Page 1

044-05207 Rev A April 2008

RACK MOUNT REPEATER

INSTALLATION AND SERVICE MANUAL

RM

NEXUS FT

RACK MOUNT RADIO

Page 2

© 2008 Powerwave Technologies Incorporated. All rights reserved.

Powerwave Technologies and the Powerwave logo are registered trademarks.

Powerwave Technologies Inc. reserves the right to make changes to documentation and equipment, including but not limited to component substitution and circuitry changes. Changes that impact this document may be subsequently incorporated in a later revision

of this document.

This Powerwave product is designed to operate within the Normal Operating (typical operating) ranges or conditions specified in this

document. Operation of this equipment beyond the specified ranges in this document may cause (1) spurious emissions that violate

regulatory requirements; (2) the equipment to be automatically removed from service when maximum thresholds are exceeded; or

(3) the equipment to not perform in accordance with its specifications. It is the Operator's responsibility to ensure this equipment is

properly installed and operated within Powerwave operating specifications to obtain proper performance from the equipment and to

comply with regulatory requirements.

The rated output power of a Nexus FT is for multiple carriers. As long as the composite power does not exceed the rated power

(20W for North America), derating is not required for multiple carriers. For situations where regulatory requirements require reduced

interference to adjacent band users, the rating would have to be reduced by 3 dB. This power reduction is to be by means of input

power or gain reduction and not by an attenuator at the output of the device. Input power is rated at 115/230VAC, 50/60Hz, and

should be protected based on the power and fuse specifications in Chapter 5 of this manual. Power strips should, at a minimum,

conform to this requirement to prevent equipment damage and possible overload.

Federal Communications Commission (FCC)

This device complies with the technical standards governing mobile radio devices in accordance with FCC Rules. This device is

intended to facilitate the reception and transmission of mobile radio devices in the cellular, PCS or other mobile services, and its

operation by end users or others requires carrier consent under FCC rules. This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to CRF47 part 15 of the FCC rules. This equipment is also certified to CRF47 part

22 (cellular), part 24 (PCS) and part 90 (iDEN800 and iDEN900) of the FCC Rules depending on the band of operation. Changes or

modifications not expressly approved by Powerwave Technologies, Inc. for compliance could void the user’s authority to operate this

equipment. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

European Requirements

The Powerwave Nexus FT apparatus introduced in EU markets are certified to ESTI EN 300 609-4 (GSM900 and DCS1800) and

ESTI EN 301 908-11 (WCDMA).

Powerwave Technlogies Inc., 1801 East St. Andrew Place, CA 92705 Santa Ana, USA.

Phone +1 714 466 1000 – Fax +1 714 466 5800 – Internet www.powerwave.com

Page 3

Warnings, Cautions, and Notes

Warnings, Cautions, and Notes are found throughout this manual where applicable. The associated

icons in warnings and cautions are used to quickly identify a potential condition that could result in the

consequences described below if precautions are not taken. Notes clarify and provide additional

information to assist the user.

WARNING: The warning symbol means danger. You are in a situation that could cause bodily

injury or death. Before you work on any equipment, be aware of the hazards

involved with electrical and RF circuitry and be familiar with standard practices

for preventing accidents.

CAUTION: The caution symbol means the potential exists for equipment damage or loss of

data.

NOTE: Notes contain helpful suggestions or references to material not covered in the docu-

ment.

044-05207 Rev A i

Page 4

Revision Record Nexus FT RMR

Revision Record

Revision Letter Date of Change Reason for Change

Rev A April 2008 Initial release

ii 044-05207 Rev A

Page 5

Preface

Safety

Any personnel involved in installation, operation, or service of units included in a Powerwave Distributed

Antenna System (DAS) must understand and follow the points below.

❑

Powerwave Nexus FT Rack Mount Radios (RMR) are designed to receive and amplify signals from one or

more base stations and retransmit the signals to one or more mobile stations. They also act the other way

round, that is to receive signals from one or more mobile stations, then amplify and retransmit the signals

to the base stations. Powerwave Nexus FT RMR systems must be used exclusively for this purpose and

nothing else.

