Powrmatic ErP NVS 30, ErP NVS 60, ErP NVS 90, ErP NVS 140 User, Installation & Servicing Manual

Doc Ref: M102 Issue 2.4 May 2018

NVS Condensing Gas Unit Heater

Industrial & Commercial Heating Systems

User, Installation

& Servicing Manual

www.powmatic.co.uk

+44 (0) 1460 53535

info@powrmatic.co.uk

Certificate of Guarantee

Dear Customer

This is to certify that this heater is guaranteed for two years parts and one year labour from the date

of original commissioning. The heater must be commissioned within 4 weeks of installation.

To make a claim

In the rst instance you must contact your appliance supplier, or installer and provide:-

1. The appliance type and serial number.

2. The original commissioning documentation. As much detail as possible on the fault.

3. Your supplier, or installer, will then contact Powrmatic to make a guarantee claim on your behalf.

Conditions of Guarantee

1. The heater must have been installed by a competent recognised installer, and in

accordance with the manufacturer’s instructions, building regulations and local regulations.

2. The heater has been professionally commissioned, within 4 weeks of installation, and a copy of

the commissioning sheet returned to Powrmatic.

3. The heater has been maintained on a yearly basis by a competent servicing company.

4. The heater has been used in accordance with the manufacturer’s instructions.

5. The correct specication fuel has been used.

6. No unauthorised repairs of modications have been made. Powrmatic ‘General Conditions of

Sales’ have been observed.

7. Except for the obligation of Powrmatic Ltd to perform warranty repairs during the guarantee

period Powrmatic will not be liable in respect of any claim for direct or indirect consequential

losses, including loss of prots or increased cost arising from loss of use of the heater, or any

event arising there from.

Exclusions

Consumables such as gaskets, ignition electrodes, ame rectication electrodes, drive belts, fusible

links, control batteries are all excluded from guarantee.

----------------------------------------------------

Powrmatic Ltd, Hort Bridge, Ilminster, Somerset, TA19 9PS

Tel: 01460 53535 Fax: 01460 52341

Web: www.powrmatic.co.uk e-mail: warranty@powrmatic.co.uk

Important: This certicate

must be kept with the appliance

Failure to provide a copy of the commissioning sheet invalidates the heater warranty

Installer

Date:________________Signed: _____________________________________Installer

Commissioned

Date:________________Signed:_______________________Commissioning Engineer

page no. 2 of 36

NVS Range Users, Installation & Servicing Instructions Doc Ref M102 issue 2.4 May 2018.

Dear Customer - thank you for choosing Powrmatic.

We appreciate you buying one of our high quality products and know that you have made the best

choice. By choosing Powrmatic, you are investing in UK manufacturing & its workforce. We pride

ourselves by manufacturing products that provide clean, comfortable and safe working environments

worldwide together with the personal & professional service and back-up you deserve. If you have

any questions or concerns regarding this product, please contact our Technical Support Team by

calling 01460 53535.

Users, Installation and Servicing Instructions

CONTENTS

Title Section Contents Page

User Instructions 4

Pre Installation

1.1 Introduction 5

Duties 6

Dimensions 7

1.2 Technical data 9

1.3 General Requirements 10

Installation

2.1 Fitting the unit 14

2.2 Flue/Combustion Air Duct System 16

2.3 General Identication of Electrical Items 19

2.4 Electrical Cable Installation 19

2.5 Wiring Diagrams 21

2.6 Commissioning and Testing 23

2.7 Servicing 27

Additional Documents

3.1 Short List of Parts 30

3.2 Gas Conversion 32

Appendices

Information required for ecodesign (ErP) Directive 2009/125 34

NVS Range Users, Installation & Servicing Instructions Doc Ref M102 issue 2.4 May 2018.

page no. 3 of 36

User Instructions

If the heater has not been left operational

proceed as follows.

A) Checks before lighting the Air Heater

The following preliminary checks should be made before

lighting the heater(s)

a) Ensure that the ELECTRICAL supply to the heater is

switched OFF.

b) Check that all warm air delivery outlets are open.

c) Check that the thermostat is set at MAX.

d) Check that the clock control is set to an ON period.

e) Check that any other controls are calling for heat.

B) Lighting the Air Heater

1. Switch on the electrical supply at the isolator

2. If the Red Limit indicator light at the front of the heater is

illuminated, press the limit interlock reset switch at the side

of the lamp.

3. The startup sequence will commence.

4. If the burners fail to light the control box will

automatically restart the ignition sequence. If after 5

attempts at ignition the burners have still failed to light

the control box will go to lockout and the Red lockout light

inside the heater (or on the low level remote reset, MC200

or Powrtrol RR if tted) will be illuminated. To restart the

ignition sequence depress the reset button for about 1-2

seconds.

WARNING: If it is not possible to light the

heater after several attempts, contact the

installer or local service company.

C) To Shut Down the Air Heater

1) For Short Periods:

Turn the room thermostat to the OFF, or set to it’s lowest

setting.

D) Description of Operation

Important: The heater must NOT be

controlled by switching ON and OFF the

main electrical supply to it.

1) Standard Units

The ignition sequence commences each time the external

controls e.g. Time clock, room thermostat etc. call for

heat. The internal exhaust fan will run and, when sucient

combustion airow is proved by the air pressure switch, the

ignition spark will be generated, the main gas valve opens

and the burners light. The heater fan will automatically

start approximately 0 - 30 seconds (depending on the

setting of the internal timer) after the burners light. When

the external controls are satised the burners will be

turned o and approximately 2 - 3 minutes later the heater

fan will be automatically stopped. If the burners fail to light

the control box will make another four attempts at ignition.

2) High / Lo & Modulating Units

When the burners are alight, the heat output will be

controlled either to high re or low re or, in the case of

modulating units, to any point between high and low re;

depending on the requirements of the space being heated

and the external controls tted.

