Reference Manual

1. Abbreviations and Acronyms

Abbreviation / Acronym

Definition

{ = Two definitions,

{ same abbreviation/acronym

ACLR....................................................... Adjacent Channel Leakage Power Ratio

ACP......................................................... Adjacent Channel Power

A/D .......................................................... Analog-to-Digital Conversion

ADC......................................................... {Analog-to-Digital Converter

{Automatic Data Collection

AM........................................................... Amplitude Modulation

AMPS ...................................................... Advanced Mobile Phone System

ANSI........................................................ American National Standards Institute

APC......................................................... Automatic Power Control

APTT ....................................................... Analog Push To Talk

ASG......................................................... Applications Support Group

ASIC........................................................ Application Specific Integrated Circuit

ATE ......................................................... Automatic (Automated) Test Equipment

ATP ......................................................... Acceptance Test Procedure

ATTEN ....................................................Attenuator

BER......................................................... Beyond Economical Repair

BOM ........................................................ Bill Of Materials

BPF ......................................................... Band Pass Filter

BS ...........................................................Base Station

BTS ......................................................... Base Transceiver Station (System)

BW ..........................................................BandWidth

°C ............................................................ Degrees Celsius

CAD......................................................... Computer Aided Design

CCA......................................................... {Circuit Card Assembly

CCW........................................................ Counter ClockWise

CDMA...................................................... Code Division Multiple Access

CDPD ...................................................... Cellular Digital Packet Data

CTRL....................................................... Control

CW .......................................................... {ClockWise

{Continuous Wave

dB............................................................ deciBels

dBc .......................................................... Referenced to a carrier level

dBm......................................................... Reference to a specific power level (one milliwatt)

dBw ......................................................... Reference to a specific power level (one watt)

DIN ......................................................... Deutsches Insitut für Normung eV

DLNA....................................................... Duplexer Low Noise Amplifier

DPTT....................................................... Digital Push To Talk

DQPSK.................................................... Differential Quadrature Phase Shift Keyed

DSP......................................................... Digital Signal Processing

DUT......................................................... Device Under Test

ECD......................................................... Estimated Completion Date

ECM ........................................................ Electronic Counter Measure

EDGE ...................................................... Enhanced Data for GSM Evolution

EEPROM................................................. Electrically-Erasable Programmable Read-Only Memory

EIA ..........................................................Electronic Industries Association

EMC ........................................................ ElectroMagnetic Compatibility

EMI.......................................................... ElectroMagnetic Interference

EPROM ................................................... {Electrically Programmable Read-Only Memory

{Erasable Programmable Read-Only Memory

044-05156 Rev C 1

ESD......................................................... ElectroStatic Discharge

ESG......................................................... Electronic Signal Generator

ETDMA.................................................... Extended Time Division Multiple Access

ETSI ........................................................ European Telecommunications Standard Institute

EUT ......................................................... Equipment Under Test

FAR ......................................................... Failure Analysis Report

FCC......................................................... Federal Communications Commission

FDMA ...................................................... Frequency Division Multiple Access

FET .........................................................Field Effect Transistor

FHMA ...................................................... Frequency Hopping Multiple Access

FM ........................................................... Frequency Modulation

FRU......................................................... Field Replaceable Unit

FSK ......................................................... Frequency Shift Key modulation

GHz ......................................................... GigaHertz

GMSK...................................................... Gaussian Minimum Shift Keying

GOLAY.................................................... See GSC

GSC ........................................................Golay Sequential Code

GSM ........................................................ Global System for Mobile Communications

HPF ......................................................... High Pass Filter

HW .......................................................... Hardware

Hz............................................................ Hertz

IAW .........................................................In Accordance With

IC............................................................. Integrated Circuit

IMD.......................................................... InterModulation Distortion

IRL........................................................... Input Return Loss

IS-54........................................................ Interim Standard 54 for TDMA

IS-95........................................................ Interim Standard 95 for CDMA

ISDN........................................................ Integrated Services Digital Network

ISM.......................................................... Industrial, Scientific and Medical unlicensed frequency bands

ISO .......................................................... {International Organization for Standardization

{ISOlator

kHz .......................................................... KiloHertz

LDA ......................................................... Linear Discrete Amplifier (Class A or AB)

LGL .........................................................Lower Guardband Limit

LMR......................................................... Land Mobile Radio

LMS......................................................... Land Mobile Systems

LNA ......................................................... Low Noise Amplifier

LO ...........................................................Local Oscillator

LPA .........................................................Linear Power Amplifier

LPF.......................................................... Low Pass Filter

LSL.......................................................... Lower Specification Limit

LVD ......................................................... Low Voltage Disconnect

MC........................................................... MultiChannel

MCA ........................................................ MultiChannel Amplifier

MCPA...................................................... {MultiCarrier Power Amplifier

{MultiChannel Power Amplifier

MCR ........................................................ MultiChannel Rack

MFRM .....................................................{Multiple Frequency Radio Mobile

{Multifunction Frequency Radio Modulation

MHz......................................................... MegaHertz

MSO ........................................................ Master Switch Office

MTBF ......................................................Mean Time Between Failures

MTSO...................................................... Master Telephone Switch Office

MU........................................................... Measurement Uncertainty

044-05156 Rev C 2

M&TE ...................................................... Measuring and Test Equipment

NAMPS ...................................................Narrow Analog Mobile Phone System

NIOSH..................................................... National Institute for Occupational Safety and Health

NIST ........................................................ National Institute for Standards and Technology

NMT ........................................................Nordic Mobile Telephone

NVM ........................................................ NonVolatile Memory

OEM ........................................................ Original Equipment Manufacturer

OFDM...................................................... Orthogonal Frequency Division Multiplexing

