Powrmatic CPx Series, CPx 30, CPx 120, CPx 150, CPx 175 User, Installation & Servicing Manual

...Page 1

www.powrmatic.co.uk

CPx

Doc Ref: M201 Issue 2.9 Nov 2018

®

User, Installation & Servicing Manual

Issue 2.9 November 2018

ErP COMPLIANT

SEPTEMBER 2018

Page 2

Certificate Of Guarantee

®

Certificate of Guarantee

This is to certify that this heater is guaranteed for two years parts and one year labour from the date

of original commissioning. The heater must be commissioned within 4 weeks of installation.

To make a claim

In the first instance you must contact your appliance supplier, or installer and provide:-

1. The appliance type and serial number.

2. The original commissioning documentation. As much detail as possible on the fault.

3. Your supplier, or installer, will then contact Powrmatic to make a guarantee claim on your behalf.

Conditions of Guarantee

1. The heater must have been installed by a competent qualified installer, and in

accordance with the manufacturer’s instructions, building regulations and local regulations.

2. The heater has been professionally commissioned, within 4 weeks of installation, and a copy of

the commissioning sheet returned to Powrmatic.

3. The heater has been maintained on a yearly basis by a competent and qualified servicing

company.

4. The heater has been used in accordance with the manufacturer’s instructions.

5. The correct specification fuel has been used.

6. No unauthorised repairs of modifications have been made. Powrmatic ‘General Conditions of

Sales’ have been observed.

7. Except for the obligation of Powrmatic Ltd to perform warranty repairs during the guarantee

period, Powrmatic will not be liable in respect of any claim for direct or indirect consequential

losses, including loss of profits or increased cost arising from loss of use of the heater, or any

event arising there from.

Exclusions

Consumables such as gaskets, ignition electrodes, flame rectification electrodes, drive belts, fusible

links, control batteries, oil nozzles and oil line filter elements are all excluded from guarantee.

----------------------------------------------------

Powrmatic Ltd, Hort Bridge, Ilminster, Somerset, TA19 9PS

Tel: 01460 53535 Fax: 01460 52341

Web: www.powrmatic.co.uk e-mail: warranty@powrmatic.co.uk

Important: This certificate

must be kept with the appliance

Failure to provide a copy of the commissioning sheet invalidates the heater warranty

page no. 2 of 68

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

Page 3

Contents

Users, Installation and Servicing Instructions

CONTENTS

Title Section Contents Page

User Instructions 4

Pre Installation

1.1 Introduction 6

Duties 7

Dimensions 8

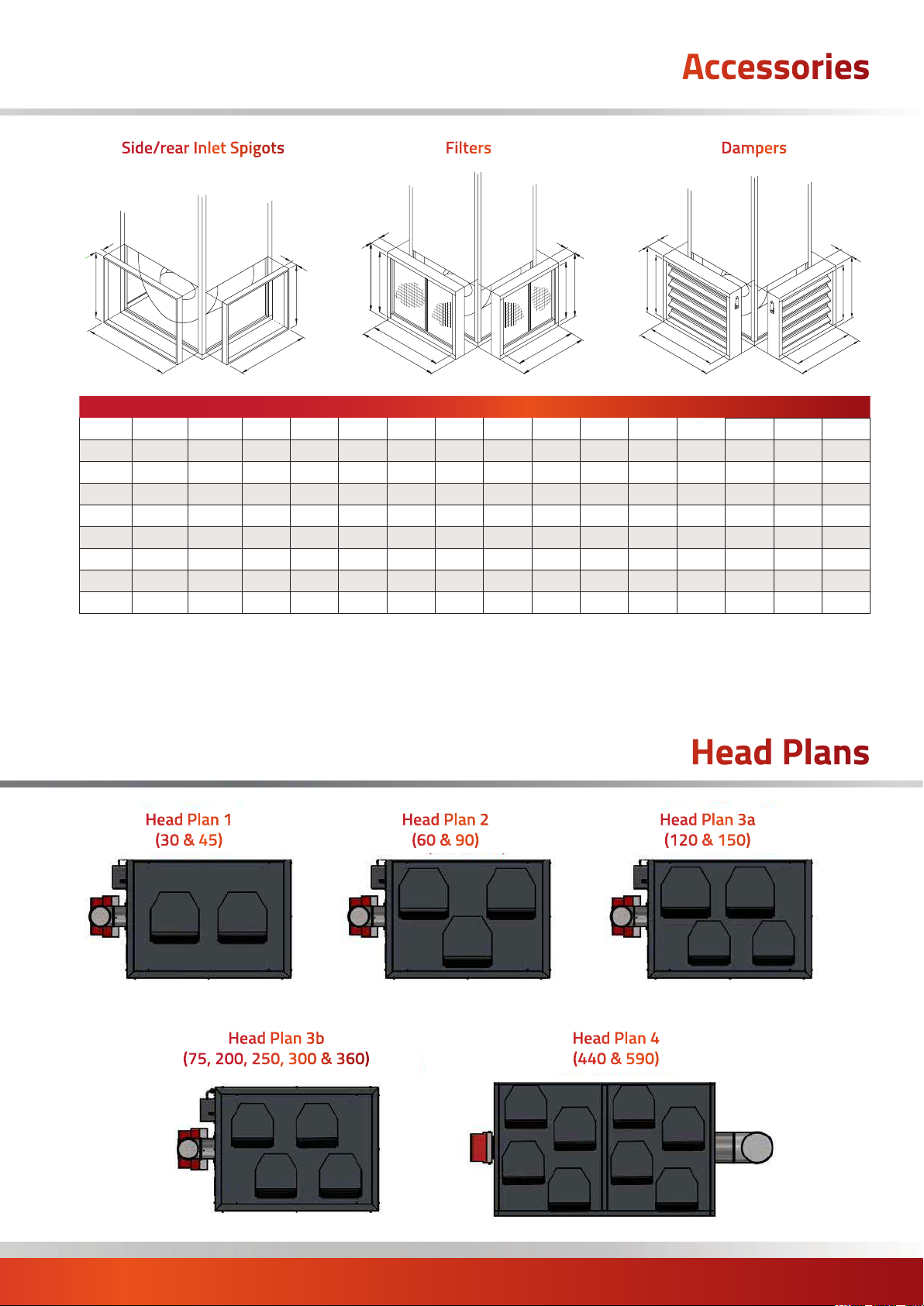

Accessories 15

Head Plans 15

1.2 Technical data 16

1.3 General Requirements 23

Installation

2.1 Fitting the unit 27

2.2 Fitting the flue 29

2.3 General Identification of Items 29

2.4 Electrical Cable Installation 30

2.5 Wiring Diagrams 33

2.6 Commissioning and Testing 36

2.7 Servicing 40

Additional Documents

3.1 Fault Finding Flow Chart 49

3.2 List of Parts 50

3.3 Fuel Conversion 59

Appendices

1. Information required for ecodesign (ErP) Directive 2009/125 64

2. Calculation of flue system equivalent resistance 65

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

page no. 3 of 68

Page 4

User Instructions

If the heater has not been left operational

proceed as follows.

A) Checks before operating the Air

Heater

The following preliminary checks should be made before

lighting the heater(s)

a) Ensure that the ELECTRICAL supply to the heater is

switched OFF.

b) Check that any warm air delivery outlets are open.

c) Check that the thermostat is set.

d) Check that the clock control is set to an ON period.

e) Check that any other controls are calling for heat.

B) Operating the Air Heater

1) Gas-Fired Heaters

1. Switch on the electrical supply at the isolator.

2. The burner air fan will run and after a pre purge period

of approximately 30 seconds the ignition spark will be

generated.

CPx 30 - 90

The main gas valves will open and the main burner will be

established

CPx 120 - 300

The start gas valves will be opened and a start gas flame

established. When a start gas flame is established the

main gas valves will be energized and the start gas flame

will expand to main flame.

NOTE: If the burner fails to light it will go to

lockout and the lockout indicator / reset

button on the burner control box will be

illuminated. To restart the burner push the

reset button.

2) Oil-fired Heaters

IMPORTANT: If it is not possible to light the

heater after 2/3 attempts contact the local

service company.

1. Switch on the electrical supply at the isolator.

2. The burner air fan will run and after a pre purge period

of approximately 30 seconds the ignition spark will be

generated and the oil valve opened. The main burner will

then fire.

NOTE: If the burner fails to light it will go to

lockout and the lockout indicator / reset button

on the burner control box will be illuminated. To

restart the burner push the reset button.

If the unit will not light after two to three

attempts then shutdown the unit and call in

a service engineer.

C) To Shut Down the Air Heater

1) For Short Periods:

Turn the room thermostat to the OFF, or set to it’s lowest

setting.

2) For Long Periods:

Complete step 1 above. Wait for 5 minutes and then turn

OFF the electrical supply at the isolator.

D) Description of Operation

Important: All heaters must be controlled by the fitted

external controls and not by use of the main switch in the

electrical supply to the heater.

The burner start up sequence will commence when the

controls e.g. timeclock, room thermostat etc. call for heat.

The burner air fan will run and after a pre purge period the

burner will light.

IMPORTANT: If the unit will not light after

four or five attempts then shutdown the unit

and call in a service engineer.

WARNING: If the main burner or a start gas

flame fails to establish the burner will go to

lockout and the lockout indicator / reset

button on the burner control box will be

illuminated. To restart the burner push the lockout reset

button. Additional, more easily accessible, controls may

be fitted that mimic the lockout indicator and reset

button functions. If the unit will not light after four or

five attempts then shut down the unit and call in a

service engineer.

page no. 4 of 68

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

Approximately 2/3 minutes after the burner lights the

heater fan will automatically start.

When the external controls are satisfied the burner will

be turned off and approximately 4 to 5 minutes later the

heater fan will automatically stop.

1) Summer / Winter Modes

Certain types of external controls will provide for two

modes of operation i.e.

Summer: The heater fan alone will run at the

dictate of the external controls to provide

air movement.

Winter: The heater will operate normally.

Page 5

E) Fan and Limit Control

The fan and limit controls are mounted towards the top of

the air heater upper front panel.

User Instructions

Warning: Flammable Materials

i) Main Air Fan MAN/Auto

When the white button is pushed to MAN the fan will run

continuously i.e not controlled by any external controls

e.g. Timeclock. When the white button is pulled out the

fan will start and stop automatically in conjunction with

the burner.

ii) Limit Thermostat

This operates if high temperatures within the heater are

detected, the burner is turned off and a red indicator

light on the front of the heater is illuminated. The fault

condition must be identified and rectified and the

thermostat manually reset.

When the unit has cooled push the reset switch on the

front of the heater to reset the limit thermostat interlock

relay, the red indicator light will go out and the unit is

operational again.

NOTE: The limit thermostat(s) can only be

reset once the unit has cooled down. Unless

the cause of the fault condition is readily

obvious, for example a power cut whilst the

heater was operating, a service engineer

should be contacted.

F) Maintenance

Regular servicing is essential to maintain efficient, reliable

and safe operation of the heater. Users are strongly

recommended to have the heater serviced at least

annually and preferably at the end of the heating season.

IMPORTANT

Free access must be maintained to and

around the heater for servicing purposes

and the air supply to the heater must not be

restricted in any way. Combustible materials must not

be stored adjacent to the heater.

Warning: Hot Surfaces

Warning: Contains Moving Parts

Read and understand this Service Manual

Instructions before operating or servicing

this appliance

If you have any safety questions reference the servicing

and installation of any of our heaters please do not

hesitate to contact our head office for expert advice.

Your safety is paramount to us.

For gas fired heaters only:

If at any time a gas leak is suspected turn

OFF the gas supply - DO NOT USE A NAKED

FLAME - and contact the National Gas

Emergency number immediately.

Gas Safety (Installation & Use) (Amendment)

Regulations

It is law that all gas appliances are installed,

adjusted and, if necessary, converted by

qualified persons* in accordance with the

current issue of the above regulations.

Failure to install appliances correctly can lead to

prosecution. It is in your own interests and that of safety

to ensure that the law is complied with.

* Gas Safe Registered Engineer

IMPORTANT

All Powrmatic heaters use either gas or oil

plus electricity to power them, they may also

contain moving parts such as pulleys and

belts. It would be hazardous to tamper with or attempt to

service unless you are a competent person in the field of

Gas and Electrical work.

Danger: Electricity

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

page no. 5 of 68

Page 6

1.1 Introduction

The Powrmatic CPx range of closed flue, fanned

circulation air heaters cover a heat output range of 30

kW to 290kW and are intended primarily for heating

commercial or industrial premises.

They are B23 type appliances fitted with either a gas fired

forced draught burner or a pressure jet oil fired burner.

Fuel Types

Gas fired units are certified for use on Natural Gas, Group

H - G20, Group L - G25 and Propane - G31.

Oil fired units are supplied as standard for use with 35sec

fuel and can be supplied for use with 28sec fuel as an

option.

In accordance with guidelines from our burner supplier,

Riello, the burners fitted to Powrmatic oil-fired heaters

are suitable for fuels with a bio content of up to 10% only.

For fuels with a bio content of more than 10% please

consult our Technical Department.

CPx heaters have a centrifugal fan assembly fitted

upstream of the combustion chamber / heat exchanger

assembly to circulate the air being heated and are

available in three styles:

Standard Style

Suitable for internal applications only and available in /UF,

/UD, /HD, /HF, /CF and /CD variants (see below). /UF and

/UD models are floor standing, /HD, /HF, are horizontally

mounted on purpose design supports. /CD models can be

plinth mounted at floor level. /CF and /CD models can be

mounted at high level on purpose design supports.

/RT - Rooftop heater with outlet duct spigot on the

underside (inlet duct spigot optional).

/SD - Upright heater with side outlet duct spigot (inlet

duct spigot optional).

Other options include High/Low or modulating burners,

uprated main fan motors, flue support bracket, deep

V filters, flat panel filters, proportional air dampers,

combustion air inlet adaptors and inlet and outlet duct

spigots.

Each air heater must be connected to a closed flue system

only.

IMPORTANT

Service and Maintenance Engineers shall

ensure that replacement items are fitted,

adjusted and set in accordance with the

data and detail set out in these instructions. If in doubt

consult Powrmatic Technical Department.

For gas fired heaters only.

Gas Safety (Installation & Use) Regulations

It is law that all gas appliances are installed,

adjusted and, if necessary, converted by

qualified persons* in accordance with the

latest edition of the above regulations. Failure to install

appliances correctly can lead to prosecution. It is in your

own interests and that of safety to ensure that the law

is complied with.

* Gas Safe Registered Engineer

CPx/NCA Style

Suitable for internal applications only and having an

extended casing that encloses the burner. Available in /UF

and /UD variants only(see below).

CPx/EA Style

Casing is extended to enclose the burner. The heater is

fully weatherproof and designed for external applications

only. Available in /TD, /HD, /RT and /SD variants.

Variant types are:-

/UF - Upright heater with free blowing rotatable heads.

/UD - Upright heater with outlet duct spigot (inlet duct

spigot optional).

/HF - Horizontal heater with free blowing rotatable

heads.

/HD - Horizontal heater with outlet duct spigot (inlet duct

spigot optional).

/CF - Counterflow heater with free blowing rotatable

heads.

/CD - Counterflow heater with outlet duct spigot (inlet

duct spigot optional).

