Page 1

Operating Instructions and Replacement Parts List 31’, 36’, 41’, 46’ Class Anchor Winch

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself

and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions

for future reference.

Unpacking

When unpacking, inspect carefully for any

damage that may have occurred during

transit. Make sure any loose fittings, bolts,

etc., are tightened before putting unit into

service.

General Safety Information

Danger means a

hazard that will

cause death or serious injury if the

warning is ignored.

Warning means a

hazard that could

cause death or serious injury if the

warning is ignored.

Caution means a

hazard that may

cause minor or moderate injury if the

warning is ignored. It also may mean a

hazard that will only cause damage to

property.

NOTE: Note means any additional

information pertaining to the product or its

proper usage.

The following safety precautions must be

followed at all times:

1. Read all manuals included

with this product carefully.

Be thoroughly familiar with

the controls and the proper

use of the equipment.

Only persons well acquainted with

these rules of safe operation should be

allowed to use the winch.

Never stand

between load or

anchor point and product. If rope breaks,

it could snap with enough force to cause

serious injury or death.

Do not use electrical wire

sizes or types other than

those specified or included

with this product.

®

Free Fall Rope and

Chain Anchor Winch

Always tie off the

mount while cruising to prevent anchor

from breaking free.

2. This product is intended to lift

anchors. Never use product to lift or

move people or animals.

3. Do not wear loose fitting clothing,

scarves, or neck ties during operations

of the product. Loose clothing may

become caught in moving parts and

result in serious personal injury or

death.

Use supplied or recommended

circuit breakers for safe

installation. The warranty will

be void and fire could result

from using improper circuit breakers.

4. Make sure area around anchor point

is clear of people or objects before

releasing or retrieving anchor.

When product

must be tied off onto a cleat to relieve motor

tension and prevent boat damage. When

trailering boat, anchor must be tied off.

5. Never substitute cable for rope.

Always disconnect

battery before attempting to install, service

or relocate unit.

6. Use of a davit with an open loop is not

recommended with this product. Use

a davit with a closed loop to prevent

serious personal injury and/or property

damage.

Never place any

while retrieving or free-falling anchor.

Serious injury could result.

Use only spliced

rodes. Shackles should not be used

to secure rope to chain. Shackles will

damage winch and could cause personal

injury. Use of shackles will also void

warranty.

anchor to a secure

is not in use, anchor

wiring harness from

object in gypsy

rope and chain

7. Stand away from product when in use

and keep children away from product

area at all times.

8. When replacing rope and chain,

always use Powerwinch® brand or

Powerwinch® certified rope and chain.

Do not attempt to

pull a load greater

than rated load of product. Personal injury

and/or property damage could occur.

9. Do not operate product under the

influence of alcohol and/or drugs.

10. Inspect entire rope for weak or worn

condition or kinking (short tight twist

or curl) before use. Replace worn or

kinked rope for proper performance

from product.

11. Inspect the entire chain for broken or

bent links before use. Chain with bent

or broken links should be replaced to

obtain proper performance.

Installation

31’, 36’, 41’ Class

Anchor Winch

This product

requires the use of a

closed loop davit or bow roller. Davit or bow

roller must be installed prior to installing

anchor winch to ensure proper performance.

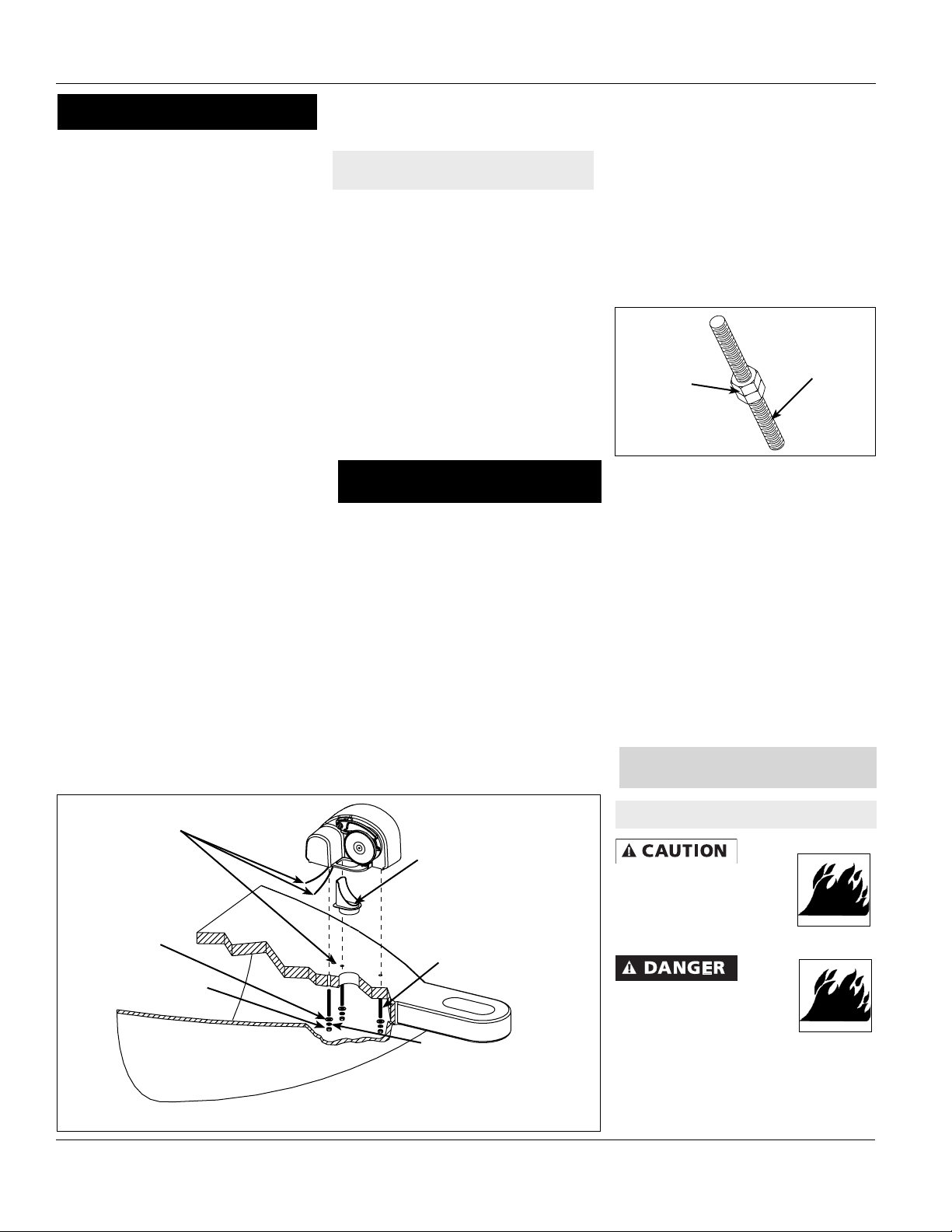

To install anchor winch, refer to Figure 1

and the following instructions:

TOOLS REQUIRED (NOT INCLUDED):

1. Electric drill

1

/

2. 2

2” hole saw

3. 11/32” drill bit

4. 5/8” drill bit

5. Adjustable wrenches

6. Terminal crimping tool and

wire cutter

7. Center punch

8. Hammer

9. Voltmeter

P1039005AVr1 April, 2012

Page 2

Operating Instructions and Replacement Parts List

Installation (Cont’d)

MATERIAL REQUIRED (INCLUDED WITH

ANCHOR WINCH):

1. Three 5/16”-18 stainless steel threaded

rods. These rods secure anchor

winch to boat. Length is determined by

thickness of boat deck.

