Page 1

www.powmatic.co.uk

+44 (0) 1460 53535

info@powrmatic.co.uk

Doc Ref: M401 Issue 5.4 Feb 2018

Industrial & Commercial Heating Systems

MC200/V3 Control System

User, Installation

& Servicing Manual

Page 2

page no. 2 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

Installer

Date:________________Signed: _____________________________________Installer

Important: This certicate

must be kept with the appliance

Failure to provide a copy of the commissioning sheet invalidates the heater warranty

----------------------------------------------------

Powrmatic Ltd, Hort Bridge, Ilminster, Somerset, TA19 9PS

Tel: 01460 53535 Fax: 01460 52341

Web: www.powrmatic.co.uk e-mail: warranty@powrmatic.co.uk

Certificate of Guarantee

Dear Customer

This is to certify that this controller is guaranteed for a period of one year from the date of original

installation.

To make a claim

In the rst instance you must contact your appliance supplier, or installer and provide:-

1. The appliance type and order number.

2. The original commissioning documentation. As much detail as possible on the fault.

3. Your supplier, or installer, will then contact Powrmatic to make a guarantee claim on your behalf.

Conditions of Guarantee

1. The controller must have been installed by a competent recognised installer, and in

accordance with the manufacturer’s instructions, I.E.E. regulations and local regulations.

2. The controller has been used in accordance with the manufactures instructions.

3. No unauthorised repairs of modications have been made. Powrmatic ‘General Conditions of

Sales’ have been observed.

4. Except for the obligation of Powrmatic Ltd to perform warranty repairs during the guarantee

period Powrmatic will not be liable in respect of any claim for direct or indirect consequential

losses, including loss of prots or increased cost arising from loss of use of the heater, or any

event arising there from.

Page 3

page no. 3 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

Dear Customer - thank you for choosing Powrmatic.

We appreciate you buying one of our high quality products and know that you have made the best

choice. By choosing Powrmatic, you are investing in UK manufacturing & its workforce. We pride

ourselves by manufacturing products that provide clean, comfortable and safe working environments

worldwide together with the personal & professional service and back-up you deserve. If you have

any questions or concerns regarding this product, please contact our Technical Support Team by

calling 01460 53535.

Title Section Contents Page

User Instructions 4

Pre Installation

1.1 Introduction 9

1.2 Technical data 11

Dimensions 11

Installation

2.1 Fitting the unit 12

2.2 Electrical Cable Installation 13

2.3 Interconnecting Wiring Diagrams 15

2.4 Commissioning and Output Sequences 19

Additional Documents

3.1 Fault Displays and Fault Finding 22

3.2 Short Parts List and Options 24

Users, Installation and Servicing Instructions

CONTENTS

Page 4

page no. 4 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

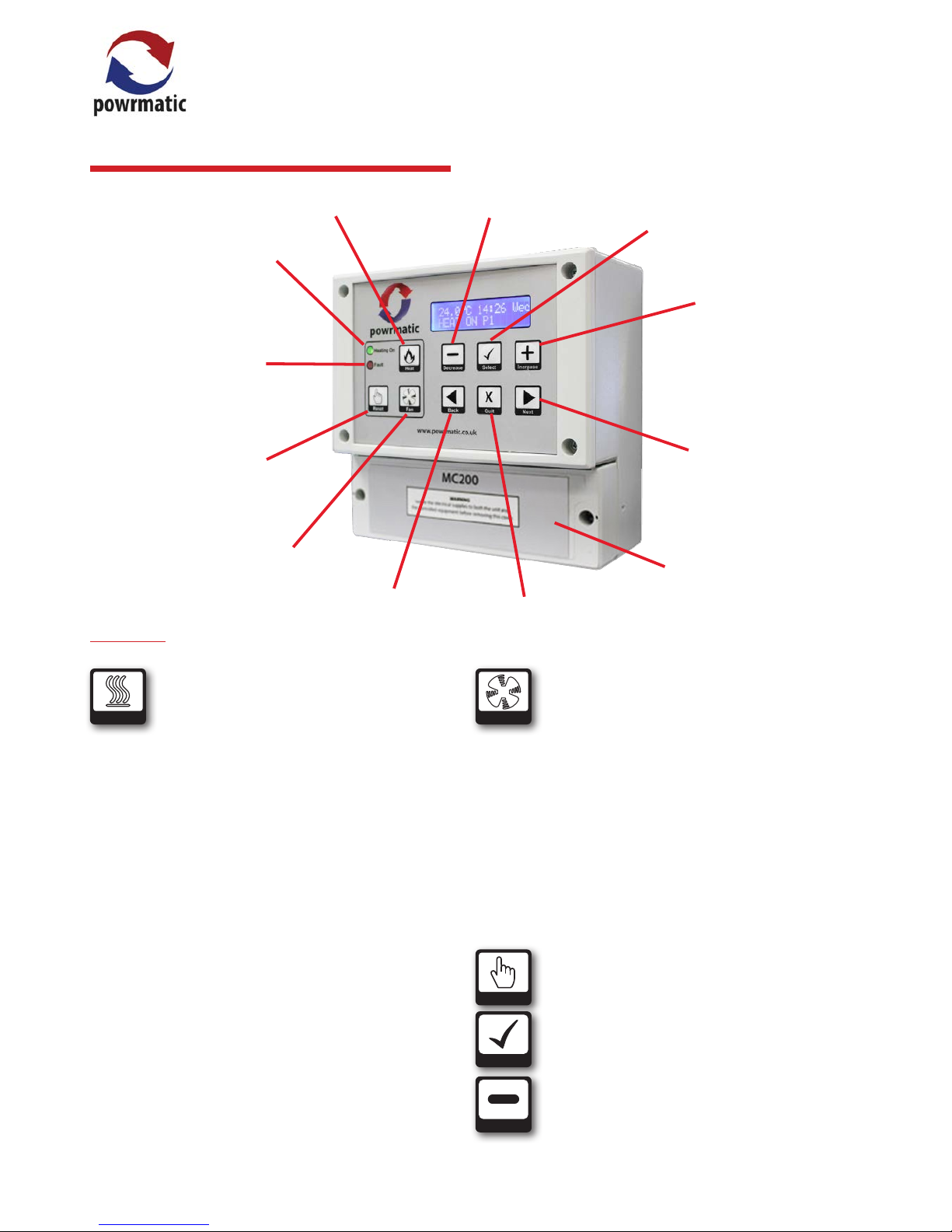

Heat Button.

Heating On Indicator

Fault Indicator

Fan Button

Burner Lockout

Reset Button

Back Button

Quit Button

Next Button

Increase Button

Select Button

Decrease Button

Heat

Heat Button - (Note: this facility may be limited

or disabled by the User).

If heating is ON (via programme)

Pressing the Heat button for less than 2 seconds overrides

the programme to OFF. Any extension time that has been

set is cancelled.

Pressing the heat button for more than 3 seconds

determines that heat will remain on for an extension time

after the programmed o time. The extension timer will

increase in 30 minute steps, up to the maximum allowed

period, and then revert to 0 minutes.

Release the button when the required extension period is

showing.

If heating is OFF (via override)

Pressing the Heat button removes override and reverts to

the current programme. If heating is OFF (via programme)

Pressing the Heat button for less than 2 seconds brings on

heating for 30 minutes.

Pressing the heat button for more than 3 seconds

will increase the on time in 30 minute steps, up to the

maximum allowed period, and then revert to 0 minutes.

Release the button when the required heating period is

showing.

Fan

Fan Button - (Note: this facility may be limited

or disabled by the User).

In WINTER mode and OFF mode, the Fan button has no

control over the air heater fan.

In SUMMER mode, the Fan button switches on the fan for

air circulation, and another press switches it o. If the fan is

left on, it will be automatically switched o at midnight.

If the fan is running because the heating is on and the fan

is in AUTO or CONST mode, the Fan button cannot switch

it o.

If the fan is in an ON mode, it always runs, in WINTER,

SUMMER and OFF. The Fan button cannot switch it o.

Reset

Reset Button - Press to reset the burner controls

from lockout, (when this facility is available on

the heater).

