Page 1

60 GOUGH ROAD, MARKHAM, ONTARIO L3R 8X7

Tel: (905) 940-1400 Toll Free: 888-86KAVAL Fax: (905) 946-3392

http://www.kaval.com

USER MANUAL FOR

BI-DIRECTIONAL AMPLIFIERS

800 & 900 MHz

MODEL BDA-1000

DCM000000001

Revision 1, May 27, 1999

l Page 1 Kaval Telecom Inc. DCM000000001

Page 2

TABLE OF CONTENTS

• FCC NOTICE 3

• INTRODUCTION 4

• BLOCK DIAGRAM 5

• TECHNICAL SPECIFICATIONS 6

• MULTIPLE CHANNEL AMPLIFICATION POWER DE-RATING REQUIREMENTS 7

• BOOSTER AUTOMATIC GAIN CONTROL (AGC) FUNCTIONAL DESCRIPTION 7

• BDA CONTROLLER OPERATION 8

• BDA Controller User Interface 9

• LED and Audible Indicators: 9

• Controls: 9

• Status Displays 10

• Current Monitor Status 10

• Thermal Monitor Status 10

• AGC Status 10

• Master Status 10

• Menus 11

• Main Menu 11

• Gain Menu 12

• Uplink & Downlink Booster Menus 12

• Uplink and Downlink PA Menus 13

• AGC Menu 13

• Temperature Menu 13

• Fan Select 13

• Battery 14

• Controller Menu 14

• Calibration Menu 14

• INSTALLATION 15

• FIELD ADJUSTMENTS 15

• TROUBLESHOOTING 16

• Maintenance & Safety 16

• Maintenance Philosophy 16

• Troubleshooting Procedure 16

l Page 2 Kaval Telecom Inc. DCM000000001

Page 3

• FCC NOTICE

l Page 3 Kaval Telecom Inc. DCM000000001

Page 4

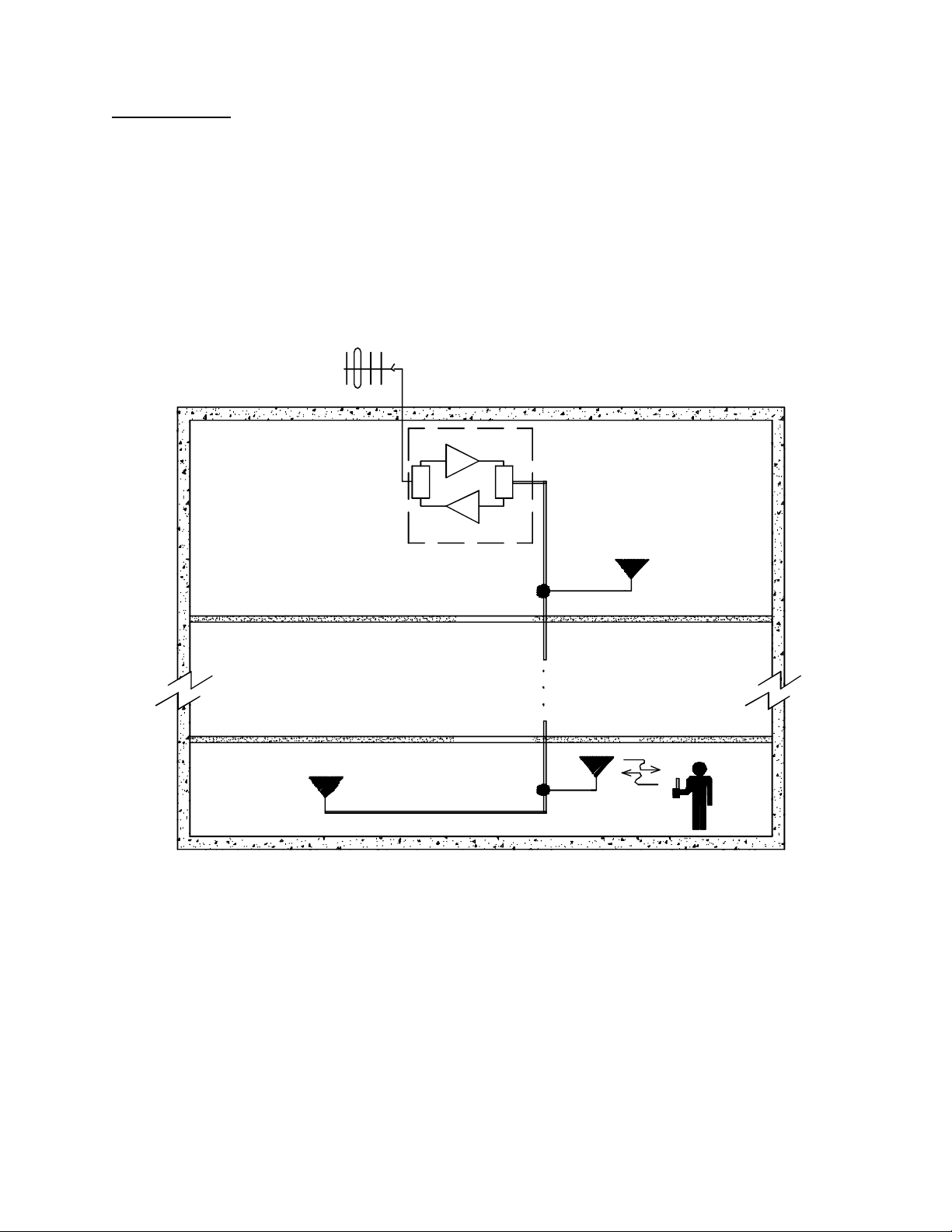

• INTRODUCTION

This Operator’s Manual covers the use, operation and installation of the BDA-1000 800 & 900 MHz Bi-Directional Amplifiers

(BDA’s). BDA’s are intended to extend radio frequency coverage into areas with coverage deficiency such as inside office

buildings, shopping malls, hospitals, tunnels etc. They are designed to be located independent of the Donor Transceiver Site and

are equipped with their own antenna systems - one to communicate with the Donor Transceiver Site and the other(s) to

communicate with radio equipment in the area with coverage deficiency.

For proper BDA System operation with no feedback problems, the RF isolation between the roof top antenna and the indoor

antenna(s) must exceed the net system gain by at least 12 dB. Note that the net system gain takes into account the BDA gain,

antenna gain, cable & connectors losses.

