B A S E S T AT IO N S O L U T I O N S

DRAFT

M C P A

I N S T A L L AT I O N A N D S E R V I C E M A N U A L

0 4 4 - 0 5 3 6 9 R E V . A M A Y 2 0 0 9

G 3 L - 2 1 2 9 - 1 4 0

© 2009 Powerwave Technologies Incorporated. All rights reserved.

DRAFT

Powerwave Technologies, and the Powerwave logo are registered trademarks.

This Powerwave product is intended only for installation in a RESTRICTED ACCESS LOCATION and

this Powerwave product is designed to operate within the normal operating (typical operating) ranges

or conditions specified in this document. Operation of this equipment beyond the specified ranges in

this document may cause:

1. Spurious emissions that violate regulatory requirements.

2. The equipment to be automatically removed from service when maximum thresholds are exceeded.

3. The equipment to not perform in accordance with its specifications.

It is the operator’s responsibility of the operator to ensure this equipment is properly installed and

operated within Powerwave operating specifications to obtain proper performance from the equipment

and to comply with regulatory requirements.

For PERMANENTLY CONNECTED EQUIPMENT, a readily accessible disconnect device shall be

incorporated in the building permanent wiring.

Warnings, Cautions, and Notes

DRAFT

Warnings, Cautions, and Notes are found throughout this manual where applicable. The associated

icons are used to quickly identify a potential condition that could result in the consequences described

below if precautions are not taken. Notes clarify and provide additional information to assist the user.

WARNING: This warning symbol means danger. You are in a situation that could

cause bodily injury or death. Before working on any equipment, be aware of the hazards involved with electrical and RF circuits and be familiar with standard practices

for preventing accidents.

CAUTION: The caution symbol means reader be careful. In this situation, the user might do

something that could result in equipment damage or loss of data.

NOTE: The note symbol means reader take note. Notes contain helpful suggestions or references to

material not covered in this document. Procedures are not contained in notes.