Select

Select Button - Press to accept changes.

Decrease

Decrease Button - Press to decrease values.

A) Buttons

Terminal Cover

User Instructions

Page 5

page no. 5 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

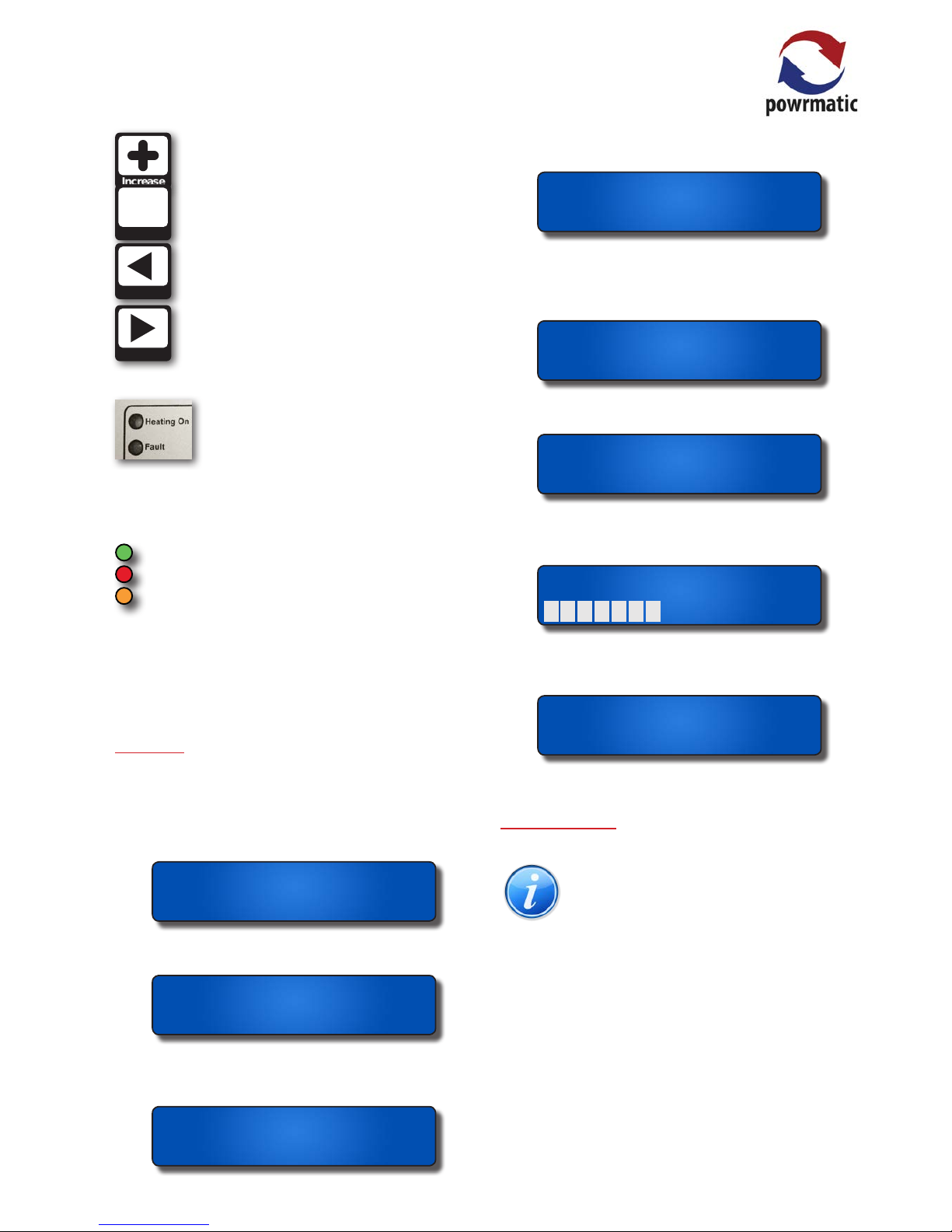

Increase

Increase Button - Press to increase values.

Quit

X

Quit Button - Press to exit without saving

changed values.

Back

Back Button - Press to enter User Menu, go

back to previous screen.

Next

Next Button - Press to enter User Menu, go

forward to next screen.

Indicators

Heating On - Is illuminated when the MC200 is calling

for heat (It does not conrm that the heating is actually

working).

Green when the heater is a single-stage burner.

Red when the heater is a Hi-Low type.

Yellow when the heater has a Modulating burner.

Fault - Flashes when the burner control is at lockout, solid

light when a service call is due (if this has been set) or when

there is a sensor fault. The bottom line of the display will

alternate between normal display and type of fault.

B) Display

The rst display normally shows:

• the current air temperature as measured by the internal

sensor, an external sensor or the average temperature if

two sensors are tted.

8.5.C 09:42 Tue

P1 HEAT ON

• the time of day using 24-hr notation. The colon ashes

once per second to conrm that the clock is running.

8.5.C 09:42 Tue

P1 HEAT ON

• the day of the week. Programmes are associated with

individual days of the week or day-groups such as weekday

or weekend.

8.5.C 09:42 Tue

P1 HEAT ON

• Programme number - Px n (where x represents the active

programme number.)

8.5.C 09:42 Tue

P1 HEAT ON

• the current setting of the heater: ON or OFF, as

determined by the internal programmes (the display will

say ON even if the MC200 is not currently calling for heat

because the thermostat is satised)

8.5.C 09:42 Tue

P1 HEAT ON

or for High/Low an indication of the heat demand. HEAT HI

or HEAT LO,

8.5.C 09:42 Tue

P1 HEAT HI

or for Modulating burners a simple bar-graph display for

modulating control heaters where 1 bar is low re and 10

bars is high re.

8.5.C 09:42 Tue

P1

• “Frost Guard” is displayed when Frost/setback is set to

ON and the space temperature is lower than the Frost/

setback temperature setting.

0.5.C 09:42 Tue

Frost guard

C) Direct Control

Note: If congured during the commissioning

stage the User has the following direct control

of the heater without using the settings menu.

• If the Fault LED is on because the heater is at lockout, the

user can reset the heater by pressing the Reset button.

• The user can switch the heating ON or OFF by pressing

the Heat button.

• The user can start or cancel extension time by pressing

the Heat button longer than 3 seconds.

• The user can run the fan without heating, by pressing the

Fan button.