ROOF TOP ANTENNA

FROM / DONOR

TRANSCEIVER

N

KAVAL

BDA

D

D

SIGNAL

TAP

SIGNAL

TAP

COAX

CABLE

F2

F1

N-1

B

l Page 4 Kaval Telecom Inc. DCM000000001

Page 5

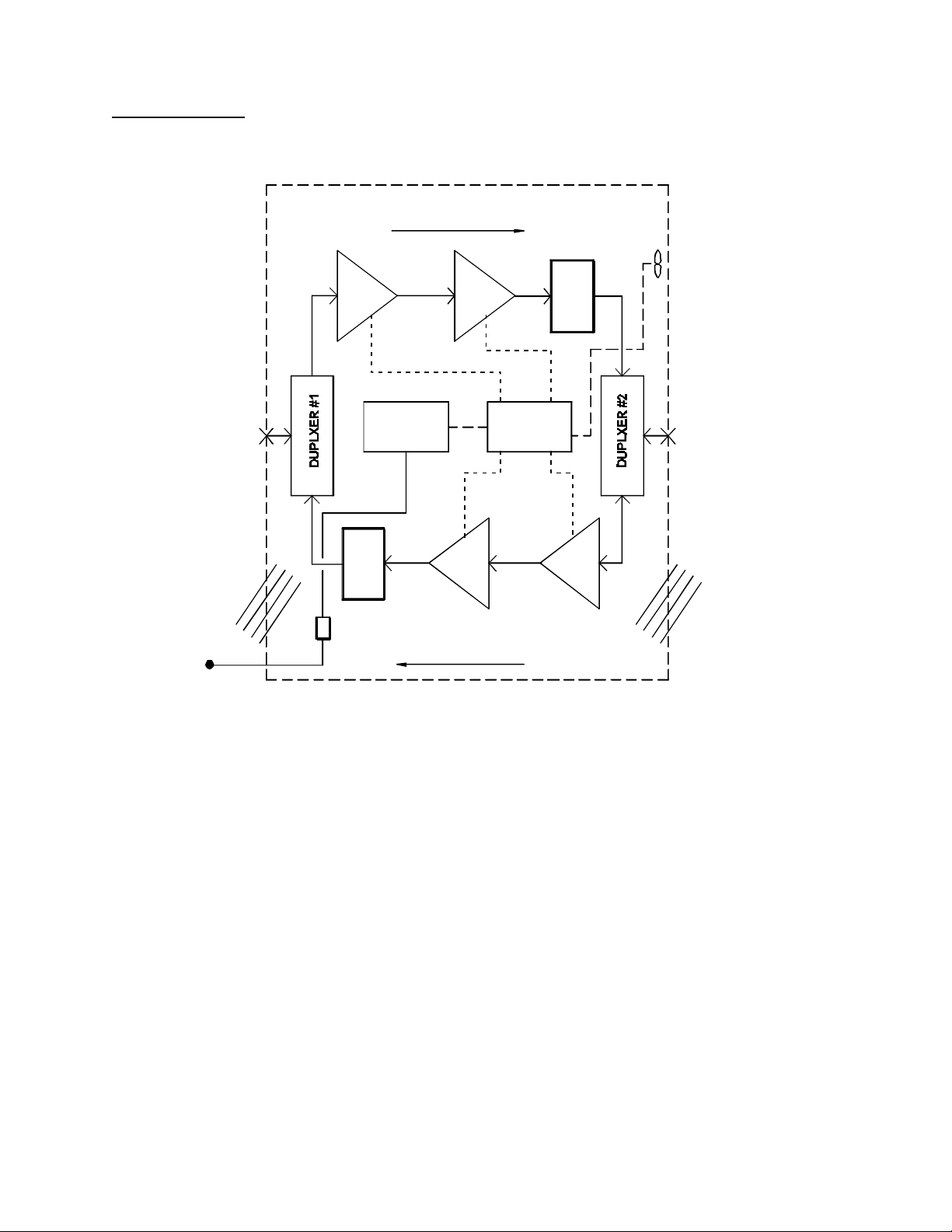

• BLOCK DIAGRAM

DOWNLINK DIRECTION

ROOF TOP

ANTENNA

VENTILATION

AC POWER

INPUT

BOOSTER #1

HP

LP

28V POWER

SUPPLY

REJECT FILTER #2

TERMINAL BLOCK

UPLINK DIRECTION

PA #1

PA #2

REJECT FILTER #1

BDA

CONTROLLER

BOOSTER #2

COOLING FANS

HP

IN BUILDING

ANTENNA

LP

VENTILATION

Power and Control Connections ------RF Connections ____

BDA Controller : An enclosed unit with microcontroller, LED indicators, buttons, and two-line display.

Temp Sense & Cooling Fans : Controlled by the BDA Controller to ensure safe and reliable operation.

28V Power Supply : Providing all DC Power, with optional Gell-Cell Battery Backup.

Duplexers : Isolating Downlink and Uplink Frequencies, and coupling to antennas.

Reject Filters : Installed if required to eliminate feedback.

Boosters : High Gain (11 to 65 dB) Linear Amplifiers supplying up to 1 Watt of RF Power. The

basic gain is adjustable via the BDA Controller over a 33 to 65 dB range, and an

Automatic Gain Control (AGC) provides an additional 23 dB range.

PA Power Amplifiers : Optional Linear Power Amplifiers providing 15 dB of additional gain, and up to 20 Watts

of RF Power.

l Page 5 Kaval Telecom Inc. DCM000000001

Page 6

• TECHNICAL SPECIFICATIONS

The BDA provides for both directions a nominal 65dB gain Booster and a 15dB gain Power Amplifier (PA). The linear Booster has

a high gain range of 11 to 65 dB supplying up to 1 Watt of RF Power. The basic gain is adjustable via the BDA Controller over a 31

dB range, and an Automatic Gain Control (AGC) provides an additional 23 dB range. The isolation between the uplink and downlink paths is provided by two high performance bandpass Duplexers.

RF Performance Downlink Uplink

1 dB Compression Point +27 dBm with Booster only

3rd Order Intercept Point IP3 +37 dBm with Booster only

