Page 1

Product Manual

for

Tower Mounted Booster amplifiers

TMBs

MMP-10065-PB1.doc © LGP Telecom AB

1 (75)

Page 2

The information in this document is subject to change without notice and

describes only the product defined in the Introduction of this documentation.

This document is intended for the use by LGP Telecom customers only for

the purposes of the agreement under which the document is submitted, and

no part of it may be reproduced or transmitted in any form or means without

the prior written permission of LGP Telecom. The document has been

prepared to be used by professional and properly trained personnel, and the

customer assumes full responsibility when using it. LGP Telecom welcomes

customer comments as part of the process of continuous development and

improvement of the documentation.

The information or statements given in this document concerning the

suitability, capacity, or performance of the mentioned hardware or software

products cannot be considered binding but shall be defined in the agreement

made between LGP Telecom and the customer. However, LGP Telecom has

made all reasonable efforts to ensure that the instructions contained in the

document are adequate and free of material errors and omissions. LGP

Telecom will, if necessary, explain issues which may not be covered by the

document.

LGP Telecom liability for any errors in the document is limited to the

documentary correction of errors. LGP Telecom WILL NOT BE

RESPONSIBLE IN ANY EVENT FOR ERRORS IN THIS DOCUMENT OR

FOR ANY DAMAGES, INCIDENTAL OR CONSEQUENTIAL (INCLUDING

MONETARY LOSSES), that might arise from the use of this document or the

information in it.

This document and the product it describes are considered protected by

copyright according to the applicable laws.

LGP Telecom logo is a registered trademark of LGP Telecom AB.

Other product names mentioned in this document may be trademarks of their

respective companies, and they are mentioned for identification purposes

only.

Copyright © LGP Telecom AB 2003. All rights reserved.

MMP-10065-PB1.doc © LGP Telecom AB

2 (76)

Page 3

1 Document history...................................................................................6

2 About the Documentation.......................................................................7

2.1 Dear Customer.......................................................................................7

2.1.1 LGP home page.....................................................................................7

2.1.2 Contact LGP ..........................................................................................7

2.2 About the documentation.......................................................................8

2.2.1 Overview ..........................................................................................8

2.2.2 TMB models ..........................................................................................8

2.2.3 Disclaimer ..........................................................................................8

2.3 Abbreviations .........................................................................................9

3 Functional Description..........................................................................10

3.1 Schematic overview .............................................................................10

3.2 The TMB enclosure.............................................................................. 12

3.3 Control Interface Unit (CIU)..................................................................14

3.4 LED indicators......................................................................................16

3.5 Antennas ........................................................................................17

3.6 Feeder cables ......................................................................................17

3.7 Software diskette or CD.......................................................................17

3.8 CIU Cables ........................................................................................18

3.9 Alternative installation using only RF feeders (CIN option) ..................19

3.10 Alarms ........................................................................................19

3.10.1 Uplink failure..............................................................................20

3.10.2 Downlink failure.........................................................................20

3.10.3 Temperature high/low................................................................20

3.10.4 Input overload............................................................................21

3.10.5 Output overload.........................................................................21

3.10.6 VSWR over threshold...............................................................22

4 Installation ........................................................................................23

4.1 Unpacking the equipment.....................................................................24

4.2 Checking the equipment.......................................................................24

4.3 Attentions prior to installation...............................................................25

4.4 Equipment and tools for mounting........................................................ 27

4.4.1 Carrying / lifting handle........................................................................27

4.5 Hoisting the TMB.................................................................................. 27

MMP-10065-PB1.doc © LGP Telecom AB

3 (76)

Page 4

4.6 Mounting the TMB on a wall.................................................................28

4.7 Mounting the TMB on a vertical / horizontal pole.................................29

4.8 Mounting the CIU.................................................................................34

4.9 Connecting the TMB and CIU ..............................................................34

4.9.1 Connecting the earth cable..................................................................34

4.9.2 Connecting the RF feeder cables......................................................... 35

4.9.3 Configuring a power supply cable for 115V/230V AC versions............36

4.9.4 Connecting the power supply cable for 115V/230V AC versions .........37

4.9.5 Specifications for the AC input voltage.................................................38

4.9.6 The fuse (AC versions only).................................................................39

4.9.7 Configuring a power supply cable for 48V DC versions.......................41

4.9.8 Specifications for the DC input voltage ................................................43

4.9.9 Connecting the CIU/TMB communication cable...................................43

4.10 Connecting the TMB and CIU using the optional Current

Injectors (CIN)...................................................................................... 46

4.11 Connecting the CIU and BTS...............................................................48

4.11.1 Opening the CIU.......................... Error! Bookmark not defined.

4.11.2 Connecting to the terminal block . Error! Bookmark not defined.

4.11.3 Connecting the CIU/BTS alarm interface cable .........................49

4.11.4 Connecting the CIU RS232 cable..............................................49

4.11.5 Using the RS232 serial interface from a BTS............................50

4.12 Installation of the Remote Access equipment ......................................50

4.12.1 Supported modems ...................................................................51

4.12.2 Nokia 6210 ................................................................................51

4.12.3 Wavecom WMOD2....................................................................51

4.12.4 Remote PC with modem............................................................52

4.12.5 Additional installation information for Remote Access...............52

5 Commissioning.....................................................................................53

5.1 Prerequisites ........................................................................................53

5.2 The commissioning procedure.............................................................53

6 Configuration & Operation....................................................................54

6.1 Introduction ........................................................................................54

6.2 Installing TMB Manager .......................................................................54

6.2.1 Prerequisites ........................................................................................54

6.3 Connecting to the TMB ........................................................................54

MMP-10065-PB1.doc © LGP Telecom AB

4 (76)

Page 5

6.3.1 RS232 connection................................................................................55

6.3.2 About the wire-less infrared (IrDa) interface.........................................55

6.4 The TMB Manager (PC program).........................................................55

6.4.1 TMB Manager program versions..........................................................55

6.4.2 Computer system requirements ...........................................................55

6.4.3 Installing the TMB Manager on your PC ..............................................56

6.5 The TMB Manager menus....................................................................56

6.5.1 Communication port configuration........................................................57

6.5.2 Access TMB options using a code .......................................................59

6.5.3 Status menu ........................................................................................60

6.5.4 Information menu .................................................................................60

6.5.5 Gain setting menu................................................................................61

6.5.6 Alarm setting menu .............................................................................. 65

6.5.7 Alarm output configuration menu ......................................................... 66

6.5.8 Failure Configuration menu.................................................................. 67

6.5.9 CIU Software updating menu...............................................................68

6.6 Remote Access option to TMB Manager..............................................70

6.6.1 Modem installation ............................................................................... 70

6.6.2 Phone book (list of TMB’s)...................................................................71

6.6.3 Dial TMB ........................................................................................72

6.6.4 Troubleshooting Remote Access problems..........................................72

7 Maintenance ........................................................................................74

7.1 Maintaining the TMB ............................................................................74

7.2 Replacing the TMB...............................................................................74

8 Troubleshooting ...................................................................................75

MMP-10065-PB1.doc © LGP Telecom AB

5 (76)

Page 6

1 Document history

Revision Content Date/Author

MMP-10065A New document number July 2002 / Jesper Trier

MMP-10065B Updated with TMB-1900 April 2003 / Jesper Trier

MMP-10065-PB1.doc © LGP Telecom AB

6 (76)

Page 7

2 About the Documentation

2.1 Dear Customer

Thank you for choosing a product from LGP Telecom. This product has been

carefully developed with your satisfaction in mind. LGP Telecom believes in

long relationships with its customers and the importance of good support.

2.1.1 LGP home page

LGP Telecom’s web site provides some public available TMB documentation

as well as the latest news on new products and product options.

LGP Telecom’s home page: http://www.lgp.com

2.1.2 Contact LGP

For further documentation, product information, questions, suggestions or

complaints, please contact your nearest LGP office or representative. You

will find an up-to-date list of offices and representatives on our home page.

You may also call the LGP Telecom head office and ask for Technical

Support.

LGP Telecom: Telephone: +46 8 507 480 00

Telefax: +46 8 507 480 10

e-mail: mailbox@lgp.se or

tech.support@lgp.se

MMP-10065-PB1.doc © LGP Telecom AB

7 (76)

Page 8

2.2 About the documentation

2.2.1 Overview

This set of documents describes the LGP Tower Mounted Boosters,

release 1. The documentation has been divided into sections, most sections

describing a specific user task.

The document format is Adobe’s PDF (Portable Document Format). The

documents can be viewed and printed with any computer running Adobe

Acrobat® Reader, version 2.1 or later. Acrobat® Reader is freeware from

Adobe Systems Incorporated.

2.2.2 TMB models

The documentation for LGP TMBs is valid for the following TMB models:

LGP 00901: P-GSM 900 (115/230 VAC)

LGP 00902: P-GSM 900 (48 VDC)

LGP 00903: E-GSM 900 (115/230 VAC)

LGP 00904: E-GSM 900 (48 VDC)

LGP 01001: GSM 1800 (115/230 VAC)

LGP 01002: GSM 1800 (48 VDC)

LGP 01101: GSM 1900 EDGE (115/230 VAC) for external LNA

LGP 01102: GSM 1900 EDGE (48 VDC) for external LNA

LGP 01105: GSM 1900 EDGE (115/230 VAC) with internal LNA

LGP 01106: GSM 1900 EDGE (48 VDC) with internal LNA

LGP 01201: CIU for TMB900

LGP 01202: CIU for TMB1800

LGP 01203: CIU for TMB1900

LGP 16901: Current Injector Kit for TMB-900, 48V models.

LGP 16902: Current Injector Kit for TMB-1800/1900, 48V models.

2.2.3 Disclaimer

The contents of these documents are subject to revision without notice due to

continued progress in methodology, design, and manufacturing. LGP

Telecom AB or its subsidiaries assume no legal responsibility for any error or

damage resulting from the use of these documents.

MMP-10065-PB1.doc © LGP Telecom AB

8 (76)

Page 9

2.3 Abbreviations

ARP Antenna Reference Point

BTS Base Transceiver Station

BW Bandwidth

CIN Current Injector

CIU Control Interface Unit

CSU Control Surveillance Unit

CW Continuos Wave

EDGE Enhanced Data for GSM Extension

E-GSM Extended GSM

GSM Global System for Mobile communications

HPA High Power Amplifier

IM Intermodulation

LED Light Emitting Diode

LNA Low Noise Amplifier

MRT Mean Repair Time

MS Mobile Station

MTBF Mean Time Between Failure

MTTR Mean Time To Restoration

NF Noise Figure

O&M Operation & Maintenance

PBU Power Back-up Unit

PSU Power Supply Unit

TMA Tower Mounted Amplifier (Low Noise)

TMB Tower Mounted Booster

MMP-10065-PB1.doc © LGP Telecom AB

9 (76)

