Page 1

OS-1933-E3-003 OS System Configuration

Activate Rectifier Modules

Table 3-4 Activate Rectifier Modules

Step Action

1 Select the System/Configuration Page. See Figure 3-15.

2 Using the pull-down menus in the Rectifier/Installed section, choose YES to activate the

3 Choose SUBMIT to accept and apply the changes. To abort changes choose another page

Rectifier Modules. Reference the rectifier positions detailed on the front rack ears of the

power system. Default is NO.

without applying submit.

Activate TMA Channels (2 per Sector)

CAUTION: This parameter sources +12 V at 500 mA maximum to antenna ports. Caution should be used

if antenna ports are connected to test equipment with 0 VDC tolerance.

To prevent a short circuit and alarm situation, all antenna port connections must be complete prior to

enabling TMA DC supplies.

NOTE: These configurations enable DC voltage at antenna ports and enable RX fault monitoring.

Each Rx channel sources +12 V at 500 mA maximum. Any current less than 40mA will generate a LO

CURRENT fault. Any current greater than 150mA will generate a HI Current fault. Any current greater than

500 mA will disable the DC source for that channel and generate a HI CURRENT fault.

A HI CURRENT condition attempts to auto-recover every five minutes by enabling the DC to Rx channel. If

fault condition is cured, alarm clears and source remains on. If fault is present, there is no change in status.

Table 3-5 Activate TMA Channels

Step Action

1 Select the System/Configuration Page. See Figure 3-15.

2 Using the pull-down menus in the TMA Main/Diversity sections choose ENABLE for the

3 Choose SUBMIT to accept and apply the changes. To abort changes choose another page

4 Navigate to the Status / Dynamic page. See Figure 3-17.

5 Verify the correct TMA channels have the correct current draw per the specifications of the

TMAs to be utilized. Default is DISABLED

without applying submit.

TMA. Currents less than 40mA or greater than 150mA will assert a fault. Currents greater

than 450mA will crowbar the power source. The system will retry every 5-minutes to enable

the channel in the event the short is remedied. A crowbar can also be reset by configuring

the channel disabled and then enabled.

3-6 044-05243 Rev A

Page 2

OS System Configuration OS-1933-E3-003

Adjust LNA Gain

Table 3-6 Adjust LNA Gain

Step Action

1 Select the System/Configuration Page. See Figure 3-15.

2 In the appropriate LNA gain section enter the desired LNA gain:

a. format = X.XdB

b. range = 0.0 to 13.0dB, default is 10.0dB

c. step size = 0.5dB

3 Choose SUBMIT to accept and apply the changes. To abort changes choose another page

without applying submit.

Adjust Tx Gain

Step Action

1 Select the System/Configuration Page. See Figure 3-15.

2 In the appropriate Tx gain section enter the desired Tx gain:

a. format = X.XdB

b. range = 0.0 to 18.0dB, default is 5.0dB

c. step size = 0.1dB

3 Choose SUBMIT to accept and apply the changes. To abort changes choose another page

without applying submit.

Adjust VSWR Alarm

Step Action

Table 3-7 Adjust Tx Gain

Table 3-8 Adjust VSWR Alarm

1 Select the System/Configuration Page. See Figure 3-15.

2 Using the pull-down menus in the VSWR Alarm section; choose a value with dependant

3 Choose SUBMIT to accept and apply the changes. To abort changes choose another page

on the system integrity. Provide adequate margin to prevent false alarms

a. value = return loss

b. format = 0.0dB

c. range = 0.0 to 12.0dB, default 0.0dB

without applying submit.

Activate External Alarm Inputs

Table 3-9 Activate External Alarm Inputs

Step Action

1 Select the System/Configuration Page. See Figure 3-15.

2 Using the pull-down menus in the External Alarms Configuration section choose one of the

3 Choose SUBMIT to accept and apply the changes. To abort changes choose another page

following dependant on external equipment:

a. OFF – default, no alarm reporting (default)

b. NO – short contact to Common for major alarm

c. NC – open contact to Common for major alarm

without applying submit.

