Index

1. Notes on thi s manual ............................................................. 2

1.1 Scope of Validation ............................................................. 2

1.2 Symbols Used ..................................................................... 2

1.3 Technical Competence ........................................................ 3

1.4 Target Group ....................................................................... 4

2. Preparation ........................................................................... 5

2.1 Safety Instructions ............................................................. 5

2.2 EC Directives ....................................................................... 7

2.3 Use condition ...................................................................... 8

2.4 Selection of fuse and cables ................................................ 9

2.5 Capacitor discharge .......................................................... 10

2.6 PE connection and leakage current ................................... 11

2.7 Safety Check ..................................................................... 12

2.8 Explanations of Symbols on Inverter ................................ 13

3. Product Information ............................................................ 16

3.1 Overview .......................................................................... 16

3.2 Major Characteristics ........................................................ 16

3.3 Product Identification ....................................................... 17

3.4 Quality Certificate Card ..................................................... 18

3.5 Further Information .......................................................... 18

3.6 Mounting Sequence ........................................................... 20

4. Electrical Connection ........................................................... 20

4.1 Safety ............................................................................... 20

4.2 Selection of fuse and cables. ............................................. 22

4.3 Overview of Connection Area ............................................ 23

5. Display ................................................................................

24

5.1 LCD Display ....................................................................... 24

5.2 Error Message ................................................................... 32

5.3 Troubleshooting ................................................................ 33

6. Recycling and Disposal ........................................................ 37

7. Maintenance ........................................................................ 37

7.1 Cleaning the Cabinet ......................................................... 37

7.2 Cleaning the Heat Sink ...................................................... 37

8. Guaranty Sc ope and Guaranty Service ................................. 39

8.1 POWFUTURE Factor y Guaranty Scope ............................... 39

8.2 Guaranty Conditions ......................................................... 39

8.3 Guaranty Exclusion ........................................................... 40

9. Accessories.......................................................................... 41

10. Contact ................................................................................ 42

11. Abbreviation ........................................................................ 43

Powfuture Science &Technology Co., Ltd

User Manual V2.0 2

1. NOTES ON THIS MANUAL

1.1 Scope of Validation

The main purpose o f th is User’s Manual is to pr ovide instructions and

detailed procedures for installing, operating, maintaining, and

troubleshooting of the following Powfuture Grid-Connected Solar

Inverters:

Venus – 3000TL

Venus – 4000TL

Venus – 3600TL for G83

Venus – 5000TL

This manual is an integral part of the unit. Please read the instruction

manual carefully befor e installation, op eration or mainte nance. Keep

this instruction manual for future reference.

All the illustrated pictures in this Manual concerning POWFUTURE

Grid-Connected Solar Inverters derive from the simulated model of

Venus – 5000TL.

Considering that dimensions and parameters of products have varied,

please take the la test doc ument as stan dard. Fur ther n otificatio n wi ll

not be issued.

User can get the latest user manual from here:

http://www.power-future.com/services.asp?sort=Download

1.2 Symbols Used

DANGER

DANGER: indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING:

indicates a hazardous situation which, if

not avoided, can r esult in serious injury or moderate

injury.

WARNING

Powfuture Science &Technology Co., Ltd

User Manual V2.0 3

Danger, Warnings, cautions and Notice tell you about the

dangerous conditions that can occur if you do not follow all instructions

in this manual. Read and follow all warnings and cautions carefully.

1.3 Technical Competence

The procedures described in this manual should be performed by

trained and authorized personnel only.

Maintenance should only be undertaken by competent individuals who

have a general knowledge of and experience with devices of this

nature. No repairs should ever be undertaken or attempted by any one

not having such qualifications.

Compliance with safety regulations depends upon installing and

configuring system correctly, including using the specified wirings. The

system must be installed only by professional assemblers who are

familiar with requir ements for safety, refrige ration system and EMC.

The assembler is responsible for ensuring that the end system

complies with all the relevant laws in the country where it is to be used.

POWFUTURE require using only genuine replacement parts,

manufactured or sold by POWFUTURE for all repair parts

replacements.

Read completely through each step in every procedure before starting

the procedure; any e xce ptions m ay r e s ult in a failure to pro pe r ly and

safely complete the attempted procedure.

The individual sub-assembly of the system shall be interconnected by

means of the wiring methods outlined in national/international

regulations such a s the Natio na l Ele ctric Co de (NFPA ) No . 7 0. o r VDE

regulation 0107.

CAUTION

CAUTION: indicates a hazardous condition which, if

not avoided, can result in moderate or minor injury.

NOTICE

NOTICE: indicates a situation that can result in

property damage, if not avoided.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 4

Servicing of this product in accordance with this manual should never

be undertaken in the absence of proper tools, test equipment and the

most recent revis ion to this manual w hich is clearly and thoro ughly

understood.

1.4 Target Group

Manuals are prepared for anyone who is intended to use POWFUTURE

Grid-Connected Solar Inverter. Before any further action, the

operators must first read all safety regulations and be aware of the

potential danger to operate high-voltage devices. Operators must also

have a complete understanding of this device’s features and functions.

All installation, commissioning, main tenance, repair and re cycling of

POWFUTURE Grid-Connected Solar Inverter must be done only by

qualified personnel.

”Installation Guide” are o nly fo r qua li fied personnel who are inte nded

to install or uninstall the POWFUTURE Grid-Connected Solar Inverter.

All installation, commissioning, maintenance, repair and recycling of

Powfuture Grid-Connected Solar Inverter must be done only by

qualified personnel.

NOTICE

Hereby qualified personnel means he/she has the

professional training, knowledge, and experience in:

Installing electrical equipment and PV power systems

(up to 1000 V).

Applying all applicable installation codes.

Analyzing and reducing the hazards involved in

performing electrical work.

Selecting and using Personal Protective Equipment

(PPE).

WARNING

Do not use this product unless it has been successfully

installed by qualified personnel in accordance with the

instructions ”Installation Guide”.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 5

2. PREPARATION

2.1 Safety Instructions

This chapter contai ns the safety instructions which you must follow

when installing, operating a nd servicing the unit. If ignor ed, physical

injury or death may follow, or damage may occur to the unit. Read the

safety ins tructions befor e you work on the unit. If you are unable to

understand the Dangers , Warnings, Cautions o r Instructio ns, contact

the manufacturer or an authorized service dealer before installing,

operating and servicing the unit.

DANGER

DANGER due to electric shock and high voltage

DO NOT touch the operating

component of the

inverter, it might result in burning or death.

TO prevent risk of electric shock during installation and

maintenance please make sure that all AC and DC

terminals are plugged out.

DO NOT touch the surface of the inverter while the

housing is wet, it might lead to electric shock.

DO NOT stay closely to the instrument s while there is

severe weather conditions including storm, lighting,

and etc.

CAUTION

The PV inverter will become hot during operation please don’t

touch the he at sink or pe ripheral surfa ce during or shortly afte r

operation.

Risks of damage due to improper modifications.

Never modify the inverter or other components of the system.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 6

WARNINGS - Do not operate device which is damaged,

lacking parts or dented. Failure to observe this warning may

result in an electric shock, injury, fire or accident.

WARNINGS - The grid connected inverter is intended to be

used with appropriate PV generator, switchgear, SPDs,

distribution board, electrical protection components and other

device to form complete end systems. Compliance with safety

regulations depends upon installing and configuring inverter

correctly, including using the specified emergency stop device

adjacent to solar inverter. The unit must be installed only by

professional assemblers who are familiar with requirements for

safety and EMC. The assembler is responsible for ensuring that

the end product or system complies with all the relevant laws in

the country where it is to be used.

WARNINGS - RS485 and USB interface is classed to be as

SELV, Only PELV or SELV voltages may be connected at these

port.