Page 10

3 Functional Description

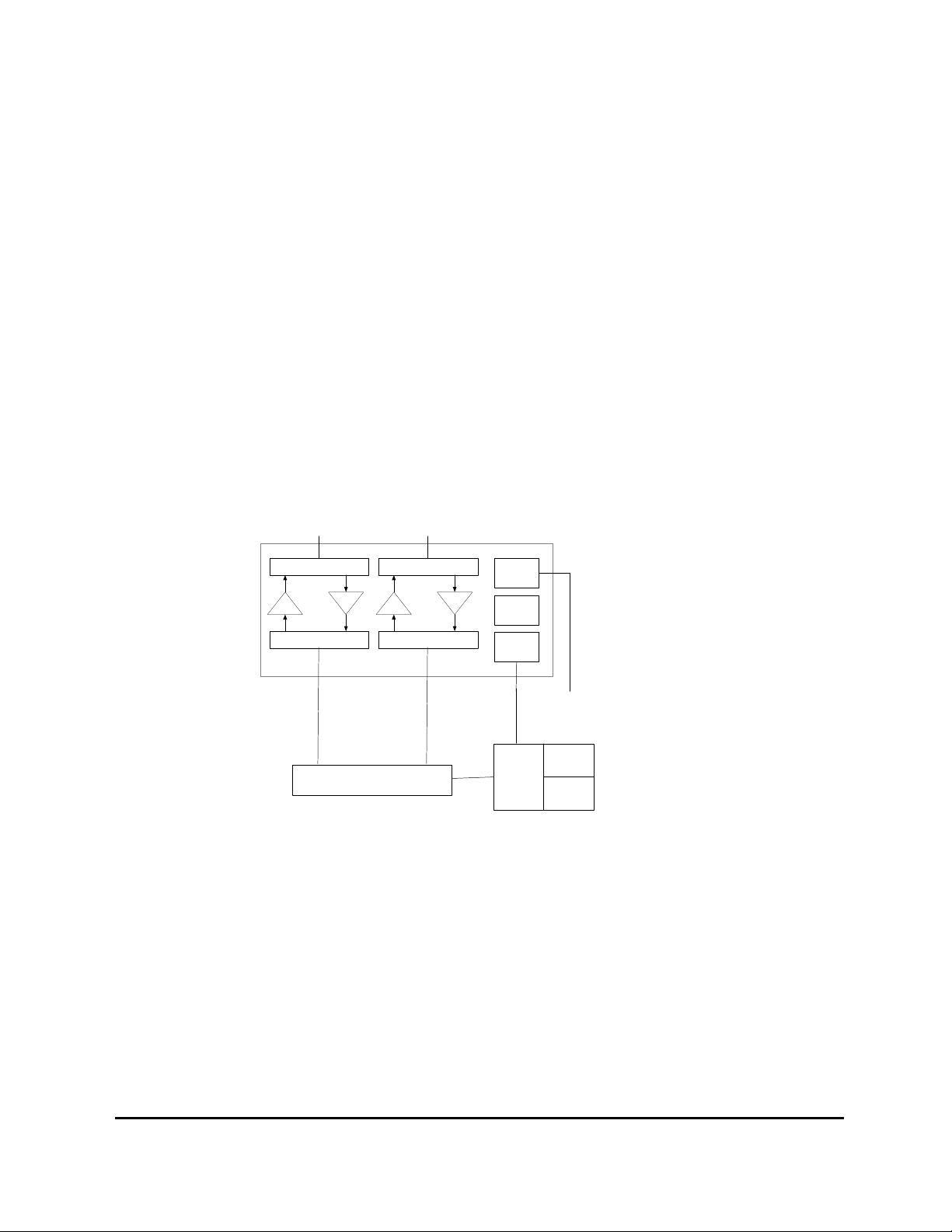

3.1 Schematic overview

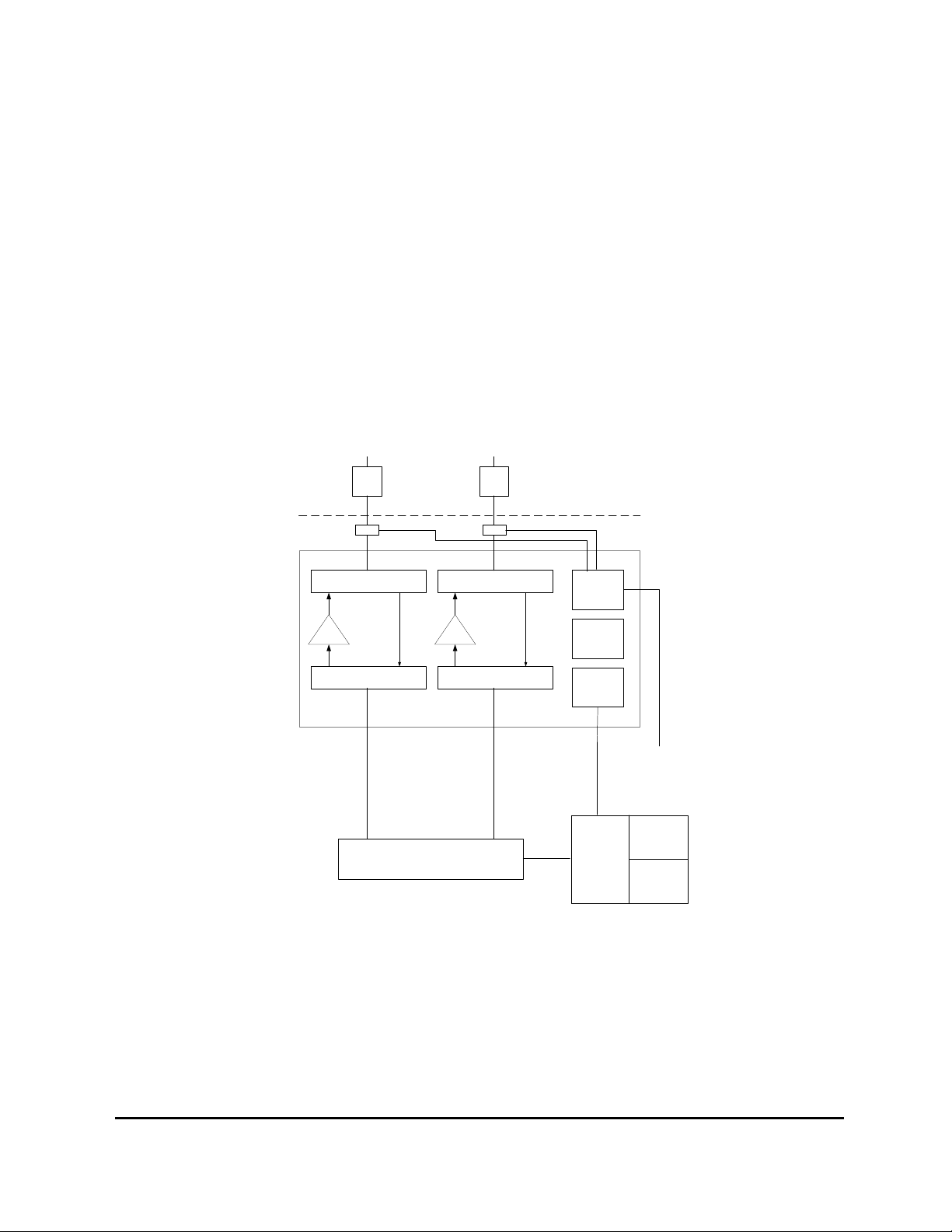

Figure 1 shows a block-diagram of the LGP TMB system with an external

Control Interface Unit. For module functionality descriptions, see the following

sections. For technical data, refer to the “Specifications” part of this document

(Chapter 8).

The TMB system includes:

• a 2-carrier integrated Tower Mounted Booster unit (TMB)

• one Control Interface Unit (CIU)

• one software package

and various optional installation kits.

TMB SYSTEM

ARP.1 ARP.2

DUPLEXFILTER

PA

DUPLEXFILTER

Tx1/Rx1

LNA

DUPLEXFILTER

PA

DUPLEXFILTER

Tx2/Rx2

LNA

Comm.

PSU

CSU

MODEM

POWER :

110 VAC,

230 V AC or

48 V DC

CIU

MODEM

CONTR-

OLLER

BTS

COMM.

INTERFACE

Figure 1a. Functional diagram of TMB with external CIU

The TMB contains one dual duplexer for each carrier; one duplexer at the

antenna port and one duplexer at the BTS port. A high power amplifier (HPA)

is in the Tx path (downlink), and a low noise amplifier (LNA) is in the Rx path

(uplink).

The TMB contains a switch mode power supply unit (PSU). The power supply

is available as either an AC or a DC version (115/230 VAC or +48 VDC).

The micro controller (CSU) handles all monitoring of the TMB as well as

communication to the CIU. Communication to the CIU is achieved via the RF

modem.

MMP-10065-PB1.doc © LGP Telecom AB

10 (76)

Page 11

The CIU is the main interface to the BTS. The CIU contains the physical

alarm interface to the BTS, which is relay contacts (3 pole), as well as the

infrared PC interface and the serial RS232 interface.

3.2 TMB-1900

The TMB-1900 is available in two configurations: With and without in-build

LNA.

The TMB-1900 with in-build LNAs is intended for Tower Top mounting close

to the antenna and is equivalent to TMB-900 and TMB-1800 as described in

figure 1a.

The TMB-1900 without LNAs is intended for base mounting close to the base

station and includes support (power supply and alarm interface) for four

external TMAs to be mounted close to the antennas. The functional diagram

is shown in figure 1b.

tower top

tower base

to ANT

TMA-

DD

CIN CIN

to ANT

TMA-

DD

DUPLEXFILTER

PA

DUPLEXFILTER

Tx1/Rx1

DUPLEXFILTER

PA

DUPLEXFILTER

Tx2/Rx2

Comm.

PSU

CSU

MODEM

POWER :

110 VAC,

230 V AC or

48 V DC

CIU

MODEM

BTS

Figure 1b. TMB-1900 with external TMAs

COMM.

INTERFACE

CONTR-

OLLER

MMP-10065-PB1.doc © LGP Telecom AB

11 (76)

Page 12

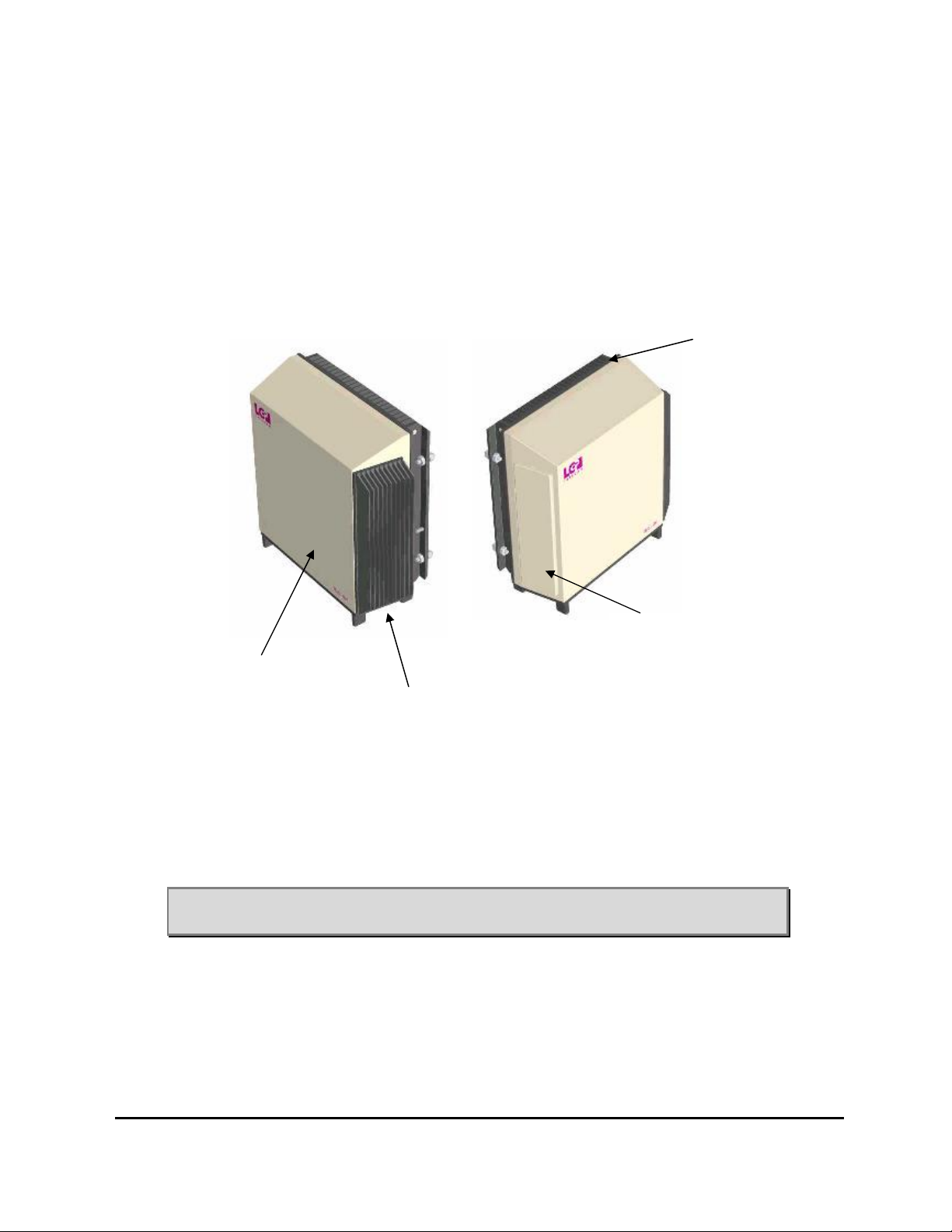

3.3 The TMB enclosure

The TMB enclosure is made of aluminium. All screws are made of stainless

steel. All metallic interconnections have seals which prevent dust and

humidity from entering the unit.