BDA Controller

Electrical

Mechanical

Frequency Range As per Band requirements and Duplexer:

Trunking: 851-869 MHz

Cellular: 869-891.5 MHz

Cellular: 880-894 MHz

Trunking: 935-941 MHz

Please consult Kaval for other 800-960

MHz band options.

Nominal Max. Gain 65 dB with Booster only

80 dB with Booster & PA

Gain Adjustment 31dB (in 1dB steps)

+40 dBm with Booster & PA

+50dBm with Booster & PA

Impedance 50 ohms Nominal

VSWR 1.5:1 Max

Features Microprocessor Controller

Current Monitoring for 2 Boosters, 2 PA’s, 2 Fans

Full Gain Control

Battery Backup Control & Charging

Primary AC Power Switchmode Universal 120/230V AC +/- 10%, 50-60Hz

Total DC Current Drain Nominal 2 to 6 Amps @ 28 VDC

BDA Controller 300 ma @ 28 VDC

1W Boosters 650 ma @ 28 VDC

Fault thresholds Typically 200 ma and 900 ma

20 Watt PA’s 1.5A @ 28 VDC

Fault thresholds Typically 160 ma and 1.8 A

Batteries Two 12 VDC Sealed Lead -Acid Batteries, 10-100 AH

Battery Backup Time: Boosters only, 20 AH - 8 hrs Typical

Battery Backup Time: Boosters & PA’s, 100 AH - 8 hrs Typical

Charge Time: 10 AH - Approx. 6 hrs, 100 AH - Approx. 48 hrs. Typical

Charge Current from BDA Controller is 3 Amps Maximum

The BDA will shut down for Battery Voltages below 21 VDC.

Dimensions W x H x D 20” x 24”x12”

Weight 100 lbs. approx.

Housing Rugged Nema-Style Cabinet - Wall Mountable

Connectors N female

As per Band requirements and Duplexer:

Trunking: 806-824 MHz

Cellular: 824-846.5 MHz

Cellular: 835-849 MHz

Trunking: 896-902 MHz

Please consult Kaval for other 800-960

MHz band options.

l Page 6 Kaval Telecom Inc. DCM000000001

Page 7

• MULTIPLE CHANNEL AMPLIFICATION POWER DE-RATING REQUIREMENTS

BDA’s will amplify all signals that fall within their Pass-Band range. The output power will be “shared” between all channels being

amplified. Another multiple channel effect is Intermodulation - off-channel signals produced from non-linear effects between the

intended channel signals. These may cause interference to receiving equipment.