3) Summer / Winter Modes

Certain types of external controls will provide for two

modes of operation i.e.

Summer: The heater fan alone will run at the dictate of the

external controls to provide air movement.

Winter: The heater will operate normally.

4) Overheat Thermostat

This operates if high temperatures within the heater are

detected, the burners are turned o and a Red indicator

switch light on the front panel is illuminated. The fault

condition must be identied and rectied and the

thermostat manually reset. The thermostat is located

next to the indicator light and unscrewing the cover cap

exposes the reset button which can then be depressed.

2) For Long Periods:

Complete step 1 above. Wait for 5 minutes and then turn

OFF the electrical supply at the isolator.

page no. 4 of 36

NVS Range Users, Installation & Servicing Instructions Doc Ref M102 issue 2.4 May 2018.

Note: The limit thermostat(s) can only be reset

once the unit has cooled down.

Unless the cause of the fault condition is

readily obvious, for example a power cut whilst

the heater was operating, a service engineer should be

contacted.

E) Maintenance

To maintain ecient, reliable and safe operation of the

heater it must serviced by a qualied person at least

annually and preferably at the end of the heating season.

F) IMPORTANT

Free access must be maintained to and around the heater

for servicing purposes and the air supply to the heater

must not be restricted in any way. Combustible materials

must not be stored adjacent to the heater.

If at any time a gas leak is suspected, turn OFF the gas

supply at the meter and contact the local gas undertaking

immediately.

to service unless you are a competent person in the eld of

Gas and Electrical work.

If you have any safety questions reference the servicing

and installation of any of our heaters please do not hesitate

to contact our head oce for expert advice. Your safety is

paramount to us.

Gas Safety (Installation & Use) (Amendment)

Regulations

It is law that all gas appliances are

installed, adjusted and, if necessary,

converted by qualied persons* in

accordance with the current issue of the

above regulations. Failure to install appliances

correctly can lead to prosecution. It is in your own

interests and that of safety to ensure that the law is

complied with.

All Powrmatic heaters use gas and electricity to power

them, they may also contain moving parts such as pulleys

and belts. It would be hazardous to tamper with or attempt

1.1 Introduction

The NVS range are highly ecient, fully condensing, gas

red, fanned circulation air heaters that cover heat outputs

of 30kW to 140kW, have a closed combustion circuit and

are supplied complete with a ue system. They are certied

for use on Natural Gas, Group H - G20, and Propane - G31

only. Appliance Categories are Cat II2H3P (GB, IE).

The heaters are designed to be suspended from suitable

roof points or alternatively to be mounted on purpose

designed brackets and are intended primarily for heating

commercial or industrial premises. All variants are for

internal use only.

NVS heaters feature a closed combustion circuit and have

an internal exhaust fan, mounted downstream of the

heat exchanger, to evacuate the products of combustion

and draw in air for combustion. The air heater must be

connected to a ue system that is approved by Powrmatic

Ltd.

* An approved class of person listed on the gas safe

register.

are for use in air handling units. NVS units are not suitable

for siting externally.

Heaters are tted as standard with inshot burners, a fully

automatic control for ignition, ame sensing, gas supply

control and safety functions, an internal exhaust fan, main

air fan (/F and /C models), and fan/limit thermostat.

Options include High/Low or Modulating burner controls,

inlet duct connection, outlet duct connection, 30°, 45°

head, 90° outlet bend, vertical/horizontal outlet louvre

assembly and a full range of modular duct components.

IMPORTANT

Service and Maintenance Engineers shall

ensure that replacement items are tted,

adjusted and set in accordance with the

data and detail set out in these instructions. If in doubt

consult Powrmatic Technical Department.

They may be used where the atmosphere inside the

premises could be contaminated e.g. Dust, oil mist etc. but

the heaters are not airtight and therefore may not be used

in areas classied as hazardous as dened in BS 5345: Part 2

or areas subjected to signicant negative pressures due to

extract systems.

NVS/F heaters have an axial fan assembly tted at the rear

to circulate the air being heated through the formed tube

heat exchanger. NVS/C units are supplied with a centrifugal

fan and NVS/D units for use with ducted systems where the

air moving fan is by others or a centrifugal fan section is

used adjacent to or remote from the heater. NVS/DH units

NVS Range Users, Installation & Servicing Instructions Doc Ref M102 issue 2.4 May 2018.

Gas Safety (Installation & Use) Regulations 1998

It is law that all gas appliances are

installed, adjusted and, if necessary,

converted by qualied persons* in

accordance with the current issue of the

above regulations. Failure to install appliances

correctly can lead to prosecution. It is in your own

interests and that of safety to ensure that the law is

complied with.

* An approved class of person listed on the gas safe

register.

