INDOOR MCPA PLATFORM

PAF

INDOOR MCPA PLATFORM

INSTALLATION AND SERVICE MANUAL

PAF-19XX-EX-XXX

044-05298 Rev A November 2007

© 2007 Powerwave Technologies Incorporated. All rights reserved.

Powerwave Technologies, and the Powerwave logo are registered trademarks.

This Powerwave product is intended only for installation in a RESTRICTED ACCESS LOCATION and is designed to

operate within the Normal Operating (typical operating) ranges or conditions specified in this document. Operation of

this equipment beyond the specified ranges in this document may cause:

1. Spurious emissions that violate regulatory requirements.

2. The equipment to be automatically removed from service when maximum thresholds are exceeded.

3. The equipment to not perform in accordance with its specifications.

It is the Operator's responsibility to ensure this equipment is properly installed and operated within Powerwave operating specifications to obtain proper performance from the equipment and to comply with regulatory requirements.

For PERMANENTLY CONNECTED EQUIPMENT, a readily accessible disconnect device shall be incorporated in the

building installation wiring.

PAF-19XX-EX-XXX Warnings, Cautions, and Notes

Warnings, Cautions, and Notes

Warnings, Cautions, and Notes are found throughout this manual where applicable. The associated

icons are used to quickly identify a potential condition that could result in the consequences described

below if precautions are not taken. Notes clarify and provide additional information to assist the user.

WARNING: This warning symbol means danger. You are in a situation that could cause

bodily injury. Before you work on any equipment, be aware of the hazards involved with

electrical and RF circuitry and be familiar with standard practices for preventing accidents

NOTE

CAUTION: This caution symbol means reader be careful. In this situation, the user might do

something that could result in equipment damage or loss of data.

This note symbol means reader take note. Notes contain helpful suggestions or references to

material not covered in the document. Procedures are not contained in notes.

044-05298 Rev A i

Revision Record PAF-19XX-EX-XXX

Revision Record

Revision Letter Date of Change Reason for Change

A November 2007 Initial release

ii 044-05298 Rev A

Table of Contents

Chapter 1 - Product Description

Introduction ................................................................................................................................................... 1-1

Scope of Manual ........................................................................................................................................... 1-1

Product Description ....................................................................................................................................... 1-1

Functional And Physical Specifications ........................................................................................................ 1-1

Chapter 2 - Controls and Indicators

Introduction ................................................................................................................................................... 2-1

Subrack ......................................................................................................................................................... 2-1

Ethernet Connector Pinout ..................................................................................................................... 2-2

RS-485 Interface .................................................................................................................................... 2-3

Filter I/O (if used) .................................................................................................................................... 2-3

MCPA ............................................................................................................................................................ 2-3

Filter (if used) ................................................................................................................................................ 2-4

Circuit Breaker Panel .................................................................................................................................... 2-6

Chapter 3 - Installation

Introduction ................................................................................................................................................... 3-1

Site Survey .................................................................................................................................................... 3-1

Space Requirements .................................................................................................................................... 3-1

Unpacking and Inspection ............................................................................................................................. 3-1

Electrical Service Recommendations ........................................................................................................... 3-1

Cooling Requirements .................................................................................................................................. 3-2

Installation Instructions ................................................................................................................................. 3-2

PAF ......................................................................................................................................................... 3-2

Seismic Brace (Optional) ........................................................................................................................ 3-3

DC Connections ..................................................................................................................................... 3-3

RS-485 Alarm Interface .......................................................................................................................... 3-5

MCPA ..................................................................................................................................................... 3-5

Initial Start-Up and Power Setting Procedures ............................................................................................. 3-6

Initial Start Up ......................................................................................................................................... 3-6

Chapter 4 - Maintenance

Introduction ................................................................................................................................................... 4-1

Periodic Maintenance ................................................................................................................................... 4-1

Troubleshooting ............................................................................................................................................ 4-1

Clearing Alarm Faults ............................................................................................................................. 4-2

System Component Part Numbers ............................................................................................................... 4-2

Field Replacement Procedures ..................................................................................................................... 4-2

MCPA ..................................................................................................................................................... 4-3

Subrack Cooling Fans ............................................................................................................................ 4-4

Inside Mount .................................................................................................................................... 4-4

