Powrmatic NCA-G Series, NCA-G 200, NCA-G 300, NCA-G 100, NCA-G 150 Installation And Servicing Instructions

Page 1

The NCA-G Range

CE

Installation and Servicing

Instructions

WARNING: THIS APPLIANCE MUST BE EARTHED

£2.50 When supplied separately.

NCA-G Range Issue 4 Feb 1999

Page 2

CONTENTS

Section Title Page

1. Introduction 1

2. Technical Data 2

3. General Requirements 3

4. Installation 4

5. Air Distribution System 5

6. Commissioning & Testing 5

7. Servicing 6

8. Connections to Powrmatic

External Controls 7

9. Fault Finding 8

10. Short List of Parts 8

Tables Title Page

1. Dimensions 2

2. Performance Data 2

3.1 Burner Pressures - Natural Gas

Group H - G20 2

3.2 Burner Pressures - Propane - G31 2

4. Electrical Loadings 3

Figure Title Page

1. Gas Control Schematic NCA-G 100 - 300 6

2a. Gas Controls Layout NCA-G 100, 150 6

2b. Gas Controls Layout NCA-G 200, 300 6

3. Honeywell L4064N 7

Appendix Title Page

A Calculation Of Flue System Inside

Equivalent Resistance Back Cover

Page 3

1. INTRODUCTION

The Powrmatic NCA -G range of gas fired for ced dr augh t, cl osed

flue, fanned circulation air heaters cover a heat output range

of 29.3 kW (100000 Btu/h) to 88.0 kW (300000 Btu/h) and

are intended primarily for heating commercial or industry

premises. They are certified for use on Natural Gas, Group H G20 and Propane - G31.

The heaters are for floor mounting and ar e av ailabl e in UF and

UD variants. (U - Upright; F - Freeblowing; D - Ducted).

NCA-G heaters have a cen trifugal f an assembly fitted upstr eam

of the combustion chamber / heat exchanger assembly to

circulate the air being heated.

Heaters are fitted as standard with fully automatic monoblock

forced draught gas burn ers and m onoblock gas contr ol assemblies.

Options include High/Lo w or modulatin g burner s, Deep V filters ,

proportional air dampers, combustion air inlet adaptors and

inlet and outlet duct spigots.

Each air heater must be conn ected t o a closed flue s ystem only.

Gas Safety (Installation & Use) Regulations 1994

It is law that all gas appliances are installed, adjusted and, if

necessary, converted by qualified persons* in accordance with

the above regulations. Failure to install appliances correctly

can lead to prosecution. It is in your own interests and that

of safety to ensure that the law is complied with.