044-05369 Rev A i

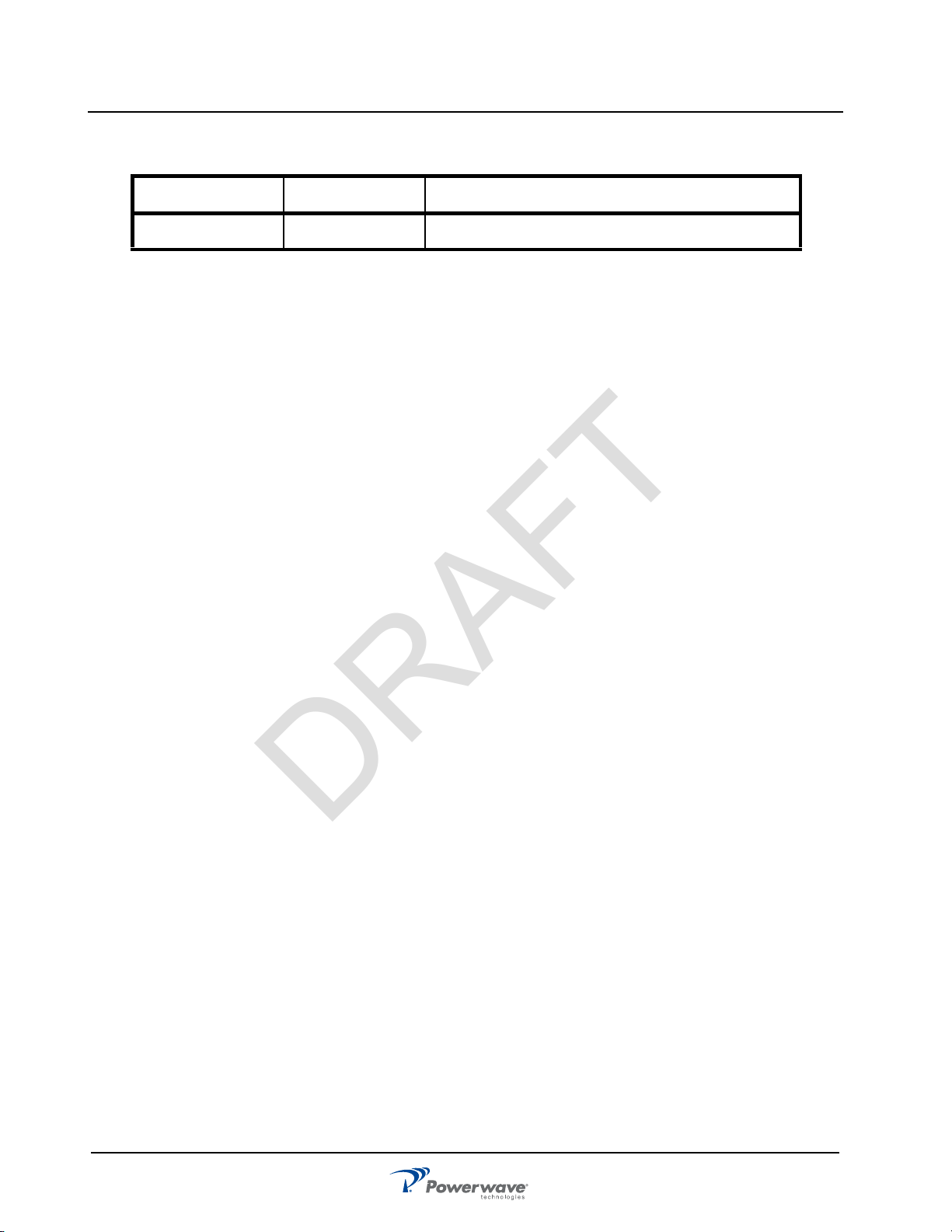

Revision Record

DRAFT

Revision Letter Date of Change Reason for Change

A May 2009 Initial Release

ii 044-05369 Rev A

Table of Contents

DRAFT

Warnings, Cautions, and Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Revision Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Product Description

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Scope of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Preamplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Main and Error Amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Feed-forward Loop Control Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Pilot Tone Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Controls and Indicators

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

MCPA Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

MCPA Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

MCPA Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Damaged Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Air Conditioning Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

MCPA Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Initial Start-up and Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Maintenance

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

MCPA Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

MCPA Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Return For Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Obtaining An RMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Repackaging for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Specifications

Multi-Carrier Power Amplifier Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

044-05369 Rev A iii

List of Figures

DRAFT

2-1 MCPA Front and Rear Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2-2 MCPA Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

3-1 MCPA Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3-2 MCPA Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

4-1 MCPA Quarter-turn fasteners and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

List of Tables

2-1 LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2-2 MCPA Alarm States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2-3 MCPA Connector Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

3-1 Unpacking Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3-2 MCPA Installation Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3-3 MCPA Start-up Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

4-1 Periodic Maintenance Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4-2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4-3 MCPA Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

5-1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

iv 044-05369 Rev A

G3L-2129-140 MCPA Introduction

DRAFT

Chapter 1

Product Description

Introduction

This manual contains information and procedures for the installation, operation, and maintenance of the

G3L-2129-140 Multi-Carrier Power Amplifier (MCPA).

Scope of Manual

This manual is intended for use by service technicians familiar with similar types of equipment. It contains

service information required for the equipment described and is current as of the printing date. Changes which

occur after the printing date may be incorporated by a complete manual revision or alternatively as additions.

The manual is organized into the following chapters:

Chapter 1 - Product Description

Chapter 2 - Controls and Indicators

Chapter 3 - Installation

Chapter 4 - Maintenance

Chapter 5 - Specifications

Product Description

The MCPA shown in Figure 1-1 MCPA Front and Rear Views is a linear, feed-forward multi-carrier power

amplifier that operates in a 60 MHz frequency band from 2110 MHz to 2170 MHz with an instantaneous

bandwidth of 45 MHz. The instantaneous bandwidth is the maximum frequency band in which any two or more

signals can occupy. The instantaneous bandwidth of the MCPA is set automatically.

The MCPA is modular in design and ideally suited for use in CDMA, W-CDMA, and LTE base stations. The

MCPA provides a gain of 63 dB to supply a 140 watt output. Refer to Figure 1-2 MCPA Functional Block

Diagram for the MCPA functional block diagram. Refer to Chapter 5 for the MCPA specifications.