❑

Units supplied with power from the mains must be connected to grounded outlets and in conformity with

the local prescriptions.

❑

Power supply units supplied from the mains contain dangerous voltage that can cause electric shock.

Disconnect the mains prior to any work in such a unit. Local regulations are to be followed when servicing

such units. Only authorized service personnel are allowed to service units while the mains are connected.

❑

All RF transmitting units, including Nexus FT RMRs, will generate radio signals and thereby give rise to

electromagnetic fields that may be hazardous to the health of any person who is extensively exposed close

to an antenna.

Human Exposure to RF Radiation

Safe distances must be kept when working around antennas. The following paragraphs describe the cautions

to be aware of during the installation and maintenance of antenna systems and how to calculate safety

distances needed for RF radiation at different antenna power and frequencies.

Antennas

To be able to receive and transmit signals, a RMR is connected to a donor antenna directed towards the base

station and a service antenna directed towards the coverage area. A fiber optic cable from the base station

might, however, be substituted for the donor antenna.

Installation and Maintenance of Antenna Systems

Installation and maintenance of all antenna systems must be performed with respect to the radiation exposure

limits for public areas. The antenna radiation level is affected by RMR output power, antenna gain, and

transmission devices such as cables, connectors, splitters and feeders. Also, the system minimum coupling

loss, typically between 25dB and 35dB, is determined by a standard with the purpose to protect base stations

from noise and other performance dropping effects.

Radiation Exposure

The World Health Organization (WHO) and International Commission on Non-Ionising Radiation Protection

(ICNIRP) have determined recommendations for radiation exposure. ICNIRP recommends not to exceed the

following radiation power for public exposure:

Frequency Radiation power

800/900 MHz 4.5W/m²

1800/1900 MHz 9.0W/m²

2100 MHz 10.0W/m²

For antennas larger than 20cm the maximum radiation power can be calculated by using the following formula:

S = Radiation power in W/m²

P = Output power in W

r = Distance between antenna and human in meters

S= P/(4

πr

2

)

044-05207 Rev A iii

Page 6

Electrostatic Discharge (ESD) Nexus FT RMR

Electrostatic Discharge (ESD)

ESD can severly damage essential parts of the equipment if not handled carefully. Parts on printed circuit

board assemblies (PCBA) as well as other parts in the equipment are sensitive to ESD. Never touch the

PCBA or uninsulated conductor surfaces unless absolutely necessary.

If you must handle the PCBAs or uninsulated conductor surfaces, use ESD protective equipment or first

touch the chassis with your hand. Never let your clothes touch PCBAs or uninsulated conductor surfaces

and always store PCBAs in ESD-safe bags.

iv 044-05207 Rev A

Page 7

Chapter 1

Product Description

Introduction

This manual contains information and procedures for installation, operation, and maintenance of the Rack

Mount Radio module as part of the Nexus FT Rack Mount Repeater. In this manual, the Nexus FT Rack Mount

Radio is referred to as the RMR. The manual is organized into chapters as follows:

❑

Chapter 1- Product Description

❑

Chapter 2- Controls and Indicators

❑

Chapter 3- Installation

❑

Chapter 4- Maintenance

❑

Chapter 5- Specifications

Scope of Manual

This manual is intended for use by service technicians familiar with similar types of equipment. It contains

service information required for the equipment described and is current as of the printing date. Changes which

occur after the printing date may be incorporated by a complete manual revision or alternatively as additions.

Overview

The RMR is a repeater designed to be part of a Distributed Antenna System (DAS). The components are

mounted on a 19” rack and are intended for use in an in-door, temperature controlled environment.

As part of a DAS, the RMR extends coverage into uncovered areas in wireless mobile systems such as base

station fringe areas, tunnels, convention centers, airports, and buildings. It receives, amplifies, and transmits

signals to/from a Base Transceiver Station (BTS) and to/from Mobile Stations (MS) with both directions being

served simultaneously.

