Pow’R’kraft PK1123, PK1128, PK1125, PK1130, PK1135 Operator's Manual

FOR YOUR SAFETY

REA D A ND UNDERSTA ND THE ENTIRE MA NUAL BEFORE OPERA TING

MA CHINE

Save Th is Manual f or F ut ure Ref er en ce

W ALK-BEHIND TRACTOR

Operator’s Manual

MODEL NUMBER :

SERIA L NUMBER :

P K 1 1 2 3 P K 1 1 2 5 P K 1 1 2 8 P K 1 1 3 0 P K 1 1 3 5

Bot h m od el num b er and serial num ber m ay b e found o n t he m ain lab el.

You should record b o t h of t hem in a safe place for fut ure use.

Or ig inal In st ruct io ns

Questions: E-mail Support@PowRkraft.com

Tractor is shipped without lubricant.

TABLE OF CONTENTS

INTRODUCTION

Ca r e f ully read t hro u g h thi s ent ire

op erator’s manual b efore using your

new unit. Take special care to heed the

caut ions and warnings.

Th e Eng i n e m anuf act ur er is resp o nsible f o r all

eng ine-related issues with regards to perform ance,

power rat ing , specif ic at io ns, w arrant y and service.

Pl e a se r e f e r t o t h e En g i n e M a n u f a c t u r e r ’s

ow ners/ operat o r’s manual, packed separat ely w it h

your unit , for m ore inf o rm atio n.

Int r o d uct ion

Specificat ions

Symb o ls

Safet y

General Safet y Rules

Specific Saf et y Rules

Cont ent s su p p lied

Mac hine A ssem b ly

Im plem ent A ssem b l y

Kn o w y o u r Tract o r

Feat ures & Cont rols

Operat ion

Mai nt enance

Storag e

Tro ub le Sho o t ing

Part s Sched ule

1

2

2

3

3

4

5

6

10

12

12

13

14

14

15

16

1

W al k-b ehin d Tract o r

Your new walk-behind tract or will more t han sat isfy

yo ur exp ectations. It has been m anufact ured und er

st r ing e n t qual it y st an d ar d s t o m eet sup er io r

perfo rmance crit eria. You w ill find it easy and safe

t o operat e, and w it h p r o p er care, it w ill giv e you

m any y ears of dep end able service.

Thanks to it s v er sat ilit y , t he all- g ear-d riven w alkb e h i n d t ract o r is u sed f o r sm all- scal e f ar m ,

horticult ural, indust rial, landscaping and home use.

It is rat io nally ab le t o m eet bot h t he requirem ents

o f t h e “ d o it y o u r self ” ent hu siast f o r sm a ll

m ai n t e n a n c e j o b s an d t h e d em an d s o f

prof essio nals w h o assid u o usly use t h e mac hin e

to turn t he work of a season int o concret e income.

Th e feat ures of var ious m o d els are dif f er ent t o

m eet t he p r ecise needs. Th e solid and d ie- c ast

alum inum st ructure m akes t he machine extrem ely

light w eig ht and m aneuverable on any gro und. The

gear b o x , w ith 4 f o rw ard and 3 rev er se speed s, is

designed w it h t h e g ear s in an o il b at h t o ensu r e

a lon g w o rking life and r eliab ilit y.

Th e co rrec t rat io b et w een t he forw ar d sp eed s

and t he power takeo ff speed enab les it to b e used

in an extrem ely p ractical w ay in a broad rang e o f

o p e r a t io n s . T h e p o w er t ak e o f f op e r a t es

ind ep endent ly from the gearb ox, with t he coupling

in an o il b at h t o elim inat e all m ain t en anc e and

ensure troub le-free op erat ion in t im e.

The ad just ab l e an d rev ersi b le desig n o f t h e

handleb ar enab les it t o b e used r at ionally b o t h

w it h front and rear att achm ents. The cont rols hav e

b e en d esi g n e d erg o n o m ic a lly , r e d u c ing t h e

op erat o r ’s f at ig u e and en ab lin g t he m ac h ine’s

performance t o be appreciat ed fu lly.