WARNING

The installation, service, recycling and disposal of the

inverters must be performed by qualified personnel

only in compliance with national and local standards

and regulations. Please c ontact your de aler to get the

information of authorized repair facility for any

maintenance or repairmen.

Any unauthorized actions including modification of

product functionality of any form will affect the

validation of warranty service; Powfuture may deny

the obligation of warranty service accordingly.

PV generator must never be grounded.

The unit is heavy. Do not lift it alone.

Do not open cover. No us er serviceable parts inside.

Servicing limited to qualified service personnel.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 7

2.2 EC Directives

This chapter follows the requirements of the European Low Voltage

Directives, contains the safety instructions and conditions of

acceptability for the end-use system, which you must follow when

installing, oper ati n g and servicing the unit. If ignor e d, ph ysical injury

or death may follow, or damage may occur to the unit. Read this

instructions before you work on the unit. If you are unable to

understand the Dangers , Warnings, Cautions o r Instructio ns, contact

the manufacturer or an authorized service dealer before installing,

operating and servicing the unit.

The Grid Connected Inverter meets the requirements stipulated in Low

Voltage Directive (LVD) 2006/95/EC and Electromagnetic

Compatibility (EMC ) Directive 2 004/108/EC. The unit is teste d based

on:

NOTICE

Public utility only

The PV inverter designed to feed AC power directly to

the public utility power grid; do not connect AC output

of the device to any private AC equipment. Before the

inverter is connected to the grid, official written

approval from the local bureau of power should be

obtained.

CAUTION

The PV inverter will become hot during operation

please don’t touch t he heat sink or peripher al surface

during or shortly after operat ion.

Risk of damage is due to improper modifications.

Never modify the inverter or other components of the

system.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 8

EN 62109-1:2010;

FprEN 62109-2:2009;

VDE 0126-1-1:2006+A1:2011.

In case of installati on in PV system, startup of the uni t (i.e. start of

designated operatio n) is prohib ited until it is de termine d that the ful l

system meets the requirements stipulated in the EC Directive

(2006/95/EC, 2004/108/EC etc.).

The grid-connected inverter leaves the factory completely c o nne cting

device and ready for connection to the mains and PV supply. The unit

shall be installed in accordance with national wiring regulations.

Compliance with safety regulations depends upon installing and

configuring system correctly, including using the specified wirings. The

system must be installed only by professional assemblers who are

familiar with requirements for safety and EMC. The assembler is

responsible for ensuring that the end system complies with all the

relevant laws in the country where it is to be used.

The individual subass embly of the sy stem shall be interconne cted by

means of the wiring methods outlined in national/international

regulations such as the National Electr ic Code (NFPA ) No. 7 0 . or VDE

regulation 0107.

2.3 Use condition

1. Overvoltage category: Overvoltage category III for MAINS

connection, overvolta ge category II for PV supplies according to

EN /IEC 60664-1.

2. Pollution degree: Pollution degree III, not intended for

heavy pollution of the air by dust, smoke, corrosive or

radioactive particles, vapors or salt.

3. Class of protection: I.

4. Protection against ingress of water: IP65, WARNINGS -

The Degree of prote ction ratin g IP54 to IEC 60529 is applicable

to the device when the supplied cable grommets are fitted into

the gland, suitable external cord was fitted and communication

port was covered. If the unit is not mounted in this way,

hazardous live parts may be exposed and the IP Rating o f the

unit will be invalid

Powfuture Science &Technology Co., Ltd

User Manual V2.0 9

5. The equipment is rated to operate at an altitude less than

2000 m.

6. Installation:

Equipment is not su itable fo r use in the presence of explosio n

gas. Equipment is not suitable for use in the presence of

explosion and flammable gas.

Not suitable for use in the presence of Exposure to strong

electric or magnetic fields.

Not suitable for use in the presence of Exposure to heavy

vibration and shocks.

Not suitable for use by untrained personnel.

7. The unit is suitable for connection to a MAINS circuit capable

of delivering not more than 1000rms symmetrical Amperes.

The absolute maximum total PV array short circuit current (d.c.)

that the inverter is rated to have connected to its PV input,

under worst-case conditions of ambient temperature,

irradiance, shall be less than 25A for Venus -3000TL, 30A for

Venus -3600TL & Venus -4000TL and 32A for Venus -5000TL.

8. PV modules for non-isolated inverters: PV modules shall

have an IEC 61730 Class A rating; PV modules must have a

maximum system voltage rating based upon the AC mains

voltage.

2.4 Selection of fuse and cables

Mains cable (AC line cable) shall be short circuit protected and

thermal overload protected.

Always fit the i nput cable with f uses. No rmal gG (U S: CC o r T) fuses

will protect the input cable in shortcircuit situations. They will also

prevent damage to adjoining equipment.

Dimension the fuses according to local safety regulations, appropriate

input voltage and the rated current of the solar inverter.

AC output protected by external fuse (gG, rated current 25 A/ 250 VAC,

for Venus-3000TL; 30A/ 250 VAC for Venus-3600TL; 30A/ 250 VAC for

Venus-4000TL; and 32A/250V for Venus-5000TL;) provided in all live

connections to the AC supply.

The rated short circuit breaking capacity of the above protective device

Powfuture Science &Technology Co., Ltd

User Manual V2.0 10

shall be at lea st equal to the prospe ctive fault c urrent a t the point o f

installation. See section technical data of this manual for details.

L,N+PE, 2x4+4 mm² @400C ambient (Venus-3000TL) with a max

length of 5m; Cu, L,N+PE, 2x4,0+4,0mm²@400C ambient

(Venus-3600TL&Venus-4000TL) with a max length of 10m, and Cu,

L,N+PE, 2x4+4 mm²@400C ambient (Venus-5000TL) with a max

length of 5m, with oper ating time of t he fuse is less tha n 5 seconds,

installation method B2 according to EN 60204-1: 2006, annex D: cable

in conduit cable tru nking system, number of loaded circuit o nly one.

Use H07RNF (cord designation 60245 IEC 66) for an ambient

temperature of 40 °C or less and use 90 °C wire for ambient

temperature between 40 °C and 60 °C.

Note 1: For conditions differing from those mentioned above,

dimension the cables according to local safety regulations, appropriate

input voltage and the load current of the unit. (You can choose a

thicker cable but the fuses must be rated according to the table.)

Note 2: Fuses must be approved by notified body.

Inverter is not prov ided galvanic isola tion from the MA INS to the PV

array, feedback current to the array is 16 A for Venus-3000TL; 18A for

Venus-3600TL; 20A for Venus-4000TL; and 25A for Venus-5000TL

based on fuse provided in the MAINS. Also, in the worst case, the

reverse current comprises the sum of the short-circuit curre nts of all

intact lines, therefore, the current-carrying capacity of the

components and sub-assemblies provided in the end-use system

(connectors, cable s, junction box, switchgear, e tc.) and the reverse

current PV module shall be considered based on feedback current and

reverse current. The direct current (DC) circuit breaker or fuse

between each solar generator and inverter shall be provided based on

solar inverter input ratings.

Select DC cables b ased on the above inverter feedback current and Isc

PV rating and Vmax ratings.

2.5 Capacitor discharge

The unit contains capacitors that remain charged to a

potentially lethal vo ltage after the MAI NS and PV supply has

been disconnected.

RISK OF ELECTRIC SHCOK!

Hazardous voltage present for up to 40 minutes after disconnection

Powfuture Science &Technology Co., Ltd

User Manual V2.0 11

from power supply.

CAUTION – Risk of electric shock from energy stored in

capacitor, never work on the solar inverter couplers, the MAINS

cable, PV cables or the PV gene rator when power is applied.