The RMR unit is a dual wide band, bi-directional, RF amplifier with two separate donor ports and a common

(duplexed) service port per band. It connects to an Optical to RF Distribution Unit (ORD) where RF signals are

combined or split and converted to an optical signal in the Uplink direction. In the Downlink direction, optical

signals are converted to RF and split to RF outputs. Two separate full duplex fibers handle signal transport

between the BTS Master Unit and the ORD. The DL signal and the UL signal combine onto one optical fiber

through a Wavelength Division Multiplexer (WDM). Wide band 4-way combiners handle RF splitting and

combining. The UL ouput signal is connected to the ORD via RF coax cable, converted to light, and sent via

fiber toward the BTS.

A Wireless Portal module distributes the DL/UL signals to/from the DAS.

The RMR is microprocessor controlled with alarm and operational status LEDs visible on the front. Cooling is

provided through forced air fans. Operational parameters, such as gain and power levels are set using a PC

running Powerwave OM-Online software which communicates with the RMRs either locally or remotely via

modem. Remote operation can be accomplished via PSTN or a GSM net. The Operation and Maintenance

System (OMS) provides for Network Operations Center (NOC) configuration and alarm monitoring.

044-05207 Rev A 1-1

Page 8

Rack Mount Radio module (RMR) Nexus FT RMR

Typical RMR position

Cabinet Design

The RMR modules are intended to be mounted in a 19 inch cabinet at least 600mm deep, similar to the one

shown Figure 1-1.

I

Figure 1-1 Powerwave RMR rack- fully equipped

Rack Mount Radio module (RMR)

Figure 1-2 RMR

RMRs can handle multiple carriers over a wide band. The rack can be equipped with up to four RMRs.

1-2 044-05207 Rev A

Page 9

Controls, Indicators and Connectors

Red

Amber

Introduction

This chapter contains descriptions of the controls, indicators and connectors for the RMR.

Indicators

Chapter 2

Figure 2-1 External Indicators

The LEDs, shown in Figure 2-1, provide easy identification of a fault in the system. The amber operation LED

lights up approximately 15 seconds after the main power is switched on. When the LED is steady, the RMR is

ready for operation. The red alarm LED indicates a system error alarm when flashing and a critical alarm

when steady.

044-05307 Rev A 2-1

Page 10

Nexus FT RMR

This page intentionally left blank

2-2 044-05307 Rev A

Page 11

Chapter 3

Installation

Introduction

This chapter contains unpacking, inspection, and installation instructions for installing and powering up the

RMR.

Site Survey

Powerwave recommends that a site survey be performed prior to equipment ordering or installation.

Performing a detailed site survey reduces or eliminates installation and turn-up delays. Pay particular

attention to power plant capacity, cooling needs, floor space, and RF/DC cabling/breaker requirements.

Cabinet dimensions and weights are listed in Chapter 5.

Unpacking and Inspection

This equipment has been operated, tested, and calibrated at the factory. Carefully open container to remove

equipment. Retain all packing material that can be reassembled in the event unit must be returned to the

factory. Perform the following steps:

❑ Visually inspect equipment for damage that may have occurred during shipment. If possible, in the

presence of the delivery person.

❑ Check for evidence of water damage, bent or warped chassis, loose screws or nuts, or extraneous

packing material in connectors.

If equipment is damaged, file a claim with the carrier once the extent of any damage is assessed.

If equipment must be returned to factory, please contact factory for a Return Material Authorization (RMA),

see Chapter 4.

RMR Rack Location

The RMR is designed for use in an indoor, temperature controlled environment mounted on a 19 inch rack as

supplied by the customer. A preferable site for the RMR is a location free of obstructions, easily accessible

and allows for proper air-flow and ventilation.

Connections

This section describes general examples of how to connect the input and output ports on the RMR.