Rear Mount ...................................................................................................................................... 4-5

Fan Inside Mount to Rear Mount Conversion .................................................................................. 4-6

Subrack .................................................................................................................................................. 4-7

Filter ........................................................................................................................................................ 4-8

Circuit Breaker Panel .............................................................................................................................. 4-9

Return For Service Procedures .................................................................................................................. 4-10

Obtaining An RMA ................................................................................................................................ 4-10

Repackaging For Shipment .................................................................................................................. 4-10

Chapter 5 - Specifications

Introduction ................................................................................................................................................... 5-1

044-05298 Rev A i

PAF-19XX-EX-XXX List of Tables

List of Tables

2-1 Subrack Faceplate Interface Connectors, and Indicators ........................................................................ 2-2

2-2 Ethernet Connector Pinout....................................................................................................................... 2-2

2-3 RS-485 Pinout.......................................................................................................................................... 2-3

2-4 MCPA Indicators and Controls................................................................................................................. 2-4

2-5 Filter Connector Descriptions................................................................................................................... 2-5

3-1 Sample of DC Cable Ratings ................................................................................................................... 3-2

3-2 PAF Frame Installation Procedure........................................................................................................... 3-3

3-3 DC Power Installation Procedure............................................................................................................. 3-4

3-4 RS-485 Alarm States ............................................................................................................................... 3-5

3-5 MCPA Installation Procedure................................................................................................................... 3-6

3-6 Initial Startup Procedure .......................................................................................................................... 3-6

4-1 Periodic Maintenance .............................................................................................................................. 4-1

4-2 Troubleshooting ....................................................................................................................................... 4-2

4-3 System Components Part Number List.................................................................................................... 4-2

4-4 MCPA Removal and Replacement Procedure......................................................................................... 4-3

4-5 Inside Mount Cooling Fan Removal and Replacement Procedure .......................................................... 4-4

4-6 Rear Mount Cooling Fan Removal and Replacement Procedure............................................................ 4-5

4-7 Fan Conversion Procedure ...................................................................................................................... 4-6

4-8 Subrack Removal and Replacement Procedure...................................................................................... 4-7

4-9 Filter Removal and Replacement Procedure ........................................................................................... 4-8

4-10 Circuit Breaker Panel Removal and Replacement Procedure ............................................................... 4-9

5-1 System Specifications.............................................................................................................................. 5-1

ii 044-05298 Rev A

List of Figures PAF-19XX-EX-XXX

List of Figures

1-1 System Block Diagram ............................................................................................................................ 1-2

1-2 PAF System Model .................................................................................................................................. 1-2

1-3 Subrack.................................................................................................................................................... 1-3

1-4 MCPA ...................................................................................................................................................... 1-3

1-5 Filter (if used)........................................................................................................................................... 1-3

1-6 Circuit Breaker Panel............................................................................................................................... 1-4

2-1 Subrack Interface Panel Connectors ....................................................................................................... 2-1

2-2 Subrack Rear +27 VDC Connector Block................................................................................................ 2-1

2-3 MCPA Controls and Indicators ................................................................................................................ 2-3

2-4 Filter Front Connections .......................................................................................................................... 2-4

2-5 Filter Front Plate Indicators...................................................................................................................... 2-5

2-6 Circuit Breaker Panel Front and Top View .............................................................................................. 2-6

3-1 Frame Installation .................................................................................................................................... 3-3

3-2 Power Connections.................................................................................................................................. 3-4

3-3 Return Bus connection ............................................................................................................................ 3-4

3-4 Frame to Halo Ground Connection Example........................................................................................... 3-5

3-5 MCPA Front Panel Features.................................................................................................................... 3-6

4-1 MCPA Removal and Replacement .......................................................................................................... 4-3

4-2 Inside Mount Cooling Fan Removal and Replacement ........................................................................... 4-4

4-3 Rear Mount Cooling Fan Removal and Replacement ............................................................................. 4-5

4-4 Fan Inside Mount to Rear Mount Conversion .......................................................................................... 4-6

4-5 Subrack Removal and Replacement ....................................................................................................... 4-7

4-6 Filter Removal and Replacement ............................................................................................................ 4-8

4-7 Breaker Panel Unit Removal and Replace .............................................................................................. 4-9

044-05298 Rev A iii

PAF-19XX-EX-XXX

This page intentionally left blank

iv 044-05298 Rev A

Chapter 1

Product Description

Introduction

This manual contains information and procedures for installation, operation, and maintenance of the

PAF-19XX-EX-XXX Multi-Carrier Power Amplifier (MCPA) Indoor System. The manual is organized into

chapters as follows.