In order to minimize Intermodulation off-channel signals, Power De-rating must be applied. In the USA there are FCC

Intermodulation Specifications published in the EIA Standard PN2009. The Tables below give the maximum per channel Output

Levels allowed as a function of the number of channel.

Note that depending on the actual amplifier input levels, the gain of the BDA may need to be reduced to comply with the above

regulations.

Number of Channels Maximum Output Power per Single Channel for Uplink or Downlink

Using both a Booster and PA

1 +40.0 dBm

2 +28.7 dBm

4 +24.0 dBm

6 +21.3 dBm

8 +19.5 dBm

10 +18.1 dBm

Number of Channels Maximum Output Power per Single Channel for Uplink or Downlink

Using only a Booster

1 +27.0 dBm

2 +20.1 dBm

4 +15.4 dBm

6 +12.7 dBm

8 +10.8 dBm

10 +9.4 dBm

Note: Above levels are established with AGC disabled. De-ratings are based on values calculated using EIA standard

PN2009. Actual Amplifier performance may exceed the above criteria.

• BOOSTER AUTOMATIC GAIN CONTROL (AGC) FUNCTIONAL DESCRIPTION

Both Downlink and Uplink paths, with Boosters only, or with Boosters and PA’s, are equipped with AGC. The Booster based AGC

has a dynamic attenuation range that maintains a factory set composite output nominal power of +23.2 dBm at the Booster output.

The AGC gain varies dynamically to maintain this level and limits strong signal levels that could cause more Intermodulation. The

AGC starts to turn on at +23.2 dBm, therefore, at a gain setting of 70 dB, the AGC will start to turn on at +23.2 – 70 = -46.8 dBm

input level, and would maintain the +23.2 dBm output at an input levels higher than –46.8 dBm. Below the AGC turn-on threshold,

the output level will decrease linearly with the input signal. With a PA installed in the path, the AGC maximum output level is 15 dB

higher.