Functional Description

The MCPA is a self-contained module typically operated in parallel with other identical MCPAs as part of a

subrack assembly.

The MCPA consists of the following major functions:

❑ Preamplifier

❑ Main and error amplifiers

❑ Feed-forward loop control circuits

❑ Pilot tone generator

❑ Controller

044-05369 Rev A 1-1

Functional Description G3L-2129-140 MCPA

Figure 1-1 MCPA Front and Rear Views

Front

Rear

DRAFT

1-2 044-05369 Rev A

G3L-2129-140 MCPA Functional Description

Figure 1-2 MCPA Functional Block Diagram

DRAFT

RF In

Preamp

Pilot Tone

Pilot Tone

Generator

FIRST LOOP

First Loop

PhaseandGain

First Loop

Control

VDC VDC VDCVDC

SECOND LOOP

Reflected

Delay

Filter

Error

Amplifier

Power

RF Out

(VSWR)

Premain

Amplifier

RF Sample

Controller

User

Interface

Second Loop

Phase and Gain

System

Faults

Delay

First Loop

Detection

-5

+5+9+15

+27 VDC

Main

Amplifier

Second Loop

Control

Status

Control

Error Out

Forward Power / Pilot Tone Detect

Front Panel

LED

ON/OFF/RESET

Switch

Preamplifier

The carrier (RF In) is applied to the input port of the MCPA and fed to the preamplifier stage where it is amplified

using two stages of class A mode amplifiers. The output of the preamplifier is split into two paths, one to the

main amplifier and one to the error amplifier.

Main and Error Amplifiers

The main amplifier provides the balance of gain and power in the 2110 MHz to 2170 MHz frequency band,

using class AB amplification for maximum efficiency. The error amplifier and feed forward loops correct signal

non-linearities introduced by the class AB main amplifier.

In the error amplifier, which operates in class A mode, the RF signal is coupled to an attenuator and phase

shifter in the first feed-forward loop, phase shifted by 180 degrees and then amplified in the premain amplifier.

The output from the pre-main amplifier is fed to the class AB main amplifier and then sampled using a coupler.

The signal (RF sample) is combined with the main input signal and input to the second feed-forward loop.

There, the RF sample is attenuated, phase shifted 180 degrees, and fed to the error amplifier where it is

amplified to a level identical to the sample output from the main amplifier. The output from the error amplifier

(Error Out) is coupled back and added to the output from the main amplifier, with the control loops continuously

making adjustments to cancel out any distortion in the final output signals.

Feed-forward Loop Control Circuits

The primary function of the first loop is to amplify the carrier signals and isolate an error signal for the second

loop. It does this by amplifying the carrier signals and isolating an error signal which is passed to the second

loop. The first loop control section phase shifts the main input signals by 180 degrees and constantly monitors

the output for correct phase and gain.

044-05369 Rev A 1-3

Cooling G3L-2129-140 MCPA

DRAFT

The primary function of the second loop is to amplify the error signal to cancel out spurious products developed

in the main amplifier. The input signal is amplified by a preamplifier and fed to a coupler and delay line. The

signal from the coupler is fed to the attenuator and phase shifter in the first loop.

The second loop control section obtains a sample of the distortion added to the output signals by the main

amplifiers. The signal is phase shifted 180 degrees, then fed to the error amplifier where it is amplified to the

same power level as the input sample. The signal is then coupled to the main amplifier output. The final output

is monitored by the second loop and adjusted to ensure that the signal distortion and intermodulation distortion

on the final output is cancelled out.

During routine operation, all normal variations are automatically compensated for by the feed-forward loop

control. If large variations occur beyond the adjustment range of the loop control, the controller shuts down the

MCPA RF section and a loop fault is reported to the system.

Pilot Tone Generator

The pilot tone is an internally generated signal with a predetermined frequency, phase, and amplitude is known.

If the pilot signal is suppressed at the amplifier output, then the distortion created by the main amplifier is also

suppressed.