2. Three lock washers (5/16” stainless

steel)

3. Three plain washers (5/16” stainless

steel)

4. Three nuts (5/16”-18 stainless steel)

MATERIAL REQUIRED (NOT INCLUDED):

NOTE: A wiring kit from Powerwinch® (Part

No. P55800) is available which contains

items 2-13.

1. Marine plywood for under deck support

(optional)

2. Six 1/4”- 20 x 1/2” hex head stainless

steel screws

3. Six 1/4”- 20 x 1/2” stainless steel nuts

4. Ten 5/16” 8-gauge ring terminals

5. #12 AWG red wire class 105°C

6. #12 AWG black wire class 105°C

7. Four 5/16” 12-gauge ring terminals

8. #8 AWG black wire class 105°C

(6-gauge 40’)

9. #8 AWG red wire class 105°C (6-Gauge

40’)

10. 1” diameter heat shrink tubing

11. 2” diameter heat shrink tubing

12. Wire ties

13. Four 12-gauge insulated female

5/8” Hole in Deck for

Motor Lead Wires

Flat Washer

Hex Nut

Figure 1 - AW31’, 36’, 41’ Class

disconnects

14. Silicone sealer

15. Loctite® 242 thread locker (optional)

MOUNTING ANCHOR WINCH ONTO

DECK

1. Place mounting template in desired

position on deck and secure with tape

into position. Ensure center-line of

gypsy lines up with centerline of davit

or bow roller.

IMPORTANT: Be certain anchor winch is

positioned above rope locker before drilling

any mounting holes. The anchor line and

chain will feed into rope locker through a

1

/

2” hole in boat deck and a molded part

2

called the rode glide. Minimum rope locker

dimensions required for proper storage of

anchor lines are shown in Chart 1.

2. Using a punch, mark center of each

Line Locker

Dimensions Dimensions (L x W)

1/2” x 200’ 15” x 17”

1/2” x 300’ 15” x 24”

5/8” x 200’ 15” x 24”

5/8” x 300’ 16” x 32”

Chart 1

mounting hole to be drilled. Remove

template and drill holes with an electric

drill. There are three

mounting studs, one 2

11/32” holes for

1

/2” hole for deck

insert, and one 5/8” hole for wiring

harness.

3. Place round side of insert into 21/2”

hole and seat deck insert so lip is flush

with boat deck. The half circle portion

Rode Glide

Stud

Lock Washer

NOTE: Mounting and gasket hardware

available in kits (P/N P10349 & P11162).

See page 11 for ordering information

of deck insert must be pointing toward

bow of boat.

4. Insert three mounting studs into

threaded holes on underside of winch.

A small amount of thread locker can be

used to secure studs in housing. Use

two mounting nuts to help tighten studs

into housing as shown in Figure 2.

5. Gently guide winch over rode glide so

loop on anchor winch housing slides

over deck insert. Slide three mount-ing

studs into the three mounting holes

Mounting StudMounting

Nuts

Figure 2

in deck. Feed wiring harness from

underside of winch through 5/8” hole.

6. The winch must fit squarely over deck

insert and onto deck. Slide flat washers

and lock washers onto mounting studs.

Tighten nuts to fully secure the winch to

the deck.

7. Examine winch to make sure unit is

securely fastened and that centerline of

gypsy is aligned with centerline of bow

roller or davit.

Wiring Installation

WIRING AND SWITCH INSTALLATION

Do not use electrical wire

sizes or types other than those

specified or included with this

product.

Use supplied or recommended

circuit breakers for safe

installation. The warranty will be

void and fire can result from using improper

circuit breakers.

2

Page 3

31’, 36’, 41’, 46’ Class Anchor Winch

Installation (Cont’d)

and attach plate using four #8 round

head wood screws.

4. Measure and cut 8-gauge red and

Always disconnect

wiring harness from

battery before attempting to install, service or

relocate unit.

Follow order of

wiring steps to ensure

power is not applied to anchor winch until all

wires and circuit breakers are installed.

black wire to run from anchor winch to

switch. Allow some slack to prevent

connections from being too short and

so connections can be crimped to

end of wire. Install wire in boat before

crimping any connections. Cable ties

can be used to secure wiring to boat.

5. When running wire from anchor winch

Always keep wires away

from intense sources

of heat. Be sure newly

installed wires are away from any exposed

bare wires.

to switch, be sure to keep wire away

from sources of intense heat or areas

where the insulation of wire could be

worn away.

6. After wire is installed and secured,

connection to anchor winch can be

made.

