Page 1

PRELIMINARY

EHP19

Integrated Power Transceiver

Installation and

Service Manual

044-05210 Rev. A

September 2005

Page 2

© 2005 Powerwave Technologies Incorporated. All rights reserved.

Powerwave Technologies, and the Powerwave logo are registered trademarks.

This Powerwave product is intended only for installation in a RESTRICTED ACCESS LOCATION.

This Powerwave product is designed to operate within the normal operating (typical operating) ranges

or conditions specified in this document. Operation of this equipment beyond the specified ranges in

this document may cause:

• spurious emissions that violate regulatory requirements.

• the equipment to be automatically removed from service when maximum thresholds are exceeded.

• the equipment to not perform in accordance with its specifications.

It is the responsibility of the operator to ensure this equipment is properly installed and operated within

Powerwave operating specifications to obtain proper performance from the equipment and to comply

with regulatory requirements.

Page 3

Warnings, Cautions, and Notes

Warnings, Cautions, and Notes are found throughout this manual where applicable. The associated

icons are used to quickly identify a potential condition that could result in the consequences described

below if precautions are not taken. Notes clarify and provide additional information to assist the user.

WARNING: This warning symbol means danger. You are in a situation that could cause

bodily injury or death. Before working on any equipment, be aware of the hazards involved

with electrical and RF circuits and be familiar with standard practices for preventing

accidents.

CAUTION: The caution symbol means reader be careful. In this situation, the user might do

something that could result in equipment damage or loss of data.

NOTE

044-05205 Rev. A i

NOTE: The note symbol means reader take note. Notes contain helpful suggestions or

references to material not covered in this document. Procedures are not contained in notes.

Page 4

Revision Record

Revision Letter Date of Change Reason for Change

Rev. A September, 2005 Preliminary Release

ii 044-05205 Rev. A

Page 5

1.1 Introduction

This manual contains information and procedures for the installation, operation, and maintenance of

the EHP19 Integrated Power Transceiver (IPT).

1.2 Scope of Manual

This manual is intended for use by service technicians familiar with similar types of equipment. It

contains service information required for the equipment described and is current as of the printing

date. Changes which occur after the printing date may be incorporated by a complete manual revision

or alternatively as additions.

The manual is organized into the following chapters:

• Chapter 1 - Product Description

• Chapter 2 - Installation

• Chapter 3 - Operation

Chapter 1

Product Description

• Chapter 4 - Maintenance

• Chapter 5 - Specifications and Drawings

1.3 Functional Description

The IPT is a high efficiency RF single channel power amplifier with an internal analog pre-distorter for

use with the Radio Base Station (RBS) digital pre-distorter system for RF output linearity. The IPT has

an operational bandwidth of 60 MHz from 1930 MHz to 1990 MHz producing a typical output of 60.2

watts (47.8 dBm). The IPT is shown in

the IPT are listed in Chapter 5.

1.3.1 RF Interface

The IPT RF interfaces consist of the TX OUT port located on the top of the IPT front panel and the

RX0 and RX1 ports located on the bottom of the IPT front panel.

1.3.2 Main Transceiver

The following circuits are part of the main transceiver section.

1.3.2.1 Customer Interface/CPRI Input

The incoming serial data stream from the customer interface (DRIC) front panel connector is applied

to a Serialiser-Deserialiser (SerDes), converted into a parallel format and decoded. The customer

interface also includes processing of the frame alignment, byte alignment and chip alignment,

including delay adjustment. A clock acts as the frequency reference for the entire transmitter. The

clock is extracted from the incoming signal using a phase locked loop (PLL). There are two outputs

Figure 1-1. Detailed functional and physical specifications for

044-05210 Rev. A 1-1

Page 6

Functional Description

from this block: control data and signal data. The control data determines parameters such as

channel frequencies, signal ramp-up/ramp down and transmit power level. These functions are

implemented in a Field Programmable Gate Array (FPGA).

1.3.2.2 Digital Up Converter (DUC)

The DUC modulates individual symbol streams from the signal data stream on to baseband carriers

and applies root-raised cosine channel filtering. This function is implemented on an ApplicationSpecific Standard Product (ASSP).