* e.g. Corgi Registered

1

Page 4

2. Technical Data

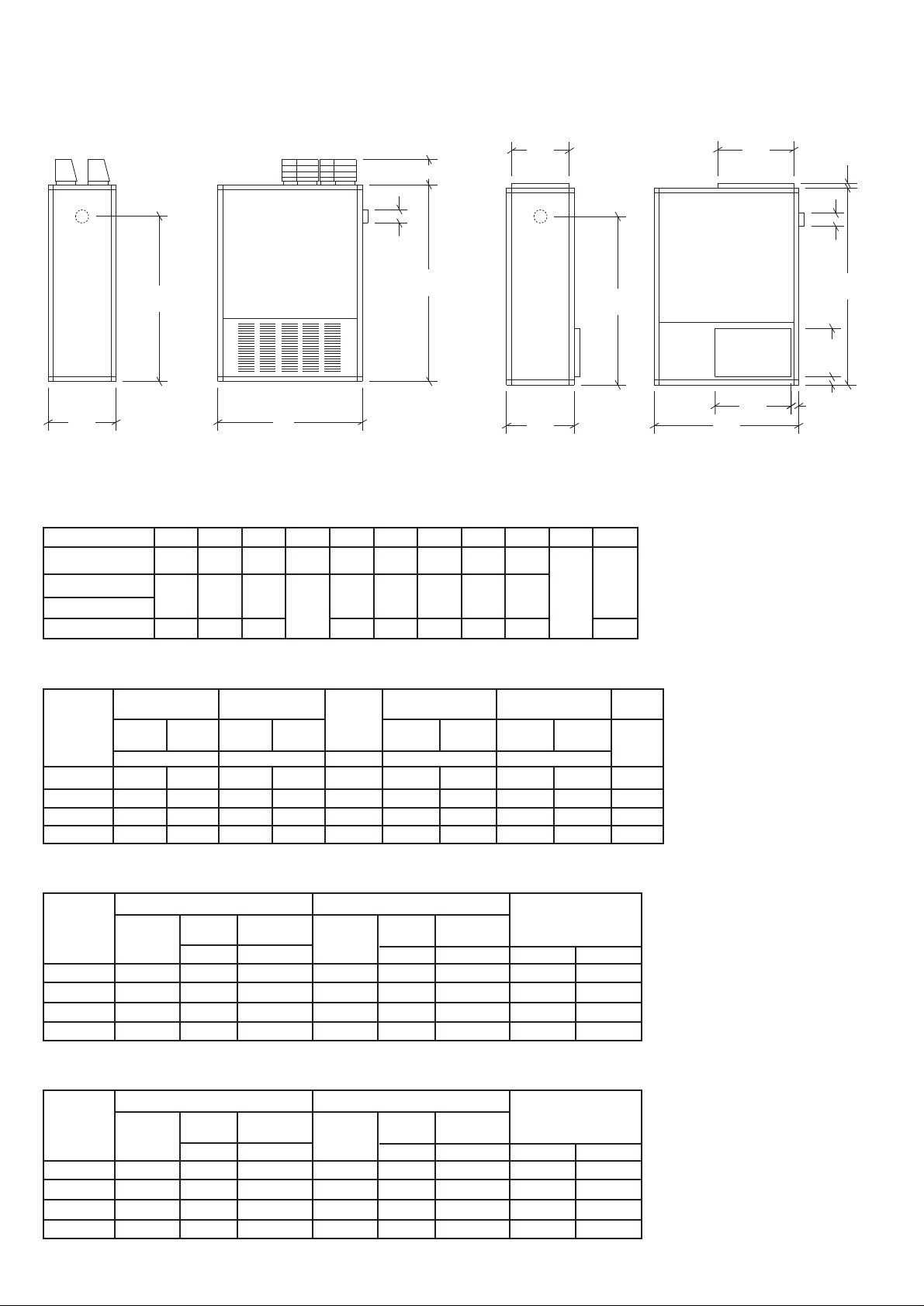

2.1 Dimensions

NCA-G 100 - 300 UF & UD Models

NCA-G 200UD SHOWN

H

D

F

C

G

B

FRONT

VIEW

A

SIDE

VIEW

B

FRONT

VIEW

Table 1 - Dimensions

A B C D F G H J K L M

NCA-G 100 1112 603 1645 254 125 1390 502 375 629

NCA-G 150

NCA-G 200 203

NCA-G 300 1390 730 2076 150 1810 629 525 756 47

1340 629 1822 125 1530 527 450 705 50

72

G

Gas connection size

All Units R½

A

SIDE

VIEW

K

L

F

C

J

K

M

M

Table 2 - Performance Data

HIGH FIRE LOW FIRE

INPUT OUTPUT

MODEL

NCA-G 100 33.3 29.3 N/A N/A 0.5192 150 N/A 0.335 N/A 152

NCA-G 150 50.0 44.0 N/A N/A 0.7788 290 N/A 0.55 N/A 215

NCA-G 200 66.9 58.6 N/A N/A 1.0383 200 N/A 0.56 N/A 215

NCA-G 300 100.0 88.0 N/A N/A 1.5575 250 N/A 1.5 N/A 304

(Net) (Net)

kw kw m³/s pa kw kg

INPUT OUTPUT

AIR

VOLUME

MAXIMUM DUCT

RESISTANCE

Standard L.H.P. Standard L.H.P.

FAN MOTOR WEIGHT

Table 3.1 - Burner Pressures - Natural Gas - Group H - G20 - NetCV (Hi) = 34.02MJ/m³

Powrmatic Burners Riello Burners

Type Pressure Pressure Type Pressure Pressure

MODEL

NCA-G 100 PCGS 2 N/A 4.8 GS 5 N/A 4.3 3.40 120.0

NCA-G 150 PCGS 2 N/A 9.9 GS 5 N/A 4.2 5.12 180.8

NCA-G 200 PCGS 3 N/A 12.2 GS 10 N/A 3.7 7.08 250.0

NCA-G 300 PCGS 5 N/A 10.4 GS 10 N/A 5.2 10.89 384.5

Start Gas Main Burner Start Gas Main Burner Gas Rate

mbar mbar mbar mbar m³/h ft³/h

Table 3.2 - Burner Pressures - Propane - G31 - NetCV (Hi) = 88.00MJ/m³

Powrmatic Burners Riello Burners

Type Pressure Pressure Type Pressure Pressure

MODEL

NCA-G 100 PCGS 2 N/A 6.9 GS 5 N/A 3.1 1.31 46.3

NCA-G 150 PCGS 2 N/A 11.3 GS 5 N/A 6.4 1.98 69.9

NCA-G 200 PCGS 3 N/A 20.0 GS 10 N/A 4.1 2.74 96.7

NCA-G 300 PCGS 5 N/A 14.2 GS 10 N/A 8.3 4.21 148.7

Start Gas Main Burner Start Gas Main Burner Gas Rate

mbar mbar mbar mbar m³/h ft³/h

2

Page 5

Table 4 Electrical Loadings

Standard Larger Horsepower Motor

NOM. PLATE START RUN FUSE NOM. PLATE START RUN FUSE

MODEL

NCA-G 100 1000 2.6 5.0 2.6 3

NCA-G 150

NCA-G 200

NCA-G 300 7.0 18.0 8.1 10

MOTOR AMPS AMPS AMPS RATING MOTOR AMPS AMPS AMPS RATING

ph R.P.M. (A) (A) (A) (A) R.P.M. (A) (A) (A) (A)

500 5.0 8.5 6.1 7

1

1000

4.1 10.0 4.5 5

N/A

3. General Requirements

3.1 Related Documents

The installation of the air heater(s) must be in accordance

with the rules in force and the relevan t requirements of th e

Gas Safety Regulations, Building Regulations and the I.E.E.