/TD - Rooftop heater with top outlet duct spigot (inlet

duct spigot optional).

page no. 6 of 68

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

Page 7

Technical Specification

CPx

Model 30 45 60 90(gas) 90(oil) 120 150 175 200 250 300 360 440 590

Output

Input (nett CV)

Old Powrmatic Reference CP 100 150 200 300 300 400 500 600 700 800 1000 1250 1500 2000

Thermal Efficiencies (Nett CV) % Min 91.5%

Heads

Airflow

Electrics

Fuel

Overall

Dimensions

Installation

Clearances

Flue Diameter mm ø 125 125 150 150 150 150 175 175 175 200 200 250 300 300

Combustion Air Spigot mm ø 150 150 150 150 150 150 150 150 150 150 150 150 175 175

Maximum Combustion Duct Length * m 34 34 21 21 21 12 8 6 4 3 2 3 2 2

Noise Level (See Note Below) dB(A) 56 61 61 63 63 70 62 73 74 75 77 78 80 82

Nett Weight (See Note Below)

Throw UF / HF m 15 21 19 24 24 24 29 29 29 41 48 48 30 40

Fan Static

Supply

Standard

Fan

Uprated

Fan (L.H.P.)

Connection

Minimum

Inlet

Pressure

Consumption

Standard

Outputs

UF Upright

Freeblowing

UF Upright

Freeblowing

G20 Gas kW 32.6 48.9 65.2 97.8 n/a 130.4 163.0 190.2 217.4 271.7 315.2 399.0 479.6 638.7

35sec Oil kW 31.9 48.7 64.3 n/a 97.7 130.5 160.3 190.3 213.3 269.4 316.1 391.6 470.8 627

Volume m

UF / HF No. 2 2 3 3 3 4 4 4 4 4 4 4 8 8

Size mm 203 254 254 305 305

Standard Pa 188 222 270 250 200 180 185 290 250 140 150 300 300 300

Up-rated Pa 250 250 400 500 450 350 400 500 500 450 500 600 600 600

Standard V/ph/Hz 230/1/50 400/3/50

Optional V/ph/Hz 400/3/50 230/1/50 n/a

Motor kW 0.55 0.55 1.1 1.5 1.4 1.4 3.0 4.0 4.0 4.0 7.5 11.0 11.0 15.0

Run amp 4.3 5.7 5.3 10.0 9.6 6.4 6.7 7.1 8.6 8.4 14.5 21.3 21.3 28.9

Start amp 8.1 17.1 16.1 25.5 28.1 12.4 23.45 23.0 19.7 28.2 50.1 127.2 127.2 182.4

Motor kW 0.75 0.75 2.2 2.2 1.5 3.0 4.0 5.5 5.5 5.5 11.0 15.0 15.0 18.5

Run amp 5.3 5.3 12.6 12.6 9.2 6.3 8.3 11.0 11.0 11.0 21.6 28.9 28.0 35.0

Start amp 15.9 15.9 37.8 37.8 27.6 22.05 29.05 38.5 38.5 38.5 75.6 182.4 182.4 221.2

Oil BSP/Rc ⅜” ⅜” ⅜” n/a ⅜” ⅜” ⅜” ⅜” ⅜” ⅜” ⅜” ⅜” ⅜” ½”

Gas BSP/Rc ½” ½” ¾” ¾” n/a ¾” 1” 1” 1” 1¼” 1¼” 1½” 1½” 1½”

Nat Gas mbar 17.5 n/a 17.5

LPG mbar 37.0 n/a 37.0

Oil l/h 3.16 4.83 6.38 n/a 9.70 12.95 15.90 18.89 21.17 26.73 31.36 38.82 47.45 63.62

Nat Gas m

LPG m

Height mm 2024 2072 2494 2585 2585 2821 2821 3054 3174 3307 3307 3657 4107 4407

Width mm 669 669 744 744 744 904 904 904 904 1104 1104 1260 1330 1330

Depth

(Excludes

burner)

Front mm 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000

Side mm 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000

Blank Side mm 150 150 150 150 150 150 150 150 150 150 150 n/a n/a n/a

Rear mm 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000

Model 30 45 60 90(gas) 90(oil) 120 150 175 200 250 300 360 440 590

* For extended combustion duct lengths please contact Powrmatic

Notes –

• Fuel consumption and output figures based upon nett calorific values as follows

- Class D light distillate fuel oil nett CV 36.28 MJ/l

- Natural gas (G20) nett CV 34.02 MJ/m³

- Propane (G31) nett CV 88.00 MJ/m³

• C Px heaters comply w ith the seasonal e fficienc y and NOx limits requirements of the Ecodesig n regulation (EU) 2015/1188, Direct ive 2009/125/EC – Lot 21 Tier 1

• Air handling data is assessed at room ambient conditions

• Throw figures provide the distance to the point where the terminal velocity degrades to 0.25 m/s

• Overall vertical heater height include heads or extended heads where appropriate

• Standard height heads can be specified where site height is restricted

• Blank and louvred lower side panels are interchangeable

• Dimensions in table above refer to upright heaters only - for horizontal and counterflow heater dimensions refer to dimensions page

• Noise levels are applicable to standard UF models and are measured 5m from appliance and in free field conditions

• Motor kW, run and start amps apply to standard electrical supply as stated. For optional data contact sales office

• Nett weight figures apply to standard upright CPx heaters only

• It is the responsibility of the installing contractor to ensure that ductwork is correctly sized and balanced when installing a ducted unit.

kW 30 45 60 90 90 120 150 175 200 250 290 366 440 586

3

/s 0.97 0.86 1.01 2.11 1.50 2.30 3.15 3.36 3.84 4.49 5.76 6.49 7.88 10.5

305/358 305/358

3

/h 3.45 5.17 6.89 10.34 n/a 13.79 17.23 20.11 22.99 28.73 33.33 41.41 50.61 67.86

3

/h 1.34 1.98 2.64 4.01 n/a 5.31 6.64 7.72 8.84 11.00 12.84 16.00 19.56 26.23

mm 732 732 927 927 927 1200 1200 1399 1399 1599 1599 1915 2165 2715

kg 168 173 231 241 241 341 386 530 530 556 556 1012 1380 1720

358 406 457 457 457 457 457

1000 1000

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

page no. 7 of 68

Page 8

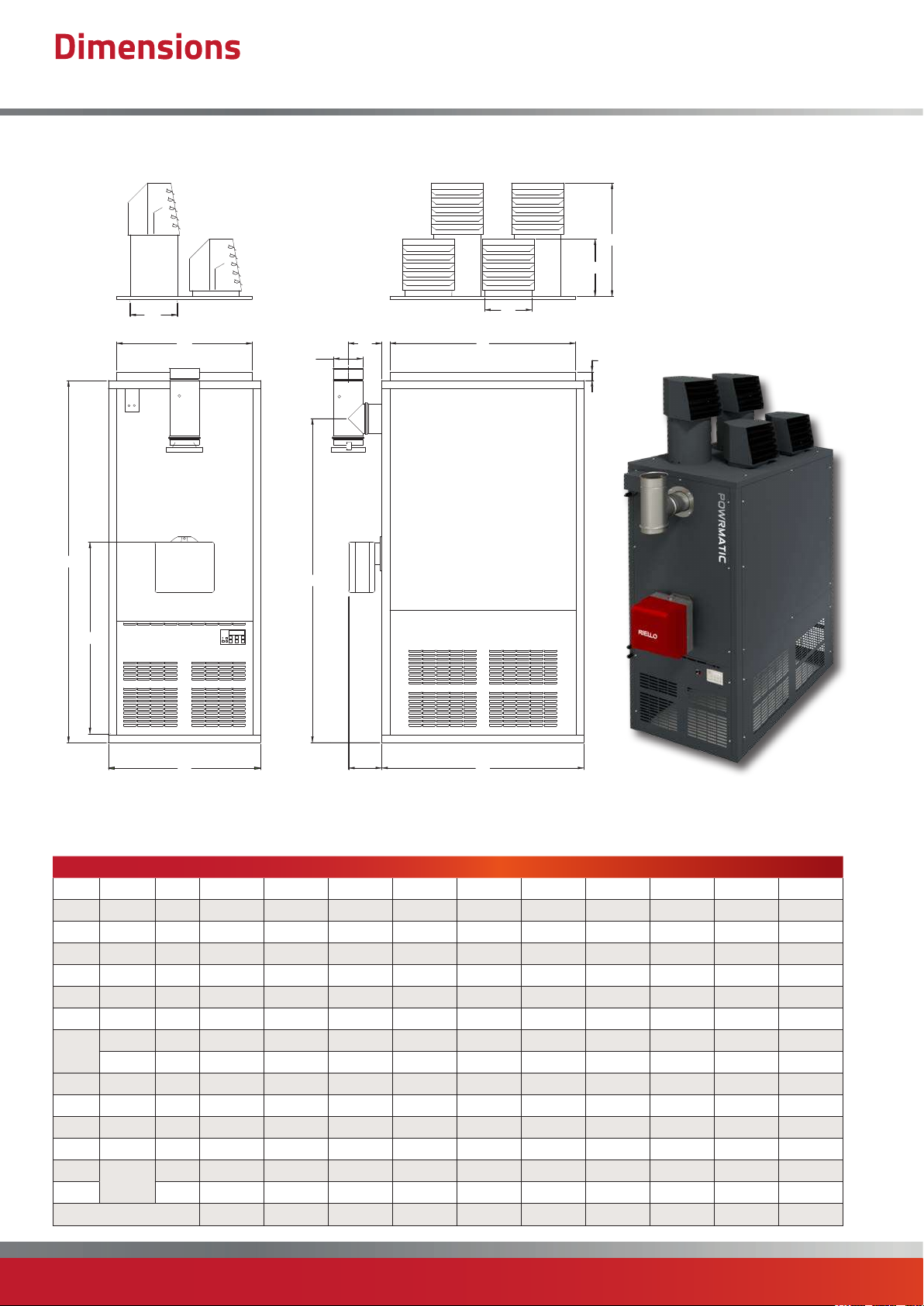

Dimensions

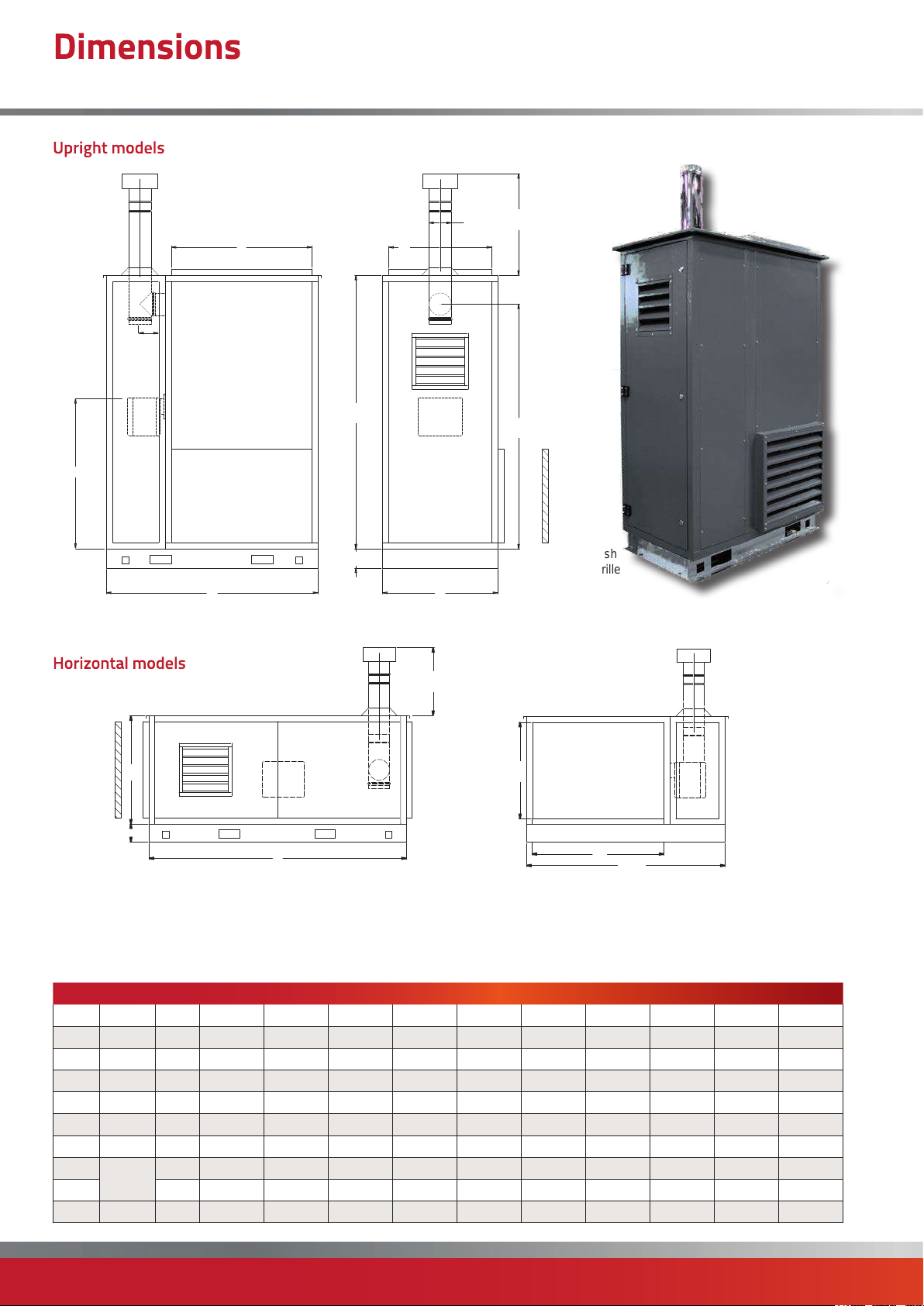

CPx UD/UF Upright Free Blowing Upright Ducted (30-300)

J1

J

K1

M

ØD

C

F

G

E

K

L

50

H

B

Notes -

• Flue tee provided as standard.

Model 30 45 60 90 120 150 175 200 250 300

A All mm 732 732 927 927 1200 1200 1399 1399 1599 1599

B All mm 669 669 744 744 904 904 904 904 1104 1104

C All mm 1767 1767 1895 1895 2149 2149 2265 2265 2265 2265

D All mm ø 125 125 150 150 150 175 175 175 200 200

E All mm 150 150 150 150 150 200 200 200 240 240

F All mm 1535 1535 1661 1661 1923 1923 2021 2021 2021 2021

G All mm 864 864 944 944 1122 1122 1122 1122 1122 1122

Gas mm 276 276 252 280 280 280 300 300 300 508

H

J1 All mm n/a n/a 581 672 672 672 788 875 1007 1007

K All mm 180 234 234 287 287 287 333 381 431 431

K1 All mm n/a n/a n/a n/a 333 333 n/a n/a n/a n/a

L

M mm 569 569 644 644 804 804 804 804 1004 1004

Oil mm 196 202 202 228 228 228 228 247 247 508

J All mm 238 286 286 340 340 340 400 442 558 558

Duct

Spigot

mm 632 632 824 824 1100 1100 1299 1299 1499 1499

Head Plan 1 1 2 2 3a 3a 3b 3b 3b 3b

A

page no. 8 of 68

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

Page 9

Dimensions

CPx HD/HF Horizontal Free Blowing Horizontal Ducted (30-300)

C

K1

B

N

G

F

H

E

ØD

M

K

J

L

A

Notes -

• Flue tee provided as standard.