• Pressing of the next button will scroll through the screen

displays available to the user

Page 6

page no. 6 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

Temperature 18.0

Date: 20/08/2017

Password ****

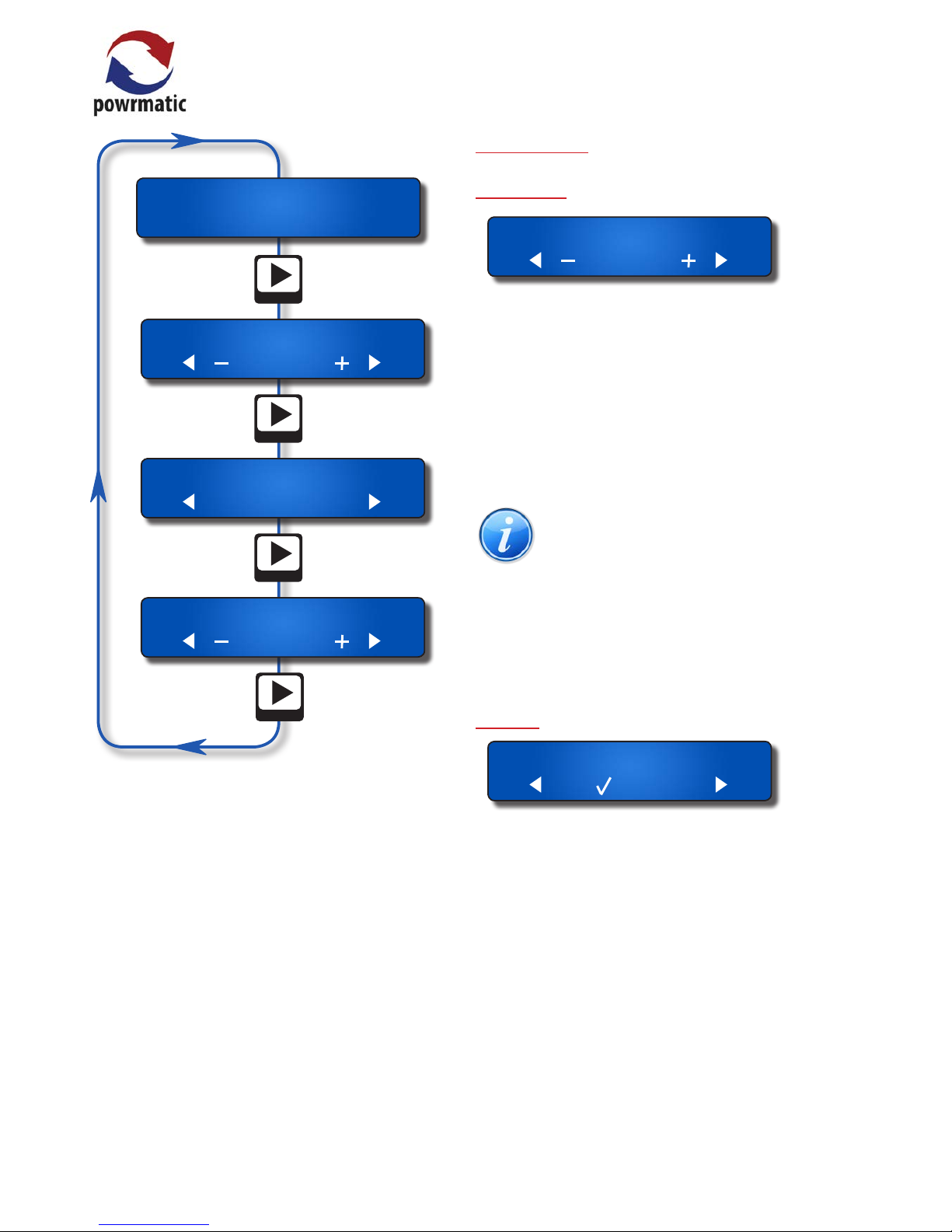

Next

Next

Next

8.5.C 09:42 Tue

HEAT OFF FAN OFF

Next

The top line will show which setting or which part of the

programmes you are viewing.

The second line of the display shows which keypad buttons

are active ( ◄ – ü X + ► ).

After changing any setting, press the ü button to save the

new setting.

To return to the normal display, press the X button or do

not touch any buttons for 15 or more seconds.

Keys ◄, ►, – and + will auto-repeat if held down longer

than approximately half a second.

The + button will automatically wrap round from the

maximum value to the minimum value and the – button

will wrap the other way

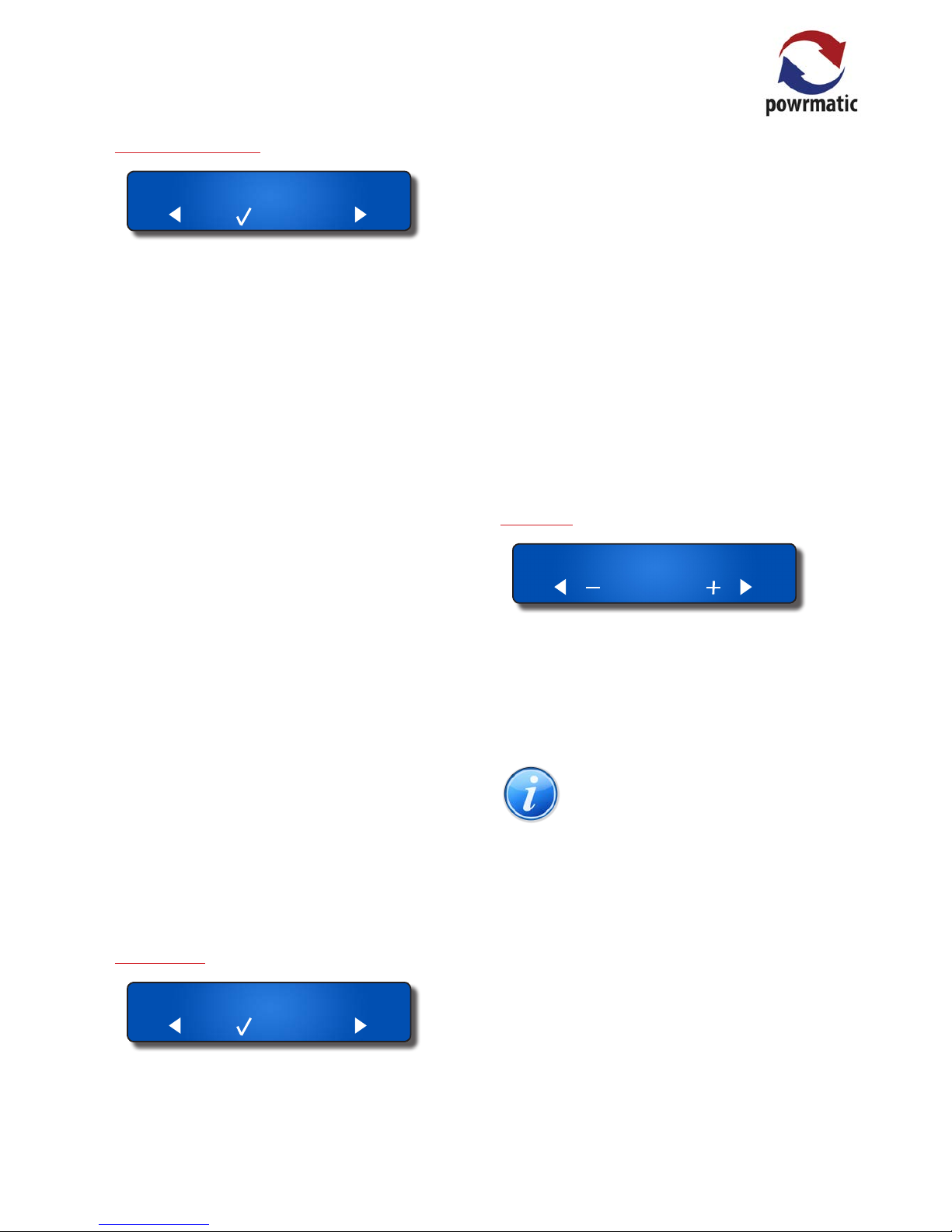

D) User Settings

Temperature

Temperature 18.0

This shows the temperature set by the currently

active programme, and it is the target temperature for

thermostatic control. The user can increase or decrease

the value to adjust comfort. This will not alter the set

temperature associated with the programme, but it will

temporarily alter the target temperature for thermostatic

control.

The eect of altering the temperature lasts until the

current programme expires or until another programme

changes the set temperature requirement.

Note: the range of adjustment permitted may

be limited during commissioning. Temperature

adjustment can be disabled by a setting within

the user menu.

• Press the + or - button to increase or decrease the day

temperature set point.

• Press the ü button to save changes, press the X button

to exit without saving, press the ► button to move to the

next setting.

Clock Set

Clock set

Sets the current date and the time of day. The correct date

allows the MC200 to know the day of the week, allows for

automatic BST-GMT changeovers, carries out the holiday

shutdown function and permits override password entry.

• Press the ü button to alter date and/or time.

• Press the ◄ or ► button to select digit to change (digit

chosen will ash).

• Press the + or - button to change the digit.

• Press the ◄ or ► button to select next digit to change

or until 'Set clock?' appears on screen

• Press the ü button to save changes, press the X button

to exit without saving, press the ► button to move to the

next setting.

Page 7

page no. 7 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

Programme settings

P rog settings

The MC200 has 14 programmes, each of which can be

assigned to any day of the week. Each programme can be

given an ON time, an OFF time and a set temperature. The

user may organize the programmes in any way that suits.

The simplest would be one programme ON in the morning,

OFF at the end of the afternoon, active Monday to Friday.

If two or more programmes are active at the same time,

for instance one is ON all day and another is ON between

11:00 and 13:00, then the set temperature of the second

programme will apply between 11:00 and 13:00, and the

set temperature of the rst programme will apply during

the rest of the working day.

