MODEL 8x

DOCUMENT BINDER

Service Manual

COPYRIGHT INFORMATION

Copyright Information

This document contains proprietary and confidential information of Powis Parker Incorporated (“Powis Parker”).

Copyright Powis Parker Incorporated 2004

All Rights Reserved.

No part of this document may be photocopied, reproduced in any form, or translated into another language without prior written

consent of Powis Parker, except as allowed under the copyright laws.

Warranty

The information contained in this document is subject to change without notice.

Powis Parker makes no warranty of any kind with respect to this information. Powis Parker specifically disclaims the implied warranty of

merchantability and fitness for a particular purpose.

PPI shall not be liable for any direct, indirect, incidental, consequential, or other damage alleged in connection with the furnishing or use

of this information.

Notice

Changes are periodically made to this document. Revisions, changes, any technical inaccuracies, and typographical errors will be

corrected in any subsequent editions.

ii FB8X Service Manual Rev. C, 9/28/10

CONTENTS

1 SUMMARY

2 OVERVIEW

2.1 Main Components of the FB8x

2.2 Diagram of the User Menu

2.3 System Block Diagram

2.4 Specifications

2.5 Bind Media

2.6 Getting the Best Bind Quality

2.7 Contacting Technical Support

3 REQUIRED SERVICE TOOLS

3.1 Hand Tools

3.2 Tools to Service the Heaters

3.3 Tools for Flash Upgrade of the Microcontroller

3.4 Tools needed to inspect the Controller Assembly

3.5 Cleaning Supplies

4 TROUBLESHOOTING

4.1 Power Problems

4.2 Error Messages

4.3 Machine Errors

4.4 Display Problems

4.5 Poor Bind Quality

5 SERVICE MENU

5.1 Accessing the Service Menu

5.2 Diagram of the Service Menu

5.3 Service Menu Descriptions

5.4 Testing and Calibration

5.4.1 Measuring the Heater Temperature

5.4.2 Checking the Sensors

5.4.3 Calibrating the Sensors, the Switches, and the Carriage Assembly

5.4.4 Entering the A_HI/A_LO values

5.4.5 Checking Motor Functions

5.4.6 Checking the Resistance of the Heater Sensors

5.4.7 Checking the Resistance of the Heater Power Connectors

FB8X Service Manual Rev. C, 9/28/10 iii

CONTENTS

6 SERVICE AND CALIBRATION PROCEDURES

(This section contains detailed procedures for removing and installing the specified component on the FB8x)

6.1 Covers

6.1.1 Left Cover

6.1.2 Right Cover

6.1.3 Front Cover

6.2 Cooling Rack

6.3 Controller Assembly

6.3.1 Inspecting the Controller Assembly

6.3.2 Removing and Installing the Controller Assembly

6.3.3 Changing the Fuses

6.4 Carriage Drive

6.5 Bender Drive

6.6 Sensors

6.6.1 Strip Present PCA

6.6.2 Book Emitter PCA

6.6.3 Book Detector PCA

6.7 Switches

6.7.1 Carriage Home Switch

6.7.2 Carriage Clamp Switch

6.8 Display

6.9 Heater Assemblies

6.9.1 Bender Assembly

6.9.2 Carriage Assembly (Back Heater)

6.9.3 Spine Assembly

6.10 Fan

6.11 Jaw Assembly

6.12 Replacing Grip Tape

7 UPGRADING FIRMWARE

7.1 Tools Required

7.2 Upgrading Firmware Procedure

8 SERVICE KIT PART NUMBERS

9 SERVICE KIT PICTURES

10 PICTURES OF FB8x PARTIALLY EXPLODED

iv FB8X Service Manual Rev. C, 9/28/10

SUMMARY

1

The newly redesigned Fastback Model 8x makes service and repair

easier than ever. While in outward appearance it looks very similar

to its predecessor, the Model 8 binder, you will find that beneath the

covers the binder has been dramatically simplified and improved. This

manual will guide you through the various routines needed to service

this machine. It will provide you with diagrams of the User Menu,

Service Menu, and Electrical Connectivity, as well as a complete list

of Service Parts and pictures of the machine partially exploded. This

manual will introduce you to the Service Menu and various functions

to test Heaters, Sensors, and Mechanisms. It will guide you through

the process of upgrading the Firmware using your computer. The

manual will provide you with a troubleshooting chart to quickly and

accurately diagnose and solve common problems, and it will tell you

how to perform routine service procedures, and how to disassemble

and reassemble the machine correctly and efficiently. In all, this

manual will tell you everything you need to know to keep the machine

binding and the customer happy.

The process by which the Model 8x binds documents has not

changed. The Model 8x has three heaters located in the binding

recess that heat the adhesive coating on the Lx-Strip or the spine on

the Halfback Cover, and adhere it to the spine, front, and back of the

document. These three heaters are called the Bender Heater, the

Spine Heater, and the Back Heater. They have been upgraded from

the previous versions with additional temperature sensing elements

that will allow the heaters to better regulate temperature.

The Model 8x binder has two sensors, the Book Sensor and the

Strip Sensor, designed to detect the presence of the document and

the strip when they are inserted in the binding recess. While the

Book Sensor determines only the presence of the book, the Strip

Sensor will sense the presence of a strip and determine whether you

are using the correct width strip for the document you are binding.

The binder is also equipped with encoders and switches that

determine the thickness of the document you are binding and the

pressure the Carriage Assembly must clamp the document to achieve

the best possible bind without overexerting the motors or any of the

other mechanical parts.

After giving the new Model 8x a few test binds you will find that the

improvements made to the binder will provide the customer and the

service technician with a machine that is both easy to use and easy to

service.

FB8X Service Manual Rev. C, 9/28/10 Page 1

2

OVERVIEW- Main Components

2.1 MAIN COMPONENTS OF THE FB8x

Left Side Cover

Tamping Platform

Front Cover

Cooling Rack

Right Side Cover

(Binder with Book Fences removed.)

LCD Display

Bender Link

Assembly

Right Bender Pivot

Bender Gear

Book Sense Detector PCA

(located inside the Carriage Assembly)

Jaw Guide

Jaw Spring

Carriage Spring

Carriage Home Switch

Carriage Drive Assembly

Jaw Spring

Spine Spring

Left Carriage Guide

Jaw Guide

Carriage Alignment Plate

Page 2 FB8X Service Manual Rev. C, 9/28/10

Left Bender Pivot

OVERVIEW- Main Components

2

2.1 MAIN COMPONENTS OF THE FB8x

Book Sense Emitter PCA

Bender Motor

Assembly

Bender Heater

Strip Detector PCA

(Picture shows Tamping Platform partially removed.)

FB8X Service Manual Rev. C, 9/28/10 Page 3

OVERVIEW- Main Components

2

2.1 MAIN COMPONENTS OF THE FB8x

Carriage Assembly

(Back Heater)

Cooling Platen

Spine Heater

Carriage Spring

Carriage Clamp Switch

(Picture shows Cooling Rack and Left Cover removed.)

Page 4 FB8X Service Manual Rev. C, 9/28/10

OVERVIEW- Main Components

2

2.1 MAIN COMPONENTS OF THE FB8x

CONTROLLER ASSEMBLY

Strip Present Emitter

Microcontroller

J10

J8

J11 J2

J3 J1

J4

J5

J6

J7

Serial Port

Fuses

J1 Spine Heater Temp Sensor Connector

Transformer

Power Entry Module

FB8X Service Manual Rev. C, 9/28/10 Page 5

J2 Bender Heater Temp Sensor Connector

J3 Back Heater Temp Sensor Connector

J4 Motors Connector

J5 Spine Heater Power Connector

J6 Bender Heater Power Connector

J7 Back Heater Power Connector

J8 Motors and Carriage Sensors Connector

J10 LCD Connector

OVERVIEW- User Menu

USER MENU

L-STRIP

SPINE BIND TIME

LANGUAGE

STRIP MODE

COVER BIND TIME

HALFBACK

PERFECTBACK LF

PERFECTBACK PS

EDIT MODE

SETTINGS

L-STRIP ON

L-STRIP OFF

-1 SECONDS

+0 SECONDS

+1 SECONDS

+2 SECONDS

+3 SECONDS

+4 SECONDS

-5 SECONDS

+0 SECONDS

+5 SECONDS

+10 SECONDS

+15 SECONDS

+20 SECONDS

-2 SECONDS

+5 SECONDS

DUTCH

DEUTSCH

FRANCAIS

ITALIANO

ESPAÑOL

NORSK

ENGLISH

SVENSKA

DANSK

SETTING LANGUAGE:

WRAPAROUND, NO "EXIT"

OPTION

SETTING SPINE BIND TIME:

NO WRAPAROUND, NO "EXIT"

OPTION

SETTING COVER BIND TIME:

NO WRAPAROUND, NO "EXIT"

OPTION

This item is present only

if the STRIP MODE is

"L-STRIP ON"

Lx-STRIP

Lx-COMP STRIP

EXIT

EXIT

EXIT

2

2.2 User Menu

Page 6 FB8X Service Manual Rev. C, 9/28/10

OVERVIEW- System Block Diagram

2

2.3 System Block Diagram

FB8X Service Manual Rev. C, 9/28/10 Page 7

OVERVIEW- Specifications

2

2.4 Specifications

Power Requirements:

Power Consumption:

Recommended Operating

Temperature and

Humidity:

Weight:

Dimensions:

Bind Capacity:

Duty Cycle:

FB8x: 115V (110-125VAC) 50-60 Hz, 8.4 Amps

FB8xE & FB8xA: 230V (220-240VAC) 50-60 Hz, 4.2 Amps

FB8xJ: 100V (90-110VAC) 50-60 Hz, 9.5 Amps

FB8x: 950 Watts while binding, 55 Watts standby

FB8xE & FB8xA: 950 Watts while binding, 55 Watts standby

FB8xJ: 950 Watts while binding, 55 Watts standby

15 to 35 degrees (C), 59 to 95 degrees (F)

Humidity Range: 5 to 80% RH non condensing

17 lbs

With book fences attached: 19.3” W x 11.1” H x 12.5” D

Without book fences attached: 19.3” W x 6.0” H x 10.6” D

Lx-Strip

.04” to 1.0” (1 mm to 25 mm), about 10-250 sheets.