❑

Chapter 1 - Product Description

❑

Chapter 2 - Controls and Indicators

❑

Chapter 3 - Installation

❑

Chapter 4 - Maintenance

❑

Chapter 5 - Specifications

Scope of Manual

This manual is intended for use by service technicians familiar with similar types of equipment. It contains

service information required for the equipment described and is current as of the printing date. Changes which

occur after the printing date may be incorporated by a complete manual revision or alternatively as additions.

Product Description

The PAF-19XX-EX-XXX system, shown in the Figure 1-1 block diagram, is an 1900 MHz, 4-way combined,

frame-mounted BTS solution. The PAF system contains three MCPA subracks, each capable of containing up

to four MCPAs, three filters, and one DC circuit breaker panel.

The MCPA subrack, shown in Figure 1-3, contains linear, feed-forward MCPAs that operate in the

1930 - 1990 MHz range. Each subrack is also equipped with automatic power control (APC), an ethernet

connection, an RS-485/RS-232 connection, a filter I/O port, and two cooling fans. The subrack is installed on

sliding rails so that it can be pulled forward to allow access to the rear of the subrack.

The MCPA, shown in Figure 1-4, is a 1900 MHz module that produces a typical output of 160 watts (52.0

dBm) before system losses, with an instantaneous bandwidth of 25 MHz.

The filter assembly, shown in Figure 1-5, if used, supresses unwanted signals and non-linear components of

the signal from the amplifiers.

The circuit breaker panel, shown in Figure 1-8, consists of two +27 VDC input buses (A and B), and a system

circuit breaker panel. The panel receives +27 VDC from the BTS and then distributes circuit breaker protected

DC power to the individual subracks.

Functional And Physical Specifications

PAF-19XX-EX-XXX system functional and physical specifications are listed in Chapter 5.

044-05298 Rev A 1-1

PAF-19XX-EX-XXX Functional And Physical Specifications

Main to/from Antenna

(TX / RX)

Analog

Input

MCPA-0

Diversity from Antenna

(RX)