After switching off the PV power and mains, always wait for 15

min to let the inte rme diate c ircuit cap acitor s dischar ge bef ore

you unplug DC input and MAINS couplers, when access to

internal circuit of solar inverter, It is very important to wait 40

minutes before working on power circuit or demounting the

electrolyte capacitors inside the device. Do not open the device

before hand since the capacitors require this long to discharge

sufficiently!

Measure the voltage between terminals UDC+ and UDC with a

multimeter (impedance at le ast 1 Mohm) to ensur e that t he de vice i s

discharged before beginning work (35VDC) inside the device.

This waiting period can be reduced by shorting the input terminals with

a 10 Ohm/10 W resis tor.

If the device is failed to discharge, do not use, call manufacturer.

Only trained and authorized professional personnel were allowed to

perform, installation, servicing and maintenance works.

The unit stop functi on does not r emove dange rous vol tages from the

unit, cut off the MIANS and PV input supply to the end use equipment

incorporating the unit.

The capacitors may fail to discharge, or be prevented from being

discharged by a voltage applied to the output terminals. If the unit has

failed in a manner that causes the display to go blank immediately, it is

possible the capacitors will not be discharged. In this case, consult

POWFUTURE or their authorized distributor.

WARNING! Do not work on the s olar inverter when the device

is running.

Never touch either the positive or negative pole of PV

connecting device. And never ever touch both at the same

time!

2.6 PE connection and leakage current

The end-use application shall monitoring of the protective

conductor by a residual current operated protective device

Powfuture Science &Technology Co., Ltd

User Manual V2.0 12

(RCD) with rated fau lt cur r e nt Ifn ≤ 30mA which automatically

disconnects the device in the case of a fault.

DC differential currents are created (caused by the insulation

resistance and through capacities of the PV generator). In order to

prevent unwanted triggering during operation, the rated residual

current of the RCD has to be min. 30mA。

The device is intended to connect to a PV generator with a capacitance

limit of approx. 300 nF

HIGH LEAKAGE CURRENT! EARTH CONNECTION ESSENTIAL

BEFORE CONNECTING SUPPLY.

Incorrect grounding can cause physical injury, death or

equipment malfunction and increase electromagnetic interference.

Make sure that grounding conductors are adequately sized as required

by safety regulations.

Do not connect the ground te rmina ls of the unit i n ser ies in case o f a

multiple installation.

This product can cause current with a d.c. component. Where a

residual current to operated protective (RCD) or monitoring (RCM)

device is used for p r o te c tion in c a se o f dir e c t or indirect contact, o nly

an RCD or RCM of Type B is allowed on the supply side of this product.

2.7 Safety Check

The following safety checks should be performed at least every 12

months by manufacturer’s qualified person who has adequate training,

knowledge, and practical experience to perform these tests. The data

should be recorded in an equipment log. If the device is not functioning

properly or fails any of tests, the device has to be repaired.

1. Inspect the equipment and accessories for mechanical and

functional damage.

2. Inspect the safety relevant labels for legibility.

3. Inspect the fuse to verify compliance with rated current and

breaking characteristics.

4. Verify that the device functions properly as described in the

instructions for use.

5. Verify that the current/voltage sensors functions properly.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 13

6. Verify software or firmware that performs safety critical application

functions properly.

7. Check earth connection, retightening of terminals.

8. Check interface protection and inverter setpoints functions

properly. Refer to section” Interface protection and Inverter set

points;

9. Measurement of insulation resistance, consult manufacturer.

10. Measurement of earth resistance, consult manufacturer.

11. Mounting structures: Verify tightness and integrity of bolts and

other fastening devices; Verify if there is significant corrosion.

12. Using manufacturer’s procedures and/or technical data on an

“as-needed” basis when performing periodic component

calibrations.

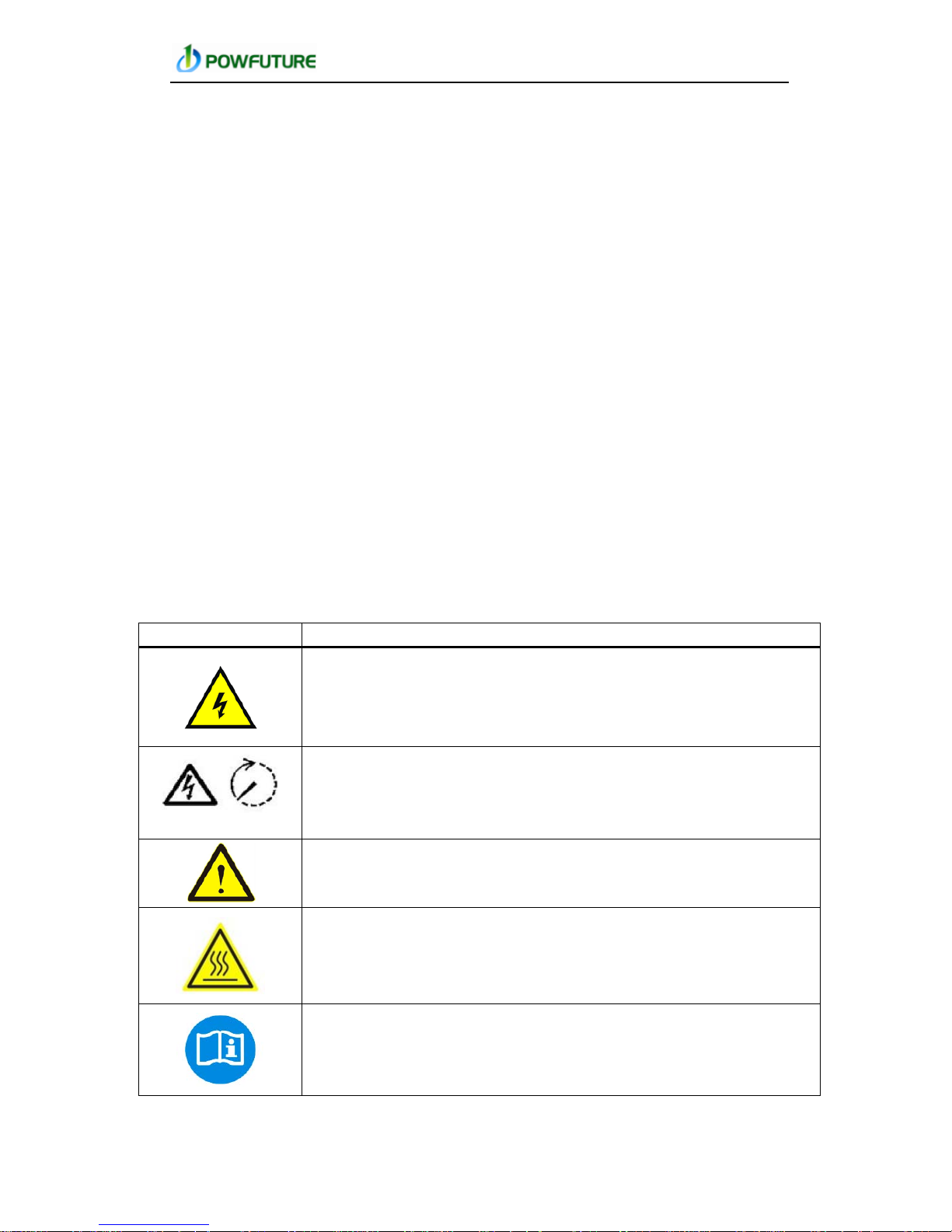

2.8 Explanations of Symbols on Inverter

Symbols, replace words on the equipment, on a display, or in manuals.

Symbol

Description

Dangerous electrical voltage

This device is directl y connected to public grid, thus all work to the

inverter shall only be carried out by qualified personnel.

30 minutes

DANGER to life due to high electrical voltage!

There might be residual currents in inverter because of large

capacitors. Wait 30 MINUTES before you remove the front lid.