l Page 7 Kaval Telecom Inc. DCM000000001

Page 8

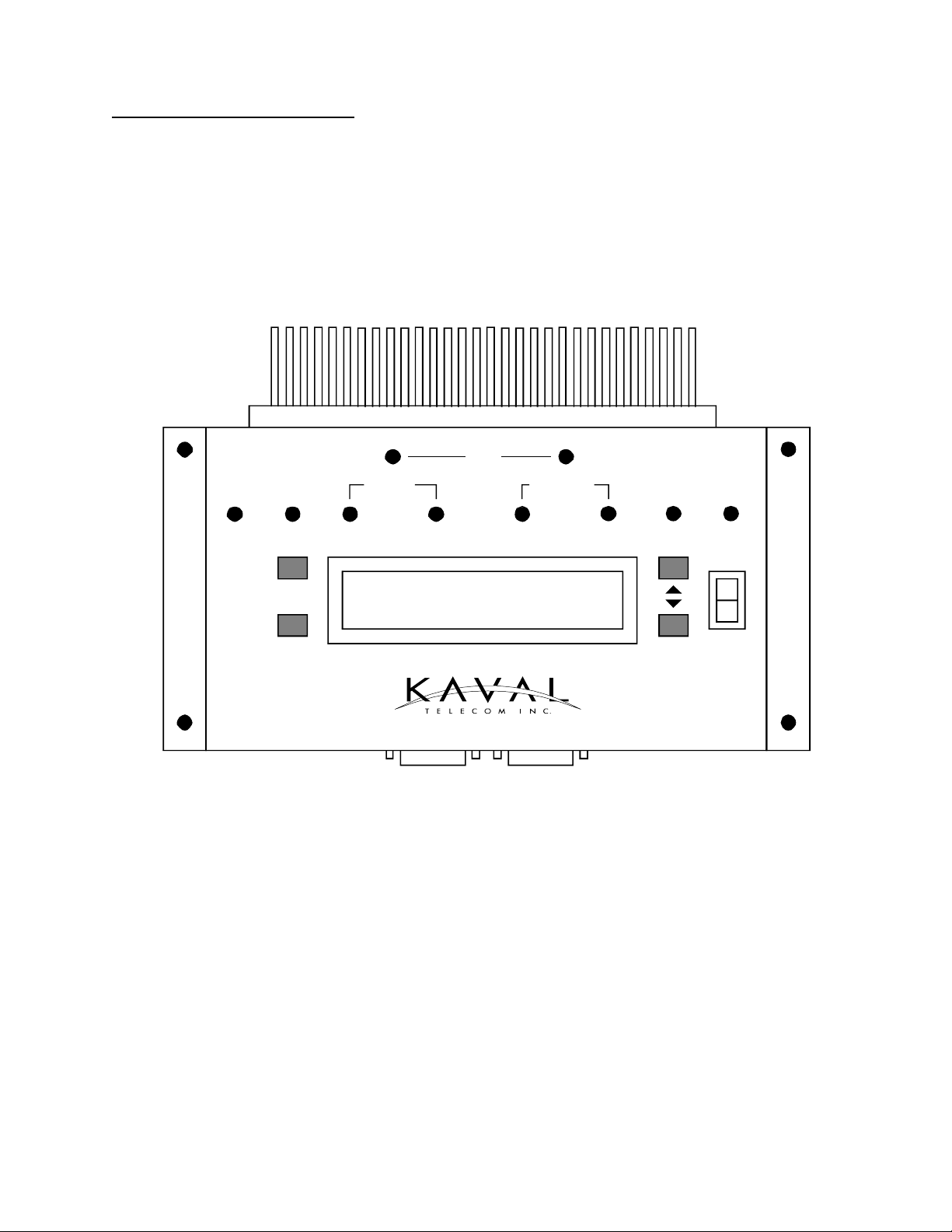

• BDA CONTROLLER OPERATION

The BDA Controller is a microprocessor based part of a Kaval BDA that provides all control, fault monitoring, and settings for the

BDA. It interfaces to the 28 VDC Power Supply, the optional 24 VDC Battery (both monitoring, transferring, and charging), control

signals to the Boosters, and provides monitored DC power for the Boosters and PA’s. Overall dimensions of the case are 9”

(including flanges) x 3.5” x 1.25”. The heatsink extends about 1.75 inches above the case and is 4 inches wide.

AGC

DOWNLINKUPLINK

PWR FAIL TEMP FAN

BDA CONTROLLER

BATT

BATT BOOST

SELECT

BDA OK

PA

BOOST PA

ADJUST

ON

OFF

POWEREXIT

The BDA Controller display is a 2 line by 20 character Vacuum Fluorescent (VFD) display. The connectors are all secure lock

types and should only be plugged and unplugged by a service technician.

l Page 8 Kaval Telecom Inc. DCM000000001

Page 9

• BDA Controller User Interface

• LED and Audible Indicators:

PWR FAIL Lights if primary power fails, and the system is on Battery Backup.

BATT Lights when the Battery (if installed) voltage drops below 24 VDC which roughly indicates 50% of backup

capacity remaining. This may occur as a result of normal discharge in a backup situation, Battery

exceeding its useful life, or a Battery failure such as water loss or shorted cell.

In addition, while running on Battery Backup, If the Battery drops below 22 VDC, the LED will begin to blink

indicating that self-shutdown is imminent. If the Battery drops below 21 VDC the BDA will shut down

completely to protect the Battery from damaging deep discharge.

UPLINK BOOST Lights if the Uplink Booster is enabled and has an overcurrent, undercurrent, or internal fault.

UPLINK PA Lights if the Uplink PA (Power Amplifier) is enabled and has an overcurrent, undercurrent, or internal fault .

DNLINK BOOST Lights if the Downlink Booster is enabled and has an overcurrent, undercurrent, or internal fault.

DNLINK PA Lights if the Downlink PA is enabled and has an overcurrent, undercurrent, or internal fault .

UPLINK AGC Lights to indicate that an Input Signal of sufficient strength is present to cause the AGC circuit (if enabled)

to act to reduce gain. The level at which AGC action occurs is not a fixed signal level. It depends upon the

user setting for output level target. When lower targets are set, the AGC will begin to act at lower input

levels. When AGC is disabled, the LED does nothing. If the Input Signal exceeds the AGC ability to reduce

gain, an overload condition exists, and the AGC LED blinks rapidly.

DNLINK AGC Operates the same as the Uplink AGC LED, but for the Downlink.

TEMP Lights when the BDA system temperature, as detected by a digital sensor in the fault monitor, exceeds the

user programmed high temperature threshold.

FAN Lights when the Cooling Fan(s) (if enabled) have an overcurrent or undercurrent condition.

BUZZER The Buzzer sounds briefly during button presses for audible feedback. Where a User Function requires a

confirmation, a short beep is emitted. During a Fault Condition, a long periodic beep is sounded (this can

be disabled). When the Battery is about to be depleted when on Battery Backup Power, the Buzzer will

sound continuously.

• Controls:

ON/OFF Power Switch for turning the BDA operation on and off. Note that this only controls the BDA Controller,

Boosters, PA’s, and Fans; the DC Power Supply is still operating.

SELECT This Button is used to enter the Main Function Menu and Submenus, and where applicable to confirm a

Function selection chosen with the Adjust Buttons.

EXIT This Button is used to cancel any Function changes, reverting to previous settings. If a Fault has occurred

and its Status is displayed, pressing the Exit Button clears the fault.