page no. 5 of 36

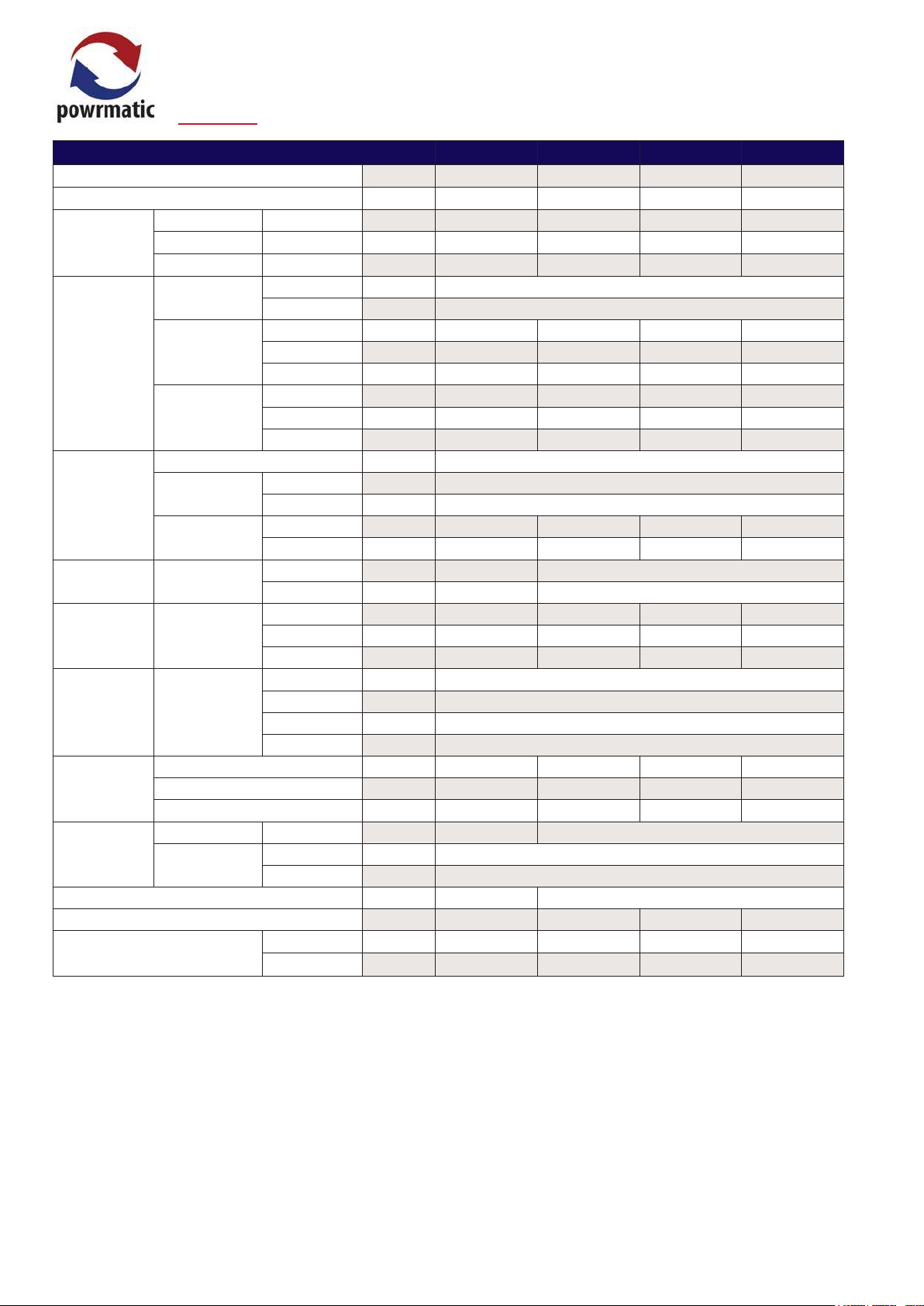

Duties

Model 30 60 90 140

Output kW 30 60 90 140

Input (nett CV) kW 29.02 59.22 86.74 137.95

Volume (All Models) m

Airflow

Throw NVS F m 24 25 31 37

Fan Static

Supply

NVS C Pa 250 250 200 285

Standard V/ph/Hz 230/1/50

Optional V/ph/Hz 415/3/50

Motor kW 0.39 0.66 2 x 0.39 2 x 0.66

Electrics

NVS F

Start amp 3.76 5.5 5.0 10.6

Run amp 1.70 2.4 2.3 5.3

Motor kW 1.10 1.40 2 x 1.10 2 x 1.40

NVS C

Start amp 18.50 28.90 31.0 40.0

Run amp 6.40 9.50 12.80 17

Connection BSP/Rc ¾”

Nat Gas mbar 17.5

LPG mbar 37.0

Nat Gas m

LPG m

Min m 2.50 3.00

Max m 3.00 5.00

Fuel

Mounting

Height

Minimum Inlet

Pressure

Consumption

NVS F

Height mm 818 818

Overall

Dimensions

NVS F

Width mm 1050 1345 2345 2345

Depth mm 1187 1204 1187 1204

Top mm 200

Installation

Clearances

NVS

LH Side mm 200

RH Side mm 1000

Rear mm 600

Connection mm 15 15 15 15

Condensate

Output

Natural Gas l/h 2.3 3.4 6.0 8.8

Propane l/h 1.2 1.7 3.0 4.4

Diameter mm ø 100 130

Flue

Maximum Length

Flue Only m 12

Room Sealed m 6

Combustion Air Spigot mm ø 100 130

Noise Level dB(A) 54 62 66 67

Nett Weight

NVS F kg 124 177 245 350

NVS C kg 195 252 384 514

3

/s 0.78 1.56 2.34 3.64

3

/h 3.07 6.26 9.17 14.60

3

/h 1.21 2.42 3.55 5.64

705 1035

Notes –

Fuel consumption and output figures based upon nett calorific values as follows

- Natural gas (G20) nett CV 34.02 MJ/m³

- Propane (G31) nett CV 88.00 MJ/m³

• Heaters have efficiency levels which meet with the minimum efficiency requirements of UK PartL2B Building Regulations

• Heaters have efficiency levels which meet the criteria of the Enhanced Capital Allowance Scheme (Excluding NVS30)

• Air handling data is assessed at room ambient conditions

• Throw figures provide the distance to the point where the terminal velocity degrades to 0.25 m/s

• Dimensions and clearance data in table above refer to NVS F units only.

• Condensate rates are approximate and for when heaters are working at maximum output.

• Noise levels are applicable to standard NVS F models and are measured 5m from appliance and in free field conditions

• Motor kW, run and start amps apply to standard electrical supply as stated. For optional data contact sales office

• Connection of combustion air duct is not required for ‘flue only’ applications.

page no. 6 of 36

NVS Range Users, Installation & Servicing Instructions Doc Ref M102 issue 2.4 May 2018.