Regulations for Electrical Installations.

It should be in accor dance al so with any r ele vant r equirem ents

of the local gas region, l ocal auth ority an d fire auth ority an d

the relevant recommendations of the following documents.

British Gas Plc Publications

IM/11 : 1989 Flues for Commercial and Industrial Gas Fired

Boilers and Air Heaters

IM/16 : 1988 Guidance notes for the installation of gas

pipework, boosters and compressors in Customer’s premises

(excluding domestic installation of 25mm and below).

British Standards Code of Practice

BS 5588 Fire precautions in the design and construction of

buildings.

Part 2 : 1985 Code of Practice for Shops

Part 3 : 1983 Code of Practice for Office Buildings

BS 6230: 1991 Installation of Gas Fired Forced Convection

Air Heaters for Commercial and Industrial Space Heating.

Those appliances having an input ratin g n ot e xceedin g 60kW

viz. NCA-G 100 and NCA-G 150 mu st be install ed in accor dance

with the relev ant recomm endations of th e follo wing documen ts.

BS 5440 Flues and Air Supply for gas appliances of rated

input not exceeding 60kW (1st and 2nd family gases).

Part 1 - Flues, Part 2 - Air Supply

For NCA-G100 and NCA-G150 units reference should also be

made to BS 5864. Code of Practice for installation of gasfired ducted-air heaters of rated input not exceeding 60kW.

3.2 Location

The location chosen for the air heater must permit the

provision of a satisfactory flue system and an adequate air

supply. The location must also provide adequate space for

servicing and air circulation around the air heater.

The heater(s) must not be installed in conditions for which

it is not specifically designed e.g. where the atmospheric is

corrosive or salty and where high wind speeds may affect

burner operation, and they are not suitable for outd oor use.

Where the location of the air heater is such that it might

suffer external mechanical damage e .g. fr om ov erh ead cr anes ,

fork lift trucks, it must be suitably protected.

NCA-G units are designed to operate in a maximum ambient

temperature of 25°C.

3.3 Gas Supply

3.3.1 Service Pipes

The local gas undertaking should be consulted at the

installation planning stage in or der to establish th e availability

of an adequate supply of gas. An existing service pipe must

not be used without prior consultation with the local gas

undertaking.

3.3.2 Meters

A gas meter is connected to the service pipe b y th e l ocal gas

undertaking or a local gas un dertakin g contr actor. An existing

meter should be check ed, pr efer ably b y th e gas un d ertaking,

to ensure that the meter is adequate to deal with the total

rate of gas supply required.

3.3.3. Installation Pipes

Installation pipes should be fitted in accordance with

IM/16:1988. Pipework from the m eter to the air heater must

be of adequate size. Do not use pipes of a smaller size than

the inlet gas connection of the heater. The complete

installation must be tested for soun dn ess as d escribed in th e

above Code. The complete installation must be tested for

soundness as described in BS 6230.

3.3.4. Boosted Supplies

Where it is necessary to employ a gas pressure booster the

controls must include a low pressure cut off switch at the

booster inlet. The local gas undertaking must be consulted

before a gas pressure booster is fitted.

3.4 Flue System

Detailed recommendations for fluing are given in BS 5440,

Part 1 (Flues) and IM/11.

The air heater must be connected to a closed flue system.

The cross sectional area of the flue serving the appliance

must be not less than the area of the flue outlet to the air

heater.

Materials used for the flue system should be mechanically

robust, resistant to internal and external corrosion,

noncombustible and durable under the conditions to which

they are likely to be subjected.

Prevention of condensation within the flue should be an

important factor in the design of the flue system. In order

to minimise condensation the use of double wall ed flue pipe

or insulation is recommended. If double walled flue pipe is

used it should be of an acceptable type.

Where condensation in the flue is unavoidable provision

should be made for condensation to flo w fr eely t o a point at

which it can be released, preferably into a gully. The

condensation pipe from th e flue t o th e disposal poin t sh oul d

be of non-corrodible material o f not l ess than 22mm diameter .

Facilities should be made for disconnecting the flue pipe(s)

from the air heater(s) for inspection and servicing purposes.

Bends with removable covers shoul d be fitted for inspection

and cleaning purposes where considered appropriate.