Digital

Input

Input

Combiner/

Splitter

MCPA-1

Combiner Filter

MCPA-2

MCPA-3

DC Power

Controller

Figure 1-1 System Block Diagram

Alcatel Lucent

Alcatel

Lucent

STA

TU

S

Alcatel Lucent

S

TATUS

R

E

S

E

T

O

N

O

F

F

Alcatel Lucent

STA

T

U

R

S

E

S

E

T

O

N

S

TA

TU

R

O

S

E

F

S

F

E

T

O

N

R

O

E

F

S

F

E

T

O

N

O

F

F

Analog 1 (Mai n ) to BTS

Analog 2 (Main) to BTS

Digital 1 (Main) to BTS

Digital (Main) to BTS

2

Analog 1 (Diversity) to BTS

Analog 2 (Diversity) to BTS

Digital 1 (Diversity) to BTS

2

Digital (Diversity) to BTS

P

C

I

/

O

P

C

I

/

O

P

C

I

/

O

P

C

I

/

850 MHz

Alc

atel

Luc

ent

STA

TUS

R

E

S

E

T

O

N

O

F

F

P

C

I

/

O

850 MHz

Alc

atel

Luc

ent

STA

TUS

R

E

S

E

T

O

N

O

F

F

P

C

I

/

O

850 MHz

O

850 MHz

850 MHz

850 MHz

Alc

atel

Luc

ent

Alc

atel

Luc

S

TA

ent

T

US

Alc

atel

Luc

STA

ent

T

US

R

E

S

E

T

O

N

STA

TU

R

O

S

E

F

S

F

E

T

O

N

R

O

E

F

S

F

E

T

O

N

O

F

F

P

C

I

/

O

P

C

I

/

O

P

C

I

/

O

850 MHz

850 MHz

850 MHz

Alc

atel

Luc

ent

Alc

atel

Luc

STA

ent

TUS

Alc

atel

Luc

STA

ent

TUS

R

E

S

E

T

O

N

STA

TUS

R

O

E

F

S

F

E

T

O

N

R

O

E

F

S

F

E

T

O

N

O

F

F

P

C

I

/

O

P

C

I

/

O

P

C

I

/

O

850 MHz

850 MHz

850 MHz

Figure 1-2 PAF System Model

1-2 044-05298 Rev A

Functional And Physical Specifications PAF-19XX-EX-XXX

Alc

atel Lu cent

Alcatel

S

RESET

ON

Lucent

T

A

T

U

S

O

FF

P

C I/O

850 MHz

Alcatel Lucent

ST

A

T

US

R

ESET

O

N

O

FF

PC I/O

850 MHz

Alc

atel

S

RESE

O

N

Lucent

TA

TU

S

S

T

A

T

U

S

T

R

OF

ESET

F

ON

O

FF

PC I/O

PC I/O

850 MHz

850 MHz

Alcatel Lucent

STA

TUS

R

E

S

E

T

O

N

O

F

F

P

C

I/O

850 MHz

Front

Front

Rear

Figure 1-3 Subrack

Rear

Figure 1-4 MCPA

Figure 1-5 Filter (if used)

044-05298 Rev A 1-3

PAF-19XX-EX-XXX Functional And Physical Specifications

Figure 1-6 Circuit Breaker Panel

1-4 044-05298 Rev A

Chapter 2

RF OUT

Controls and Indicators

Introduction

This chapter contains descriptions of the PAF-19XX-EX-XXX subrack, MCPA, filter, and circuit breaker panel

interface connections, controls and indicators.

Subrack

The location of the subrack interface controls, connectors, and indicator are shown in Figures 2-1 and 2-2 and

feature descriptions are listed in Table 2-1.

DIGITAL

ETHERNET

RS485

FILTER I/O

CDMA1 CDMA2 CDMA3 CDMA4 CDMA5 CDMA6

Figure 2-1 Subrack Interface Panel Connectors

DC POWER

+27V

0

1

RETURN

3

2

0

3

2

1

Figure 2-2 Subrack Rear +27 VDC Connector Block

044-05298 Rev A 2-1

Subrack PAF-19XX-EX-XXX

Table 2-1 Subrack Faceplate Interface Connectors, and Indicators

Connectors Description

RF

DIGITAL (CDMA1

through CDMA6)

RF OUTPUT 7/16 DIN connector, composite transmit

Status

ETHERNET RJ-45 connector used for host alarm

RS-232/RS-485 DB-9 connector used for host alarm

Filter

Filter I/O DB-15 connector to provide control and

DC Power

+27 VDC Connector

Block (Rear of Subrack)

Six SMA input connectors

signal output.

reporting, Pin layout is listed in Table 2-2

reporting. Pin Layout is listed in Table 2-3

communication to filter (if used)

Provide connections for +27 VDC circuit

breaker protected power from breaker panel

and frame ground bus return connections.

Ethernet Connector Pinout

The Ethernet port is used for commuication with a personal computer (PC) or with a base station. The pin

layout for the Ethernet interface is listed in Table 2-2.

Table 2-2 Ethernet Connector Pinout

Pin Description

1 Transmit Data (TX) +

2 Transmit Data (TX) -

3 Receive Data (RX) +

4NC

5 NC

6 Receive Data (RX) -

7 NC

8NC

2-2 044-05298 Rev A

PAF-19XX-EX-XXX MCPA

z

RS-485 Interface

This RS-485 connector is used for serial communication and as an interface to the system for delivery of

alarms. Grounding pin 8 disables RS-485 communication. Table 2-3 lists the pin descriptions.

Table 2-3 RS-485 Pinout

Pin Description

1 RS-485 RX+

2N/C

3 N/C

4 RS-485 RX-

5 Ground

6 RS-485 TX-

7 RS-485 TX+

8 Select = 1 (Not grounded)

9 Ground

Filter I/O (if used)

This port is used for communication with the filter tray associated with the subrack.

MCPA

The controls and indicators for the MCPA consist of an OFF/ON/RESET switch and tri-color LED status

indicator as shown in Figure 2-3 with detailed functions listed in Table 2-2.

