Powr-Flite CAS16 User Manual

OPERATOR’S MANUAL & PARTS LIST

COMPACT AUTOMATIC SCRUBBER

Model CAS16

WARNING: OPERATOR MUST READ AND UNDERSTAND THIS MANUAL

©

Tacony, Inc., All rights reserved

COMPLETELY BEFORE OPERATING THIS EQUIPMENT.

CAS16-Man 7/2016

Save These Instructions

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

GROUNDING SCREW

GROUNDING

ADAPTER

*When using an electrical scrubber, basic precautions should be followed.

*Read all instructions before using your scrubber.

IMPORTANT SAFETY ADVICE

When using electrical equipment basic safety precautions should be followed including the following:

You must have training in the operation of this machine before using it.

Read all instructions carefully before use.

l Keep children and unauthorized persons away from the machine

when in use.

l Do not leave the machine plugged in when not in use.

l Switch the machine off before removing the plug from the outlet.

l When unplugging, pull the plug, not the cord.

l The machine must be unplugged prior to cleaning or servicing

the machine.

l Keep the power cord clear of moving parts.

l Do not run the machine over the power cord.

l Do not operate the machine with a damaged power cord or plug,

or if the machine malfunctions or is damaged in any way.

l Do not use where hazardous dust is present.

l Do not use in an explosive atmosphere.

l Do not use where flammable liquids or gasses are present.

l Do not use or pick up flammable chemicals or liquids with

this machine.

l Take care when using the machine near the top of stairs to avoid

overbalancing.

l Maintenance and repair must be done by authorized personnel only.

l Loose objects on the floor can become dangerous projectiles if struck

by the high-speed brush. Remove them before operating this machine.

l Wear suitable footwear to avoid slipping.

l Do not operate this machine in bare feet or with open-toed shoes

or sandals.

l Keep hands and feet well clear of the rotating brush.

l Do not smoke when using the machine.

l CAUTION:-This machine is for indoor use only and should not be

used or stored outdoors or in wet conditions.

TRANSPORTING THE MACHINE

OUTLET

GROUNDED

OUTLET BOX

( A )

CAUTION – This machine is heavy.

Do not attempt to lift the machine without assistance. Incorrect lifting

techniques may result in personal injury. It is recommended two people

lift the machine using a lifting point at the front and rear. DO NOT lift the

machine by the handle. Empty both the recovery and the solution tank

before lifting.

To move the machine to the work area, lock the handle and tilt it backwards to raise the front off the floor and wheel into position.

( B )

2

METAL

SCREW

( C )

TAB FOR

PREPARING FOR USE

Before connecting the machine to the power supply, check that the supply voltage corresponds with that marked on the rating label on the rear

of the machine.

IMPORTANT – If the power cord is damaged, it must only be replaced with

the appropriate type cord, available from the manufacturer.

Should an extension cord by used, ensure the cord rating is adequate

for the equipment. Do not use extension cord in coiled condition as this

could result in overheating of the cord.

WARNING: This machine must be grounded.

ADJUSTING THE HANDLE HEIGHT

1. Select the most comfortable handle height using the adjustment lever

on the handle and lock in position.

FILLING THE SOLUTION TANK

1. The solution tank can be filled on or off the machine. To fill the tank

off the machine the recovery tank must first be removed.

2. Remove vacuum hose and clear dome from recovery tank and lift

off tank.

3. Disconnect solution feed hose from solution

tank and lift tank off base. To release hose pull

connector collar forward.

4. Fill the solution tank with clean water using a

bucket, tap or hose, and an appropriate

measure of detergent.

5. Replace tanks on base and reconnect hoses.

Ensure solution hose is fully engaged and

captive in the connector allowing solution to

flow, thus preventing the pump from

overheating.

IMPORTANT – Only chemicals recommended by the manufacturer should

be used, i.e. low foaming, and follow the chemical manufacturer’s directions regarding use, handling, disposal and health and safety provisions.

The tank capacity is 4 gallons. Do not overfill the tank as spillage may

occur when in use.

IMPORTANT – When the

solution tank has emptied, switch off the

machine and empty the

recovery tank before

refilling the solution

tank.