Programme times increment in 5 minute steps.

Extension time (if set) applies when all programmes have

reached the end of their set period for that day.

Optimum start applies at the beginning of the rst

programme to switch on and optimum stop applies at the

end of the last programme to switch o.

• Press the ü button to set/alter programme.

• Press the ü button to alter programme P1 or the + or button to select specic programme number then press

the ü button to accept.

• Press the + or - button to alter/set the HEAT ON time.

• Press the ► button to move to the HEAT OFF time

• Press the + or - button to alter/set the HEAT OFF time.

• Press the ► button to move to the temperature

• Press the + or - button to change the temperature.

• Press the ► button to move to the Programmed days

• Press the + or - button to alter between: Mon-Fri; SatSun;

7 days; O or individual days.

• Press the ► button to and 'Save Prog x?' will appear.

• Press the ü button to save changes, press the X button

to exit without saving, press the ► button to move to the

next setting.

Holiday Date

H oliday date

A future date can be set so that the heating will not

operate on that date, and remains “OFF” for a consecutive

number of days from that date. The date includes the year

number, ensuring that the holiday shutdown date is not

automatically repeated the following year.

During the holiday period the heater will only operate

if the temperature falls below the frost temperature

and if frost temperature operation is selected “ON” in

the engineer menu. The night temperature setting is

ignored during holidays. During the holiday period,

manual operation of the fan or heater is permitted. Any

manual operation still on at midnight will be automatically

cancelled.

• Press the ü button to add a holiday period.

• Press the + or - button to set the start date.

• Press the ► button to select the month to change.

• Press the + or - button to set the month.

• Press the ► button to select the year to change.

• Press the + or - button to set the year.

• Press the ► button to select the number of days.

• Press the + or - button to enter the number of days.

• Press the ► button to and 'Holiday save?' will appear.

• Press the ü button to save changes, press the X button

to exit without saving, press the ► button to move to the

next setting.

Run Mode

Run mode: WINTER

The MC200 has three Run modes: WINTER, SUMMER and

OFF.

Winter - the heating operates when any programme is in a

“HEAT ON” period. The heating also operates to maintain

the Night Temperature if this has been set. The heating

also operates when the temperature drops below the frost

temperature.

NOTE: Summer/Winter mode has no

connection with the clock change from GMT to

BST.

Summer - the fan operates to circulate air when switched

on manually. With certain types of heater or certain types

of installation, Fan-only operation may not be appropriate

and the fan control circuit should not be used.

In SUMMER the heating never operates unless the

temperature drops below the frost temperature.

During commissioning the frost temperature operation will

be set to be ON or OFF. If the frost setting is OFF, the heater

will not operate under frost conditions in any User mode.

OFF - the heater never operates unless the temperature

drops below the frost temperature (see above)

• Press the + or - button to change between WINTER,

SUMMER & OFF.

• Press the ü button to save changes, press the X button

to exit without saving, press the ► button to move to the

next setting.

Page 8

page no. 8 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

User Button Permission

P ermissions

This menu option facilitates the user to enable or disable

the following controls separately if it is required to restrict

unauthorised access to user controls.

NOTE: User permissions are only eective when

User access to the menu is protected by a

password.

Reset - Allows operation of the reset button

Change temperature - Allows temporary adjustment of

the current set temperature

Heat Override - Allows switching ON/OFF and extension

of Heat ON time

Fan override - Allows switching ON/OFF of the fan

• Press the ü button to alter the permissions.

• Press the + or - button to toggle between YES & NO..

• Press the ► button to select next digit to change or until

'Save??' appears on screen

• Press the ü button to save changes, press the X button

to exit without saving, press the ► button to move to the

next setting.

Set Password

SetPassw ****

The user may enter a 4-digit password here. Once set, the

password must be given before selected user controls may

be accessed or changed. “Set password” cannot be entered

unless the password has been given.

As delivered, the MC200 has no User password restrictions,

the user password being set to 0000. Entering a password

of 0000 will remove all restrictions.

• Press the + or - button to set the rst digit.

• Press the ► button to select the next digit.

• Press the + or - button to set the second digit.

• Press the ► button to select the next digit.

• Press the + or - button to set the third digit.

• Press the ► button to select the next digit.

• Press the + or - button to set the last digit.

• Press the ü button to save changes - 'SET OK' will appear

briey, press the X button to exit without saving, press the

► button to move to the next setting.

Extension Time

Extend time 1:00

A user can extend the heating to operate beyond the

switch-o time of the last programme of the day, in

30minute increments, by pressing the Heat button. This

menu option allows a maximum extension period to be

set, in units of 30minutes.

If set to 0 minutes, extension is not permitted.

Factory default setting: 1hour. Maximum setting 3hours.

• Press the + or - button to set the appropriate extended

time.

• Press the ü button to save changes - 'Setting saved' will

appear briey, press the X button to exit without saving,

press the ► button to move to the next setting.

Cost Log

C ost Log

This option shows the total hours run and the total cost

of running since the log was last cleared. The display will

show the date when it was last cleared. For this option to

function it is necessary to enter the fuel cost and heater

rating (see Engineer Menu for the latter). The cost log

should be cleared whenever the heater type is changed.

For Hi/Lo heaters, there are two heater power entries and

the MC200 will calculate the run cost according to the level

of heat requested.

In the case of modulating control heaters, the cost is an

estimate based on half the full heater power.

• Press the ü button to enter the submenu. Display shows

Start Date.

• Press the ► button to select next screen 'Total Hours'.

• Press the ► button to select next screen 'Total Cost'.

• Press the ► button to select next screen 'Clear Log?'.

• Press the ü button to clear log. This will reset the start

date to the current date.

• Press the ► button to select next screen 'costs per kWh'

• Press the + or - button to change th cost per kWh.

• Press the ü button to save changes, press the X button

to exit without saving, press the ► button to move to the

next setting.

Page 9

page no. 9 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

Password

Password ****

Once a password has been set, the password must be

entered at this menu option to allow access to selected

user controls.

Once entered the password gives access to the User menu

functions for 60 minutes.

To re-apply the restrictions before the end of the 60 minute

period, select the ‘Enter password’ option and press the ü

button without entering any digits. The display will show

‘Password CLOSED’.

• Press the + or - button to set the rst digit.

• Press the ► button to select the next digit.

• Press the + or - button to set the second digit.

• Press the ► button to select the next digit.

• Press the + or - button to set the third digit.

• Press the ► button to select the next digit.

• Press the + or - button to set the lat digit.

• Press the ü button to save changes - VALID will appear

briey, press the X button to exit without saving, press the

► button to move to the next setting.

If 'FAIL' appears on the screen, the incorrect password has

been entered. Repeat entry sequence.

E) Additional notications

Service Date

When the MC200 is installed the Commissioning Engineer

may have entered a date for when the heating equipment

requires servicing.

When this date is reached the MC200 fault indicator will

be illuminated and the display will alternate between the

normal display and "Service due, call engineer".

S ervice due,call

engineer

The Service Engineer can clear this display by entering a

new service date when the heating equipment has been

serviced.

The MC200/V3 is a high specication heating controller

designed specically to meet the demands of modern fuel

ecient heating equipment and the latest energy saving

and environmental guidelines and uses a simple menu

based structure for entering User settings.

Optimum start technology is available that will continually

monitor the heating systems previous performance to

determine the optimum time to turn the heating on to

raise the space temperature to the required level for when

occupancy begins. Optimum stop can also be selected

which can save energy at the end of the heating period.

The MC200/V3 is protected by 2 levels of password. The

User password may be set to restrict access to certain User

controls. The second password is for use by commissioning

and servicing engineers and allows access to parameters

normally used only in the initial setting of the controller, a

fault log and system reset facility.

The user keypad allows easy selection of the heating and

fan only modes, the override functions and fault reset.

These may also be locked in various combinations to allow

dierent levels of user accessibility.

The MC200/V3 can give a readout of the hours the burner

has operated, to help accessing servicing intervals and

after being programmed with the correct data, can also

give an indication of the running costs of the heating

appliance. In addition a forward service date can be

programmed. When the due date is reached a notication

will be shown which alternates with the normal display.