Main Power and Grounding

Local regulations need to be followed for the main power connection. RMRs are approved in accordance with

EN and UL/cUL regulations. This is, however, only valid if a classified power cord is used. For the Nexus FTto

meet these regulations you must select one of the following classified and approved cord types:

❑ EN – H 05 W5 - F HMR

❑ UL – AWM Style 2587

❑ CSA– AWM 1 A/B 11 A/B

WARNING: For RMRs supplied from the main power source, the main outlet must be

grounded.

044-05207 Rev A 3-1

Page 12

Connections Nexus FT RMR

1

2

1

2

RF Connections

RF cable connections should be verified both internally and externally before powering up the equipment.

This section illustrates the general internal connections of the RMR. Verify these connections with the as-built

drawings and documents for your specific system configuration. Table 3-1 and Figure 3-2 show the steps to

connect the RMR to the Optical and RF Distribution(ORD) module.

Table 3-1 RMR Cable Connection Procedure

Step Action

1 Connect an RF cable between RMR Donor 1 IN terminal and A1 terminal on ORD RFM 1. Then

connect an RF cable between A terminal of RFM 1 to bottom terminal of FMR 1.

2 Connect an RF cable between RMR Donor 2 IN terminal and B1 terminal on ORD RFM 1. Then

connect an RF cable between B terminal of ORD RFM 1 to top terminal of ORD FMR 2.

3 Connect an RF cable between RMR Donor 1 OUT terminal and A1 terminal on ORD RFM 2. Then

connect an RF cable between A terminal of ORD RFM 2 to top terminal of ORD FMR 1.

4 Connect an RF cable between RMR Donor 2OUT terminal and B1 terminal on ORD RFM 2. Then

connect an RF cable between B terminal of RFM 2 to bottom terminal of FMR 2.

Figure 3-1 RMR to ORD cable connections

3-2 044-05207 Rev A

Page 13

Nexus FT RMR Commissioning

Commissioning

Before proceeding, carefully read the Safety section and check all connections made during the installation.

A RMR can be configured locally with OM-Online by connecting a standard serial cable from the COM port on

the PC to the P31 PC port (RS-232) located on the front of the RMR Details on using OM-Online are

described in the OM-Online User ManualConnecting a PC for Local Access

Initial Startup

To complete the inital start-up of the RMR, follow the steps listed in Table 3-3.

Table 3-2 Initial Statup Procedure

Step Action

1 Turn main power on

2 Check the LEDs on the RMR. Refer to Figure 2-1 in Chapter 2 for correct power up indications.

NOTE When optimizing RMRs, offset the UL gain 20dB less than the DL gain as a star ting point.

Always monitor the UL pass bands for noise levels and/or IMDs when optimizing and

commissioning.

044-05207 Rev A 3-3

Page 14

Commissioning Nexus FT RMR

This page intentionally left blank

3-4 044-05207 Rev A

Page 15

Chapter 4

Maintenance

Introduction

This chapter contains periodic maintenance and performance test procedures for the RMR.

Periodic Maintenance

Periodic maintenance requirements are listed in Table 4-1, as well as the intervals at which the tasks should

be performed.