The flue should terminate in a freely exposed position and

must be so situated as to pre v ent th e pr oduct s o f combustion

entering any opening in a building in such concentration as

to be prejudicial to health or a nuisance.

It is recommended that consideration be given to th e fittin g

of a terminal at the flue outlet, however, where the heater

flue is less than 200mm in diameter an approved terminal

must be fitted.

3.5 Air Supply

In buildings having a design air change rate of less than

0.5/h, and where NCA-G h eater s ar e to be in stall ed in h eated

spaces having a volume less than 4.7 m3 /kW of total rated

heat input grilles shall be provide at low level as follows:-

3

Page 6

(1) for heaters of heat input less than 60 kW, the total

minimum free area shall not be less than 4.5 cm2 per

kilowatt of rated heat input.

(2) for heaters of h eat input 60 kW or more, the total minimum

free area shall not be less than 270cm2 plus 2.25 cm

per kilowatt in excess of 60 kW rated heat input.

The air vent(s) should have negligible resistance and must

not be sited in any position where it is likely to be easily

blocked or flooded or in an y position a djacent t o an extr action

system which is carrying flammable vapour.

Where the air heater(s) is t o be in stall ed in a plant room the

air heater(s) requires the plant room housing it to have

permanent air vent s comm unicating dir ectly with the out sid e

air, at high l e vel an d at lo w l ev el. Wher e comm unication with

the outside air is possible only by means of high level air

vents, ducting down to floor l e v el f or the lower vent s sh oul d

be used.

Air vents should have negligible resistance an d must not be

sited in any position where th ey ar e likely to be easily bl ocked

or flooded or in any position a djacen t to an e xtra ction sy stem

which is carrying flammable vapour.

Grilles or louvres should be so designed that high velocity

air streams do not occur within the plant room.

2

clear of sources of smells and fumes, and in special

circumstances where there is any possibility of pollution of

the air by dust, shavings etc., precautions mu st be taken by

carefully positioning return air intakes and by the provision

of screens to prevent contamination.

In addition, where there is a risk of combustible material

being placed close to the warm air outlets, suitable barrier

rails should be pr ovided to preven t any combustible material

being within 900mm of the outlets.

3.7 Electrical Supply

Wiring external to the air h eater must be in stalled in accordan ce

with the I.E.E. Regulations for Electrical Installations and

any local regulation s which apply . Wirin g shoul d be completed

in flexible conduit.

Heaters NCA-G 100 - 300 are supplied by 230V - 1ph, 50Hz.

The method of connection to the main electricity supply

must facilitate the complete electrical isolation of the air

heater(s) and the supply shoul d serv e only th e air h eater(s).

The isolator must have a contact separation of at least 3mm

in all poles. The method of connection should be provided

adjacent to the air heater(s) in a readily accessible position.

See the accompanyin g wiring dia gram f or the h eater electrical

connections.

The basic minimum effective area requirements of the air

vents are as follows:

(a) Low Level (inlet)

(1) for heaters of total rated heat input less than 60

kW: 9 cm2 per kilowatt of rated heat input;

(2) for heaters of total rated heat input 60 kW or mor e:

540 cm2 plus 4.5 cm2 per kilowatt in excess of

60 kW total rated input.

(b) High Level (outlet)

(1) for heaters of total rated heat input less than 60

kW: 4.5 cm2 per kilowatt of rated heat input;

(2) for heaters of total rated heat input 60 kW or mor e:

270 cm2 plus 2.25 cm2 per kilowatt in excess of

60kW total rated input.

3.6 Air Distribution System

The following notes are of particular importance.

For free-blowing units it must be taken into account that

the buoyancy of the heated air leaving the heater and air

patterns within the space being heated will modify the air

throw pattern achieved. In buildings having a low heat loss

where single units are required to cover a large floor area

and in buildings with high roof or ceiling heights Calecon

thermal economiser units should be fitted to ensure even

heat distribution and minimise stratification respectively.

Care should be taken to avoid impeding the air throw with

racking, partitions, plant or machinery etc.

For ducted units all delivery and return air ducts, including

air filters, jointing and any insulation or lining must be

constructed entirely of materials which will not contribute

to a fire, are of adequate strength and dimensionally stable

for the maximum internal an d external temper atures t o which

they are to be exposed during commissioning and normal

operation. In the selection of materials account must be

taken of the working environment and the air temper atures

which will result when the ov erh eat limit therm ostat is being

commissioned. Where inter-joist spaces are used as duct

routes they should be suitably lined with a fire-resisting

material.

A full and unobstructed return air path to the air heater(s)

must be provided.

If the air heater(s) is installed in a plan t room the return air

intake(s) and the w arm air outl et(s) fr om th e h eater(s) m u st

be fully ducted, in to and out of the plant room to avoid

interference with the oper ation of the flue b y the air circulation

fan.