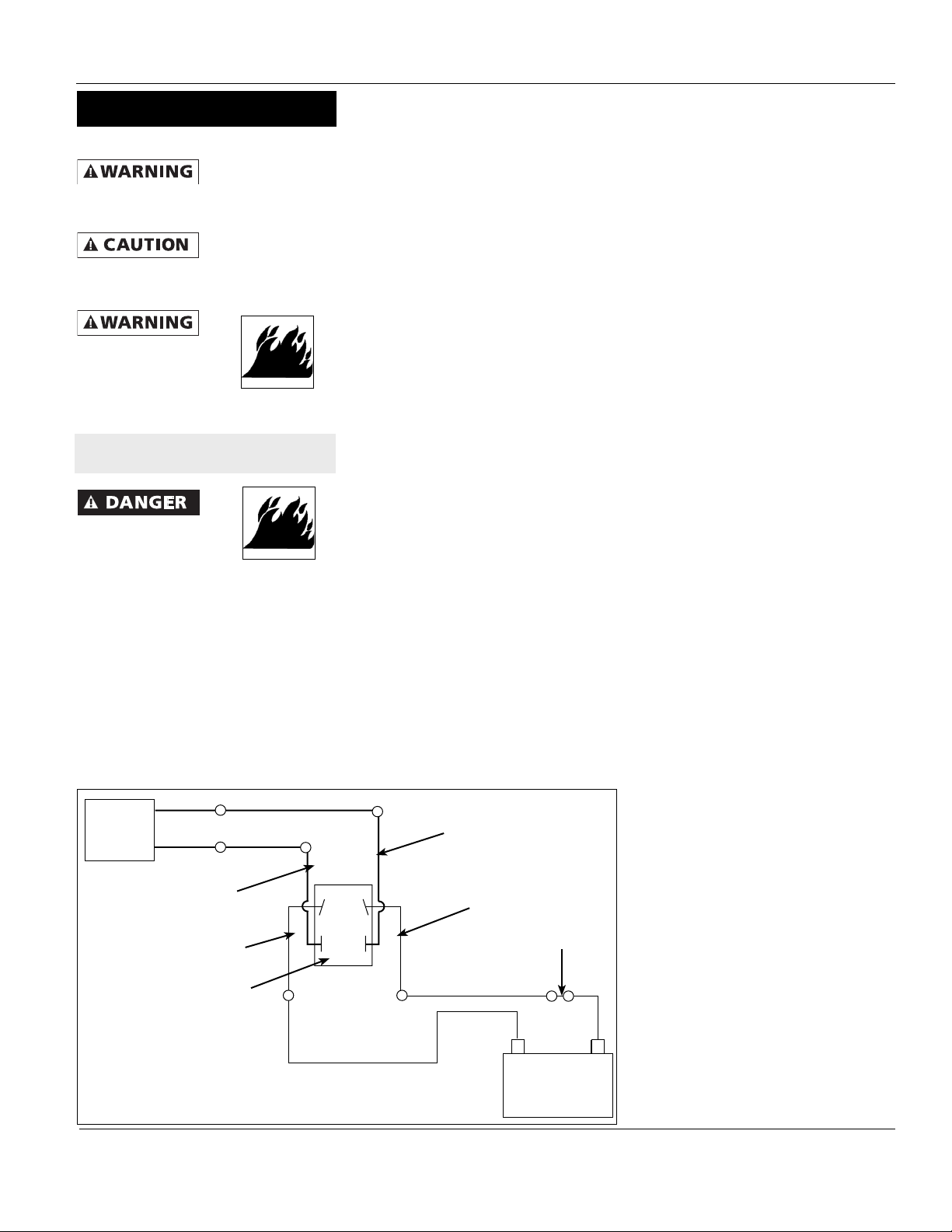

SWITCH INSTALLATION

Make sure all crimps/

connections can withstand

at least 25 pounds of pullout

force. Failure to make strong enough crimps

between wire connectors and wires could

create a fire hazard.

1. Select a suitable location (console,

etc.) to locate switch. Make sure

there is enough room behind switch

mounting surface for entire switch and

wires.

2. Cut a hole 1

3/4” high and 1” wide.

3. Apply a thin bead of silicone sealer

around edge of switch mounting plate

Anchor

Winch

*NOTE: 41’ Class uses

6-gauge red & black wire

Figure 3 - Wiring Diagram for 31’, 36’, 41’ Anchor Winch

Black

Wire

Green

Wire

12-Gauge

Red Wire

12-Gauge

Black Wire

Control Switch

(Back View)

*8-Gauge Black Wire

*8-Gauge

Red Wire

*8-Gauge Black Wire

7. Crimp a 5/16” ring terminal to 8-gauge

red wire just cut.

8. Using a 1/4”-20 x 1/2” screw, connect

8-gauge red wire to ring terminal on

the green wire coming from anchor

winch. Tighten a

1/4”-20 nut to secure ring terminals

together. Protect junction by placing a

1” diameter piece of heat shrink tubing

over connection and applying heat

until tubing is secure.

9. Crimp a 5/16” ring terminal to 8-gauge

black wire just cut.

10. Using a 1/4”-20 x 1/2” screw, connect

8-gauge black wire to ring terminal on

black wire coming from anchor winch.

Tighten a 1/4”-20 nut to secure ring

D

C

A

B

12-Gauge

Black Wire

12-Gauge

Red Wire

*8-Gauge Red Wire

-

Circuit

Breaker

Battery

terminals together. Protect junction

by placing a 1” diameter piece of

heat shrink tubing over connection

and applying heat until the tubing is

secure.

SWITCH TO ANCHOR WINCH

The switch needs 12-gauge wire

connections and wiring just run is 8gauge. To complete anchor winch

to switch connections construct two

conversion wires by following these steps:

1. This switch wire is for the positive

(red) lead.

2. Cut a 1 foot section of 12-gauge red

wire and crimp a 5/16” ring terminal to

one end.

3. Crimp an insulated female disconnect

to other end.

4. Crimp a 5/16” ring terminal to 8gauge red wire coming from anchor

winch.

5. Using a 1/4”-20 x 1/2” screw, connect

8-gauge red wire coming from anchor

winch to ring terminal on red switch

wire. Tighten a 1/4”-20 nut to secure

ring terminals together. Protect

junction by placing a 1” diameter piece

of heat shrink tubing over connection

and applying heat until tubing is

secure.

6. Plug insulated female disconnect on

end of red switch wire to rocker switch

on terminal marked “A”.

7. To construct second switch wire and

make connection to switch, cut a 1

foot section of 12-gauge black wire

and crimp a 5/16” ring terminal to one

end.

8. Crimp an insulated female disconnect

to other end.

9. Crimp a 5/16” ring terminal to 8- gauge

black wire coming from anchor winch.

10. Using a 1/4”-20 x 1/2” screw, connect

8-gauge black wire coming from anchor

winch to ring terminal on black switch

wire. Tighten a 1/4”-20 nut to secure

ring terminals together. Protect junction

by placing a 1” diameter piece of heat

shrink tubing over connection and

applying heat until tubing is secure.

+

11. Plug insulated female disconnect on end

of black switch wire to rocker switch on

terminal marked “B”.

3

Page 4

Operating Instructions and Replacement Parts List

Installation (Cont’d)

SWITCH TO BATTERY

Make sure all crimps/

connections can withstand

at least 25 pounds of pullout

force. Failure to make strong enough crimps

between wire connectors and wires could

create a fire hazard.

1. Measure and cut 8-gauge red and black

wire to run from switch to battery. Allow

some slack to prevent connections

being too short leaving enough room to

crimp end of wire. Install wire in boat

before crimping any connections. Use

cable ties to secure wiring to boat.

2. When running wire from switch to

battery, be sure to keep wire away from

sources of intense heat or areas where

insulation of wire could be worn away.

3. After wire is installed and secured, make

remaining switch connections .

4. Make two more conversion wires

t

o attach battery wiring to switch by

following these steps:

a. This switch wire is for the positive

(red) lead to battery.

b. Cut a 1 foot section of 12-gauge red

wire and crimp a 5/16” ring terminal

to one end.

c. Crimp an insulated female

disconnect to other end.

d. Crimp a 5/16” ring terminal to 8-

gauge red wire coming from battery.

e. Using a 1/4”-20 x 1/2” screw,

connect 8-gauge red wire coming

from battery to ring terminal on red

switch wire. Tighten a 1/4”-20 nut

to secure ring terminals together.

Protect junction by placing a 1”

diameter piece of heat shrink tubing

over connection and applying heat

until tubing is secure.

f. Plug insulated female disconnect

on end of red switch wire to rocker

switch on terminal marked “D”.

g. To c

onstruct second switch wire and

make connection to switch, cut a 1

foot section of 12-gauge black wire

and crimp a 5/16” ring terminal to

one end.

h. Crimp an insulated female

disconnect to other end.

i. Crimp a 5/16” ring terminal to

8- gauge black wire coming from

battery.

j. Using a 1/4”-20 x 1/2” screw,

connect 8-gauge black wire coming

from battery to ring terminal on

black switch wire. Tighten a 1/4”20 nut to secure ring terminals

together. Protect junction by

placing a 1” diameter piece of heat

shrink tubing over connection and

applying heat until tubing is secure.

k. Plug insulated female disconnect on

end of black switch wire to r

ocker

switch on terminal marked “C”.