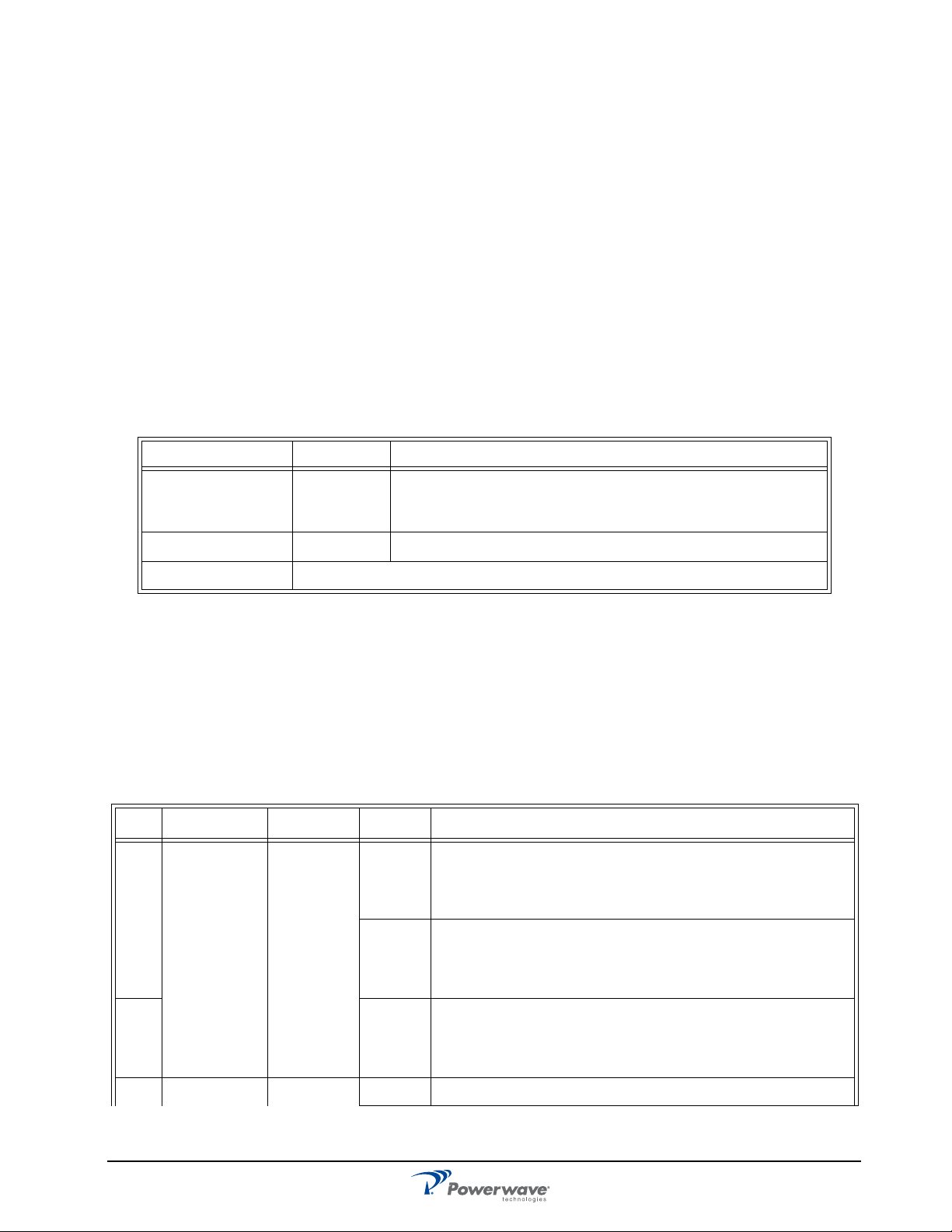

Table 4-1 Recommended Periodic Maintenance

Task Interval Action

Inspection of cables

and connectors

Clean equipment Clean as required depending on operating environment

12 months Inspect power, RF and Fiber cables for signs of damage or wear

(frayed insulation, cracks, punctures, etc.) Check connections to be

sure they are tight

Optional Perform cable sweeps

Troubleshooting

The sections that follow contain a list of problems that could occur and a few suggested actions that might

correct each problem. If the suggested corrective action does not eliminate the problem, please contact your

Powerwave field representative or help line for further instruction.

Clearing Alarm Faults

Table 4-2 lists the alarms that can be generated in the RMR. Critical, Error and Warning alarms are sent

automatically from a RMR to OM-Online, stored and then viewed in the Alarm window.