Figure 2 shows the mechanical layout of the TMB.

Front cover

Figure 2 TMB mechanical layout

Rear heat sink

Side ventilation

Side heat sink

Front cover

The TMB front cover is attached to the large heat sink on the back of the unit

as well as to the bottom plate. The cover is made of aluminium.

Note: Do not remove the front cover. Unauthorised opening of the TMB will

destroy the seals and will void LGP Telecom’s product warranty.

MMP-10065-PB1.doc © LGP Telecom AB

12 (76)

Page 13

Rear heat sink

The large heat sink on the rear of the TMB forms the back of the TMB. In

most installations the heat sink is protected from direct sun (solar radiation,

heat) due to the mounting plate and structure on which the TMB is fitted.

Although the TMB is designed to withstand direct sun, it is recommended to

prevent/minimise direct exposure to solar radiation.

The air-gap between the main heat sink and the mounting plate serves as a

“chimney”, to which airflow should not be restricted.

Note: Do not paint the heat sink.

Note: Do not restrict free airflow to the rear heat sink.

Side heat sink

The smaller heat sink located on the right hand side of the TMB provides

heat sink for the power supply.

Note: Restriction of free airflow to the heat sink must be avoided.

Note: Do not paint the heat sink.

Side ventilation

The left side of the TMB contains the ventilation system. The ventilation

design works in such a way that any moisture (condensation) inside the TMB

will be vented out. The arrangement will accept direct rain (tropical rain). The

unit is IP65 classified.

Note: Restriction of free air to this part must be avoided.

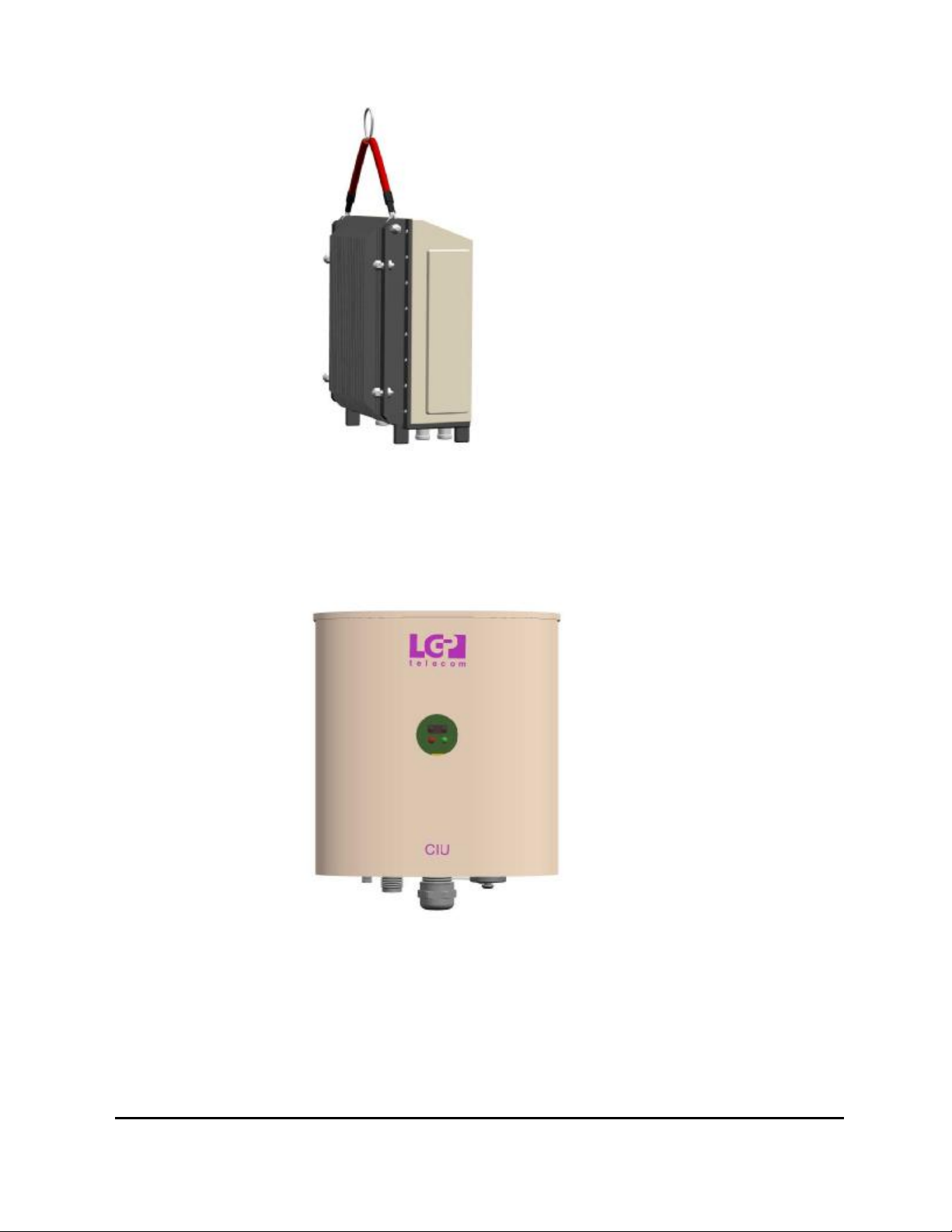

Handle

The handle is to be used when hand carrying the unit or lifting the unit up

onto a tower. The handle can be left attached to the TMB after installation

(recommended) or removed.

MMP-10065-PB1.doc © LGP Telecom AB

13 (76)

Page 14

Figure 3 TMB with handle/lifting wire

3.4 Control Interface Unit (CIU)

Figure 4. CIU outline view

The CIU is the remote control element of the TMB system. The CIU handles

all communications with the BTS as well as a PC during setup.

Having the controller of the TMB system as a remote unit enables a flexible

installation. The CIU interfaces with the TMB via a RF modem using a coaxial

cable (TNC connector).

MMP-10065-PB1.doc © LGP Telecom AB

14 (76)

Page 15

The small size of the CIU will in some cases allow for installation inside the

macro BTS. However, the CIU is shielded according to IP55 and does not

require additional weather protection. Therefore an outdoor installation of the

CIU next to a micro BTS is an example of an alternative highlighting the

flexibility of installation.

The CIU is powered via the communication cable between the TMB and the

CIU and does not need a separate power supply line.

The CIU contains three types of interfaces:

• RS232

• Alarm relay contacts

The alarm lines are relay contacts (closed or open). See “Operation” chapter

for more detail.

The CIU is the “master” and the TMB the “slave” in the overall control

architecture of the TMB system. Both the TMB and the CIU contains

microprocessors with peripheral memory circuits. The control architecture is

however very robust. In case the connection between the CIU and the TMB is

lost (broken cable) the TMB will continue service without interruption using its

current settings. However, no alarms or new settings can be handled until the

TMB/CIU interface is re-established.

Software updates (user interface software) can be downloaded into the CIU

via the RS232 interface. This software is stored in flash PROM. For

downloading procedure please see “Operation”.

RS-232 interface can also be used to remotely access the TMB using a

GSM-type modem or data-enabled handset. This is described in chapter 6.

MMP-10065-PB1.doc © LGP Telecom AB

15 (76)

Page 16

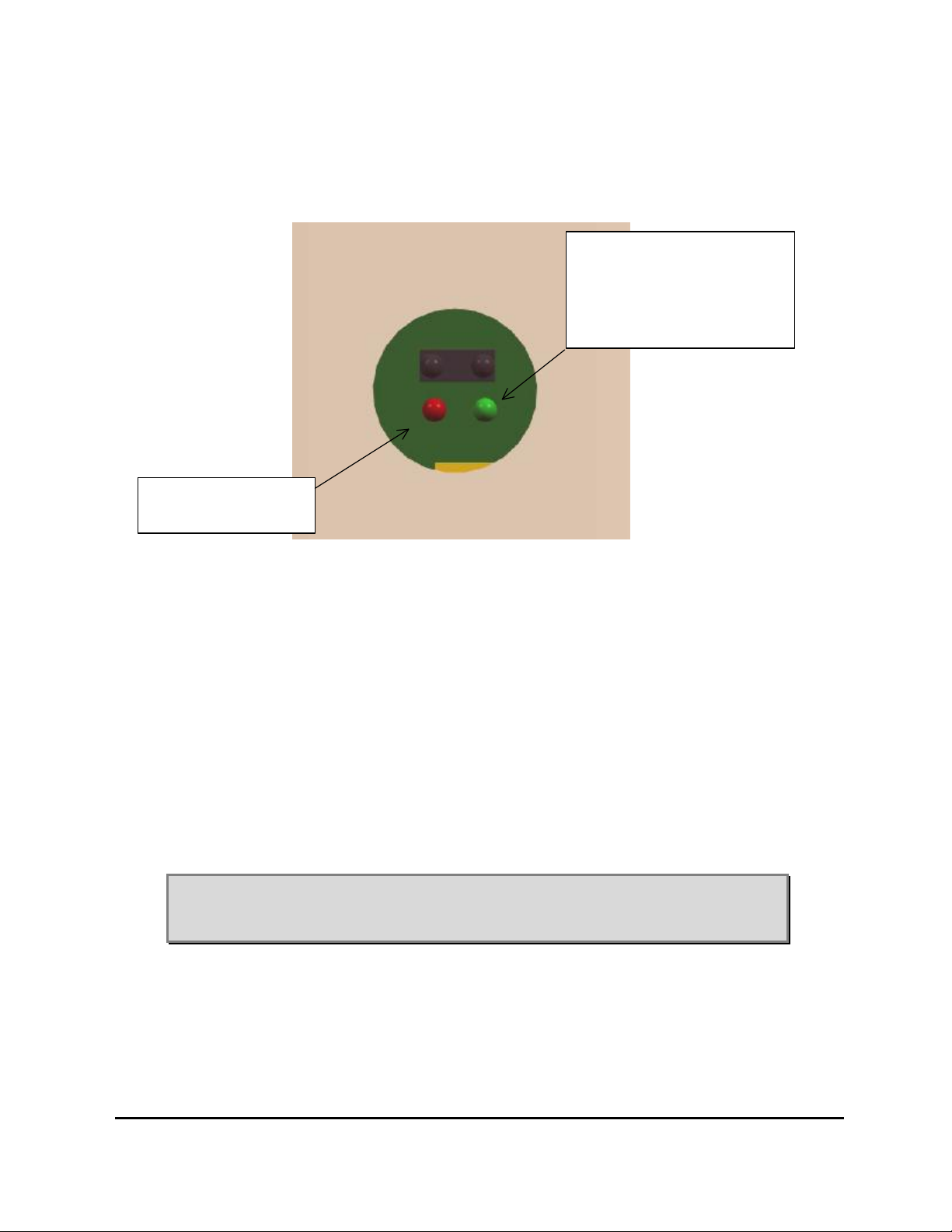

3.5 LED indicators

Green LED: normal operation

Flashing when

communicating with PC

Red LED:

alarm conditon

Figure 5 Zoom view of the LEDs on the CIU

There are no LED indicators on the TMB itself.