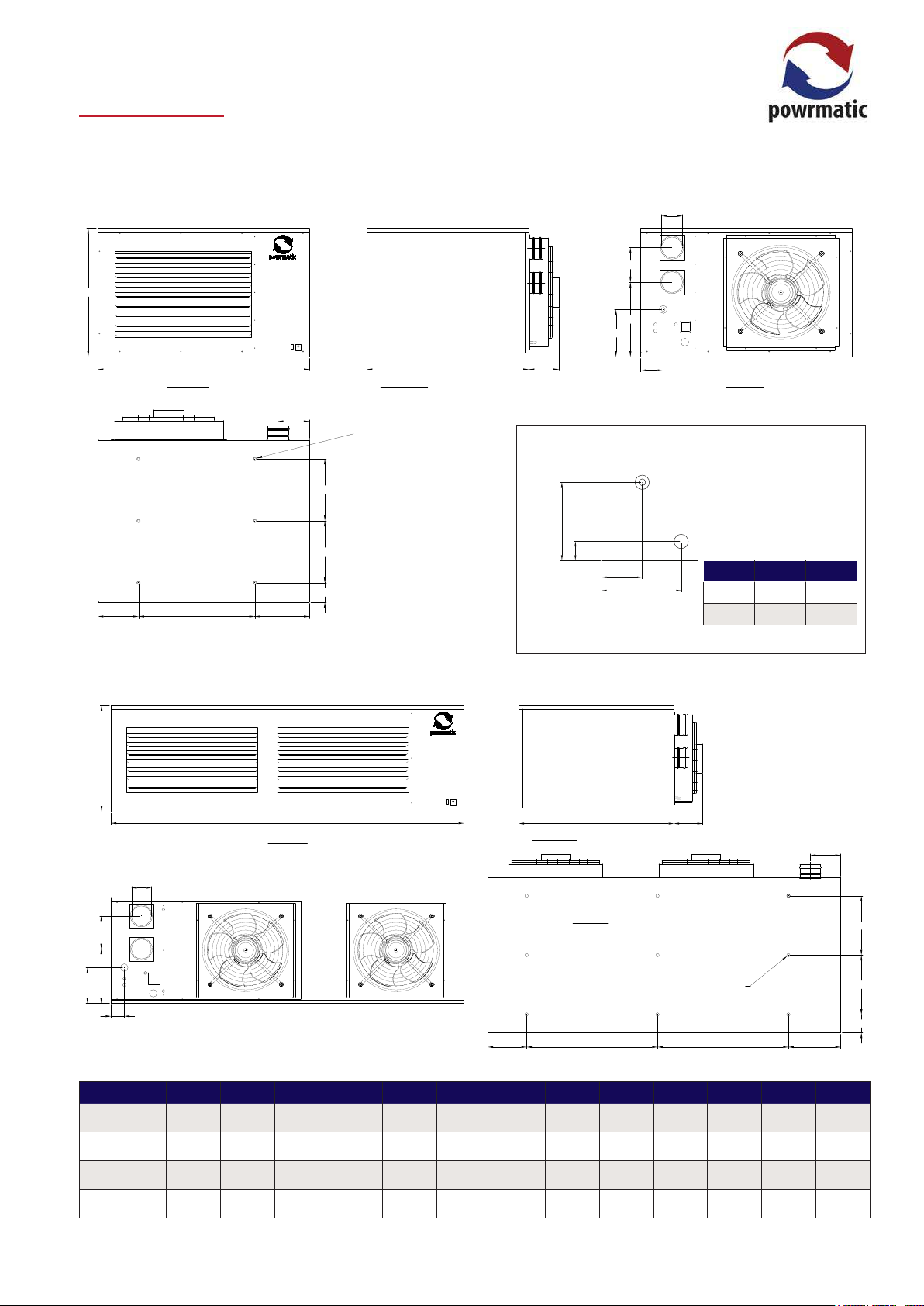

P

Y

N

X

GAS ENTRY POINT

CONDENSATE DRAIN POINT

FRONT VIEW

PLAN VIEW

R/H SIDE VIEW

GAS ENTRY POINT

REAR VIEW

C

A

B

Q

ØD

G

F

P

N

122

394

394

M

K

J

H

SUSPENSION POINTS M10

P

Dimensions

NVS F - Axial Fan Crossow Units

NVS 30 & 60

ØD

G

C

P

A B

FRONT VIEW

M

K

NVS 90 & 140

PLAN VIEW

J

394

394

122

H

R/H SIDE VIEW

SUSPENSION POINTS M10

Q

Detailed View Of Gas Entry Point & Condensate Drain Point

GAS ENTRY POINT

F

N

REAR VIEW

Model X Y

30/60 280 90

90/140 280 65

C

ØD

G

GAS ENTRY POINT

F

N

A

FRONT VIEW

REAR VIEW

K

B

R/H SIDE VIEW

PLAN VIEW

J J

Q

SUSPENSION POINTS M10

M

394

394

122

H

Model A B C D F G H J K M N P Q

NVS-F 30 1050 1031

818

100 552

142

347 445 258 201 144 225 156

NVS-F 60 1345 1031 818 130 475 220 347 740 258 201 144 301 173

NVS-F 90

NVS-F 140 2345 1031

NVS Range Users, Installation & Servicing Instructions Doc Ref M102 issue 2.4 May 2018.