1.3.2.3 Crest Factor Reduction (CFR)

The CFR function is implemented in the FPGA. The CPR varies the DUC signals to reduce the peakto average power of the transmit signal to allow the P-Mod to operate with higher efficiency ensuring

the transmit signals stay in the occupied bandwidth/spectral mask limits.

1.3.2.4 D ata Interpolation (INT)

The interpolation function, which is implemented in the FPGA, changes the sampling rate up to 92.16

Msps.

1.3.2.5 Digital Predistortion (DPD)

The DPD function, which uses an ASSP DPD engine, and a Digital Signal Processor (DSP),

processes the forward path signal to compensate for the non-linearities in the forward path. The DPD

function ensures that the transmitter operates at the correct power level over variations in supply

voltage, load impedance, temperature and aging.

The DPD function also provides compensation for imperfections in the AUC such as differential delay,

I-Q amplitude and phase balance and DC offset/carr ie r leaka ge. the lin eari sa tion lock func tio n

monitors the operation of the signal and turns off the transmitter if the system is not functioning

correctly. The digital output signal from the DPD engine is converted back to an analog signal in a

high-speed digital-to-analogue converter (DAC).

1.3.2.6 Analog Up Converter (AUC)

The AUC uses a direct-conversion architecture (I-Q modulator) to transform the I-Q baseband signals

from the DPD up to the operating RF frequency.

1.3.2.7 Observation Path (OBS)

The OBS act as a high performance radio receiver tuned to the RF transmit frequency. The OBS

converts the sampled RF transmit signal to a VHF intermediate frequency where it is sampled by a

high-speed analogue-to-digital converter (ADC). The output of the ADC is fed to the DPD block,

compared with the drive signal and then used to update the parameters in the DPD algorithms

running on the DSP .

1.3.2.8 Clock Module

The FPGA high-speed serial interface (SerDes) extracts a timing clock from the incoming data

stream, the transmit frequency stability depends on the accuracy of the incoming input signal. The

recovered clock is used to synchronize a crystal oscillator used as a clean frequency reference for the

timing functions on the TRx board (RF LOs, DAC and ADC clocks, Tx, Rx and lineariser signal

processing clocks).

The reference is used as a direct reference for the RL local oscillators. Except for the digital clocks,

the reference is passed to a PLL VCO, which is then subdivided. All RF PLLs include lock-detect

signals to allow the transmitter to be turned off if there is a fault with a PLL.

1-2 044-05210 Rev. A

Page 7

Functional Description

FRONT

Figure 1-1 Integrated Power Transceiver Front and Rear Isometric View

1.3.3 Power Module

The P-Mod is a multi-stage amplifier, which amplifies the low level signal from the AUC up to the RF

output power level of +47.8 dBm (60.25 W). The P-Mod consists of a two-stage pre-driver, a driver

amplifier and an output stage. The bias currents are electronically calibrated during factory test and

bias setting and temperature compensation are controlled by a master control unit on the P-Mod

PCB. The P-Mod also includes a directional coupler, which allows a sample of the transmit signal to

be fed to the observation path and an isolator, which protects the P-Mod from damage or potential

oscillation under adverse RF load conditions. An RF switch allows either the observation signal or the

reflected power from the antenna connector, measured at the third port of the isolator, to be passed to

the TRx

1.3.4 Front Panel

The front panel contains a RESET switch and four status and alarm LEDs.

REAR

044-05210 Rev. A 1-3

Page 8

Functional Description

1.3.5 Operational States

The IPT has three operational states: Operational, Disabled and Not Ready.

The IPT remains in the Not Ready state during start-up until all parameters are met for the IPT to

become operational.

The IPT is normally in the Operational state: no faults are present, the IPT internal temperature is

within limits, appropriate DC power is applied, and the IPT is producing RF output. The green

operational (O) LED on the Man Machine Interface is lit.

The Disabled state is ordered from the RBS (if there is a fault in the IPT or in other RBS units) or

entered automatically when a critical hardware error is detected by the IPT. The Disabled state

causes the IPT to shut down, but it can be enabled by the RBS if the fault is cleared.

1.3.6 State Transitions

The IPT has five state transitions: Reset, Status OK, Alarm, Disable, and Enable.

Reset initiates the Not Ready state. This state is entered when power is initially applied to the IPT or

from a dedicated reset signal from the RBS to the IPT.