This notication can only be removed by a Service

Engineer.

The MC200/V3 can be used to directly control both Hi/

Lo and Modulating burners, the latter by an internally

generated 0-10V signal.

1.1.2 Clock

• The unit date range is from 01/01/2001 to 31/12/2099

• Leap years are recognised

• BST begins on the last Sunday in March and ends on the

last Sunday in October. The time changes at 01:00 GMT.

• The clock may gain or lose up to 10 minutes in a year.

1.1.3 Programme

• 14 timers are provided in the software, and each can be

assigned to any single day of the week, or to day groupings

such as weekdays or weekends. This allows greatest

exibility in operating the heating whenever required.

• It is possible to schedule timers so that one starts

before another has nished. The heating will be on while

1.1 Introduction

Page 10

page no. 10 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

Important: Optional sensors are available

from Powrmatic Ltd. Alternative types must

not be used.

It can also be used in conjunction with an additional

remote sensor which will give an average of the two

temperature readings.

Options are:

• Default internal sensor only

• Remote sensor only

• Internal sensor plus remote sensor

• Remote sensor plus remote sensor

The remote sensor should be sited no further than 100m

from the main unit. Siting of the sensor is important in that

it must be tted where the temperature will be generally

representative of the area to be heated.

It should be installed 1.7m above oor level and away

from draughty areas or areas subjected to direct heat from

sunlight, radiators etc.

The second 'sensor' input can also accept a volt free switch

input i.e. a volt free switch is connected across Terminals

Com & In2 to facilitate a remote on (BMS) or remote o.

Heating will be overridden by the switch operation during

programmed heating times. Heating control returns to

normal when the switch reverts, or when the programmed

control period ends.

The switched control does not occur while heating is

turned on due to manual override in non-programmed

times, and does not occur during the manually-selected

extension time at the end of a programmed control period.

If heating has been manually overridden to be o during a

programmed heating period, the switched control cannot

bring on the heating.

The ‘Heat on’ option means that heat will be turned fully

on by the switch. For high-low burners, the high and low

relays will be on, and for modulating burners, the control

output will be 10v.

Cost logging operates as usual. During these switch control

periods the burn time is recorded at the maximum rate.

If the sensor goes open-circuit (if either of the sensors goes

open-circuit where two are tted), the Fault LED will ash.

The LCD display will show “sensor failed”.

Important: The earlier MC100 sensor cannot

be used with the MC200/V3 and the MC200/

V3 sensor cannot be used with the MC100.

any timer is requiring Heat On, and the heating will turn

o only when all timers have reached Heat O. The

requested temperature will be set by the most recent timer

to switch On. When an overlapping timer switches O,

the requested temperature will be set by the remaining

timer(s).

• No timer can be programmed to run past midnight,

because it is assigned to a day of the week. If timed

heating is required across midnight, it must be provided

by two timers, one ending at 23:59 and the other starting

at 00:00. At midnight, all manual over-rides and extensions

are cleared.

1.1.4 Optimum Start

A control system which starts plant operation at the latest

possible time such that internal conditions will be up to

required limits at the start of the occupancy period.

• The MC200/V3 achieves Optimum start by keeping

a moving record of how many minutes it takes to

increase the temperature per degree in each 3° band

of temperature from 5°C to 20°C. The current overnight

temperature is referenced and the MC200/V3 can estimate

how many minutes are required to bring the temperature

to the required level.

When Optimum Start is enabled the switch-on time for

the heater is then advanced accordingly to achieve the

required temperature by the Heat On time i.e. the warmer

the night time temperature the closer the switch on time

will be to the Heat On time.

NOTE: If optimum start is selected, no program

time should be selected to start before 2:00am.

1.1.5 Optimim Stop

A control system which stops plant operation at the earliest

possible time such that internal conditions will not deteriorate

beyond preset limits by the end of the occupancy period.

• The MC200/V3 keeps a note of how many minutes are

taken for the temperature to drop the number of degrees

entered against this parameter when the heating period

ends. When Optimum Stop is enabled, the MC200/V3

switches o the heating that number of minutes early.

1.1.6 Temperature Sensors

The MC200 has an in-built temperature sensor by default.

This can me removed and replaced with a remote sensor if

the controller is outside the area to be heated.

The remote sensor may be either a room (warm air), black

bulb (for radiant) or duct type.

Page 11

page no. 11 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

Dimensions

165mm

160mm

85mm

Electricity supply 230V 50Hz Fused at 6A.

Internal Fuses F1 20mm 6.3A 230V.(HRC), F2 20mm 500mA 230V. (Non replaceable)

Display 2 line 5mm Backlit L.C.D.

Day set point range 10 - 60°C.

Night set point range 1 - 15°C.

Temperature accuracy 0.5 °C.

Overall switching dierential Adjustable 0.5 - 10.0°C for Hi/Lo burner types.

Sensing Element Internal or remotely mounted up to 100m from control.

Switching contacts ratings 12A. 230V.ac. (resistive). All Volt Free

Modulating Control 0-10V dc

Heating ON Indicator

Green L.E.D. when the heater is a single-stage burner,

Red when the burner is a Hi-Low type,

Yellow when the burner is a Modulating type.

Fault (Lockout) Indicator Orange L.E.D.

Protection Rating IP20

Software versions G

1.2 Technical Data

Page 12

page no. 12 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

2.1.1 Fitting space requirement

The controller will be delivered to site in a cardboard box.

The box may have a xing template on the rear to aid

drilling the xing holes. If not, the base of the controller

housing has the xing dimensions imprinted into the

plastic.

All of the packaging can be recycled. Please

make use of local recycling facilities.

Important: The MC200/V3 and sensor

MUST NOT be sited in areas of high

electromagnetic elds, i.e. distribution

boards, transformers or heavy duty supply

cables.

2.1.1 Location

Siting of the MC200/V3 is important in that it must be

tted where the temperature will be representative of the

area being heated.

It should be installed 1.7m above oor level (unless a

remote sensor is being used) and away from draughty

areas or areas subjected to direct heat from sunlight,

radiators etc. It must also be easily accessible for

programming and operation.

2.1.2 Fixing

The MC200/V3 will accept cable entry from the bottom

and the back.

112mm

151mm

15mm

Remove the two screws from the terminal cover and

remove.

Check that the unit ts in the intended mounting position.

Using the template on the packaging box (invert if

necessary) or using the dimensions on the back of the

housing, mark the location of the three xing holes.

Fit the top (or bottom if inverted) screw leaving

approximately 5mm protruding. Locate the MC200 on the

top (or bottom if inverted) xing screw, line up the bottom

(or top if inverted) xing holes and secure using two

screws.

The warning label supplied loose must be applied centrally

to the terminal cover.

If required the unit may be inverted by the following

procedure so that cable entry is from the top.

NOTE: that in this orientation the internal

sensor cannot be used and a remote sensor

must be used instead albeit it can be alongside

the MC200/V3.

Remove the four screws that secure the top (keypad and

display) section.

Rotate the section through 180°, the ribbon cable is long

enough to allow this, and ret the top section to the case.

Alternatively a sub base is available, as an optional extra, to

allow cable entry from the top or side.

2.1.2 Remote Sensor Fixing (optional)

The remote sensor should be installed 1.7m above oor

level and away from draughty areas or areas subjected to

direct heat from sunlight, radiators etc. and should be sited

no further than 100m from the main unit

Additionally, Radiant Black Bulb sensors should also be in

sight of at least one of the radiant tubes.

Duct sensors should be placed in a position to receive a

representation of the duct temperature.

Remove cover and oer the sensor up to the intended

mounting position and mark two xing holes.

Fix sensor base plate to the wall, complete wiring

connections (2 core screened cable) and ret cover.

2.1 Fitting the Unit

Page 13

page no. 13 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

2.2.1 Electrical Connections

Warning: Wiring external to the MC200 must

be installed in accordance with I.E.E.

Regulations together with any local

regulations which may apply.

Wiring terminals are located beneath the electrical lower

front cover. Wiring should be completed in conduit, for

which knockouts are provided in the bottom of the casing.