Multi-Color

Status LED

3-Position

Switch:

RESET

ON

OFF

Connector

RJ-11

Figure 2-3 MCPA Controls and Indicators

Alcatel Lucent

STATUS

RESET

ON

OFF

PC I/O

850 MH

044-05298 Rev A 2-3

Filter (if used) PAF-19XX-EX-XXX

Table 2-4 MCPA Indicators and Controls

Control/Indicator Description

STATUS (Multi-colored

LED Indicator)

LED Color MCPA Status.

Green (solid) RF enabled, OFF/ON/RESET switch

set to ON (middle position).

Green (blinking) Standby.

Yellow (solid) Major Alarm

Yellow (blinking) APC Activated

Red (solid) Critical Alarm, MCPA disabled.

Red (blinking) Over Temperature Alarm

Red/Yellow (blinking together) High Reverse Output Power 1 minute

validation period

Red/Yellow (alternating) Critical Alarm during remote firmware

download or checksum failure

Toggle Switch positions:

RESET (Up)

ON (Middle)

OFF (Down)

Resets MCPA. LED indicates boot mode, then turns solid green.

Enables MCPA. LED indicates solid green.

Disables MCPA. LED Indicates solid red.

RJ-11 RS-232 PC Interface for factory use only.

Filter (if used)

Figure 2-4 shows the front plate of the filter. Table 2-3 lists the descriptions of the connectors. Figure 2-5

shows the five indicators on the filter front panel. The LED will display a green light during normal operation

and red light if the indicated stage has suffered a catastrophic failure.

Antenna Main Antenna Diversity

MCPA RF Out

IIC

Forward Main Power Coupler Port

Main Antenna Receive LNA Output Ports

CDMA 1

CDMA 2 CDMA 2

DC Power

RF Test Port

Diversity Antenna Receive LNA output port

CDMA 1

Figure 2-4 Filter Front Connections

2-4 044-05298 Rev A

PAF-19XX-EX-XXX Filter (if used)

Table 2-5 Filter Connector Descriptions

Connector/Cable Description

Antenna Connections

Antenna Main 7/16 connector - Dx0 (bi-directional) antenna port

Antenna Diversity 7/16 connector - Dx1 (simplex RX) antenna port

Subrack Connection

MCPA RF Out 7/16 connector - connects subrack to receive output signal

IIC DB-15 connector for communication between filter and subrack

BTS Connections

CDMA 1 Dx0 Receive LNA Output Port CDMA

CDMA 2 Dx0 Receive LNA Output Port CDMA

Dx0 Receive LNA Input Port AMPS

Dx0 Receive LNA Output Port AMPS

CDMA 1 Dx1 Receive LNA Output Port CDMA

CDMA 2 Dx1 Recevie LNA Output Port CDMA

Dx1 Receive LNA Output Port AMPS

Dx1 Receive LNA Output Port AMPS

Test Port Connections

RF Test Port SMA connector - Switched Coupler Port (4-way)

Forward Main Coupler Port SMA connector - Dx0 Forward Power Coupler Port

Power Connection

Power Power connection

DC Power

IIC

Figure 2-5 Filter Front Plate Indicators

044-05298 Rev A 2-5

TTLNA

DX1DX0

LNA

RF

ON

Circuit Breaker Panel PAF-19XX-EX-XXX

Circuit Breaker Panel

Figure 2-6 shows the switches on the front of the breaker panel and the cable connections on the rear.

Chapter 3 discusses power cable connection.

SECTOR 0 SECTOR 1 SECTOR 2

ALPHA BETA GAMMA

AMP 0 AMP 2 AMP 0 AMP 2 AMP 0 AMP 2 AMP 1 AMP 3 AMP 1 AMP 3 AMP 1 AMP 3DIV 0 DIV 1

ONIONIONIONIONIONION

OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

LOWEST SUBRACK LOWEST SUBRACK

FILTERS FILTERS

I

SECTOR 0 SECTOR 1 SECTOR 2

ALPHA BETA GAMMA

ONIONIONIONIONIONION

Top

Figure 2-6 Circuit Breaker Panel Front and Top View

I

Alcatel Lucent

2-6 044-05298 Rev A

Chapter 3

Installation

Introduction

This chapter contains unpacking, inspection, installation instructions, and recommendations for installing the

PAF-19XX-EX-XXX MCPA Indoor System.