044-05243 Rev A 3-7

Page 3

OS-1933-E3-003 Rectifier

LED Indicator

Status Verification

Table 3-10 Status Verification

Step Action

1 Select the Status/Static Page. See Figure 3-16.

2 Verify the OS System is configured correctly.

3 Select the Status/Alarms Page. See Figure 3-18.

4 Verify that none of the parameters display FAIL.

5 Select the Status/Dynamic Page. See Figure 3-17.

6 View the operating performance of measured system parameters:

a. Forward and Reflected Sector Power

b. Sector Output Return Loss

c. Alarm Status

d. MCPA and Rectifier module status

e. Critical temperatures, voltages and currents

Rectifier

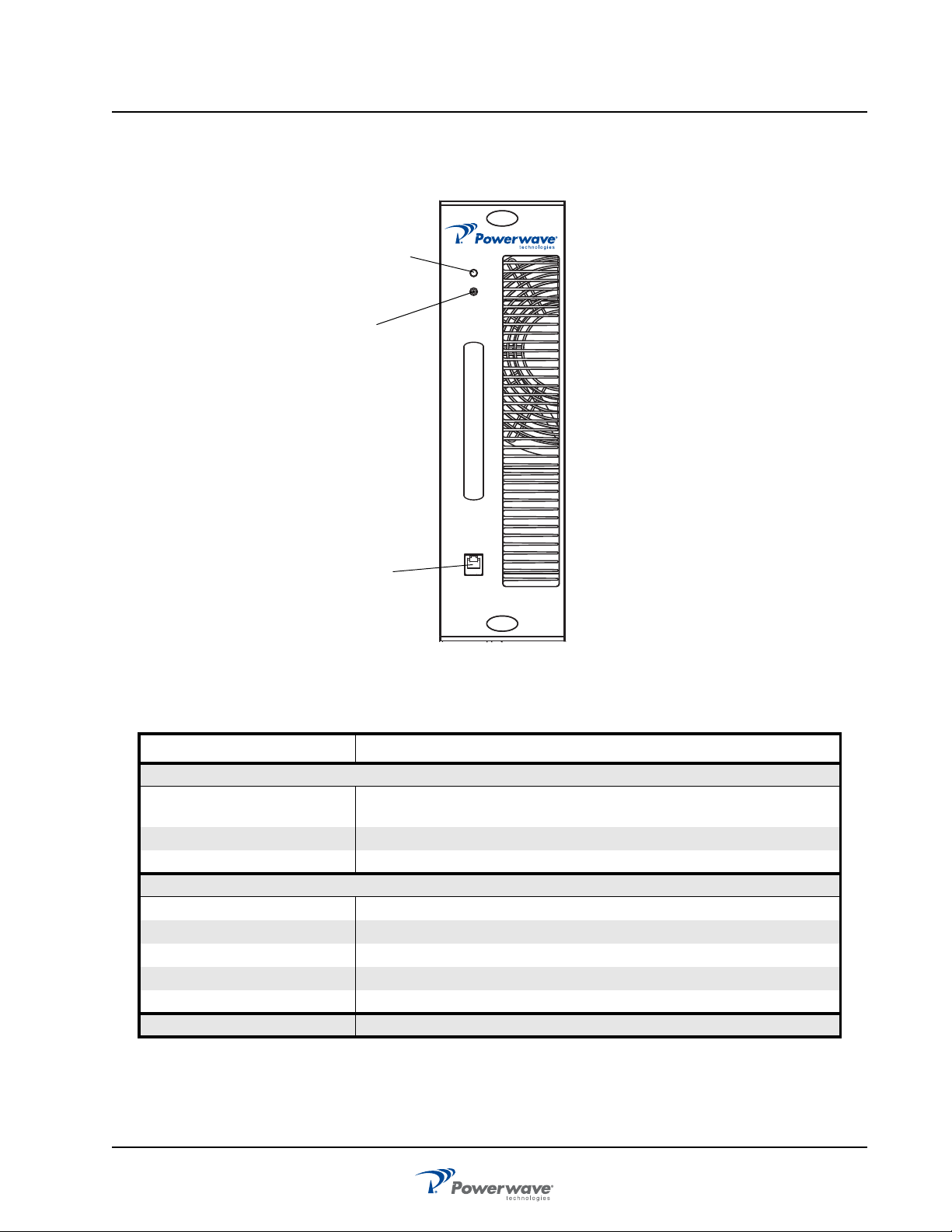

The rectifier module, shown in Figure 3-6, powers up automatically when AC power is applied to the OS. The

dual color LED indicator located at the upper-right side of the front panel displays rectifier status as listed in

Table 3-11.