BATTERY CONNECTIONS

1. Crimp a 5/16” ring terminal to end of

8-gauge red and black wire coming

from switch.

2. Create a jumper to connect circuit

breaker to battery by cutting a 1

foot piece of 8-gauge red wire and

crimping a 5/16” ring terminal to each

end.

3. Assemble circuit breaker to jumper by

placing ring terminal onto post marked

“bat” and secure with nut on circuit

breaker

4. Assemble circuit breaker to switch by

attaching remaining 8-gauge wire to

post on circuit breaker marked “aux.”

5. Protect connection by placing a piece

of 2” diameter heat shrink tubing over

connection and applying heat until

tubing i

s secure.

6. Connect 8-gauge black wire from

switch to negative (-) battery terminal.

7. Connect 8-gauge black wire from

switch to negative (+) battery terminal.

8. Snap control switch into switch plate

and proceed to unit test instructions.

UNIT TEST

1. With no rope or chain in gypsy, press

switch in upward position. If wiring to

switch terminals is correct, gypsy will

spin counterclockwise.

2. If gypsy does not turn, but motor runs,

switch is incorrectly wired.

3. To correct, exchange wires at terminals

A and B on switch.

46’ Class Anchor Winch

This product

closed loop davit or bow roller. The davit

or bow roller must be installed on boat

prior to installing product to ensure proper

performance.

To install anchor winch, refer to Figure 4

and the following instructions:

TOOLS REQUIRED (NOT INCLUDED):

1. Electric drill

1

/2” hole saw

2. 2

11/32” drill bit

3.

4. 5/8” drill bit

5. Adjustable wrenches

6. Terminal crimping tool and

wire cutter

7. Center punch

8. Hammer

9. Voltmeter

MATERIAL REQUIRED (INCLUDED

WITH ANCHOR WINCH):

1. Three 5/16”-18 stainless steel

threaded rods. These rods secure

anchor winch to boat. Length is

determined by thickness of boat deck.

2. Three lock washers (5/16” stainless

steel)

3. Three plain washers (5/16” stainless

steel)

4. Three nuts (5/16”-18 stainless steel)

MATERIAL REQUIRED (NOT

INCLUDED):

NOTE: A wiring kit from Powerwinch®

(Part No. P10284) is available which

contains items 2-15.

1. Marine plywood for under deck

support (optional)

Six 3/8” 6-gauge ring terminals

2.

3. #6 AWG red wire class 105°C

8. #6 AWG black wire class 105°C

4. Two 5/16” 16-gauge ring terminals

5. #16 AWG black wire class 105°C

6. #16 AWG white wire class 105°C

7. #16 AWG red wire class 105°C

8. Six 16-gauge insulated female

disconnects

9. Two 1/4”-20 x 1/2” stainless steel hex

head screw

requires use of

a

4

Page 5

31’, 36’, 41’, 46’ Class Anchor Winch

Installation (Cont’d)

10. Two 1/4”-20 x 1/2” stainless steel nuts

11. 1” diameter heat shrink tubing

12. 2” diameter heat shrink tubing

13. ATO inline fuse holder

14. 10A ATO style fuse

15. Wire ties

16. Loctite® 242 thread locker (optional)

17. Silicone sealer

18. four 3/8” 6-gauge female disconnects

LOCATING MOUNTING HOLES FOR

ANCHOR WINCH

1. Place mounting template in desired

position on deck and secure with tape

into position. Ensure center-line of

gypsy lines up with centerline of davit

or bow roller.

IMPORTANT: Be certain anchor winch

is positioned above rope locker before

drilling any mounting holes. The anchor

line and chain will feed into rope locker

through a 2

molded part called deck insert. Minimum

rope locker dimensions required for

proper storage of anchor lines are shown

in Chart 2.

2. Spot holes with center punch as

shown on template. Use an electric

drill to drill holes. There are three

32

2” hole for deck insert, and one 5/8”

hole for wiring harness.

3. Place round side of insert into 2

and seat deck insert so lip is flush with

Figure 4 - AW46’ Class

1

/

2” hole in boat deck and a

11/

” holes for mounting studs, one 21/

1

/2” hole

5/8” Hole in Deck for

Motor Lead Wires

Hex Nut

Line Locker

Dimensions Dimensions (L x W)

1/2” x 200’ 15” x 17”

1/2” x 300’ 15” x 24”

5/8” x 200’ 15” x 24”

5/8” x 300’ 16” x 32”

Chart 2

boat deck. The half circle portion of

deck insert must be pointing toward

bow of boat.

4. Insert three mounting studs into

threaded holes on underside of winch.

A small amount of thread locker can

be used to secure studs in housing.

Use two mounting nuts to help tighten

studs into housing as shown in Figure

5.

5. Gently guide winch over rode glide

Mounting StudMounting

Nuts

Figure 5

so loop on anchor winch housing

slides over deck insert. Slide three

mounting studs into three mounting

holes in deck. Feed wiring harness

from underside of winch through 5/8”

hole.

6. The winch must fit squarely over

deck insert and onto deck. Slide

flat washers and lock washers onto

Rode Glide

Stud

Flat Washer

Lock Washer

NOTE: Mounting and gasket hardware

available in kits (P/N P10349 & P11162)

mounting studs. Tighten nuts to fully

secure winch to deck.

8. Examine winch to make sure unit is

securely fastened and that center-line

of gypsy is aligned with centerline of

bow roller or davit.

WIRING AND SWITCH INSTALLATION

Do not use electrical wire

sizes or types other than

those specified or included

with this product.

Use supplied or recommended

circuit breakers for safe

installation. The warranty will

be void and fire could result

from using improper circuit

breakers.

Always disconnect

battery before attempting to install, service

or relocate unit.

Follow order of

ensure power is not applied to anchor

winch until all wires and circuit breakers

are installed.

Always keep wires away

from intense sources of heat.

Be sure newly installed wires

are away from any exposed bare wires.

wiring harness from

wiring steps to

SWITCH AND SOLENOID LOCATION

1. Select a suitable location (console,

etc.) to locate switch. Make sure

there is enough room behind switch

mounting surface for entire switch

and wires.

3

2. Cut a hole 1

/

4” high and 1” wide.

3. Apply a thin band of silicone sealer

around edge of switch mounting plate

and attach plate using four #8 round

head wood screws.

4. Select a suitable location for relay

(reversing switch). Locate reversing

switch within 6-8 feet of switch plate

and in a location away from exposure

to water. Mount relay with power

terminals facing up.