The openings in the structure of the plant room through

which the ducting passes must be fire stopped.

Care must be taken t o en sur e that return-air in tak es are k ept

4. Installation of Air Heater(s)

4.1 General

Before installation, check that the local distribution

conditions, nature of gas and pressure, and adjustment

of the appliance are compatible.

The air heater must be in stall ed in a ccor dan ce with th e rul es

in force and the r el e van t r equir emen t s of any fire regulations

or insurance company’s requirements appertaining to the

area in which the heater is located, particularly wh er e special

risks are involved such as areas where petrol vehicles are

housed, where cellulose spraying is carried out, in wood

working departments etc.

The followin g minimum clear ances for installation an d servicing

must be observed.

To the front The depth of the heater

To the rear 1.0m

To at least one side 1.0m

Above the heater 1.00m

Any combustible material adjacent to the air heater and the

flue system must be so placed or shielded as to ensure that

its temperature does not exceed 65°C.

IMPORTANT:

1. No air heater shall be installed where there is a f oreseeable

risk of flammable particles, gases vapours or corrosion

inducing gases or vapours being drawn into either the

heated air stream or the air for combustion. In such

cases installation may only proceed if the air to be

heated and the air for combustion are ducted to the

heater from an uncontaminated sour ce preferably out side

the building. In certain situations where only airborne

particles are present it may suffice to fit filters on the

air inlet ducts of the heater. Advice in these instances

may be obtained from Powrmatic Ltd.

4.2 Fitting the Air Heater

The heaters must be installed on a level noncombustible

surface.

If noise level s ar e o f particular importan ce th e h eater sh oul d

be insulated from the structure of the building by in stalling

it on suitable anti-vibration mountings. In all such cases it

is essential that all gas, duct, electrical an d flue conn ection s

to the heater are ma d e with fl e xibl e connection s t o main tain

continuity of connection. In the case of the flue connection

single wall stainless steel flue is deemed to flex sufficiently

to meet the requirements.

4

Page 7

4.3 Connection of Air Heater(s) to Flue System

A single wall Tee piece is supplied with each heater and must

be fitted to the flue outlet socket on the heater. The flue

system then connects directly on to the tee. For flue sizes

refer to Table 1, Page 2. Horizontal runs of flue are not

permitted. If necessary a single offset using two 45° bends

can be included to av oid obstructions . The maximum equival ent

resistance of the flue system must not exceed 20pa. Details

of how to calculate the resistance of the flue t o be installed

are given in Appendix A.

4.4 Condensate Drainage

The design of the flue s y stem sh oul d minimise the f ormation

of condensation, however when this is envisaged to be a

problem provision should be made for condensation to flow

to a joint where it can be drained, preferably into a gully.

4.5 Gas Connection

A servicing valve and downstream union must be fitted at

the inlet to the air heater gas controls assembly to fa cilitate

servicing. The gas supply to the air h eater m ust be compl eted

in solid pipework and be adequately supported.

Warning: When completing the final gas connection to the

heater do not place undue strain on the gas pipework of th e

heater.

4.6 Electrical Connections

All units are fully pre-wired an d only requir e final connections

for the incoming main s supply an d compl etion of th e con tr ol

circuit (230V) via a room thermostat, time clock etc. The

electrical supply must be run to a point adjacent to the

heater and be suitably terminated to provide an isolation

point that will prevent remote activation of th e unit during

servicing. The heater electrical panel is located behind the

front panel and cabl e entry poin ts are pr ovided in th e adja cent

heater framework. Reference must be ma de to Table 4 (Page

3) to ascertain the electrical loading of the air heater(s)

being installed so that cables of adequate cross-sectional

area to safely carry that load are used for the electrical

installation. The length of the conductors betw een the cord

anchorage and the terminals must be such that the current

carrying conductors become taut before the earth condu ct or

if the cable or cord slips out of the cord anchorage. All

external controls must be of an approved type.

See the wiring diagram accompanying these instructions.

5. Air Distribution System

5.1 General

NCA-G ###UD models are designed for use with duct w ork t o

more precisely defin e the poin t of air d elivery, and /or provide

ducted return air or ducted fresh air inlet. All ducting must

be independently supported of the air heater. Joints and

seams of supply ducts an d fittin g s m u st be secur ely f asten ed

and made airtight.

5.2 Noise Reduction

If deemed necessary consid eration shoul d be given to m ounting

the heater on resilient pads, or equivalent, to minimise

transfer of noise an d vibration t o the structur e of the buil ding.

It is recommended that ducting should be connected t o the

heater spigots via an airtight flexible coupling of

noncombustible material. Before fitting coupling it must be

ensured that a maximum clear ance of 13mm will be main tained

between the ends of the ducting and the heater spigots.