The pilot tone signal is injected into the first loop and detected at the feedforward output of the second loop. The

pilot tone is coupled off of the main amplifier creating a second pilot tone that is attenuated and phase shifted

180 degrees to be used as the reference. The second pilot tone is amplified in the error amplifier and mixed with

the signals from the main signal path.

The first and second pilot tones should cancel each other out in an ideal situation. If the output detector senses

that the pilot tones do not cancel each other out, the information feeds back to control the gain and phase of

both the main and error amplifier paths minimizing output distortion.

Controller

The controller constantly compares the active RF paths with internal references for dynamic correction of small

variations through the RF feedback control circuits to maintain constant gain, and also provides the alarm

monitoring and control for the MCPA.

A front panel mounted tri-color LED provides MCPA operational status to the local operator. The OFF/ON/

RESET switch allows the operator to power on, power off or reset the MCPA. System faults are sent to a remote

location through the user interface.

Cooling

The MCPA components are mounted on a heatsink and cooled by forced air flowing over the heatsink fins.

System fans draw external air through the MCPA front panel inlet and exhaust air through the MCPA rear panel

outlet. The internal temperature is monitored to keep the MCPA within the specified operating temperature.

Power Distribution

The host system provides +26 to 28 VDC power for the MCPA. The DC/DC converter and voltage regulator in

the MCPA converts the +27 VDC to +15 VDC, +9 VDC, +5 VDC, and -5 VDC for internal use. The MCPA has

no built-in short-circuit protection.

The MCPA operates at full power if the system DC supply is within 26 to 30 VDC. The MCPA shuts down if the

applied DC power is less than 20.5 VDC or greater than 30.5 VDC.

1-4 044-05369 Rev A

Chapter 2

Multi-color

OFF/ON/RESET Switch

LED Status Indicator

DRAFT

Controls and Indicators

Introduction

This chapter contains descriptions of the G3L-2129-140 Multi-Carrier Power Amplifier (MCPA) controls and

indicators.

MCPA Controls and Indicators

The location of the MCPA controls and indicators are illustrated in Figure 2-1 and listed with descriptions in

Table 2-1.

Figure 2-1 MCPA Controls and Indicators

Table 2-1 LED Indicators

Controls and Indicators Description

Toggle Switch, Three Position

RESET (Up) Resets MCPA. LED indicates boot mode (red), then turns solid

ON (Center) Enables MCPA. LED indicates solid green

OFF (Down) Disables MCPA. LED Indicates solid red

LED, Status

Green (solid) RF enabled, OFF/ON/RESET switch set to On (center position),

Green (blinking) Standby

Yellow (solid) Minor Alarm - APC function enabled

Yellow (blinking) VSWR Warning

Red (solid) Major alarm - Critical fault present.

Red/Yellow (alternating) Downloading. Do not interrupt power.

green

normal operation, no alarm

044-05369 Rev A 2-1

MCPA Controls and Indicators G3L-2129-140 MCPA

DRAFT

MCPA Alarms

MCPA alarm conditions are reported to the system as logic level signals through the rear connector. The front

panel LED provides a visual reference for the operator of MCPA status. Refer to Table 2-1 for a listing of LED

status. Refer to Table 2-2 for a listing of Alarm states.

Table 2-2 MCPA Alarm States

Alarm Definition Alarm type/LED Auto-Recovery

Output

Overpower

Automatic

Power Control

(APC)

Input

Overdrive

Disables MCPA immediately if

output power is >+2 dB over rated

output RF power.

Enabled if output power is > 52.17

dBm.*

Disables MCPA immediately if input

RF drive is >-5 dBm

Major

(Red)

Minor

(Yellow)

Major

(Red)

Input power decreases below APC

threshold (-11.2 dBm)

MCPA auto-recovers when output

power drops below rated maximum

output power.

Input power decreases below APC

threshold (-11.2 dBm)

High

Temperature

High Reverse

Power

Exceed

Maximum

Voltage

Below

Minimum

Voltage

Loop Fail

(Linearization

Alarm)

Internal DC

Fail

Device Fail Alarm if one or more output power

*Note: If MCPA cannot compensate gain to maintain compliance, Output Overpower or Input Overdrive faults protect

MCPA.