2

W alk-behind Tr act o r

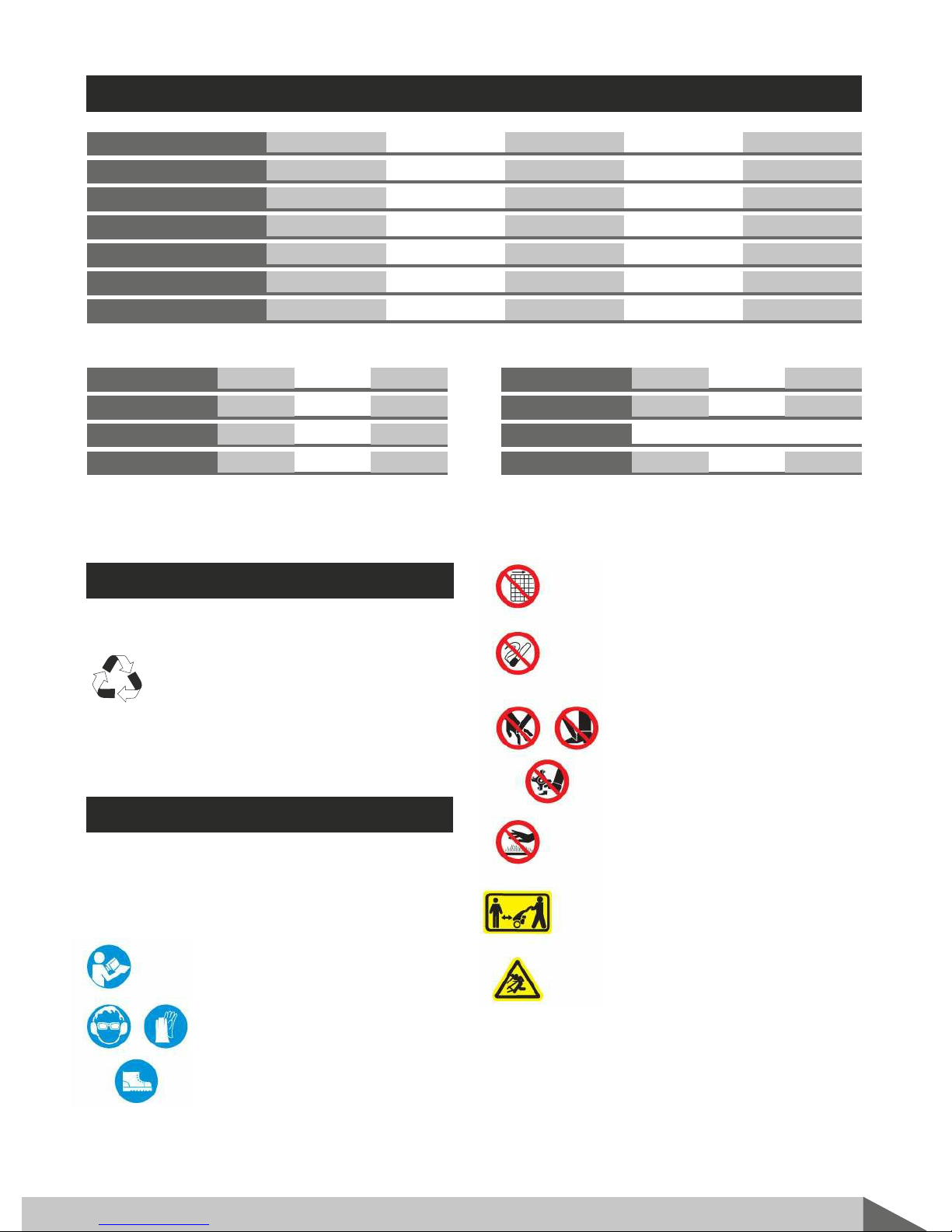

ENVIRONMENTA L

Rec y c le unw anted m ater ials inst ead of

disposing of them as w aste. A ll tools, hoses

and packaging sho uld be resort ed , taken

to the local recy cling center and disposed

of in an enviro nm ent ally safe w ay .

Read t hese instruct io ns for use car ef ully .

Use saf et y eq u ip m ent . A lw ays

w ear eye and hearing pro t ec t ion,

sa f et y f o o t w ear , g lo v es an d

helm et w hile operat ing.

It is fo r b id den t o rem ove o r t amp er w it h

the pro t ection devices and safety devices.

Do no t sm o ke o r h av e open flam es.

Use e x t r e m e c aut io n w he n st o r in g ,

hand ling and using fuels, as they are highly

volat ile and ex p losive in vapor st at e.

Keep aw ay from rot at in g p art s

an d Knifes. They can b e ve r y

dangerous.

Do n o t t o u c h p ar t s w hich are hot f r o m

operat ion, ser io us b urns may r esu lt .

Keep child r en and b y st anders o f f an d

aw ay.

Never d irec t dischar g e to w ard ot her

people. Throw n object s can cause injury.

The ra t ing p lat e on yo u r machin e may sho w

sym b o ls. These rep r esent im p ortant informat io n

ab out t he p roduct or in st r uctio ns on it s use.

SYMBOLS

Opt ional Sickle Bar Mower Implement s

Item No.

Tilling Widt h, mm

Num ber o f Tines

W eight , kg

32 823

50 0

4 x4

25 .0

Opt ional Tiller Implements

SPECIFICA TIONS

It em No .

Eng ine

Tire

Tran sm i ssion

Fo r w ar d Speed , k m / h

Rev erse Speed, km / h

W eig ht , kg

PK 1123

19 6 c c, 6 .5HP

4 .0 0 -8

Gearbox

1.11-11.24

1.11

64 .5

It em No .

Cutting Width, mm

Tran sm i ssion

W eig ht , kg

Sing le Blad e Act io n, Ro cker

PK11125

205cc 900

4 .0 0 -8

Gearbox

1.11-2.59

1.11-2.59

65.0

PK 1128

24 2cc , 9 HP

4 .0 0 -8

Gearbox

1.11-2.59-11.24

1.11-2.59

72.5

PK11130

305cc 1450

4 .0 0 -10

Gearbox

1.11-2.59-4 .4 5

1.11-2.59-4 .4 5

74 .0

PK 113 5

270 cc, 9HP

4 .0 0 -10

Gearbox

1.11-2.59-4.45-11.24

1.11-2.59-4 .4 5

74 .5

32 828

720

6x4

33 .0

32 830

720

6x6

37.5

33 826

1225

37.0

33 833

1530

4 3.0

33 824

970

3 1 .0

Specification subject to change without notice

Und erstand yo ur m ach ine

Read an d un d erstand t he operat or’s m anual and

lab els affixed t o t he machine. Learn its applicat ion

and lim it at ions as w ell as t h e sp ecif ic p ot ent ial

hazar d s peculiar t o it .