The CIU has two LEDs.

• A red LED (steady light) is indicating “TMB has alarm condition” and

service of the TMB system may be required, depending on the type of

alarm.

• A green LED (steady light) indicates “power on” and normal operation.

When flashing, it indicates that communication with the PC is in progress.

Note: The user can program the CIU in order to enable/disable all LEDs

making them non-visible; this, in example, if visible LEDs may

provoke vandalism of the equipment.

MMP-10065-PB1.doc © LGP Telecom AB

16 (76)

Page 17

3.6 Antennas

The antennas are connected to the antenna ports (“ANT”) of the TMB via a

standard RF jumper cable and aligned traditionally to give coverage in the

intended area. Virtually any antennas can be used given the desired

coverage pattern. Dual polarised antennas can be used with one TRX on

each polarisation.

The only requirement is that the antenna isolation between the two TRX’s is

better than 30 dB (ETSI requirement for cross-polar antennas) to comply with

–120 dBm reverse intermodulation specification. Antenna isolation may on a

real site installation be lower than stated by the manufacturer due to

reflections. If the isolation of minimum 30 dB between antennas (or between

the two polarisations inside a dual polarised antenna) is not fulfilled, a

different frequency planning will solve the problem.

3.7 Feeder cables

The BTS feeder cables are connected to the TMB “BTS” port. Virtually any

type of RF feeders can be used. The concept of using TMBs means that the

high power is being generated at the antenna, which means that feeder loss

is relatively uncritical. As the power supply to the TMB is using a separate

cable, even thin lossy RF feeders can be used. Using thin RF feeders might

result in more flexible and easier installations.

Using thin RF feeders has also a big cost impact on the site cost.

Note: Using thin RF feeders, which result in high loss, will however mean

that the output power will be very low if the by-pass mode is

activated, as the total attenuation in this case is very high.

Note: Using thin RF feeder cables cannot be combined with the CIN

option.

Note: It is recommended to use jumper cables from the feeder lines to the

TMB to avoid stress in the connectors on the TMB.

3.8 Software diskette or CD

The TMB is controlled by a client software installed on a PC. The Windows

based software is supplied with the unit. Installation of the software is

described on the page that pops up on the screen when the CD is inserted,

or in the “readme.txt” file on the diskette. It is also described in chapter

“Configuration & Operation” of this manual.

MMP-10065-PB1.doc © LGP Telecom AB

17 (76)

Page 18

3.9 CIU Cables

Various cables are supplied as options with the TMB. You may want to

configure your own cables, in this case consult “Installation”.

CIU – TMB comm. cable: The TMB is controlled by the CIU. A thin (RG58 or

similar) coaxial cable is needed to connect the two units. The cable type is

uncritical and maximum allowed cable attenuation between the CIU and the

TMB is 20 dB @10 MHz and 10 ohm DC resistance. This means that the

choice of communication cable type is relatively free and flexible allowing for

high degree of freedom in terms of installation.

Note: The cable must be fitted with watertight TNC type male connectors

at both ends. Proposed is Huber & Suhner type 11TNC–50-3-6 or

equivalent.

CIU – BTS alarm cable: The CIU-BTS alarm cable interfaces the TMB alarms

to the BTS via the CIU. There is a total of 4 alarm relays on the CIU available

for wiring up to the external alarm interface on the BTS. The relays have

three terminals allowing for either “normal closed” or “normal open”. The

wires are attached inside the CIU by simple screw terminals. The relays are

operated as failsafe. This means that the relays are engaged during normal

operation.

Note: Be sure to tighten the water tight cable gland arrangement for the

alarm cable.

CIU – RS232 cable: This cable provides the interface between the CIU and a

BTS controller or a PC - using the on-board RS232 interface connection on

the CIU.

Note: Place moisture cap on CIU’s RS232 connector when the RS232

cable is not attached.

See “Installation” concerning cable configuration.

MMP-10065-PB1.doc © LGP Telecom AB

18 (76)

Page 19

3.10 Alternative installation using only RF feeders (CIN option)

A Current Injector (CIN) option is available for the 48V DC version of the

TMB. This eliminates the need for a separate power cable and the CIU-TMB

cable. A CIN is mounted external to the TMB on the BTS2 port. A similar CIN

is then mounted at the BTS on the feeder that connects to BTS2 of the TMB.

The DC power to the TMB and the communication between the TMB and the

CIU is now all done on one of the RF feeders.

In this case the CIU will be connected to the BTS CIN. The 48V supply will

also be connected to the BTS CIN.

The details of the CIN installation is described in chapter 4.10.

3.11 Alarms

The following table shows the available alarms on the TMB (per carrier).

Uplink minor (one LNA) failure

Uplink major (both LNA’s) failure

Downlink minor (HPA) failure

Downlink major (HPA) failure

Temperature high/low

Input power overload

Output power overload

VSWR above threshold (available at additional cost)

TMB communication error

TMA alarm (TMB-1900 only)

All alarms can be monitored on the O&M interface. A total of 4 relays (12

wires) are available from the CIU to the BTS. Software configuration

determines which alarms are presented to the BTS. Normally closed (NC) or

normally open (NO) for all relays can be configured independently.

The relay operation is ‘fail-safe’, meaning that the relays will engage during

normal operation, and will disengage when there is an alarm condition. This

also means that a power failure will generate an alarm condition.

The TMB system operates with “Auto Recovery”, meaning that it

automatically will try to come back to normal operation / performance

following an alarm situation.

MMP-10065-PB1.doc © LGP Telecom AB

19 (76)

Page 20

3.11.1 Uplink failure

Uplink failure alarm has two levels, minor and major. This alarm is indicating

that the low-noise amplifiers are deviating from original setting/performances.

The uplink LNA amplifiers are balanced, i.e. two LNA devices working in

parallel for each carrier.

A minor alarm will be activated if one of the LNA amplifiers of a balanced pair

is failing. A major alarm is activated if both LNAs are out of operation.

It is configurable by software, what action shall be taken upon an uplink

failure. You have the choice between:

For Uplink Minor alarm For Uplink Major alarm

Alarm only Alarm only

Increase gain in LNA By-pass mode

“Increase gain in LNA”: An action that can be set to compensate for a failing

transistor. In this case the “surviving” transistor will “attempt” to bring back the

uplink gain to the original value by increasing its gain and thereby

compensate for the failing transistor. This can be used if the uplink gain is set

lower than the maximum gain (12 dB).

“By-pass mode”: The by-pass relay will be activated upon a transistor failure,

and the entire uplink LNA amplifier by-passed.

“Alarm only”: This setting will only report an uplink amplifier failure, but will

take no further action.

3.11.2 Downlink failure

The downlink failure alarm has two levels, minor and major. This alarm

indicates that the power amplifiers are deviating from original

setting/performance.

A minor alarm will be generated if the TMB system automatically reduces the

output power, either because of “output overload” (see below) or because of

an internal decision by the system in order to prevent destruction of the TMB

(see below as well). The TMB system will revert to normal setting when the

fault condition disappears.

Downlink major failure alarm will be generated if there is a fatal error with the

power amplifiers, i.e. transistor failure. Upon such a failure, the PIN diode

switch will be activated automatically and will by-pass the power amplifier.

3.11.3 Temperature high/low

The temperature inside the TMB is monitored at three test points: on the two

power amplifiers and on the power supply. The temperatures are shown on

the Info or Status menu in the control software.

MMP-10065-PB1.doc © LGP Telecom AB

20 (76)

Page 21

The “Temperature Low” alarm is a minor alarm and may show up at cold

start, when the TMB is started up from extreme cold temperatures like –40

ºC. In this extreme situation the TMB may run with reduced output power until

the temperature inside the TMB has reached a level where it is safe to run

the TMB with max output power (2 x 20 W).

This “Temperature Low” alarm will not be set, if the TMB is already running in

normal traffic mode and the outside temperature falls to- 40 ºC. In this case

the self heating of the TMB is sufficient to maintain full performance.

“Temperature High” alarm will be set, if the TMB gets overheated. The TMB

is designed for an ambient temperature of up to +55 ºC and designed to be

exposed to direct sunlight. However, in order to protect the TMB from

destruction and ensure prolonged trouble-free operation (high MTBF), the

system monitors extreme high temperatures.

At a “Temperature High” alarm a minor alarm will be sent and the TMB will

automatically reduce the output power gradually and ensure that the internal

temperature does not exceed +85 ºC.

When this “normal” temperature level is reached the TMB will revert to its

original power setting. This reduction of output power is considered a

‘downlink minor alarm’.

3.11.4 Input overload

The TMB is designed to withstand +43 dBm input power (20 W). Exceeding

+43 dBm may damage the TMB.

The “Input Overload” alarm will be raised when the input power level is

reaching a critical high level. The input power level will together with the

current gain setting determine how strong the internal circuitry (bypass,

power amplifiers, etc.) is driven. In other words: is there a risk of product

destruction, extreme intermodulation levels, etc.?

In this case the TMB will automatically reduce the gain to avoid overload and

thereby prevent the TMB from saturation and destruction.

If the TMB downlink gain is already set at minimum (5 dB) the gain cannot be

reduced further and the system is not able to compensate for this false

operation of input overload.

The input overload alarm will always be preceded by the output overload

alarm, as the output saturates before the input is damaged.

3.11.5 Output overload

The TMB is designed to run at maximum 20 watt output power (+43 dBm).

Exceeding +43 dBm output power results in the power transistors entering

their saturation level and the heat generation will increase dramatically.

If the TMB is operating with a certain gain value, which results in full output

power (+43 dBm), and the input power is subsequently increased, then due

to the fixed gain, the power amplifiers will be pushed into saturation.

MMP-10065-PB1.doc © LGP Telecom AB

21 (76)

Page 22

A saturated power amplifier will generate intermodulation and may cause

interference. Overheating of the TMB will reduce the lifetime of the TMB

(MTBF). Consequently the TMB system will send an “Output Overload” alarm

and reduce the gain to a non-critical setting.

3.11.6 VSWR over threshold

The TMB can be provided with an antenna Voltage Standing Wave Ratio

(VSWR) monitor built into the system (optional). The VSWR alarm is not an

exact return loss measurement, but a simple broad band detection of the

termination impedance at the Antenna port of the TMB.

The VSWR alarm sensor is capable of detecting a poor antenna VSWR, i.e.

when the antenna is not present or the jumper cable is defective.

The VSWR function is only operational between 5W and 20W output power

(37 - 43 dBm).

Nominal VSWR threshold is 4.5:1 (Return Loss equal to 4 dB). This will

guarantee an actual threshold between 1 and 8 dB (all phases).

3.11.7 TMB communication error

3.11.8 TMB fail

Not implemented. Reserved for future use.

3.11.9 TMA failure

This alarm is only used for TMB-1900 with external TMAs.