NOTICE, danger!

This device directly connected with electricity generators and

public grid.

Danger of hot surface

The components inside the inverter will release a log of heat

during operation, DO NOT touch aluminum housing during

operating.

An error has occurred

Please go to Chapter 9 “Trouble Shooting” to remedy th e error.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 14

This device SHALL NOT be disposed of in residential

waste

Please go to Chapter 8 “Recycling and Disposal” for proper

treatments.

Without Transformer

This inverter does not use transformer for the isolation function.

CE Mark

CE mark is attached to the solar inverter to verify that the unit

follows the provisions of the European Low Voltage and EMC

Directives Equipment with the CE mark fulfils the basic

requirements of the Guideline Governing Low Voltage and

Electro-magnetic Compatibility.

No unauthorized perforations or modifications

Any unauthorized perforations or modifications are strictly

forbidden, if any defect or damage (device/person) is occurred,

POWFUTURE shall not take any responsibility for it.

Trademark

No access for unauthorized personal

Symbol for the marking of electrical and electronics devices

according to Directive 2002/96/EC. Indicates that the device,

accessories and the pa cka gi n g mus t no t be di sposed as unsorted

municipal waste and must be collected separately at the end of

the usage Please follow Local Ordinances or Regulations for

disposal or contact an authorized representative of the

manufacturer fo r information concerning the de co mmi ssioning of

equipment.

Direct current

Alternating current

Protective conductor

Powfuture Science &Technology Co., Ltd

User Manual V2.0 15

Earth (ground) TERMINAL

PROTECTIVE CONDUCTOR TERMINAL

Isc PV

Absolute maxim um to t al PV ar ray s hor t cir c uit cu r ren t (d. c. ) t h a t

the inverter is rated to have connected to its PV input, under

worst-case conditions of ambient temperature, irradiance,etc.

This rating o f the PCE re fers to the a bsolute max imum curre nt the

PV input to the solar inverter is designed for under conditions of

expected use. Thi s diff ers f ro m the si mple s um o f the marke d Isc

ratings of the conn ected PV modules, since thos

e markings are

based on shortcircuit conditions under standard test conditions,

and may be exceeded in cold temperatures or with irradiance

above the standard level.

OVC

overvoltage category (OVC), numeral designation defining a

classification of transient overvoltage conditions

Vmax PV

maximum rated d.c. input voltage the PCE is designed to

withstand from the PV array (i.e. maximum opencircuit voltage)

under worst case conditions of ambient temperature, irradiance,

etc.

PV

Photovoltaic

+

DC terminal, indicating the polarity of the connections, positive,

all positive connections shall be made with Red

Insulated wire .

-

DC terminal, indicating the polarity of the connections, negative,

all negative connections with Black insulated wires.

PCS

Power conversion equ ipment, hereby is our DC/AC inverter.

service

personnel

a person having appropriate technical training and experience

necessary to be aware of hazards to which that person may be

exposed in performing a task and of measures to minimize the

risks to that person or other persons.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 16

3. PRODUCT INFORMATION

3.1 Overview

Industrial Layout Reduced Heat Sink

3.2 Major Characteristics

Powfuture Grid-Connected solar inverter has following characteristics

which make POWFUTURE inverter “High Efficiency, High Reliability,

High price-to–performance ratio”.

Higher DC input voltage, can be connected with more PV panels.

Wider MPPT voltage range can fit in differ ent locations or various

weather conditions.

Qualified

personnel

Person adequately advise d or supe rvised by an elect rically ski lled

person to enable him o r her to perceive risks and to avoid hazards

which electricity can create. For the purpose of the safety

informat

ion of this ma nual, a "qualifie d person" is some one who is

familiar with requirements for safety, refrigeration system and

EMC and is authorized to energize, ground, and tag equipment,

systems, and circuits in accordance with established safety

procedures.

The inverter and e n d u se sys te m may only be commissioned a n d

operated by qualified personnel.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 17

Higher MPP tracking accuracy, catch most of electricity from panels

and reduces your Payback Period.

Complete protection integrated within the inverter.

Also, following protection methods are integrated in inverter:

Internal over voltage

DC insulation monitoring

Ground fault protection

Grid monitoring

Ground fault current monitoring

DC current Injection monitoring

3.3 Product Identification

You can identify the inverte r by the sid e type label. Info rmation s uc h

as serial number (SN.), type of the inverter, as well as inverter

specifications are specified on the side type label. The type label is on

the middle part of the right side of the inverter housing.

(Side type label example as on Venus 5000TL)

Powfuture Science &Technology Co., Ltd

User Manual V2.0 18

3.4 Quality Certificate Card

When the single product passe d a series of automation per formance

and safety tests, a quality certificate card, which represents the

outcome of internal inspection, will be issued by POWFUTURE’s quality

assurance department rather than by the third party (authoritative

laboratory or testing institute). With this card we want to convince our

clients that POWFUTURE puts a new premium on the quality of

products.

3.5 Further Information

If you have any further questions concerning the type of accessories or

installation, please check our website www.Power-future.com or contact

our service hotline (+86)-27-86635836.

WARNINGS: In case of installation in PV system, startup of the unit

(i.e. start of desi gnate d ope ratio n) is pr ohibite d unt il it i s d ete rmine d

that the full system meets the requirements stipulated in the EC

Directive (2006/95/EC, 2004/108/EC etc.).

The grid-Connected Inverter leaves the factory completely connecting

device and ready for connection to the mains and PV supply. The unit

shall be installed in accordance with national wiring regulations.

Compliance with safety regulations depends upon installing and

configuring system correctly, including using the specified wirings. The

system must be installed only by professional assemblers who are

familiar with requirements for safety and EMC. The assembler is

Powfuture Science &Technology Co., Ltd

User Manual V2.0 19

responsible for ensuring that the end system complies with all the

relevant laws in the country where it is to be used.

The individual subass embly of the sy stem shall be inter connected by

means of the wiring methods outlined in national/international

regulations such a s the Natio na l Ele ctric Co de (NFPA) No. 70 . or VDE

regulation 0107.

To ensure the safe op eration of the dev ices, they may b e installed and

commissioned only by qualified pe rsonnel in ful l compliance with the

warnings referred to in this manual.

Open the package and pick the product, check that if there is any

distortion or impaired during transpo r tatio n, m e anw h ile , check that if

all the relating accessories and materials ar e here, you can see the

accessories list in the “Appendix”.

The instruction manual is an integral part of the unit and should

therefore be read and kept carefully.

It is recommended that the packa g in g sho uld no t be re mo ve d unti l

the unit is located in the installation site.

Do not dispose of packaging materials in the environment or leave

them within reach of children as they may represent a hazard.

Check that there are no signs of damage. Before attempting

installation and operation, check the information on the type

designation label of the unit to verify that the unit is of the correct type.

The label includes a n IEC ratin g and CE markings , a type code and a

serial number, which allow individual recognition of each unit.

Check the mechanical and electrical installation of the unit before

startup. Go through the checklist below together with another person.

Read the sections “Safety instruction and EC Directives” and “Interface

protection and Inverter setpoints’ on the previous pages of this manual

before you work on the unit.

During lifting procedures ensure the unit is firmly secured to avoid the

risk of accidental tipping or dropping.

Use a solid hard wall or metal structure.

Before installing the unit, agree with the customer the site.

Do not allow foreign object into the unit.

Not intended for multiple installation.

The rating plate and warning marking must be readable after

installation.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 20

DANGER to life due to potential fire or electric shock.

With the inverter powered, comply with all prevailing

national regulations on accidents prevention.

This inverter will be directly connected with HIGH

VOLTAGE power generation device, the installation

must be performed by qualified personnel only in

compliance with national and local standards and

regulations.

Installed to be clear of obstruction. The enclosure must never be

covered.