Be t horo ughly fam iliar w it h the cont ro ls and t heir

prop er operat io n. Kno w how t o st op t he m achine

and d iseng ag e t he c ontrols q uic kly.

Make su r e t o r e a d an d u nd e r st an d al l t he

instruct ions and safet y precautio ns as o ut lined in

t he En g i n e Man u f a c t u r e r ’ s Manu a l , p ac k e d

sep arat ely w it h y o ur unit . Do n o t at t em p t t o

op erat e t he m ach ine unt il y o u fully und erst an d

ho w t o p r op erly o p er at e and m aint ain the Eng ine

an d ho w t o avo i d ac c id en t al i n jur ies an d / o r

propert y d am age.

W ork ar ea

Nev er st ar t or run t he unit in side a closed ar ea.

Th e exhaust f u m es are d an g erous, co n t ain ing

car b o n m o noxid e, an o d orless and d ead ly g as.

Op erat e this unit o nly in a w ell vent ilated o ut d oor

area.

Never operat e t he machine w ithout good v isibilit y

or lig h t .

Never op erat e t he m ac h ine on a st e ep slo p e.

A lw ay s w o rk t ransversally , not up and dow n.

Per so nal safet y

Do no t o p erat e the m achine w h ile un d er t h e

influence of d rugs, alcoho l, or any med ic at ion t hat

cou ld af f ec t y our abilit y to use it p r op er ly.

Dress pro p er ly . W ear heavy long pants, b oot s and

glo v es. D o not w ear loose clo t hing, sh o r t pant s,

and jew elry o f an y kind . Secu re long hair so it is

above sho ulder lev el. Keep your hair, clothing and

g loves aw ay from movin g p ar t s. Lo ose c lot h es,

jew elry or long hair can be caught in m oving p arts.

Check yo ur machine befo re starting it. Keep guards

in p lace and in w orking o rder . Make sure all n ut s,

b o lt s, et c . ar e sec u r ely t ig ht en ed , in p art icular

t hose f ix ing t he imp lem en t to t he m achine.

Never oper at e t h e m achine w hen it is in need of

repair or is in p o o r m ec hanical cond it ion. Replac e

dam ag ed, m issing or failed p ar t s b ef o r e using it .

Ch eck fo r fuel leaks. Keep the m achin e in saf e

w o rking cond it ion.

Do no t use the m achine if the engine’s sw it ch does

not turn it on or off. A ny gasoline pow ered machine

t hat c an not b e co nt rolled w it h t he eng ine sw it ch

is d ang erou s and must b e rep laced.

Fo rm a hab it of chec kin g t o see t h at key s and

ad just ing w renches are r emo v ed f r o m m achine

area b efore start ing it. A wrench or a key t hat is

left att ached t o a rot at ing part of the m achine may

result in personal injury.

St ay aler t , w at c h w hat yo u ar e d o ing and use

com m o n sense w hen op er at ing t he m ach in e.

Do not o v er reach. D o n o t o p er at e t he m achine

w hile barefoot or w hen w ear ing sandals o r sim ilar

light w eig ht foot w ear. W ear p r o t ec t iv e f o o t w ear

that w ill protect your feet and improve your foo t ing

on slipp ery su r f aces. Keep p r o p er f o o t ing and

balance at all t imes. This enab les b ett er cont rol of

t he m achine in unexpect ed sit uatio ns.

Avoid acc id ent al st ar t ing . Be sure t he engine is of f

b efore t ransp ort ing t he m achin e or p erform ing

any m aint enance or ad just m en t on the unit .

Fuel safety

Fuel is highly flammable, and its vap ors can exp lode

if ig nit ed . Tak e p recaut ions w hen using to reduce

t he c hance of ser io us p erso nal injury .

W hen r efilling o r d r aining t he fuel t an k , use an

ap p r o v ed f uel st o r ag e co nt ainer w hile in a clean,

w ell-vent ilat ed out d o o r . Do not sm oke, or allo w

sp ar k s, o p en flam es o r ot h er so u rces o f ig nit io n

near the area w hile ad d ing fuel or o p erat ing t he

unit .

Keep gro und ed cond uctive objec t s, such as t o ols,

aw ay fro m ex p o sed , live elec t rical part s and

connect ions t o av oid sp arkin g or ar c ing. These

event s co uld ig nit e fum es or vapors.

Alw ays stop t he eng ine and allow it to co ol b efore

filling t he fuel t ank. N ever rem ove t he cap o f the

fuel t ank o r ad d fuel w hile t he en g ine is run ning

or when t h e engine is h o t . D o no t o p erat e t he

m achine w it h kn ow n leak s in the fuel system .