5

Page 6

Operating Instructions and Replacement Parts List

Installation (Cont’d)

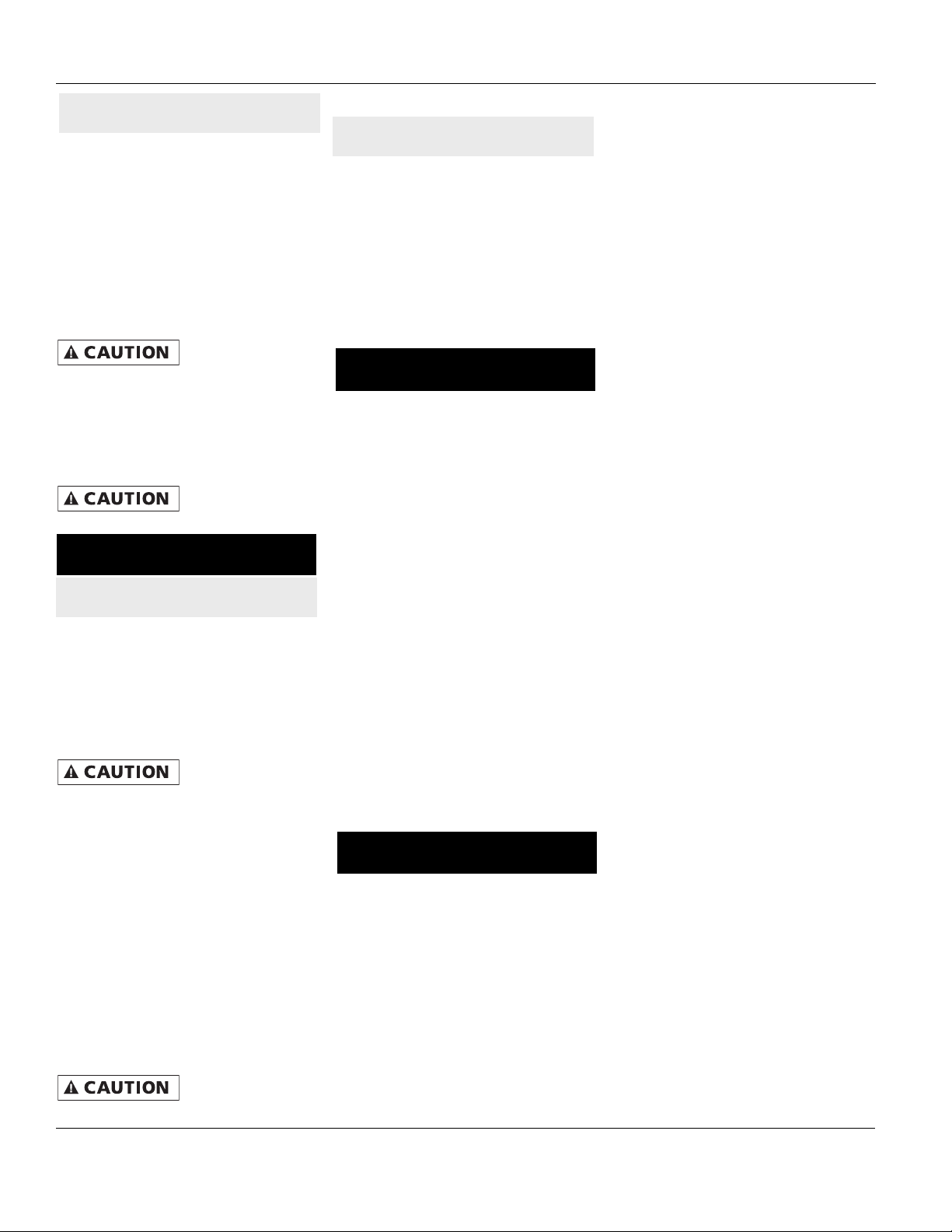

WIRING ANCHOR WINCH TO

RELAY (REFER TO FIGURE 6)

Make sure all crimps/

connections can withstand

at least 25 pounds of pullout

force. Failure to make strong

enough crimps between wire

connectors and wires could

create a fire hazard.

1. Measure and cut 6-gauge red and

black wire to run from anchor winch to

relay. Allow some slack to prevent

connections being too short leaving

enough room to crimp end of wire.

Install wire in boat before crimping any

connections. Use cable ties to secure

wiring to boat.

2. When running wire from anchor winch

to relay, be sure to keep wire away

Red

t or areas

Black 6-Gauge

Red 6-Gauge

from sources of intense hea

where insulation of wire could be worn

away. Cable ties can be used to secure

wiring to boat.

3. After wire is installed and secured,

connection to anchor winch can be

made.

4. Crimp 3/8” ring terminals to 6-gauge

red and black wire connected to anchor

winch.

5.

Attach 6-gauge red wire to red wire

coming from anchor winch. Secure

junction by placing a 1/4”-20 x 1/2”

Black

Anchor

(from motor)

Winch

(from motor)

screw through ring terminals and tighten

a 1/4”-20 nut on screw. Protect junction

by placing a 1” diameter piece of heat

shrink tubing over connection and

applying heat until tubing is secure.

6. Attach 6-gauge black wire to black wire

coming from anchor winch. The junction

can be secured in same manner as 6gauge red wire in step 5.

7. The connections at relay from

anchor winch can now be made.

8. Crimp 3

/8” female disconnects to red and

black wires to be attached to relay.

9. Connect 6-gauge red wire to relay

on post marked M1 and secure

by tightening supplied nut.

10. Connect 6-gauge black wire to relay

on post marked M2 and secure

by tightening supplied nut.

WIRING SWITCH TO RELAY

Make sure all crimps/

connections can withstand

at least 25 pounds of pullout

force. Failure to make strong

enough crimps between wire

connectors and wires could

create a fire hazard.

1. Measure a 16-gauge red, white,

and black wire to run from switch to

relay. Allow some slack to prevent

connections being too short leaving

enough room to crimp end of wire.

Install wire in boat before crimping any

nnections. Use cable ties to secure

co

wiring to boat.

2. When running wire from switch to

relay, be sure to keep wire away

from sources of intense heat or areas

where insulation of wire could be worn

away. Cable tie

s can be used to secure

wiring to boat.

3. Once wires are run and secured,

connect wires from switch to relay.

4. Starting on the wire ends for switch,

crimp one 16-gauge insulated female

disconnect to red wire.

5. Plug red wire into middle post on back

of switch.

6. Next, crimp a 16-gauge insulated

female disconnect to white wire.

7. Plug white wire into top post on back of

switch.

8. Crimp a 16-gauge insulated female

disconnect to black wire.

9. Plug black wire into bottom post on

back of switch.

10. Make connections at relay.

11. Crimp a 16-gauge insulated female

disconnect to white wire.

12. Plug wh

e into terminal marked S1

ite wir

on the relay.

13. Crimp a 16-gauge insulated female

disconnect to black wire.

14. Plug black wire into terminal marked S2

on relay.

15. Using a 16-gauge butt connector,

connect fuse holder to red wire.

16. Crimp a 16-gauge insulated female disconnect

to remaining open end of fuse holder.

17. Attach fuse holder with disconnect

crimped to it to terminal marked S3

on relay.

18. Insert 10 amp ATO style fuse in fu

se

holder.