ADJUST These buttons Scroll up and down between Status, Function, and Menu display items. They also adjust

programmable numeric values up and down.

l Page 9 Kaval Telecom Inc. DCM000000001

Page 10

• Status Displays

The BDA Controller’s Display normally shows one of 4 Status Displays. Pressing the Adjust Buttons sequences

through the 4. Pressing the Select Button from any status screen enters the Main Menu. Pressing the Exit Button

does nothing, except when a Fault condition exists and Exit Button clears the fault. If a Fault occurs, the display

switches to the Master Status display and shows a text message for the Fault(s).

• Current Monitor Status

This Screen displays the current drawn by each Booster and PA in the system. The top row shows abbreviated

names for the amplifiers, the bottom row shows the current being drawn by each module. Entries for modules

disabled by another module’s fault show “Dsbl”. Entries for modules that are manually disabled are blank. Modules

that have a fault have their current indication blinking. If an overcurrent has occurred, then the word “Over” appears

instead of a number.

Up-B Up-P Dn-B Dn-P

0.65 Over 0.60 2.35

• Thermal Monitor Status

This Screen shows current temperature fan and battery status. Temperature readout is in degrees Celsius. If an

over-temperature condition exists, temperature will flash. Each fan has an indication of On, Off or Fail. Battery

voltage is displayed in volts to a resolution of 10 mV. If battery is not installed, display says “None” Battery voltage

flashes if it is low.

Temp FanA FanB Batt

53C ON Fail 26.25

• AGC Status

This Screen displays data about AGC operation and current gain setting. If AGC is disabled, then the readout for that

direction shows “Off” (*). If AGC is enabled, but input signal is below minimum input level for AGC action, readout

shows “Ok”. If AGC is enabled, and AGC is acting, then readout shows equivalent single carrier input level for that

direction in dBm. (*) If AGC is enabled, and amplifier is overdriven, readout shows blinking “Over” (*).

GN-UP-AGC GN-DN-AGC

65dB Dsbl 78dB 23dB

• Master Status

This Screen shows normally ;

BDA OK

If a Fault occurs, then a display such as ;

Fault!

Overtemperature

Will be shown.

l Page 10 Kaval Telecom Inc. DCM000000001

Page 11

Fault Displays include ;

Up Boost Overcurrent Up PA Overcurrent

Dn Boost Overcurrent Dn PA Overcurrent

Up Boost Undercurr. Up PA Undercurrent

Dn Boost Undercurr. Dn PA Undercurr

Fan A Fail Fan B Fail

Battery Low Imminent Shutdown

Primary Power Fail Overtemperature

Up Boost Internal Up PA Internal

Dn Boost Internal Dn PA Internal

External Fault Controller Fault

Calibration Fail Up Boost EEPROM

Dn Boost EEPROM Uplink Overdrive

Downlink Overdrive RS-232 Active

• Menus

• Main Menu

The Main Menu is entered by pressing the Select Button from any Status Display. If the Password is set to anything

but 000 (default), then a Password Entry Screen appears. The user uses the Adjust Buttons to select a digit, and

presses the Select Button to enter that digit. The cursor moves to the next digit and enters it. When the third digit is

entered, and the Password is correct, the Main Menu becomes available. If an incorrect Password is entered, then the

message “Wrong Password” appears for a few seconds and the user must start again. If the Password is set to 000

(disabled) the Main Menu is available immediately.

Enter Password

4**

Main Menu entries are used to group Functions by category. The User selects the Category and a Sub-Menu appears

listing available Functions. While in the Main Menu, the top row of the display shows “Main Menu”, and the bottom row

shows the Sub-Menu headings as one scrolls through them. When a Sub-Menu is selected, the Sub-Menu heading

replaces the Main Menu heading in the top row, and the bottom row then shows the Sub-Menu entries. If no Buttons

are pressed for 5 minutes while in any Menu the Display reverts to the last Status Display.

Available main Menu entries are:

Gain Uplink Booster

Uplink PA Downlink Booster

Downlink PA Temperature

Fans Battery

Controller Calibration

l Page 11 Kaval Telecom Inc. DCM000000001

Page 12

• Gain Menu

The gain menu allows adjustment of overall System Gain in dB for each direction. These functions take into account

programmed module gain values entered by the user, or entered during factory calibration. The values it considers

include Booster maximum gain and PA gain. These gains must be entered in the appropriate menus and must

account for system cable and duplexer losses. Invalid gains cannot be called up. Gain is set in 1 dB increments.