If required sound attenuators may be fitted in inlet and

outlet ducts to reduce airborne fan noise. Materials used in

outlet sound attenuators must be capable of withstanding

100°C air temperature without any deterioration.

temperature is concerned. Draughty areas, areas subjected

to direct heat e.g. from the sun, and areas where the air

movement is relatively stagnant e.g. in recesses, are all

positions to be avoided for siting the thermostat.

The thermostat should be mounted about 1.5m from the

floor.

Any room therm ostat, fr ost th ermostat, time clock etc. mu st

be suitable for switching 230V, 5A and must be of the 'snap

action' type to minimise contact bounce.

For electrical connections of external controls see the

accompanying wiring diagram.

6. Commissioning & Testing

6.1 Electrical Installation

Checks to ensure electrical safety must be carried out by a

competent person.

6.2 Gas Installation

The whole of th e gas in stallation, inclu ding th e meter, should

be inspected and tested for soundn ess and purg ed in accordance

with the recommendations of IM/16:1988.

6.3 Air Distribution System

The system shoul d be ch eck ed to en sur e that th e installation

work has been carried out in accordance with the design

requirements.

Particular attention shoul d be given to th e correct arran gemen t

of delivery ducts and registers, return air ducts and grills

and general adequacy of return air paths.

For NCA-G ###UD heaters ensure that the total duct system

resistance does not exceed the available air pressure of the

equipment supplied refer to Table 2, (Page 2). If the duct

system resistance is less than the available air pressure of

the equipment supplied additional resistance must be

introduced e.g. by adjustment of duct outlet nozzles and

balancing of the duct system.

6.4 Lighting the Air Heater

6.4.1 Gas Controls Assembly - Soundness Check

1. Ensure the gas service valve at the inl et to th e gas control s

assembly is shut.

2. To prove soun dn ess of th e fir st main safety sh ut-off v alv e

and first start gas safety shut-off valve:a) Connect pressure gauge to the inlet pressure test

point on the main valve block or inlet pipework.

b) Open gas service valv e and allow pressure to stabilise

before shutting it again. The valves are sound if

no pressure drop is observerved. If a pressure drop

is observed do not proceed until the fault has been

rectified. Remove pressure gauge and refit sealing

screw in pressure test point.

6.4.2 Sequence Check

1. Ensure that the gas service valve is closed and that the

main electrical supply to the heater is switched off.

2. Check that all external controls are eith er "ON" or at "MAX"

3. Turn "ON" the main electrical supply and check that the

following sequence of events occurs.

i) Burner fan runs

ii) Ignition spark is heard

iii) Main gas valves open.

iv) Burner goes to lockout as there is no gas supply.

4. Switch off main electricity supply.

6.4.3 Final Adjustment

IMPORT ANT: Th e maxium flo w and start gas flo w adju stmen ts

provided on the GM main gas block valve assembly

(Fig 2b - 4) are not used and must not be adjusted.

5.3 Room Thermostat Siting

The room thermostat should be fitted at a point which will

be generally representative of the heated area as far as

1. Remove the sealing screw from the pressure test point

located on the side of the gas inlet to the burner head

and attach a pressure gauge. Remove the sample point

5

Page 8

Fig 1 Gas Controls Schematics

1st Main Gas

Safety Shut-off

Valve

Gas

Inlet

Fig 2a Gas Controls Layout NCA-G 100, 150

1) 1st Main gas safety shut off valve.

2) 2nd Main gas safety shut off valve.

3) Main burner pressure adjustment screw.

Notes:-

i) Electrical connection plugs not shown.

Fig 2b Gas Controls Layout NCA-G 200, 300

1) Main gas safety shut-off

valves.

3

2) Main burner pressure

adjustment screw.

3) Inlet Pressure test point.

4) Flow rate and valve opening

speed adjustments.

Gas

Inlet

2nd Main Gas

Safety Shut-off

Main Gas

Governor

Inlet

1

Gas

Valve

Pressure

Test

Point

To Burner

1 2

To

Burner

3

2

4

To

T

E

P

S

O

.

I

N

G

E

T

R

T

R

A

T

S

X

V

A

M

V

3

Burner

cover plug from the outlet flue length and insert a CO

measuring instrument.

2. Turn "ON" the main electricity supply and check that the

following sequence of events occur.

i) Burner fan runs.

ii) Ignition spark is heard

iii) Main gas valves open

iv) Main gas flame is established.

3. Check that the main burner gas pressure agr ees with that

in Tables 3.1 or 3.2. If necessary adjust the main burner

gas pressure (Fig 2a - 3 or Fig 2b - 2).

4. Measure the CO2 content of the flue gases. If necessary

adjust the combustion air damper of the burner (Refer to

the Burner Supplement) to obtain a r ea din g o f 9.0 - 9.5%.

5. Turn "OFF" the main electricity supply, remove pressure

gauge and refit sealing screw in pressure test point and

flue sample point cover plug.

6.5 Final Soundness Test

1. After making final gas rate checks all joints on the gas

controls assenbly mu st be tested f or soundn ess u sing l eak

detection fluid.