The equipment is classed as one not accessible to the general public.

A suitable guarding which is keep min. 1.5mm distance around the

perimeter of the device is mandatory to prevent against access to

general public, especially for children or infirm persons when the

device is located in an unprotected area.

Make sure that dust from drilling does not enter the unit when

installing.

Do not place flammable materials near the unit. Failure to observe this

warning may result in a fire.

3.6 Mounting Sequence

1. Read the manual, pay special attention to the section on safety.

2. Install the inverter according to 《Installation Guide》.

3. Turn on PV by turning the DC switch on.

4. The inverter is now ready for operation.

4. ELECTRICAL CONNECTION

4.1 Safety

DANGER

Powfuture Science &Technology Co., Ltd

User Manual V2.0 21

The unit shall be installed in accordance with national wiring

regulations. Compliance with safety regulations depends upon

installing and configuring system correctly, including using the

specified wirings . The system must be ins talled only by pro fessional

assemblers who are familiar with requirements for safety and EMC.

The assembler is responsible for ensuring that the end system

complies with all the relevant laws in the country where it is to be used.

The individual sub-assembly of the system shall be interconnected by

means of the wiring methods outlined in national/international

regulations such a s the Natio na l Ele ctric Co de (NFPA ) No . 7 0. o r VDE

regulation 0107.

Power to the unit must be turned on only after installat ion work has

been completed. All electrical connections must be carried out by

qualified personnel in accordance with legislation in force in the

country concerned.

Before connecting, disconnect the connection between solar

generator and inverter and locked it to the open position during

installation. Place a warning sign “do not turn on – maintenance

in progress” on the external disconnecting switch when it is

shut down, and make sure that on-off remote controls are

inhibited. Refer to this manual, section 3.Safety instruction and

EC Directives – isolation device.

The open-circuit voltage of PV generator under worst case

conditions of ambient temperature, irradiance, etc. shall never

not exceed 500V, failure to observe this, it may cause elctric

shock hazards or completely damage of the inverter.

WARNING: HIGH LEAKAGE CURRENT, EARTH CONNECTION

ESSENTIAL BEFORE CONNECTING SUPPLY.

For the cables connected to PV inverter and Grid, choose the

appropriate wires according to the capacity of the inverter and PV

components.Calculate the max. input current and max. output current

of The inverter according to the actually system , inverter rating Label

NOTICE

Electrical connections shall be carried out in

accordance with the applicable regulations, such as

conductors, fuses, PE connection.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 22

and Te chnical paramete r. For details, r efer to this manu al, Scetion 3

Safety instruction and EC Directives.

4.2 Selection of fuse and cables.

The cables we recommend are as follow.

Model

AC cable

(Cu) mm2

DC cable

AC Circuit breaker

A V IZ

Venus-3000TL 2x4,0+4,0 See below 25 250 1,45 x Iz

Venus-3600TL 2x4,0+4,0 See below 30 250 1,45 x Iz

Venus-4000TL 2x4,0+4,0 See below 30 250 1,45 x Iz

Venus-5000TL 2x4,0+4,0 See below 32 250 1,45 x Iz

Check that the operating time of the circuit breaker and fuse is

below 5 seconds.

To select power supply cables as specified in the above table (for

details, the cable manufacturer should be consulted.)

Dimension the mains (input power) and DC input cables according

to local regulations.

Double insulated shielded symmetrical copper cable with a max.

length of 5m is required for power circuit.

AC cable: Rated voltage of the cable amount to at least Uo/U=

300V/500V (in accordance with DIN VDE 0298), VDE or equivalent

approved cord, see section [Selection of fuse and cables].

DC cable: Code designation: PV1F; min.2, 5²mm, but not less than

nominal cross-sectional area of mains cable as specified as above.

Rated voltage AC U0/U 0, 6/1 kV; ambient temperature:–40 °C to

+90 °C; Max. Conductor temperature: 120 °C; TUV or equivalent

approved recommended.

All positive connections shall be made with Red insulated wire, and

all negative connections with Black insulated wires.

To guarantee the deg ree of protection IP54, the RS 485 plugs, cable

gland and cables must be matched to each other and all unused

connections must be provided with blanking plugs.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 23

4.3 Overview of Connection Area

Recommended fuse rated current value

Object Description

A

DC fuse, outside the scope of our supply

B

Photovoltaic arrays

C

Logger, outside the scope of our supply

. User can order it

from POWFUTURE.

D

Remote PC, outside the scope of our supply. User can order it

from POWFUTURE.

E

AC fuse, outside the scope of our supply

F

Power grid

Model

DC fuse

( recommended)

AC fuse

( recommended)

Venus-3000TL

26A

26A

Venus-3600TL

30A

30A

Venus-4000TL

30A

30A

Venus-5000TL

32A

32A

Powfuture Science &Technology Co., Ltd

User Manual V2.0 24

5. DISPLAY

5.1 LCD Display

After the inverte r is started, system will be ini tia lize d and d ispla y the

connection screen showing as follows;

HostStatus:Waiting

2012-08-10 12:00:00

Safty Type:VDE0126

Connecting 60s ......

After the connect ion delay, if there are no faults found, system w ill

work normally, and if there is no button pressed, the system will

display the system current information, PV, AC and every day energy

record in turn;

DC AC

HostStatus:Normal

2012-08-10 12:00:00

400.6V

6.30A

229.2V

16.45A

HostStatus:Normal

2012-08-10 12:00:00

Fgrid 50.01 Hz

Igrid 16.45 A

Pac 3768 W

Vgrid 229.2 V

MaxP 3935 W

HostStatus:Normal

2012-08-10 12:00:00

Ipv1 6.30 A

Vpv1 400.6 V

Vpv2 400.6 V

Ipv2 3.21 A

TempR 37 C

TempA 34 C

HostStatus:Normal

2012-08-10 12:00:00

80

60

40

20

10

9

8

7

6

kWh

0

By pressing the “UP”, “DOWN”, “OK” and “ESC” button on display panel

you can also review all informat ion relevant to the system, suc h as

yield power, fault info, etc.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 25

Main menu

HostStatus:Normal

2012-08-10 12:00:00

Current Value

Fault Information

History Data

Configuration

Device Information

Yield Power

Yield Power

Select “Yield Power ” optio n to ente r the sub menu and the c umulated

power generation by Day will be presented on the screen;

Yield power

HostStatus:Normal

2012-08-10 12:00:00

Today 13.60 kWh

Total 198.20 kWh

Current Value

Press “ESC” button to exit from the submenu and back to main menu.

Press the “down” button to select the “Current Value” option with “OK”

for confirmation. Subsequently, you have the free choice to check the

current value from the corresponding objects PV string1 or AC through

operation of “up” and “down” button.

PV String1

HostStatus:Normal

2012-08-10 12:00:00

AC

PV String2

PV String1 Power

HostStatus:Normal

2012-08-10 12:00:00

2523 W

PV String1 Voltage

400.6 V

PV String1 Current

6.30 A

PV String2 Power

HostStatus:Normal

2012-08-10 12:00:00

1285 W

PV String2 Voltage

400.6 V

PV String2 Current

3.21 A

Powfuture Science &Technology Co., Ltd

User Manual V2.0 26

AC Power

HostStatus:Normal

2012-08-10 12:00:00

3768 W

AC Voltage

229.2 V

AC Frequency

50.01 Hz

Fault Information.

Press “ESC” button to exit from the submenu and back to main menu.

Press the “down” button to select the “Fault Information.” option with

“OK” for confirmation. You are able to check all fault information

generated at different mome nts during the running of inverter or to

delete all the fault records.