• Screened air intake (SAI) fitted as standard on HF models. Duct spigot option available.

• Direction of airflow to be specified at time of order. Left to Right (L-R when looking at the burner) airflow shown above.

Model 30 45 60 90 120 150 175 200 250 300

A All mm 732 732 927 927 1200 1200 1399 1399 1599 1599

B All mm 669 669 744 744 904 904 904 904 1104 1104

C All mm 1767 1767 1895 1895 2151 2151 2265 2265 2265 2265

D All mm ø 125 125 150 150 150 175 175 175 200 200

E All mm 150 150 150 150 150 200 200 200 240 240

F All mm 1535 1535 1661 1661 1923 1923 2021 2021 2021 2021

G All mm 864 864 944 944 1122 1122 1122 1122 1122 1122

Gas mm 276 276 252 280 280 280 300 300 300 508

H

J All mm 227 227 260 260

K All mm 180 234 234 287 287 287 333 381 431 431

K1 All mm n/a n/a n/a n/a 333 333 n/a n/a n/a n/a

L

M mm 569 569 644 644 804 804 804 804 1004 1004

N All mm 125 125 125 125 150 150 150 150 150 150

Oil mm 196 202 202 228 228 228 228 247 247 508

260 260 297 297 367 367

Duct

Spigot

mm 632 632 824 824 1100 1100 1299 1299 1499 1499

Head Plan 1 1 2 2 3a 3a 3b 3b 3b 3b

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

page no. 9 of 68

Page 10

Dimensions

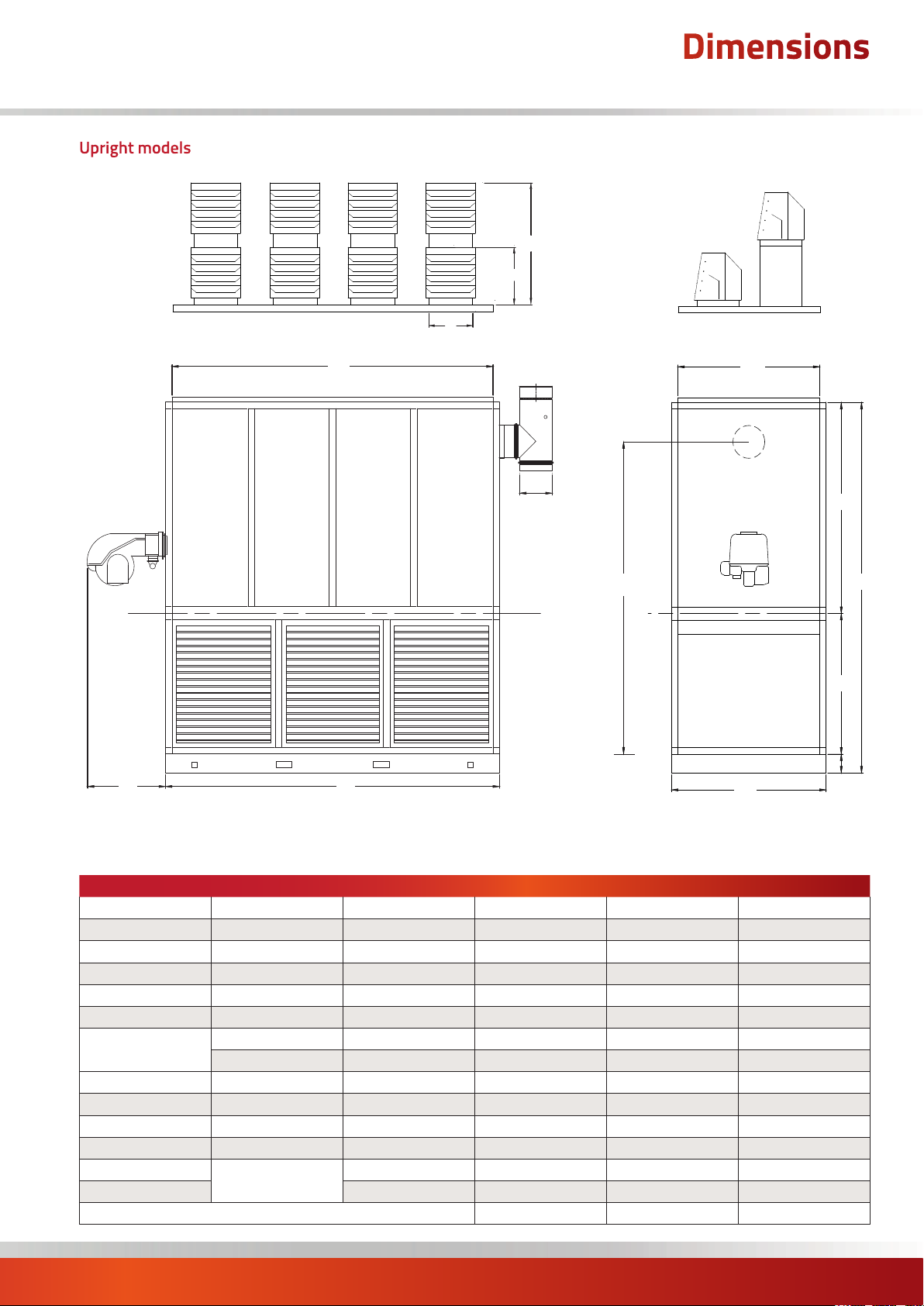

CPx-EA External Cabinet Heaters (30-300)

Upright models

ØD

1 mtr

E

G

Horizontal models

L

C

N

A

M

F

Optional Fresh

Air Intake Grille

B

1 mtr

Optional

Fresh Air

Intake

Grille

Notes -

• Direction of airflow to be specified at time of order. Left to Right (L-R when looking at the burner) airflow shown above.

• Inlet and Outlet duct spigots have the same dimensions (Horizontal units only)

• Primary flue length, cowl and flashing provided as standard.

A All mm 1184 1184 1379 1379 1692 1692 1891 1891 2280 2280

B All mm 669 669 744 744 904 904 904 904 1104 1104

C All mm 1767 1767 1895 1895 2149 2149 2265 2265 2265 2265

D All mm ø 125 125 150 150 150 175 175 175 200 200

E All mm 150 150 150 150 150 200 200 200 240 240

F All mm 1535 1535 1661 1661 1923 1923 2021 2021 2021 2021

G All mm 864 864 944 944 1122 1122 1122 1122 1122 1122

L

M mm 569 569 644 644 804 804 804 804 1004 1004

N All mm 125 125 125

B

N

C

Model 30 45 60 90 120 150 175 200 250 300

Duct

Spigot

mm 632 632 824 824 1100 1100 1299 1299 1499 1499

125 150 150 150 150 150 150

M

L

A

page no. 10 of 68

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

Page 11

Upright models

Dimensions

CPx UD/UF Upright Free Blowing Upright Ducted (360-590)

J1

J

K

L

G

Notes -

• The Heat Exchanger and Fan Section can be split on the ‘Section Split Line’.

• Flue tee provided as standard.

A

ØD

Section

Split Line

M

F

H

B

C

E

200

Model 360 440 590

A All mm 1915 2165 2715

B All mm 1260 1330 1330

C All mm 2615 3065 3365

D All mm ø 250 300 300

E All mm 865 965 1265

F All mm 1550 1900 1900

G

H All mm 2152 2537 2837

J All mm 558 558 558

J1 All mm 1007 1007 1007

K All mm 431 431 431

L

M mm 1160 1230 1230

Gas mm 508 580 840

Oil mm 508 468 680

Duct Spigot

mm 1815 2065 2615

Head Plan 3b 4 4

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

page no. 11 of 68

Page 12

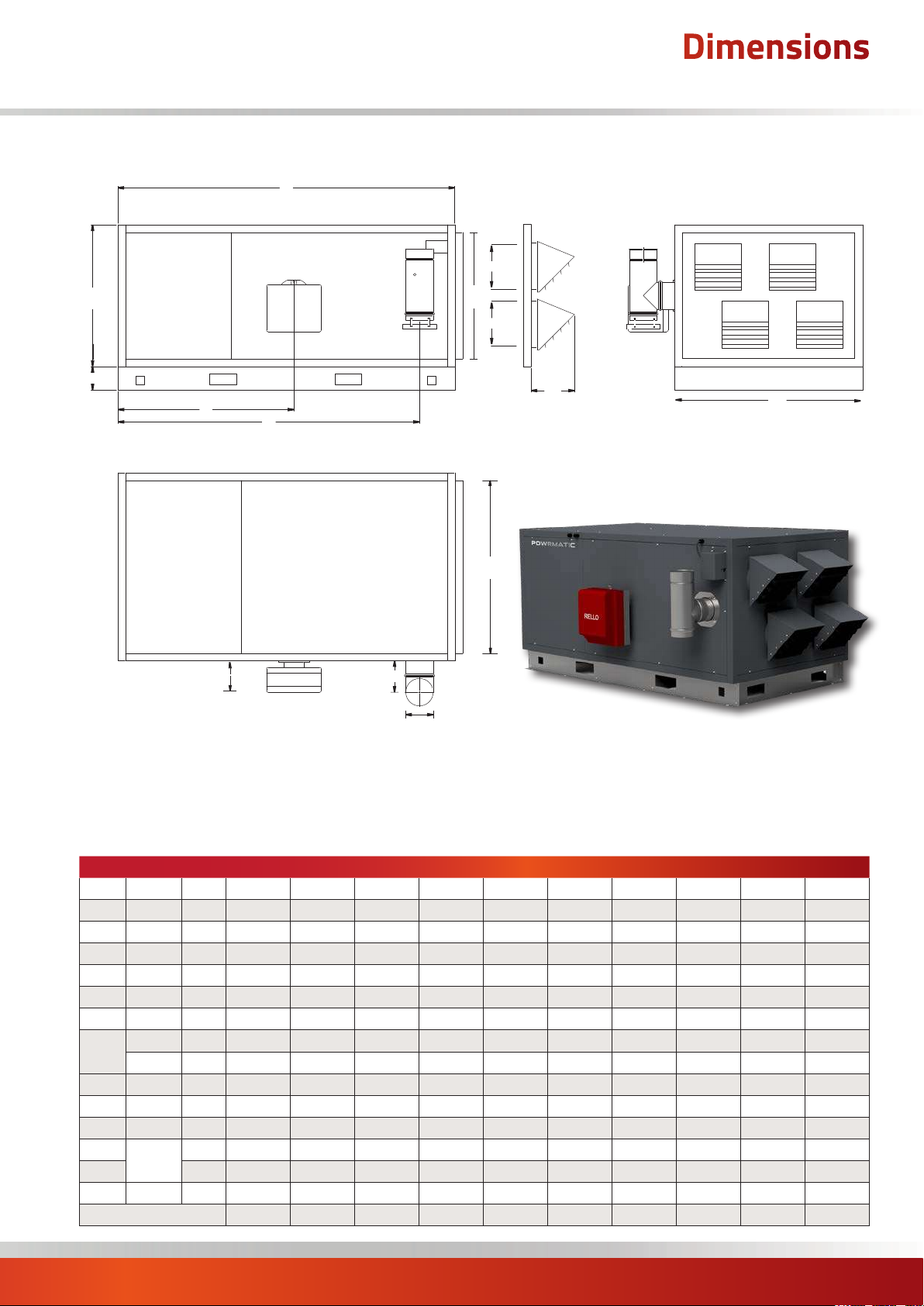

Dimensions

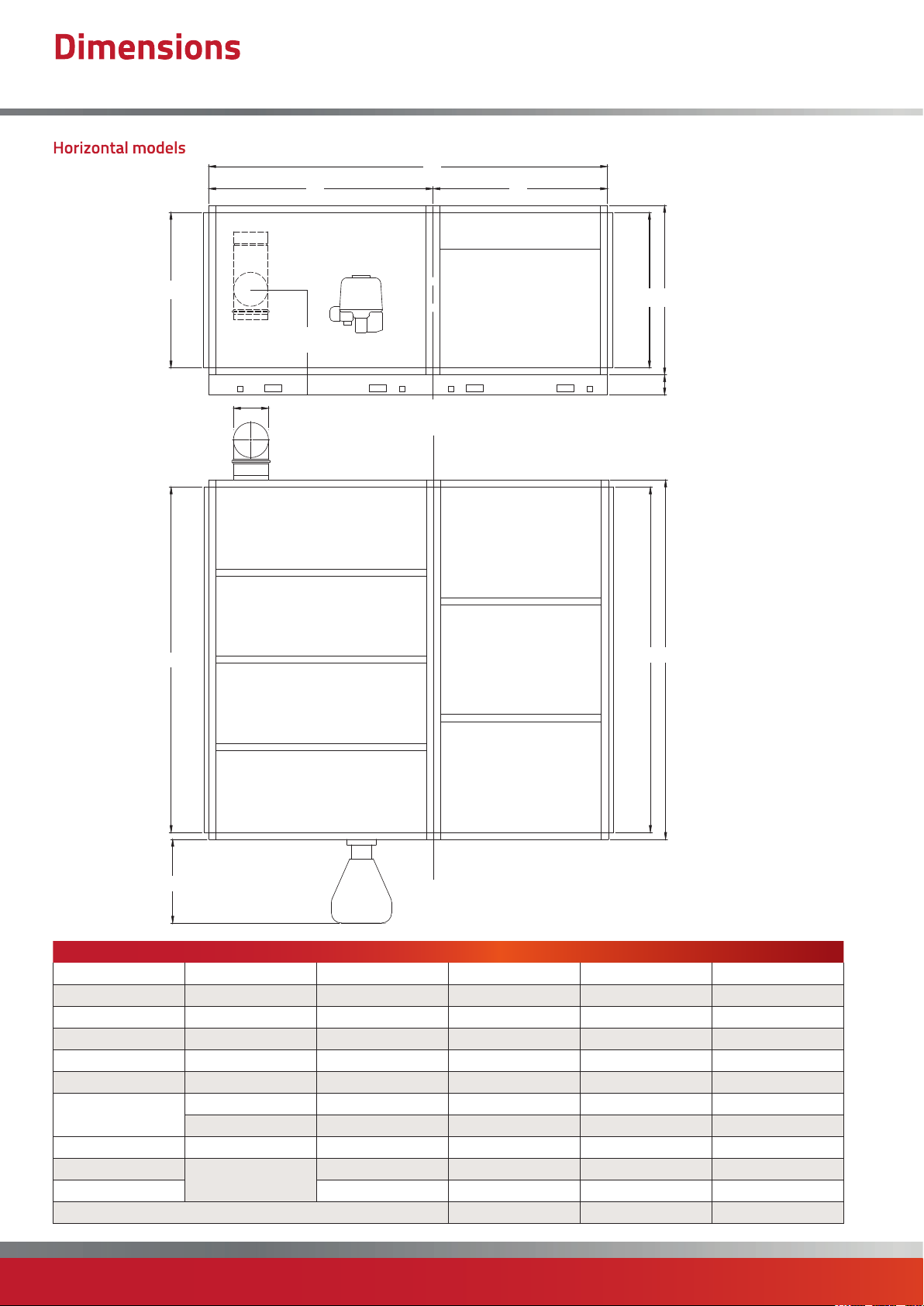

CPx HD/HF Upright Free Blowing Upright Ducted (360-590)

Horizontal models

M

ØD

C

F

H

Section

Split Line

E

M B

200

L

L

Notes -

G

Model 360 440 590

A All mm 1915 2165 2715

B All mm 1260 1330 1330

C All mm 2800 3250 3600

D All mm ø 250 300 300

E All mm 1250 1350 1700

F All mm 1550 1900 1900

G

H All mm 830 865 865

L

M mm 1160 1230 1230

Gas mm 580 580 840

Oil mm 468 468 680

Duct Spigot

mm 1815 2065 2615

Head Plan 3b 4 4

• The Heat Exchanger and Fan Section can be split on the ‘Section Split

Line’. Flue tee provided as standard.