2

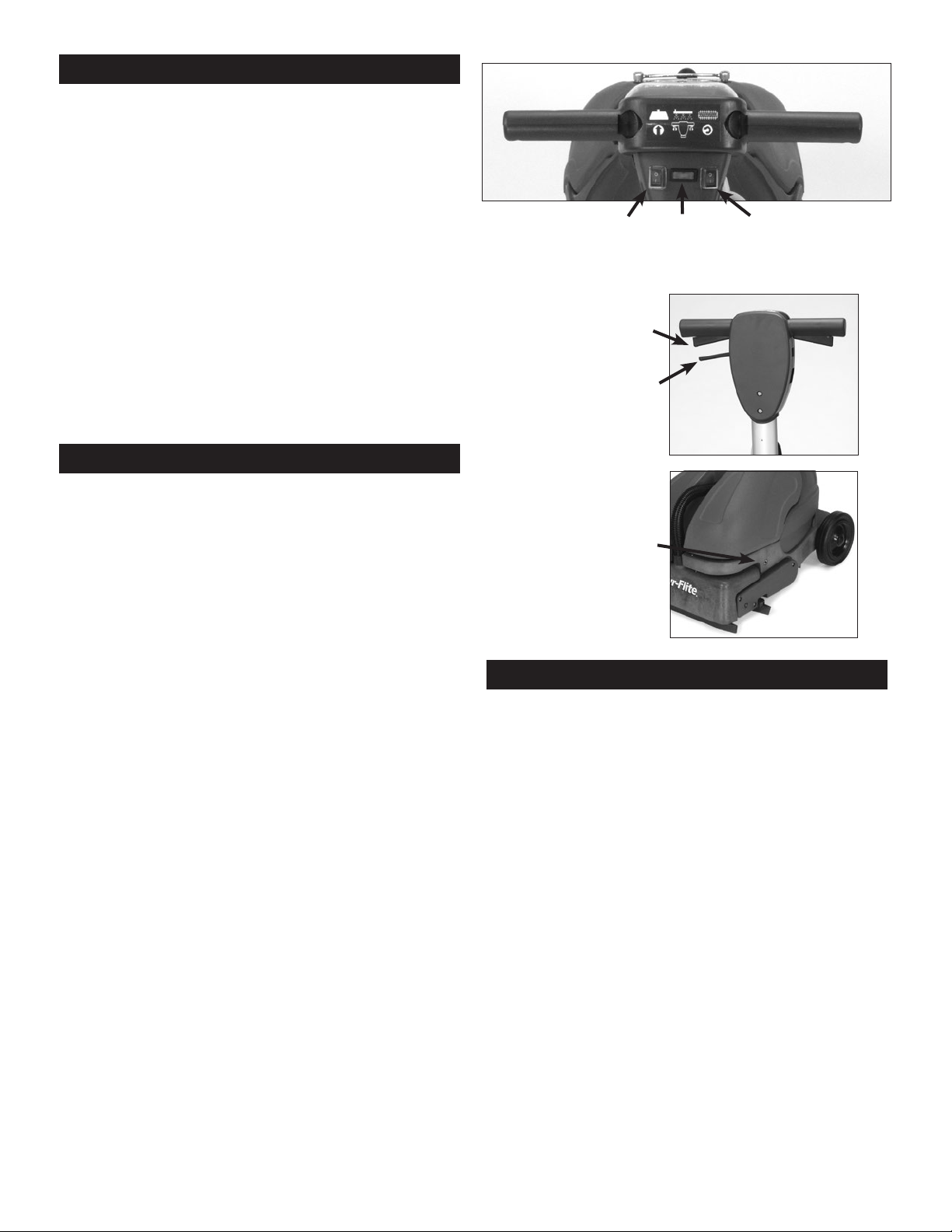

CONTROLS

The operating controls are located on the handle.

Brush motor switch

Used to switch motor ON and OFF. Lights when in the ON position.

Neon indicator

Lights when the machine is connected to the power supply

Vacuum motor switch

Used to switch motor ON and OFF. Provides suction at the squeegee.

Lights when in the ON position.

Solution feed triggers

Supplies cleaning solution to the brush head when squeezed.

Handle adjustment lever

Used to adjust handle to comfortable working height.

Solution feed triggers

Neon indicatorVacuum motor switch

Brush motor switch

Thermal reset button

Thermal protects brush motor from overheating. Press button once to

reset cut-out and restart motor.