10-125 sheets = Narrow Lx-Strip

126-250 sheets = Medium Lx-Strip

L-Strip .04” to 0.7” (1 mm to 18 mm), about 10-175 sheets.

10-80 sheets = Narrow L-Strip

81-175 sheets = Medium L-Strip

Not compatible with Wide L-Strip.

Halfback covers .04” to 0.8” (1 mm to 20 mm), about 10-200 sheets.

10-100 sheets = Narrow Halfback

101-200 sheets = Medium Halfback

Does not work with Wide Halfback Covers.

Perfectback Strips .04” to 1.0” (1 mm to 25 mm), about 10-250 sheets.

10-125 sheets = Narrow Perfectback Lx-Strip

126-250 sheets = Medium Perfectback Lx-Strip

500 binds per month average

Bind Speed:

Safety Certications:

Page 8 FB8X Service Manual Rev. C, 9/28/10

35-55 seconds

UL60950

IEC60950/EN60950

OVERVIEW- Bind Media

2

2.5 Bind Media

The newly redesigned Model 8x Binder is capable of binding the following strips:

Lx-Strip

Lx-Comp Strip

L-Strip

Halfback Covers (Narrow and Medium only)

Perfectback® PS Strips

Perfectback

Selecting the Binding Mode

To bind with any of these various binding strips, enter the User Menu and select the

binding strip you wish to bind with.

Bind Memory

When the machine is turned off and on, the last bind setting will be retained.

(Narrow and Medium only)

® LF Strips

Binding Widths

The Model 8x binder is not compatible with wide L Strips or wide Halfback Covers.

(See 2.5 Specifications).

Binding Hard Cover Books

Use Lx-Strip or L-Strip to bind book blocks to be made into Hard Cover Books.

FB8X Service Manual Rev. C, 9/28/10 Page 9

OVERVIEW- Getting the Best Bind Quality

2

2.6 Getting the Best Bind Quality

• Before binding, make sure the binder is set in the correct binding mode.

• Before placing the strip into the binding recess, fold the strip in 90° angle making

sure the adhesive side faces inward

• Place the strip into the binding recess with the adhesive side facing up. The short

side of the bent “L” should be resting against the back wall. Slide the strip all the

way to the right of the machine.

• Before binding, tap the pages several times to ensure that they are even when the

document is in the binding recess. The right edge of the strip and right edge of the

document should line up and be justified against the right side of the binding recess.

• The grain of the paper should run parallel to the binding edge of the document. All

paper has a grain — it is a result of the fibers that make up the paper. If the grain

runs parallel to the long side of the sheet, the paper is “grain long”. When the grain

runs parallel to the short side of the paper, it is “grain short”.

.

A sheet of paper will naturally flex more easily along the direction of its grain. Try

it and see. (Hold a piece of paper the long way lightly in your fingertips and gently

bow the paper, allowing it to flex. Now try it the other way. See the difference?

Most copy papers are grain long, so you should not have any problems with the

bind. Grain long paper will give you the best bind. Occasionally you may find papers

that are grain short, so we recommend you test unfamiliar papers before binding

large numbers of documents.

• Coated papers, and papers with heavy ink or toner coverage may also experience

problems with binding. If you have documents with heavy ink or toner coverage,

always do a test bind first to ensure that your documents will bind properly.

• After the binding cycle, be sure to place your document entirely upright, with the

bound side down, against one of the two rear book support fences for five minutes.

Improper cooling of your document may result in a crooked spine. Bind strength

reaches the maximum strength after 24 hours.

• NOTE: When placing multiple documents on the Cooling Rack, make sure it

doesn’t get overloaded to where the front document hangs off the metal step.

MAINTENANCE TIP : Minor glue buildup on the heaters is expected. When

cleaning the heaters, turn the machine off and unplug it. Wait for the heaters to

cool, and then wipe off any glue using a clean dry lint free cloth. Cleaning solution is

not necessary.

(Caution: The heaters are very delicate. Do not use anything sharp to remove glue

from the clamps, platen, or interior surfaces of the binder. )

Page 10 FB8X Service Manual Rev. C, 9/28/10

OVERVIEW- Technical Assistance

2

2.7 Contacting Technical Support

If there are any questions not answered in this manual, please contact the

Powis Parker Technical Support Dept: 510-848-2463.

FB8X Service Manual Rev. C, 9/28/10 Page 11

OVERVIEW

2

THIS PAGE IS INTENTIONALLY LEFT BLANK

Page 12 FB8X Service Manual Rev. C, 9/28/10

REQUIRED SERVICE TOOLS

3

When servicing a Model 8x binder the following tools are required:

3.1 HAND TOOLS

Phillips Screwdrivers #1 and #2

Needle Nosed Pliers

Diagonal Cutters

Fuse Puller

2.5mm Hex Key

Pen

Exacto Knife

3.2 TOOLS TO SERVICE THE HEATERS

Temperature Meter (

K-820-011)

Straight Temperature Probe (K-820-012)

Right Angle Temperature Probe (K-820-3436)

Ohmmeter

3.3 TOOLS FOR FLASH UPGRADE OF FIRMWARE

P31 Printer Cable (K-551-1685)

PC with either Windows 98, 2000, XP, or ME, and a 9-pin com port

Internet Access

3.4 TOOLS NEEDED TO INSPECT THE CONTROLLER ASSEMBLY

Ground Strap

3.5 CLEANING SUPPLIES

Citrus Cleaning Solution (K-212-001)

Lint Free Cloth

FB8X Service Manual Rev. C, 9/28/10 Page 13

TROUBLESHOOTING GUIDE

4

4.1 Power Problems

• NO POWER

Possible Cause Solution

Power Cord is not securely plugged in. Check that the Power Cord is securely plugged into the

Electrical outlet is not functioning. Plug the machine into another electrical outlet.

Machine is plugged into the wrong voltage outlet. Use the correct voltage outlet to power the machine.

Wire Harness connections are loose. Check that all wire connectors are securely

Blown Fuse. Check fuses on the Controller Assembly and

Failed Controller Assembly. Replace the Controller Assembly.

• POWER FLICKERS ON AND OFF

machine and into the outlet in the wall.

plugged into the Controller Assembly.

replace if any are blown.

Possible Cause Solution

A 230v machine in plugged into a 115v outlet. Plug the machine into a 230v outlet.

Failed Controller Assembly. Replace the Controller Assembly.

• BACKLIGHT COMES ON, NOTHING ELSE HAPPENS

Possible Cause Solution

A 230v machine in plugged into a 115v outlet. Plug the machine into a 230v outlet.

See the “NO POWER” troubleshooting table above.

• WHEN TURNED ON, THE MOTORS MOVE BUT NOTHING IS ON THE DISPLAY

Possible Cause Solution

A problem with the display. See troubleshooting section 4.4 “Display Problems”.

• FUSES BLOW REPEATEDLY

Possible Cause Solution

Short circuit in heaters. Check the resistance of the Heaters. See Section

5.4.7 “Checking the Resistance of the Heater Power

Connectors”.

Short in the Controller Assembly. If none of the heaters have shorted out, the

problem lies in the Controller Assembly. Replace

the Controller Assembly.

Page 14 FB8X Service Manual Rev. C, 9/28/10

• Error Message: “INSERT BOOK”

Possible Cause Solution

TROUBLESHOOTING GUIDE

4

4.2 Error Messages

The operator pressed the Bind button without inserting a

book into the binding recess.

The sheets are not fully justified against the right side of the

binding recess.

The Book Sensor is damaged. Replace the Book Sensor.

Failed Controller. Replace the Controller

• Error Message: “USE SMALLER SIZE”

Possible Cause Solution

The strip is too wide for the amount of sheets placed in the

binding recess.

The strip is not folded. Make sure to fully fold the strip into a 90 degree angle.

The strip is not lined up properly. Make sure the strip and the sheets are justified against

The machine is configured to bind the new Lx-Strip and

you tried to bind using the original type L-Strip.

Place a book into the machine and then press the Bind

button.

Tap the edges of the sheets until the book is flush

against the right side of the binding recess prior to

pressing the BIND button.

Add more sheets or use a narrower width strip.

the back of the binding recess.

In settings, select the L-STRIP ON menu option in the

STRIP MODE Settings menu.

• Error Message: “BOOK TOO THICK”

Possible Cause Solution

You are trying to bind too many sheets with the medium strip. Remove some sheets.

• Error Message: “USE MEDIUM SIZE”

Possible Cause Solution

You are trying to bind too many sheets with a narrow strip. Remove some sheets or use a medium width strip.

There is no strip in the binding recess. Insert a medium strip.

• Error Message: “USE NARROW SIZE”

Possible Cause Solution

You are trying to bind too few sheets with a medium strip. Add some sheets or use a narrow width strip.

There is no strip in the binding recess. Insert a narrow strip.

• Error Message: “REVERSE STRIP”

Possible Cause Solution

The strip is inserted into the machine backwards. Make sure the short end of the strip is vertical and the

long end of the strip is flat.

Make sure the strip is flat. An over folded or curled strip

can cause a “Reverse Strip” error.