The current consumption of the TMAs is measured by the TMB and if outside

limits (<40 mA or >160 mA), an alarm is raised.

The TMA power supply also has short circuit protection which turn off the DC

at a current higher than 300 mA.

MMP-10065-PB1.doc © LGP Telecom AB

22 (76)

Page 23

4 Installation

4.1 Safety precautions

The TMB is intended for professional use and must be installed by

qualified personnel only.

Please pay close attention to the following safety precautions before

handling, installing and operating the TMB:

• The TMB does not contain any serviceable parts inside. Do

not open the TMB.

• The TMB might have sharp edged on the heat sinks. Use

durable gloves when handling the TMB.

• When the TMB is in operation, the heat sinks are hot, up to

80°C. Do not touch heat sinks.

• The TMB does not radiate (microwave , X-ray, radioactive) by

itself, but only when connected to antennas. Do not touch

antennas connected to a TMB in operation.

• Keep clear of antennas connected to a TMB in operation

(microwave radiation).

• The grounding wire must be installed before connecting the

power supply. The grounding is protective.

• All cables must be connected before the TMB is turned on.

Please contact LGP Telecom if in any doubt about handling, installing

or operating the TMB.

MMP-10065-PB1.doc © LGP Telecom AB

23 (76)

Page 24

4.2 Unpacking the equipment

The TMB and its accessories are packed in a strong cardboard box, to

protect them from damage in transit. We recommend that this crate is kept for

future transportation.

After unpacking the TMB, check that the equipment, as indicated by its type

label, corresponds to the order.

Note: Warranty is only valid if original TMB crate material is used when

returning the unit.

4.3 Checking the equipment

Before mounting, check that the equipment is complete and unharmed.

The TMB standard package contains the following parts.

Standard delivery:

1. TMB unit

2. Mounting plate for the TMB

3. CIU unit

4. Mounting plate for the CIU

5. Power supply connector for the power supply cable

6. Two TNC connectors

7. Test sheet incl. unit specific data (S/N, hard- and software version etc.)

8. Simple mounting instruction

9. TMB/CIU interface cable, 30 meters

Following options may also be in the box:

1. TMB installation kit which consists of:

• Handle / lifting wire

• RS232 cable to the PC (4 meter)

• Disk or CD containing PC software

• Technical Product Manual (this document)

MMP-10065-PB1.doc © LGP Telecom AB

24 (76)

Page 25

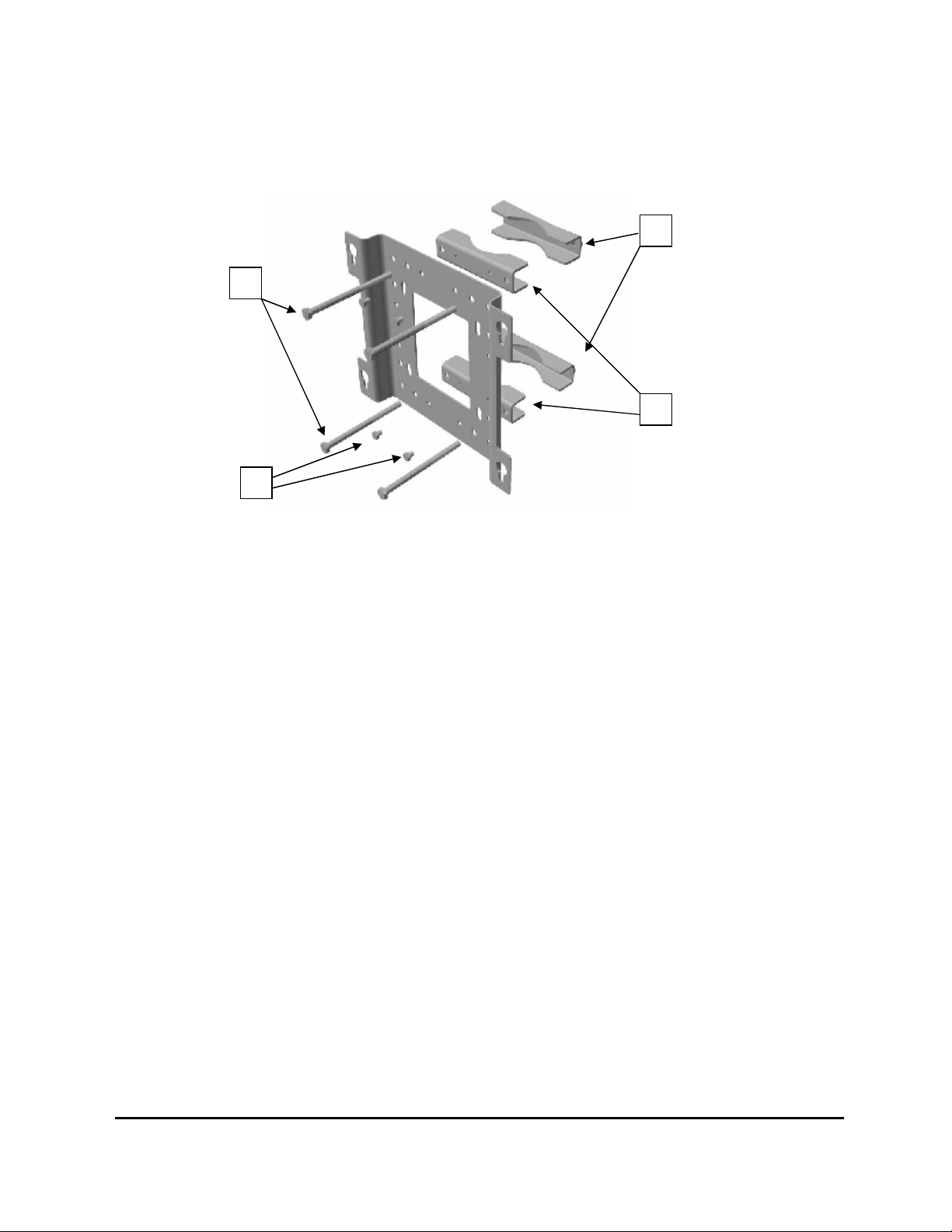

2. Pole mounting brackets incl. bolts and nuts

• Two inner clamp halves

• Two outer clamp halves, each with 2 holes and a reinforced M8

thread

• Four M8 × 12 mm bolts, for securing the inner clamps to the

mounting plate

• Four M10 × 200 mm bolts, for joining the inner and outer clamp

halves, when mounting to a vertical pole having a diameter of

90 – 140 mm.

• Four M10 × 140 mm bolts, for joining the inner and outer clamp

halves, when mounting to a vertical pole having a diameter of

60 – 90 mm.

3. Current Injector Kit.

• CIN for mounting by TMB

• CIN for mounting by BTS

• Short TNC cable

• Long TNC cable

• Short DC supply cable

4. Remote Access Cable.

• RS-232 cable to modem

Other items, such as AC/DC power supply cables, RF jumpers etc. will also

be needed for the job, but should be provided by the installer and is therefore

not specified here.

4.4 Attentions prior to installation

Rear heat sink

In most installations the heat sink is protected from direct sun (solar radiation,

heat) due to the mounting plate and structure on which the TMB is fitted.

Although the TMB is designed to withstand direct sun, it is recommended to

prevent/minimise direct exposure to solar radiation.

Note: Do not paint the heat sink.

Note: Do not restrict free airflow to the rear heat sink.

MMP-10065-PB1.doc © LGP Telecom AB

25 (76)

Page 26

Side heat sink

The smaller heat sink located on the right hand side of the TMB provides

heat sink for the power supply.

Note: Restriction of free airflow to the heat sink must be avoided.

Note: Do not paint the heat sink.

Side ventilation

The left side of the TMB contains the ventilation system. The ventilation

design works in such a way that any moisture (condensation) inside the TMB

will be vented out. The arrangement will accept direct rain (tropical rain). The

unit is IP65 classified.

Note: Restriction of free air to this part must be avoided.

MMP-10065-PB1.doc © LGP Telecom AB

26 (76)

Page 27

4.5 Equipment and tools for mounting

4.5.1 Carrying / lifting handle

The carrying handle / lifting wire is used to carry the TMB by hand or when

lifting the TMB in a wire. The handle is easily attached to the bolts found on

the back upper most of the big heat sink. The handle can be left on the TMB

after installation (recommended) or removed.

Handle / lifting wire is

connected to the two

bolts located on the big

heat sink.

Note: The handle should be removed after the installation. Replace the

bolts when the handle has been removed.

4.6 Hoisting the TMB

The handle can be used for hoisting the TMB by attaching a rope or wire to it.

Note: The wire uses for hoisting MUST be fixed to the loop of the

handle.

Figure 6 TMB with handle

When hoisting a TMB it is strongly recommended that you

ensure the TMB from banging into the tower etc. by having a

steering rope from the TMB and down to the ground.

MMP-10065-PB1.doc © LGP Telecom AB

27 (76)

Page 28

4.7 Mounting the TMB on a wall

Wall mounting comprises two steps:

Securing the mounting plate to the wall

Fitting the TMB to the mounting plate

Securing the mounting plate

The holes in the mounting plate can be used for securing the plate to the

wall, as shown below. If necessary, new holes may be drilled in the plate, as

long as this does not detrimentally reduce the strength of the mounting plate.

The installer decides how to fit the plate to the wall. However, in order to

ensure proper cooling and ventilation, the TMB must be installed in vertical

position.

Figure 7: Install the mounting plate on a wall using normal plugs and

screws. Use existing holes in the mounting plate, or drill

new ones as required.

Mounting the TMB

Fit the TMB to the mounting plate and tighten the screws to a torque of 40

Nm.

MMP-10065-PB1.doc © LGP Telecom AB

28 (76)

Page 29

Mounting screws must

be loosened prior to

mounting

Figure 8: Loosen the four big mounting screws on the back of the

TMB. Fit the TMB to the mounting plate and tighten the

screws to a torque of 40 Nm.

4.8 Mounting the TMB on a vertical / horizontal pole

The pole mounting hardware is designed for pole diameters in the range of

60 mm – 140 mm (2.4" – 5.5"). For your convenience, two sets of bolts are

found in the mounting gear.

• M 10 x 140 mm for pole diameter: 60 – 90 mm

• M 10 x 200 mm for pole diameter: 90 – 140 mm

Mounting the TMB on a vertical pole comprises two steps:

• preparations on the ground

• mounting.

Before installing the heavy TMB, install the mounting plate on the pole using

the procedure described below.

Note: The TMB must always be installed upright to ensure best

cooling. If at all tilted make sure the TMB is tilted backwards and

maximum 5 degrees.

MMP-10065-PB1.doc © LGP Telecom AB

29 (76)

Page 30

On the ground

Step 1: Check that the four mounting screws on the back of the TMB are un-

tightened to the extent of slotting on to the mounting plate. The

screws cannot drop out. Fig. 9.

Mounting screws must

be loosened prior to

mounting

Figure 9: Un-tighten the four mounting screws on the back of

the TMB before you hook it onto the mounting

plate.

Note: Check that all four screws leave enough space for the mounting

plate.

MMP-10065-PB1.doc © LGP Telecom AB

30 (76)

Page 31

2 4 3

Step 2: Join the inner clamp halves (1) and the mounting plate, using the

four M8 × 12 mm bolts (2). Tightening torque, 21 Nm. See figure 10.

1

Figure 10: Fix the inner clamps to the mounting plate by using the

four small screws.

Step 3: Then mount the outer clamps (3) loosely, each with one of the long

bolts (4) (M 10 × 200 mm or M 10 x 140 mm). Check that there is

enough space for the pole. See figure 10.

Step 4: Finally check that the two remaining long bolts (4) are accessible.