OPERATION

STARTING THE MACHINE

1. Fully unwind the supply cord and plug in to a convenient socket outlet.

2. With the solution tank filled and the handle set at a comfortable height,

the machine is ready for use.

3. Switch ON the brush motor, followed by the vacuum motor.

4. Release cleaning solution at regular intervals by squeezing the

handle triggers.

WARNING – Always ensure adequate solution is on the floor. Scrubbing

without solution could damage the floor surface and/or the machine

brush. Keep the machine moving while the brush is rotating.

IMPORTANT – Should the brush stop rotating due to operation of the thermal reset button on the brush motor, switch the machine OFF and allow

to cool for a few minutes. Press the thermal reset button on left hand side

and restart the machine.

WARNING – If foam or liquid is emitted, switch off immediately and empty

recovery tank. Liquid emitted could be hazardous as a result of its temperature, or chemical content.

5. To stop the machine, release solution feed triggers, switch OFF brush

motor and then vacuum motor.

6. Normal movement of the machine is in a forward and backward

direction.

7. Proceed to operate the machine in the normal manner, releasing

cleaning solution as required.

8. For heavy soil, scrub floor with cleaning solution but with vacuum

motor OFF. Scrub floor again the pick up the solution.

9. When scrubbing is complete, unplug the machine from the power

supply, empty the solution tank and recovery tanks and clean and

dry the machine.

IMPORTANT – Dispose of unused cleaning solution in accordance with the

manufacturer’s directions.

Handle adjustment lever

Thermal reset button

MAINTENANCE

WARNING – Before undertaking maintenance operations or adjustments,

switch machine OFF and unplug from the electricity supply.

The machine requires minimum maintenance apart from the following

checks by a trained operator.

Power cord – regularly inspect sheath, plug and cord anchorage for

damage or loose connection. Only replace the power cord with the type

specified in these instructions.

Solution tank – check water flow, if restricted inspect tubing for blockage. Check that filter is clean and undamaged. A damaged filter must be

replaced.

Recovery tank – check condition and clean tank.

Squeegee blades – check condition and replace worn or damaged

blades.

Solution spray bar – remove the brush to access the spray bar. Check

that the solution feed holes are not blocked or restricted and clean as

necessary.