FB8X Service Manual Rev. C, 9/28/10 Page 15

TROUBLESHOOTING GUIDE

4

4 . 3 M a c h i n e E r r o r s

• Error Message: MACHINE ERROR 11, 21, or 31

This error indicates an under-temp error in one of the heaters.

Possible Cause Solution

Heater sensor leads are not plugged in correctly. Check that the connectors J1, J2, and J3 are plugged in

Heater sensor malfunction. Check the resistance of the Heaters. See Section 5.4.6

Machine is extremely cold. The FB8x is not designed to function below 0°C/32°F.

Failed Controller Assembly. Replace the Controller Assembly.

• Error Message: MACHINE ERROR 12, 15, 22, 25, 32, or 35

This error indicates an over-temp error in one of the heaters.

correctly.

“Checking the Resistance of the Heater Sensors”.

Possible Cause Solution

Heater sensor leads are not plugged in correctly. Check that the connectors J1, J2, and J3 are plugged in

correctly.

Heater sensor malfunction. Check the resistance of the Heaters. See Section 5.4.6

“Checking the Resistance of the Heater Sensors”.

Heater calibration is inaccurate. Recalibrate the heaters. See Section 5.3.2 “Cal Heaters”.

Heater A_HI/A_LO INPUT values are incorrect. Verify the A_HI/A_LO values on the heater tags match

the values in the A_HI/A_LO INPUT menu. See section

5.4.4.

Failed Controller Assembly. Replace the Controller Assembly.

• Error Message: MACHINE ERROR 13, 14, 23, 24, 33, or 34

This error indicates a problem with the heater temperature settings.

Possible Cause Solution

Heater calibration is inaccurate. Recalibrate the heaters. See Section 5.3.2 “Cal Heaters”.

Heater A_HI/A_LO INPUT values are incorrect. Verify the A_HI/A_LO values on the heater tags match

the values in the A_HI/A_LO INPUT menu. See section

5.4.4.

Failed Controller Assembly. Replace the Controller Assembly.

Page 16 FB8X Service Manual Rev. C, 9/28/10

TROUBLESHOOTING GUIDE

4

4 . 3 M a c h i n e E r r o r s

• Error Message: MACHINE ERROR 50

This error occurs when a user tries to bind a book and the carriage does not move.

Possible Cause Solution

Carriage Motor/Carriage Assembly is jammed or obstructed. Remove any obstructions that may cause the Carriage

Assembly to jam.

Carriage Motor is burnt out. Replace the Carriage Motor if it is burnt out.

Carriage Home Switch or Carriage Clamp Switch problem. Check the functionality of the Carriage Home Switch

and the Carriage Clamp Switch. See Section 5.4.2

“Checking the Sensors”. Replace the Switches if

necessary.

Failed Controller Assembly. Replace the Controller Assembly.

• Error Message: MACHINE ERROR 51

This error indicates a carriage jam.

Possible Cause Solution

Carriage Clamp Switch or Carriage Home Switch failure. Check the function of both switches in the CHECK

SENSORS menu. Replace any damaged switches.

Obstructions in the binding recess. Check for obstructions in the binding recess. If

necessary remove the Carriage Assembly to check for

any obstructions.

• Error Message: MACHINE ERROR 52

This error indicates a problem with the Carriage Home Switch.

Possible Cause Solution

An obstruction prevents the Carriage Assembly from

returning to its home position.

Carriage Home Switch failure. Check the functionality of the Carriage Home Switch.

Failed Controller Assembly. Replace the Controller Assembly.

Remove any obstructions.

See Section 5.4.2 “Checking the Sensors”. Replace the

Switch if necessary.

• Error Message: MACHINE ERROR 60 or 61

This error indicates a problem with the line voltage.

Possible Cause Solution

Electrical supply is not 50 Hz or 60 Hz. Switch to a regulated power supply.

Failed Controller Assembly. Replace the Controller Assembly.

FB8X Service Manual Rev. C, 9/28/10 Page 17

TROUBLESHOOTING GUIDE

4

4 . 3 M a c h i n e E r r o r s

• Error Message: MACHINE ERROR 70-75

This error indicates a problem with the A_HI/A_LO values entered into the machine.

Possible Cause Solution

Heater A_HI/A_LO values are incorrect. Verify the A_HI/A_LO values on the heater tags match

Failed Controller Assembly. If the error reoccurs after the A_HI/A_LO values have

• Error Message: MACHINE ERROR 80-82

This error indicates a problem with the EEPROM.

Possible Cause Solution

the values in the A_HI/A_LO INPUT menu. See section

5.4.4.

been reentered, the Controller Assembly has failed.

Replace the Controller Assembly.

Firmware/EEPROM mismatch. Upgrade the firmware as shown in Section 7.

• Error Message: FIRMWARE ERROR

Possible Cause Solution

Firmware is corrupted or the firmware transfer was

interrupted.

Failed Controller Assembly. Replace the Controller Assembly.

Perform the Flash Upgrade again with the current

firmware.

Page 18 FB8X Service Manual Rev. C, 9/28/10

TROUBLESHOOTING GUIDE

4

4.4 Display Problems

• NO CHARACTER DISPLAYED

Possible Cause Solution

Display is not connected. Reconnect the Display.

Failed Display Replace the Display.

Failed Controller Assembly. Replace the Controller Assembly.

• INCORRECT DISPLAY

Possible Cause Solution

Failed Display. Replace the Display.

Failed Controller Assembly. Replace the Controller Assembly.

• NO BACKLIGHT

Possible Cause Solution

Failed Display. Replace the Display.

Failed Controller Assembly. Replace the Controller Assembly.

FB8X Service Manual Rev. C, 9/28/10 Page 19

TROUBLESHOOTING GUIDE

4

4.5 Poor Bind Quality

• SPINE IS NOT SQUARE

Possible Cause Solution

The Strip is not folded in a 90 degree angle. Fold the Lx-Strip into a 90 degree angle. The

The book was not placed in the Cooling Rack after being

bound.

• PAGES PROTRUDE PAST THE STRIP

Possible Cause Solution

The edges of the pages are not even. Tap on the top and left sides of the pages until

better you fold the strip the more square the

spine will be.

After binding, make sure the book is placed in the

Cooling Rack to properly cool down.

the edges are even.

The Strip is not flush against the right side of the binding

recess.

• BIND QUALITY IS UNSATISFACTORY

Part of the pages separate from the strip

There are gaps in the pages where the strip can be seen

There is Thermo-plastic adhesive leakage.

Possible Cause Solution

The machine is not set to the correct binding style. Verify the machine is set to the correct binding style.

• PAGES DO NOT ADHERE TO THE STRIP VERY WELL

Possible Cause Solution

Some paper stocks and some heavy cover material can be

difficult to bind.

Make sure the strip is flush against the right side of the

binding recess.

The bind may be improved by increasing the Spine Bind

time in the Setting Menu.

Page 20 FB8X Service Manual Rev. C, 9/28/10

TROUBLESHOOTING GUIDE

4

THIS PAGE IS INTENTIONALLY LEFT BLANK

FB8X Service Manual Rev. C, 9/28/10 Page 21

THIS PAGE IS INTENTIONALLY LEFT BLANK

Page 22 FB8X Service Manual Rev. C, 9/28/10

SERVICE MENU

5

5.1 Accessing the Service Menu

To access the Service Menu press the OPEN and MENU buttons at the same time while

turning the machine on. Keep the buttons pressed until SYSTEM CHECK appears on the display. After

SYSTEM CHECK appears on the screen, an OK message should appear, followed by the date of the

currently installed firmware. After a couple seconds, AUTO-CYCLES will appear.

5.1.1 Navigating through the Service Menu.

Use the orange OPEN and MENU buttons to toggle through the menu options.

Use the green BIND button to select the menu option currently displayed.

5.1.2 Warnings!

Be very careful when navigating through the Service Menu. Altering any of the settings

can greatly affect the performance of the machine.

FB8X Service Manual Rev. C, 9/28/10 Page 23

SERVICE MENU

5

5.2 Service Menu Diagram

Page 24 FB8X Service Manual Rev. C, 9/28/10

SERVICE MENU

5

5.2 Service Menu Diagram

FB8X Service Manual Rev. C, 9/28/10 Page 25

SERVICE MENU

5

5.3 Service Menu Descriptions

5.3.1 AUTOCYCLES

This option offer two choices for continuous cycling of the machine. It is recommended the while running

in either Autocycle mode, that a book or pages be inserted into the binding cavity, secured to the Book Fence with tape.

Note: Do not use a strip! If you are running continuous cycles, glue will leak out of the ends of the strip, dirtying up the

heaters.

STANDARD

To stop the binder, press the OPEN button when the Carriage returns to the home position and the display says

AUTOCYCLES, otherwise the binder will automatically stop the Autocycling after 500 cycles.

FAST

Selecting this menu option causes the machine to go through full length binding cycles at normal speed.

the OPEN button when the Carriage returns to the home position and the display says AUTOCYCLES,

otherwise the binder will automatically stop the Autocycling after 500 cycles.

Selecting this menu option causes the binder to go through continuous, fast-speed cycles. To stop the cycling, press

NOTE: To stop Autocycling at any point of the cycle, turn the machine off.

5.3.2 CALIBRATION

This option allows you to calibrate the Book Sensor, the Strip Sensor, the Carriage Assembly, and the Heaters.

CAL BOOK SENSOR

Selecting this menu option will allow you to calibrate the Book Sensor only. When calibrating the Book Sensor

make sure there is nothing in the binding recess. If the calibration is successful, a result number will appear followed

by the message “SUCCESS”. If the calibration is unsuccessful, a failure massage will appear. For more details, see

section 5.4.3, Calibrating the Book Sensor.

