Page 1

OPERATION AND PARTS MANUAL

®

BOAT TRAILER WINCH

MODEL 915

READ CAREFULLY BEFORE ATTEMPTING TO ASSEMBLE, INSTALL, OPERATE OR MAINTAIN THE

PRODUCT DESCRIBED. PROTECT YOURSELF AND OTHERS BY OBSERVING ALL SAFETY IN FOR MA TION.

FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY

DAMAGE. RETAIN INSTRUCTIONS FOR FUTURE REFERENCE.

Description

Trailer winches are used for launching and loading

boats. This winch features power-in and power-out

ca pa bil i ties with a hand-held re mote con trol device.

Unpacking

When unpacking this product, carefully inspect for any

damage that may have occurred during transit.

DESIGNED TO HOLD RATED LOADS. ALWAYS

LEAVE A MIN I MUM OF FIVE WRAPS OF CA BLE ON

THE DRUM AT THE BOTTOM LAYER TO ACHIEVE A

RATED LOAD.

General Safety (Continued)

THE CABLE FASTENERS ON THIS OR ANY

WINCH ARE NOT

General Safety Information

The following safety precautions must be followed at

all times:

1. Read all manuals included with this product careful ly. Be thoroughly familiar with the controls and

the proper use of the equipment. Only persons

well acquainted with these rules of safe operation

should be allowed to use the winch.

8. Inspect the entire cable for weak or worn condition or

9. When replacing the cable, always use a Powerwinch

10. Never substitute rope for cable. Possible injury

11. Do not attempt to pull a load greater than the rated

12. Do not use the winch to hold or support the load

ALWAYS UNPLUG

THE WIRING HARNESS TO PREVENT AC CIDEN TAL STARTING BEFORE AT TEMPT ING TO

INSTALL, SERVICE, RELOCATE OR PERFORM

ANY MAINTENANCE.

2. Never use the winch to lift or move people or animals.

3. Stand away from the winch when in use and keep

chil dren free from winch area at all times.

ALWAYS STAND

CLEAR OF THE AREA BE TWEEN THE LOAD OR

ANCHOR POINT AND THE WINCH. SERIOUS

INJURY COULD OCCUR, IF THE CABLE BREAKS.

4. Always keep hands clear of cable spool (drum

area).

5. Do not wear loose fitting clothing, scarves, or neck

ties. Loose clothing may become caught in moving parts and result in serious personal injury.

6. Never use the winch for over head lifting.

7. Always wire the winch with circuit breakers. Failure

to use the breakers could cause overheating thus

creating a potential fire hazard or motor damage.

13. Never wrap the winch cable around the load. Use

14. Always wear leather gloves when handling the

socket to avoid moisture collection in the socket

and prevent the pos si bil i ty of short circuiting.

15. Always block the vehicle wheels to help prevent

16. Do not operate the winch under the influence of

Various load conditions will affect the winch per formance. The line pull required for a specific application depends on the weight of the load, condition of

the trailer rollers, and the degree of the loading ramp

incline. The chart on the following page is based on a

single line pull and is a guideline to aid in calculating

pulling requirements.

kinking (short tight twist or curl) before each use.

cable with the same winch rating and cable

strength.

could occur.

load of the winch.

once a job is complete or to permanently secure

the load. Damage could occur to the winch or the

load..

an Ecostrap™ or chain to prevent the cable from

kinking or fraying.

cable. Steel cable can cause hand injuries.

After using the winch,

always disconnect the

pow er cord from the

the vehicle from rolling when pulling a load with

the winch.

drugs, alcohol, or other medication.