Mains supply and control circuit wiring should be

completed in cables not less than 0.5mm² and fan circuit in

not less than 1.5mm².

The connection to the mains electrical supply can be taken

from the appliance or a separate ‘local’ supply, but in both

cases a local isolator must be tted adjacent to the MC200.

Should more than one appliance be controlled from one

MC200 an interfacing relay box MUST BE USED with the

MC200 driving the relay coils.

Warning: Sensor cable must be screened two

core and a minimum of 0.6mm² if solid and 7 x

0.2mm² if multistrand. The screen must be

grounded only at the MC200.

Wiring for the temperature sensor MUST BE RUN

SEPARATELY and apart from ALL other wiring. Failure

to regard this instruction may cause the MC200 to

malfunction and may render it faulty.

Under no circumstances must voltage be applied to the

sensor connections.

Warning: Burner Reset terminal is

internally connected to NEUTRAL when the

reset button is pressed.

2.2 Electrical Cable Installation

Terminal Type Function Terminals

SEN1 Input Connection for prime external sensor (not polarity sensitive)

COM Input Common connection for sensors and/or auxiliary switch

IN2 Input Connection for 2nd sensor (averaging) and or auxiliary switch

0-10V + Output 0-10Vdc output for modulation control MODULATION BURNERS ONLY

0-10V - Output 0Vdc (ground) output for modulation control MODUL ATION BURNERS ONLY

RESET Output NEUTRAL reset output (internally connected)

LOCKOUT Input Receives mains voltage lockout signal from burner

Heat Hi IN Input Hi Heat input (common relay contact)

Heat Hi OUT Output Hi Heat output (normally open relay contact)

Heat Lo IN Input Low heat/Heat input (common relay contact)

Heat Lo OUT Output Low heat/Heat output (normally open relay contact)

Fan IN Input Fan input (common relay contact)

Fan OUT Output Fan output (normally open relay contact)

L OUT Output 6.3A fused 230V output terminal for heat/fan circuits where required

N Input NEUTRAL

E Earth EARTH

L Input LIVE

Notes:

No Voltage - Voltage must not be applied to the sensor terminals. If a switch is tted accross COM and IN2, it must be volt free.

230V 50Hz Mains Voltage

Volt Free pair - If a voltage is required (230V, 24V, 110V etc) the appropriate voltage must be applied to the corresponding input

terminal.

MC200V3

SEN 1

COM

IN 2

0-10v +

0-10v -

Reset

Lockout

Heat Hi

In

Heat Hi

Out

Heat Lo

In

Heat Lo

Out

Fan In

Fan Out

L Out

N

E

L

6.3A

HRC

Page 14

page no. 14 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

2.2.2 External Wiring

Notes:

Wiring for High/Low burners only

Wiring for modulation burners only

2.2.2.1 Wiring details for current Powrmatic heaters utilising fused live output terminal 14 and detailing 'link' wires.

Fan Only

circuit

Low Heat

circuit

Lockout

Reset

0-10Vdc

0Vdc

IN2/Sen 2

COM⁄

Sen 2

NEUTRAL

EARTH

LIVE

High Heat

circuit

Fan Only

Low Heat

Lockout

Reset

0-10Vdc

0Vdc

IN2/Sen 2

COM⁄

Sen 2

NEUTRAL

EARTH

LIVE

High Heat

2.2.2.2 Wiring details for older Powrmatic heaters utilising volt free heat and fan terminals

Wiring for external remote sensor only

Wiring for remore switch only

Wiring for Burner Lockout heaters only

Page 15

page no. 15 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

2.3 Interconnecting Wiring Diagrams to typical heaters

MC200 Controlling

High/Low ErP NVx or VPC

MC200 Controlling

Modulating ErP NVx or VPC

MC200 Controlling

High/Low ErP OUH

SEN 1

COM

IN 2

0-10v +

0-10v -

Reset

Lockout

Heat HiInHeat Hi

Heat Lo

Out

In

Heat Lo

Fan In

Out

Fan Out

N

L Out

E

L

E654321

MC200 Fuelsaver

NVx or VPc ErP High/Low

6.3A

HRC

1110987

L

N E

L

N E

SEN 1

COM

IN 2

0-10v +

0-10v -

Reset

Lockout

Heat HiInHeat Hi

Heat Lo

Out

In

Heat Lo

Fan In

Out

Fan Out

N

L Out

E

L

E654321

MC200 Fuelsaver

NVx or VPc ErP Modulating

6.3A

HRC

1110987

L

N E

L

N E

v - v +

SEN 1

COM

IN 2

0-10v +

0-10v -

Reset

Lockout

Heat HiInHeat Hi

Heat Lo

Out

In

Heat Lo

Fan In

Out

Fan Out

N

L Out

E

L

E654321

MC200 Fuelsaver

OUH ErP High/Low

6.3A

HRC

1110987

L

N E

L

N E

2.3.1 2018 ErP Products

Page 16

page no. 16 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

SEN 1

COM

IN 2

0-10v +

0-10v -

Reset *

Lockout

Heat HiInHeat Hi

Heat Lo

Out

In

Heat Lo

Fan In

Out

Fan Out

N

L Out

E

L

11109876

MC200 Fuelsaver

CPX ErP High/Low

6.3A

HRC

15141312

L

N E

L

N

E

* not used on Oil fired units

MC200 Controlling

High/Low ErP CPx

2.3.2 Non- ErP Products

SEN 1

COM

IN 2

0-10v +

0-10v -

Reset

Lockout

Heat HiInHeat Hi

Out

Heat Lo

In

Heat Lo

Out

Fan In

Fan Out

L Out

N

E

L

MC200 CONTROLLING

ON/OFF NVx or VPc

EN

L

654321

MC200 Fuelsaver

ON/OFF

NVx or VPc

N

L

E

6.3A

HRC

MC200 CONTROLLING

Hi/Lo NVx / VPc

SEN 1

COM

IN 2

0-10v +

0-10v -

Reset

Lockout

Heat HiInHeat Hi

Out

Heat Lo

In

Heat Lo

Out

Fan In

Fan Out

L Out

N

E

L

EN

L

654321

MC200 Fuelsaver

Hi/Lo

NVx or VPc

N

L

E

6.3A

HRC

MC200 Controlling

ON/OFF NVx or VPC

MC200 Controlling

HI/LOW NVx or VPC

Page 17

page no. 17 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

MC200 Controlling

ON/OFF CPx

MC200 Controlling

HI/LOW CPx

SEN 1

COM

IN 2

0-10v +

0-10v -

Reset

Lockout

Heat HiInHeat Hi

Out

Heat Lo

In

Heat Lo

Out

Fan In

Fan Out

L Out

N

E

L

EN

L

10

9876

MC200 Fuelsaver

ON/OFF

CPx

N

L

E

6.3A

HRC

SEN 1

COM

IN 2

0-10v +

0-10v -

Reset

Lockout

Heat HiInHeat Hi

Out

Heat Lo

In

Heat Lo

Out

Fan In

Fan Out

L Out

N

E

L

EN

L

1413

876

MC200 Fuelsaver

Hi/Lo

CPx

N

L

E

6.3A

HRC

MC200 CONTROLLING

Modulating NVx / VPc

SEN 1

COM

IN 2

0-10v +

0-10v -

Reset

Lockout

Heat HiInHeat Hi

Out

Heat Lo

In

Heat Lo

Out

Fan In

Fan Out

L Out

N

E

L

EN

L

654321

MC200 Fuelsaver

Modulating

NVx or VPc

N

L

E

6.3A

HRC

MC200 Controlling

Modulation NVx or VPC

Page 18

page no. 18 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

MC200 Controlling

ON/OFF NVS

SEN 1

COM

IN 2

0-10v +

0-10v -

Reset

Lockout

Heat HiInHeat Hi

Out

Heat Lo

In

Heat Lo

Out

Fan In

Fan Out

L Out

N

E

L

EN

L

10 11 12 13 14

9876

MC200 Fuelsaver

ON/OFF

OUH

N

L

E

6.3A

HRC

MC200 Controlling

ON/OFF OUH

SEN 1

COM

IN 2

0-10v +

0-10v -

Reset

Lockout

Heat HiInHeat Hi

Out

Heat Lo

In

Heat Lo

Out

Fan In

Fan Out

L Out

N

E

L

EN

L

131492

MC200 Fuelsaver

ON/OFF

NVS

N

L

E

6.3A

HRC

SEN 1

COM

IN 2

0-10v +

0-10v -

Reset

Lockout

Heat HiInHeat Hi

Out

Heat Lo

In

Heat Lo

Out

Fan In

Fan Out

L Out

N

E

L

EN

L

13141892

MC200 Fuelsaver

Hi/Lo

NVS

N

L

E

6.3A

HRC

MC200 Controlling

HI/LOW NVS

Page 19

page no. 19 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

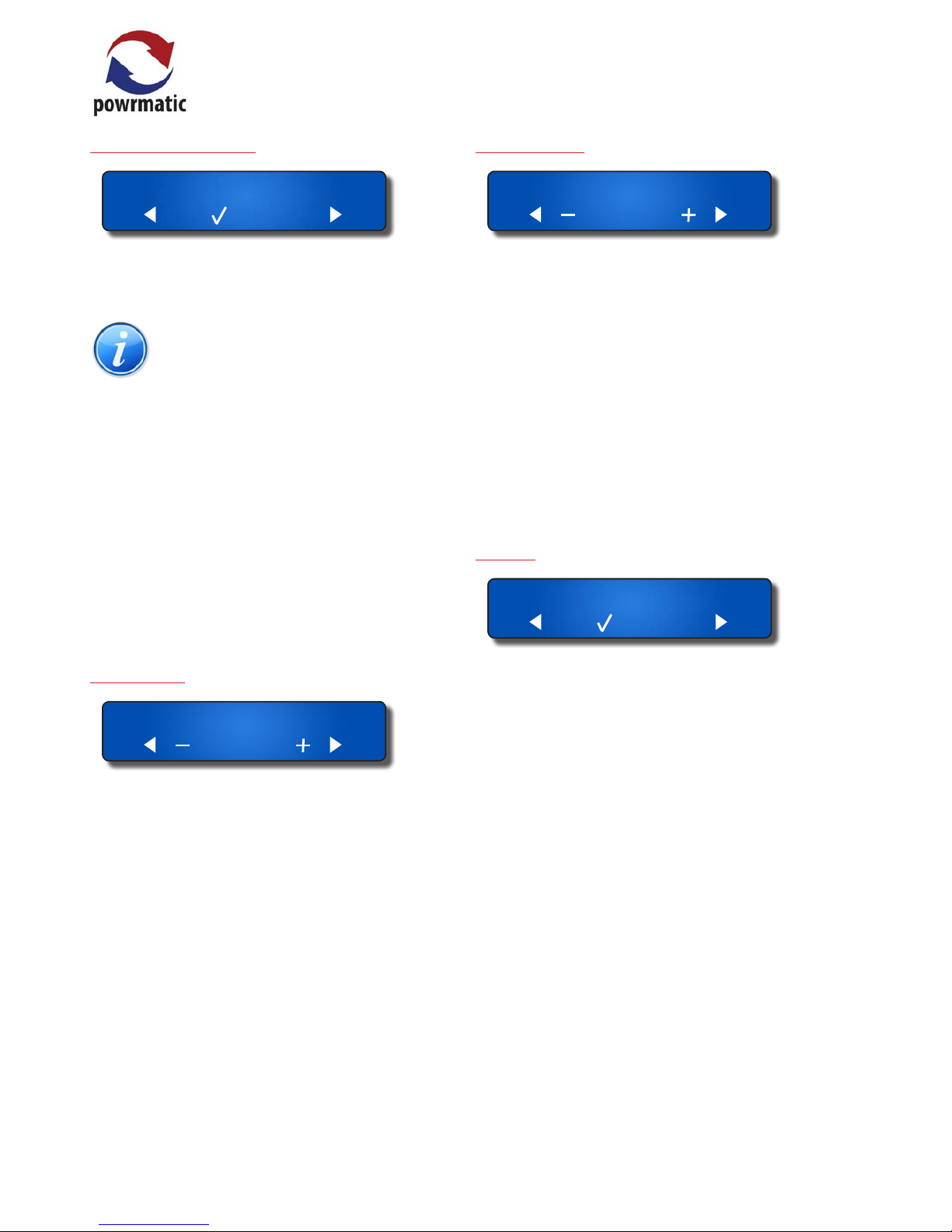

2.4.1. Engineers Settings

The engineer menu is enabled by entering the engineer

passcode at the Password menu option.

Password ****

In order to ensure that the engineer code and the user

code are always distinct, the engineer code is a 3-digit

number and one asterisk. See label on the reverse of the

terminal cover.

Use the + button to increase or the - button to decrease

the rst digit. Use the ► button to move to the next digit

(*). Once the passcode has been entered, press the ü

button to select. If 'FAIL' appears on the display, try again.

Password VALID

Note: Once the engineer code has been

correctly entered no user or engineer codes will

be required for a period of 1 hour.

Pressing the ◄ button will move to the Engineers menus.

Press the ü button to select.

Engineer menus

Press the ◄ or ► buttons to move through the options.

Press the + or - buttons to alter a setting.

Press the ü button to aect the change.

Setting saved

At any point, press the X button to exit from the engineer

sub-menu back to the User menu.

Many of the Engineer settings are determined by the

installed equipment however others will be to the end

users preferences. The latter should be left at default

settings if there is no end user when the control is being

commissioned. If the Users menu is password protected

the Engineer code permits access to both the Engineer

menu and the User menu.

2.4.2. Engineers Menus

Burner: On-Off

Denes the type of controlled burner. (Default: On/O)

Options: On/O, High-Low, Modulating

your setting here

BurnerHi 0120 kW

Denes the high heat input (in kW) of the controlled

burner for cost calculations. (Default: 120kW)

your setting here

BurnerLo 0012 kW

*

*Note: This menu item only appears when Hi/Lo burner type

has been selected.

Denes the Low heat input (in kW) of the controlled burner

for cost calculations. (Default: 12kW)

your setting here

Burner Test

Facilitates direct testing of the controlled burner(s)

irrespective of current control settings, times etc.

*(On/O Options: BURNER OFF, BURNER ON)

*(Hi/Low Options: BURNER OFF, BURNER HI, BURNER LO)

*(Modulation Options: level 1 thro level 10. where 1 is lowest

heat output and 10 is high heat output)

*Note: dependent upon which burner type is set above.

HiLo Diff 6.0.C

*Note: This menu item only appears when Hi/Lo burner type

has been selected.

Sets the temperature dierence between the Hi and Lo

stages of Hi/Lo burners . (Default: 6.0°C)

Range of adjustment: 0.5°C to 10.0°C

your setting here

2.4 Commissioning and Output Sequences

Page 20

page no. 20 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

Trim temp +0.0.C

A temperature oset can be entered here to adjust

the displayed temperature to agree with the sensor

temperature. (Default: 0.0°C)

Range of adjustment: -5°C to +5°C

your setting here

UserTempMin 15.0

Sets the minimum temperature that the User can select.

(Default: 15°C)

Range of adjustment: 10°C - 20°C.

your setting here

UserTempMax 30.0

Sets the maximum temperature that the user can select.

(Default: 30°C)

Range of adjustment: 20°C - 60°C.

your setting here

Temp adjust 3.0

Sets °C that User can temporarily adjust the current set

point up or down. (Default: 3°C), Range is 0.5°C to 30°C.

your setting here

ConstFan: Off

Sets the mode of Fan operation between:

OFF: For Summer operation - fan only operates when Fan

button is pressed and will remain on until Fan button is

pressed again or until midnight,

Auto: fan runs at dictate of fan thermostat on heater),

Const: fan runs continuously when timer is in Heat On

state, or

ON: fan runs 24/7. (Default: OFF)

your setting here

ModOffset 6.0.C

*Note: This menu item only appears when Modulation burner

type has been selected.