Figure 3-7 Rectifier Front Panel

Table 3-11 Rectifier Status Indicator

LED Conditions Function

GREEN DC on

AMBER/GREEN Warning

AMBER DC off

3-8 044-05243 Rev A

Page 4

MCPA OS-1933-E3-003

STATUS

RESET

THE POWER IN WIRELESS

TM

PC I/O

ON

OFF

Status

Indicator

RF Switch:

RESET

ON

OFF

PC I/O

RJ-11

Connector

MCPA

MCPA controls and indicators listed in Table 3-12, are located on the MCPA front panel. MCPA operation is

controlled by the OFF/ON/RESET RF toggle switch. MCPA status is displayed by a tri-colored LED.

Table 3-12 MCPA Controls and Indicators

Controls/Indicator Description

Controls (RF)

Toggle Switch - RESET (Up

Momentary)

Toggle Switch - ON (Center) Enables RF

Toggle Switch - OFF (Down) Disables RF

Indicator

Tri-Color LED GREEN (solid) MCPA enabled, no alarm

PC I/O Factory use only

Figure 3-8 MCPA Front Panel

Resets the MCPA

GREEN (blinking) MCPA in standby, no output power

Yellow (solid) Automatic Power Control (APC)

Yellow (blinking) VSWR alarm

Red (solid) MCPA disabled

044-05243 Rev A 3-9

Page 5

OS-1933-E3-003 Controller Web Pages

Controller Web Pages

Figure 3-9 Controller Module

System – Download

Displays the current firmware version and allows firmware related functions. The Controller accommodates two

versions of firmware. The download page will allow the user to toggle between side “A” and side “B” firmware

versions or to download new firmware versions.

Software Download

Downloading a new version of code from the Web Page interface is very easy. It involves selecting only a

couple of options and pressing the “Download Now” button as shown in Figure 3-10. The software will access

the FTP server running on your PC and download the selected file. A CRC check will be performed on the

downloaded file and, if correct, the software will write the downloaded file to flash memory. After the flash

memory write is complete, the software will automatically reset and start executing on the newly downloaded

software.

Follow the steps in Table 3-13 to use the web page for downloading code.

Figure 3-10 Download Web Page

Table 3-13 Downloading Code

Step Action

1 Verify an FTP server is running at the IP address listed on the download page, as shown

2 Place the file to download in the default FTP directory, for example “c:\ftproot”.

3 Select the side to download to, ‘A’ or ‘B’ as shown in Figure 3-10.

4 Press the Browse button and navigate to the FTP download directory as shown in Figure

in Figure 3-10. Usually this is your PC’s IP address.

A free FTP server is “GuildFtpd” and can be downloaded from http://www.guildftpd.com/.

3-11. Select the file to download.

3-10 044-05243 Rev A

Page 6

Controller Web Pages OS-1933-E3-003

Table 3-13 Downloading Code (Continued)

5 Press “Download Now” to start downloading as shown in Figure 3-12. Note that the status

6 Once the download is complete, as shown in Figure 3-14, the Status will indicate

indicates “Download Initialized.” The status will be updated with download progress.

“Successful” and will automatically reset to the side selected for download.

The system will reset and all web pages will have expired. So, when using your browser,

you must re-navigate to the opening web page and log in again.

Figure 3-11 Select File to Download

Figure 3-12 Download Now

044-05243 Rev A 3-11

Page 7

OS-1933-E3-003 Controller Web Pages

Figure 3-13 Download In Progress

Figure 3-14 Download Complete

System – Configuration

This page allows modifications to the system such as Gain adjustment, TMA control, VSWR Alarm threshold,

and Sector and Hardware configurations. All System functions are accessible through this page.