• Direction of airflow to be specified at time of order.

Right to Left (R-L when looking at the burner) airflow shown above.

A

page no. 12 of 68

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

Page 13

H

Upright models

Dimensions

CPx-EA External Cabinet Heaters (360-590)

1 mtr

L

ØD

Section

Split Line

P

L

G

A

H

M

F

C

E

200

B

Notes -

• The Heat Exchanger and Fan Section can be split on the ‘Section Split Line’.

• Return air via inlet duct spigot is standard. Optional fresh air grille is available.

• Primary flue and cowl provided as standard.

Model 360 440 590

A All mm 1915 2165 2715

B All mm 1260 1330 1330

C All mm 2615 3065 3365

D All mm ø 250 300 300

E All mm 865 965 1265

F All mm 1550 1900 1900

G All mm 650 650 950

H All mm 2565 2815 3665

L

M mm 1160 1230 1230

P All mm 760 860 1160

Duct Spigot

mm 1815 2065 2615

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

page no. 13 of 68

Page 14

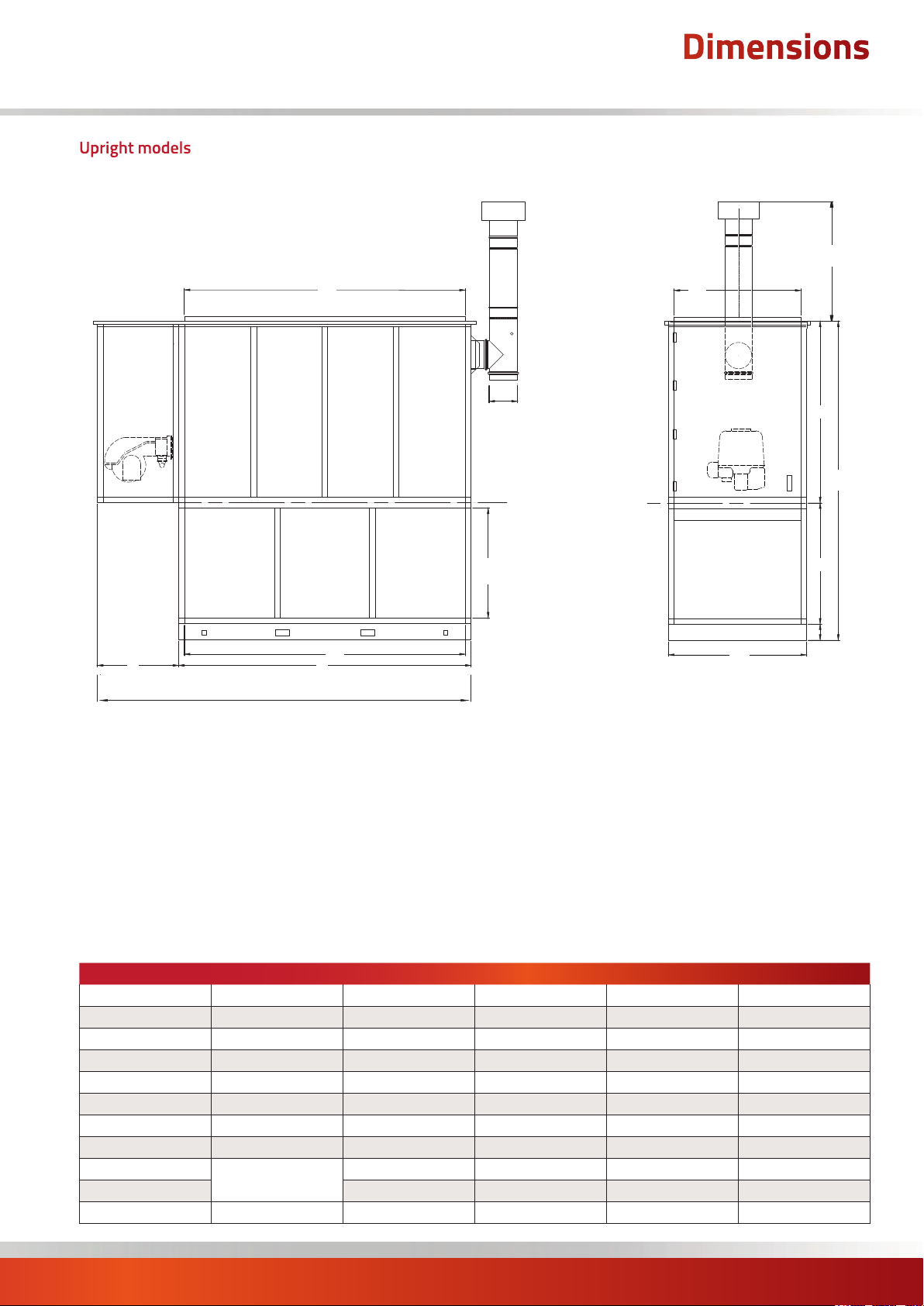

Dimensions

CPx-EA External Cabinet Heaters (360-590)

Horizontal models

1 mtr

M

L

ØD

F

C

Section

Split Line

Section

Split Line

E

M

B

200

A

L

H

G

Notes -

• The Heat Exchanger and Fan Section can be split on the ‘Section Split Line’. Primary flue and cowl provided as standard.

• Direction of airflow to be specified at time of order. Right to Left (R-L when looking at the burner) airflow shown above.

Model 360 440 590

A All mm 1915 2165 2715

B All mm 1260 1330 1330

C All mm 2800 3250 3600

D All mm ø 250 300 300

E All mm 1250 1350 1700

F All mm 1550 1900 1900

G All mm 650 650 950

H All mm 2565 2815 3665

L

M mm 1160 1230 1230

Duct Spigot

mm 1815 2065 2615

page no. 14 of 68

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

Page 15

Accessories

Side/rear Inlet Spigots Filters Dampers

50

G

SIDE REAR

C

50

H

D

J

E

G

SIDE REAR

C

A

J

F

H

D

B

K

E

G

SIDE REAR

C

A

Model 30 45 60 90 120 150 175 200 250 300 360 440 590

A All mm 732 732 927 927 1200 1200 1399 1399 1599 1599 1915 2165 2715

B All mm 669 669 744 744 904 904 904 904 1105 1105 n/a n/a n/a

C All mm 630 630 825 825 1098 1098 1300 1300 1500 1500 1815 2065 2615

D All mm 567 567 642 642 802 802 802 802 1003 1003 n/a n/a n/a

E All mm 685 685 738 738 838 838 838 838 838 838 865 965 1265

F All mm 627 627 677 677 775 775 775 775 775 775 n/a n/a n/a

G All mm 585 585 640 640 738 738 738 738 738 738 765 865 1165

H All mm 527 527 577 577 675 675 675 675 675 675 n/a n/a n/a

J All mm 136 136 136 136 136 136 136 136 136 136 250 250 250

Notes -

• All dimensions are outside dimensions

• Vertical units shown - for horizontal units please contact our sales office

• Standard filter specification is 10ppi

• Higher specification filters available on request - contact our sales team for more information

• Standard dampers are manual operation - motorised options available

K

F

H

D

B

Head Plan 1

(30 & 45)

Head Plan 3b

(75, 200, 250, 300 & 360)

Head Plan 2

(60 & 90)

Head Plans

Head Plan 3a

(120 & 150)

Head Plan 4

(440 & 590)

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

page no. 15 of 68

Page 16

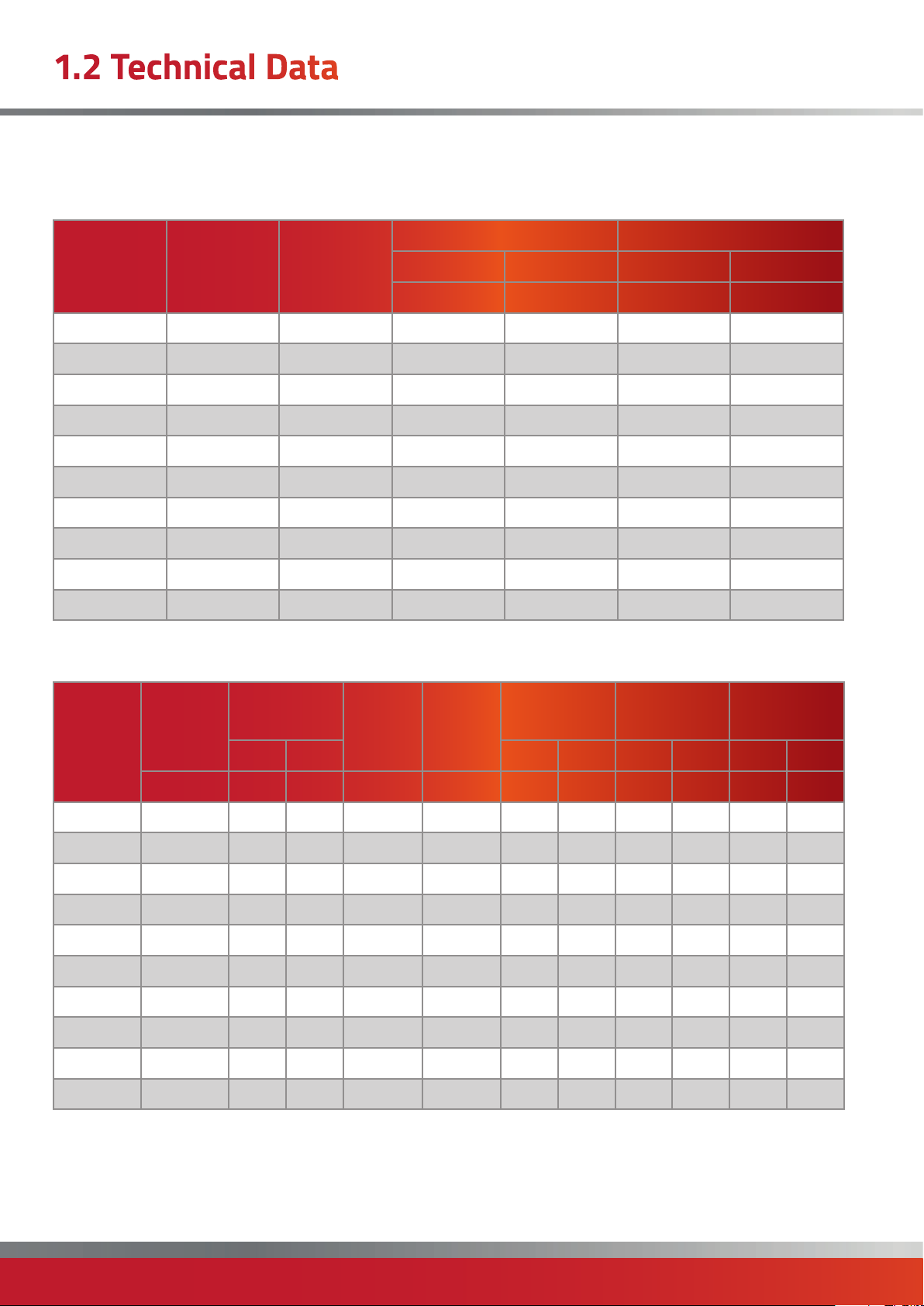

1.2 Technical Data

Riello Burner Settings - Natural Gas - Group H - G20 Net CV (Hi = 34.02MJ/m³)

Nominal Inlet Pressure = 20mbar

Minimum Inlet Pressure = 17.5mbar

High Fire Low Fire

MODEL Burner Type Gas Control

CPx30 BS1D MB405/2 3.4 3.45 1.5 2.11

CPx45 BS1D MB405/2 6.4 5.00 2.5 2.85

CPx60 BS2D MB407/2 5.8 6.89 2.5 4. 32

CPx90 BS3D MB407/2 4.2 10.34 1.9 6.82

CP x120 BS3D M B 407/ 2 6.0 13. 47 2.6 8 . 61

CP x150 BS3D MB 410/2 9.1 17. 23 3.3 10.02

CP x175 BS4D MB410/2 8.3 20.10 3.5 13.90

CPx200 RS5D MB410/2 6.9 22.99 4.1 16.15

CPx250 RS5D MB 412/2 9.3 28.46 5.8 14.38

CPx300 RS34 MZ MBDLE415 tbc tbc tbc tbc

MODEL

Head

Setting

no.

Combustion Air

Pressure

High Fire Low Fire High Fire Low Fire High Fire Low Fire High Fire Low Fire

Burner Pressure Gas Rate Burner Pressure Gas Rate

mbar m/h mbar m/h

Air

Switch*

Flue

Pressure

Switch*

Nominal CO2

(±0.5)

Nox Nett Flue Temp

No. No. No. mbar Pa % % ppm ppm °C °C

CPx30 1 2.8 1.0 2.1 40 9.2 8.75 24.7 26.8 132 74

CPx45 4 6.0 1.0 2.7 20 8.7 9 .1 23.5 29.4 171 75

CPx60 4 2.0 1.0 2.0 120 8.75 9.0 27. 9 28.8 145 78

CPx90 1 1.3 0.25 3.0 110 8.8 9.3 27. 5 33.2 154 92

CPx120 5 2 .1 1.0 5.0 280 9.2 8.8 34.5 31.9 174 102

CPx150 7 5.0 1.1 5.0 220 9.3 9.2 29.5 35.5 165 82

CP x175 7 5.3 1.8 3.6 270 9.3 8.6 28.4 32.3 158 89

CPx200 0 (39) (22) 4.0 300 9.0 8.8 41.4 40.0 141

CPx250 10 (63) (30) 4.0 300 8.8 8.4 44.0 44.3 142 79

CPx300 tbc tbc tbc tbc tbc tbc tbc tbc tbc tbc tbc

Notes: CO2 values and Nett flue gas temperatures are given for guidance and measured values will depend on site conditions.

* Air Pressure Switch settings are given for guidance and measured values will depend on site conditions.