Mounting

There are two stages involved in mounting the TMB on a vertical pole:

Step 1 Clamping the mounting plate to the pole

Step 2 Fitting the TMB to the mounting plate

Clamping the mounting plate to the pole

Position the clamps around the pole and insert the two remaining long bolts

(M10 × 200 mm or M10 x 140 mm). Position (4) on figure 10. Tighten all four

bolts, taking care to keep the two halves of each clamp parallel. See figure

11.

MMP-10065-PB1.doc © LGP Telecom AB

31 (76)

Page 32

Tighten the

bolts

Figure 11: Fixing the mounting plate on a pole.

Finally, tighten the bolts to a torque of 25 Nm.

Note: Be sure to tighten the bolts hard on the pole in order to prevent the

TMB from turning around the pole during high wind load.

Fitting the TMB to the mounting plate

First pass the heads of the screws through the keyhole slots in the mounting

plate and lower the TMB until the screw heads are retained by the narrow

lower portions of the slots, see figure 12.

Tighten the screws to a torque of 40 Nm.

MMP-10065-PB1.doc © LGP Telecom AB

32 (76)

Page 33

Figure 12 Insert the heads of the screws through the keyhole slots in

the mounting plate and lower the TMB until the screw

heads are retained by the narrow portions of the slots. (2):

Tighten the screws.

The TMB can also be mounted on a horizontal pole using the same

hardware, as shown below in figure 13.

Figure 13 The TMB mounted on a horizontal pole

MMP-10065-PB1.doc © LGP Telecom AB

33 (76)

Page 34

4.9 Mounting the CIU

The CIU comes with a small mounting plate. The plate is prepared for wall

mounting as well as pole mounting.

For wall mounting use two or four screws appropriate to the nature of the

wall.

In case of pole mounting use the metallic belt.

The CIU slides on to the mounting plate and is locked in position with the lock

screw (Allen key) on the side of the CIU. The Allen key is part of the

installation kit.

Figure 14 The CIU can be wall or pole mounted using the small

mounting place.

4.10 Connecting the TMB and CIU

4.10.1 Connecting the earth cable

The TMB cabinet must be connected to earth. For this purpose, it has an M6

bolt in the lower left corner (when looked at from behind) with a locking

washer and a nut.

Fit the lug of the earth cable over the bolt and then fit the locking washer.

Secure the lug and washer with the outermost nut.

Minimum cable size for ground connection: AWG 4. Use green/yellow cable.

MMP-10065-PB1.doc © LGP Telecom AB

34 (76)

Page 35

Grounding

Figure 15 Grounding stud is found on the right hand side of the big heat

sink.

Note: It is recommended to use a 16 mm² cross section grounding wire

(AWG 5)

4.10.2 Connecting the RF feeder cables

Connect the RF feeder cables to the respective RF connectors at the bottom

plate of the TMB. The RF connectors are clearly marked “Antenna” and

“BTS”.

Antenna # 1

BTS # 1

Power

connector

Fuse

Antenna # 2

BTS # 2

CIU interface

Figure 16 All connectors are found on the bottom plate of the TMB, giving

the best natural weather protection. All connectors are clearly

marked.

MMP-10065-PB1.doc © LGP Telecom AB

35 (76)

Page 36

Note: Be sure always to connect the RF feeder cables and the

grounding wire before the power cable. The power plug is made

of rigid plastic, but it can be broken by a big spanner used to

tighten the RF feeders.

4.10.3 Configuring a power supply cable for 115V/230V AC versions

The TMB is supplied with a female connector for the power cable fitting.

Disassemble the connector as shown below by un-screwing the small front

ring.

Un-tighten the cable retaining nut and guide the power cable through.

The maximum outer dimension of the power cable is 6-8 mm.

Figure 17 Power supply connector shown disassembled.

The connector has three terminals. They are clearly marked:

N = Neutral

L = Line (phase or Live)

0 = Earth (ground)

Cable recommendations:

UV resistant

LS0H (Low Smoke, Zero Halogen)

Outdoor cable

Extended temperature range

MMP-10065-PB1.doc © LGP Telecom AB

36 (76)

Page 37

Phase

4.10.4 Connecting the power supply cable for 115V/230V AC versions

The TMB has always a preinstalled power supply connector (male) located at

the bottom plate.

Power supply

connector

Figure 18 Close up view of the TMB bottom plate where the power

supply connector (AC) is located.

Power supply connector type: Bulgin mini Buccaneer IP68

Pin configuration of male connector (front view):

Ground

Neutral

Live/phase

Figure 19 Enlarged view of the pin configuration of the power supply

connector (AC) placed at the bottom of the TMB.

Note: It is recommended that the power supply cable is properly

dimensioned and securely attached to the tower/building.

Note: It is recommended that the main power supply cable from the

base/BTS is terminated in a small interconnection box, from

which a short jumper is routed to the TMB power inlet connector.

MMP-10065-PB1.doc © LGP Telecom AB

Guide / grip

37 (76)

Page 38

Note: It is recommended that the main power supply cable for the TMB

is connected to a separate circuit breaker at the base.

Small power

cable jumper

Figure 20 The TMB shown with a small power interconnection box

installed right next to the TMB.

4.10.5 Specifications for the AC input voltage

The AC input voltage for the 115V/230V AC version accepts all voltages in

the range of 85 V – 265 V AC. However, for power-factor correction to be

active the input voltage must be in the range of 85 V – 255 V AC.

The cable must have a maximum resistance of 2.5 ohms (both wires total)

between the AC supply and the TMB.

Interconnection box

MMP-10065-PB1.doc © LGP Telecom AB

38 (76)

Page 39

4.10.6 The fuse for TMB-900 and TMB-1800 (AC version)

The AC versions of TMB-900, TMB-1800 has a fuse located at the bottom

plate. The fuse is required by regulations.

Fuse type (AC versions): 5 mm, 6.3A slow

Recommended type: Wickmann series 19181, 6.3 A or similar.

TMB fuse

Figure 21a. The fuse on the TMB is located at the bottom of the TMB

at the connector plate.

4.10.7 The fuse for TMB-1900 (AC version)

The AC versions of TMB-1900 has a fuse located at the bottom plate. The

fuse is required by regulations.

Fuse type:

Recommended type: .

Billede

Figure 21b. The fuse on the TMB is located at the bottom of the TMB

at the connector plate.

TMB fuse

MMP-10065-PB1.doc © LGP Telecom AB

39 (76)

Page 40

4.10.8 The fuse for TMB-1900 (DC version)

The DC versions of TMB-1900 has a fuse located at the bottom plate. The

fuse is required by regulations.

Fuse type:

Recommended type: .

Billede

Figure 21c. The fuse on the TMB is located at the bottom of the TMB

at the connector plate.

TMB fuse

MMP-10065-PB1.doc © LGP Telecom AB

40 (76)

Page 41

4.10.9 Configuring a power supply cable for 48V DC versions

The TMB is supplied with a female connector for the power cable fitting.

The type is: Amphenol C016 20E005 103 2

Disassemble the connector as shown below by un-screwing the small front

ring.

Un-tighten the cable retaining nut and guide the power cable through.

The maximum outer dimension of the power cable is 13 mm.

Figure 22 Power supply connector shown disassembled.

The connector has five (5) terminals. The following terminals are used:

Terminal 4 = plus (+), the positive 48V DC

Terminal 5 = minus (-), the negative 48V DC

= Earth (ground)

Nyt billede, som fig. 19

Figure 23 Connections shown from the back of the connector.

MMP-10065-PB1.doc © LGP Telecom AB

41 (76)

Page 42

444

p.4=+

444

GND

p.4=+

Note: Inside the TMB, the plus (+) and minus (-) are isolated from

ground. This makes it possible to wire the TMB as a

+48V DC or a –48V DC.

To configure the TMB for a positive (+48V) voltage relative to ground,

connect like this:

+48V

GND

p.5=−

To configure the TMB for a negative (-48V) voltage relative to ground,

connect like this:

GND

-48V

GND

p.5=−

Note: It is VERY IMPORTANT that + and – are connected correctly to

the terminals of the power connector. Failure to do so will

damage the TMB permanently.

Cable recommendations:

UV resistant

LS0H (Low Smoke, Zero Halogen)

Outdoor cable

Extended temperature range

Note: It is recommended that the power supply cable is properly

dimensioned and securely attached to the tower/building.

MMP-10065-PB1.doc © LGP Telecom AB

42 (76)

Page 43

Note: It is recommended that the power supply cable from the

base/BTS is terminated in a small interconnection box, from

which a short jumper is routed to the TMB power inlet connector.

4.10.10 Specifications for the DC input voltage

The 48 V DC version of the TMB accepts all DC voltages in the range of 36 V

to 76 V DC. Be aware that the current will increase for a lower voltage. It is

recommended that the DC power cable is chosen so that the input voltage

will never be lower than 40 V DC.

The cable must have a maximum resistance of 0.75 ohms (both wires total)

between the 48V supply and the TMB. This results in the following

recommended wire gauges:

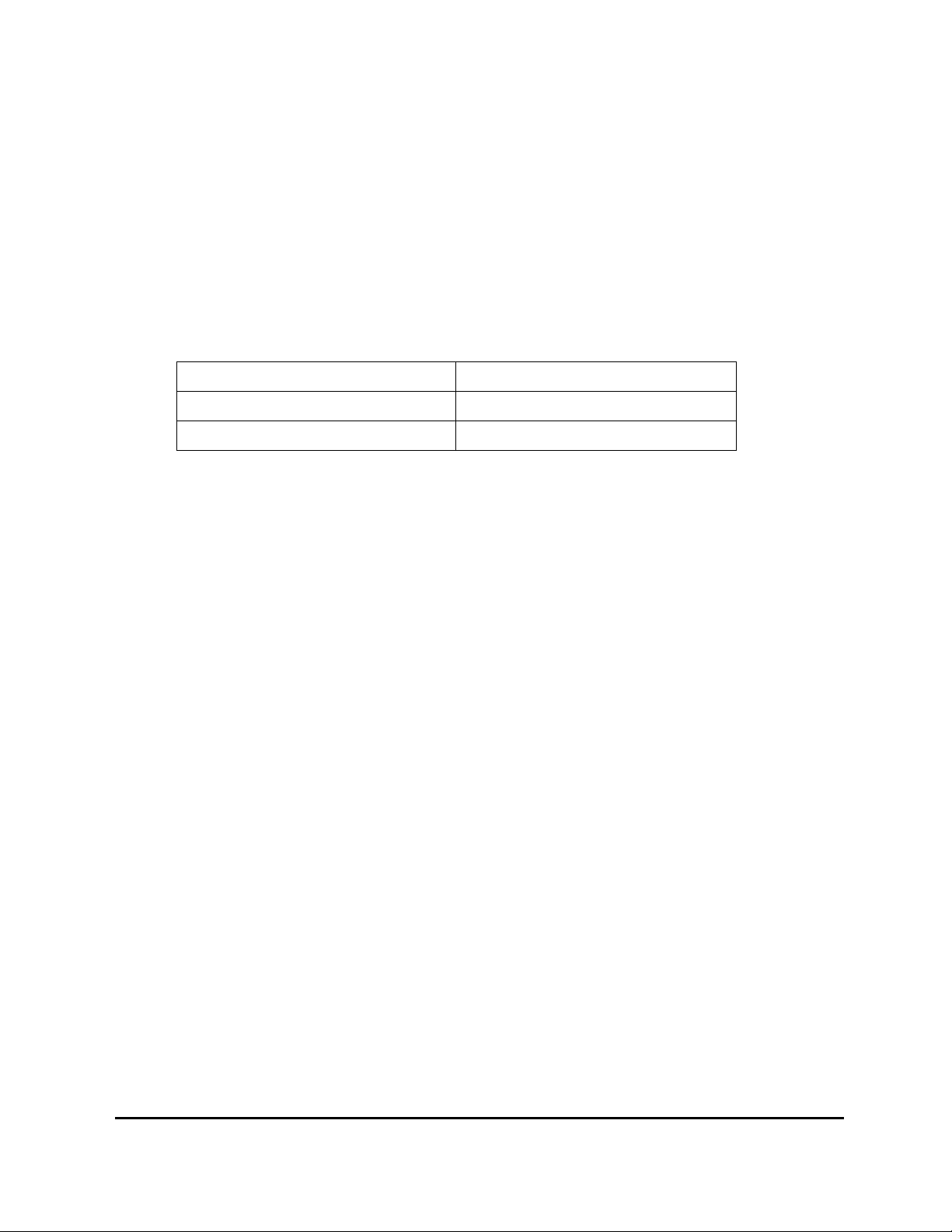

Cable size Max. length (between TMB

and Power Source)

mm2 AWG no. Meters feet

1.0 17 20 66

1.5 15 30 98

2.5 13 50 164

4.0 11 80 262

6.0 9 120 394

4.10.11 Connecting the CIU/TMB communication cable

The TMB may be delivered with or without CIU communication cable.