Table 4-2 Alarm Troubleshooting

ID Alarm Text Alarm Unit Alarm Description

1 Power PSM Critical PSM does not work properly. A sum signal from the PSM

indicates that at least one voltage output has dropped. If no mains

breakdown relay is used, then the alarm will also be sent at mains

breakdown

Ceasing PSM. Ceasing is sent if the PSM works at start-up, and there is a

corresponding critical PSM alarm logged in the Events log. The

RMR will restart when the power is back and this alarm will be

sent

Ceasing PSU2 in the cover works properly again. Ceasing is sent if the

PSU2 works at start-up, and there is a corresponding critical

PSU2 alarm logged in the Events Log. The RMR will restart when

the power is back and this alarm will be sent

Ceasing The cause of the alarm has ceased

044-05207 Rev A 4-1

Page 16

Troubleshooting Nexus FT RMR

Table 4-2 Alarm Troubleshooting (Continued)

ID Alarm Text Alarm Unit Alarm Description

2 RMR restart CU None Power on start, or user ordered reboot. Logged to indicate a

normal power up, or a restart ordered by the operator

Warning Software error restart, 1st – 7th time. Restart 1st to 7th time during

a 14 day period. The counter is reset every 14th day, counted

from power up

Error Software error restart 8th – 10th time. Restart 8th to 10th time

during the 14 day period. At the 11th time, the SW bank will be

blocked and not used anymore until a user ordered reset is

performed, or power is switched off/on

3Mains

breakdown

4 Alarm reset CU None Alarm reset by the user. All alarms are reset. The cause of the

5 Local bus

error

6 Main bkd w

backup

7Err in AD-

converter

8 New unit

detected

9 Inst. unit lost Error Compared to the last power on, the CU lacks at least one

External Critical The mains power is gone. Used with an external relay indicating

mains breakdown. The external relay should be connected to

External Alarm 1 and the RMR configured to indicate this alarm. If

no relay is used, a mains breakdown will be reported as a PSM

fault

Ceasing The mains power is back. Sent if there is a corresponding critical

mains breakdown alarm logged in the Events Log. The RMR will

restart when the power is back

alarm will be re-evaluated and reported, if still active

WBA #,

MCPA#

External Error Used to indicate that the mains is no longer available. RMR is

Error Error when communicating on the bus. The CU has no contact

with the WBA, or MCPA PCBA, which is taken out of service

powered by external battery backup unit. Suggested remedy:

Check the mains power

Ceasing The cause of the alarm has ceased

Warning The analog-to-digital converter on the CU PCBA does not give

reliable values

None Compared to the last power on, the CU has recognized at least

one additional hardware unit

hardware unit

10 EEPROM

error

11 Log memory

fault

12 High temp CU Warning The CU PCBA temperature is higher than 90°C

13 REFO error Error Significant REFO drift or error detected by CU

14 Ext REFO

error

CU Error EEP read or write fail. Data cannot be written or read from the

EEPROM on the CU PCBA. User parameters are stored in the

EEPROM

Error Log memory fault. Indicates that the log memory on the CU PCBA

is faulty. The RMR will not work. Not available in all CU software

versions

Ceasing The CU PCBA temperature has fallen below 90°C

Warning Suggested remedy: Check the reference source and the cables

4-2 044-05207 Rev A

Page 17

Nexus FT RMR Troubleshooting

Table 4-2 Alarm Troubleshooting (Continued)

ID Alarm Text Alarm Unit Alarm Description

15 CU battery

fault

16 SW load error CU Error Software load error. An error has occurred during a software load

17 Log cleared CU None Log memory has been cleared. The check sum in the Events Log

18 RTC restarted CU None The time is changed by the operator (logged to keep track of

19 RTC error Error RTC does not operate. The CU has detected an error in the RTC

21 External

alarm 1

CU Warning CU RAM battery fault. The battery for the RAM on the CU PCBA

has a voltage outside the normal 2.7 to 3.5 Volt. An alarm may be

initiated at start-up if the RMR has been stored out of power for a

long time. Suggested remedy: Ensure jumper P3 on the CU PCBA

is mounted to charge the battery

Ceasing The cause of the alarm has ceased

process. The flash memory does not contain a proper software.

