.0 24.19 21.22 1.0405

NVx50

54.23 50.0 28.40 24.83 1.3006

N/A 0.040 53

140

0.250

91.5

N/A

0.120

59.5

145 0.370 106.5

N/A 0.070 69.5

177 0.370 120.5

N/A 0.180 74.5

143 0.370 126.5

N/A 0.180 96.0

250 1.100 166.5

N/A 0.300 108.0

236 1.100 168.5

N/A 0.440 123.0

205 1.100

183

F

D

F

D

F

D

F

D

F

D

F

D

F

D

HIGH FIRE LOW FIRE

AIR

VOLUME

MAXIMUM

DUCT

RESISTANCE

FAN

MOTOR

WEIGHT

NVx60

65.22 60.0 35.63 31.49 1.5608

N/A 0.550 138.5

250 1.50

213

D

F

F

D

F

D

D

F

NVx75

NVx90

NVx120

81.5 75.0

97.8 90.0

130.4 120.0

42.61 37.50

58.50 54.50

75.45 71.00

1.9510

2.3412

3.1215

N/A 0.550 158.0

260 1.50 234

N/A 2 x 0.440 204.0

200 2 x 1.10 343

N/A 2 x 0.550 260

284 2 x 1.50 363.5

D

F

NVx140

152.1 140.0 98.92 92.55 3.6418

N/A 2 x 0.550 260

285 2 x 1.50 424

NOISE

LEVEL

dB(A) @ 3m

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

46

54

52

53

54

58

61

62

62

66

67

67

NVx35

F

D

39.32 34.95 23.1 19.0 1.000

936

1405

1873

2341

2809

3746

4682

5619

7024

8428

11237

13110

3600

N/A 0.300 96.0

210 1.100 166.5

N/A

58

Loading...

Loading...