Latest Fault

HostStatus:Normal

2012-08-10 12:00:00

Fault List

Delete Record

Error No: 2

HostStatus:Normal

2012-08-10 12:00:00

2012-06-08 09:41:50

Grid Volt Fault

Grid Freq Fault

Utility Loss

History Information

Press “ESC” button to exit from the submenu and back to main menu.

Pressing the “down” key to select the “History Information” option with

“OK” for confirmation you can check the power generation by figure or

list within 30 days.

Figure

HostStatus:Normal

2012-08-10 12:00:00

List

HostStatus:Normal

2012-08-10 12:00:00

80

60

40

20

10

9

8

7

6

kWh

0

Powfuture Science &Technology Co., Ltd

User Manual V2.0 27

Date Energy

HostStatus:Normal

2012-08-10 12:00:00

2012-08-10 13kWh

2012-08-09 32kWh

2012-08-08 46kWh

2012-08-07 39kWh

2012-08-06 49kWh

Configuration

Press “ESC” button to exit from the submenu and back to main menu.

Press the “down” button to select the “Configuration” option with “OK”

for confirmation. Subsequently, you are able to set up the “Language”,

“Date/Time”, “Address”, “Protection Set” and able to test the

overvoltage/undervoltage and overfrequency/underfrequency by

pressing the “Self Test” button.

HostStatus:Normal

2012-08-10 12:00:00

Date/time

Address

Language

Protection Set

Self Test

Language Set:

HostStatus:Normal

2012-08-10 12:00:00

Deutsch

Italiano

English

Españo

Dansk

Français

Date/Time Set:

2012-08-10 12:00:00

HostStatus:Normal

2012-08-10 12:00:00

Address Set:

HostStatus:Normal

2012-08-10 12:00:00

001

Protection Set:

Users need input password for protection setting, the interface is

showed as following

Powfuture Science &Technology Co., Ltd

User Manual V2.0 28

HostStatus:Normal

2012-08-10 12:00:00

PassWord:

0000

PassWord Set

The default password is 3816.You also can change the password by

selection the “Password Set” menu. Please remember the password

setting by yourself.

When Input the correct password, system protection parameters can

be set showing as follows.

HostStatus:Normal

2012-08-10 12:00:00

Parameter Set

Maxpower Set

Safety Type

Press “UP” or “DOWN” button to select safety type, parameter set or

maximum power set.

Safety Type

Safety Type

HostStatus:Normal

2012-08-10 12:00:00

VDE0126

Countdown Thr:

060S

Parameter Set

HostStatus:Normal

2012-08-10 12:00:00

Upper Volt:280.0V

Lower Volt:180.0V

Upper Freq:54.99Hz

Lower Freq:45.00Hz

DCI Set: 0.999A

These five parameters is set bit by bit , every bit is set by press ing the

“UP” or “DOWN” button. When setting is ok, please press the “OK”

button to set next bit, until the last bit of DCI Set to finish parameters

set.

MaxPower Set

Powfuture Science &Technology Co., Ltd

User Manual V2.0 29

MaxPower means the maximum power that system can output.

HostStatus:Normal

2012-08-010 12:00:00

5200 W

Password setting interface is showed as follows

HostStatus:Normal

2012-08-10 12:00:00

0000

New PassWord:

Original PassWord

Confirm PassWord:

0000

0000

First you shall input the current password correctly, and then press

“OK” button to set the new password, next input the new password

again to confirm the new password.

Self Test (Optional except Italy necessary)

Press the “down” button to select the “ S e lf T e s t” o ptio n w i th “OK” for

confirmation. Then machine will enlighten you as following.

HostStatus:Normal

2012-08-06 09:14:29

Self Test

OK CANCEL

Result of Test

If the “OK” button is pr essed, the machine w ill enter into “Self T est”

mode. The following is an example of self test. Every time the machine

will save the result of test automatically and cover the older test

record.

The first is the minimum frequency limi tatio n te st

FW Version:Msv200

HostStatus:Normal

2012-08-06 09:37:36

Min Freq CHECK

Threshold Reading

49.75Hz Waiting

100 mS Waiting

Waiting

While test is finished, system will show the results of test.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 30

FW Version:Msv200

HostStatus:Normal

2012-08-06 09:37:58

Min Freq CHECK

Threshold Reading

49.75Hz 49.80Hz

100 mS 87mS

PASS

Then the maximum frequency limitation test is started.

FW Version:Msv200

HostStatus:Normal

2012-08-06 09:38:34

Max Freq CHECK

Threshold Reading

50.25Hz Waiting

100 mS Waiting

Waiting

While test is finished, system will show the results of test.

FW Version:Msv200

HostStatus:Normal

2012-08-06 09:38:59

Max Freq CHECK

Threshold Reading

50.25Hz 50.15Hz

100 mS 72 mS

PASS

Next is the minimum voltage limitation test

FW Version:Msv200

HostStatus:Normal

2012-08-06 09:39:36

Min Vol CHECK

Threshold Reading

190 V Waiting

200 mS Waiting

Waiting

While test is finished, system will show the results of test.

FW Version:Msv200

HostStatus:Normal

2012-08-06 09:40:24

Min Vol CHECK

Threshold Reading

190 V 198.5 V

200 mS 096 mS

PASS

The Last is the maximum voltage limitation test

FW Version:Msv200

HostStatus:Normal

2012-08-06 09:41:04

Max Vol CHECK

Threshold Reading

265 V Waiting

100 mS Waiting

Waiting

While test is finished, system will show the results of test.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 31

FW Version:Msv200

HostStatus:Normal

2012-08-06 09:41:51

Max Freq CHECK

Threshold Reading

265 V 262 V

100 mS 083 mS

PASS

After complete the all test, you can view the final re sults b y se le ctio n

the “Result of Test” menu.

Press “UP” or “DOWN” button to view the result of minimum/maximum

frequency test and minimum/maximum voltage test result.

FW Version:Msv200

HostStatus:Normal

2012-08-10 12:00:00

Min Freq CHECK

Threshold Reading

49.75Hz 49.80Hz

100 mS 87mS

2012-08-06 09:41:56

FW Version:Msv200

HostStatus:Normal

2012-08-10 12:00:00

Max Freq CHECK

Threshold Reading

50.25Hz 50.15Hz

100 mS 72 mS

2012-08-06 09:41:56

FW Version:Msv200

HostStatus:Normal

2012-08-10 12:00:00

Min Vol CHECK

Threshold Reading

190 V 198.5 V

200 mS 096 mS

2012-08-06 09:41:56

FW Version:Msv200

HostStatus:Normal

2012-08-10 12:00:00

Max Freq CHECK

Threshold Reading

265 V 262 V

100 mS 083 mS

2012-08-06 09:41:56

Device Information

Press “ESC” button to exit from the submenu and back to main menu.

Press the “DOWN” button to select the “Device Information” option

with “OK” for confirmation. Then you can get access to system

information involving company information and ARM software version

Powfuture Science &Technology Co., Ltd

User Manual V2.0 32

HostStatus:Normal

2012-08-10 12:00:00

Product SN:

Machine Type:

01111AAX28B4U4X3

Venus5000

Safety Type:

VDE0126

HostStatus:Normal

2012-08-10 12:00:00

Monitor FW Version:

Msv200-20120730

Master FW Version:

Vdv200-00000000

Slave FW Version:

Vdv200-00000000

5.2 Error Message

If any of the following messages occurs in LCD Screen, or the status of

“Fault” LED is on, there is one or m ore error that has b een detected by

POWFUTURE Inverter.