6.6 Flame Safeguard

1. Whilst the burner is in operation close the gas service

valve. The burner should go to lockout within 1 second.

2

6.7 Handing over the Air Heater

Hand the Users Instructions to the user or purchaser for

retention and instruct in the efficient and safe operation of

the air heater and associated controls.

Adjust the automatic controls to those values required by

the User.

Finally, advise the user or purchaser that, for continued

efficient and safe operation of the air heater, it is important

that servicing is carried out annually.

In the event that the premises are not yet occupied turn off

the gas and electricity supplies and leave instructional

literature adjacent to gas meter.

7. Servicing

WARNING: Always switch off and disconnect electricity

supply and close the gas service valve before carrying out

any servicing work or replacement of failed components.

7.1 General

Full maintenance should be undertaken not less than once

per year. After any servicing work has been complete or any

component replaced the air heater(s) must be fully

commissioned and tested for soundness as described in

Section 6.

6

Page 9

7.2 Burner Maintenance

1. Refer to the Burner Supplemen t supplied with th e heater.

Note: Any referen ces th erein t o th e gas con trol s assembly

should be ignored.

7.3 Heat Exchanger Cleaning

1. Disconnect the gas supply at the inlet to the gas con tr ol s

assembly.

2. Disconnect the electrical connections from the heater

electrical panel to the buner at the burner.

3. Remove the nut s securing the burn er to the h eat exchan ger

and remove the burner.

4. Remove the fan/limit thermostat as described in 7.5.4

and then remove the inner panel of th e h eater t o expose

the heat exchanger clean out panel. Remove the nuts

securing the panel and remove the panel.

5. Remove the nuts securing the heat exchanger baffles

retention strip and remove strip.Withdraw the baffles.

6. Brush through heat exchanger tubes and remove loose

material using a vacuum cl eaner . R emove an y loose material

from the base of the combu stion chamber , workin g through

the burner port.

7. Reassemble all components in reverse order. Inspect all

gaskets and replace if necessary.

7.4 Fan Assembly

1. Remove the upper and lower side panels on one side of

the heater to gain access to the fan.

2. Inspect the fan blades to see that they are not damaged

and that there is no excessive build up of deposits that

could give rise to an imbalance. If necessary clean the

fan blades using a stiff brush and vacuum cleaner. If it

is required to rem o v e th e fan f or cl eanin g r efer t o section

7.4.3

7.5 Replacement of Faulty Components

the heater.

3. Remove the two set screws, one on each side of the fan

mounting flange, the secure the fan to the fan shroud.

4. Withdraw the fan from the slide rails.

5. Reassemble in reverse order.

7.5.4 Fan and Limit Thermostat (Honeywell L4064N )

1. Release the single screw securing the fan and limit

thermostat cover and remove cover by pulling forward.

2. Release wiring from clamp terminals by pushing a small

screwdriver into the clamp release holes adjacent to the

clamps.

3. Remove the 2 scre ws securin g the therm ostat to th e heater

panel and withdraw thermostat.

4. Reassemble new unit in reverse order refering to the

heater wiring diagram to ensure correct wiring location.

Fig 3 Honeywell L4064N

Set Point Dial

Fan Circuit

Summer /

Winter

Switch

0

2

T

CAUTION

DO NOT ROTATE - HOLD

2

0

DIAL WHEN SETTING POINTERS

4

1

I

M

I

0

L

0

F

N

A

1

0

8

0

6

0

Limit Circuit

Limit Reset

7.5.1. Burner Components

1. Refer to the burner supplemen t supplied with th e h eater.

7.5.2 Gas Controls Assembly

7.5.2.1 NCA-G 100, 150

7.5.2.1.1 Gas Valve Coil.

1. To fit a new valve operating coil remove the electrical

supply plug, release the securing nut on top of the valve

stemand remove the nut and washer. Lift of the faulty

coil and fit the new coil in reverse order.

7.5.2.1.2 Block Valve Assemby.

1. Remove the electrical supply plug,

2. Release the unions on the connection s at ea ch end o f th e

assemby and remo ve compl ete assembly. Fit new assembly

in reverse order ensuring the valv e assembly is correctly

orientated for the direction of gas flow.

7.5.2.2 NCA-G 200, 300

7.5.2.2.1 Block Valve Assembly.

1. Release the union on the gas service valve

2. Remove the electrical conn ection from th e valv e assembly.

3. Release the socket head cap scr ews securin g the connection

flanges to the main gas bl ock v alve an d rem o ve th e block.

Fit new assembly in reverse order ensuring correct

orientated for the direction of gas flow.

7.5.3 Main Air Fan and Motor

Note: On heaters supplied as specials with 3ph m ot ors en sure

that the fan direction of rotation corresponds with the

direction of rotation arrow on the fan guard or case. If

necessary reverse the direction of rotation by in terchanging

any two of the motor live leads at the terminal strip in the

electrical panel.