97

page no. 16 of 68

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

Page 17

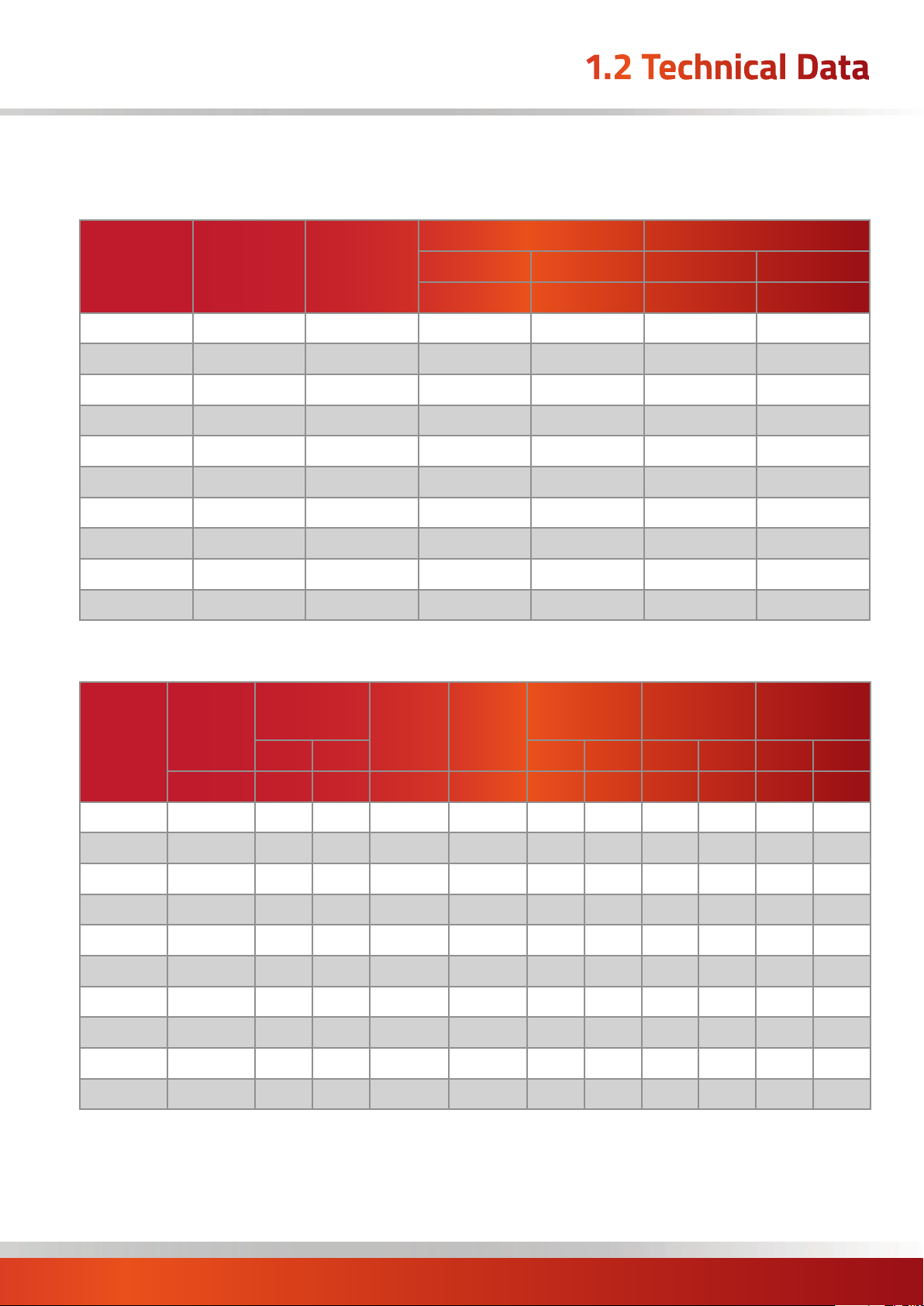

Riello Burner Settings - Propane G31 Net CV (Hi = 88.00MJ/m³)

Nominal Inlet Pressure = 37mbar

Minimum Inlet Pressure = 37mbar

High Fire Low Fire

1.2 Technical Data

MODEL Burner Type Gas Control

CPx30 BS1D MB405/2 5.0 1.33 2.7 0.91

CPx45 BS1D MB405/2 10.2 1.93 3.9 1.1

CPx60 BS2D M B4 07/ 2 8.2 2.67 3.5 1.67

CPx90 BS3D MB 407/2 5.5 4.0 2.6 2.64

CPx120 BS3D MB 4 07/2 7.6 5.21 3.5 3.33

CPx150 BS3D M B 410/2 10.6 6.66 4.4 3.87

CP x175 BS4D MB 410/2 tbc tbc tbc tbc

CPx200 RS5D M B410/ 2 6.9 8.8 3.9 6.24

CPx250 RS5D MB 412/2 10.0 11.0 4.7 7.49

CPx300 RS34MZ MBDLE415 tbc tbc tbc tbc

MODEL

Head

Setting

no.

Combustion Air

Pressure

High Fire Low Fire High Fire Low Fire High Fire Low Fire High Fire Low Fire

Burner Pressure Gas Rate Burner Pressure Gas Rate

mbar m/h mbar m/h

Air

Switch*

Flue

Pressure

Switch*

Nominal CO2

(±0.5)

Nox Nett Flue Temp

No. No. No. mbar Pa % % ppm ppm °C °C

CPx30 3 1.1 1.0 1.5 60 9.6 9.0 40.5 40.0 118 73

CPx45 4 6.0 1.4 2.7 100 10.9 10.3 35.4 40.4 166 82

CPx60 3 2.3 1.0 2 150 9.5 9.8 29.2 47.7 160 81

CPx90 2 1.3 0.5 3 110 10.5 9.95 46.2 48.8 148 94

CPx120 4 2 .1 0.9 5 280 10.73 9.9 50.3 49.5 177 122

CPx150 6 3.6 1.0 4 220 10.9 10.26 46.8 48.0 137 73

CP x175 tbc tbc tbc tbc tbc tbc tbc tbc tbc tbc tbc

CPx200 2 39 29 4 300 10.33 9.9 64 53.0 140

CPx250 7 50 21 3 300 11.1 11.1 74 75.0 125 72

CPx300 tbc tbc tbc tbc tbc tbc tbc tbc tbc tbc tbc

Notes: CO2 values and Nett flue gas temperatures are given for guidance and measured values will depend on site conditions.

* Air Pressure Switch settings are given for guidance and measured values will depend on site conditions.

105

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

page no. 17 of 68

Page 18

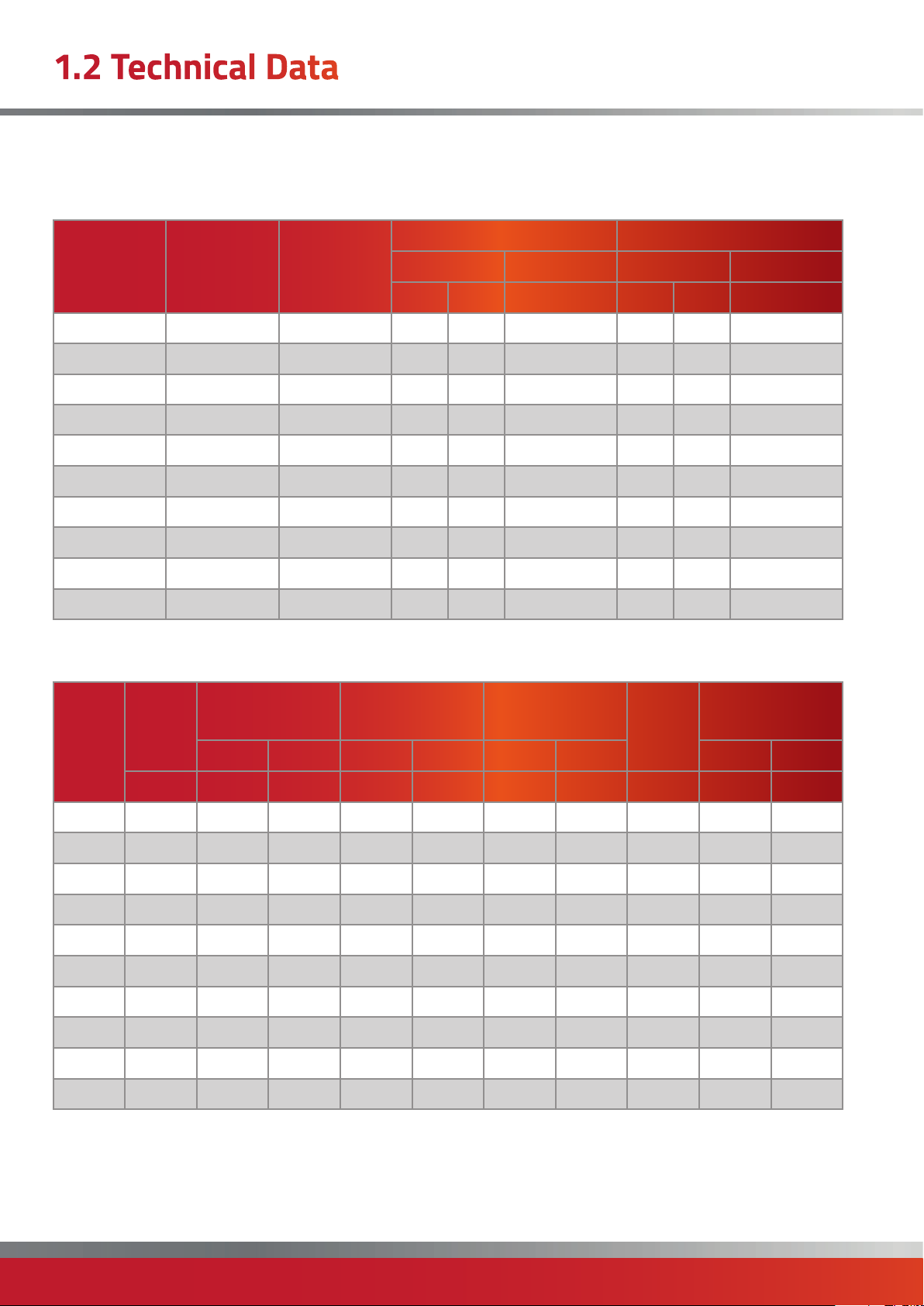

1.2 Technical Data

Riello Burner Settings - 35sec Oil - Diesel - Net CV (Hi = 42.69MJ/kg)

High Fire Low Fire

MODEL Burner Type Nozzle

CPx30 RG1RKD 0.65 x 80S 13.44 195 2.70 8.96 130 1.89

CPx45 RG2D 1.00 x 60S 14.48 210 4.15 8.96 130 3.27

CPx60 RG2D 1.25 x 60S 14 .13 205 5.36 8.96 130 4.07

CPx90 RG3D 2.00 x 60S 13.79 200 8.28 8.27 120 6 .16

CPx120 RG3D 2.75 x 60S 12.07 175 10.91 8.96 130 8.50

CPx150 RG3D 3.00 x 60S 15.17 220 13.45 8.96 130 9.82

CP x175 RG4D 3.75 x 60B 15 .17 220 16.45 8.27 120 11.59

CPx200 RG5D 2.5 + 2.0 x 60S 13 .10 190 17. 9 6 13.10 190 10.01

CPx250 RG5D 3.0 + 2.5 x 60S 13.1 0 190 23.69 13 .10 190 13.07

CPx300 RL34 MZ TC 4.0 + 2.75 x 60S 11.03 160 25.30 11.03 160 15.00

MODEL

Head

Setting

no.

Combustion Air Nominal CO (±0.5) Nox

High Fire Low Fire High Fire Low Fire High Fire Low Fire High Fire Low Fire

Burner Pressure Fuel Input Burner Pressure Fuel Input

bar psi kg/h bar psi kg/h

Nett Flue Temp

Smoke

No. No. No. % % ppm ppm No. °C °C

CPx30 1.3 1.5 0.25 11. 8 12.5 67. 5 65.5 0 -1 133 96

CPx45 0 1.1 0.25 12.5 12.6 70.3 65.3 0-1 209 138

CPx60 2 1.9 0.45 12.7 12.6 74.5 65.0 0 -1 158 110

CPx90 0.5 0.8 0.2 12.5 12.5 80.3 68.2 0 -1 214 138

CPx120 3 1.6 0.4 12.7 12.5 57.6 4 9 .1 0-1 213 169

CPx150 5 2.9 0.8 12.7 12. 2 65.3 49.9 0-1 182 139

CP x175 3 4.2 0.5 13.0 11. 8 68.5 51.8 0-1 213 146

CPx200 6 4.0 0.4 12.4 12.1 91.2 65.8 0 -1 157 79

CPx250 8 6.0 0.6 12.7 12.4 83.6 62.4 0 -1 219 117

CPx300 6 (70) (30) 12.6 12.1

Notes: CO values and Nett flue gas temperatures are given for guidance and measured values will depend on site conditions.

* Air Pressure Switch settings are given for guidance and measured values will depend on site conditions.

tbc tbc 0 -1 tbc tba

page no. 18 of 68

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

Page 19

1.2 Technical Data

Riello Burner Settings - 28sec Oil - Kerosene - Net CV (Hi = 47.00MJ/kg)

High Fire Low Fire

MODEL Burner Type Nozzle

CPx30 RG1RKD 0.75 x 60S 10.0 140 2.70 7. 0 100 1.89

CPx45 RG2D 1.25 x 60S 10.0 140 4.15 7.0 100 3.27

CPx60 RG2D 1.50 x 60S 10.0 140 5.36 7.0 100 4.07

CPx90 RG3D 2.50 x 60S 10.0 140 8.28 7.0 100 6 .16

CPx120 RG3D 3.00 x 60S 10.0 140 10.91 7.0 100 8.50

CPx150 RG3D 3.75 x 60B 10.0 140 13.45 7. 0 100 9.82

CP x175 RG4D 4.50 x 60B 10.0 140 16.45 7.0 100 11.60

CPx200 RG5D 2.5 + 2.0 x 60S 10.0 140 17.9 6 10.0 140 10.00

CPx250 RG5D 3.5 + 3.0 x 60S 10.0 140 23.69 10.0 140 13.10

CPx300 RL34 MZ TC

Head

MODEL

Setting

no.

High Fire Low Fire High Fire Low Fire High Fire Low Fire High Fire Low Fire

Combustion Air Nominal CO (±0.5) Nox

4.5x60B + 3x60S

Burner Pressure Fuel Input Burner Pressure Fuel Input

bar psi kg/h bar psi kg/h

tbc tbc tbc tbc tbc tbc

Nett Flue Temp

Smoke

No. No. No. % % ppm ppm No. °C °C

CPx30 1.3 1.5 0.25 11. 8 12.5 67. 5 65.5 0 -1 133 96

CPx45 0 1.1 0.25 12.5 12.6 70.3 65.3 0-1 209 138

CPx60 2 1.9 0.45 12.7 12.6 74.5 65.0 0 -1 158 110

CPx90 0.5 0.8 0.2 12.5 12.5 80.3 68.2 0 -1 214 138

CPx120 3 1.6 0.4 12.7 12.6 57.6 4 9 .1 0-1 213 169

CPx150 5 2.9 0.8 12.7 12. 2 65.3 49.9 0-1 182 139

CP x175 3 4.2 0.5 13.0 11. 8 68.5 51.8 0-1 213 146

CPx200 6 4.0 0.4 12.4 12.1 91.2 65.8 0 -1 157 79

CPx250 8 6.0 0.6 12.7 12.4 83.3 62.4 0-1 219 117

CPx300 tbc tbc tbc tbc tbc

Notes: CO values and Nett flue gas temperatures are given for guidance and measured values will depend on site conditions.