Site Survey

Powerwave recommends that a site survey be performed prior to equipment ordering or installation.

Performing a detailed site survey reduces or eliminates installation and turn-up delays. Pay particular

attention to AC or DC power availability, cooling needs, floor space, and RF/DC cabling/breaker

requirements. See Chapter 5 for system dimensions and weights.

Space Requirements

The PAF system requires the following floor space for clearance (W x D x H): 28.5 inches (724 mm) x 78.2

inches (1986 mm) x 38.5 inches (978 mm). To properly service the system, an additional 48 inches (1220

mm) is required in the front of the unit. To permit proper airflow, allow a minimum of 8.27 inches (210 mm)

behind the PAF.

Unpacking and Inspection

This equipment has been operated, tested and calibrated at the factory. Carefully open the containers and

remove the equipment. Retain all packing material that can be reassembled in the event that the unit must be

returned to the factory. Please perform the following steps:

❑ Visually inspect equipment for damage that may have occurred during shipment. If possible, in

the presence of the delivery person.

❑ Check for evidence of water damage, bent or warped chassis, loose screws or nuts, or extrane-

ous packing material in connectors.

If the equipment is damaged, file a claim with the carrier once the extent of any damage is assessed.

If the equipment must be returned to the factory, contact the factory for a Return Material Authorization (RMA)

as described in Chapter 4.

Electrical Service Recommendations

Proper AC line conditioning and surge suppression is necessary on the primary AC input to the +27 VDC

power source. Powerwave recommends that all electrical service be installed in accordance with the National

Electrical Code (NEC) and any applicable state or local codes.

Table 3-1 lists a sample of DC cable ratings.