3

W al k-b ehin d Tract o r

SAFETY

General Safety Rules

Loo se the fu el t ank cap slo w ly t o r eliev e an y

pressure in t h e tank.

Nev er o v erfill fuel t an k ( t here sho uld be n o f uel

ab ove the upper lim it m ark)

Rep lace all fuel t ank and contain er caps sec urely

and w ip e up spilled fuel. Never o p erat e t he unit

w ithout t he fuel cap securely in p lace.

A void creat ing a so urce o f ig n it ion f or spilled fuel.

If f uel is sp illed , do not at t em p t to start the engine

b u t m o v e t h e m achine aw ay f ro m t h e ar ea of

spillag e and avoid c reat ing any sourc e of ig nit ion

un t il f uel vapors have d issip at ed .

Never sto re fuel or m ac hine w it h fuel in t he t ank

inside a b uild ing w here f um es may r eac h a spark,

open flam e, o r ot her sourc es o f ig n it ion, su ch as

a w at er heater, furnace, clot hes dryer and t he like.

A llo w t h e engine t o cool b efo r e st o r ing in an y

enclosur e.

Mac hine use and c ar e

Never p ic k up or carry a machine w hile t he eng ine

is running.

Do not force t he machine. Use the correc t m achine

for your ap p licat ion. The correct m achine w ill do

t h e jo b b et t er and saf er at t h e r at e for w h ich it

w as desig ned.

Do no t c hang e t h e eng ine g o v erno r set t ing s or

over-speed the engine. The g overno r cont rols t he

m axim um saf e operat ing sp eed o f t he eng ine.

Do not run t he eng in e at a h igh sp eed w hen not

in use.

Do no t p ut hand s o r f eet near ro t at ing p ar t s.

Avoid cont act w it h ho t fuel, oil, exhaust fum es and

ho t surfaces. Do no t t ouc h t he en g ine or m uffler .

Th ese p art s g et ext rem ely ho t fro m o p er at ion.

They rem ain hot f or a short tim e after yo u t urn off

t h e un it . A llo w t he eng in e t o c o o l b efore d oin g

m aint enance or m ak in g adjustm ent s.

If t he m ac hin e should start t o m ake an unusual

noise or vib ration, immediat ely shut off the engine,

disconnect t he spark p lug w ire, and check f o r t he

cau se. Un usu al no ise or vi b rat io n is g ener ally

w ar ning o f t roub le.

Use only at t ach m ent s and ac cesso r ies approved

by t he m anuf act urer. Failure to do so can resu lt

in p er so nal injur y.

Maint ain t he m achine. Check fo r m isalig nm ent o r

bin d ing of m ovin g p art s, b r eakag e o f part s and

any o t her condit ion t hat m ay affect the m achine’s

operation. If dam ag ed, have t he m ac hine repaired

bef ore u se. Many acc idents ar e caused b y p oorly

m aint ained eq uip m ent .

Keep t he eng ine and muff ler free of g rass, leaves,

excessiv e g r ease o r carb o n build up t o red uce t he

chance o f a fire hazard.

Keep c u t t ing t o o ls shar p and clean . Pro p erly

maint ained cut t ing t o o ls w it h sharp cut t ing ed g es

are less likely t o bin d and are easier t o cont rol.

Never d ouse o r sq uirt t h e unit w it h w at er or any

other liq uid. Keep handles dry , clean and f ree fro m

deb r is. Clean af t er eac h use.

Observ e p roper d isp o sal law s and reg ulat io ns for

gas, oil, et c. to p rot ect t h e environm ent .

St o r e id le m achine o u t o f t he reach o f children

and d o n o t allow ch ild r en o r p er so n s unfam iliar

w it h t he m achine o r t hese inst r uctions to op erat e

it . Machine is dangerous in t he hand s of untrained

users.

Service

Before c leanin g , rep air , insp ect ing , o r ad ju st in g ,

shu t off t he en g ine and m ak e c ert ain all m o v ing

parts hav e stopped. Alw ay s m ake sure the engine

switch is in its “OFF” po sit ion. Disconnect t he spark

plug w ir e, and keep t he w ir e aw ay fro m t he p lug

t o p r event ac cid ent al st ar t ing .

Have y o u r m ac hin e ser v iced b y q u alified rep air

personnel using only id entic al replac em ent parts.

Th is w ill ensu r e t hat t he saf et y of t he m achine

m aint ained .

Specific Safet y Rules

4

W alk-behind Tr act o r

Bef o re st ar t ing wo r k, r em o v e all fo r eig n m at t er

(sto nes, met al wires, rod s etc.) f rom t he area where

t he equipm ent is to b e used.

This machine has been designed and manuf actured

for bein g u sed b y o ne op erat or only.

Keep all b y st an d er s, c h ild r en, and p et s at least

23m (75 f eet ) aw ay. If you ar e ap proached , st o p

t he unit im m ediat ely.

W alk, never ru n w it h t h e machine.

A lw ay s o p erat e t he m ac hine from b ehind , never

pass or st and in front o f t he m ac hin e w h en t he

engine is running .

Diseng ag e all comm and lev er s bef ore starting t he

engine.