Disables MCPA if sensor

temperature is > +95° C.

Disables MCPA if the reverse RF

output power is higher than 49 dBm

for a duration of 1-minute.

Disables MCPA immediately if

supply DC voltage > +30.5 VDC.

Disables MCPA immediately if

supply DC Voltage < +20.5 VDC

Disables MCPA if loop convergence

fails.

Alarm if internal voltages fail or out

of range.

devices fail.

Major

(Red)

Minor (Yellow)

during 1minute

validation

period then

changes to

Major (Red)

Major

(Red)

Major

(Red)

Major

(Red)

Minor

(None)

Minor

(None)

MCPA auto-recovers when sensor

temperature drops to less than +85

°C.

Reverse power must be < 48.3 dBm.

Auto-recovery when supply voltage

drops to < +29.5 VDC.

Auto-recovery when supply voltage

increases to >+24.0 VDC

Auto-recovery when loop converges.

MCPA tries to auto recover ten times

before permanent shut down. Two

minutes and 5 seconds for each try.

Auto-recovery once voltage is within

range. No shutdown until linearization

alarm occurs.

No auto-recovery. No shutdown until

linearization alarm occurs.

MCPA Connectors

The MCPA power, alarm, control, and RF connections are made through a D-sub combination male interface

connector located on the rear of the MCPA. Pin assignments are illustrated in Figure 2-2 and listed in Table 2-

3. Alarms are interpreted and generated by the MCPA and reported to the base station as a system level alarm.

The PC I/O RJ-11 connector on the front of the MCPA is for factory use only.

2-2 044-05369 Rev A

G3L-2129-140 MCPA MCPA Controls and Indicators

123

A1

A2

A3

A4

456789

10 11 12 13 14 15 16 17

DRAFT

Figure 2-2 MCPA Interface Connector

Table 2-3 MCPA Connector Pin Assignments

Pin Function Pin Function

A1

A2

A3

A4

1

2

3

4

5

6

7

RF Input (Coaxial Contact)

+27 VDC (Power Contact)

Ground (Power Contact)

RF Output (Coaxial Contact)

TX_H (RS-485)

TX_L (RS-485)

GND

RX_H (RS-485)

RX_L (RS-485)

GND

MOD_DET (Module Detection)

10

11

12

13

14

15

16

17

8

9

Summary_Fault

DC (On/Off)

NC

NC

NC

NC

NC

NC

HPE (High Power Enable)

NC

044-05369 Rev A 2-3

MCPA Controls and Indicators G3L-2129-140 MCPA

DRAFT

This page intentionally left blank.

2-4 044-05369 Rev A

Chapter 3

DRAFT

Installation

Introduction

This chapter contains unpacking, inspection, startup and installation procedures for the G3L-2129-140 MultiCarrier Power Amplifier (MCPA).

❑ Review this chapter prior to equipment installation.

❑ Review any government and local codes applicable to this installation.

❑ Read the instructions in this Chapter and Chapter 4 before operating the equipment.

Unpacking and Inspection

Perform the steps in Table 3-1 to unpack and inspect the MCPA.

Table 3-1 Unpacking steps

Step Action

1

Carefully open container and remove MCPA.

2

Visually inspect MCPA for damage that may have occurred during shipment.

Check for evidence of water damage, bent or warped chassis, loose screws or

nuts, or extraneous packing material in connectors. If possible, inspect equipment

in the presence of the delivery person.

3

If possible, retain all packing material that can be reused for repackaging

components.

Damaged Equipment

If the MCPA is damaged, a claim should be filed with the carrier when the extent of any damage is assessed.

Contact the factory for a return material authorization (RMA). Refer to Chapter 4 for the return procedure.

Air Conditioning Requirement

The MCPA generates 2770 BTUs of heat at 36 amps, 27 VDC and 140 watts average RF power output. The

MCPA operates within the extended low temperature and high temperature environments as listed in

Chapter 5.