2345

1031 705 130 356 220 347 870 258 201 88 237 156

1035

130

686

220 347 870 258 201 88 147 173

page no. 7 of 36

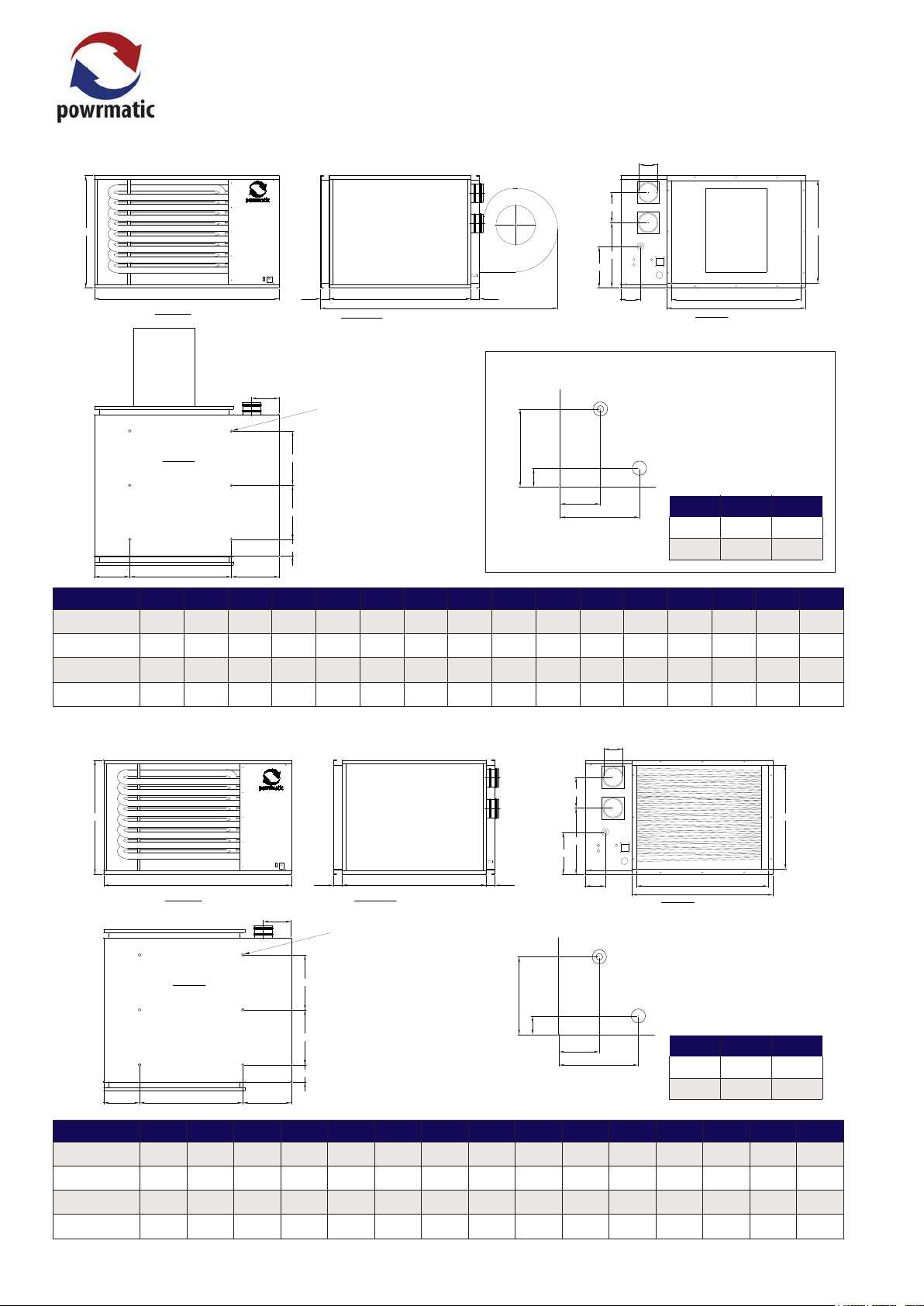

NVS C - Centrifugal Close Coupled Fan Units

P

Y

N

X

GAS ENTRY POINT

CONDENSATE DRAIN POINT

FRONT VIEW

PLAN VIEW

R/H SIDE VIEW

GAS ENTRY POINT

REAR VIEW

C

A B

63

ØD

G

F

P

N

122

394

394

M

K

J

H

SUSPENSION POINTS M10

63

L

S

R

T

P

Y

N

X

GAS ENTRY POINT

CONDENSATE DRAIN POINT

C

ØD

G

GAS ENTRY POINT

F

P

T

A B

FRONT VIEW

63

R/H SIDE VIEW

L

63

N

REAR VIEW

S

R

Detailed View Of Gas Entry Point & Condensate Drain Point

M

SUSPENSION POINTS M10

PLAN VIEW

K

J

394

394

122

H

Model X Y

30/60 280 90

90/140 280 65

Model A B C D F G H J K L M N P R S T

NVS-C 30 1050 1031

NVS-C 60 1345 1031 818 130 475 220 347 740 258 1589 201 144 301 1010 940 748

2345

1031 705 130 356 220 347 870 258 1589 201 88 237 2014 1944 635

NVS-C 90

NVS-C 140 2345 1031

NVS D - Ducted Heat Module Units (No fan)

818

1035

100 552

130

142

347 445 258 1589 201 144 225 696 626 748

686

220 347 870 258 1664 201 88 147 2014 1944 965

ØD

C

FRONT VIEW

PLAN VIEW

K

A B

J

H

63

R/H SIDE VIEW

M

SUSPENSION POINTS M10

394

394

122

63

Detailed View Of Gas Entry Point & Condensate Drain Point

G

GAS ENTRY POINT

F

P

N

REAR VIEW

S

R

T

Model X Y

30/60 280 90

90/140 280 65

Model A B C D F G H J K M N P R S T

NVS-D 30 1050 1031

818

100 552

142

347 445 258 201 144 225 696 626 748

NVS-D 60 1345 1031 818 130 475 220 347 740 258 201 144 301 1010 940 748

NVS-D 90

NVS-D 140 2345 1031

page no. 8 of 36

2345

1031 705 130 356 220 347 870 258 201 88 237 2014 1944 635

1035

130

686

220 347 870 258 201 88 147 2014 1944 965

NVS Range Users, Installation & Servicing Instructions Doc Ref M102 issue 2.4 May 2018.