This unit has a clut ch. Squeeze t he clut ch cont r o l

lever an d ch eck t h at it r eturns aut o m at ically t o

the neut ral position. If it do es not , have unit adjusted

by a qualif ied rep air per sonnel.

Eng ag e the clutch g radually. Sud d en engagem ent

cou ld cause t he m achine to rear -up.

A lw ay s ho ld th e un i t w it h b o t h han d s w hen

operat ing . Keep a firm g rip on t he han d lebars. Be

aw are that t he machine may unexpect edly b ounce

up w ard or jump f o rw ard .

If t he unit st rikes a fo reig n object , stop t he eng ine,

disconnect t he spark p lug, thoro ughly inspect t he

m ac hine f o r any dam ag e, and repair the d amag e

bef ore r estart in g and operat ing t he m achine.

Use ex t rem e c aut ion w h en in r ever se or pulling

t he m achine t o w ard s y o u.

Do no t overlo ad t he machine’s cap ac ity.

Never op erate t he un it at hig h t ransport sp eed s

on har d or slip p ery surf ac es.

Exer cise ex t rem e caut ion w h en op erat ing on or

cro ssing g r av el d rives, w alks, or road s. St ay alert

f o r h id d e n h azar d s o r t raf f ic. D o no t c ar r y

passeng er s o r o b ject s.

Never leav e t he o p erat ing p o sitio n and leave t he

t ract o r unatt end ed w hen t he eng ine is running .

A lw ays st op t he eng ine and disengage t he Power

Takeoff d urin g m ovem en t t o and from t h e area

of w o r k.

Pay at t ent io n w hen reversing t he machine not t o

trip ov er anyt hing. If yo u loose your balance, release

t he hand lebar s im m ed iately , t h e d isengag em ent

w ill im m ediat ely st o p t he m achine.

Do no t t rav el d o w n hill w it h the clutch diseng ag ed

or the g ears in id le.

A lw ay s park t he unit on a f irm and level surfac e

and shut t h e tool o f f .

To red uc e exp o sure t o v ibrat ion, lim it t he hour s

of o p erat ion and t ake periodic breaks t o minim ize

rep et it io n and rest y o ur hand. Red uc e t h e sp eed

and force in which yo u do the repet it ive mo vement .

Tr y t o f ill each d ay w it h job s w h ere o p erat in g

hand - held pow er eq uipm ent is no t required .