Specifications

Copyright, 2006 Carefree of Colorado

P7040104AV 12/06

Page 2

P7040104AV MODEL 915

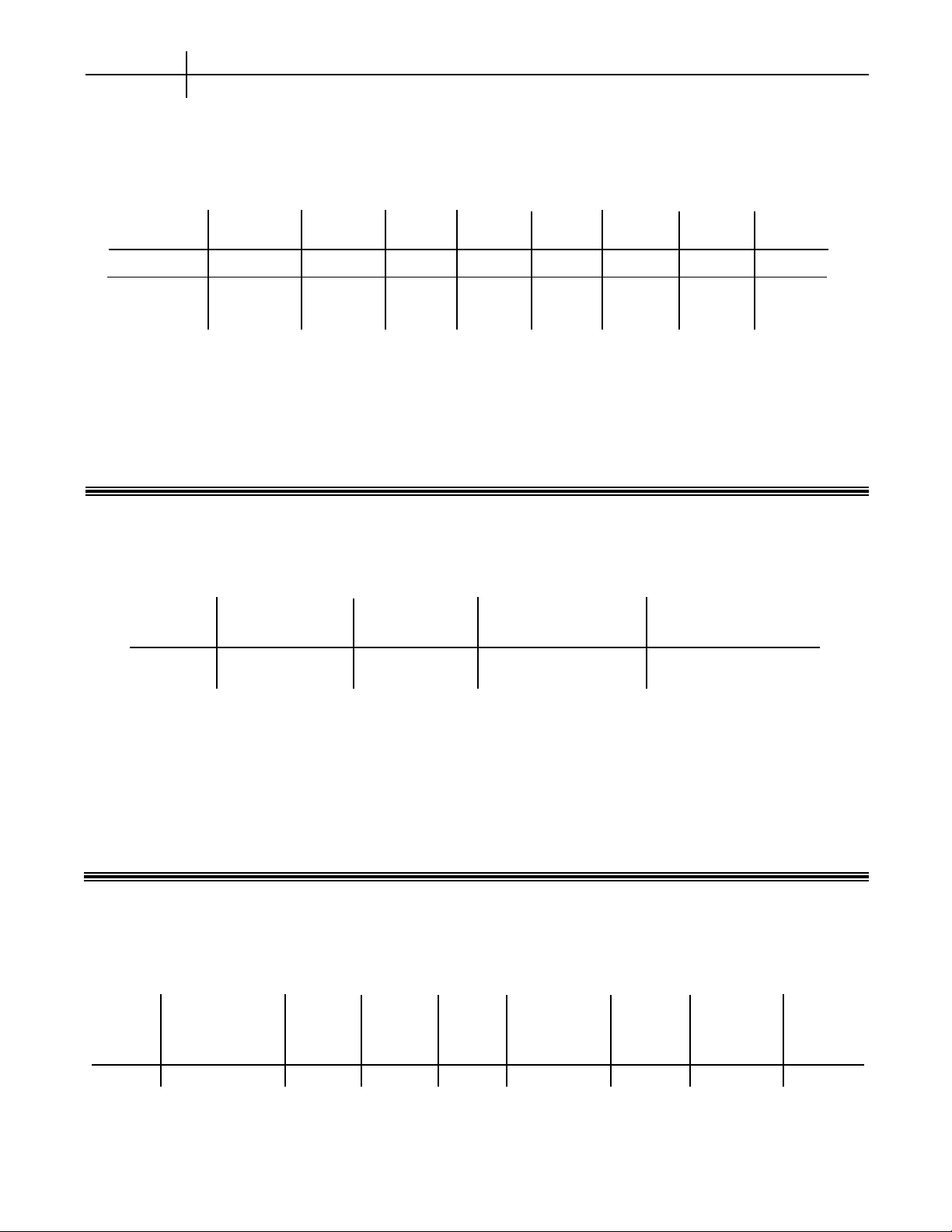

Chart 1 Approximate Rolling Load Capacities

Level

% incline Surface 5% 10% 20% 30% 50% 70% 100%

(° incline) 0° 3° 6° 11° 17° 26° 35° 45°

Boat Wt.

(in lbs.) 32,000 20,010 15,060 10,200 7,830 5,580 4,590 3,870

• A 10% incline (or 6°) is 1 ft rise in 10 feet.

• To convert pounds to kilos divide by 2.2.

• Capacity can be increased (almost doubled) by using a pulley block.

Chart 2 Winch and Boat Capacities

Single Double Approximate* Approximate*

Model Line Pull Line Pull Boat Weight Boat Size

915 3,200 lbs 5,900 lbs 9,500 lbs 22-29 ft

* Boat size and weight are approximate and varies depending on boat type. When cal cu lat ing the boat

weight, be sure to use fully loaded weight in clud ing boat, motor, fuel ,etc.

Chart 3 Winch Specifications

Line Speed @ Gear Voltage Circuit Unit Weight

Model Capacity (FPM) Ratio (volts) Breaker (lbs) Depth Height Width

(amps)

915 10 450:1 12 60 40 10” 10” 8”

– 2 –

Page 3

P7040104AV MODEL 915

Installation

MOUNTING

The winch can be mounted on the trailer in the same

position and location as a present winch. After re moving the hand winch, bolt the Powerwinch unit using a

min i mum of (2) 3/8” Grade 5 machine bolts and lock

nuts. The Powerwinch Quick Mount Kit (P7700000AJ)

is avail able from the dealer.