Sets the temperature at which the 0-10V signal will be 10V

and the burner will be at High Fire. (Default: 6°C)

Range of adjustment: 3.0°C to 30.0°C

your setting here

Auto reset OFF

Sets whether the control will complete an automatic reset

of lockout, If lockout signal is not removed by a manual

reset the MC200 will initiate an automatic reset 30 minutes

after the lockout signal and then once every 24hrs.

(Default: OFF)

Options - ON, OFF

your setting here

Reset time 1 sec

Sets how long the lockout reset terminal is connected to

neutral when the reset button is pressed. (Default: 1 second)

Options: 1 second, 3 seconds, 5 seconds)

your setting here

Snsr2: Not used

Sets the function of sensor 2 input (alos known as IN2).

(Default: Not used)

Options: Not Used, Remote, Close = o, Close = on, Open =

o, Open = on

Not used: The sensor 2 terminals are ignored

Remote: A temperature sensor is connected

Close = o A switch is tted. When it closes, heating

goes o

Close = on A switch is tted. When it closes, heating

goes on

Open = o A switch is tted. When it opens, heating

goes o

Open = on A switch is tted. When it opens, heating

goes on

your setting here

Page 21

page no. 21 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

Frost/setbackOFF

Sets frost protection/night setback to active or inactive.

(Default: OFF)

Options: ON, OFF

your setting here

SetbackTemp 5.0

Set back temperature value for burner to enable outside a

program period . (Default: 5.0°C)

Range of adjustment: 1°C to 15°C

your setting here

Hysteresis 5.0.C

Hysteresis (°C) Switching dierential band. (Default: 5.0°C)

Range of adjustment: 0.5°C to 6.0°C

On the default setting, the heat demand will switch on &

o at 0.5° of the target temperature. i.e. target temperature

is 20°C, the heater will turn OFF at 20.5°C and turn back ON

again once the temperature falls below 19.5°C.

If the Hysteresis is set to for example 3°C and the target

temperature is 20°C, the heating will turn OFF at 20.5°C and

turn back ON again once the temperature has fallen below

17.0°C. (-3° of target temperature).

your setting here

OptimumStart OFF

Sets whether Optimum Start is active.

(Default: OFF)

Options: ON, OFF

your setting here

Opt Stop 0.0.C

Sets the Optimum Stop temperature.

(Default: 0.0°C)

Range of adjustment: 0°C - 6°C.

your setting here

S ervice date

Allows a service date to be set

L ockout Log

Displays the most recent lockout time and date

Note: If lockout log is not cleared newer events

will over-write older ones.

Restore Defaults

Restore Resets all parameters to factory default settings.

Note This action returns the unit to the main

screen and also clears the Engineers password.

2.4.3. Outputs

2.4.3.1 Single burner

When congured for a single burner heater, the Low heat

relay (Terminals Heat In Lo and Heat Out Lo) operates when

the sensor temperature is below the set temperature.

2.4.3.2 Two-stage

When congured for a two-stage burner heater, the Low

heat relay (Terminals Heat In Lo and Heat Out Lo) operates

when the sensor temperature is below the set temperature

i.e. as ON/OFF. The High heat relay (Terminals Heat In Hi

and Heat Out Hi) operates when the sensor temperature

is below the set temperature by more than the number of

degrees set in the Hi/Lo dierential parameter to switch

from low re to high re e.g. If the set temperatures is

18°C and the Hi/Lo dierential is set to 4°C the high heat

relay will operate at <14°C. The Low Level relay remains

operated while the High heat relay is operated.

2.4.3.1 Modulating

The 0-10Vdc output stays at zero and the Low heat relay

(Terminals Heat In Lo and Heat Out Lo) will remain

de-energized while the sensor temperature is at or above

the set temperature. Below the set temperature, the Low

heat relay (Terminals Heat In Lo and Heat Out Lo) will

operate and the modulating output voltage (Terminals

0-10v+ and 0-10v-) increases, reaching 10v when the sensor

temperature falls to the threshold set i.e 0V at low re, 10V

at High Fire.

Page 22

page no. 22 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

3.1 Fault displays and Fault Finding

Heater Lockout

'Heater lockout' appears on he display if the MC200

receives a fault voltage onto terminal 7. The Fault LED will

also be illuminated.

8.5.C 09:42 Tue

Heater lockout

The lockout can be cleared by pressing the reset button on

the front of the controller. This will send a pulse of neutral

back up to the heater to remove the lockout condition.

If the lockout continues to display once the reset has

been pressed, it may mean the interconnecting reset

cable to the heater is not wired correctly or the heater

has developed a permanent fault that requires a service

engineer to identify.

Sensor Fault

'Sensor fault' appears when there is a break in the circuit

between terminals 'SEN1' and 'COM' or if tted, 'IN2 and

'COM'.

8.5.C 09:42 Tue

Sensor fault

This could be either a faulty sensor bead, an incorrect

terminal connection or a break in a cable.

Clock Fault

'Clock failure' will appear on the screen if the in-built

battery has gone at. This specially occurs if the power has

been turned o to the controller for a long period.

8.5.C 09:42 Tue

Clock failure

Leave the power connected for at least 48hrs to re-charge

the battery (one whole week is more realistic dependent

on the age of the battery itself)

Also check the ribbon cable between the two pcb's is

making good contact

Service Date

When the MC200 is installed the Commissioning Engineer

may have entered a date for when the heating equipment

requires servicing.

When this date is reached the MC200 fault indicator will

be illuminated and the display will alternate between the

normal display and "Service due, call engineer".

S

ervice due,call

engineer

The Service Engineer can clear this display by entering a

new service date when the heating equipment has been

serviced.

Blank Screen

A blank screen is present on the display but the backlit

light is still on.

Before replacing the MC200 ensure the controller has been

powered up for more than 48hrs.

If the screen is still blank, isolate the power and remove the

controller facia pad. Ensure the ribbon cable is connected

to the pcb and pushed in tightly to its terminal housing on

the backboard.

*With the power back on check the display. If still blank,

push the power reset button on the rear of the pcb.

*only be undertaken by a competent person.

If the screen remains blank, contact Powrmatic technical

department.

Page 23

page no. 23 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

No Supply to Heat In/Fan IN

If there is voltage at the mains terminals (L,N & E) and

there is no mains suply on the Heat In or Fan IN terminals

and you are utilising terminal 14 (L Out) to energise these

terminals, then the 6.3A fuse requires replacing.

Isolate the power and remove the controller facia pad. Pull

o the clear plastic fuse cover and replace with new fuse.

No Heat

If the display shows 'HEAT ON' but no heat output, then the

room temperature may be greater than set point.

8.5.C 09:42 Tue

P1 HEAT ON

Follow the 'PROGRAMMING' procedure and raise the

programme temperature. Also check above.

No Heat On LED

Pressing the Heat Button has no eect - no heating on LED.

1. The room temperature may be greater than the set

point.

Temperature 18.0

Navigate to the 'Temperature' setting and increase the day

set point using the + button.

If the temperature wont adjust, check the permissions

setting as above.

If the temperature doesn't increase past a particular point,

the range could be limited within the engineers setting.

UserTempMax 30.0

Increase the max available temperature.

2. The heat button may be turned o within the

permissions settings

P ermissions

Page 24

page no. 24 of 24

MC200/V3 Users, Installation & Servicing Instructions Doc Ref M401 issue 5.4 Feb 2018.

HEATING DIVISION

Hort Bridge

Ilminster, Somerset TA19 9PS

Tel: 01460 53535

Fax: 01460 52341

Every effort is made to ensure accuracy at time of going to press. However as part of continued product improvement,

we reserve the right to alter specication without prior notice.

More information is available from our web site on:-

http://www.powrmatic.co.uk/products/heating/browse/view/product/powrmatic-mc200bl/

https://www.youtube.com/user/PowrmaticVideos

Set up instructional videos now available on our website/YouTube:-

3.2 Spare Parts & Options

Item Description Part No.

Internal Sensor Bead 143070034

Internal PCB 143070033

Warm Air Sensor 143070031

Black Bulb Sensor 143070032

Duct Sensor 143070035

Loading...

Loading...