UP

DWN

Control

Switch

White 16-Gauge

Red 16-Gauge

Black 16-Gauge

10A Inline Fuse

M1 M2

S1

S3

S2

Relay

Module

Red 6-Gauge

Black 6-Gauge

6

Circuit Breaker

Battery

PW46001

WIRING RELAY TO BATTERY

Make sure all

connections can

at least 25 pounds of pullout

force. Failure to make strong

enough crimps between wire

connectors and wires could create a fire

hazard.

crimps/

withstand

1. Measure 6-gauge red and black wire

to run from relay to battery. Allow

Page 7

31’, 36’, 41’, 46’ Class Anchor Winch

Installation (Cont’d)

some slack to prevent connections

being too short leaving enough room to

crimp end of wire. Install wire in boat

before crimping any connections. Use

cable ties to secure wiring to boat.

2. When running wire from solenoid to

battery, keep wire away from sources of

intense heat or areas where insulation

of wire could be worn away.

3. Once wires are run and secured,

connect wires from switch to solenoid.

4. Crimp 3/8” ring terminals to 6-gauge

red and black wire to be connected to

solenoid.

5. Attach 6-gauge red wire to post marked

“+” on solenoid. Secure with supplied

nut.

6. Attach 6-gauge black wire to post

marked “-” on solenoid. Secure with

supplied nut.

7. Attach end of the jumper with ring

terminal to terminal marked “-” on

solenoid.

8. At end of 6-gauge red wire coming from

solenoid, crimp a 3/8” ring terminal.

9. At end of 6-gauge black wire coming

from solenoid, crimp a 3/8” ring terminal.

10. Create a jumper to connect circuit

breaker to battery by cutting a 5/16” ring

terminal to each end.

11. Attach circuit breaker to jumper just

created by securing post marked “bat”

through one of the ring terminals.

Secure with nut on circuit breaker post.

12. Attach remaining 6-gauge red wire

coming from the solenoid on circuit

breaker to post . The post on circuit

breaker marked “aux” must be

connected to this wire.

13. Protect connection by placing a piece

of 2” diameter heat shrink tube over

connection and applying heat until

tubing is secure.

14. The 6-gauge black wire from solenoid

can now be connected to negative (-)

battery terminal.

15. The 6-gauge red wire with circuit

breaker can now be connected to

positive (+) battery terminal.

16. The connections are now complete.

17. Snap control switch into switch plate and

proceed with unit test instructions.

UNIT TEST

1. Without rope or chain in gypsy, press

and hold switch in upward position. If

wiring to switch terminals is correct,

gypsy will spin counterclockwise.

2. If gypsy does not turn, but motor runs,

switch is incorrectly wired.

3. To correct, exchange locations of black

and white wires on back of switch.

4. If motor does not run, check to make

sure fuse has been installed in fuse

holder located in 16-gauge red switch

wire.

Anchoring Instructions

LOADING ROPE AND CHAIN

Use of rope NOT

specified by

Powerwinch® could cause unit or property

damage or personal injury and will void

warranty.

1. Feed rope through davit or bow roller

and pull toward anchor winch. Make

sure rope is not twisted or kinked and

can freely run through bow roller or

davit.

2. Lift finger and insert rope into rode

glide and down into rope locker. Allow

enough slack so rope can be tied off in

rope locker.

3. Release finger and make sure rope is

firmly seated in the gypsy.

4. Go below to rope locker and tie rope off.

5. Press switch up and begin retrieving

rope and chain into rope locker.

USING PROPER ROPE AND CHAIN

Powerwinch® Recommended Rope and Chain

Product Model Required Rope Required Chain

31’/36’ Class

41’/46’ Class

FAILURE TO USE RECOMMENDED ROPE AND CHAIN WILL VOID PRODUCT

WARRANTY

Chart 3 - Recommended Rope and Chain

1/2” diameter, three strand,

medium lay, premium nylon

Powerwinch® rope or New

England Rope

5/8” diameter, three strand

medium lay, premium nylon

Powerwinch® rope or New

England Rope

1/4” Acco G4 Hi-Test chain.

Failure to use recommended

chain will invalidate the

warranty of the product

5/16” Acco G4 Hi-Test chain.

Failure to use recommended

chain will invalidate the

warranty of the product

7

This product is a uniquely designed device

to raise and lower anchors using spliced

rope and chain rodes (a rode is a length of

rope and chain). It is very important that

only sizes and brands of spliced rope and

chain rodes specified by Powerwinch® are

used in this product. Use of non-specified

ropes and chains could cause reduced

levels of performance or serious personal

injury and/or property damage. Use of

non-specified ropes and chains will also

invalidate the product warranty. The ropes

and chain rodes specified for this anchor

winch are shown on page 7 in Chart 3.

Once an anchoring spot and depth is

determined, anchor may be released.

Page 8

Operating Instructions and Replacement Parts List

ANCHORING

• Turn boat into wind and place

motor(s) in neutral.

• After boat has stopped all forward

progress, drop anchor by pressing

anchor winch switch to down position

for five seconds.

• The anchor will release from bow

roller or davit and free-fall to sea bed.

Once anchor has begun free-falling,

it is safe to release switch.

After desired

amount of scope has

been released from anchor winch, retrieve

3-5 feet of line with anchor winch by pressing

switch to up position.

• Place boat’s motor(s) in neutral and

allow boat to drift back and set anchor

in sea bed.

Tie off anchor line

to a deck cleat. Do

NOT use anchor winch to tie off anchor.

Unit Operation

RETRIEVING THE ANCHOR

• Untie anchor line from deck cleat.

• To retrieve anchor, align bow of boat

with anchor rode.

• Place motor(s) in forward and move

boat slowly toward anchor point.

While moving, press anchor winch

switch up and retrieve anchor rode.

Do NOT pull boat

to anchor point

solely with anchor winch. The anchor

winch’s gear train or motor could suffer

damage. The boat’s motor MUST be used

to move boat toward anchor point.

• When chain begins entering gypsy,

this is an indication that the rode is

almost retrieved. Take care to prevent

anchor from being pulled up too

quickly into davit or bow roller.

• When anchor enters davit or bow

roller, do not place too much tension

on chain between anchor winch and

anchor. This could cause damage to

gypsy or davit. It may also degrade

free-fall performance on next anchor

drop.

Never use anchor

winch to break

anchor free. Never reverse anchor winch

while unit is in free-fall.

ANCHOR RELEASE (FREE-FALL)

To release anchor, push switch to down

position and hold for 5 seconds. The unit

will disengage and anchor will fall freely.

When sufficient line has been released and

gypsy has stopped turning, push switch to

up position and pull in slack on rode.

To retrieve anchor, push switch to up

position. When anchor is in bow roller or

davit, release switch. Make sure anchor is

secured in davit or bow roller.

Maintenance

1. Following each boat outing, flush

exterior of winch with fresh water. Use

only mild detergents to clean exterior.

Use of solvents may cause damage

and reduce effectiveness of corrosion

resistant parts, paint and gaskets, as

well as void product warranty.