5

W al k-b ehin d Tract o r

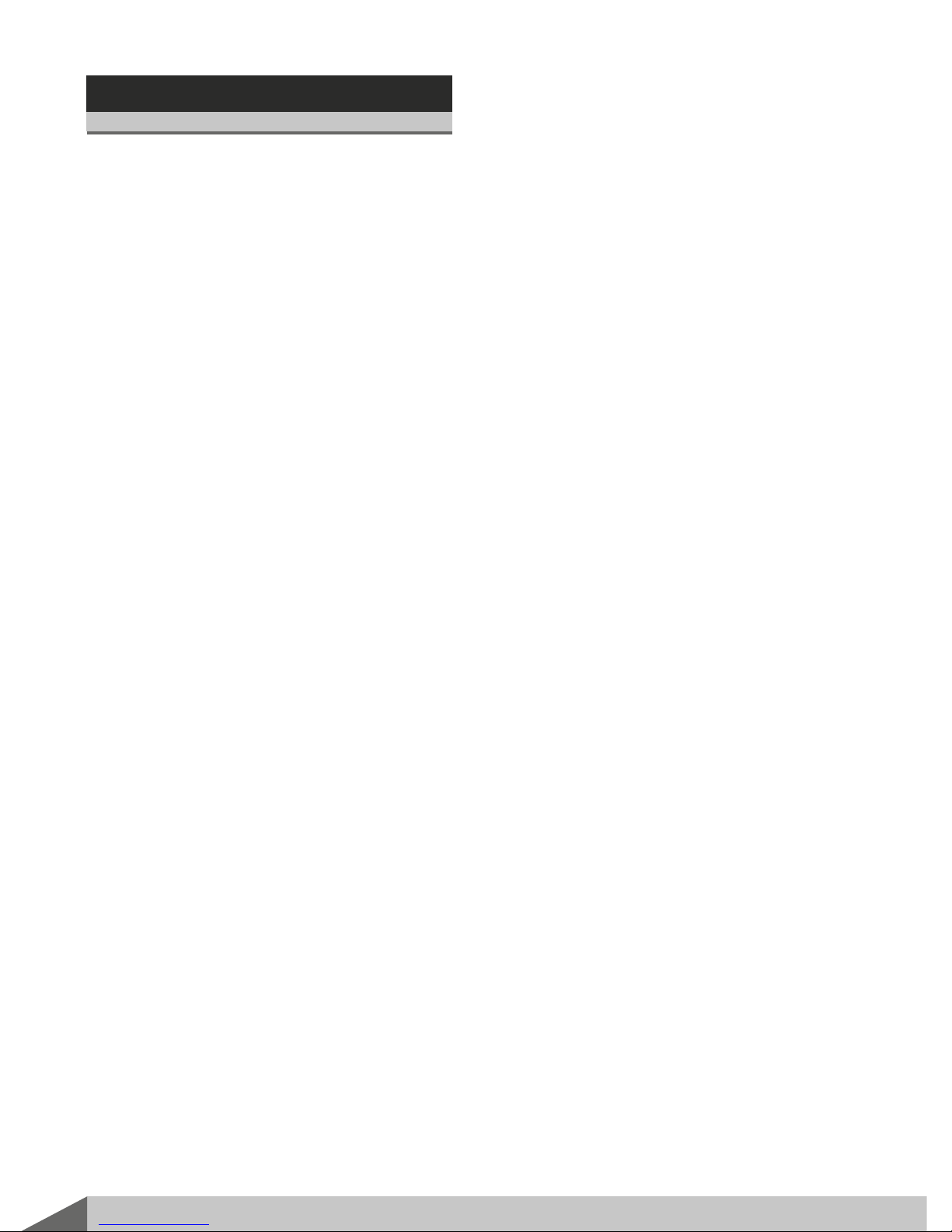

CONTENTS SUPPLIED

The w alk-behind tractor co m es part ially assembled

and is ship p ed in caref ully p acked cart on. After all

the part s hav e b een removed from the carton, you

sho uld have:

1

2

3

4

6

W alk-behind Tr act o r

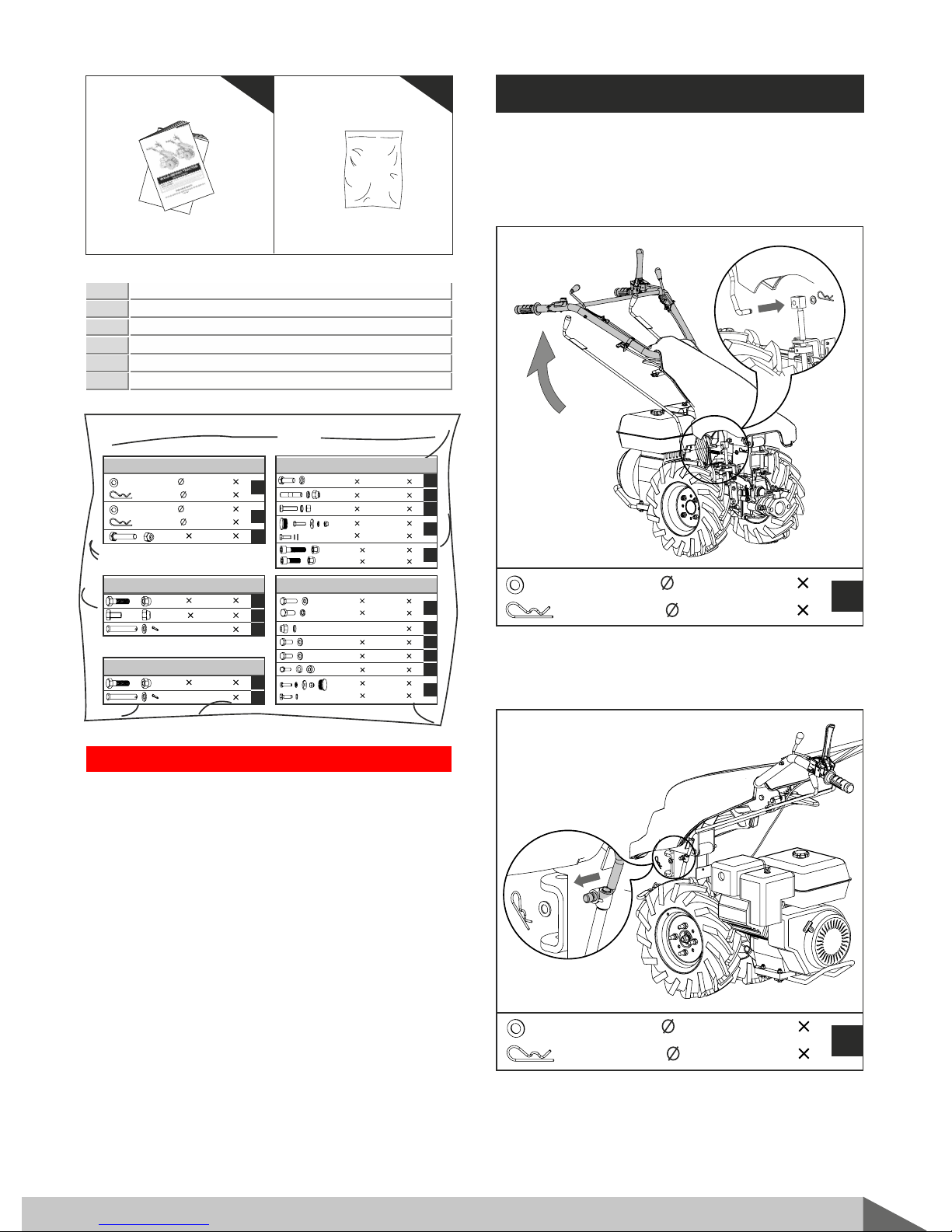

Car r ier A ssemb ly

MACHINE A SSEMBLY

Fo llow ing t he assembly d irec t ions b elow , you w ill

assem ble t he unit in a f ew minut es.