MCPA Installation Instructions

CAUTION: Do not slam the MCPA into the system subrack during installation. Using excessive

force can damage the MCPA interface connector.

The modular MCPA can be installed in a variety of systems. All system connections to the MCPA are made

through the MCPA rear connector, no additional wiring is required. Perform the steps in Table 3-2 to install the

MCPA. Refer to Figure 3-1 MCPA Quarter-turn fasteners and Connectors for quarter-turn fastener position and

switch location.

044-05369 Rev A 3-1

Initial Start-up and Operating Procedures G3L-2129-140 MCPA

RF Switch:

RJ-11

Connector

(Factory use only)

Quarter-turn

fastener

RESET

ON

OFF

Quarter-turn

fastener

Interface

Connector

Unlocked

Locked

DRAFT

Table 3-2 MCPA Installation Steps

Step Action

1

Set MCPA OFF/ON/RESET switch to the OFF (down) position.

2

Ensure quarter-turn fasteners are in unlocked position.

3

Lift and insert MCPA into the subrack. Turn the quarter-turn fasteners to locked

position to secure MCPA into subrack.

Initial Start-up and Operating Procedures

Perform the MCPA initial start-up per the instructions in Table 3-3.

3-2 044-05369 Rev A

Figure 3-1 MCPA Quarter-turn fasteners and Connectors

CAUTION: Before applying power, ensure input and output cables are properly terminated at the

Duplexer front panel. Do not operate MCPA without a load attached. Excessive input power may

damage the MCPA. Refer to Chapter 5 for input power requirements.

Table 3-3 MCPA Start-up Steps

Step Action

1

Verify all system input and output cables are properly connected.

2

Verify +27 VDC (+/- 1 VDC) supply is available.

3

Set MCPA OFF/ON/RESET switch to ON (center) position.

4

Allow MCPA to warm-up for a minimum of two minutes before taking power

readings.

Chapter 4

DRAFT

Maintenance

Introduction

This chapter contains instructions for periodic maintenance, testing and troubleshooting for the G3L-2129-140

Multi-Carrier Power Amplifier (MCPA).

Periodic Maintenance

NOTE: Check your sales order and equipment warranty before attempting to service or repair unit. Do not

break seals on equipment under warranty or warranty will be null and void. Do not return equipment for

warranty or repair service until proper shipping instructions are received from factory.

Periodic maintenance requirements for the MCPA are listed in Table 4-1.

Table 4-1 Periodic Maintenance Requirements

Task Interval Action

Cleaning 3 Months Inspect for debris especially around front panel vents. Remove

Performance tests Optional Perform testing in accordance with Paragraph paragraph 6 on

MCPA Performance Tests

MCPA Performance tests are only performed at the factory. Refer to the troubleshooting instructions below.

Troubleshooting

Perform the instructions in Table 4-2 in the case of an MCPA fault or alarm.

Table 4-2 Troubleshooting

Step Action

1 Check for proper DC supply voltage.

2 Set the OFF/ON/RESET switch momentarily to RESET (Up) position.

3 Contact your field representative or the factory if fault does not clear.

dust with a soft cloth/brush or vacuum cleaner

page 1.

044-05369 Rev A 4-1

MCPA Removal and Replacement G3L-2129-140 MCPA

DRAFT

MCPA Removal and Replacement

Perform the instructions in Table 4-3 to remove and replace a MCPA.

CAUTION: Do not slam the MCPA into the system during installation. Using excessive force can

damage the MCPA connector.

CAUTION: When removing the MCPA from the system, support the MCPA to prevent the rear of

the MCPA from suddenly dropping when the guide rail disengages from the track. Dropping the

MCPA can damage the rear multi-pin connector. The MCPA weighs approximately 28.60 lbs.

(12.97 kg).

Table 4-3 MCPA Removal and Replacement

Step Action

1 Set MCPA OFF/ON/RESET switch to OFF (down).

2 Loosen two quarter-turn fasteners that secure MCPA to the subrack.

3 With steady even pressure, use handle on front of the MCPA to pull the MCPA out of the

system.