In case the CIU communication cable has been ordered and supplied with

the TMB unit, it is already fitted with TNC connectors in both ends. In this

case connect it to the clearly marked “CIU” connector at the bottom plate.

In case the TMB is ordered without CIU communication cable, use the two

TNC connectors delivered with the TMB with an RG58 cable or use any other

shielded 50 ohm cable that meets the requirements, see below.

CIU communication male connector type: TNC. Proposed type is Huber &

Suhner type 11 TNC–50-3-6 or equivalent.

MMP-10065-PB1.doc © LGP Telecom AB

43 (76)

Page 44

Cable recommendations:

UV resistant

LS0H (Low Smoke, Zero Halogen)

Outdoor cable

Extended temperature range

Cable electrical requirements:

Maximum allowed cable attenuation: 20 dB @10 MHz.

Maximum allowed DC resistance: 10 ohms.

TMB

TNC fitted

communication

cable between the

TMB and the CIU

CIU

Figure 24 Communication cable connection between the TMB

and the CIU.

MMP-10065-PB1.doc © LGP Telecom AB

44 (76)

Page 45

4.10.12 TMB-1900 with external TMAs

The TMB-1900

The TMA-DD 1900 supported is LGP139..

CIN kit:

Photo.

MMP-10065-PB1.doc © LGP Telecom AB

45 (76)

Page 46

4.11 Connecting the TMB and CIU using the optional Current Injectors (CIN)

An alternative installation can be made in order to avoid the separate power

supply cable and the separate TMB-CIU cable.

This installation uses the CIN option which consists of two Current Injectors.

The first CIN (mounted on the BTS), combines the DC power and the CIU

communication and the RF onto the RF feeder. This must be the feeder that

is connected to BTS2 on the TMB.

The second CIN (mounted on the TMB, BTS2), separates the DC power and

the CIU communication onto separate cables that connect to the normal

power and CIU connectors of the TMB.

The TMB itself is the same regardless of using CIN’s, the only limitation is

that the TMB has to be a 48V DC version. The CIN’s cannot be used on AC

versions.

Note: The CIN option can only be used on DC versions,

NOT on AC versions.

Note: Make sure the BTS CIN is connected to the correct feeder

(BTS2). Connecting it to the feeder connected to BTS1 is harmful

to the CIN and the power supply, as BTS1 is DC shorted.

Figure 25a. TMB CIN overview

MMP-10065-PB1.doc © LGP Telecom AB

46 (76)

Page 47

Feeder with RX/T

X1,

no DC

Feeder with RX/TX2

and DC and CIU

Communication

Tower Top

Figure 25b. Installation of the CIN option.

Base Station

Feeder with RX/TX2

and DC and CIU

Communication

MMP-10065-PB1.doc © LGP Telecom AB

47 (76)

Page 48

4.12 Connecting the CIU and BTS

The CIU has to be hard wired to the BTS for alarm purposes. An RS232

connection can also be made. The CIU is supplied with a 4 meters multi wire

cable, which contains all the wired alarms.

Function Abbreviation Connection Colour

Alarm output Relay # 4

Alarm output Relay # 3

Alarm output Relay # 2

Alarm output Relay # 1

A4-2 NC Yellow

A4-1 NO Violet

A4-0 Common Brown

A3-2 NC Green

A3-1 NO White

A3-0 Common Black

A2-2 NC Pink

A2-1 NO Grey

A2-0 Common Grey/Pink

A1-2 NC Blue

A1-1 NO Red

A1-0 Common Red/Blue

Note: As the alarm relays are wired as ‘fail-safe’, NC (normally closed)

means that the contact set is closed in case of normal operation and

the relay is engaged. Power off would then result in an open circuit

which should be wired as an alarm.

MMP-10065-PB1.doc © LGP Telecom AB

48 (76)

Page 49

4.12.1 Connecting the CIU/BTS alarm interface cable

The port codes are:

Alarm Connection Alarm No alarm

A1-1 to A1-0 Closed Open Alarm output # 1

A1-2 to A1-0 Open Closed

A2-1 to A2-0 Closed Open Alarm output # 2

A2-2 to A2-0 Open Closed

A3-1 to A3-0 Closed Open Alarm output # 3

A3-2 to A3-0 Open Closed

A4-1 to A4-0 Closed Open Alarm output # 4

A4-2 to A4-0 Open Closed

4.12.2 Connecting the CIU RS232 cable

The CIU has a serial RS232 communication interface. Total control of the

TMB system is available on this line.

The RS-232 has its own connector of the type 5S DIN (five pins), connections

are shown below. If you have an older CIU, it may be fitted with a 3 pin

connector instead.

Rx

Figure 28 Picture shows the pin configuration of the RS232 DIN

connector. Seen from outside of the CIU.

When the configuration of the TMB is completed, and you want to disconnect

the computer from the CIU you can either remove the serial cable from the

CIU, or leave the cable attached to the CIU. In case you leave the cable

attached to the CIU, make sure the PC connector is appropriately weather

protected.

Tx

GND

MMP-10065-PB1.doc © LGP Telecom AB

49 (76)

Page 50

4.12.3 Using the RS232 serial interface from a BTS

You can use the RS-232 serial interface to completely control a TMB. This

possibility can be used instead of the Windows program to control a TMB

from a BTS. Complete information will be available such as

• Information about S/N etc.

• Gain settings

• Performing Autocal

• Alarm settings

If you decide to use this interface, please contact LGP for a description of

valid commands to the CIU, and the CIU responses.

4.13 Installation of the Remote Access equipment

It is possible to substitute the RS-232 line between the CIU and the PC with a

wireless connection, using a line modem, a radio modem or a GSM modem.

This feature is called Remote Access.

Figure 29 Remote Access to TMB/CIU via GSM modem

This feature requires a different cable from the CIU that replaces the normal

PC RS-232 cable. The new cable has a male DB-9 connector that will allow

connection to most modems.

This feature has to be enabled by an option code, before it can be used. See

Chapter 6. The option code has to be purchased separately.

MMP-10065-PB1.doc © LGP Telecom AB

50 (76)

Page 51

4.13.1 Supported modems

In principle, any data-enabled phone that has an RS-232 interface can be

used for this application. However, only a few modems have been tested and

can be listed as supported by LGP.

The modem or phone must be equipped with a SIM-card that is enabled for

incoming data calls. This means they have a separate GSM number for

incoming data calls.

4.13.2 Nokia 6210

The Nokia 6210 has been tested, and is well suited for this application. In

addition to the phone, a Nokia data cable is necessary, type: DLR-3P. This

data-cable converts the proprietary Nokia connector at the bottom of the

handset to a normal DB-9 RS-232 connector (female). This connector will fit

to the data cable described in section 4.13.

4.13.3 Wavecom WMOD2

The Wavecom WMOD2 has been tested, and is well suited for this

application. In addition to the modem, an external antenna and a Wavecom

data cable is necessary. This data-cable converts the DB-15 (VGA type, 3

rows) connector to a normal DB-9 RS-232 connector (female). This

connector will fit to the data cable described in section 4.13.

Nokia 6210

Wavecom WMOD2

The use of the Wavecom modem also requires a small antenna, and a power

supply.

MMP-10065-PB1.doc © LGP Telecom AB

51 (76)

Page 52

4.13.4 Remote PC with modem

When using the remote access feature, there must also be a modem at the

other end of the line, to be able to dial the TMB’s.

This can be any normal modem (Data rate >=9600 baud) for use with a PC

and compatible with Microsoft Windows 98/NT/2000. Note that for use with

the Remote Access option, Windows 95 is NOT supported.

The use of the Remote Access software is described in chapter 6.

4.13.5 Additional installation information for Remote Access

When setting up the Remote Access option, it must always be verified that

the TMB is functioning properly and installed correctly before attempting to

make a remote connection. This is done by using a PC and the normal

RS-232 cable.

When the TMB is installed properly, simply remove the RS-232 cable

between the CIU and the PC, and replace it with the new cable connected to

the modem.

Turn the modem on and access a GSM network.

Always leave the power supply or charger connected to the modem or phone

to ensure the battery in the phone does not get discharged.

Now try to dial the TMB using a PC with a modem using the Remote Access

version of the PC software (TMB manager version X1L or later).

For the communication on the RS-232 line, the CIU is using a proprietary

own protocol. If the TMB is being dialled using a text-based modem program

(such as Hyperterminal or ProComm), no information of the TMB can be

extracted, and no setting can be made. The caller must use the program

designed for the TMB.

MMP-10065-PB1.doc © LGP Telecom AB

52 (76)

Page 53

5 Commissioning

5.1 Prerequisites

Before the TMB can be commissioned, it must be installed correctly, as

described in the “Installation” part of this document.

5.2 The commissioning procedure

The LGP TMBs have been carefully designed, manufactured and extensively

tested. The commissioning procedure is therefore relatively easy, and can be

outlined as follows:

1. Verify that the TMB is correctly and securely installed (see

“Installation” section of the manual if needed).

2. Verify that RF feeders, CIU interconnection cable, grounding wire

and power supply cables are attached correctly.

3. Check that the power supply voltage is according to the TMB

configuration (230 / 115 VAC or 48 VDC).

4. Switch on AC (or DC) power to the TMB unit.

5. Wait a few seconds for the TMB Self Test to finish.

6. Check that the green LED indicator on the CIU is on.

7. Boot your portable PC and open the LGP TMB application.

8. Click on the “Status” menu.

9. Check alarms.

10. Set the desired parameters. Use the Autocal feature to align power

levels.

11. The PC does not have to be connected to the CIU at all times.

When the configuration is completed, you can close the application

and remove the PC.

The commissioning procedure is finished. Consult the “Configuration &

Operation” chapter of this manual for further guidance.

Should there be any problems, please consult the “Trouble Shooting” chapter

of this manual.

MMP-10065-PB1.doc © LGP Telecom AB

53 (76)

Page 54

6 Configuration & Operation

The main operation and configuration interface is the RS232. The same

control can be obtained using the infrared Laptop interface on the CIU.

This chapter outlines the O&M options in detail.

6.1 Introduction

To simplify the configuration and control of the TMB, LGP has chosen a

straightforward interface using a PC program called TMB Manager. The TMB

Manager has one Status information window, which contains the current

setting and several sub-menu configuration windows for each particular

operation.