Figure 3-15 System - Configuration page

3-12 044-05243 Rev A

Page 8

Controller Web Pages OS-1933-E3-003

• Installed – Allows sector configuration. Select YES for sectors to be active, choose NO for sectors to

remain vacant. Choose SUBMIT to accept the changes to the page. Initial default is enabled.

• Tx Gain – Allows sector’s TX gain adjustment. Type in the desired gain value in 0.1 dB steps.

Choose SUBMIT to accept the changes to the page. Initially set to 5.0dB.

• LNA Gain - Allows sector’s LNA gain adjustment. Type in the desired gain value in 0.5 dB steps.

Choose SUBMIT to accept the changes to the page. One LNA Gain value per sector applies to the

main and diversity LNA channels. Initially set to 0.0dB.

• TMA Main – Controls the operation of the Main TMAs. Choose ENABLE for TMA use and DISABLE

to suspend TMA use. Choose SUBMIT to accept the changes to the page. Initial default is disabled.

• TMA Diversity – Controls the operation of the Diversity TMAs. Choose ENABLE for TMA use and

DISABLE to suspend TMA use. Choose SUBMIT to accept the changes to the page. Initial default

is disabled.

• VSWR Alarm LL – Allows configuration of the VSWR Alarm threshold. The range is 0.0 to 12.0.

Adjustment does not alter protection shutdown thresholds.

• RECTIFIERS – Controls alarm reporting for each rectifier module (4-total). Configuration does not

effect the operation of the rectifier modules. The rectifier modules are plug n’ play, if they are

inserted with a green LED they are operating. Choose YES for every inserted module to ensure

proper alarm reporting. Choose NO for vacant rectifier slots. Choose SUBMIT to accept the changes

to the page. Initial default is YES. Vacant rectifier slots should be plugged with blank panels to optimize thermal characteristics of the system.

• External Alarms – The system has the capability to detect four form-c inputs. The configuration

allows the each of the four alarms to be configured individually. Choose OFF (default) to disable an

alarm channel. Choose NO (Normally Open) to receive a normally open form-c alarm. Choose NC

(Normally Closed) to receive a normally closed form-c alarm. Received faults will assert a system

Major alarm. Choose SUBMIT to accept the changes to the page.

Status – Static

This page displays the current configuration of the system. The items displayed are not editable and are for

information only.

Figure 3-16 Status - Static page

• Installed – Installed sectors are Yes. Disabled sectors are No.

• Firmware – System and MCPA firmware versions.

• Tx1 Gain – Displays the Tx1 gain setting for each sector.

• Tx2 Gain – Displays the Tx2 gain setting for each sector.

• Tx3 Gain – Displays the Tx3 gain setting for each sector.

• Tx4 Gain – Displays the Tx4 gain setting for each sector.

• LNA Gain – Displays a LNA gain setting for each sector, showing the main and diversity channels.

• TMA Main – Displays the status of each channel.

• TMA Diversity – Displays the status of each channel.

044-05243 Rev A 3-13

Page 9

OS-1933-E3-003 Controller Web Pages

Status – Dynamic

This page displays the current status of the system. The items displayed are not editable and are for

information only.

Figure 3-17 Status - Dynamic page

State

• DEGRADE = Minor system fault Fan / Intrusion / ……

• PASS = Enabled and no faults

• FAIL = Faulted (see the STATUS – ALARM page for details)

• MISSING = Sector is Enabled with missing components, critical sector alarm state.

Temperature – Display of real time temperature sensors for the main system components.

Forward Power – The output power detected at the TX/RX ANT Port for each sector in Watts.

Reverse Power - The reverse power detected at the TX/RX ANT Port for each sector in Watts.

Return Loss – Real-time measurement of the return loss at the TX/RX ANT Port in dB.

TMA Main – Each TMA channels current draw in mA.

TMA Diversity – Each TMA channels current draw in mA.

Alarm Summary – MINOR, MAJOR, CRITICAL status for each sector or system. See the Status – Alarm page

for details

MCPA APC

• OFF — No APC

• ON — APC active and gain display is in accurate and channel is overdriven. Reduce input source or

reduce sector gain.