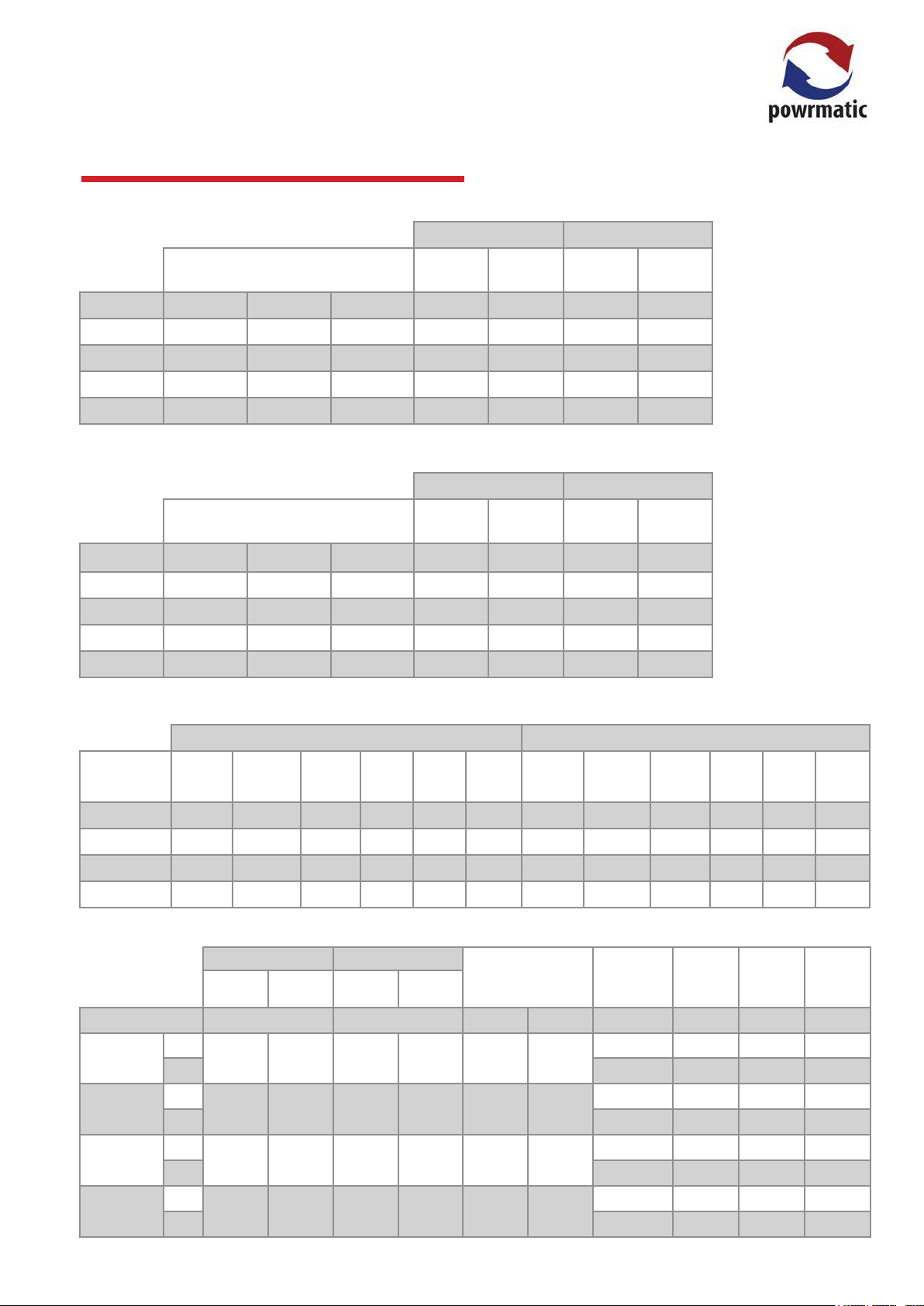

1.2 Technical Data

Injector Sizes & Burner Pressures - Natural Gas - Group H - G20 Net CV (Hi = 34.02MJ/m³)

High Fire Low Fire

Injectors

MODEL No. Size (mm)

Burner

Pressure

Marked mbar m³/h mbar m³/h

Gas Rate

Burner

Pressure

Gas Rate

NVS30 6 1.94 194 10.0 3.07 3.3 1.67

NVS60 8 2.54 254 8.3 6.26 2.6 3.46

NVS90 6 3.5 350 8.2 9.17 2.8 5.40

NVS140 10 3.5 350 7.9 14.60 2.3 8 .17

Injector Sizes & Burner Pressures - Propane G31 Net CV (Hi = 88.00MJ/m³)

High Fire Low Fire

Injectors

MODEL No. Size (mm)

Burner

Pressure

Marked mbar m³/h mbar m³/h

Gas Rate

Burner

Pressure

Gas Rate

NVS30 6 1.25 125 26.5 1.21 7.6 0.65

NVS60 8 1.55 155 20.0 2.42 7.4 1. 34

NVS90 6 2.1 210 24.0 3.55 8.4 2.08

NVS140 10 2.10 210 22.6 5.64 6.9 3.16

Electrical Loadings - 1Pha

Nominal Inlet

Pressure = 20mbar

Minimum Inlet

Pressure = 17.5mbar

Nominal Inlet

Pressure = 37mbar

Minimum Inlet

Pressure = 37mbar

Motor

MODEL

NVS30

NVS60

NVS90

NVS140

kW

0.39 930 1.8 3.76 1.7 3 1.1 900 9.8 18.5 6.4 7

0.66 860 3.0 5.5 2.8 5 1.4 930 10.0 28.9 9.5 16

2 x 0.39 930 2 x 1.8 5.0 2.3 5 2 x 1.1 900 2 x 8.0 31.0 12.8 16

2 x 0.66 860 2 x 3.0 10.6 5.3 7 2 x 1.4 900 2 x 10 40.0 17.0 20

Heater Specications

Input

(Nett)