Status OK is entered from the Not Ready state and initiates the Operational state when commanded

by the IPT

Alarm initiates the Disabled state from the Operational state if the IPT detects a hardware or

temperature fault. The RBS reads the potential fault cause for fault logging.

Disable is ordered from the RBS to force the IPT to go to the Disabled state and shut down. Power on

of the IPT after a Disable can only be ordered by the RBS through a RESET command.

Enable is ordered from the RBS to power on the IPT after it has been disabled. The IPT enters the

Operational state after checking status and temperatures and re-perform start-up if required.

1.3.7 DC Power (DC)

DC power (-48 Vdc nominal) is supplied by the RBS to the IPT through the rear mounted connector.

Refer to

Table 1-1 for a description of the DC connector inputs.

Pins Signal Name Description

1,2 GND (-48V_RTN) DC plus (isolated from amplifier chassis)

3,4 -48V DC minus (isolated from amplifier chassis)

5,6 GND (NC) Not connected

1.3.7.1 Power Supply

The power supply assembly contains two subassemblies. The DC/DC converter produces regulated

+28 Vdc, +9 Vdc and +6.5 Vdc from the -48 Vdc supply for the IPT internal supply. The low voltage

supply uses the +6.5 Vdc from the DC/DC converter to provide regulated 3.3 Vdc, 1.8 Vdc and 1.5

Vdc reference level supplies.

Table 1-1 DC Power Connections

1-4 044-05210 Rev. A

Page 9

Functional Description

044-05210 Rev. A 1-5

Page 10

This page intentionally left blank.

1-6 044-05210 Rev. A

Page 11

2.1 Introduction

This chapter contains unpacking, inspection and installation instructions for the EHP19 Integrated

Power Transcei ver (IPT).

• Carefully read and understand all material in the chapter prior to installation.

• Review any government and local codes applicable to this installation.

• Before operating the equipment, read the operating instructions in Chapter 3.

2.2 Unpacking and Inspection

Perform the steps in Table 2-1 to unpack and inspect the IPT.

Table 2-1 IPT Unpacking and Inspection Instructions

Step Action

1 Carefully open the container and remove the IPT.

Chapter 2

Installation

2 Visually inspect the IPT for damage that may have occurred during shipment. Check for

evidence of water damage, bent or warped chassis, loose screws or nuts, or extraneous

packing material in connectors. If possible, inspect the equipment in the presence of the

delivery person.

3 If possible, retain all packing material that can be reused for repackaging the components.

2.2.1 Damaged Equipment

If the equipment is damaged, a claim should be filed with the carrier when the extent of any damage

is assessed. Contact the factory for a return material authorization (RMA). Refer to Chapter 4.

2.3 Installation Instructions

Perform the following to install the IPT.

WARNING: Ensure the RF power has been removed from the RF input cable before

connecting the RF input cable.

044-05210 Rev. A 2-1

Page 12

Installation Instructions

Step Action

1 Carefully slide the IPT into the subrack.

2 Secure the IPT in the subrack by tightening the thumbscrews.

3 Connect the TX cable, RX0 and RX1 cables as shown in Figure 2-1.

Transmit Output (TX)

Table 2-2 IPT Installation

Receive 0

(RX0) Input

Receive 1

(RX1) Input

Figure 2-1 IPT Connector Locations

2-2 044-05210 Rev. A

Page 13

3.1 Introduction

This chapter contains operating instructions for the EHP19 Integrated Power Transceiver (IPT).

3.2 Controls and Indicators

The IPT provides one switch, four LED indicators, one ethernet connector, one serial connector and

two RS-485 connectors as shown in

Chapter 3

Operation

Figure 3-1.

Figure 3-1 IPT Indicators and Controls

3.2.1 Reset Switch

The Reset recessed pushbutton switch allows the operator to reset the IPT control circuits.

044-05205 Rev A 3-1

Page 14

Initial Start-Up and Operating Proc edu res

3.2.2 Status and Alarm Indicators

MCPA alarm conditions are reported to the system as logic level signals through the rear connector.