MCPA Front Panel Switch

• OFF — MCPA disabled via the front panel switch

• ON — MCPA front panel switch is on.

Rectifiers – Installed

• YES — Alarm reporting for this channel is enabled.

• NO — Alarm reporting is disabled for this rectifier channel.

Rectifiers – Comm Status

• Comm — Rectifier module installed, alarm reporting enabled and no faults

3-14 044-05243 Rev A

Page 10

Controller Web Pages OS-1933-E3-003

Rectifiers – Current

The DC current output of each rectifier module. Total DC consumption is the sum of the four rectifiers. Current

sharing technology allows for equal readings for each channel. The DC current is displayed in Amperes.

Rectifiers – Voltage Out –The DC voltage output sensed from each rectifier module. Voltage should be

~28.5Vdc.

Rectifiers – Temperature –The temperature of each rectifier module in degrees Celsius.

Fans – Speed –The RPM display of each of the systems fans. If the system only utilizes 2 fans the FT (front

top) and RT (rear top) positions are active. Maximum RPMs are >4000.

Status – Alarms

This page displays the current detailed alarm status of the system. The items displayed are not editable and

are for information only.

Figure 3-18 Status - Alarms page

The alarms page is organized in a top and bottom section. The top lists on 3 columns the detailed system

alarms related to common system components. The bottom section is divided into the 3 sectors and detail RF

performance issues. A PASS should be displayed for all parameters. A FAIL signifies an issue to be resolved.

This page should be displayed during every maintenance visit.

User

This page allows for modifications to system identification, password and serial number display.

Figure 3-19 User page

044-05243 Rev A 3-15

Page 11

OS-1933-E3-003 Alarm Functions

My ID Number – Entry will assign a unique address to the system. The address is useful for identifying

individual booster cabinets.

Cascade Code – Enter the code required for wireless modem interface.

Serial Number – Display only.

Misc – System Version, display only.

User ID – Change from default “User”.

Password – Change from default “Password”.

Submit – Click to accept all changes.

Alarm Functions

Alarm Status Indicators (front panel)

There are three dual element LEDs displaying the system status. Each LED is mapped to a sector. The LED is

defined by the following chart:

Table 3-14 LED Functions

RATE COLOR PURPOSE

Solid Green Normal

1 Hz Green FW Download

Solid Red Critical Fault / Bypass

Solid Red &

Green

Minor/Major Fault

PC Interface (front panel)

An RS232 interface for testing purposes.

Ethernet Interface (front panel)

Connect Ethernet on controller to Ethernet interface on PC with a crossover RJ45 cable. This port is intended

for local control and monitoring on a temporary basis

3-16 044-05243 Rev A

Page 12

Alarm Functions OS-1933-E3-003

Ethernet Web Page Procedure

Table 3-15 Ethernet Web Procedure

Step Action

1

2

3

4

5

6

7

8

9

10

Connect Ethernet crossover cable from PC to modem front panel ETHERNET connector.

Boot up PC.

On PC, go to Start-Settings-Control Panel Network Connections. Right click on Local Area Connection,

then select Properties.

After Local Area Connection Properties window opens, deselect all functions except Internet Protocol

(TCP/IP).

Double click on Internet Protocol (TCP/IP) to open Internet Protocol (TCP/IP) Properties window.

Select “Use the following IP address”.

At “IP address” type in 192.168.0.2, then press Tab key. Subnet mask fills in 255.255.255.0. Select OK to

close window.

Select OK to close Local Area Connection Properties window.

Open Internet Explorer.

Using Internet Explorer Address bar, type http://192.168.0.1, then press Enter key. The Powerwave

Twoport application is enabled and Log In screen is displayed.

Ethernet Interface (rear panel)

This port is intended for control and monitoring by a BTS or Remote Network Management System on a

permanent basis.

Form-C / External Alarm Interface (rear panel)

Reference the Form-C and External Alarm interface section in chapter 2 for pin-outs and installation.

Form-C Alarms

The alarm status is reported via Form-C contacts. There are five Form-C alarms: ALARM1 through ALARM5.