044-05298 Rev A 3-1

Cooling Requirements PAF-19XX-EX-XXX

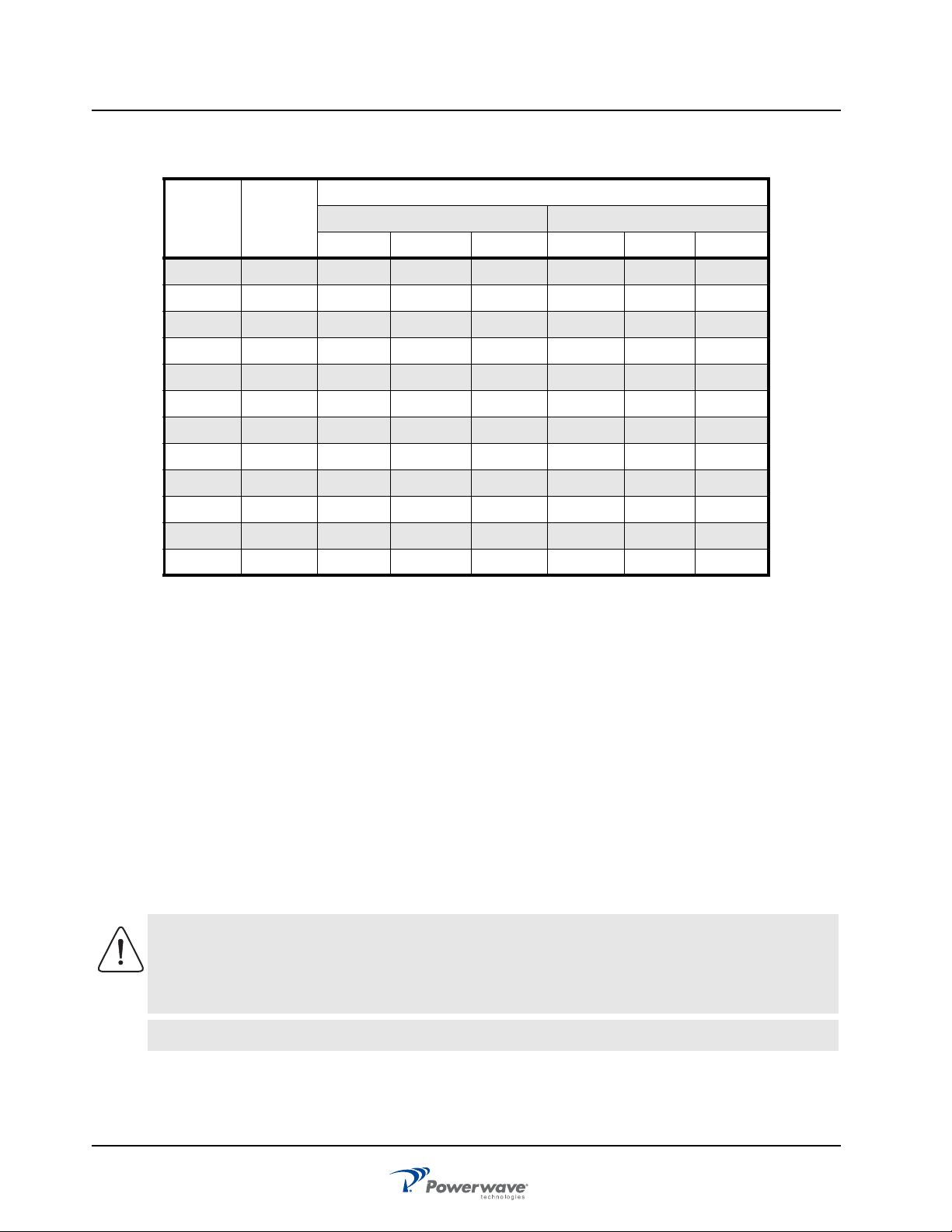

Table 3-1 Sample of DC Cable Ratings

AWG

or

MCM

10 5 40 45 50 55 65

8 8 57 55 60 70 75 85

6 13 76 70 80 95 100 120

4 21 101 95 105 125 135 160

2 34 135 125 135 170 185 210

1 42 158 145 160 195 215 245

0 53 183 165 190 230 250 285

00 67 212 195 265 300

000 85 245 225 310 350

0000 107 287 260 360 405

MCM250 127 320 290 405 455

MCM300 152 359 320 445 505

Based on ambient temperature of 30×C (86×F)100% Load Factor

Source: Industrial Electric Wire & Cable Inc., Technical Guide Vol. 4M 11/99, Table III Suggested

Ampacities - All Types of Insulations; Based on National Electric Code

mm

2

3 Conductor In Raceway Single Conductor In Free Air

75°C 90°C 110°C 75°C90°C110°C

Copper

Cooling Requirements

Each MCPA at full power generates the BTUs per hour listed in Table 3-3. A 1-ton air conditioner offsets

12,000 BTUs of heat. The MCPA operates within the temperature environment specified in Chapter 5.

Fan speed is dependent on MCPA operating temperature. The fans remain off until the MCPAs exceed +43°C

base plate temperature. Once enabled, the fan remains on until all MCPA base plate temperatures are below

+41°C.

Installation Instructions

Install the PAF frame, DC and RF connections, alarms, and MCPAs as described in the following paragraphs.

PAF

To install the PAF frame, perform the instructions in Table 3-4.

CAUTION: The PAF frame, as factory shipped, weighs approximately 250 lbs (113 kg) to 428

lbs (194 kg) depending on configuration (MCPAs not included).

During unpacking and installation, be careful with the semi-rigid cables.

Protect the cables from damage by avoiding contact with doorways or other equipment.

Do not use the cables as handles for moving the components or the frame.

NOTE

Reuse shipping pallet washers to secure PAF to installation site floor.

3-2 044-05298 Rev A

PAF-19XX-EX-XXX Installation Instructions

Table 3-2 PAF Frame Installation Procedure

Step Action

1. Set PAF frame in planned location

2. Mark floor drill holes on floor where lag bolts will be installed. Move frame to side. Refer

to lag bolt manufacturer’s instructions for hole depth and diameter

3. Move frame back over drilled holes

4. Use a level to ensure frame is not leaning. Insert shims between frame base and floor to

level frame. Shims should wrap around lag bolts as shown in Figure 3-2

5. Secure frame in place with red eye lag bolts and appropriate washers

Lag Bolt

Lock Washer

Flat Washer

Cabinet

Shim

Lag Anchor

Concrete

Figure 3-1 Frame Installation

Seismic Brace (Optional)

The PAF system meets GR-63-CORE, Section 4.4.1, Zone 4 compliance. If additional bracing is required,

Powerwave offers an optional seismic brace kit for those circumstances. Please contact a Powerwave sales

representative for additional information and assistance.