CAL STRIP SENSOR

sure there is nothing obstructing the small crescent shaped hole in the Spine Heater. If the calibration is successful,

a result number will appear followed by the message “SUCCESS”. If the calibration is unsuccessful, a failure message

will appear. For more details, see section 5.4.3, Calibrating the Strip Sensor.

Selecting this menu option will allow you to calibrate the Strip Sensor only. When calibrating the Strip Sensor make

CAL CARRIAGE

Selecting this menu option will allow you to calibrate the Carriage Assembly only. When calibrating the Carriage

Assembly make sure there is nothing in the binding recess. If the calibration is successful, a result number will

appear followed by the message CAL SAVED!. If the calibration is unsuccessful, a failure message will appear. For

more details, see section 5.4.3, Calibrating the Carriage Assembly.

Page 26 FB8X Service Manual Rev. C, 9/28/10

SERVICE MENU

5

5.3 Service Menu Descriptions

CAL HEATERS

Heaters it is very important that the Heaters are at room temperature. If the calibration is successful, the

display will read SUCCESS. If the calibration is unsuccessful, a failure message will appear on the display.

SHOW CALIBRATION

toggle through the list of values.

BOOK: XX OK/NG

This menu option displays the book calibration value. There will be an OK if the value is in the

acceptable range or an NG message if the out of range.

Selecting this menu option will allow you to calibrate all three Heaters. When calibrating the

This menu displays the calibration values for the machine. Use the OPEN and MENU button to

STRIP: XX OK/NG

This menu option displays the strip calibration value. There will be an OK if the value is in the

acceptable range or an NG message if the out of range.

CARR: XX OK/NG

This menu option displays the carriage calibration value. There will be an OK if the value is in the

acceptable range or an NG message if the out of range.

TEMP: XX OK/NG

This menu option displays the room temperature reading taken during the heater calibration.

There will be an OK if the value is in the acceptable range or an NG message if the out of range.

SPINE: XX OK/NG

This menu option displays the Spine Heater calibration reading during heater calibration.

There will be an OK if the value is in the acceptable range or an NG message if the out of range.

BEND: XX OK/NG

This menu option displays the Bender Heater calibration reading during heater calibration.

There will be an OK if the value is in the acceptable range or an NG message if the out of range.

BACK: XX OK/NG

This menu option displays the Back Heater calibration reading during heater calibration.

There will be an OK if the value is in the acceptable range or an NG message if the out of range.

FB8X Service Manual Rev. C, 9/28/10 Page 27

SERVICE MENU

5

5.3 Service Menu Descriptions

5.3.3 SENSORS

AC LINE INFO

50/51 for a 50 Hz supply or 59/60/61 for a 60 Hz supply. The second value is proportional to the line voltage and

should be 3000 +/- 300 for 115/230V machines, and 2600 +/- 300 for 100V machines.

CHECK SENSORS

Selecting this menu will display six numbers, each one either zero or non-zero depending on the state of a binary

sensor.

Selecting this menu will display two values: The first value represents the line frequency. This value should be 49/

Sensors: 1 2 3 4 1 2

1 if at home position, 0 if not in home position.

Carriage Home Switch.

Carriage Clamp Switch

2 if not clamped, 0 if clamped.

Encoder on Bender Motor Assembly

Encoder on Carriage Motor

Assembly

Book Sensor

3 if blocked, 0 if clear

Strip Sensor

4 if blocked, 0 if clear

CHECK BOOK BEAM

binding recess) the first value should be 2750 +/- 150. The second value should be between 100 and 2400. The

` numbers will change from moment to moment, but should not vary by no more than 100.

This menu displays two numeric readings from the Book Sensor. With the beam open (no book present in the

CHECK STRIP BEAM

crescent shaped hole in the Spine Heater) the first value should be 2750 +/- 150. The second value should be

between 100 and 2400. The numbers will change from moment to moment, but should not vary by no more

than 100.

This menu displays two numeric readings from the Strip Sensor. With the beam open (no strip blocking the

CHECK HEATER SN

This menu displays three numeric readings from the heater temperature sensors. If the heaters are at room

temperature, each value should be 1000 +/- 200.

AMBIENT TEMP

alternate between the “raw” values, the temperature in Celsius, and the temperature in Fahrenheit.

The first value corresponds to the temperature sensor on the Spine extrusion. This value can fall between the room

temperature and the target temperature of the Spine Heater (330°F/166°C).

The second value corresponds to the temperature sensor on the Controller Assembly. This value should be

between room temperature and 20°C/36°F.

Page 28 FB8X Service Manual Rev. C, 9/28/10

This menu displays the temperature readings of the two temperature sensors inside the machine. These values

5.3.4 INFO

SHOW COUNTS

SERVICE MENU

5

5.3 Service Menu Descriptions

cycles. Binding a book counts for 1 bind + 1 cycle. Running an autocycle in either Standard or Fast mode, counts

for only 1 cycle.

This menu displays two alternating values for the number of binds the machine has performed and the number of

SHOW VERSION

This menu displays the version of firmware installed in the binder.

5.3.5 HEATERS

HEATER TEST

TEST ALL

button to turn the heaters on and off. During the heater test, internal diagnostic values will appear on the

display. The diagnostic values are for use by Powis Parker technicians only.

Selecting this menu will allow you to turn on and test all three heaters at the same time. Press the BIND

TEST SPINE

heater on and off. During the heater test, internal diagnostic values will appear on the display.

The diagnostic values are for use by Powis Parker technicians only.

Selecting this menu will allow you to turn on the Spine Heater only. Press the BIND button to turn the

TEST BENDER

heater on and off. During the heater test, internal diagnostic values will appear on the display.

The diagnostic values are for use by Powis Parker technicians only.

Selecting this menu will allow you to turn on the Bender Heater only. Press the BIND button to turn the

TEST BACK

heater on and off. During the heater test, internal diagnostic values will appear on the display.

The diagnostic values are for use by Powis Parker technicians only.

This menu sets the fan function during heater tests. This menu is for Powis Parker Technicians only.

Selecting this menu will allow you to turn on the Back Heater only. Press the BIND button to turn the

SET FAN

SHOW HEATER SETS

This menu displays the thermostat values for the three heaters. The first value is for the Spine Heater. This

value should be between 1550 and 2150 . The second value represents the Bender Heater. This value should be

between 1200 and 1700. The third value represents the Back Heater. This value should be between

1200 and 1700.

FB8X Service Manual Rev. C, 9/28/10 Page 29

SERVICE MENU

5

5.3 Service Menu Descriptions

CHECK HEATER SN

This menu displays three numeric readings from the heater temperature sensors. If the heaters are at room

temperature, each value should be 1000 +/- 200.

A_HI/A_LO INPUT

In this menu, the A_HI and A_LO values for each of the heaters can be entered. The A_HI and A_LO values are

located on the heater tags. See section 5.4.4 “Entering A_HI/A_LO Values” for more details.

SPINE HIGH

This menu allows for viewing and editing of the A_HI value of the Spine Heater.

SPINE LOW

This menu allows for viewing and editing of the A_LO value of the Spine Heater.

BENDER HIGH

This menu allows for viewing and editing of the A_HI value of the Bender Heater.

BENDER LOW

This menu allows for viewing and editing of the A_LO value of the Bender Heater.

BACK HIGH

This menu allows for viewing and editing of the A HI value of the Back Heater.

BACK LOW

This menu allows for viewing and editing of the A_LO value of the Back Heater.

Page 30 FB8X Service Manual Rev. C, 9/28/10

5.3.6 MOTORS

CARRIAGE

SERVICE MENU

5

5.3 Service Menu Descriptions

Assembly forward, and press the BIND button to move the Carriage Assembly backward and into the home

position. When the Carriage Assembly is all the way back in its home position, a home offset value (+/- 25) will

appear on the display. When the Carriage Assembly is moved all the way forward (with the binding cavity empty),

three values will appear on the display. The first value must be 2000 +/-64.

In this menu, you can test the function of the Carriage Assembly. Press the MENU button to move the Carriage

BENDER1

In this menu, you can test the function of the Bender mechanism. Press the BIND button to move the Bender

Heater up, and the MENU button to move the Bender Heater down. After moving the Bender Heater up, the

display will read UP and a value will appear. This value should be 50 +/- 5. After moving the Bender Heater down,

the display will read DOWN and a value will appear. This value should be 0 +/- 5.

BENDER2

move the Bender Heater in either the up position, the down position, or the middle position.

In this menu, you can test the function of the Bender mechanism. Pressing either the BIND or MENU buttons will

TOGGLE HEATERS

heaters on, toggle back through the menu by pressing the MENU or OPEN button and select the Motor test you

want to perform. After testing the motor, go back to the TOGGLE HEATERS menu and turn the heaters off.

The heaters do not turn off on their own. Leaving the heaters on for extended periods of time is not

recommended for safety reasons.

In this menu, you can turn on all three heaters while performing one of the other motor tests. After turning the

5.3.7 FACTORY USE

FB8X Service Manual Rev. C, 9/28/10 Page 31

This menu is for use at the factory when the machine is manufactured.

SERVICE MENU

5

5.4 TESTING AND CALIBRATION

5.4.1 MEASURING HEATER TEMPERATURE

Temperature Probe (K-820-012), and a Right Angled Temperature Probe (K-820-3436).

When measuring the heater temperature, it is necessary to keep the Temperature Probe on the heater for at least

90 seconds.

Take the temperature in the middle of the heater, as shown in each of the pictures. Use the crescent shaped hole

in the Spine Heater and the Hot Symbol Label as reference points.