3

MAINTENANCE

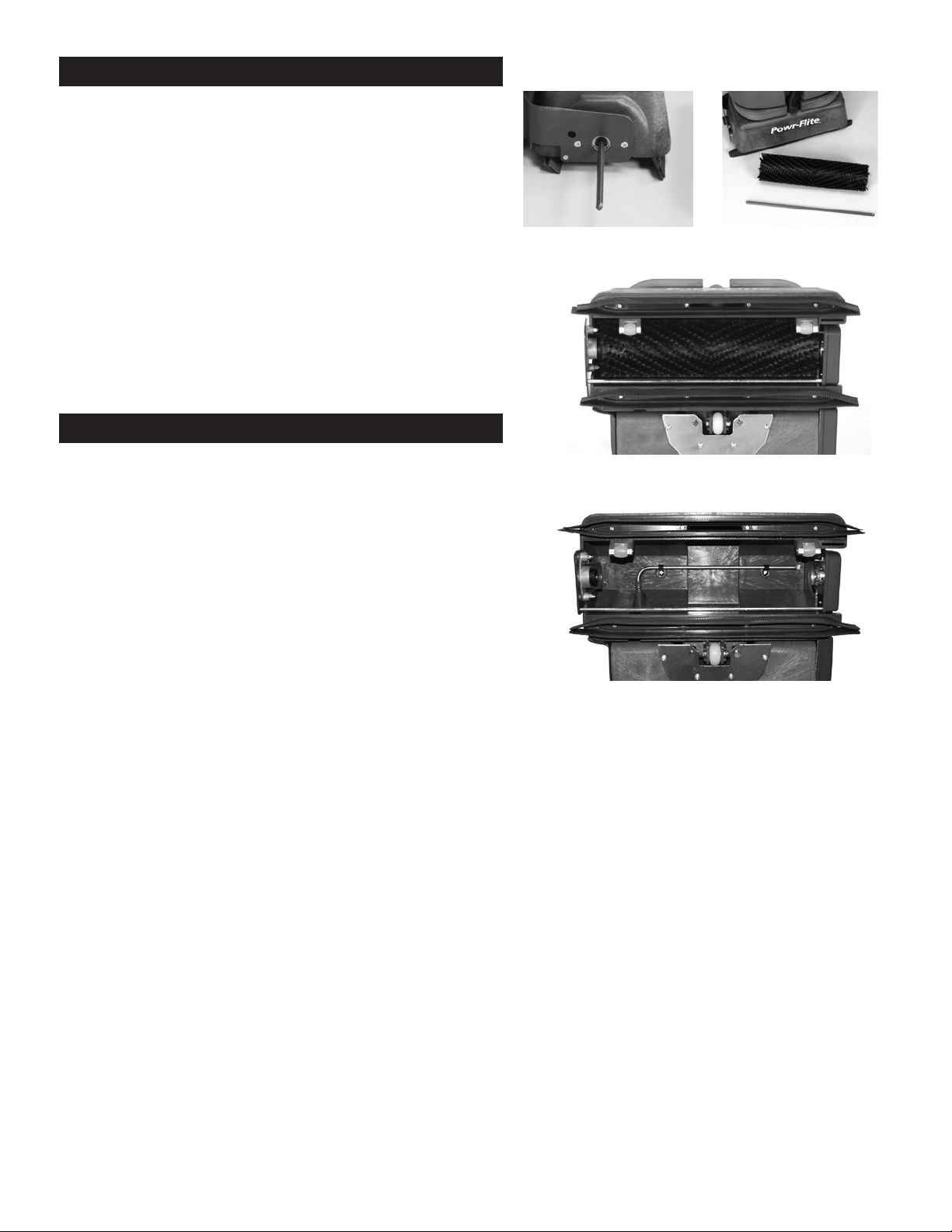

CHANGING THE BRUSH

WARNING – This has been designed for use with the brushes specified by the

manufacturer. The fitting of other brushes may affect its safety.

Always ensure machine is unplugged before fitting or removing parts.

1. To change the brush, first remove both the recovery and solution tanks.

2. Move handle to upright position, pull backwards and downwards to rest on

the floor with the base raised.

3. Push end of brush shaft with a finger and withdraw shaft completely.

4. Place new brush in position and insert shaft through brush until is clicks

into place.

5. Return machine to the floor, replace tanks and reconnect hoses, etc.

Changing squeegee blades

The squeegee blades are self adjusting for wear. However, when wet pick-up

becomes ineffective, or blades are damaged they should be replaced.

1. Raise machine base as for a brush change.

2. Slide squeegee blades out sideways from the holder.

3. Slide new blades into place with the ribbed side facing outwards.

4. Return machine to the floor, replace tanks and reconnect hoses.

STORAGE

Withdraw shaft completely.

1. When cleaning is finished, unplug the machine from the power supply and lift

off and empty the recovery and solution tanks over a suitable sink or drain.

2. Flush out the recovery tank with clean water.

3. Replace tanks and wipe the machine with a damp cloth. Wipe squeegee

blades clean.

IMPORTANT – Dispose of unused cleaning solution in accordance with the manufacturer’s directions.

4. Remove brush and wash in warm soapy water, rinse and allow to

dry naturally.

After use always wipe down and dry the machine and remove and clean the

brush. The solution tank and recovery tank should be emptied and flushed out

with clean water. When storing the machine for long periods, raise the base

to protect the brush and squeegee from possible distortion. Wrap power cord

around the handlebar and cable winder, ensuring that the plug is not trailing on

the floor. Fold handle down as necessary. Store the machine in a dry indoor

area only.

Slide squeegee blades out sideways from the holder.

Clean and inspect spray bar.