The front panel LED provides a visual reference for the operator of MCPA status. Refer to

The IPT ALARM (INT.) lights when a IPT fault occurs. The IPT control logic provides the following

alarms to the RBS when a fault occurs:

• Temperature out of range

• Voltage out of range

• Current out of range

• Open circuit (reported as a voltage out or range alarm)

• Short circuit (reported as a current out of range alarm)

• Hardware fault. A hardware fault always requires removal and replacement of the IPT to resolve

the fault condition.

Some MCPA alarms are caused by faults external to the IPT such as an out of tolerance DC supply or

RF supply. A major fault will disable the RF output of the IPT, a minor fault has no effect on the RF

output. Conditions external to the IPT should be investigated before replacing the IPT.

Table 3-1.

3.3 Initial Start-Up and Operating Procedures

CAUTION: Before applying power, ensure the input and output of the system is properly

terminated at 50 ohms. Do not operate the system without a load attached. Refer to

5 for input power requirements, excessive input power may damage the IPT.

No operator action is required during start-up and normal operations: the IPT powers up when -48

Vdc power is applied, the IPT internal temperature is within operating range, no faults are present, RF

input and output are within specifications and the IPT is commanded to power up by the RBS logic. If

the IPT does not power up or the ALARM (INT.) LED stays lit, refer to Paragraph

troubleshooting instructions.

Chapter

4.3 for

3-2 044-05205 Rev. A

Page 15

Chapter 4

Maintenance

4.1 Introduction

This chapter contains the periodic maintenance, troubleshooting and removal and replacement

instructions for the EHP19 Integrated Power Transceiver (IPT).

NOTE Check your sales order and equipment warranty before attempting any service or repair activity.

Do not break the seals on equipment under warranty or the warranty will be null and void. Do not

return equipment for warranty or repair service until proper shipping instructions are received from