To measure the temperature of the heaters you will need a Thermocouple Meter (K-820-011), a straight

CHECKING THE SPINE HEATER TEMPERATURE

1. Enter HEATERS menu.

2. Select HEATER TEST.

3. Select TEST SPINE by pressing the green BIND button.

The fan will turn on and the heater will begin to heat up.

4. Place the straight Temperature Probe right below the

crescent shaped hole in the Spine Heater. Keep the probe

on the heater for at least 90 seconds, until the

temperature stabilizes.

To turn off the Spine Heater, press the orange OPEN button.

Spine Heater Temperature Range

Turn off the machine if the temperature

exceeds 350°F (177°C). Then contact Powis Parker

Technical Service.

Page 32 FB8X Service Manual Rev. C, 9/28/10

300°F- 330°F

149°C-166°C

SERVICE MENU

5

5.4 TESTING AND CALIBRATION

5.4.1 MEASURING HEATER TEMPERATURE

CHECKING THE BENDER HEATER TEMPERATURE

1. Enter HEATERS menu.

2. Select HEATER TEST.

3. Select TEST BENDER by pressing the green BIN

button. The Bender Heater will then rotate up into the

upright position.

4. Press the BIND button again and the fan will turn on and

the heater will start to heat up.

5. Place the Right Angled Probe in the middle of the heater,

in line with the crescent shaped hole in the Spine Heater.

Keep the probe on the heater for at least 90 seconds

until the temperature stabilizes.

Bender Heater Temperature Range

225°F- 245°F

107°C-118°C

To turn off the Bender Heater, press the orange OPEN

button.

Turn off the machine if the temperature

exceeds 260° F (127°C). Then contact Powis Parker

Technical Service.

CHECKING THE BACK HEATER TEMPERATURE

1. Enter HEATERS menu.

2. Select HEATER TEST.

3. Select TEST BACK by pressing the green BIND button.

The fan will turn on and the heater will begin to heat up.

4. Place the Right Angled Probe in the middle of the heater

in line with the Hot Symbol Label. Keep the probe on

the heater for at least 90 seconds until the temperature

stabilizes.

To turn off the Back Heater, press the orange OPEN button.

Back Heater Temperature Range

205°F- 225°F

Turn off the machine if the temperature

exceeds 260° F (127°C). Then contact Powis

Parker Technical Service.

96°C-107°C

FB8X Service Manual Rev. C, 9/28/10 Page 33

SERVICE MENU

5

5.4 TESTING AND CALIBRATION

5.4.2 CHECKING THE SENSORS

To check the sensors, select CHECK SENSORS in the SENSORS menu. A series of numbers will appear

representing each of the sensors and switches.

Sensors: 1 2 0 0 0 0

Checking the Book Sensor

To activate the Book Sensor, insert a piece

of paper into the binding recess as shown. The

third number will turn to 3 when the Book Sensor is

blocked.

Sensors: 1 2 3 0 0 0

Carriage Home Switch

Carriage Clamp Switch

Book Sensor

Bender Motor

Carriage Motor

Strip Sensor

Checking the Strip Sensor

To activate the Strip Sensor, block the cres-

cent shaped hole in the Spine Heater. The fourth

number will change to 4 when the Strip Sensor is

blocked.

Sensors: 1 2 0 4 0 0

Page 34 FB8X Service Manual Rev. C, 9/28/10

SERVICE MENU

5

5.4 TESTING AND CALIBRATION

Checking the Carriage Motor

and the Carriage Home Switch

Remove the screws attaching the Right Cover but keep

the cover plugged into the Wire Harness, taking care

the cover does not interfere with the mechanism or

encoder.

To check if the Carriage Motor sensor and the Carriage

Home Switch function properly, rotate the Carriage

Drive Belt and move the Carriage Assembly from its

home position.

When the Carriage Assembly moves forward from it’s

home position, the first number will change to 0.

As you rotate the Drive Belt, the fifth number will

alternate between 0 and 1.

Sensors: 0 2 0 0 1 0

Checking the Carriage Clamp Switch

To check the Carriage Clamp Switch, the Carriage

Assembly must be moved forward out of it’s home

position.

Remove the Right Cover making sure to keep the cover

plugged into the Wire Harness. Rotate the Carriage

Drive Belt and move the Carriage a little bit forward.

To check the Carriage Clamp Switch, squeeze the

Carriage Assembly so that it goes back as shown. If

the Carriage Clamp Switch is functioning properly, the

second number will change to 0.

Sensors: 0 0 0 0 1 0

Checking the Bender Motor

To check the Bender Motor, remove the Right Cover

making sure to keep it plugged into the Wire Harness.

Rotate the Bender Motor Gear as shown. If the Bender

Motor sensor is working properly, the sixth number will

alternate between 0 and 2 when the gear is rotated.

Sensors: 1 2 0 0 0 2

FB8X Service Manual Rev. C, 9/28/10 Page 35

SERVICE MENU

5

5.4 TESTING AND CALIBRATION

5.4.3 Calibrating the Sensors, Switches, and Carriage

Calibrating the Book Sensor

To calibrate the Book Sensor enter the service menu and select CALIBRATION.

1.

2. Select CAL BOOK SENSOR.

3. Make sure there is nothin

sensor.

If the calibration is successful, a result number will appear followed by the message “SUCCESS”.

If the calibration is unsuccessful, a failure message will appear. If a failure message appears double check and make sure there

is nothing blocking the Book Sensor and calibrate again. If you continue to get a failure message, contact Powis Parker

technical support.

Calibrating the Strip Sensor

To calibrate the Strip Sensor enter the service menu and select CALIBRATION.

1.

2. Select CAL STRIP SENSOR.

3. Make sure there is nothing in the binding recess that can block the crescent shaped hole in the Spine heater. Press the

BIND button to calibrate the sensor.

If the calibration is successful, a result number will appear followed by the message “SUCCESS”.

g in the binding recess that can block the Book Sensor. Press the BIND button to calibrate the

If the calibration is unsuccessful, a failure message will appear. If a failure message appears double check and make sure there

is nothing blocking the crescent shaped hole and calibrate again. If you continue to get a failure message, contact Powis

Parker technical support.

Calibrating the Carriage

To calibrate the Carriage Assembly enter the service menu and select CALIBRATION.

1.

2. Select CAL CARRIAGE.

3. Make sure there is nothing in the binding recess. Press the BIND button.

4. A confirmation message “CAL NOW?” will appear on the display. Press the BIND button to calibrate. The Carriage Assembly will move forward twice. A value will briefly appear on the display each time. If the calibration is successful, the

display will say CAL SAVED! followed by a value. This value must be between -64 and +64.

If the calibration is unsuccessful, a failure message will appear. If a failure message appears double check and make sure there

is nothing binding recess and calibrate again. If you continue to get a failure message, contact Powis Parker technical support.

Calibrating the Heaters

NOTE: The heaters must be at room temperature to be calibrated. The binder must be turned off for 1/2 hour- 1

hour for the heaters to return to room temperature. Directing a fan onto the heaters can speed up the cool down

process.

1. To calibrate the Heaters enter the service menu and select CALIBRATION.

2. Select CAL HEATERS.

3. The fan will turn on for 30 seconds and then the machine will take heater temperature readings for 16 seconds. If the

calibration is successful, the display will say SUCCESS. Press the MENU button to turn off the heaters and stop the

calibration.

If the calibration is unsuccessful, a failure message will appear. If a failure message appears, check that each of the heaters are

plugged in and that the heaters are at room temperature. Calibrate the heaters again. If the failure message appears again,

call Powis Parker technical support.

Page 36 FB8X Service Manual Rev. C, 9/28/10

SERVICE MENU

5

5.4 TESTING AND CALIBRATION

5.4.4 Entering A_HI/A_LO values

CAUTION: Entering the wrong values

can damage the unit and lead to bind

problems.

1. Enter the Service Menu and select the HEATERS

menu.

2. Select the A_HI/A_LO INPUT menu.

The A_HI/A_LO INPUT menu consists of

these six submenus:

SPINE HIGH

Fig 1

The A HI and A LO values are located on the heater tags.

Disregard any negative (-) symbol in front of the A LOW and A

HIGH value if present.

SPINE LOW

BENDER HIGH

BENDER LOW

BACK HIGH

BACK LOW

3. Select the appropriate menu for the heater you are

inputting the value. For example, if you are entering the A_HI value for the Spine Heater, select the

SPINE HIGH menu.

4. A_HI/LO: XXX.X will appear on the display. Press

the Bind button.

5. “EDIT? bind = yes” will appear on the display.

Press the Bind button to confirm that you want to

edit the value.

6. A_HI: XXX.X will appear on the display with the

last value blinking. Enter the A_HI or A_LO value

starting with the last value first. The A_HI and A_LO

values are located on the heater tags (fig 1).

Use the orange Menu and Open buttons to toggle

through numbers and press the green Bind button save

the number. When you press the Bind button you will

be forwarded to the next number.