The cable hook on the winch and the bow eye on the

boat should be at the same height when the boat is in

the fully loaded position on the trailer. If the bow eye is

too high, extra pull is required of the winch and extra

stress is exerted on the boat’s stern and bow eye.

To achieve equal height of the winch and boat, raise or

lower the winch stand. In most cases, the trailer manu fac tur er will have an adapter available for use with a

inch.

A minimum of 12 inch

clearance is required

be tween the winch and the bow eye to prevent the

cable hook from being drawn into the winch drum

when the boat is in the fully loaded position on the

trailer.

If necessary, extend the bow stop to obtain the clearance.

When using a double line pull (using a pulley block),

install an appropriate eye bolt on the winch stand as

close as possible to the base of the winch. If a Quick

Mount Kit is used, make sure the winch is in the forward position before installing the eye bolt.

PERMANENT WIRING

To permanently wire the winch, refer to Figure 1 follow

the outlined procedures.

Rear Mounted Winch

1. Attach the circuit breaker to the positive (+) battery

post or to the positive (+) battery side of the starter

solenoid (See Figure 1).

Never attach the circuit breaker to the

battery ground terminal.

2. Run the wire under the vehicle to the battery, at taching at suitable intervals to the vehicle frame. Use

nylon wire ties (not supplied) to secure the wire to

the vehicle frame about every 18 inches. If no wire

ties are available use electrician’s tape. Avoid sharp

edges or places where the wire might rub.

3. Attach the ground wire (black) to the vehicle frame

using a 5/16” bolt and lock nut. Before attaching

the wire, clean the metal with a wire brush, steel

wool, or sandpaper.

4. Remove the knock out plug in the spare tire well and

draw the excess wire up into the vehicle.

Front Mounted Winch

1. Attach the circuit breaker to the positive (+) battery

post or to the positive (+) battery side of the starter

solenoid (See Figure 1).

2. Cut the harness at the circuit breaker end to the

required length.

BATTERY

TERMINAL

*

12 VOLT CAR

OR TRUCK

BATTERY

NOT SUPPLIED

*

Figure 1 Permanent Wiring Hookup

– 3 –

5/16" BOLT

5/16"LOCK WASHER

AND NUT

*

VEHICLE

FRAME

*

Page 4

P7040104AV

Installation (continued)

MODEL 915

1. Attach the winch cable hook to the bow eye on the

boat (See Figure 2).

3. Run the wire under the vehicle to the battery, at taching at suitable intervals to the vehicle frame. Use

nylon wire ties (not supplied) to secure the wire to

the vehicle frame about every 18 inches. If no wire

ties are available use electrician’s tape. Avoid sharp

edg es, hot or moving engine parts (manifold, ra di ator, hoses etc.) or places where the wire might rub.

3. Attach the ground wire (black) to the vehicle frame

using a 5/16” bolt and lock nut. Before attaching

the wire, clean the metal with a wire brush, steel

wool, or sandpaper.

TEMPORARY WIRING

To temporary wire the winch, follow the outlined pro cedures. A complete wiring harness is available from the

dealer (Part Number P7866000AJ).

1. Attach two large “alligator” type clips, one to the circuit breaker and one to the end of the black wire.

2. Run the red wire (with the circuit breaker) to the battery and clip the wire to the hot (positive) side of

the battery.

3. Clip the black wire to the vehicle frame or negative

side of the battery.

Operation (continued)

CLEAR THE AREA AROUND AND BEHIND THE

BOAT OF PEOPLE, ANIMALS, AND OB STRUCT ING

OBJECTS BEFORE LOADING OR UN LOAD ING.

POS SI BLE INJURY COULD OCCUR.

2. Remove the boat tie downs.

ALWAYS STAND CLEAR OF THE AREA BE TWEEN

THE LOAD OR ANCHOR POINT AND THE WINCH.

SERIOUS INJURY COULD OCCUR, IF THE CABLE

BREAKS.

3. Step clear of the winch and winch cable area. Use

the remote control switch and power-out the cable

until the boat is completely unloaded.

4. Remove the winch cable hook from the bow eye and

power-in the cable.

LOADING

To load the boat, follow the outlined procedures.

1. Align the boat and trailer.

Operation

UNLOADING

To unload the boat, refer to Figure 2 and follow the

outlined pro ce dures.

WINCH

CABLE

Figure 2 Operation Components

2. Power-out the winch cable and attach the winch

cable hook to the bow eye on the boat.