Suggested remedy: Check the CU software using the OM-Online

SW Manager. Do NOT restart the RMR

memory is faulty. The log is cleared. Can be caused of a bad RAM

battery backup or low voltage to the RAM

changes made to the RTC)

Warning Time reset to 1994-01-01. The RTC was unable to keep track of

the time and did a reset. Suggested remedy: Ensure jumper P3 on

the CU PCBA is mounted to charge the battery

operation which makes the time unreliable. Suggested remedy:

Replace the CU PCBA

External Config External alarm input EA1 active more than 1 second

Ceasing External alarm input EA1 no longer active

22 External

alarm 2

23 External

alarm 3

24 External

alarm 4

34 Login failed None Invalid RMR password

40 Battery fault RCU Error The backup battery on the RCU does not work properly.

External Config External alarm input EA2 active more than 1 second

Ceasing External alarm input EA2 no longer active

External Config External alarm input EA3 active more than 1 second

Ceasing External alarm input EA3 no longer active

External Config External alarm input EA4 active more than 1 second

Ceasing External alarm input EA4 no longer active

Warning No connection at alarm call. The RMR has tried to call as many

times as stated in the alarm call settings. No connection was

established. This alarm does not generate a new attempt to report

alarm by alarm call.

Suggested remedy: Check cables or replace battery

Ceasing The cause of the alarm has ceased

044-05207 Rev A 4-3

Page 18

Troubleshooting Nexus FT RMR

Table 4-2 Alarm Troubleshooting (Continued)

ID Alarm Text Alarm Unit Alarm Description

42 Antenna

isolation

48 Battery

backup fault

70 Bad table

alarm

71 Table not

found

72 Table

database

error

80 Antenna

SWR alarm

WBA #,

Channel #,

UL/DL

External Error If a battery backup unit alarm is connected to external alarm 2,

CU Error Requested table contains incorrect information (SW error)

CU Error Requested table not found in the database (SW or calibration

CU Error Table database not found (calibration error)

Donor

antenna

service

antenna

Warning Low antenna isolation. The antenna isolation is lower than the

gain set. Gain is reduced by 10dB – 13dB below the oscillation

point. Suggested remedy: Decrease gain or increase antenna

isolation

Error Low antenna isolation at lowest gain. The gain has been reduced

as much as possible but the oscillation still remains. The amplifier

is turned off. Suggested remedy: Decrease gain or increase

antenna isolation

Ceasing Normal operation again, that is no oscillation can be detected

13dB above the gain set

then the operator can configure the RMR to display this alarm

when the battery backup unit indicates alarm

Ceasing The cause of the alarm has ceased

error)

Error Too low antenna return loss, causesd by cables, connectors, or

antenna problems.

Suggested remedy: Check antenna and cables

Ceasing The cause of the alarm has ceased

245 Not In

Allowed Area

CU None RMR is moved from the operating area and the RF HW is

switched on or off

Remarks:

The Main power breakdown alarm requires an optional relay described in the Main Power Breakdown Relay

section of Chapter 3.

4-4 044-05207 Rev A

Page 19

Nexus FT RMR Field Replaceable Units

Field Replaceable Units

The fan assembly is the only field replaceable component. If any other components fail please contact

Powerwave for service.

Fan replacement

NetWay Manager (NWM)

NWM is a Powerwave software package for network management. NWM can be used to access repeaters for

alarm reception, radio parameter configuration, software downloading and the scheduling of activities.

Return For Service Procedures

When returning products to Powerwave, the following procedures will ensure optimum response.

Obtaining an RMA

A Return Material Authorization (RMA) number must be obtained prior to returning equipment to the factory

for service. Pease contact our Repair Department at +1-714-466-1000 to obtain this number, or FAX your

request to +1-714-466-5800. Failure to obtain this RMA number may result in delays in receiving repair

service.