1. Disconnect the fan motor electrical l ea ds fr om th e h eater

terminal strip (Refer to the Wiring Diagram supplied)

2. Remove the upper and lower side panels on one side of

Limit CircuitFan Circuit

Jumper Location

Important: As supplied by the Manufacturer this fan/limit

thermostat is fitted with a brass jumper between th e bott om

fan terminal and the bottom limit terminal (situated in the

slot between the two terminals). This MUST be removed, by

using a pair of thin nose pliers, before the replacement

thermostat is installed.

5. Ensure that the fan and limit settings are as follows:Fan ON 50°C

Fan OFF 30°C

Limit 110°C

8. Connections to Powrmatic External Contr ols

8.1 Powrtrol

NCA-G

Terminals Terminals

connect to

1 1

2 2

8 5

9 6

Powrtrol

8.2 Eurotrol

NCA-G

Terminals Terminals

connect to

1 CTRL CCT

2 CTRL CCT

8 FAN CCT

9 FAN CCT

Eurotrol

7

Page 10

9. Fault Finding

Refer also to the burner supplement supplied with the heater

Fault Cause Action

Main burner will not light Electrical 1. Check electrical and gas supplies are ON.

2. Check controls are ON or calling for heat.

Main burner lights, but goes Electrical 1. Unit goes out on high limit out before main fan comes on. a. Check fan thermostat setting - See Section

7.6.5.

b. Faulty fan thermostat - change

c. Check limit thermostat setting - See Section

7.6.5.

d. Faulty limit thermostat - change.

2. Faulty fan assembly - change.

3. (Ducted Units Only) -fan motor out on thermal

overload. - Check running amps. See table 4.check duct resistance See Table 5.

Main fan runs continuously Electrical 1. Summer/Winter switch set to Summer.

2. Fan thermostat set too low - check setting. See

Section 7.6.5

3. Faulty fan thermostat - change

Main fan fails to run Electrical 1. Fan motor or capacitor failed - replace.

2. Fan thermostat faulty - replace.

3. Fan contactor failed - replace (3ph units)

10. Short List of Parts

Refer also to the burner supplement supplied with the heater.

Refer to Powrmatic Ltd for the details of any parts not listed here.

ITEM APPLICATION PART NUMBER

Johnson Controls GM-7742-3503 - ½"BSP. 100, 150 141379957

Johnson Controls GM-2540-2000 - ¾"BSP 200, 300 141379954

Thermostat - Fan / Limit Honeywell L4064N. ALL 143000303

Heat Exchanger Cleanout Door Gasket. ALL 170246006

Pressure Relief Door Gasket - 114mm dia. ALL 142202110

Pressure Relief Door Gasket - 95mm dia. ALL 142202257

Pressure Relief Door Gasket - 166mm x 166mm. ALL 142202310

Burner Gasket - Nu-Way PCGS 2/3/5. ALL 144704004

Burner Gasket - Riello GS5. 100 141937080

Burner Gasket - Riello GS510 150 - 300 141930806

8

Page 11

Appendix A

Calculation Of Flue System Equivalent Resistance

The pressure resistance of the flue system (Pr) can be calculated from

Pr = 1.5 * [(PFF*H/D+SRF)Q

m/Wm

2]

Where Pr = Pressure resistance of the flue system in pa

PRF = Pipe Friction Factor

H = Effective flue height in m

D = Internal Diameter of flue in m

SRF = Sum of individual resistance factors

Q

= Mean Density of the column of exhaust gas in kg/m

m

W

= Mean exhaust gas velocity in m/s

m

PRF

3

Can be calculated from

PRF = 0.118*(0.21147/D

0.4

)

Where D = Internal Diameter of flue in m

SRF

Typical resistance factors for individual components are as follows

Segmented 90° bend 0.5

45° Elbow 0.4

Cowl 1.0

Q

m

Q

= 97000/(300*Tm)

m

Where The mean temperature of the column of exhaust gas (T

T

= 288+((Te-TL)/0.2)*(0.18)

m

Where Te is the exhaust gas temperature in °C

T

W

m

L is the external air temperature in °C

Wm = M/(A*Qm)

Where A is the cross sectional area of the flue in m

2

M is the exhaust gas mass flow in kg/s which is as follows for the various units

m) can be calculated from

Page 12

BSI Registered Firm

FM 414

Ind. & Comm. Air Heaters;

Air Moving Equipment;

Flues & Chimneys; Natural

Smoke & Heat Ventilators;

Powered Supply & Extract

Fans & Systems.

HEATING DIVISION

Winterhay Lane

Ilminster, Somerset TA19 9PQ

Tel: 01460 53535 Fax: 01460 52341

Every effort is made to ensure accuracy at time of going to press. However as part of our policy of continual product improvement, we reserve the right to alter specifications without prior notice.

Loading...

Loading...