ALWAY STAND

CLEAR OF THE AREA

BE TWEEN THE LOAD

HOOK

– 4 –

Page 5

P7040104AV

MODEL 915

Operation (continued) Maintenance (continued)

OR ANCHOR POINT AND THE WINCH. SERIOUS

INJURY COULD OCCUR, IF THE CABLE BREAKS.

3. Step clear of the winch and winch cable area. Use

the remote control switch and power-in the cable

until the boat hits the bow stop.

4. When the boat is fully loaded, secure the boat to the

trailer with tie-downs. It is not recommeded to use

the winch to hold the load because damage could

occur to the winch.

5. Remove the winch cable hook from the bow eye and

power-in the cable.

Maintenance

CABLE REPLACEMENT

To replace the cable, follow the outlined procedures.

Use an exact replacement Powerwinch cable. The

winch rating and cable strength are carefully matched.

Never replace the cable with rope.

ALWAYS UNPLUG THE WIRING HARNESS TO PREVENT AC CI DEN TAL STARTING BEFORE AT TEMPTING TO INSTALL, SERVICE, RELOCATE OR PERFORM ANY MAINTENANCE.

1. Power-out the cable using the remote control de vice

and unplug the wiring harness.

LUBRICATION

Once a year, the cable should be lubricated with

Whitmore’s Wire Rope Spray, WD40 or a similar product. Spray the drum and the cable as the cable is being

wound. Remove the cover and lubricate the gears once

a year with a lithium base grease. Be careful not to get

grease on the clutch lining.

2. Remove the two cov er rods and the four cover

screws

3. Cut the old cable approximately 2” from the drum

and push the remaining cable and fastener through

the drum to remove (See Figure 3).

CABLE

FASTENER

COUNTERBORE

2"

INSERT

NEW

CABLE

CABLE DRUM

Figure 3 Cable Replacement

– 5 –

Page 6

P7040104AV

MODEL 915

Maintenance (continued)

4. Insert the new cable into the drum shaft hole at

the end opposite the counterbored end. Draw the

cable through the hole and out the counterbored

side of the shaft.

5. Push the cable through the fastener until the cable is

flush with the end of the fastener.

6. Crimp the fastener onto the cable and pull the cable

through the drum shaft until the fastener seats

inside the counterbore.

7. Install the cover, two cover rods and the four cover

screws and connect the wiring harness.

8. Power-in the cable with a light load to help wind the

cable straight into the drum.

1. Make sure a load is not attached to the winch. Locate

the jam nuts on the rear shaft on the left side of the

winch while facing the cable opening.

2. Loosen the outer jam nut and tighten the inner nut.

Turn the inner nut clockwise to increase the load

capacity or turn counterclockwise to decrease the

load capacity. The inner nut should be tight enough

to keep the load from slipping or creeping.

Do not overtighten the

inner nut. Overtightening the inner nut shortens the motor life.

3. Tighten the outer nut against the inner nut to se cure

LEVELWIND PLATE

When powering-in the cable, the motor will continue to

run for a few seconds after releasing the toggle switch

on the remote control device, especially without a load.

Be sure to allow for this. Do not let the cable hook go

into the winch and bend the level wind plate. When

winding the cable onto the drum with no load, keep the

cable taut (tight) going into the drum.

BRAKE ADJUSTMENT

The winch is equipped with a friction brake which holds

the load when the power is off. If the load creeps while

the power is off or if the brake slips while powering the

load in or out, the brake needs adjustment.

To adjust the brake, follow the outlined procedures and

refer to Figure 4.

Do not adjust the brake

with a load attached

to the winch. The load

could release and cause load dam age or personal

injury.

INNER

JAM NUT

STORAGE

The winch cable must be lubricated before storing.

Lu bri cate the cable with Whitmore’s Wire Rope Spray,

WD40 or a similar product. Spray the drum and the

cable as the cable is being wound.

Technical Service and Replacement Parts

Information

For information re gard ing the op era tion or repair of

this product, please call 1-800-243-3097 and have the

following information available:

• Model number

• Serial number

• Part number and description

Address correspondence to:

Carefree/Powerwinch

2145 West 6th Ave

Broomfield, CO 80020

OUTER

JAM NUT

Figure 4 Brake Adjustment

– 6 –

Page 7

P7040104AV

MODEL 915

General Troubleshooting Guide

SYMPTOM POSSIBLE CAUSE (S) CORRECTIVE ACTION

Winch will not

operate.

Clutch does not

hold.