The alarms are detailed as follows:

Alarm 1

Minor Alarm - all sectors:

• Any cabinet fan fault.

• Intrusion – if one or both booster doors are opened.

• Rectifier Communication Fault.

Alarm 2

A Major Alarm - all sectors:

• TMA1 or TMA2 is faulted (if both enabled), but not both faulted.

• TMA3 or TMA4 is faulted (if both enabled), but not both faulted.

• TMA5 or TMA6 is faulted (if both enabled), but not both faulted.

• LNA1 or LNA2 is faulted, but not both faulted.

• LNA3 or LNA4 is faulted, but not both faulted.

• LNA5 or LNA6 is faulted, but not both faulted.

• Any rectifier fault.

• Any External Alarm fault.

• No communication from the MODEM (if applicable).

044-05243 Rev A 3-17

Page 13

OS-1933-E3-003 Alarm Functions

Alarm 3

A Critical alarm Sector “A” will be asserted if:

• MCPA_A is disabled or vacant.

• All enabled Sector A TMA channels are faulted.

• All Sector A LNA channels are faulted.

• A VSWR fault on Sector A.

• All Rectifiers Faulted.

• RFCU_A removed.

• If the BYPASS_V_A or +5V_EXT_A signals are faulted.

Alarm 4

A critical alarm Sector “B” will be asserted if:

• MCPA_B is disabled or vacant.

• All enabled Sector B TMA channels are faulted.

• All Sector B LNA channels are faulted.

• A VSWR fault on Sector B.

• All Rectifiers Faulted.

• RFCU_B removed.

• If the BYPASS_V_B or +5V_EXT_B signals are faulted.

Alarm 5

A critical alarm Sector “C” will be asserted if:

• MCPA_C is disabled or vacant.

• All enabled Sector C TMA channels are faulted.

• All Sector C LNA channels are faulted.

• All Rectifiers Faulted.

• RFCU_C removed.

• A VSWR fault on Sector C.

• If the BYPASS_V_C or +5V_EXT_C signals are faulted.

External Alarm Inputs

Reference the External Alarm interface section on page 2-7 for pin-outs and installation. Utilize the System/

Configuration page; External Alarms section for configuration options.

3-18 044-05243 Rev A

Page 14

Chapter 4

Maintenance

Introduction

This chapter provides periodic maintenance and removal and replacement procedures for the OS-1933-E0003 Outdoor MCPA System.

Periodic Maintenance

Suggested periodic maintenance requirements are listed in Table 4-1.

WARNING: Wear proper eye protection to avoid eye injury when using compressed air.

CAUTION: Use only dry compressed air when cleaning the OS, do not use pressure washers.

To ensure proper cooling and prevent MCPA over temperature shutdown, one of the two booster doors

must be closed and secure at all times.

NOTE: Do not break the seals on equipment under warranty or the warranty will be null and void. Do not

return equipment for warranty or repair service until proper shipping instructions are received from the factory.

Table 4-1 Periodic Maintenance

Task Interval Action

Cleaning:

Filters 12 months Inspect and clean air filters.

Air Vents

Inspection:

Cables and

Connectors

During periodic

site maintenance

During periodic

site maintenance

Inspect and clean inlet and outlet air vents. If equipment is

operated in a dusty or industrial environment, inlets and outlets

should be inspected more often.

Inspect signal and power cables for frayed insulation. Check RF

connectors to ensure tightness.

Cleaning Air Inlets/Outlets/Filter

The air inlets and outlets should be cleaned during periodic site maintenance. If the equipment is operated in a

heavy industrial or severe dust environment, the inlets and outlets should be cleaned as necessary. Cooling

efficiency can be reduced if dust and dirt are allowed to accumulate. Remove the panel and, using either

compressed air or a brush with soft bristles, loosen and remove accumulated dust and dirt from the air inlet

and outlet panels. Replace the panel when cleaned.

The air filters, located in the front and rear panels, also must be removed and cleaned using compressed air.

Refer to Air Filter Cleaning, page 4-10,Table 4-9, Figure 4-6 for filter cleaning and replacement instructions.