Error No. Information

0 Grid Volt. Fault

1 Grid Volt .10min Fault

2 Grid Freq. Fault

3 Utility Loss

4 AC-Over current

5 DC Bus-Over voltage

6 PV-Over voltage

7 Device Fault

8 Cur. Sensor Fault

9 Comm. disturbed

10 Consistence Fault

11 GFCI Fault

12 GFCI Device Fault

13 DC INJ Fault

14 DC INJ Device Fault

15 Isolation Fault

16 Varistor Fa ult

Powfuture Science &Technology Co., Ltd

User Manual V2.0 33

17 CPU Ref 2.5V Fault

18 EEPROM R/W Fail

19 Relay Fault

20 Over-temperature

5.3 Troubleshooting

Error No. Message Corresponding Action

0

“Grid volt. Fault”

The gird voltage has exceeded the

permitted range according to local

gird regulations.

• Check the grid voltage.

• Check the grid connection

of the inverter.

If the grid voltage exceeds the

permitted range because of

local grid conditions, pl ease ask

the utility operator if the

voltage can be adjusted at the

feed-in point or if changes in

the values of the monitored

operational limits are possible.

If the grid vol tage tha t checke d

is within the permitted range,

yet this error is still showing in

the LCD screen, please contact

Powfuture Service Line.

1

“Grid volt. 10min Fault”

The average gird voltage over 10

minutes has been outside the

permitted range according to local

gird regulations.

Following causes might lead to

error 0 or error 1:

• Grid volt

age is too high at the

point of common coupling to the

inverter.

• Grid impedance a t t he ter mi nal

of the inverter is too high.

For safety consideration, the

inverter will disconnect itself from

the grid for a short period of time,

and it will reconnect to th

e grid

automatically af ter a short perio d of

time if the grid voltage is back to

the permitte d r a nge.

2

“Grid Frequency Fault”

The grid frequency has left the

permitted range.

For safety consideration, the

inverter will disconnect itself from

the grid f or a short period of time,

and it will reconnect to the grid

automatically af ter a short perio d of

time if the grid fre quency is back to

the permitte d r a nge.

• Within safety scope, check

the grid frequency and obse rve

how often major deviations

occur.

If there are repeated frequency

turbulences which lead to this

error, ple ase co n ta ct Powfuture

Service Line.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 34

Error No. Message Corresponding Action

3

“Utility Loss”

The inverter has detected an error

in the cabling and cannot connect

to the grid.Following causes might

lead to this error:

•

Grid connection installation

failure.

• Cabling failure.

• Incorrect country set ti ng.

• Check AC installation.

• Check grid connectio n.

• Check if the co untry setti ng

is correct:

− Via LCD screen

If this error is not solvable,

please cont

act Powfuture

Service Line.

4

“AC-Over current”

The detected AC current has

exceeded the pre-

set Max. AC

Current.

Following causes might lead to this

error:

•

Short circuit happens in the

output circuit.

If this event occurs often:

•

Please contact Powfuture

Service line.

5

“DC Bus-Overvoltage”

The voltage of the Bus which

paralleling connected with the

string is too high.

Following causes might lead to this

error:

• The DC input vo ltage connecte d

to the inverter is too high.

• Sudden DC surge.

For safety conside

ration, the

inverter will shutdown itself.

•

Please immediately

disconnect the inverter from

the PV strings (se e ch a p te r 6 .5

“DC side Disconnection”) or

else the inverter might be

damaged.

•

Check the DC voltage of

the strings fo r adherence to the

maximum inpu

t voltage of the

inverter, before you reconnect

the inverte r to the PV st rings.

6

“PV-Overvoltage”

The DC input voltage which

connects to t he inve rter is too high.

Following causes might lead to this

error:

• The open-

circuit voltage of the

PV generator is

higher than the

maximum DC input voltage of the

inverter.

• Sudden DC surge.

•

Junction temperature of solar

panel too low.

•

Please immediately

disconnect the inverter from

the PV strings (se e ch a p te r 6 .5

“DC side Disconnection”) or

else the inverter might be

damaged.

•

Check the DC voltage of

the strings fo r adherence to the

maximum input voltage of the

inverter, before you reconnect

the inverte r to the PV st rings.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 35

Error No. Message Corresponding Action

7

“Device Fault”

A fault ha s o ccur red i n o ne o r more

major components of the inverter.

For safety consideration, the

inverter will shutdown itself.

If this event occurs:

−

Please contact

Powfuture Service line.

8

“Current Sens o r Fault”

A fault ha s o ccur red i n o ne o r more

current sensor of the inverter.

For safety

consideration, the

inverter will shutdown itself.

If this event occurs:

−

Please contact

Powfuture Service line.

9

“Comm. Disturbed”

A fault has occurred in the internal

communication of the inverter.

However, the inverter continues

feeding into the grid.

If this event occurs often:

−

Please contact

Powfuture Service Line.

10

“Consistence Fault”

Following causes might lead to this

error:

• Interference device

If this event occurs often:

−

Please contact

Powfuture Service Line.

11

“GFCI Fault”

The inverter has detected a ground

fault in the PV generator.

•

The installer of the PV

generator must solve the

ground faults before you

re-connect t he s tri ng s .

• If this error is not solvable,

please contact Powfuture

Service Line.

12

“GFCI Device Fault”

The internal sensor h

as detected

that the GFCI Device is out of

function.

For safety consideration, the

inverter will shutdown itself.

If this event occurs:

−

Please contact

Powfuture Service Line.

13

“DC INJ Fa ult”

The direct component of the AC

current is out of the permitted

range.

If this event occurs often:

−

Please contact

Powfuture Service Line.

14

“DC INJ Device Fault”

A fault has occurred in the sensor

which detect s the direct com ponent

of the AC current.

For safety consideration, the

inverter will shutdown itself.

If this event occurs:

−

Please contact

Powfuture Service Line.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 36

Error No. Message Corresponding Action

15

“Isolation Fault”

There is a sudden isolation fault

which is detected by the inverter.

Normally this fault will only exist for

a very short period of time and shall

not have any bad influence to the

inverter.

If this event occurs often:

−

Please contact

Powfuture Service Line.

16

“Vari sto r Fault”

At least one of the varistors from

the DC or AC side is defected.

Following causes might lead to this

error:

• Varis

tor is bust due to

over-voltage protection.

If this event occurs:

−

Please check the

varistors as chapter 5.6

“Check Varistors”.

If this error is not solvable,

please contact Powfuture

Service Line.

17

“CPU Ref 2.5V Fault”

The CPU voltage that detected by

i

nternal sensor is deviating the

pre-set 2.5V reference line.

If this event occurs:

−

Please contact

Powfuture Service Line.

18

“EEPROM R/W Fail”

Internal devic e f a ul t.

For safety consideration, the

inverter will shutdown itself.

If this event occurs:

− Please contact

Powfuture Service Line.

19

“Relay Fault”

A fault has occurred in the relay

which will automatically disconnect

the inverter from the grid.

For safety consideration, the

inverter will shutdown itself.

If this event occurs:

−

Please contact

Powfuture Service Line.

20

“Over-temperature”

The delivered power of the inverter

was reduced below rated power

because of abnormal temperature

within 0.5s.

Following causes might lead to this

error:

•

At least one or more of the

thermally monitored varistors are

defective.

• Overheating inside.

• Not sufficient v entilation.

If this event occurs of t en:

•

Please ensure sufficient

ventilation.

• Check the varis to r s.

• If this error is not solvable,

please contact Powfuture

Service Line.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 37

6. RECYCLING AND DISPOSAL

To comply with European Directive 2002/96/EC on waste Electrical and

Electronic Equipment and its implementation as national law, electrical

equipment that has reached the end of its life must be collected

separately and retur ned to a n approve d recyc ling fa cility. Any device

that you no longer require d must be returned to your dealer or you

must fine an approved collection and recycling facility in your area.

Ignoring this EU Directive may have severe affects on the environment

and your health.

7. MAINTENANCE

Normally, the inver te r needs no maintenance o r calib ra tio n . It s ho uld

be ensured, however , that the cool ing is not o bstructed an d that the

inverter is kept dry.