MODEL

NVS30

NVS60

NVS90

NVS140

F

29.02 30.0 15.78 15. 2 0.7804 2809

C 250 1.1 n/a 195

F

59.22 60.0 32.72 32.29 1.5608 5618

C 250 1.4 n/a 252

F

86.74 90.0 51.00 52.53 2. 3412 8428

C 200 2 x 1.1 n/a 384

F

137.95 140.0 77.26 76.64 3.6418 13110

C 285 2 x 1.40 n/a 514

/F Models /CCF Models

Nominal

Motor

R. P.M .

High Fire Low Fire

kW kW m³/s m³/h Pa kW dB(A) kg

Output

Rated

Amps

(A)

Start

Amps

Input

(Nett)

(A)

Run

Amps

(A)

Output

Fuse

Rating

(A)

Air Volume

Motor

kW

Nominal

Motor

R. P.M .

Maximum

Resistance

Duct

Rated

Amps

(A)

Motor

Fan

Start

Amps

(A)

Amps

Noise

Level

n/a 0.39 54 124

n/a 0.66 62 176.5

n/a 2 x 0.39 66 245

n/a 2 x 0.66 67 350

Run

(A)

Fuse

Rating

(A)

Weight

NVS Range Users, Installation & Servicing Instructions Doc Ref M102 issue 2.4 May 2018.

page no. 9 of 36

1.3 General Requirements

1.3.1. Related Documents

The installation of the air heater(s) must be in accordance

with the rules in force and the relevant requirements of the

Gas Safety Regulations, Building Regulations and the I.E.E.

Regulations for Electrical Installations. It should also be in

accordance with any relevant requirements of the local gas

region, local authority and re authority and the relevant

recommendations of the following documents.

Institution of Gas Engineers & Managers

IGE/UP/1 (Ed.2) Strength and tightness testing and

purging of industrial and commercial gas installations.

IGE/UP/1A Soundness testing and direct purging of small

low pressure industrial and commercial gas installations.

IGE/UP/2 Gas installation pipe work, boosters and

compressors on industrial and commercial premises.

IGE/UP/10 (with Amendments October 2010) Installation

gas appliances in industrial and commercial premises.

British Standards Code of Practice

BS 5588 Fire precautions in the design and construction of

buildings.

Part 2 : 1985 Code of Practice for Shops

Part 3 : 1983 Code of Practice for Oce Buildings

BS 6230 Installation of Gas Fired Forced Convection Air

Heaters for Commercial and Industrial Space Heating.

Those appliances having a gross input rating not exceeding

60kW viz. NVS30 and installed to take their combustion air

from within the building must be installed in accordance

with the relevant recommendations of the following

document.

BS 5440 Flues and Air Supply for gas appliances of rated

input not exceeding 60kW (1st and 2nd family gases), Part

2 – Air Supply

For NVS30/D units, reference should also be made to:

BS 5864 Code of Practice for installation of gas-red

ducted-air heaters of rated input not exceeding 60kW.

Electromagnetic Compatibility (EMC)

These heaters pass the following standards for

Electromagnetic Compatibility: EN 61000-6-3:2007 A1

(Generic Emissions for Residential, Commercial and Light

Industrial Environments) and EN 61000-6-2:2005 (Generic

Immunity for Industrial Environments).

1.3.2 Location

Powrmatic NVS units are designed to operate within an

ambient temperature range of -10 to 25°C.

NVS heaters can be installed in several ways: i) suspended

from ‘drop rods’ via purpose designed M10 suspension

xing points on the heater, ii) attached to our optional

wall support brackets or iii) positioned on a level, noncombustible base. In all cases, it is important that all

supporting structures have been assessed with regard to

the relevant weight loadings.

Consideration should be given to ue routes and points of

exit, condensate, gas, electrical and control connections.

Consideration should also be given to the throw

characteristics of the heater, issues of public access and

siting of environmental control stations and/or remote

temperature sensors where the position needs to be

representative of the zone temperature to which they refer.

Where the location of the air heater is such that it might

suer external mechanical damage e.g. from overhead

cranes, fork lift trucks, it must be suitably protected.

Heaters should not be installed in hazardous areas or areas

where there is a foreseeable risk of ammable or corrosion

inducing particles, gases or vapours being drawn into the

combustion air or main fan circuits.

Areas where special consideration or advice may be

required could include but is not limited to –

• Where de-greasing solvents are present, even in

minute concentrations

• Where paint spraying is carried out

• Where styrenes or other laminating products are

used

• Where airborne silicone is present

• Where petrol engine vehicles are stored or main

tained

• Where dust is present (i.e. wood working or

joinery shops)

• Where high levels of extract persist

Installation in such areas may be possible under specic

conditions. Please consult our Technical Department for

further information.

1.3.2.1 Sizing of the heater

The heater should be correctly sized for the area that it is

heating, Full calculations need to be preformed to ensure

the correct KW output heater is tted (CIBSE elemental

methodology can be used, or the Powrmatic Technical

Department can provide guidelines).

page no. 10 of 36

NVS Range Users, Installation & Servicing Instructions Doc Ref M102 issue 2.4 May 2018.

1.3.3 Electrical Supply

1.3.5 Flue System

Wiring external to the air heater must be installed in

accordance with the I.E.E. Regulations for Electrical

Installations and any local regulations which apply.

All standard heaters are supplied by 230V - 1ph, 50Hz. The

method of connection to the main electricity supply must:-

- facilitate the complete electrical isolation of the unit(s)

- be in a readily accessible position adjacent to the unit(s)

- serve only the unit(s)

- have a contact separation of at least 3mm in all poles. See

the accompanying wiring diagram for the heater electrical

connections

NVS/C and fan/silencer units can also be supplied for 400V

3N, 50Hz.