Unfold t he h andleb ar and inst all t he PTO ro d

as show n.

1.1

A

Mount t he shift r o d as show n.1.2

B

1

1

10

2

1

1

10

2

5 6

1 W al k-b ehin d t r act o r w it h Eng in e

2 Till er Im p lem ent s ( Opt ional )

3 Tr an sm issio n A ssemb ly (Op t ional )

4 Si ckl e Bar ( O p t i o nal)

5 Oper at o r ’s Manual & En g ine Manual

6 Hardw ar e Bag, in clu d ing

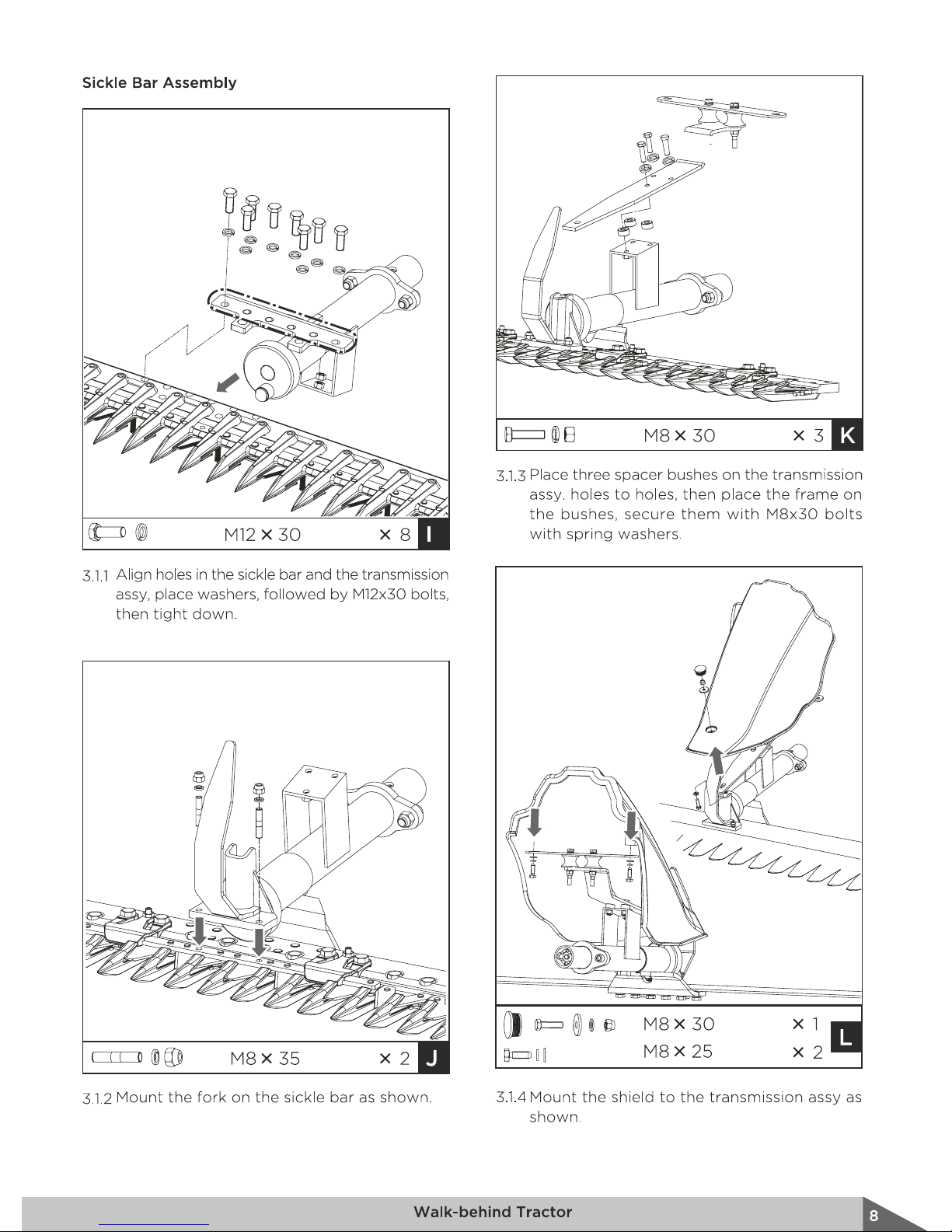

I

8M12 30

J

2M8 35

K

3M8 30

L

1M8 30

M8 25

2

M

2

2

M10 4 5

M10 30

N

2

M8 3 0

4

M8 2 5

O

2

M8

4

P

M8 2 0

Q

6M8 2 0

R

3M8 30

S

1M8 30

2M8 25

Sickle Bar ( 338 24 only)

Sickle Bar ( 338 26 3 38 33 )

Tille r (3 28 30 328 28)

D

E

F

1M8 30

4

2

M8 16

Tille r (3 28 23 only )

G

H

1M8 30

2

B

A

1

1

10

2

1

1

10

2

Tille r

C

2M8 45

Tractor is shipped without lubricant.

Always fill transmission before using

tractor. Even if unit is picked up from

local seller, it is your responsibility to

check transmission for lubricant

before use. Damage due to no or low

oil lever is not covered by warranty.