* Air Pressure Switch settings are given for guidance and measured values will depend on site conditions.

tbc tbc tbc tbc tbc

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

page no. 19 of 68

Page 20

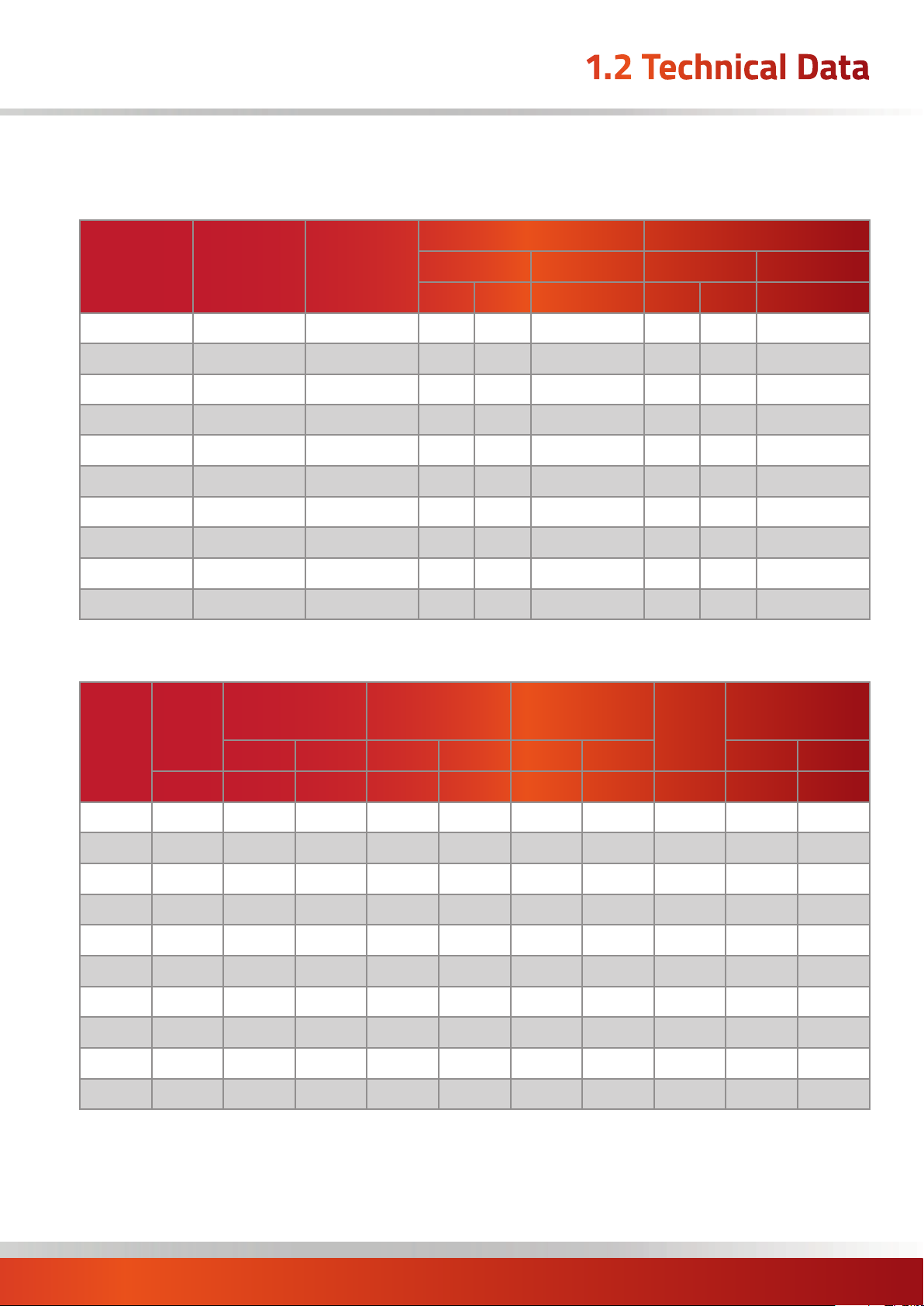

1.2 Technical Data

Electrical Loadings

Standard Motor Uprated Motor (fitted to EA models as standard)

MODEL

CPx30 0.55 1 1500 8.1 4.3 6 0.75 1 1500 15.9 5.3 6

CPx45 0.55 1 1500 17.1 5.7 10 0.75 1 1500 15.9 5.3 6

CPx60 1.1 1 1000 16 .1 5.3 6 2.2 1 1500 3 7. 8 12.6 16

CPx90G 1.5 1 1500 25.5 10.0 16 2.2 1 1500 37. 8 12.6 16

CPx90O 1.4 1 1000 2 8 .1 9.6 16 1.5 1 1500 27.6 9.2 16

CPx120 1.7 3 1000 12.4 6.4 10 3.0 3 1500 22.05 6.3 10

CPx150 3.0 3 1500 23.5 6.7 10 4.0 3 1500 29.05 8.3 10

CP x175 4.0 3 1500 23.0 7.1 10 5.5 3 1500

CPx200 4.0 3 1500 19.7 8.6 10 5.5 3 1500 38.5 11.0 16

CPx250 4.0 3 1500 28.2 8.4 10 5.5 3 1500 38.5 11.0 16

CPx300 7.5 3 1500 5 0.1 14.5 16 11.0 3 150 0 75.6 21.6 32

Motor Pha

kW r.p.m A A A kW r.p.m A A A

Nominal

Motor

Start

Amps

Run

Amps

Fuse

Rating

Motor Pha

Nominal

Motor

Start

Amps

38.5 11.0 16

Run

Amps

Heater Specifications

MODEL

Air Volume

(UF/HF)

m³/s m ³/h qty mm m Pa Pa dB(A) kg kg kg

Heads

Throw

(UF/

HF)

Max Duct Resistance

Std Motor Uprated

Noise

Level (std

UF/HF)

Weight

CPx

Weight

CPX/

NCA

Fuse

Rating

Weight

CPx/

EA

CPx30 0.97 3492 2 203 15 188 250 67.7 168 tbc tbc

CPx45 0.86 3096 2 254 21 222 250 35.8 173 tbc tbc

CPx60 1.01 3636 3 254 19 270 400 63.9 231 tbc tbc

CPx90G 2.11 7596 3 305 24 250 500 70.5 241 tbc tbc

CPx90O 1.50 5400 3 305 24 200 450 69.2 241 tbc tbc

CPx120 2.30 8280 4

CPx150 3.15 113 40 4

CP x175 3.36 12096 4 256 29 290 500 71.0 530 tbc tbc

CPx200

CPx250 4.49 16164 4 457 41 140 450 72.7 556 tbc tbc

CPx300 5.76 20736 4 457 48 150 500 77. 0 556 tbc tbc

3.84 13824 4 406 29 250 500 72.0 530 tbc tbc

305/358

305/358

24 180 350 71.5 341 tbc tbc

29 185 400 70.0 386 tbc tbc

Heat Exchanger Baffles

Model 30 45 60 90 120 150 175 200 250 300

Nat Gas G20 None Top tubes Top tubes All tubes Top tubes All tubes Top t u b es All tubes All tubes All tubes

Propane G31 None Top tubes Top tubes All tubes Top tube s All tubes Top tubes All tubes All tubes All tubes

Oil - 35 sec None None None Top tubes None To p t ubes None Top tubes None Top t ubes

Oil - 28 sec None None None Top tubes None All tubes None Top t ubes None Top tubes

page no. 20 of 68

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

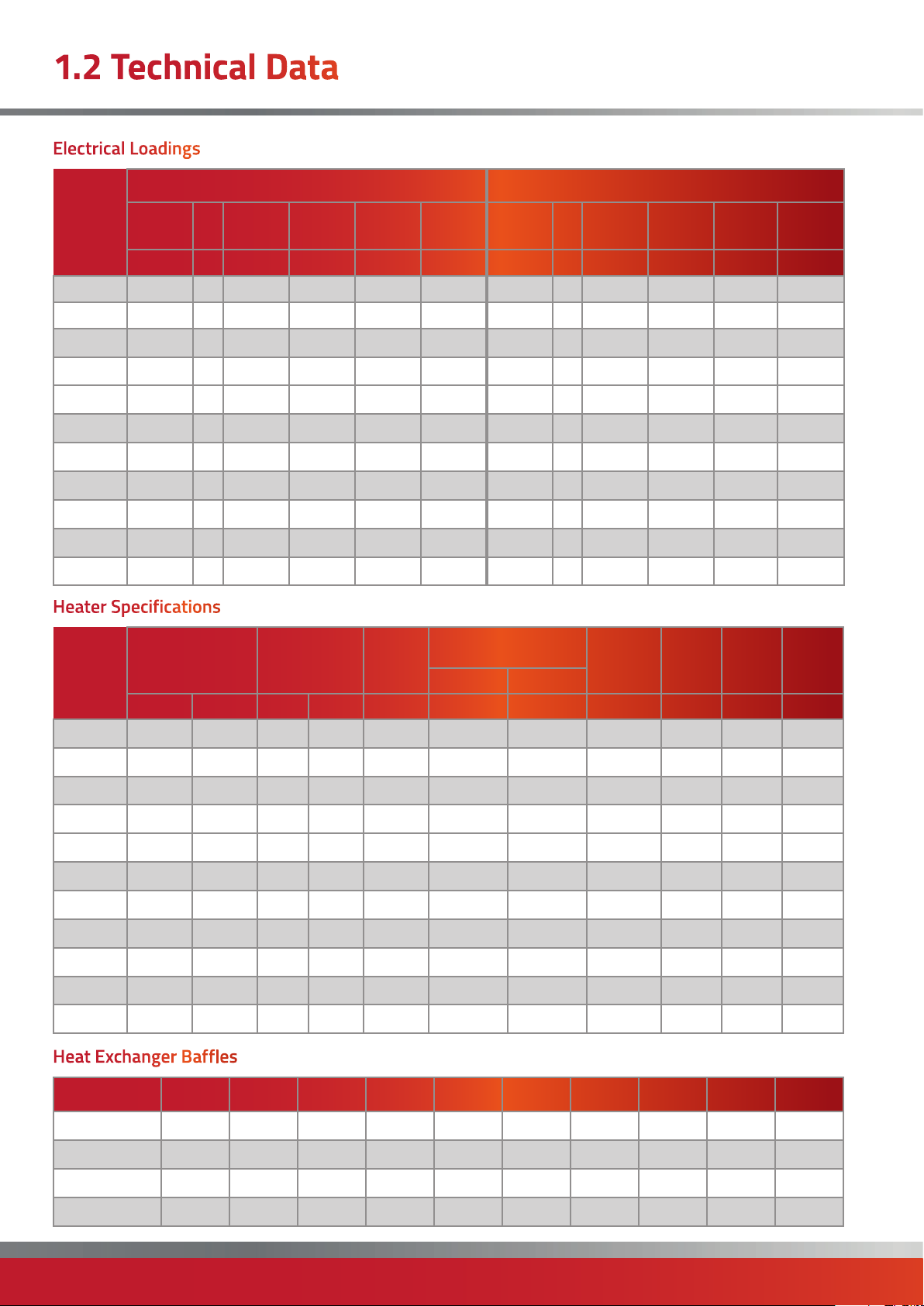

Page 21

Drive Data - Standard Motor

1.2 Technical Data

MODEL

CPx30

CPx45

CPx60

CPx90G

CPx90O

CPx120

CPx150

CP x175

CPx200

CPx250

CPx300

Fan Pulley (e)

Motor (a) Motor Pulley (b)

kW Pha RPM Pt no. Size Pt no. Size Pt no.

0.55 1 1500 n/a n/a n/a n/a n/a 1 270 x 270 1402CFAN150/T/15

0.55 1 1500 n/a n/a n/a n/a n/a 1 270 x 270 1402CFAN14 0/T/15

1.1 1 1000 n/a n/a n/a n/a n/a 1 321 x 321 1402CFAN210/T15

1.5 1 150 0 140001908 170 x1 SPA 142001689 1610 -24 142003360 2 381 x 381 1402CFAN510/T

1.4 1 1000 n/a n/a n/a n/a n/a 1 381 x 381 1402CFAN560/T/15

1.7 3 1000 n/a n/a n/a n/a n/a 1 381 x 381 1402CFAN580/T/15/3P

3.0 3 1500 140002055 95x1 SPA 142000602 1210 -28 142003856 2 457 x 486 1402CFAN820/T

4.0 3 150 0 140002108 95x1 SPA 142000602 1210 -28 142003856 2 457 x 486 1402CFAN820/T

4.0 3 150 0 140002108 95x1 SPA 142000602 1210 -28 142003856 2 457 x 486 1402CFAN820/T

4.0 3 150 0 140002108 160x1 SPA 142001619 1610 -28 142161028 3 381 x 381 x2 1402CFAN510/T/2DECK

7.5 3 1500 140002251 160x1 SPA 142001619 1610 -3 8 142003655 3 381 x 381 x2 1402CFAN510/T/2DECK

Fan Pulley

TaperLock (f)

Belt(s) (g) Fuse

Motor Pulley

TaperLock (c)

Centrifugal Fan (d)

Size Pt no.

type

Contactor/Relay/

Soft Start

Overload

Size Pt no. Size Pt no. Size Pt no. T (A) Pt no. Type Pt no. Type Pt no.

n/a n/a n/a n/a n/a n/a 6A 140700046 JOX 143000816 n/a n/a

n/a n/a n/a n/a n/a n/a 6A 140700046 JOX 143000816 n/a n/a

n/a n/a n/a n/a n/a n/a 10A 140700040 JOX 143000816 n/a n/a

280X1 SPA 142002604 2012-25 142201225 A1690/65 142116903 12 A 140700042 JOX 143000816 n/a n/a

n/a n/a n/a n/a n/a n/a 12 A 140700042 JOX 143000816 n/a n/a

n/a n/a n/a n/a n/a n/a n/a n/a 5.5kW AC3 143000601 5-8A 143000802

200x1 SPA 142001825 2012-25 142201225 XPA170 0 142119742 n/a n/a 5.5kW AC3 143000601 5-8A 143000802

170x1 SPA 142001689 1610-25 142003370 XPA1632 142119730 n/a n/a 5.5kW AC3 143000601 7-11A 143000801

160x1 SPA 142001619 1610-25 142003370 XPA163 2 142119730 n/a n/a 5.5kW AC3 143000601 7-11A 143000801

280x1 SPA 142002604 2012-25 142201225

250x1 SPA 142002494 2012-25 142201225 XPA1632 142119730 n/a n/a 11.0 kW MCI 143000621 12-18A 143000800