2. Every 6 months inspect gypsy, stripper,

finger and deck insert for wear. Replace

any worn components.

3. Check electrical connections every 6

months for corrosion. Replace any

connection or wire which is damaged,

corroded, frayed or worn.

4. Check rope periodically for abrasion or

deep cuts. Never splice an old rope

with a new rope. If replacement is

necessary, use only Powerwinch® rope

specifically designed for this product.

5. Check chain periodically for bent links

and corrosion. Damaged links can

become jammed in gypsy or damage

stripper and finger. Use of damaged

chain will void warranty.

Technical Service

For information regarding operation or

repair of this product, please call 800-2433097 for assistance.

8

Page 9

31’, 36’, 41’, 46’ Class Anchor Winch

Troubleshooting Guide

Symptom Possible Cause(s) Corrective Action

Product will not operate

Rope slips or jams when

retrieving

Chain slips or jams when

retrieving or free falling

Anchor line will not freefall

1. Disconnected, bad wiring or bad

circuit breakers

2. 10A fuse not in fuse holder or

burned out (AW46’ only)

1. Wrong rope size

2. Rope is frayed and worn

3. Rope is too stiff

1. Wrong chain size

2. Chain links are bent or corroded

3. Chain is kinked

1. Rope tangled in rope locker

2. Chain is kinked

3. Anchor is wedged in bow roller

1. Check each connection with a voltmeter and with switch

engaged. Check circuit breaker connection closely

2. Replace fuse

1. Replace rope with Powerwinch® certified 1/2“ or 5/8“ rope

2. Replace rope

3. Replace rope

1. Replace chain with Powerwinch® certified 1/4“ or 5/16“

Acco G4 High Test chain

2. Replace chain

3. Unkink chain

1. Be sure rope is not kinked or twisted before anchoring

2. Unkink chain

3. Free anchor

LIMITED WARRANTY

A.This Limited Warranty is given by the Powerwinch Division of the Scott Fetzer Company (the “Company”) to the original purchaser (the

“Purchaser”) of a Powerwinch Product (the “Product”) specified in this manual. This Limited Warranty is not transferable to any other

party.

B. Responsibilities of the Company under this Limited Warranty:

1. Repair or replace (at the discretion of the Company) any part or parts of the Product found by the Company to be defective within a

2 year (AW31’), 3 year (36’/41’/46’) period from the date of purchase.

2. The Company will pay the transportation charge for shipment back to the Purchaser of any Product received for legitimate Warranty

repair.

C. Responsibilities of the Purchaser under this Limited Warranty:

1. Complete (fully and accurately) and return to the Company, the Warranty card included in the box. Otherwise, Purchaser will have

to show dated proof of purchase to qualify for service under the provisions of the Limited Warranty.

2. Promptly notify the Seller or the Company of any claim hereunder.

3. Use reasonable care in maintenance, operation, use and storage of the Product in accordance with the instructions contained in the

Owner’s Manual.

4. Have Warranty work performed by an authorized Powerwinch warranty repair center or representative approved by the Company.

5. Except as noted in B.2., transportation charges are the responsibility of the Purchaser.

D. This Limited Warranty covers:

1. Defects in workmanship or materials.

2. Any part or parts of the Product sold or manufactured by the Company.

E. This Limited Warranty does not cover:

1. Any failure that results from improper installation of the Product.

2. Any failure that results from accident, Purchaser’s abuse, neglect, modification, improper maintenance, or failure to operate and

use the Product in accordance with the instructions provided in the Owner’s Manual supplied with the Product.

F. There is no other express warranty. Implied warranties, including those of merchantability and fitness for a particular purpose, are

limited to one (1) year from date of purchase. This is the exclusive remedy and any liability for any and all incidental or consequential

damages or expenses whatsoever is excluded. Some states do not allow limitations on how long an implied warranty lasts, or do not

allow exclusion or limitation of incidental or consequential damages, the above limitations may not apply to you.

Do Not Return Your Product To The Factory. Unauthorized Returns Will Delay Repair of Your Product and Incurr Additional

Shipping Charges to You.

This Limited Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Powerwinch reserves the right to alter specifications on any product without notice.

All rights reserved. This publication or parts thereof may not be reproduced in any form without written permission.