Transmission takes 1.6 liters of 75W90 lubricant.

32 82 3 only

32 82 3 only

7

W al k-b ehin d Tract o r

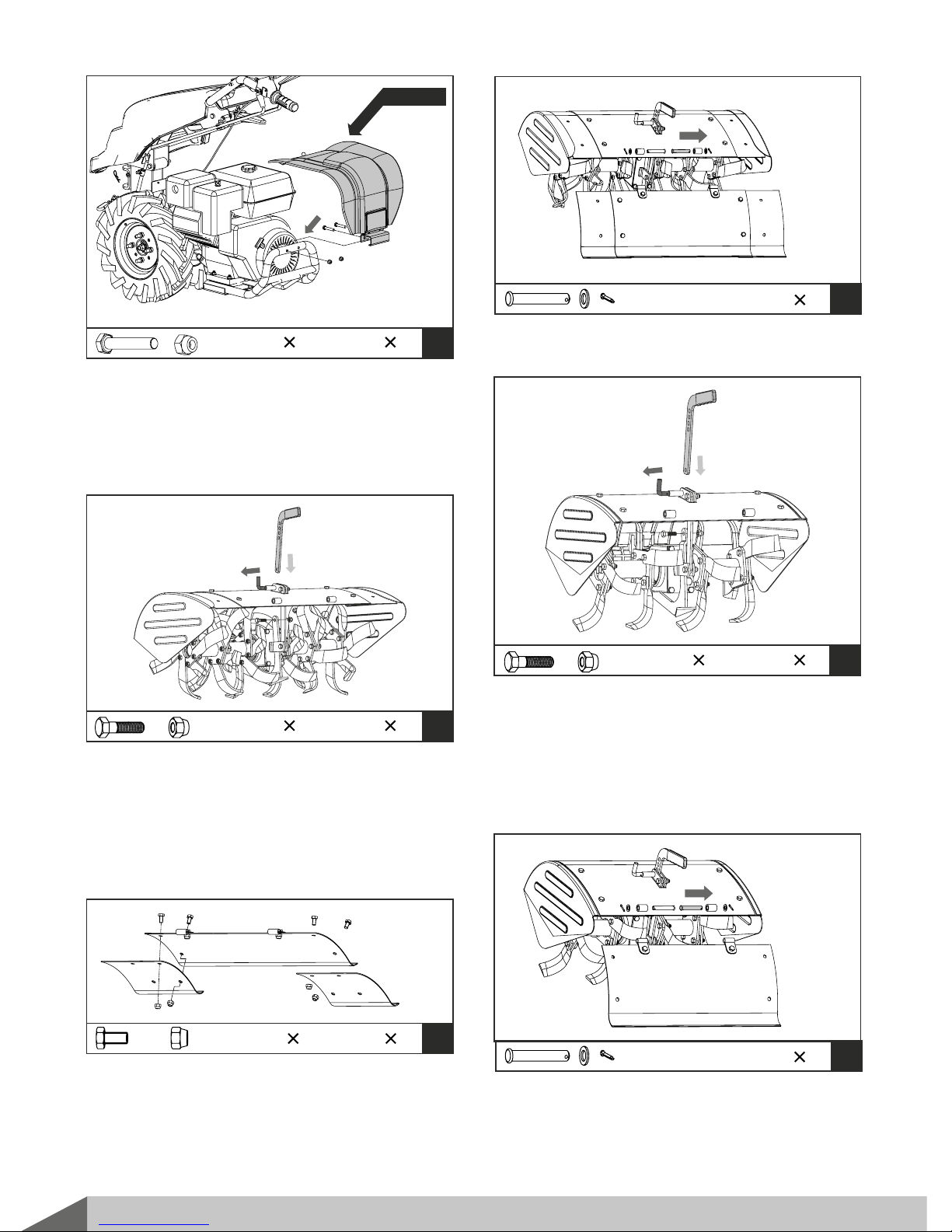

Mo unt t he shield as show n .2.1.3

F

Insert t h e d ep t h reg ulator ro d t hroug h h o le

in b racket f r o m the t o p d o w n w it h c urve t o

t he rear of t he unit and secure w it h a M8x30

screw and nut throug h t he holes in the bracket ,

passing t hrough t he d esired hole in t he dept h

regulat o r r o d .

2.2.1

G

Mo unt t he shield as show n .2.2.2

H

2

1M8 30

2

Tiller A ssem b l y

Insert t h e d ep t h reg ulator rod t hroug h h o le

in b racket f r o m t he t o p d ow n w it h c urve t o

t he r ear of t he unit and sec ure w it h a M8x30

screw and nut throug h t he ho les in the bracket ,

passing t hrough t he desired h ole in t he dept h

regulat o r r o d .

2.1.1

D

Align the holes in the shield and side extensions.

Combine t hem w it h M8x16 screw s and nut s.

2.1.2

E

1M8 30

4M8 16

C

2M8 4 5

OPTI ONAL

Line u p t h e holes in t he engine handle and

guard . Insert M8x45 screws from one side, and

tig hten dow n w ith nuts from t he ot her side.

1.3

Loading...

Loading...