XPA1700 142119742 n/a n/a 5.5kW AC3 143000601 12-18A 143000801

d

Fan type 2

e

a

b

Fan type 1

f

g

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

c

page no. 21 of 68

Page 22

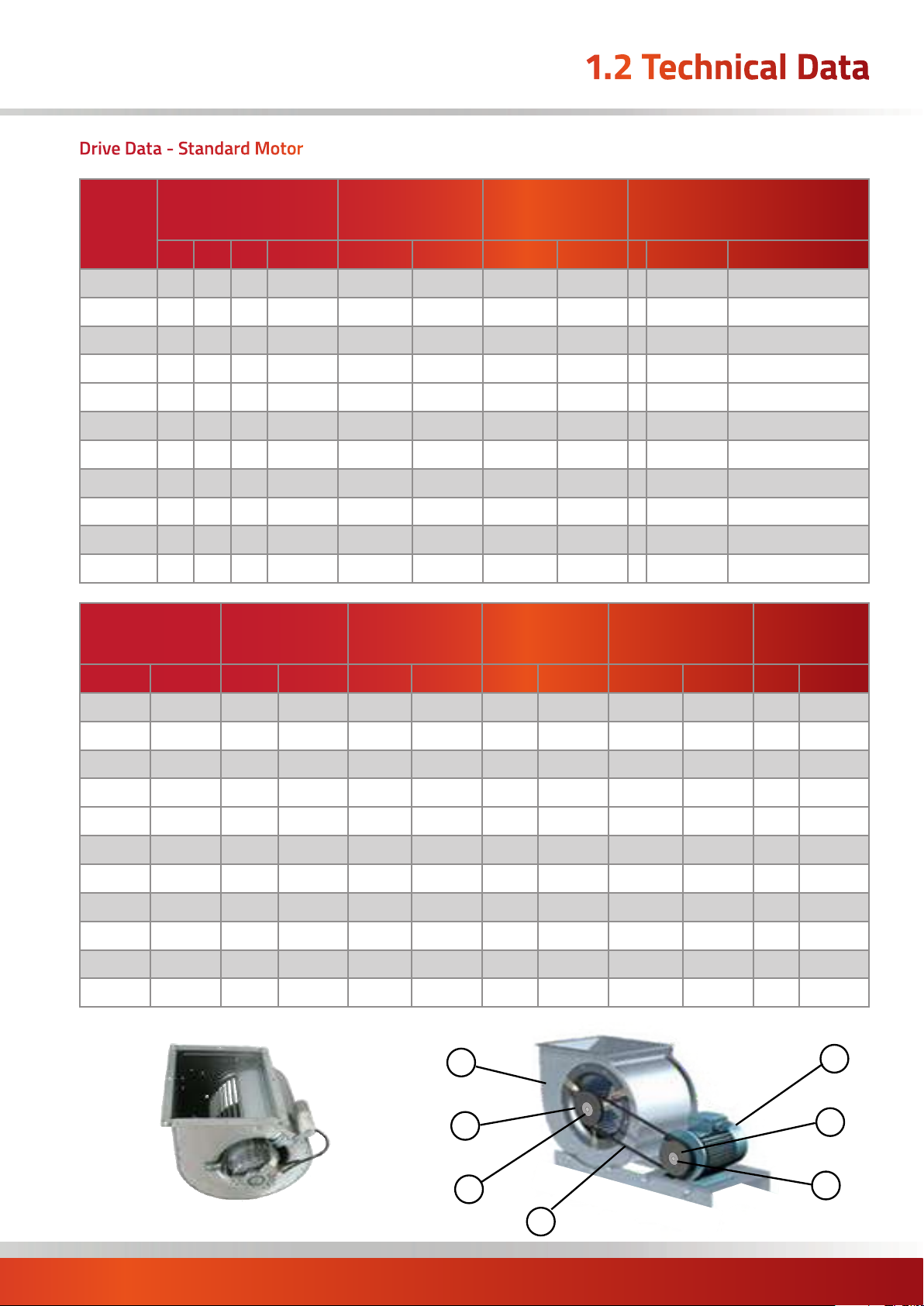

1.2 Technical Data

Drive Data - LHP (Larger Horsepower) Motor

MODEL

CPx30

CPx45

CPx60

CPx90G

CPx90O

CPx120

CPx150

CP x175

CPx200

CPx250

CPx300

Fan Pulley (e)

Motor (a) Motor Pulley (b)

kW Pha RPM Pt no. Size Pt no. Size Pt no.

0.75 1 150 0 140001520 95x1 SPA 142000602 1210-24 142003350 2 321 x 321 1402CFAN240/T

0.75 1 150 0 140001520 95x1 SPA 142000602 1210-24 142003350 2 321 x 321 1402CFAN240/T

2.2 1 150 0 140001998 170x1 SPA 142001689 1610-24 142003360 2 381 x 381 1402CFAN510/T

2.2 1 150 0 140001998 180x1 SPA 142001675 1610 -24 142003360 2 381 x 381 1402CFAN510/T

1.5 1 150 0 140001908 170 x1 SPA 142001689 1610 -24 142003360 2 381 x 381 1402CFAN510/T

3.0 3 1500 140002055 95x1 SPA 142000602 1210 -28 142003856 2 457 x 486 1402CFAN820/T

4.0 3 150 0 140002108 100x1 SPA 142000601 1610 -28 142161028 2 457 x 486 1402CFAN820/T

5.5 3 1450 140002206 95x1 SPA 142000602 1210-28 142003856 2 457 x 486 1402CFAN820/T

5.5 3 1450 140002206 100x1 SPA 142000601 1610-28 142003655 2 457 x 486 1402CFAN820/T

5.5 3 1450 140002206 170 x1 SPA 142001689 1610-28 142003655 3 381 x 381 x2 1402CFAN510/T/2DECK

11.0 3 1500 140002610 140x2 SPA 142001013 2012-42 142201242 3 381 x 381 x2 1402CFAN510/T/2DECK

Fan Pulley

TaperLock (f)

Belt(s) (g) Fuse

Motor Pulley

TaperLock (c)

Centrifugal Fan (d)

Size Pt no.

type

Contactor/Relay/

Soft Start

Overload

Size Pt no. Size Pt no. Size Pt no. T (A) Pt no. Ty pe Pt no. Type Pt no.

170x1 SPA 142001689 1610-25 142003370 A10 20/44 142111504 6A 140700046 JOX 143000816 n/a n/a

180x1 SPA 142001675 1610 -25 142003370 A1020/44 142111504 6A 140700046 JOX 143000816 n/a n/a

280x1 SPA 1420026 04 2012-25 142201225 A1690/65 142116903 12 A 140700042 5.5kW AC3 143000601 12-18A 143000800

280x1 SPA 1420026 04 2012-25 142201225 A1690/65 142116903 n/a n/a 5.5kW AC3 143000601 12-18A 143000800

280x1 SPA 1420026 04 2012-25 142201225 A1690/65 142116903 12 A 140700042 JOX 143000816 n/a n/a

200x1 SPA 142001825 2012-25 142201225 X PA1700 142119742 n/a n/a 5.5kW AC3 143000601 5-8A 143000802

200x1 SPA 142001825 2012-25 142201225 X PA1700 142119742 n/a n/a 5.5kW AC3 143000601 7-11A 143000801

160x1 SPA 142001619 1610 -25 142003370 XPA1632 142119730 n/a n/a 7.5k W M C I 143000620 9-13A 143000828

160x1 SPA 142001619 1610 -25 142003370 XPA1632 142119730 n/a n/a 7.5k W M C I 143000620 9-13A 143000828

280x1 SPA 1420026 04 2012-25 142201225

190x2 SPA 142001823 2012-25 142201225 XPA15 5 0 142119725 n/a n/a 11.0K W MCI 143000621 17-24A 143000807

d

e

XPA1700 142119742 n/a n/a 7.5k W M C I 143000620 9-13A 143000828

a

b

page no. 22 of 68

f

g

c

Fan type 3

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

Page 23

1.3 General Requirements

1.3.1. General

Before installation, check that the local distribution

conditions, fuel specification, and adjustment of the

appliance (see data plate) are compatible.

IMPORTANT:

Copper Sulphide / ‘Black Dust’

In some areas of the UK, particularly

Northern Ireland, problems have been

experienced with copper sulphide (more commonly

referred to as ‘Black Dust’) forming on the inner

surfaces of copper gas supply pipework. This dust can

enter the gas stream and may lead to blockages of

valves, filters and injectors.

If this heater is being installed in an area where ‘Black

Dust’ is known to be a problem, and copper gas supply

pipework is used, it is recommended that a filter

having a stainless steel 50 micron mesh and suitable

for Natural Gas is fitted at the inlet to the appliance

immediately downstream of the main appliance

isolation valve. The end user should be advised that the

filter will require periodic cleaning or replacement at

least once per year,during the annual service, or more

often if the problem is severe.

1.3.2 Location

IMPORTANT:

Heaters shall not be installed in:a) Those parts of spaces within buildings

that have been classified as hazardous areas

as defined in BS EN 60079-14.

b) Where there is a foreseeable risk of flammable

particles or gases or corrosion inducing gases or vapours

being drawn into either the heated air stream or the

air for combustion. In such cases installation may only

proceed if both air sources are from an uncontaminated

source, preferably from outside the building. It may

also be necessary to purge the air heater before the

burner is allowed to fire. In certain situations where only

airborne particles are present it may suffice to fit filters

on the main air inlet duct of the heater. Advice in these

instances must be obtained from Powrmatic Ltd.

c) In areas subjected to significant negative pressures

due to extract systems.

1.3.3 Sizing of the heater

The heater should be correctly sized for the area that it is

heating. Full calculations need to be preformed to ensure

the correct KW output heater is fitted (CIBSE elemental

methodology can be used, or the Powrmatic Technical

Department can provide guidelines).

The location chosen for the air heater must permit:

- the provision of a satisfactory flue system and an

adequate air supply.

- adequate space for servicing and air circulation around

the air heater.

The heater(s) must not be installed in conditions for which

it is not specifically designed e.g. where the atmosphere

is corrosive or salty, and they are not suitable for outdoor

use unless the CPx/EA style is specified. CPx/EA heaters

must be installed on a plinth such that there is a minimum

distance of 0.5m between ground level and the lowest

point of any air inlet grilles.

Where the location of the air heater is such that it might

suffer external mechanical damage e.g. from overhead

cranes, fork lift trucks, it must be suitably protected.

CPx heaters are for normal operation within an ambient

temperature range of -10 to 25°C.

The air heater must be installed in accordance with

the rules in force and the relevant requirements of any

fire regulations or insurance company's requirements

appertaining to the area in which the heater is located,

particularly where special risks are involved such as

areas where petrol vehicles are housed, where cellulose

spraying is carried out, in wood working departments etc.

1.3.4. Electrical Supply

Wiring external to the air heater must be installed in

accordance with the I.E.E. Regulations for Electrical

Installations and any local regulations which apply.

All heaters are supplied by either 230V - 1ph, 50Hz or

415V - 3ph, 50Hz (see technical data or data plate on

heater for exact). The method of connection to the main

electricity supply must:-

- facilitate the complete electrical isolation of the unit(s)

- be in a readily accessible position adjacent to the unit(s)

- serve only the unit(s)

- have a contact separation of at least 3mm in all poles.

See the accompanying wiring diagram for the heater

electrical connections.

1.3.5 Flue System

Only flue systems supplied through Powrmatic Ltd may

be used with CPx units. Several configurations of flue and

combustion air ducts are available.

The flue must terminate in a freely exposed position and

be sited to prevent the products of combustion entering

any opening in a building in such concentration as to be

prejudicial to health or a nuisance.

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

page no. 23 of 68

Page 24

1.3 General Requirements

1.3.6. Gas Fired Heaters

1.3.6.1. Related Documents

All Gas Fired CPx heaters comply with the following

European Directives:

Energy Related Product Directive: 2009/125/EC*

Gas Appliance Directive: 2009/142/EC

Electromagnetic Compatibility Directive: 2004/108/EC

Low Voltage Directive: 2006/95/EC

Machinery Directive: 2006/42/EC

Air heater(s) must be installed in accordance with BS6230

and BS5440 plus any relevant requirements of local and

national building codes. * where appropriate.

1.3.6.2 Gas Supply

A servicing valve and union to facilitate servicing must

be fitted to the gas inlet pipe work of the heater. The

gas supply must be completed in solid pipe work and

be adequately supported. Heaters suspended by drop

rods, straps or chains must have a flexible connection as

the final link between the gas supply pipe work and the

heater. Sufficient slack must be left in the connection to

take account of normal movement of the heater.

1.3.7. Gas Fired Heaters

1.3.7.1. Related Documents

All Oil Fired CPx heaters comply with the following

European Directives:

Energy Related Product Directive: 2009/125/EC*

Electromagnetic Compatibility Directive: 2004/108/EC

Low Voltage Directive: 2006/95/EC

Machinery Directive: 2006/42/EC

Air heater(s) must be installed in accordance with BS6230

and BS5440 plus any relevant requirements of local and

national building codes. * where appropriate

It should also be in accordance with any relevant

requirements of the local authority and fire authority and

the relevant recommendations of the following documents:

OFTEC Technical Book 3: Domestic & Commercial

requirements for oil storage and supply equipment.

OFTEC Technical Book 4: Oil fired appliances & system

installation requirements.

OFTEC Easy Guides to non domestic oil feed pipes and oil

storage.

1.3.7.2 Oil Supply

1.3.6.2 Service Pipes

The local gas undertaking should be consulted at the

installation planning stage in order to establish the

availability of an adequate supply of gas. An existing

service pipe must not be used without prior consultation

with the local gas undertaking.

1.3.6.3 Meters

A gas meter is connected to the service pipe by the local

gas undertaking or a local gas undertaking contractor. An

existing meter should be checked, preferably by the gas

undertaking, to ensure that the meter is adequate to deal

with the total rate of gas supply required.

1.3.6.4. Installation Pipes

Installation pipes should be fitted in accordance with IGE/

UP/2. Pipework from the meter to the air heater must

be of adequate size. Do not use pipes of a smaller size

than the inlet gas connection of the heater. The complete

installation must be tested for soundness as described in

the above Code.

Construction and installation of service tanks and fittings

should be in accordance with: (a) BS 5410 Part 2 Section 6,

(b) BS 799 Part 5 & (c) BS 1563

In addition the service tank installation must comply with

local regulations and by-laws and with the requirements of

insurance companies

Refer to the detail provided in the burner handbook

regarding oil pipe sizing. These must be generally in

accordance with BS799 Part 3 and BS5410 Part 2.

Particular attention is drawn to the following:

a) Pipe jointing compounds must be capable of

withstanding the solvent action of the fuel oil under all

operating temperatures and pressures. Jointing compounds

containing oil shall not be used. Hemp and other fibrous

materials shall not be used as packing for screwed joints.

b) Soft solder copper tube fittings and galvanised pipes and

fittings must not be used.

c) Oil lines must be completely air-tight.

d) The pump suction must not exceed a maximum of 0.4

bar (30cm Hg). Beyond this limit gas may be released from

the oil.

WARNING: The burners are supplied adjusted

for a single pipe system. If the burner is to be

used on a twin pipe system the Internal

bypass plug of the burner oil pump must be

fitted. Refer to the burner instruction booklet.

page no. 24 of 68

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

Page 25

1.3 General Requirements

Ideally the return pipe should terminate within the oil tank

at the same level as the suction line, both being below the

minimum oil level.

1.3.7.3. Fire Valve

It is recommended that the fire valves should be installed

as follows:

1. Main storage to service tank supply (if applicable)

2. Main storage to burner supply

3. Service tank to burner supply (if applicable)

Fire valves should be installed generally in accordance

with the requirements of BS799: Part 5. The fire valve

should be situated in an easily accessible position as near

the tank as possible and where practicable within the

boundary of the tank chamber or catchpit retaining wall.

1.3.8. Combustion & Ventilation Air

Supply

Type B flued installations.

Where CPx heaters are installed within the heated space

(ie not in a plant room or an enclosure) and having a

building design air change rate of greater than 0.5/h,

additional provision for ventilation is not required.

If the building design air change rate is less than 0.5/h,

additional provision for natural or mechanical ventilation

is required. These being:

Natural Ventilation:

Grilles having a free area of at least 2cm² per kW of rated

heat input shall be provided at low level i.e. below the level

of the heater flue connection.

Mechanical Ventilation:

Must ensure that the space air change rate is at least

0.5/h, must be of the ‘input’ type and interlocked to

ensure the heaters cannot work if the input system is not

working.

Type B flued installations.

Where CPx heaters are installed in a plant room or

an enclosure (ie not within the heated space) having

combustion air drawn directly from the room and

connected to a flue that evacuates the products of

combustion directly from the room additional provision

for natural or mechanical ventilation is required.