1.3.4 Gas Supply

A servicing valve and union to facilitate servicing must

be tted to the gas inlet pipe work of the heater. The gas

supply must be completed in solid pipe work and be

adequately supported. Heaters suspended by drop rods,

straps or chains must have a exible connection as the

nal link between the gas supply pipe work and the heater.

Sucient slack must be left in the connection to take

account of normal movement of the heater.

Warning

When completing the nal gas connection

to the heater do not place undue strain on

the gas pipe work of the heater.

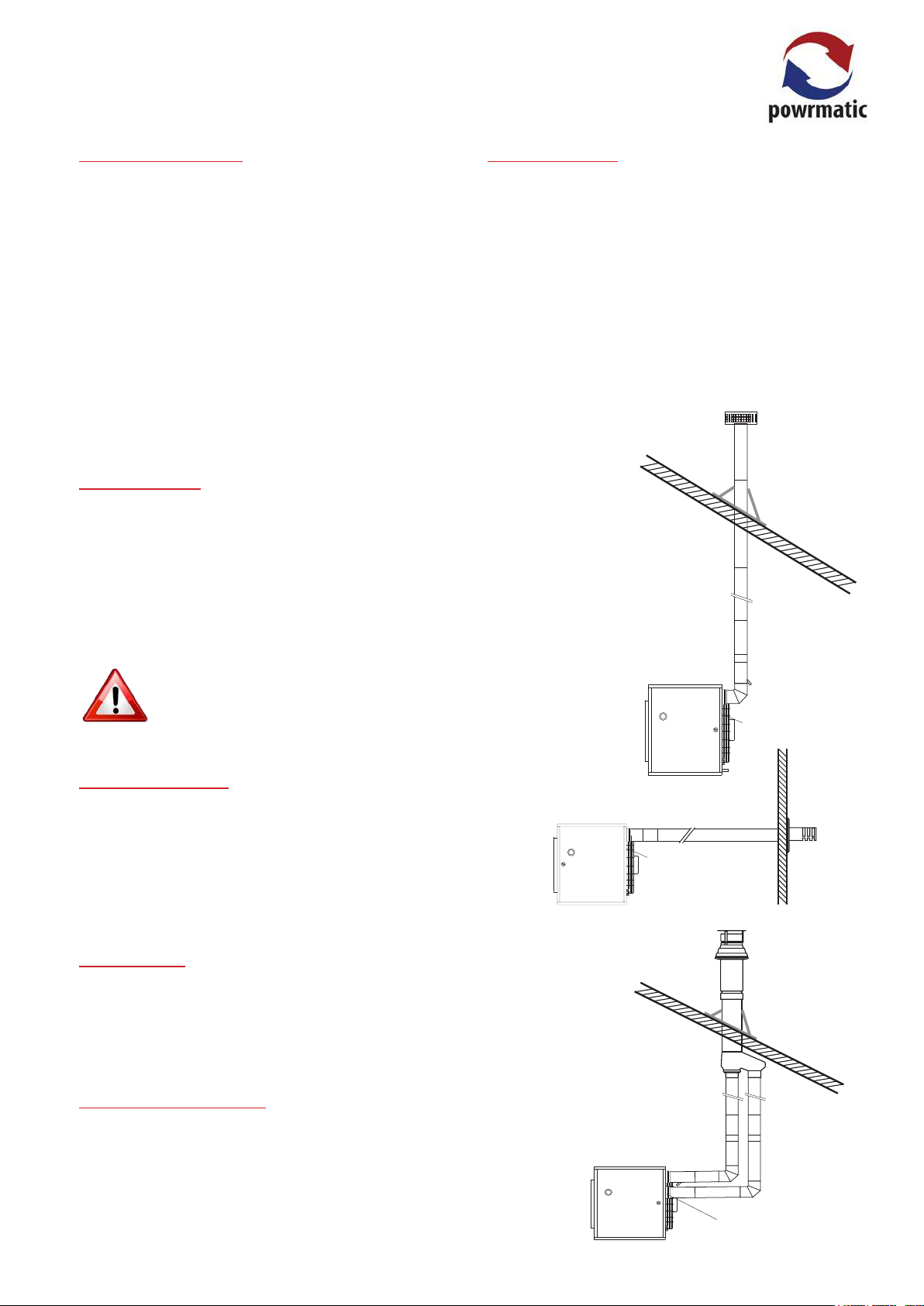

NVS units feature a closed combustion circuit and have an

internal exhaust fan, mounted downstream of the heat

exchanger, to evacuate the products of combustion and

draw in air for combustion.

The air heater must be connected to the ue system that is

provided by Powrmatic Ltd. Several congurations of ue

and combustion air ducts are available.

The ue must terminate in a freely exposed position and

be sited to prevent the products of combustion entering

any opening in a building in such concentration as to be

prejudicial to health or a nuisance

Type B22 Installation.

Combustion air entry

(fitted with inlet grille and

inlet bend (not shown))

1.3.4.1 Service Pipes

The local gas undertaking should be consulted at the

installation planning stage in order to establish the

availability of an adequate supply of gas. An existing

service pipe must not be used without prior consultation

with the local gas undertaking. The inlet gas pressure

under running conditions must not be less than 17.5mb.

1.3.4.2 Meters

An existing meter should be checked, preferably by the gas

undertaking, to ensure that the meter is adequate to deal

with the total rate of gas supply required by all connected

equipment.

1.3.4.3. Installation Pipes

Installation pipes should be tted in accordance with IGE/

UP/2. Pipe work from the meter to the air heater must be

of adequate size. Do not use pipes of a smaller size than

the inlet gas connection of the heater. The complete

installation must be tested for soundness as described in

the above Code.

Type C32 Installation.

Combustion air entry

(fitted with inlet grille and

inlet bend (not shown))

Combustion

air socke t

NVS Range Users, Installation & Servicing Instructions Doc Ref M102 issue 2.4 May 2018.

page no. 11 of 36

Loading...

Loading...