6.2 Installing TMB Manager

The TMB Manager software is compatible with the following versions of

Microsoft Windows:

• Windows 95 / Windows 98 / Windows 2000 / Windows NT4 /

Windows XP

However, for the remote access version, Windows 95 is no longer supported.

6.2.1 Prerequisites

Before you proceed, make sure that the TMB has been commissioned

correctly, as described in the “Commissioning” part of this documentation.

6.3 Connecting to the TMB

There are three ways of connecting a computer to the TMB. Choose

between:

- Locally, making a direct serial connection to the CIU via the RS232

interface.

- Locally, making an infrared interface connection to the CIU.

- Remotely, using the Remote Access feature and a GSM modem

In all cases the graphical user interface/presentation will be the same.

The infrared and the serial connections operate in parallel. However, a

detection of interface will take place automatically and communication will be

routed to this interface and locked to it as long as there is active

communication.

MMP-10065-PB1.doc © LGP Telecom AB

54 (76)

Page 55

6.3.1 RS232 connection

The CIU has a serial RS232 communication interface built in. Total control of

the TMB system is available on this line. The RS232 interface functions in

parallel to the infrared IrDa interface. The CIU will automatically scan the

COM ports (infrared or RS232) in a continuous manner.

See chapter “Installation” for interconnection details.

6.3.2 About the wire-less infrared (IrDa) interface

The infrared interface complies to the international IrDa standard:

This interface type avoid using wired connection and hence complications

with connectors, adapters, protection, etc.

Stand within one (1) meter from the CIU and point the infrared sensor on the

portable Laptop/Palmtop towards the infrared sensor on the CIU, when

communicating with the TMB. Note that a green LED will flash inside the

window on the CIU and a small transmission indicator will be activated on the

PC screen.

In very clear and strong sun light problems can occur. In case of problems try

to create shadow on the infrared sensors.

The performance of the Infrared connection is limited by the IrDa standard

and by the performance of the Infrared device in the PC you are using. If

Infrared performance is not satisfactory, please revert to using the RS-232

interface.

6.4 The TMB Manager (PC program)

6.4.1 TMB Manager program versions

The TMB Manager program is compatible with Microsoft Windows

operating system.

The screenshots shown in this manual is valid for the following version of the

program:

TMB-Manager.exe 2002-06-28

Earlier versions of the program has been called ‘PCOIU’. The funcionality

remains the same.

6.4.2 Computer system requirements

The TMB Manager program is supplied with the TMB. To run it, you will need:

• A 486DX computer or better, running Windows 95/98/NT/2000/XP

MMP-10065-PB1.doc © LGP Telecom AB

55 (76)

Page 56

• An SVGA monitor

• One megabyte of free hard disk space. The TMB Manager can also

run from a diskette.

6.4.3 Installing the TMB Manager on your PC

The TMB Manager consists of a single executable file, and there is therefore

no installation procedure.

Copy the program (File: TMB Manager.exe) to the preferred directory on your

PC.

Just double-click the TMB Manager icon to start the program

In case you need to install a new version of the program (distribution file)

which you have received from LGP, then copy the distribution file to the same

directory as the old program and run the TMB Manager again.

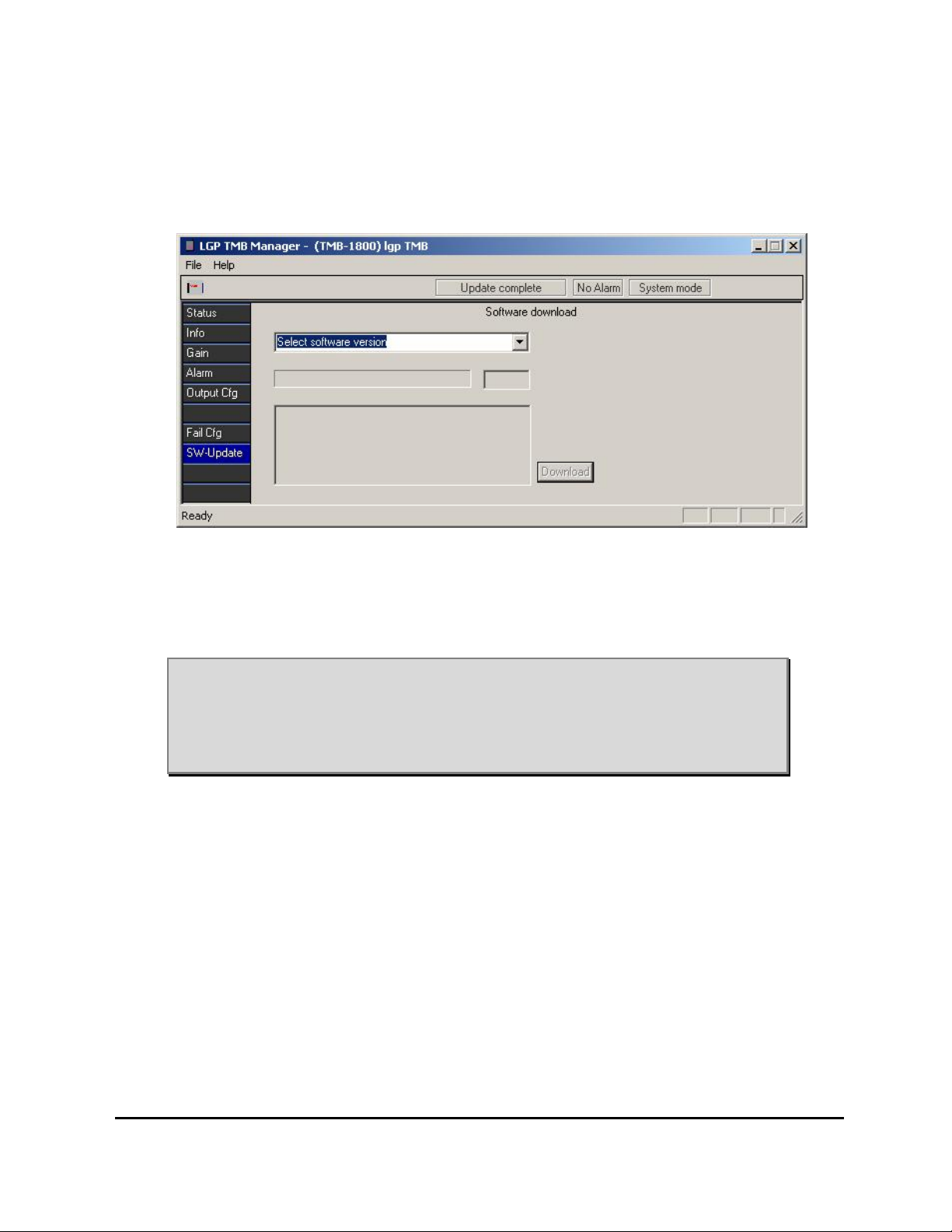

6.5 The TMB Manager menus

Below you will find a description of the various menus.

The main window is showing the possible sub-menus. Click on a sub-menu

icon in the left of the picture to access the menu.

MMP-10065-PB1.doc © LGP Telecom AB

56 (76)

Page 57

6.5.1 Communication port configuration

In case there is no communication to the CIU, “Not connected to TMB” will be

displayed in the top status bar.

No communication can be caused by:

• The TMB is switched off

• The CIU is not connected to the TMB

• The CIU is not connected to the PC

• The COM port is occupied by an other program. Close the program

and re-start the TMB Manager

• A wrong COM port has been selected

MMP-10065-PB1.doc © LGP Telecom AB

57 (76)

Page 58

To configure the COM port, enter the File menu and click on “Configuration”

Select the appropriate COM port

Refer to the user manual of the PC to select the appropriate communication

port as this depends on the hardware configuration of the PC. This

particularly applies to the location of the IrDa port.

MMP-10065-PB1.doc © LGP Telecom AB

58 (76)

Page 59

6.5.2 Access TMB options using a code

Some features of the TMB are optional. These features require a code, in

order to make them available. The codes can be purchased with LGP

Telecom Customer Service.

Currently, two options are available:

- Antenna Monitor (VSWR alarm)

- Remote Access

LGP Telecom Customer Service needs the serial numbers of the TMB and

will via this number provide the unique password code for the product option.

The serial number needed is the exact text string listed in the ‘Serial No’ field

in the ‘Info’ menu.

Enter the code which you have received and click OK. The option is now

enabled. This can be verified in the Help-About window.

MMP-10065-PB1.doc © LGP Telecom AB

59 (76)

Page 60

Note: The code for the Antenna Monitoring function (VSWR) is unique for

each individual TMB and is derived from the product serial number.

Note: If Antenna Monitor option isn’t accessed, the “VSWR-alarm” menu

and LED is not available.

6.5.3 Status menu

A pure information menu. The current configuration status is shown along

with identity and location information.

Note: The power indicators shown for each channel are designed to help

you visualise that there is output power from the TMB. It is by no

means an exact measurement.

6.5.4 Information menu

The TMB Info menu contains various information about the TMB and enables

entering of user information as well.

MMP-10065-PB1.doc © LGP Telecom AB

60 (76)

Page 61

“Identity” and “Location” are text strings that can be entered by the user. The

lower fields are information about the product, which can not be modified.

The software version is updated when a new software version is installed.

6.5.5 Gain setting menu

In this sub-menu you can enable or disable the amplifiers and set the gain of

all four amplifiers.

The first screen picture is only showing the status of the gain setting.

The gain setting of the downlink amplifier (HPA) can either be done manually

or automatically. The uplink amplifier (LNA) shall in all cases be set manually.

MMP-10065-PB1.doc © LGP Telecom AB

61 (76)

Page 62

Manual setting is used where the cable path loss from the BTS to the TMB is

known, or if equipment is available to verify the output power of the TMB.

Also, if data already exists from field measurements indicating a certain link

balance problem of x dB, then the manual gain setting can be used with

advantage.

The automatic setting is used where the cable path loss is unknown or

unaccurate and only a certain power to the antenna is desired.

Note: Due to the tolerances of gain on the TMB, and tolerances of output

power from the BTS, the automatic gain setting is very useful to

ensure the correct output power.

Manual Setting

A click on the Manual button will allow manual gain setting of four amplifiers

individually. Also, it is possible to put a carrier in bypass mode.

If bypass is chosen, both up- and down-link will be bypassed. Please note

that in the event of a failure, the bypass switches do function individually, so

only the faulty link is bypassed.

Click on the scroll down arrow of each gain setting window and pick the

desired gain.

All gain settings can be different as the amplifiers work completely

independent.

Having entered the desired gain values click OK and the new setting will be

applied, or click Cancel if you do not want to change the current setting.

MMP-10065-PB1.doc © LGP Telecom AB

62 (76)

Page 63

Auto Setting

Automatic calibration of the gain is done by clicking on the Auto button. The

screen picture will change slightly. The carriers can still be enabled or

disabled and the Uplink (LNA) gain can be set. However, the Downlink (HPA)

power level must now be set instead of the HPA gain. The indicated power

level is pr. carrier and valid at the TMB output antenna connector.

Having entered the desired Uplink gain and Downlink power level, click

Calibrate.

The TMB will now require that the BTS power is set at its nominal power

level. Using this power level as input reference level to the TMB, the

Downlink gain resulting in the desired output power can be calculated by the

TMB.

Adjust the BTS to the desired nominal power and click OK.

MMP-10065-PB1.doc © LGP Telecom AB

63 (76)

Page 64

Note 1: It is preferred to run the TMB at high gain and the BTS at low power

due to feeder cable loss.

Note 2: Running the BTS at reduced power and the TMB at full power will

add some “safety” to the site. In case the downlink amplifier (HPA) in

the TMB fails for some reason and by-pass mode is activated, then

the BTS can use this alarm signal to increase the BTS output power

and thereby compensate for the lost output power.