1. Disconnected or bad wiring or

bad circuit breakers.

2. Bad plug.

3. Bad switch or motor.

1. Jam nuts too loose.

2. Worn gears or clutch lining

1. Start checking the wiring at the battery. Bypass the

circuit breakers and test the winch. If the winch

operates, replace the circuit breakers.

2. Check the wiring insulation for worn or bare spots

that may be causing a short.

3. Check all connections for tightness.

1. Check the male connection at the end of the wiring kit by using probe light across the two prongs

inside the plug. If the light illuminates, the wiring

is correct.

2. Remove the two cover connecting screws and rods

(See Figure 3) from the cover containing the female

socket. Plug the male socket into the female socket.

Use a probe light across the two connections on the

underside of the female socket. Replace the ap propri ate socket if the light does not illuminate. If the

light illuminates, check the switch and/or motor.

1. Test the switch by using a jumper wire to bypass the

switch. Keep fingers away from the winch mech anism. If power gets to the motor, replace the switch.

If no power gets to the motor, replace the motor.

1. Adjust the brake (See brake adjustment section in

this manual).

2. Replace gears or clutch lining.

– 7 –

Page 8

P7040104AV MODEL 915

Limited Warranty

A. This Limited Warranty is given by the Pow er winch Di vi sion of the

Scott Fetzer Com pa ny (the “Com pa ny”) to the orig i nal purchaser

(the “Purchaser”) of a Pow er winch Prod uct (the “Product”) speci fied in this man u al. This Limited War ran ty is not trans fer able to

any other party.

B. Responsibilities of the Company under this Limited Warranty:

1. Re pair or replace (at the discretion of the Com pa ny)

any part or parts of the Prod uct found by the Com pany to be defective within a two (2) year period from the

date of pur chase.

2. The Company will pay the transportation charge

for ship ment back to the Purchaser of any Prod uct

re ceived for legitimate War ran ty re pair.

C. Responsibilities of the Purchaser under this Limited War ran ty:

1. Complete (fully and accurately) and re turn to the

Com pa ny, the Warranty card included in the box. Other wise, Pur chas er will have to show dated proof of

pur chase to qualify for service under the pro vi sions of

the Limited Warranty.

2. Promptly notify the Seller or the Com pa ny of any claim

hereunder.

3. At the Option of the Company, return the Product to

the Company for inspection. Au tho ri za tion must be

given pri or to any Prod uct re turn. Call the Company at

1-800-243-3097 or write the Com pa ny at 2145 West

6th Ave, Broomfield, CO 80020, for authorization and

com plete in struc tions on how to return the Prod uct

di rect ly to the Com pa ny.

4. Use reasonable care in maintenance, op er a tion, use

and storage of the Product in ac cor dance with the

in struc tions con tained in the Own er’s Man u al.

5. Have Warranty work performed by a deal er or rep resen ta tive ap proved by the Com pa ny.

6. Except as noted in B.2., transportation charg es are

the re spon si bil i ty of the Pur chas er.

D. This Limited Warranty covers:

1. Defects in workmanship or materials.

2. Any part or parts of the Product sold or man u fac tured

by the Com pa ny.

E. This Limited Warranty does not cover:

1. Any failure that results from improper in stal la tion of

the Product.

2. Any failure that results from accident, Pur chas er’s

abuse, neglect, modification, improper main te nance,

or fail ure to operate and use the Product in ac cordance with the in

Man u al sup plied with the Prod uct.

F. THERE IS NO OTHER EXPRESS WAR RAN TY. IM PLIED WAR-

RAN TIES, IN CLUD ING THOSE OF MER CHANT ABIL I TY AND

FIT NESS FOR A PAR TIC U LAR PUR POSE, ARE LIM ITED TO

TWO (2) YEARS FROM DATE OF PUR CHASE. THIS IS THE

EX CLU SIVE REM EDY AND ANY LIABILITY FOR ANY AND

ALL IN CI DEN TAL OR CON SE QUEN TIAL DAM AG ES OR

EX PENS ES WHAT SO EV ER IS EX CLUD ED.

Some states do not allow lim i ta tions on how long an implied warran ty lasts, or do not allow ex clu sion or limitation of in ci den tal or

con se quen tial dam ag es, the above lim i ta tions may not apply to

you. This Lim it ed Warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

struc tions pro vid ed in the Own er’s

All rights reserved. This publication, or parts thereof, may not be reproduced in any form without written permission. Powerwinch reserves the

right to alter specifications on any product without notice.

Loading...

Loading...