the factory. Refer to Paragraph

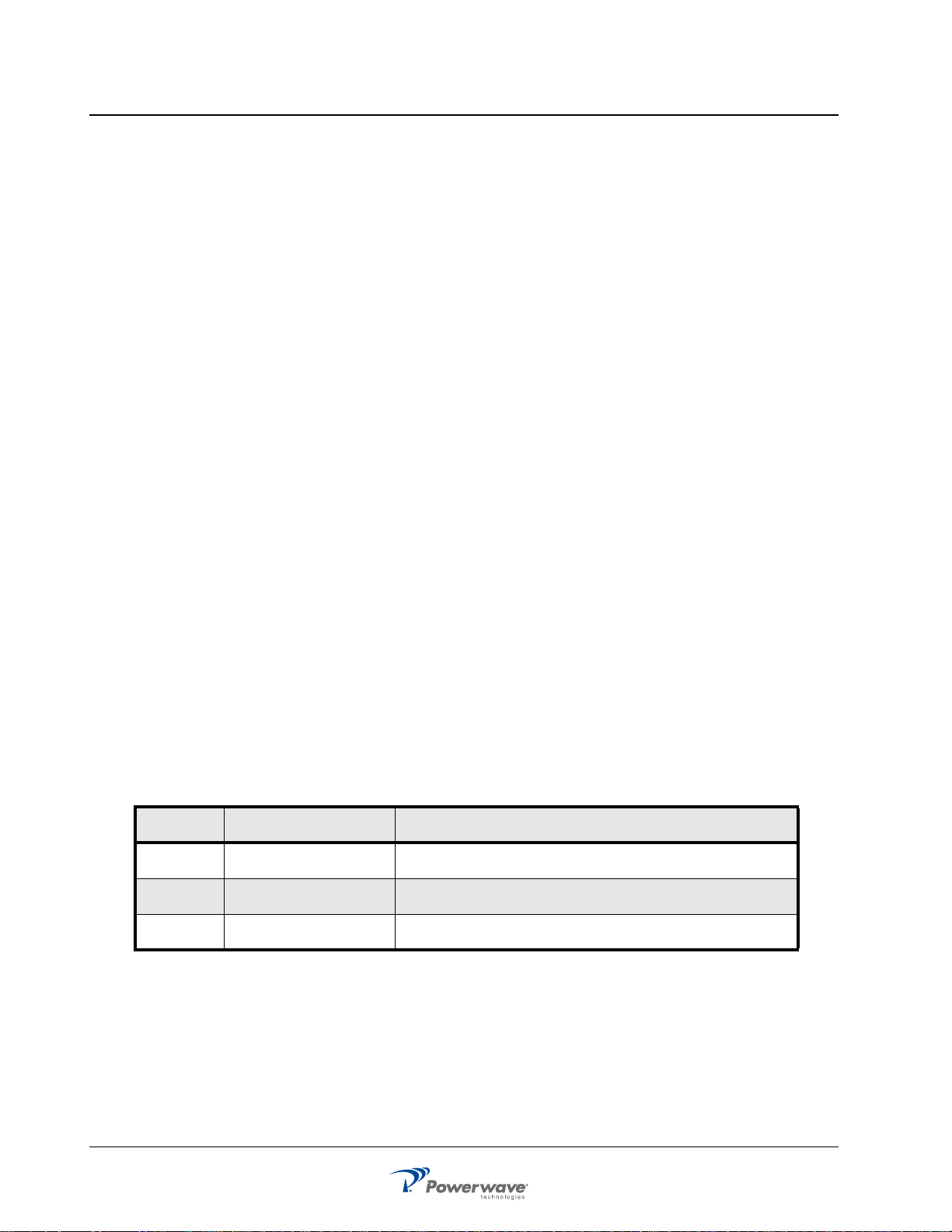

4.2 Periodic Maintenance

Recommended periodic maintenance requirements are listed in Table 4-1.

Table 4-1 Recommended Periodic Maintenance

Task Interval Action

4.5.

Inspection of cables and connectors 12 months Inspect signal and power connectors for frayed

Cleaning As Required Clean as requir ed depend ing on eq uipment o perating

insulation. Check RF connectors for tightness.

environment.

4.3 Troubleshooting

Perform the instructions in Table 4-2 if the IPT becomes inoperative.

Table 4-2 Troubleshooting

Step Action

1 Press the IPT RESET button. Check to see if the fault clears.

2 Check for proper DC supply voltage.

3 Verify all RF connections are tight.

4 Verify that the MCPA does not have a major fault.

5 Contact your field representative or the factory if major fault does not clear.

4.4 Module Field Replacement

The IPT should be removed and replaced only by a qualified technician with experience maintaining

RF power amplifiers and similar equipment.

044-05210 Rev. A 4-1

Page 16

Return For Service Procedures

4.4.1 IPT Removal and Replacement Procedure

Perform the following to remove and replac e the IPT:

WARNING: Ensure the RF power has been removed from the RF input cable before

disconnecting or reconnecting the RF input cable.

Table 4-3 IPT Removal and Replacement

Step Action

1 DIsconnect cables at the TX, RX0 and RX1 inputs.

2 Loosen the thumbscrews and slide the IPT out of the subrack.

3 To rep lace the IPT, ca refully slide the IP T back into the s ubrack slot, tighten th e thumbscrews

and replac e the RF cables .

4.5 Return For Service Procedures

Perform the instructions in the following paragraphs to ensure optimum response when returning

products to Powerwave.

4.5.1 Obtaining An RMA

A Return Material Authorization (RMA) number must be obtained prior to returning equipment to the

factory for service. Contact Powerwave at (714) 466-1000 or send a fax to (714) 466-5800 for an

RMA number. Failure to obtain the RMA number can result in delays in receiving repair service.

4.5.2 Repackaging For Shipment

Reuse the original package designed for shipping the amplifier to ensure safe shipment of the

amplifier. Contact Powerwave for packing materials if the original packaging is not available.

4-2 044-05210 Rev A

Page 17

Specifications

5.1 Power Amplifier Unit (IPT) Specifications

Table 5-1 IPT Functional and Physical Specifications

Frequency Range 1925 to 1995 MHz

Instantaneous Bandwidth 5 MHz

Total Typical / Maximum Input Power 2.9 dBm (1.9 mW) typical / 12.0 dBm (15.8 mW) maximum

Total Output Power 26.3 watts typical / 33.1 watts maximum

Adjacent Channel Leakage Power Ratio ACLR1 less than -33.5 dBc

ACLR2 less than -54.8 dBc

RF Gain 42.3 dB +/- 2 dB over the frequency and temperature range

Gain Flatness Less than 1.5 dB

Output Protection Mismatch protected

Input Port Return Loss Less than -15 dB

Harmonics Less than -34 dBm / 1 Mhz

Chapter 5

Out of Band Spurious Lower -27 dBm / Higher -27 dBm

Duty Cycle Continuous

DC Input Power From -57.0 Vdc to -38.5 Vdc (-48 Vdc nominal)