When you enter the final value, the display will say

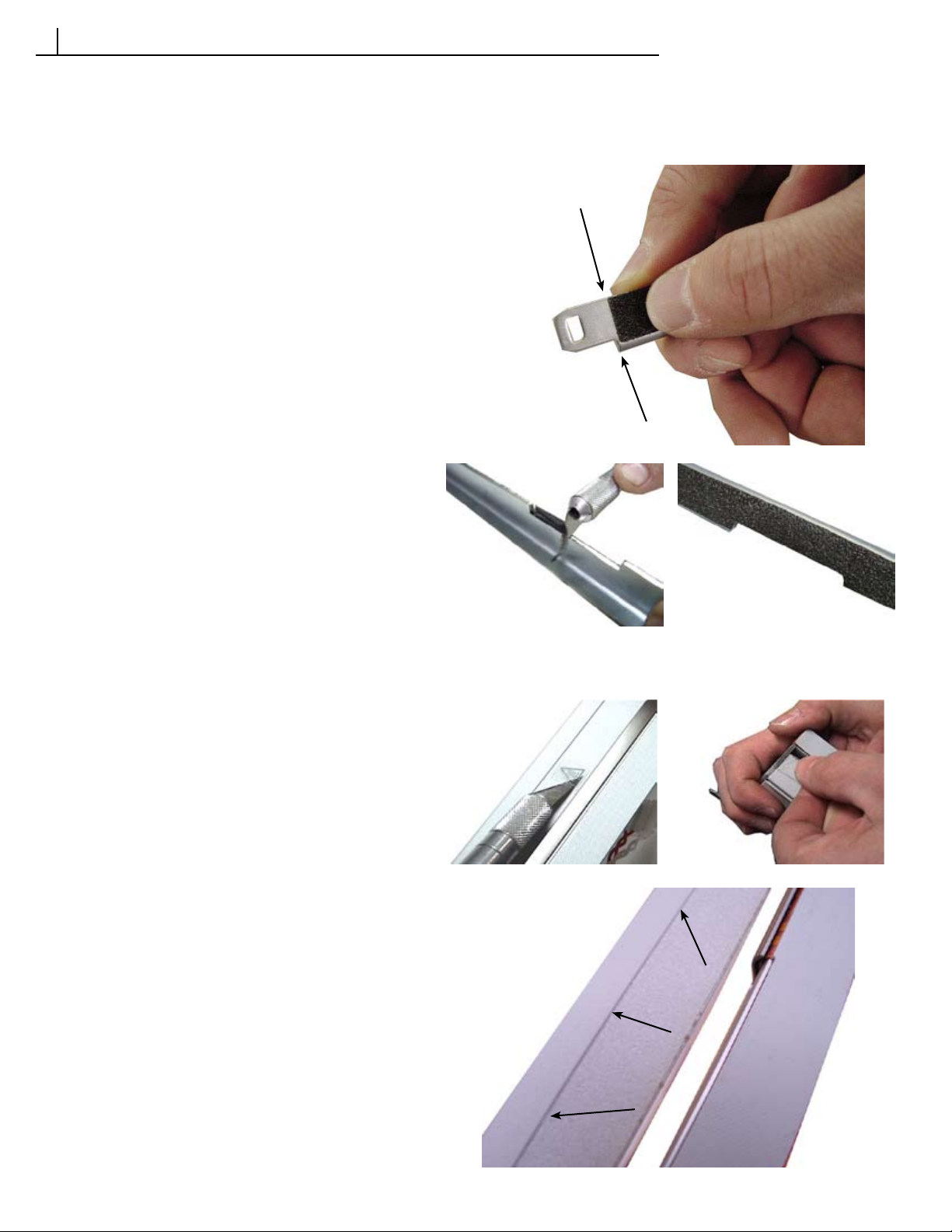

“SAVING...” and then you will be taken out of this submenu and returned to the A_HI/A_LO INPUT menu.

7. After entering the A_HI or A_LO values for the

heater, it is recommended you go back into those

menus and verify the correct values have been

inputted.

FB8X Service Manual Rev. C, 9/28/10 Page 37

SERVICE MENU

5

5.4 TESTING AND CALIBRATION

5.4.5 Checking motor functions

Checking the Carriage Motor

1. Enter the MOTORS menu.

2. Select CARRIAGE.

3. Press the orange MENU button to move the Carriage Assembly forward and the green BIND button to move

the Carriage Assembly backward.

When the Carriage Assembly closes three numbers

will be displayed. If the binding recess was empty,

the first number should be 2000 +/- 64.

When the Carriage Assembly is all the way back

and in the home position a home offset value

(+/- 25) appears on the display.

Checking the Bender Motor

1. Enter the MOTORS menu.

2. Select BENDER1.

3. Press the orange MENU button to rotate the Bender Heater down and the green BIND button to rotate the

Bender Heater up.

When the Bender Heater is in the down position, a

value (0 +/- 5) will appear on the display.

Page 38 FB8X Service Manual Rev. C, 9/28/10

When the Bender Heater is in the up position, a

value (50 +/- 5) will appear on the display.

SERVICE MENU

5

5.4 TESTING AND CALIBRATION

Checking the Bender Motor in the BENDER2 menu.

1. Enter the MOTORS menu.

2. Select BENDER2.

3. Press the orange MENU button or the green BIND button to rotate the Bender Heater in the down position,

the halfway position, or the up position.

FB8X Service Manual Rev. C, 9/28/10 Page 39

SERVICE MENU

5

5.4 TESTING AND CALIBRATION

TOOLS REQUIRED: #1 Phillips Screwdriver, Ohmmeter

5.4.6 Checking the Resistance of the Heater Sensors

1. Turn off the machine. Make sure the machine is

unplugged.

2. Remove the Front Cover.

3. Disconnect the Heater Sensor connections

(J1/J2/J3).

4. Touch the red and black probes to each connector

as shown.

5. Verify all Heater sensor connectors have a reading

of 120 ohm +/- 15% at 20°C/68°F.

J1

J3

J2

(J1) Spine Heater Connector

(J3) Back Heater Connector

6. Attach a ground connector to the chassis of the machine as shown.

Touch the red probe to each sensor connector. Each heater should

have a reading greater than 100,000 ohm. Reconnect the heaters.

Ground Connector

(J2) Bender Heater Connector

Page 40 FB8X Service Manual Rev. C, 9/28/10

SERVICE MENU

5

5.4 TESTING AND CALIBRATION

TOOLS REQUIRED: #1 Phillips Screwdriver, Ohmmeter

5.4.7 Checking the Resistance of the Heater Power

Connectors

1. Turn off the machine. Make sure the machine is

unplugged.

2. Drop the Controller Assembly down.

2. Disconnect the Heater Power Connectors

(J5/J6/J7).

3. Touch the two probes to the Heater Power

connector.

4. Verify the readings on the Ohmmeter are as

follows:

HEATER RESISTANCE

(J5) Spine Heater

(J5) SPINE HEATER 115v/100v 27 ohm +/- 15%

(J5) SPINE HEATER 230v 108 ohm +/- 15%

(J6) BENDER HEATER 115v/100v 46 ohm +/- 15%

(J6) BENDER HEATER 230v 186 ohm +/- 15%

(J7) BACK HEATER 115v/100v 68 ohm +/- 15%

(J7) BACK HEATER 230v 273 ohm +/- 15%

(J6) Bender Heater

(J7) Back Heater

5. Attach a ground connector to the chassis of the

machine as shown. Touch the red probe to

the heater connector. Each heater should have a

reading greater than 100,000 ohm. Reconnect the

heaters.

Ground Connector

FB8X Service Manual Rev. C, 9/28/10 Page 41

SERVICE AND CALIBRATION PROCEDURES

6

The focus of these service procedures is to explain how to safely and efficiently remove and replace components

of the binder. Each part of this section deals with a specific component.

Following each of the procedures, may be a list of tasks that must be performed for the procedure to be

completed. The tasks must be completed in the order in which they appear.

6.1 Covers

TOOLS REQUIRED: #1 Phillips Screwdriver

6.1.1 Left Cover

The Left Cover is attached

by one M3x6 LG Flat Head Screw

in the Binding Recess (fig 1) and two

M3x10 PAN Head Plastite Screws on

the underside of the machine (fig 2).

To remove the two screws

on the underside of the machine, flip

the binder on its back end (fig 2) to

prevent scratching the top surface of

the binder.

Fig 1

TOOLS REQUIRED: #1 Phillips Screwdriver

6.1.2 Right Cover

The Right Cover is attached

by one M3x6 LG Flat Head Screw

in the Binding Recess (fig 1) and

two M3x10 SEM PAN Head Plastite

Screws on the underside of the machine.

To remove the two screws

on the underside of the machine, flip

the binder on its back end to

prevent scratching the top surface of

the binder.

To fully remove the Right

Cover, remove the three screws

and then unplug the wire harness

connector (fig 2).

After reinstalling the Right Cover, perform the following task:

Fig 1

Fig 2

Fig 2

TASK 1

Page 42 FB8X Service Manual Rev. C, 9/28/10

Turn the binder on and make sure the buttons on the Right Cover function properly.

SERVICE AND CALIBRATION PROCEDURES

6

TOOLS REQUIRED: #1 Phillips Screwdriver

6.1.3 Front Cover

Removing the Front Cover

1. Remove the Skirt The Skirt is attached by two M3x6 SEM PH PHIL

Screws (fig 1).

2. Use your hands and pry off the bottom of the Front Cover as shown.

Rotate the Cover upwards until it

can be removed from the Tamping

Platform (fig 2).

Attaching the Front Cover

1. Insert the lip of the Front Cover into

the crevice on the Tamping Platform

(fig 3) and then snap the bottom of

the Front Cover into each of the locking places in the base (fig 4).

2. Reattach the Skirt.

Fig 1

Fig 3

Fig 2

Fig 4

Fig 5

Fig 7

6.2 Cooling Rack

TOOLS REQUIRED: #1 & #2 Phillips Screwdrivers

Fig 6

Removing the Cooling Rack

1. Remove the Right and Left

Covers.

2. Remove the Cooling Rack. The

Cooling Rack is attached by

four M4x10 PH PHIL Screws

(fig 5 & 6).

Attaching the Cooling Rack

Fig 8

1. Insert the slot on the underside of

the Cooling Rack into the edge of

the Backside Plate (fig 7).

2. Use the four M4x10 Screws to

reattach the Cooling Rack, making

sure the edge of the Cooling Rack

is even with the top edge of the

side plates (fig 8).