4

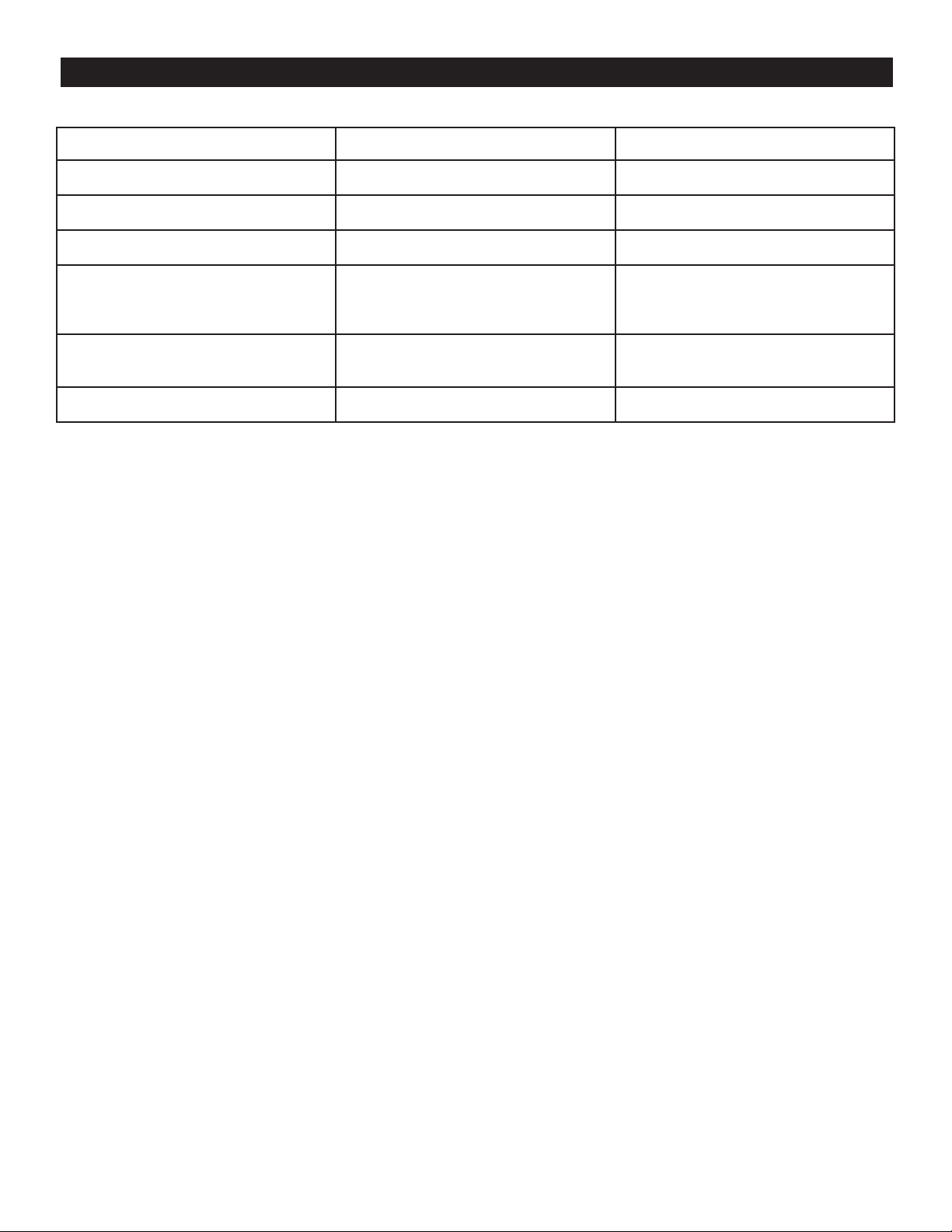

TROUBLESHOOTING

The following simple checks may be performed by the operator

Problem Reason Remedy

Machine not working, motors not running. Lack of voltage/electrical supply. Check supply cord, plug and socket outlet.

Vacuum motor not running, switch illuminated. Faulty motor. Contact service.

Brush motor running, but brush not rotating.

Cleaning solution not flowing.

Vacuum motor running but squeegee not

picking up.

Brush motor not running. Thermal reset button tripped. Check thermal reset button

Brush shaft incorrectly positioned. Loose or

broken drive belt.

Solution hose not correctly fitted to tank connector. Hose blocked. Waterways in spray bar

blocked. Solution tank empty. Blocked filter in

solution tank. Damaged pump.

Hose from squeegee blocked or split.

Squeegee slot blocked or blades damaged.

Vacuum dome out of position.

Refit shaft. Contact service.

Check connection is secure. Check and clear

hose, Check and clean spray bar. Refill tank.

Contact service.

Check and clear hose. Check and clean

squeegee. Reposition dome.

Contact service.

5

Loading...

Loading...