044-05243 Rev A 4-1

Page 15

OS-1933-E3-003 Troubleshooting

Troubleshooting

Status of each individual module can be determined by the status of the LED (MCPAs, Rectifier, Controller

represents system and RFCUs). All LEDs should illuminate a solid green; any other indication requires access

to the Status / Alarm page. Some common alarms and there remedies are detailed in the following sections.

MCPA does not have a solid green LED

Table 4-2 MCPA - no solid green LED

LED Color Status Action

Red Solid

No LED No LED

Yellow Blinking

Yellow Solid

Red/Yellow Blinking

Open Status / Alarms page for details about the MCPA fault.

Check Power system or verify the appropriate fuse located on the

rear of the power system.

The MCPA is measuring >50W of reflected power.

i. Ensure that the TX/RX ANT ports are terminated adequately

ii. Ensure that the MCPA is installed fully and the latches are

secured.

iii. Try reseating the MCPA; disable the MCPA by the front panel

switch (down) before removing.

iv.If not remedied the MCPA will shutdown in one minute. If shutdown

for VSWR, the MCPA will require a manual reset with the front panel

switch (up position) to recover.

The MCPA has reduced gain to compensate for an excessive input

level.

i. Ensure the input sources are within the specified power levels.

ii. Ensure the TX Gain is configured in accordance to the

specifications in Section 5.

iii. The MCPA can only compensate for 6dB. The MCPA could

disable and require a manual reset via the front panel switch (up

position).

iv. Operating the OS System equipment under this condition could

manifest into a system shutdown due to excessive temperature and/

or RF power.

Firmware is not loading correctly

i. Extract module from the OS system

ii. Place the front panel switch in the ON position (middle)

iii. Re-insert the MCPA into the OS system

iv. Latch to top and bottom fasteners.

The MCPA is ready to enable, but something in the system is

preventing this. Check the following

i. Verify the Sector is enabled via the System/Configuration page,

Installed section.

ii. Attempt re-seating the MCPA and ensuring the latches are locked.

iii. Try another MCPA.

Green Blinking

iv. View the Status/Alarm page for more details

v. If the communication to the system cannot be established the

controller is not operating. Cycle the AC source to restart the system.

vi. Ensure DC power is getting to the controller; check the fuse on the

rear of the power system. Measure the +28.5Vdc on the controller

JX.

vii. Replace controller. See page 4-7.

4-2 044-05243 Rev A

Page 16

Troubleshooting OS-1933-E3-003

Rectifier Module with a Red LED or Individual Faults

– Any rectifier module fault is remedied by replacing a known good module with the suspected unit. Refer to

the Status/Alarm page for exact details. Reference the Rectifier Module section in Chapter 2 for the procedure

on Rectifier Module replacement.

RECT ALL COMM Fault

Could to the result of a bad RJ45 interface cable at the rear of the system linking the controller with the power

system. A non-crossover network cable could be temporarily installed to validate the connection.

Rectifier Voltage Fault

Measure the AC input and/or DC Output (all 4 fused outputs) and validate that the voltage is within the

specified range detailed in section 5.

Fans Not Operating –

• Check the status of the fans on the Status/Dynamic page.

• The fan of a specific door will not operate if that door is not secured. Ensure that the front and rear

doors are secured and that both fans are operating any time there is a site visit.

• The fan circuitry has an auto-resettable fuse. Unplugging a bad fan and installing a known good fan

should reset the fuse. The intrusion plunger must be pulled to the out position to simulate a door closure and allow the fan to operate.

• The OS System components are not >41 C. Fans do not operate below this threshold.

RFCU Alarms

Status/Alarm Page Faults – Bypass V, 5V, LNA Alarm 1/2 could be an indication of a bad RFCU. Replace the

RFCU module per the procedure in the RFCU section of Chapter 2.

RF Performance Issues -

• No power out or gain:

• View the Status/Alarm page correct all detected alarms

• Disable the MCPA to force the sector into bypass, using external measuring equipment validate the

RF passing through the OS System.

• Disable the MCPA first then reseat the MCPA and RFCU modules, enable the MCPA

• Replace the MCPA and/or RFCU with a known good module.

044-05243 Rev A 4-3

Loading...

Loading...