4 To replace MCPA, set MCPA OFF/ON/RESET switch to OFF (down).

5 Turn quarter-turn fasteners to Unlocked position.

6 Insert MCPA into subrack. Turn quarter-turn fasteners to locked position to secure MCPA.

Return For Service Procedures

When returning products to Powerwave, the following procedures will ensure optimum response.

Obtaining An RMA

A Return Material Authorization (RMA) number must be obtained prior to returning equipment and to reduce

delays in receiving repair service. Please contact our Repair Department at (714) 466-1000 to obtain this

number, or FAX your request to (714) 466-5800.

Repackaging for Shipment

To ensure safe shipment of a component, it is recommended that the original packing materials be reused If

this is not possible, use suitable shipping cartons and foam inserts to prevent damage in transit.

4-2 044-05369 Rev A

Chapter 5

DRAFT

Specifications

Multi-Carrier Power Amplifier Specifications

The performance and physical specifications for the G3L-2129-140 MCPA are listed in Table 5-1..

Table 5-1 Specifications

Electrical Specifications/Features

Operating Frequency Band 2110-2170 MHz

Instantaneous Bandwidth 45 MHz

Air Interface CDMA, W-CDMA, LTE

RF Output Power 140 W with crest factor reduced signals CCDF 1e-4 <= 9.0dB

Maximum Input (before shutdown) -5 dBm

Duty Cycle Continuous

BTUs 2770 at 36 Amps, 27 V and 160 W average RF power output

RF Gain 63 dB

Gain Flatness ±0.5 dB (Max.)

Gain Variation over Temperature ±0.5 dB (Max.)

Intermodulation Distortion -62 dBc (Max.)

Harmonics -13 dBm (Max.) 1 MHz Bandwidth; -50 dBc (Max.)

Out of Band Spurious -60 dBc (Max) ITU-R, SM329-9, Category B

Input Return Loss 14 dB (Min.)

Output Return Loss 16 dB (Min.)

Input Voltage Range +26 VDC to 28 VDC nominal; Operational range of 21.0 VDC to 30

DC Current:

(Max @ APC)

(Nominal)

Efficiency

Mechanical Specifications/Features

Controls Three position toggle switch: OFF/ON/RESET.

Alarm Indication LED; Green (normal), Yellow (minor alarm), Red (Major alarm).

Platform Compatibility Everest Power Amplifier (PA) will reduce power level to Harley/

RF Input / Output / Status / Alarm /

Control / DC Input Connector

DImensions 354.6 mm high, 99 mm wide, 499.9 mm deep (including handles)

Weight 12.97 kg (28.5 lbs)

Environmental Specifications/Features

Operating Temperature Range -33 ºC. to +50 ºC.

Storage Temperature -40 ºC. to +70 ºC.

Operating Humidity, Normal 5% to 95% relative humidity (non-condensing).

Storage Humidity 5% to 95% relative humidity (non-condensing).

125 W with Gaussian signals CCDF 1e-4 10.5dB

VDC.

MCPA disables at less than 20.5 VDC or greater than+30.5 VDC.

36 Amps at 26 V and 160 W average RF power output.

34.8 Amps at 27 V and 160 W average RF power output.

>17%

Python APC levels if placed in a Harley/Python subrack. PA will

perform at rated power levels with Software upgrade for subrack.

21-pin D-subminiature combo connector.

(13.96” H X 3.9” W X 19.7” D)

044-05369 Rev A 5-1

DRAFT

Worldwide Corporate Headquarters

1801 East St. Andrew Place

Santa Ana, CA 92705 USA

+1 714 466 1000

+1 714 466 5800 FAX

www.powerwave.com

Powerwave Technologies, Inc. All rights reserved. Powerwave, Powerwave Technologies, and the Powerwave logo are registered trademarks of Powerwave Technologies, Inc.

Main European Office

Knarrarnasgatan 7 8tr.

164 40 Kista, Sweden

+46 8-540-822-00

+46 8-540-824-91 FAX

Main Asia-Pacific Office

23 F Tai Yau Building

181 Johnston Road

Wanchai, Hong Kong

+852 2512 6123

+852 2575 4860 FAX

Loading...

Loading...