FB8X Service Manual Rev. C, 9/28/10 Page 43

SERVICE AND CALIBRATION PROCEDURES

6

6.3 Controller Assembly

TOOLS REQUIRED: #2 Phillips Screwdriver, Ground Strap

6.3.1 Inspecting the Controller Assembly

The Controller Assembly can be accessed by either removing the

Front Cover (fig 1) or by propping the machine up and then dropping it

down by removing the two screws attaching it the back of the Base Plate

(fig 2 & 3). The Controller Assembly is attached with two M4x6 PH PHIL

Screws.

SAFETY NOTE: When working with the Controller Assembly, always

disconnect the Power Cord and always wear a Ground Strap to protect

NOTE: Removing the Front Cover provides the

best access to all the Wire Harness connections.

the board from ESD.

Fig 1

NOTE: Dropping the

Controller Assembly

down provides the best

access to the Heater

Connections.

Fig 3

Fig 2

CONTROLLER NOTE: Please be aware that there is two types of FB8X Controllers.

One is a NON-RoHS and the other RoHS. They can be identified by their part numbers and colors. Please

refer to pages 71 & 72.

* Please note that the controllers are not interchangable.

6.3.2 Removing the Controller Assembly

1. Disconnect the power cord from the

machine.

2. Remove the Front Cover.

3. Disconnect all the Wire Harness

connections from the Controller

Assembly (fig 4).

4. Prop the back of the machine up and

Fig 4

remove the two M4x6 Screws attaching

the Controller Assembly to the back of

the Base Plate.

5. Gently lower the Controller Assembly

down and disconnect the three heater

connectors.

6. Remove the Controller Assembly (fig 5).

Page 44 FB8X Service Manual Rev. C, 9/28/10

Fig 5

SERVICE AND CALIBRATION PROCEDURES

6

6.3 Controller Assembly

Fig 2

Fig 1

Fig 3

If the same Controller Assembly is removed and then reinstalled, perform the following tasks:

6.3.2 Installing the Controller Assembly

1. Prop the back end of the machine up

and place the Controller Assembly

underneath.

2. Connect the three Heater connections.

3. Connect the Wire Harness connections

in the front of the of the Controller

Assembly

4. Insert the Controller Assembly bracket

into the Base Plate (fig 1). Verify the

bracket is not placed outside the base

plate as shown (fig 2).

5. Lift up on the Controller Assembly and

attach to the back of the Base Plate using

the two M4x6 Screws (fig 3).

TASK 1

Check the Sensors.

TASK 2 Verify heaters are plugged in by selecting the CHECK HEATER SN menu.

TASK 3 Test the heaters.

If a new Controller Assembly is installed, perform the following tasks:

TASK 1

Calibrate the Book Sensor, the Strip Sensor, the Carriage, and the Heaters in CALIBRATION menu.

TASK 2 Input new A_HI/A_LO INPUT values for each of the heaters. The A HI/ A LO values are located on

each of the heater tags.

6.3.3 Changing the Fuses

1. Disconnect the Power Cord.

2. Prop the machine up and drop the

Controller Assembly down.

3. Use a fuse puller to remove the Fuses.

4. Insert the new fuse(s) by snapping them

in place by hand.

Left photo: NON-RoHS / Right Photo: RoHS

ESD PROTECTION: Wear a Ground Strap

while working with the Controller Assembly.

If any fuses are replaced, perform the following task:

TASK 1

FB8X Service Manual Rev. C, 9/28/10 Page 45

Test the heaters.

SERVICE AND CALIBRATION PROCEDURES

6

6.4 Carriage Drive

TOOLS REQUIRED: #2 Phillips Screwdriver, Needle Nosed Pliers, Diagonal Cutters

Removing the Carriage Drive

1. Remove the Right and Left Covers.

2. Remove the Cooling Rack.

3. Cut the cable tie attaching the Wire

Harness to the Carriage Motor sensor board using Diagonal Cutters.

4. Disconnect the Wire Harness

connector from the Carriage Motor.

5. Remove the two Carriage Springs

using Needle Nosed Pliers (fig 1 & 2).

6. Move the Carriage Assembly forward

so that the two screws attaching the

Drive Nut Bracket are accessible (fig

3). This will ensure that no damage

is done to the sensor board on the

Carriage Drive Motor.

6. Remove the two M4x20 PH PHIL

Screws attaching the Drive Nut

Bracket, the Right Carriage Guide,

and the Carriage Guide Back together

(fig 3).

7. Remove the Carriage Guide Back.

8. Flip the Drive Nut Bracket down and

remove (fig 4).

9. Remove the three M4x8 PH PHIL

Screws attaching the Carriage Drive

Plate to the Right Side Plate (fig 5).

10. Remove the Carriage Drive

Assembly.

Fig 2

Fig 1

Fig 4

Fig 3

Fig 5

Page 46 FB8X Service Manual Rev. C, 9/28/10

SERVICE AND CALIBRATION PROCEDURES

6

6.4 Carriage Drive

TOOLS REQUIRED: #2 Phillips Screwdriver, Needle Nosed Pliers, Diagonal Cutters

Fig 2

Fig 1

Fig 3

Installing the Carriage Drive

1. Insert the half shears on the Carriage Drive Plate into the hole and

slot in the Right Side Plate (fig 1).

2. Attach the Carriage Drive to the

Right Side Plate using the three

M4x8 PH PHIL Screws. Ensure the

Carriage Drive Plate is flush against

the Right Side Plate (fig 2). Ensure

the Carriage Drive does not pinch

the Carriage Home Switch (fig 3).

2. Place the Carriage Back Guide

against the Right Carriage Guide in

the orientation shown (fig 4).

3. Attach the Drive Nut Bracket to

the Drive Nut as shown (fig 5).

4. Flip the Drive Nut Bracket up

and use the two M4x20 Screws

to attach the Drive Nut Bracket,

the Right Carriage Guide, and the

Carriage Guide Back together.

5. Attach the two Carriage Springs

using Needle Nosed Pliers.

6. Connect the Wire Harness connector to the Carriage Motor.

7. Cable Tie the wire to the Carriage

Motor sensor board (fig 6). The

wires must be routed to the motor

side of the circuit board.

8. Reinstall the Cooling Rack.

9. Reinstall the Right and Left Covers.

Fig 4

Fig 6

Fig 5

After replacing the Carriage Drive, perform the following tasks:

TASK 1

Test the Carriage Motor

TASK 2 Recalibrate the Carriage Assembly in the CAL CARRIAGE menu.

FB8X Service Manual Rev. C, 9/28/10 Page 47

SERVICE AND CALIBRATION PROCEDURES

6

6.5 Bender Drive

TOOLS REQUIRED: #1 & #2 Phillips Screwdrivers

Removing the Bender Drive

1. Remove the Right Cover.

2. Remove the Front Cover.

3. Remove the two M3x6 SEM PH PHIL

Screws attaching the Bender Drive to the

Right Side Plate (fig 1).

4. Disconnect the Wire Harness connector

from the Bender Drive.

Fig 1

Installing the Bender Drive

1. Connect the Wire Harness connector

to the Bender Drive.

2. Insert the Bender Drive through the hole

in the Right Side Plate, making sure the

sensor board is pointing towards the

inside of the machine and that the teeth

of the Bender Drive gear and the Bender

Gear engage each other (fig 2).

3. Attach the Bender Drive to the Right

Side Plate using two M3x6 SEM PH PHIL

Screws.

Fig 2

After replacing the Bender Motor, perform the following tasks:

TASK 1

Test the Bender Motor in the BENDER1 menu.

Page 48 FB8X Service Manual Rev. C, 9/28/10

SERVICE AND CALIBRATION PROCEDURES

6

6.6 Sensors

TOOLS REQUIRED: #1 & #2 Phillips Screwdrivers

Fig 3

Fig 1 Fig 2

6.6.1 Removing the Strip Present PCA

1. Remove the Right and Left Covers.

2. Remove the Front Cover.

3. Remove the four M4x10 PH PHIL Screws

attaching the Tamping Platform to the

Right and Left Side Plates (fig 1 & 2).

4. Disconnect the Wire Harness connector

from the Strip Sensor.

5. Remove the M3x6 PH PHIL Screw attaching the Strip Sensor bracket to the

Tamping Platform.

6. Remove the M3x6 LG PH PHIL Screw

attaching the Strip Sensor to the Bracket.

Installing the Strip Present PCA

1. Attach the Strip Sensor to the Strip

Sensor Bracket using one M3x6 LG PH

PHIL Screw.

2. Attach the Strip Sensor bracket to the

Tamping Platform using the M3x6 Screw.

3. Insert the Wire Harness connector

through the hole on the other side and

connect to the Strip Sensor (fig 3).

4. Reattach the Tamping Platform using the

four M4x10 Screws.

5. Reattach the Right and Left Covers.

6. Reattach the Front Cover.

After replacing the Strip Present PCA, perform the following tasks:

TASK 1

Recalibrate Strip Sensor in the CAL STRIP SENSOR menu.

TASK 2 Check Strip Sensor in the CHECK SENSORS menu.

FB8X Service Manual Rev. C, 9/28/10 Page 49

SERVICE AND CALIBRATION PROCEDURES

6

6.6 Sensors

TOOLS REQUIRED: #1 & #2 Phillips Screwdrivers

6.6.2 Removing the Book Sense Emitter PCA

1. Remove the Front Cover.

2. Remove the M4x8 PH PHIL Screw attaching

the Book Emitter PCA to the Tamping Platform.

3. Disconnect the Wire Harness connector from

the Book Emitter PCA.

Fig 4

Installing the Book Sense Emitter PCA

1. Attach the Book Emitter PCA to the Tamping

Platform using one M4x8 PH PHIL Screw.