Repackaging for Shipment

To ensure safe shipment of the unit, it is recommended that the original package designed for shipping the

unit be reused. If it is not available, contact Powerwave’s Customer Service Department at 1-800-797-9283,

+1-714-466-100 or by e-mail at support@pwav.com for packing material.

044-05207 Rev A 4-5

Page 20

Return For Service Procedures Nexus FT RMR

This page intentionally left blank

4-6 044-05207 Rev A

Page 21

Introduction

This chapter provides specifications for the RMR.

Table 5-1: RMR Specifications

Electrical

Frequency band UL 824 to 849 MHz (Cellular)

806 to 824 MHz (800 iDEN)

896 to 902 MHz (900 iDEN)

1850 to 1910 MHz (PCS)

Frequency band DL 869 to 894 MHz (Cellular)

851 to 869 MHz (800 iDEN)

935 to 941 MHz (900 iDEN)

1930 to 1990 MHz (PCS)

Max absolute delay <300 ns

Gain adjustment range (in 1 dB steps) 30 dB

Chapter 5

Specifications

Gain

Uplink

Downlink

Variation

*These are typical values and may vary due

to cable length.

Instantaneous bandwidth 25 MHz (Cellular)

Uplink AGC limit 0 dBm at donor output port

Downlink AGC limit 43 dBm at antenna port

Return Loss 11 dB (Service Port), 14 dB (Donor Port)

Downlink, Spurious and Emissions level -13 dBm/1 MHz (FCC)

Downlink power +43 dBm RMS (20 Watts) (for FCC)

Noise figure excluding fiber optic link 4 dB

Fiber-Optic Link Budget 10 dBo

Receiver input port return loss 14 dB

35 to 60 dB typical - Excluding fiber link

45 to 70 dB typical - Excluding fiber link

± 1.5 dB versus temperature including fiber link

± 2.0 dB versus DL frequency including fiber link

± 0.5 dB versus DL output power including fiber link

± 0.5 dB versus input voltage including fiber link

± 2.0 dB versus UL frequency including fiber link

18 MHz (800 iDEN)

6 MHz (900 iDEN)

60 MHz (PCS)

Power supply voltage 115/230 VAC

Maximum Current Draw (Single Band) 6.5 A @ 115 VAC

3 A @ 230 VAC

044-05307 Rev A 5-1

Page 22

Introduction Nexus FT RMR

Table 5-1: RMR Specifications (Continued)

Maximum Current Draw (Dual Band) 6 A @ 115 VAC

3 A @ 230 VAC

Recommended Fuse size 10 A for AC voltage

20 A for AC voltage

Power consumption 420 W typical, 600 W max

Impedance

Input

Output 50 Ω

Mechanical

Dimensions (W x H x D in inches) 403 x 265.9 x 551 mm (15.9 x 10.5 x 21.7in)

Weight <45 kg (100 lbs)

Service Antenna port connector Female N-Type

Donor port connector SMA

Environmental

Operating Temperature Range -25 °C to +55 °C (-13°F to +131°F)

Altitude -142 m to 4000 m (-466 ft. to 13100 ft.

Casing class NEMA4/IP65

5-2 044-05307 Rev A

Page 23

Powerwave Installation and Service Manual

Worldwide Corporate Headquarters

801 East St. Andrew Place

anta Ana, CA 92705 USA

Tel: 714-466-1000

Fax: 714-466-5800

www.powerwav e.com

©Copyright 2008, Powerwave Technologies, Inc. All Rights reserved. Powerwave, Powerwave Technologies, The Power in Wireless and the Powerwave logo are registered trademarks of Powerwave Technologies, Inc.

Main European Office

Knarramasgatan 7 8tr

164 40 Kista, Sweden

Sweden

Tel: +46 8 540 822 00

Fax: +46 8 540 824 91

Main Asia-Pacific Office

23 F Tai Yau Building

181 Johnston Road

Wanchai, Hong Kong

Tel: +852 2512 6123

Fax: +852 2575 4860

Loading...

Loading...