DC Connections

Connect and verify DC power cables between the BTS power plant and the PAF system circuit breaker panel

and PAF return bus located at the top of the PAF as instructed in Table 3-5. Required power is +27 VBC, and

each power input is directly connected through the circuit breaker in the front of the panel to the power output

directly below it in the panel.

WARNING: Turn off external DC power before connecting DC power cables.

044-05298 Rev A 3-3

Installation Instructions PAF-19XX-EX-XXX

Table 3-3 DC Power Installation Procedure

Step Action

1. Remove circuit breaker panel top protective cover

2. Connect fourteen individual red power cables, one to each input on the upper row of

connections. (designated Row A Figure 3-2)

3. Attach opposite ends of red MCM 250 powr cables to power plant’s main DC bus bar

after main shunt.

4. Insert fourteen individual black power cables into front of yellow and green ground

connections as shown in Figure 3-3 and tighten screws

5. Attach opposite ends of black power cables to power plant's main DC return bus bar

6. Connect PAF frame to halo grounding system at frame top (four locations) using green 6

AWG cable as shown in Figure 3-4

7. Reinstall circuit breaker panel top protective cover.

8. Affix supplied ground sticker directly beneath one utilized frame grounding points shown

in Figure 3-4

Row A

Row B

Figure 3-2 Power Connections

Ground Return Connections

Figure 3-3 Return Bus connection

3-4 044-05298 Rev A

PAF-19XX-EX-XXX Installation Instructions

NOTE

DO NOT remove metallic tape at frame top when connecting to Halo ground system. Removing

tape voids PAF frame warranty.

To Halo

Ground

To Halo

Ground

Metallic

Tape

Ground

Sticker

Figure 3-4 Frame to Halo Ground Connection Example

RS-485 Alarm Interface

The RS-485 alarm interface provides the BTS controller with system status via a 1 byte protocol. The baud

rate is fixed at 15.6 K. Table 3-6 lists the available alarm states.

Table 3-4 RS-485 Alarm States

AlarmState Definition

No Alarm

Minor Alarm Any or all fans fail

Major Alarm Any one MCPA module disabled

Critical All MCPA modules disabled

MCPA

Install the MCPAs as instructed in Table 3-7.

CAUTION: Slowly insert MCPA into subrack. Forcing MCPA into subrack may cause pins on

the MCPA D-sub connector to become recessed or broken.

044-05298 Rev A 3-5

Initial Start-Up and Power Setting Procedures PAF-19XX-EX-XXX

Table 3-5 MCPA Installation Procedure

Step Action

1. Inspect MCPA 21-pin connector. Verify all pins are straight, no pins are recessed, and

alignment shield is not bent

2. Set MCPA power OFF/ON/RESET switch to OFF

3. Rotate MCPA quarter-turn fasteners counter-clockwise to unlock position shown in

Figure 3-8

4. Install MCPA(s) into subrack. To secure each MCPA, rotate quarter-turn fasteners

clockwise to lock position as shown in Figure 3-8

Quarter-Turn

Fasteners

Alcatel Lucent

Locked

ON

OFF

LED Status

Indicator

RF Switch:

RESET

ON

OFF

Unlocked

Alcatel Lucent

ON

OFF

Figure 3-5 MCPA Front Panel Features

Initial Start-Up and Power Setting Procedures

The following paragraphs provide initial startup, and power setting procedures.

Initial Start Up

To complete initial startup, perform the instructions listed in Table 3-8.

CAUTION: Excessive input power may damage MCPA. Before applying power, ensure MCPA

inputs and outputs are properly terminated at 50 ohms. Do not operate MCPA without a load

attached. Refer to Chapter 5 for input power requirements.

Table 3-6 Initial Startup Procedure

Step Action

1. Verify all input and output cables are properly connected

2. Turn on +27 VDC supply to MCPA

3. Set all MCPA front panel OFF/ON/RESET switches to ON (middle) position

4. Allow MCPAs to warm up for at least two minutes before taking power readings

3-6 044-05298 Rev A

Loading...

Loading...