These being:

Natural Ventilation:

There must be permanent air vents communicating

directly with the outside air, at high level and at low level.

Plant Rooms

Low level (inlet) 4cm²/kw of total rated net heat input

High level (outlet) 2cm²/kw of total rated net heat input

Enclosures

Low level (inlet) 10cm²/kw of total rated net heat input

High level (outlet) 5cm²/kw of total rated net heat input

Mechanical Ventilation:

The minimum flow rate of ventilation shall be 4.14m³/h

per kilowatt of total rated heat input.

Typ e B23 Installation (these refer to section 1.4.3 of these instructions)

Air vents shall be permanently open.

Figures in column 1 are for heaters installed in the space they are heating.

Figures in column 2 are for heaters installed in a plant room, ventilation to outside air.

Figures in column 3 are for heaters installed in a enclosures, ventilation to outside air.

In all cases figures are per heater installed.

For multi heaters installations the appropriate values for each heater must be added together.

In the heated

CPx

30 32.29 64.6 129.2 64.6 322.9 161.5

45 48.97 97. 9 195.9 97.9 489.7 244.8

60 64.62 129.2 258.5 129.2 646.2 323 .1

90 98.31 196.6 393.2 196.6 9 83 .1 491.5

120 127.43 254.9 509.7 254.9 1274.3 6 37.1

150 162.90 325.8 651.6 325.8 1629.0 814.5

175 190.07 3 80 .1 760.3 38 0.1 1900.7 950.4

200 215.87 431.7 863.5 431.7 2158.7 1079.3

250 269.86 539.7 1079.4 539.7 2698.6 1349.3

Input

kW

space

Low level grille.

Free area cm²

In a plant room, ventilation to

outside

Low level grille.

Free area cm²

High level grille.

Free area cm²

In an enclosure, ventilation to

outside

Low level grille.

Free area cm²

High level grille.

Free area cm²

300 316.25 632.5 1265.0 632.5 3162.5 1581.2

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

page no. 25 of 68

Page 26

1.3 General Requirements

1.3.9. Air Distribution System

1.3.9.1. Freeblowing UF/HF/CF/RF

These are equipped with rotatable air delivery heads fixed

to the top panel of the unit providing rotational and lateral

direction. The quantity of heads depend on the heater size

(see Head Plans in section 1.2) and consist of a number

of standard and extended heads. Extended heads are

placed on the rear of the heater when located adjacent to

a wall to allow complete freeblowing access without any

restrictions.

NOTE: We do not recommend removing and

blanking off any of these heads or removing

singular heads and replacing with similar sized

spiral ductwork. Ducted units are available for

these applications.

For free-blowing units installed in buildings having a low

heat loss i.e. where single units are required to cover a

large floor area, and in buildings with high roof or ceiling

heights Calecon thermal economiser units should be

fitted to ensure even heat distribution and minimise

stratification.

Care should be taken to avoid impeding the heater air

throw with racking, partitions, plant or machinery etc.

Various outlet configurations are available as optional

extras to modify the air throw pattern to suit particular

site conditions.

1.3.9.2. Ducted UD/HD/CD/RD units

These are designed for use with duct work to more

precisely define the point of air delivery, and /or provide

ducted return air or ducted fresh air inlet.

Ductwork must be specially calculated to comply with the

maximum static resistance available for the specific model

installed. (see table)

If fitting horizontal ductwork, it is recommended that a

plenum box with the same external dimension as the duct

spigot with a minimum height of 1.0m be fitted to the

heater outlet spigot to allow for even distribution of air.

If fitting vertical ductwork it is recommended that a

plenum box with the same external dimension as the

duct spigot with a minimum height of 1.0m be fitted to

heater outlet spigot prior to any restriction in ductwork. All

ducting must be independently supported of the air heater.

All delivery and return air ducts, including air filters,

jointing and any insulation or lining must be constructed

entirely of materials which will not contribute to a fire,

are of adequate strength and dimensionally stable for the

maximum internal and external temperatures to which

they are to be exposed during commissioning and normal

operation.

Where inter-joist spaces are used as duct routes they

should be suitably lined with a fire-resisting material.

A full and unobstructed return air path to the air heater(s)

must be provided. If the air heater(s) is installed in a plant

room the return air intake(s) and the warm air outlet(s)

from the heater(s) must be fully ducted, into and out of the

plant room to avoid interference with the operation of the

heater from other equipment.

The openings in the structure of the plant room through

which the ducting passes must be fire stopped. Care must

be taken to ensure that return-air intakes are kept clear

of sources of smells and fumes, and where there is any

possibility of pollution of the air by dust, shavings etc.,

precautions must be taken to prevent contamination.

Standard Motor LHP Motor

Model

CPx30 0.97 188 250

CPx45 0.86 222 250

CPx60 1.01 270 400

CPx90G 2.11 250 500

CPx90O 1.5 200 450

CPx120 2.3 180 350

CPx150 3 .15 185 400

CP x175 3.36 290 500

CPx200 3.84 250 500

CPx250 4.49 140 450

CPx300 5.76 150 500

page no. 26 of 68

Air Volume

(m³/s)

Max Duct

Resistance (Pa)

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

Max Duct

Resistance (Pa)

If necessary suitable barrier rails should be

provided to prevent any combustible material

being placed within 900mm of the outlets.

Joints and seams of supply ducts and fittings must

be securely fastened and made airtight.

It is recommended that ducting should be

connected to the heater spigots via an airtight

flexible coupling of noncombustible material.

Before fitting coupling it must be ensured that an

adequate clearance will be maintained between

the ends of the ducting and the heater spigots.

If required sound attenuators may be fitted in

inlet and outlet ducts to reduce airborne fan noise.

Materials used in outlet sound attenuators must

be capable of withstanding 100°C air temperature

without any deterioration.

Page 27

2.1.1 Fitting space requirement

C

2.1 Fitting the Unit

B

D*

E*

A

Model 30 45 60 90 120 150 175 200 250 300

A Front mm 750 750 950 950 1250 1250 1450 1450 1650 1650

B Rear mm 1000

C Above mm 1000

D Side (Blank panel)* mm 150

E Side (Louvred)* mm 1000

To the front The depth of the heater

To the rear 1.0m

To the side having louvred lower panels* 1.0m

To the side having blank lower panels (see below)* 0.15m

Above the heater 1.0m

* Side panels are interchangeable to ease with installation against walls etc.

Therefore D can = 1.0m if E = 0.15m OR E can = 0.15m if D = 1.0m

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

page no. 27 of 68

Page 28

2.1 Fitting the Unit

2.1.2. General

Before installation, check that the local distribution

conditions, fuel specification, and adjustment of the

appliance (see data plate) are compatible.

IMPORTANT:

Copper Sulphide / ‘Black Dust’

In some areas of the UK, particularly

Northern Ireland, problems have been

experienced with copper sulphide (more commonly

referred to as ‘Black Dust’) forming on the inner

surfaces of copper gas supply pipework. This dust can

enter the gas stream and may lead to blockages of

valves, filters and injectors.

If this heater is being installed in an area where ‘Black

Dust’ is known to be a problem, and copper gas supply

pipework is used, it is recommended that a filter having a

stainless steel 50 micron mesh and suitable for Natural

Gas is fitted at the inlet to the appliance immediately

downstream of the main appliance isolation valve. The

end user should be advised that the filter will require

periodic cleaning or replacement at least once per year,

during the annual service, or more often if the problem is

severe.

that the blank panel is facing the wall, interchanging the

two side panels if necessary.

Any combustible material adjacent to the air heater and

the flue system must be so placed or shielded as to ensure

that its temperature does not exceed 65 °C.

If the method of mounting allows for any movement of

the heater it is essential that all gas, duct, and electrical

connections to the heater are made with flexible

connections to maintain continuity of connection.

2.1.4. Gas Connection (where

neccessary)

• A servicing valve and union must be fitted at the gas inlet

to the heater to facilitate servicing.

• The gas supply to the air heater must be completed in

solid pipe work and be adequately supported.

• Heaters suspended by drop rods, straps or chains must

have a flexible connection as the final link between the gas

supply pipe work and the heater. Sufficient slack must be

left in the connection to take account of normal movement

of the heater.

2.1.3. Installing the Heater

If necessary consideration should be given to mounting

the heater on resilient pads, or equivalent, to minimize

transfer of noise and vibration to the structure of the

building.

Floor mounted heaters must be installed on a level

noncombustible surface.

Heaters mounted at high level must be supported on

a purpose designed platform or framework that is

suspended from vertical drop rods, chains or straps or

mounted on specifically designed cantilever brackets

from a non-combustible wall. The method of installation

support must be capable of adequately supporting the

weight of the unit and any ancillary equipment. Before

installing the heater the existing structure must be

inspected to ensure it is suitable. All supports should be

protected against the effects of rust or corrosion.

Whichever method of mounting the air heater is used

the following minimum clearances for installation and

servicing must be observed.

NOTE:

CPx 250 & CPx 300 heaters have louvred lower

panels on both sides. The minimum clearance

of 0.15m is increased to 0.5m.

NOTE: Smaller heaters are supplied with one

blank side panel and one louvred side panel. If

the heater is installed against a wall ensure

Warning:

When completing the final gas connection to

the heater do not place undue strain on the

gas pipe work of the heater.

2.1.5. Oil Connection (where

neccessary)

Refer to the supplied burner installation instructions for

details regarding oil supply options.

2.1.6 Room Thermostat Siting

If a remote room thermostat, or controller with an integral

sensor, is used it should be fitted at a point which will

be generally representative of the heated area as far as

temperature is concerned. Draughty areas, areas subjected

to direct heat e.g. from the sun, and areas where the air

movement is relatively stagnant e.g. in recesses, are all

positions to be avoided for siting the thermostat.

The thermostat should be mounted about 1.5m (5ft) from

floor level.

Any room thermostat, frost thermostat, time clock etc.

must be suitable for switching 230V, 5A and must be of

the 'snap action' type to minimise contact bounce.

For electrical connections of external controls

see section 2.5 or the accompanying wiring

diagram.

page no. 28 of 68

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

Page 29

2.2 Fitting the Flue

A single wall tee piece is supplied with each heater

and must be fitted to the flue outlet socket on the

heater. A closed chimney system that conforms to

the requirements of EN1856-1 and has a designation

appropriate to the application must be connected to the

outlet of this tee. The cross sectional area of the chimney

serving the appliance must be not less than the area of

the flue outlet of the air heater. The chimney must have

a minimum height, from the heater to the flue terminal,

of 2m (1m for external EA units). Horizontal runs of flue

must be minimised but where they are unavoidable the

ratio of vertical to horizontal flue should be not less than

3:1.

If necessary a single offset using two 45° bends can be

included to avoid obstructions. The minimum equivalent

resistance of the flue system should not be less than

0.0mb, the maximum not greater than 0.5mb. Details of

how to calculate the resistance of the flue to be installed

are given in Appendix A.

In order to minimise condensation the use of twin wall

chimney is recommended. With high efficiency heaters

some condensation in the chimney, particularly at the

terminal, is unavoidable and in addition there can also be

rain water ingress. Use of a chimney system having joint

seals will minimise any leakage from the flue system. The

heater tee is provided with a collection tray and the outlet

from this should be run to a drainage point e.g. a gully. The

condensation pipe from the collection tray to the

disposal point should be of non-corrodible material of not less

than 22mm (3/4") size.

Facilities should be made for disconnecting the chimney

pipe(s) from the air heater(s) for inspection and servicing

purposes.

The chimney outlet must be fitted with a terminal and

where the heater chimney is less than 200mm (8") in

diameter an approved terminal must be used.

The chimney must be supported independently of the air

heater.

The chimney must terminate in a freely exposed position

and must be situated so as to prevent the products of

combustion entering any opening in a building in such

concentration as to be prejudicial to health or a nuisance.

The chimney terminal must be installed not less than:

- 300mm below an opening e.g. window, air brick etc.

- 200mm below eaves or gutter.

- 300mm from an internal or external corner.

- 1200mm from a surface facing the terminal.

- 1500mm vertically from another terminal on the same wall.

- 300mm horizontally from another terminal on the same wall.

- 2000mm from ground level.

2.3 General Identification of Items

Air Outlet Turrets

Exhaust Flue

High Limit Reset

Water Drip Tray

Data Plate

Burner Lockout Reset

Burner

MC200 Controller

High Limit Indication

Electrical Connections (behind cover)

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

page no. 29 of 68

Page 30

2.4 Electrical Cable Installation

2.4.1. Electrical Connections

Warning: THIS APPLIANCE MUST BE

EARTHED.

Warning: Wiring external to the unit must be

carried out by an appropriately qualified

person to current IEE regulations for

Electrical Installations and any local regulations which

apply.

The local electrical supply must be run to a point adjacent

to the heater and be suitably terminated to provide an

isolation point that will prevent remote activation of

the unit during servicing. Wiring should be completed in

flexible conduit.

The local electrical supply conditions must be compatible

with the electrical data given on the appliance data plate.

Heaters are for use with 230V, 1N, 50Hz or 400V, 3N,

50Hz supplies (see heater data plate).

Heaters supplied less main fan must be electrically

interlocked to the air movement system so that this is

started in the same manner as the air heater fan would

be viz. A connection from the appropriate heater terminal

(see wiring diagram with the heater) must be made to one

side of the fan motor contactor coil, the other side of the

coil being connected to Neutral. Under no circumstances

must the fan motor electrical supply be taken direct from

the internal wiring of the heater.

2.4.2. Typical Wiring Installation

showing remote controller

Key:

A = 2 core and earth (single phase)

4 core and earth (three phase)

B* = MC200 On/Off = 5 core and earth

MC200 High/Low = 7 core and earth

MC200 Mod = 7 core and earth

C= Screened 2 core (MC200 models only)**

** (screen must be grounded only at the MC200, See

instructions supplied with controller for wiring sizing,

Max. 100m)

The method of connection to the main electricity supply

must:-

- facilitate the complete electrical isolation of the

heater(s) that will prevent remote activation of the heater

during servicing.

- be in a readily accessible position adjacent to the

heater(s).

- serve only the heater(s).

- have a contact separation of at least 3mm in all

poles. See the wiring diagram for the heater electrical

connections.

All units are fully prewired and only require final

connections for the incoming mains supply. Heaters not

supplied with inbuilt time and temperature controls will

also require completion of the external control circuit

(230V) via a room thermostat, time clock etc. and, if

applicable, the remote low level lockout reset.

Reference must be made to Section 1.2 to ascertain the

electrical loading of the unit(s) being installed so that

cables of adequate cross-sectional area are used for

the electrical installation. The length of the conductors

between the cord anchorage and the terminals must be

such that the current carrying conductors become taut

before the earth conductor if the cable or cord slips out

of the cord anchorage. All external controls must be of an

approved type.

Typical wiring

installation

Optional

Remote Controller

(MC200 shown)

Remote

Sensor

(optional)

Fused

Isolator

230V Supply shown

(415V option on 120-300)

page no. 30 of 68

CPx Range Users, Installation & Servicing Instructions Doc Ref M201 issue 2.9 Nov 2018.

Page 31

2.4.3. Wiring

2.4 Electrical Cable Installation

The wiring terminals, both mains input and controller, are

located on the electrical chassis panel behind the bottom

front panel of the heater which firstly has to be removed.

2.4.3.1. Mains Supply

L

1 phase

E

N

2.4.3.2. Intergral Control Wiring