9

Page 10

Operating Instructions and Replacement Parts List

For Replacement Parts, Call 1-800-243-3097

J

I

J

J

J

F, G

F, G

F

F, G

G

J

K

G

H

H

H,J

H,J

F,G,J

J

L

M

D

H,J

E,J

A

A,J

A

B

H,J

D,K

C,J

E

I

J

B

C

B,J

J

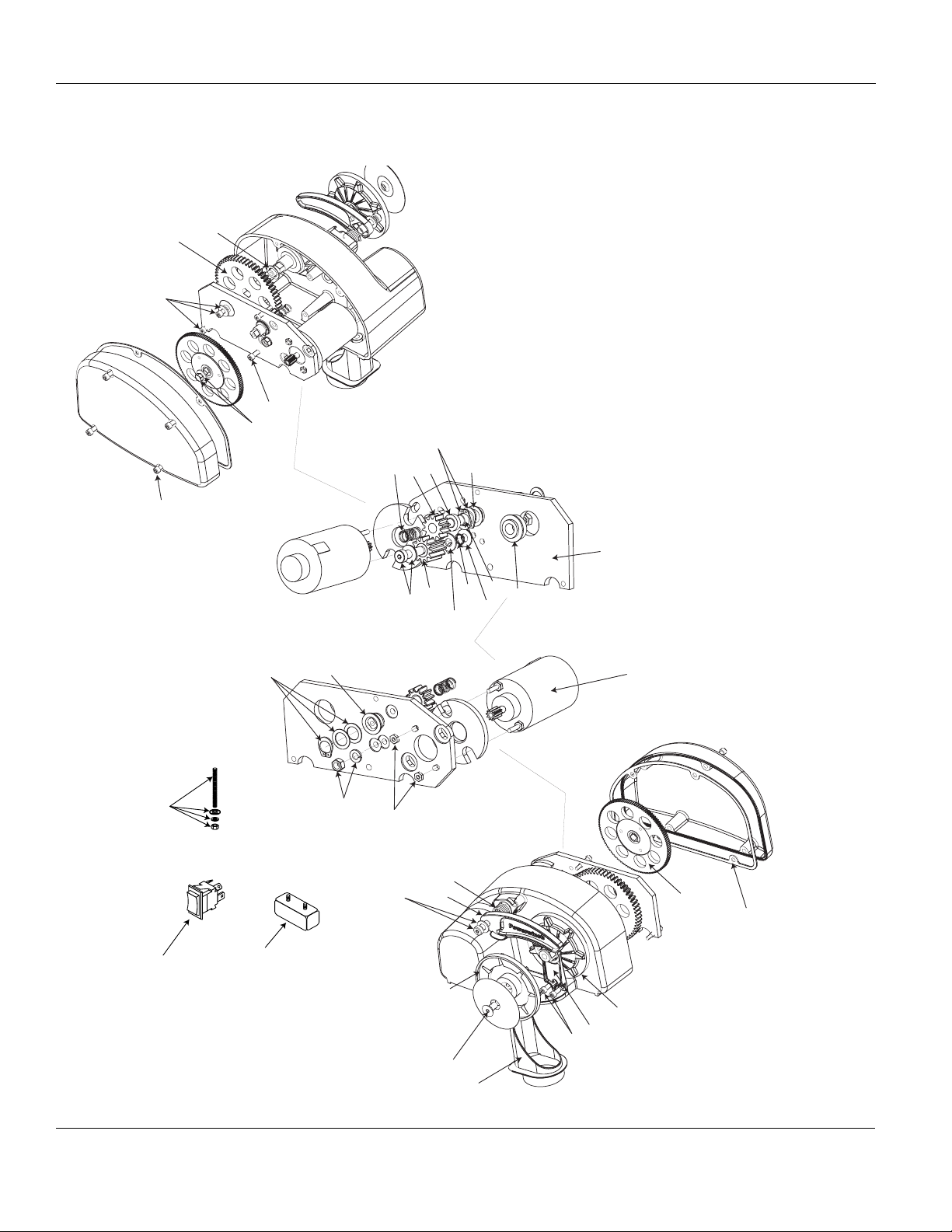

Figure 7 - Replacement Parts Illustration for 31’, 36’, 41’ Class Anchor Winch

10

Page 11

31’, 36’, 41’, 46’ Class Anchor Winch

For Replacement Parts, Call 1-800-243-3097

J

I

J

H,J

H

F,G

N

H,J

E

F,G

G

K

D,K

J

J

D

G,J

G

H,J

J

L

Figure 8 - Replacement Parts Illustration for 46’ Class Anchor Winch

M

A,J

A

B

B,J

A

I

J

B

C

C,J

J

11

Page 12

For Replacement Parts, Call 1-800-243-3097

Please provide following information: Address parts correspondence to:

-Model number Carefree/Powerwinch

-Serial number (if any) 2145 West 6th Street

-Part description and number as shown in parts list Broomfield, CO 80020.

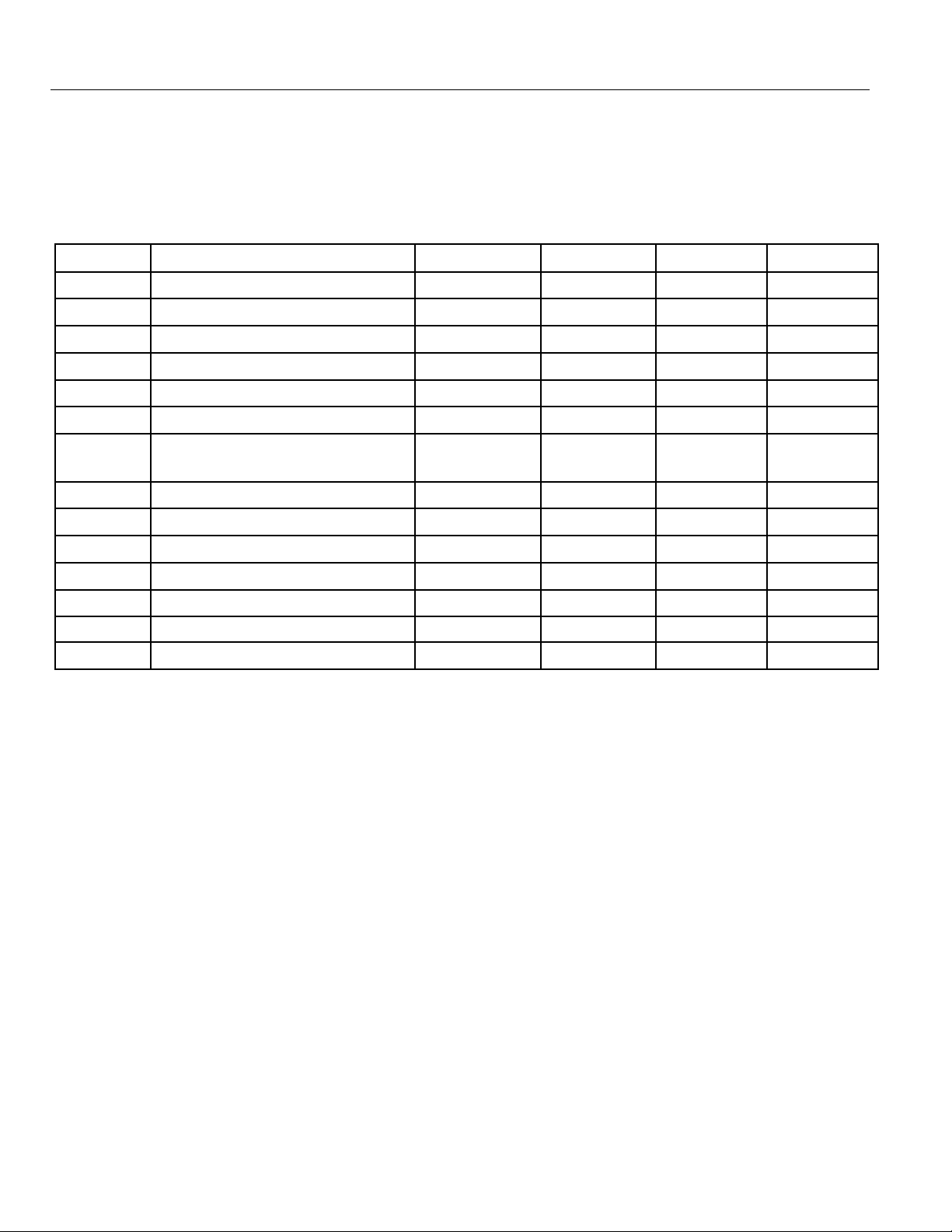

Ref. Letter Description 31’ Class 36’ Class 41’ Class

A Replacement Finger Kit R001430 R001443 R001443

B Replacement Gypsy Kit R001431 R001431 R001449

C Replacement Stripper Kit R001432 R001432 R001432

D Replacement Bearing Kit R001433 R001433 R001433

E Replacement Motor Kit R001434 R001434 R001434

46’ Class

R001443

R001449

R001432

R001443

R001450

F Replacement Shock Absorber Kit R001435 R001435 R001435

G Replacement Spinoff Gear/Shaft

R001436 R001436 R001436

R001446

Kit

H Replacement Locking Gear Kit R001437 R001437 R001437

I Replacement Gear Kit R001438 R001438 R001438

J Replacement Fastener Kit R001439 R001439 R001439

K Replacement Motor Plate Kit R001440 R001440 R001440

L Replacement Switch Kit R001441 R001441 R001441

R001445

R001438

R001444

R001440

R001447

M Replacement Circuit Breaker Kit P1027600AJ P1027600AJ P1027600AJ P1064800AJ

N Replacement Relay Kit - - -

P1028200AJ

-

Page 13

Operating Instructions and Replacement Parts List

Notes

31’, 36’, 41’, 46’ Class Anchor Winch

Loading...

Loading...