Current limit is 8 amps maximin for less than 10 milliseconds

Operating Temperature -33 to +45 °C Normal Operation

-45 to +55 °C Exceptional Operation*

-50 to +60 °C Nondestructive Operation**

Storage Temperature -25 to +55 °C

Operating Humidity 15 to 100% Normal Operation

8 to 100% Exceptional Operation*

5 to 100% Nondestructive Operation**

Storage Humidity 10 to 100 per cent

RBS / IPT communication Dual

RF Input Connector SMA-Female

RF Output Connector SMA-Female

Power Consumption Less than 207 watts maximum during normal operation

186 watts typical, 60 watts maximum at low temperature start

Weight 7.3 lbs. (3.3 kg.)

I²c serial bus, 0 to 100 KHz baud rate

Dimensions 14.6 in. (37.1 cm) wide by 2.1 in. (5.3 cm) high by 9.8 in. (24.9 cm) deep

044-05210 Rev A 5-1

Page 18

in

Figure 5-1 Model EHP19 IPT Front View

in

5-2 044-05210 Rev A

Page 19

Figure 5-2 Model EHP19 IPT Side View

in

044-05210 Rev. A 5-3

Page 20

5-4 044-05210 Rev A

Page 21

5.1 Specifications

Table 5-1 IPT Functional and Physical Specifications

Frequency Range 1930 to 1990 MHz

Instantaneous Bandwidth 15 MHz

Total T yp ical / Max imum Inp ut Power N/A

Total Output Power 60.2 watts (47.8 dBm) typical

Adjacent Channel Leakage Power Ratio ACLR1 less than -33.5 dBc

ACLR2 less than -54.8 dBc

RF Gain N/A

Gain Flatness Better than +/- 0.5 dB

Output Protection Mismatch protected

Input Port Return Loss N/A

Harmonics Less than -34 dBm / 1 Mhz

Chapter 5

Specifications

Out of Band Spurious Lower -27 dBm / H igher -27 dBm

Duty Cycle Continuous

DC Input Power From -57.6 Vdc to -38.4 Vdc (-48 Vdc nominal)

Current limit is 10.1 amps, 9.8 amps typical (at -48 Vdc)

Operating Temperatu re -33 to +45 °C Normal Operation

-45 to +55 °C Exceptional Operation*

-50 to +60 °C Nondestructive Operation**

Storage Temperature -25 to +55 °C

Operating Humidity 15 to 100% Normal Operation

8 to 100% Exceptional Operation*

5 to 100% Nondestructive Operation**

Storage Humidity 10 to 100 per cent

RBS / IPT communication

RF Input Connector SMA-Female

RF Output Connector SMA-Female

Power Consumption Less than 207 watts maximum during normal operation

186 watts typical, 60 watts maximum at low temperature start

Weight 7.3 lbs. (3.3 kg.)

Dimensions Refer to Figure Figure 5-1 and Figure 5-2

044-05210 Rev A 5-1

Page 22

357 mm

Figure 5-1 EHP19 IPT Side View

290 mm

5-2 044-05210 Rev A

Page 23

356 mm

59 mm

Figure 5-2 EHP19 IPT Front View

044-05210 Rev. A 5-3

Page 24

5-4 044-05210 Rev A

Page 25

Page 26

Powerwave Installation and Service Manual

Corporate Headquarters

Powerwave Technologies, Inc.

1801 East St. Andrew Place

Santa Ana, CA 92705 USA

©Copyright March 2005, Powerwave Technologies, Inc. All Rights reserved. Powerwave, Powerwave Technologies, The Power in Wireless and the Powerwave logo are registered trademarks of Powerwave Technologies, Inc.

Tel: 714-466-1000

Fax: 714-466-5800

www.powerwav e.com

Main European Office

Antennvägen 6

SE-187 80 Täby

Sweden

Tel: +46 8 540 822 00

Fax: +46 8 540 823 40

Main Asia-Pacific Office

23 F Tai Yau Building

181 Johnston Road

Wanchai, Hong Kong

Tel: +852 2512 6123

Fax: +852 2575 4860

Loading...

Loading...