To ensure the functiona lity of the DC switch, all switches should be

switched on and off (by t urnin g the sw i t c h to o n and o ff po sitio ns te n

times)once a year.

7.1 Cleaning the Cabinet

Clean inverter with a soft cloth. Do not use aggressive chemicals,

cleaning solvents or strong detergents to clean the inverter.

7.2 Cleaning the Heat Sink

In order to secure proper function and long inverter life, it is essential

that the free air circulation around the heat sink is not obstructed.

WARNIN

This device SHALL NOT be disposed

of in residential waste.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 38

No use-serviceable parts inside, before servicing and in the

event of internal malfunction the unit, send the inverter to

authorized representative or manufacturer!

Never operate this product and change any part of inverter yourself.

Only trained and authorized professional personnel WHO ARE

FAMTLIAR WITH THE REQUIREMENTS OF SAFETY was allowed to

perform servicing and maintenance work.

Wear gloves and safety glasses.

Turn off the device with the button on the front panel.

Turn off the power fuses of the device feeder cable.

Turn off DC isolating switc h in t he PV generat or and inverter.

Disconnect AC

Connection an d protec t aga inst be ing s witche d on aga in a ccide nta lly,

refer to this manual, sect ion “Safety instruction a nd EC Directives –

Isolating device”.

Waiting for 45 minutes since the internal capacitors require this long to

discharge sufficiently, the n loosen cable glands, disconne ct covering

plate from the connection area. Disconnect the power cables and

communication cables.

Unlock device by removing the holding screws in back under the

bottom cover, li ft the device from the wall and send it to a uthorized

representative or manufacturer.

You may also call authorized representative or manufacturer to

remove the invert er.

Safety checks

Safety checks should be performed at least every 12 months by

manufacturer’s qualified person who has adequate training,

knowledge, and practical experience to perform these tests. The data

should be recorded in an equipment log. If the device is not functioning

properly or fails any of tests, the device has to be repaired.

For safety check details, refer to this manual, section “Safety

instruction and EC Directives”.

Maintain periodically

Only qualified person may perform the following works.

During the process of using the inverter, the manage person shall

examine and maintain the machine regularly. The concrete operations

are as follow.

1、Check that if the inlet and outlet of the inverter are blocked, if the

fans work normally, the machine can be cleaned and abso rbed dust

when necessary. This work shall be check time to time.

2、Check that if the indicators of the inverter are in normal state, check

if the keys of inver t e r ar e in n or ma l state, check that if the dis p lay of

the inverter is normal. This check should be performed at least every 6

months.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 39

3、Check if the input and output wires are damaged or aged. This check

should be performed at least every 6 months.

4、 You should get the inverter panels cleaned and their security

checked at least every 6 months.

Before cleaning the inverter:

Wear gloves and safety glasses.

Turn off the device with the button on the front panel.

Turn off the power fuses of the device feeder cable.

Turn off DC isolating switch in the PV generator and inverter.

Disconnect AC connection and protect against being switched on again

accidentally, refer to this manual, section 3 Safety instruction and EC

Directives – Isolating device.

Clean the inverter with wet cloth carefully.

8. GUARANTY SCOPE AND GUARANTY SERVICE

8.1 POWFUTURE Factory Guaranty Scope

This guaranty declaration is solely applied to the following

POWFUTURE Grid-Connected Solar Inverter:

Venus – 3000TL

Venus – 3600TL for G83

Venus – 4000TL

Venus – 5000TL

For the above named products, you will receive a POWFUTURE factory

warranty card whic h will valid for 5 years from the date of purchase.

The POWFUTURE factory warranty covers any costs which you incur for

repair or replacement parts during the agreed period beginning at the

date of purchase of the device, subject to the guaranty conditions

listed below. This is not associated with a durability warranty.

You have the possibility of purchasing an extension of this

POWFUTURE factory warranty within the 5 years term of the

POWFUTURE factory warranty. The prices are based on the respective

POWFUTURE price list valid a t the time the warranty ext ension was

signed.

8.2 Guaranty Conditions

This guaranty declaration is solely applied when any defect of

POWFUTURE inverter is detected.

If a device becomes defective during the POWFUTURE guaranty period,

Powfuture Science &Technology Co., Ltd

User Manual V2.0 40

and it is proved that further functional performance is impossible, the

device will be, as selected by POwfuture:

Repair the defect at the factory free o f cha rge w it hin t he g uar anty

period.

Exchange for a replacement device of equivalent value according to

model and age.

If it is the latter case, the remainder of the warranty entitlement will be

automatically transferred to the replacement device. In this case, you

will not receive a new certificate since your entitlement is already

documented at POWFUTURE if the rest warranty period is more than 1

year. If a replacement occurs when rest warranty period is less than 1

year, it will automatically extend the rest warranty period to exactly 1

year.

POWFUTURE will only perform guaranty service only if the user

provides a copy of invoice which was issued to the user by the dealer

and a completed warranty c ard. If any one of these two is missing,

POWFUTURE has the rights to deny the guaranty service or only

provide paid service.

8.3 Guaranty Exclusion

Guaranty declaration is excluded in the following cases:

Transport damage

Improper installation and installation that does not comply with

standards

Use of the devices in ways not intended

Improper operations without following the user manual

Operation of units with defective protective equipment which might

lead to damage

Unauthorized modifications to the units or repair attempts

NOTICE

If exchange for a replacement device of equivalent

value according to mode l and age is needed. The

defected unit must, where possible, be returned in

its original or equivalent packaging.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 41

Influence of foreign objects and force majeure (lightning, grid over

voltage, severe weather, fire)

Insufficient ventilation of the unit

Failure to observe the relevant safety regulations

If the device becomes defective when in any of the above cases,

POWFUTURE will not perform guaranty service and the user shall take

whole responsibility for the defects.

9. ACCESSORIES

You will find the corresponding accessories and replacement parts for

you product in the following overview. If required, you can order these

from POWFUTURE.

Description Brief description

Powfutrue order

number

DC plug connector Field plug for condu ctor H4CF(M)C6DC

AC plug connector Field plug for conductor 96-031-4154-3

Powfuture Science &Technology Co., Ltd

User Manual V2.0 42

10. CONTACT

Wuhan Headquarter

Wuhan POWFUTURE Science and Technology Co.,Ltd.

Canglong Building

Changzui Optoelectronics Industrial Park

No. 18 Jiufeng Street, Jiangxia District,

Wuhan, 430074, Hubei, P.R.China

Tel: (+86)-27-86635836

Fax: (+86)-27-86635896

Email: info@ Power-future.com

www.Power-future.com

Service line

Tel: (+86)-27-86635836

Fax: (+86)-27-86635896

Email: service@Power-future.com

www.Power-future.com

Powfuture Science &Technology Co., Ltd

User Manual V2.0 43

11. ABBREVIATION

LCD

Liquid Crystal Di spl ay

LED

Light Emitting Diod e

MPPT

Maximum Power Po int Tr acki ng

PV Photovoltaic

GFCI Gro und Faul t Circ uit In ter rupter

Vdc Voltage at the DC s ide

Vac Voltage at the AC s ide

Vmpp

Voltage at the Max imum Powe r Poin t

Impp

Amperage at Maximum Power Point

Voc

Open Circuit Vo ltag e

Isc Short Circuit Current

AC Alternating Cur rent ( Form of e lectrici ty supp lied by

Utility Compan y )

DC Direct Curre nt ( Fo rm of electr icity genera ted by PV

modules )

VDE

0126-1-1

German standards for establishing suitability for Grid

Connection of the Inverter.

UL 1741

US standards for establishing suitability for Grid

Connection of the Inverter.

Powfuture Science &Technology Co., Ltd

User Manual V2.0 44

Loading...

Loading...