2. Connect the Wire Harness connector (fig 4).

3. Reinstall the Front Cover.

After replacing the Book Sense Emitter PCA, perform the following tasks:

TASK 1

Recalibrate Book Sensor in the CAL BOOK SENSOR menu.

TASK 2 Check Book Sensor in the CHECK SENSORS menu.

Page 50 FB8X Service Manual Rev. C, 9/28/10

SERVICE AND CALIBRATION PROCEDURES

6

6.6 Sensors

Replacing the Book Detector requires you to partially disassemble the Carriage Assembly. It is recommend that

before you replace the Book Detector, you first replace the Book Emitter only, and then check the sensors in the CHECK

SENSORS menu. If the sensor test fails, follow the instructions to replace the Book Detector.

TOOLS REQUIRED: #1 & #2 Phillips Screwdrivers

Fig 1

Fig 3

Fig 2

6.6.3 Removing the Book Sense

Detector PCA

1. Remove the Right and Left Covers.

2. Remove the Cooling Rack.

3. Remove the Carriage Assembly but do

not disconnect it from the Controller

Assembly.

4. Remove the four M3x12 FH PHIL

Screws attaching the Carriage Top

(fig 1 & 2).

5. Disconnect the Wire Harness connector from the Book Detector PCA.

6. Pull the Book Sense Detector PCA

from the pinched slot.

Installing the Book Sense Detector

PCA

1. Insert the Book Sense Detector PCA

into the pinched slot making sure that it

is firmly seated inside the slot.

2. Connect the Wire Harness connector

(fig 3).

3. Reattach the Carriage Top using the

four M3x12 FH PHIL Screws and making sure the top edge of the PCA fits

into the slot on the underside of the

plate.

4. Reinstall the Carriage Assembly.

5. Reinstall the Cooling Rack.

6. Reinstall the Right and Left Covers.

7. Reinstall the Front Cover.

After replacing the Book Detector, perform the following tasks:

TASK 1

Recalibrate Book Sensor in the CAL BOOK SENSOR menu.

TASK 2 Check Book Sensor in the CHECK SENSORS menu.

TASK 3 Recalibrate the Carriage Assembly in the CAL CARRIAGE menu.

FB8X Service Manual Rev. C, 9/28/10 Page 51

SERVICE AND CALIBRATION PROCEDURES

6

6.7 Switches

TOOLS REQUIRED: #1 & #2 Phillips Screwdrivers, 2.5 Hex Key

6.7.1 Removing the Carriage Home Switch

1. Remove the Right and Left Covers.

2. Remove the Cooling Rack.

3. Remove the M3x10 SH CAP Screw using a

2.5mm Hex Key (fig 1).

4. Unplug the Carriage Home Switch from the

Wire Harness from inside the machine.

Fig 1

Installing the Carriage Home Switch

1. Insert the Carriage Home Switch wire

through the hole in the Right Side Plate and

connect it to the Wire Harness (fig 2).

2. Attach the Switch to the Right Side Plate

using a M3x10 SH CAP Screw and a 2.5mm

Hex Key.

3. Reinstall the Cooling Rack.

4. Reinstall the Right and Left Covers.

Fig 2

After replacing the Carriage Home Switch, perform the following tasks:

TASK 1

Check the switch in the CHECK SENSORS menu.

TASK 2 Recalibrate the Carriage.

Page 52 FB8X Service Manual Rev. C, 9/28/10

SERVICE AND CALIBRATION PROCEDURES

6

Fig 1

The little black cable tie on the Switches wire must be next

to the 1/8” wide cable tie.

6.7 Switches

TOOLS REQUIRED: #1 & #2 Phillips Screwdrivers, Diagonal Cutters

6.7.2 Removing the Carriage Clamp Switch

1. Remove the Right and Left Covers.

2. Remove the Cooling Rack.

3. Remove the M3x10 SH CAP Screw using a 2.5mm Hex Key.

4. Cut the head of the cable tie attaching the Switch’s wire to

the Wire Harness bundle.

5. Unplug the Carriage Clamp Switch connector from the Wire

Harness (fig 1).

Installing the Carriage Clamp Switch

1. Connect the Carriage Clamp Switch connector to the Wire

Harness.

2. Attach the Carriage Clamp Switch to the bracket on the

Carriage Assembly using the M3x10 SH CAP Screw. The

Switch is positioned by a round tab that engages a hole in the

bracket. Make sure the wire is routed as shown in the picture.

3. Cable tie the Switch’s wire and the Wire Harness bundle to

the Base Plate using a 1/8” wide cable tie.

4. Verify the little black cable tie on the Switch’s wire is next to

the 1/8” Cable tie. Trim excess on 1/8” cable tie.

After replacing the Carriage Clamp Switch, perform the following tasks:

TASK 1

Check the switch in the CHECK SENSORS menu.

TASK 2 Recalibrate the Carriage.

Fig 3

6.8 Display

TOOLS REQUIRED: #1 Phillips Screwdriver

Removing the Display

1. Remove the Right Cover.

2. Remove the Front Cover.

3. Pull the Display up out of the slot in

the Right Side Plate.

4. Disconnect the Wire Harness

connector.

Fig 4

Installing the Display

1. Connect the Wire Harness to the

Display (fig 3).

2. Insert the Display into the slot in the

Right Side Plate (fig 4).

3. Reinstall the Right Cover.

4. Reinstall the Front Cover.

After replacing the Carriage Home Switch, perform the following tasks:

TASK 1

FB8X Service Manual Rev. C, 9/28/10 Page 53

Turn the binder on and make sure characters appear on the display.

SERVICE AND CALIBRATION PROCEDURES

6

6 . 9 H e a t e r A s s e m b l i e s

TOOLS REQUIRED: #1 & #2 Phillips Screwdrivers, Diagonal Cutters

6.9. 1 Removing the Bender Assembly

1. Remove the Right and Left Covers.

2. Remove the Front Cover.

3. Cut the cable tie attaching the Bender

Heater wires to the Tamping Platform.

4. Remove the four M4x10 PH PHIL

Screws attaching the Tamping Platform

to the Right and Left Side Plates.

5. Do not remove the Tamping Platform

completely. Keep the Strip Present PCA

attached to the Wire Harness and just

flip the Tamping Platform out of the way

so as to gain better access to the Bender

Heater (fig 1).

5. Remove the two M4x16 PH PHIL

Screws attaching the Bender Heater to

the Right and Left Bender Pivots

(fig 2 & 3).

6, Disconnect the Bender Heater connec-

tions from the Controller Assembly.

Fig 1

Fig 2

Fig 3

Installing the Bender Assembly

1. Insert the tabs on the Bender Pivots into

the holes on the ends of the Bender

Heater (fig 4).

2. Attach the heater to the Bender Pivots

using the two M4x16 PH PHIL Screws.

3. Reattach the Tamping Platform using the

four M4x10 Screws.

4. Connect the two Bender Heater connections to the Controller Assembly.

5. Cable tie the wires to the Tamping

Platform (fig 5). Ensure there is proper

slack in the wires for the Bender Heater

to rotate up and down.

After replacing the Bender Heater, perform the following tasks:

TASK 1

Input A_HI/A_LO INPUT values. A_HI/ A_LO values are located on the heater tags.

NOTE: This is only necessary if a new Bender Heater has been installed.

Fig 4

Fig 5

TASK 2 Calibrate the Bender Heater in CAL HEATERS menu.

TASK 3 Test the heater and measure the temperature.

Page 54 FB8X Service Manual Rev. C, 9/28/10

Fig 3

SERVICE AND CALIBRATION PROCEDURES

6

6.9 Heater Assemblies

TOOLS REQUIRED: #1 & #2 Phillips Screwdrivers, Needle Nosed Pliers, 2.5mm Hex Key

6.9.2 Removing the Carriage Assembly

(Back Heater)

1. Remove the Right and Left Covers.

2. Remove the Front Cover.

3. Remove the Cooling Rack.

4. Remove the M3x10 SH CAP Screw

attaching the Carriage Clamp Switch using a 2.5mm Hex Key (fig 1).

Fig 1

Fig 4

5. Remove the Carriage Springs.

Fig 2

6. Remove the Left Carriage Guide by

unscrewing the two M3x10 PH PHIL

Screws (fig 2).

7. Remove the two M4x20 PH PHIL Screws

attaching the Drive Nut Plate, the Right

Carriage Guide, and the Carriage Back

Guide (fig 3).

8. Remove the Right Carriage Guide by

moving the Carriage Assembly towards

the front of the machine and sliding the

guide all the way forward and out of the

slot (fig 4).

9. Disconnect the Wire Harness from the

Book Detector PCA.

10. Disconnect the Back Heater wires from

the Controller Assembly.

11. Remove the Carriage Assembly.

FB8X Service Manual Rev. C, 9/28/10 Page 55

SERVICE AND CALIBRATION PROCEDURES

6

6.9 Heater Assemblies

TOOLS REQUIRED: #1 & #2 Phillips Screwdrivers, Needle Nosed Pliers

6.9.2 Installing the Carriage Assembly

(Back Heater)

1. Connect the Heater connections to the

Controller Assembly.

2. Install the Carriage Assembly by feeding the

tab on the right side of the Carriage Assembly into the long slot in the Right Side

Plate (fig 1). When installed, the Carriage

will be sitting on the Carriage Alignment

Gears.

3. Move the Carriage Assembly forward and

check the alignment to the Spine Heater.

The left side of the Carriage should be

ever so slightly more forward than the

right side (fig 2 & 3). If it is not, lift one

side of the Carriage off the gears and realign.

4. Connect the Wire Harness connector to

the Book Detector PCA (fig 4).