Gain menu entries (typical) are:

Uplink Gain: 80dB

Downlink Gain:75dB

• Uplink & Downlink Booster Menus

These Menus allow programming of Booster parameters. Current program range is up to 1 Amp. If max current is

reduced below the minimum current setting, the minimum current setting is pushed down automatically, and kept

50mA less than the max current setting. If the minimum current setting is raised above the maximum current setting,

the maximum current setting is pushed up and kept 50 mA higher. Current settings use 50 mA increments. Maximum

gain setting is 80 dB. This applies to Booster gain, not System Gain. Booster Gain entries should account for losses

before the booster. Menu selections are as follows (with typical data):

Enable: Yes

Max Current: 1.00A

Min Current: 0.25A

Max Gain: 70 dB

Interlock

The Interlock entry, if selected, calls up a Sub-Menu that allows the user to select what modules are disabled if

the Booster has a fault. In this menu, the top row shows:

Up Boost Interlock

The bottom row shows one of the other module names followed by Yes or No, which are toggled using the scroll

keys.. The Interlock entries for the other amplifier modules operate in a similar manner. If all interlocks are off,

then no deliberate shutdown occurs, and the fault detection is used for indication only.

Uplink Boost: Yes

Uplink PA: Yes

Downlink Boost:Yes

Downlink PA: Yes

l Page 12 Kaval Telecom Inc. DCM000000001

Page 13

• Uplink and Downlink PA Menus

The PA Menus are almost identical to the Booster menus except current programming range is up to 5 Amps.

Maximum gain setting is 40 dB. Entries are as below:

Enable: Yes

Output: 10dBm

Max Current: 1.00A

Min Current: 0.25A

Max Gain: 12 dB

Interlock

• AGC Menu

The AGC Menu allows the user to turn AGC on or off. The AGC target is set in terms of equivalent single carrier

output level at BDA antenna terminal. AGC menu entries are:

Uplink AGC: On

Uplink Output:+22dBm

Downlink AGC: Off

Downlink O/P: +5dBm

• Temperature Menu

This Menu allows setting of the over-temperature threshold and recovery temperature threshold. The recovery

temperature is the temperature that the system has to cool down to for Boosters and PA’s to be re-energized. A third

menu item allows user to select whether an over-temperature will actually cause a system shutdown. Menu entries

are:

Temp Limit: 60C

Recovery Temp: 40C

Temp Shutdown: Yes

• Fan Select

This is a single entry Menu which allows selection of the primary fan. Allowable entries are Off, A, B and Both. If A is

selected, then a fan A failure energizes fan B. If B is selected, fan A energizes in case of fan B failure. If both are

selected, both fans are on all the time. If A or B are selected, then the second fan comes on if an over-temperature

fault occurs, and stays on until the recovery temperature is reached.

Main Menu

Fan Select: A

l Page 13 Kaval Telecom Inc. DCM000000001

Page 14

• Battery

This Menu allows the user to tell the controller whether a backup battery is installed (Yes/No), and allows setting of

battery voltage thresholds. If not installed, then no battery faults will signal, and no voltage display is shown.

Battery Menu

Batt. Installed? Yes

Low Voltage: 24.0

Warn Voltage: 21.5

Cutoff Voltage: 21.0

• Controller Menu

This Menu allows the user to display the Software Revision, change the Password, perform a Lamp Test, control the

Buzzer and reset to Factory Settings.. Pressing select key with Lamp test shown causes a test pattern to be shown

on the VFD, and all LEDs light up all at once, then are lit individually in sequence. If the Factory Defaults function is

selected, a confirmation screen appears asking the user to toggle the entry to yes and hit select before memory is

cleared. Selecting “Set Password” allows user to enter a new password. The entry must be made a second time to

confirm. In this case, display says “Confirm password”. If password is set to 000, then no password check is done

(factory default). If password is forgotten, then EEPROM in controller must be replaced. Controller menu entries are:

Software Rev: 1.3

Set Password

Lamp Test:

Beep: Yes

Factory Defaults?Yes

• Calibration Menu

This Menu is for future use by the Kaval Factory only, and should not be used.

l Page 14 Kaval Telecom Inc. DCM000000001

Page 15

• INSTALLATION

l Upon receiving the BDA shipment, examine the packaging and the Cabinet for damage.

l Each BDA is carefully packaged for air shipment. Any damage incurred during the transportation must be claimed from the

shipper.

l The BDA is fully contained in a single Nema-style wall mountable cabinet.

l Prior to installing the Roof Top Antenna and the Distribution Antenna System make sure that enough Antenna Isolation. If

there is insufficient Isolation between the antennas, the amplifier gain must be set to a minimum of 12dB lower than the

available Antenna Isolation. As a rule, this is easily achievable with in-building installation.

l Check for and remove all packing materials prior to installing this unit.

l The physical installation is accomplished by mounting the enclosure onto a vertical wall. Ensure that the unit is mounted in the

upright position, as indicated by the upright Kaval logo and the door hinge on the left side of the housing. Four mounting lugs

on the enclosure provided for this purpose. The cabinet is equipped on the left and right sides with an intake ventilation air at

the bottom and exhaust fan at the top. Ensure that free air flow is available on both sides of the cabinet.

l The AC electrical wiring is accessible via an opening at the bottom left hand side of the cabinet. The AC Terminal Strip is

provided at the bottom of the cabinet:

Connection North American Standard Color Code

Hot Line BLACK

Neutral Line WHITE

Ground connection BARE

It is highly recommended that AC Power Wiring be performed by a qualified Electrician so as to ensure compliance with all

National and Local Electrical Wiring Regulations.

l AC Power and RF Connections should be installed with all standard installation practices for lightning protection. This includes

the grounding and electrical bonding together of all equipment racks and cabinets in the room. It also includes a grounding of

the primary antenna cable and the installation of proper surge suppression (lightning arrestor) equipment at the entrance to the

equipment room.

l Connect the Roof Top Antenna feeder cable to the “Donor Cell Site” Antenna.

l Connect the Distribution Antenna System feeder cable to the “In-building Antenna” port.

l Make sure that the BDA Controller Power On/Off Switch is “Off”. Activate the circuit breaker or plug in the AC. The BDA

Controller should light up momentarily then shut off. Turn the BDA Controller Power On/Off Switch to “On”. The BDA

Controller screen should become active, and Cooling Fans should be running. Check the BDA Controller for any reported

Fault conditions.

• FIELD ADJUSTMENTS

The proper operation of the BDA in providing RF coverage extension is a function of not only the BDA, but also of proper systems

engineering including isolation measurements and in building RF distribution design. The most critical requirement for the BDA

installation is that the isolation between the “Roof-Top” Antenna and the in-building Antenna distribution system exceed the overall

BDA System Gain by at least 12dB. The actual gain requirement for each Installation must be determined by the available antenna

isolation and the operational requirements determined by local Systems Engineering.

Each BDA has a Factory determined minimum gain both for the Uplink and Downlink Paths. The final Path Gain from Antenna Port

in to Antenna Port out, is set by the BDA Controller.

Follow through the BDA Controller Menus to set all configurable items as are appropriate for the installation.

l Page 15 Kaval Telecom Inc. DCM000000001

Page 16

• TROUBLESHOOTING

BDA Field Failures are often due to reasons not related to the BDA’s themselves. Before attempting to troubleshoot the BDA,

ensure that the Donor Repeater, the Portable Radios, Antennas and the in-building Distributed Antenna System are all functioning

properly.

• Maintenance & Safety

The BDA has been engineered for easy maintenance and for safe operation. This has been achieved as follows :

l The 28V DC Power-supply is over-rated for actual requirements.

l Boosters are monitored for both Over-current and Under-current (most failures are sensed this way).

l PA’s are monitored for both Over-current and Under-current (most failures are sensed this way).

l Cabinet temperature is monitored for excessive temperature.

l Components are easily removable via quick connect DC and RF connectors.

• Maintenance Philosophy

Field maintenance should require a screwdriver, a multi-meter, spares of each of the active BDA component parts, and a Portable

Radio to monitor off the air signals. There is no requirement to have any test equipment to accomplish most service repairs.

l All BDA component parts have been designed for reliable long life operation.

l The BDA Controller performs ongoing extensive built in diagnostics.

l Corrective action can often be taken without detailed technical knowledge or the need for any test equipment.

• Troubleshooting Procedure

Once it has been determined that the Donor Site and Portable Radio Equipment are performing satisfactorily, and the BDA itself is

suspect, proceed as follows:

1) Open the BDA door and observe the BDA Controller display. If none of the Status LED’s are lit, and there is nothing

on the Display, then the AC Power and / or Battery Backup Power (if present) has been lost / disconnected, the

BDA’s DC Power Supply has failed, or the BDA Controller itself has failed. Check the AC Circuit Breaker feeding the

AC circuit that powers the BDA, or possibly the AC plug has been pulled. If AC is present, try turning it off, wait 1

minute, then on again; this may clear a DC Power Supply internal thermal fuse that has tripped. Also check that the

Power On/Off Switch on the BDA Controller is On. If AC power appears to be present, then check for

approximately 28 VDC from the BDA DC Power Supply. If there is no DC Voltage at the Power Supply terminals, it

has likely failed. from Also check for 22 to 28 VDC on the Battery terminals if present. If the BDA Controller still has

no lit LED’s or Display Status then the BDA Controller has likely failed.

2) If the BDA Controller is functioning with any Fault Status indicated, then check the indicated failed component. Over

or Under Current on Boosters, PA’s or Fans may mean that the power and/or control wiring to that component has

been disconnected or is broken, or that the component has failed and needs replacement. Suspected broken or

faulty cables should be disconnected and reconnected to see if the Fault clears.

3) Over-temperature indications on the BDA Controller may occur as a result of failed Cooling Fans, blocked ventilation

openings, faulty over-heating Boosters or PA’s, or excessive ambient temperature (> 60oC).

4) Other problems may include connector & cable failures or related problems, specification failure in a Booster or PA,

etc. Problems of this sort are best referred to Kaval Service, or other supporting RF Test Lab.

l Page 16 Kaval Telecom Inc. DCM000000001

Loading...

Loading...