OMS ........................................................ Operational Method Sheet

OOB ........................................................ Out Of Box

O/P .......................................................... Output

OPAF ......................................................Outdoor Power Amplifier Frame

OSHA ...................................................... Occupational Safety and Health Administration

PA ...........................................................Power Amplifier

PAF ......................................................... Powerwave Amplifier Frame

PAR......................................................... Peak to Average Ration

PCB......................................................... Printed Circuit Board

PCMCIA .................................................. Personal Computer Memory Card International Association

PCN......................................................... Personal Communications Network

PCS......................................................... {Personal Communications Services

{Personal Communication System(s)

PDA......................................................... Personal Digital Assistant

PEP ......................................................... Peak Envelope Power

PF............................................................ PicoFarads

PHS......................................................... Personal Handyphone System – Japan

PLC ......................................................... Product Life Cycle

PLL.......................................................... Phase Locked Loop

PM........................................................... {Phase Modulation

{Preventive Maintenance

PMR ........................................................ Peak to Minimum Ratio

PO ........................................................... Purchase Order

PPM ........................................................Parts Per Million

PSC......................................................... {PCS Single Channel

................................................................ {Product Serialization Code

PSTN....................................................... Public Switched Telephone Network

PTI........................................................... Powerwave Technologies, Inc.

PTT .........................................................Push To Talk

PWAV...................................................... PowerWAVe

QA ........................................................... Quality Assurance

QAM ........................................................ Quadrature Amplitude Modulation

RBW........................................................ Resolution BandWidth

RF ...........................................................Radio Frequency

RFI ..........................................................Radio Frequency Interference

RFQ......................................................... Request For Quotation

RFS ......................................................... RF Solutions

RFSU ......................................................RF Switching Unit

RGO ........................................................ Return Goods Order

RH ........................................................... Relative Humidity

RL............................................................ Return Loss

RMA ........................................................ {Rack-Mounted Amplifier

{Return Material Authorization

RMP ........................................................ Reliability Monitoring Plan (Procedure)

RMS ........................................................ Root Mean Square

RSS......................................................... Root Sum Square

Rx............................................................ Receive, Receiver

044-05156 Rev C 3

SCHPA.................................................... Single-Channel High Power Amplifier

SCPA ......................................................Single Channel Power Amplifier

SIM.......................................................... System Interface Module

SMA ........................................................SubMiniature Type A (coaxial connector)

SMT......................................................... Surface Mount Technology

SN ........................................................... Serial Number

SO ........................................................... System Outage

SOE......................................................... Sequence of Events

SW ..........................................................SoftWare

TBC ......................................................... To Be Confirmed

TBD ......................................................... To Be Determined (To Be Defined)

TCXO ...................................................... Temperature Controlled crystal Oscillator

TD ...........................................................{Temperature Drift

................................................................ {Temporary Deviation

TDMA ...................................................... Time Division Multiple Access

TRU......................................................... Transmit Receive Unit

TRX ......................................................... Transceiver (Transmit / Receiver) Unit

Tx ............................................................ Transmit, Transmitter

UAI .......................................................... Use As Is

UART ......................................................Universal Asynchronous Receiver Transmitter

UCL ......................................................... Upper Control Limit

UCLR ......................................................Upper Control Limit for Range

UGL......................................................... Upper Guardband Limit

UL............................................................ Underwriters Laboratories

UMTS ...................................................... Universal Mobile Telecommunications System

UNL ......................................................... Unit Nominal Level

URG ........................................................ Unit Reference Gain

USL ......................................................... Upper Specification Limit

UUT......................................................... Unit Under Test

VADJ ....................................................... Voltage ADJust (signal name frequently found on schematic or block

diagrams)

VBW ........................................................ Video BandWidth

VCO ........................................................Voltage Controlled Oscillator

VFWD...................................................... Voltage ForWarD (signal name frequently found on schematic or block

diagrams)

VREFL..................................................... Voltage REFLected (signal name frequently found on schematic or block

diagrams)

VSWR .....................................................Voltage Standing Wave Ratio

VVA ......................................................... Voltage Variable Attenuator

WCDMA .................................................. Wideband Code Division Multiple Access

XMT......................................................... Transmit

XMTR ...................................................... Transmitter

044-05156 Rev C 4

2. Revision History

Release Date Revision Level Comments

Jan 23, 2004 Rev. A Initial Draft

May 14, 2004 Rev. A.01 Revised layout (no formatting)

Separated sections to independent manuals

Significant updates to all text and graphics

Rev. B Correct battery part number in section 4.0

Updated cabinet figures in section 4.0

Minor update to SIM interface in AC Power Wiring Diagrams in section 4.1

Inserted all new documentation for sections 4.7.2 to end of document

3. Introduction

3.1 Symbols - Warnings, Cautions, and Notes

Warnings, Cautions, and Notes are found throughout this manual where applicable. The associated icons are used

to quickly identify a potential condition that could result in the consequences described below if precautions are not

taken. Notes clarify and provide additional information to assist the user.

Warning This warning symbol means danger. You are in a situation that could cause bodily injury.

Before you work on any equipment, be aware of the hazards involved with electrical and RF

circuitry and be familiar with standard practices for preventing accidents.

Caution

This caution symbol means reader be careful. In this situation, the user might do something that

could result in equipment damage or loss of data.

Note This note symbol means reader take note. Notes contain helpful suggestions or references to

material not covered in the document. Procedures are not contained in notes.

3.2 Equipment Changes

Powerwave Technologies, Inc. reserves the right to make changes to the subject equipment, including but not

necessarily limited to component substitution and circuits. Changes that impact this manual may subsequently be

incorporated in later revisions.

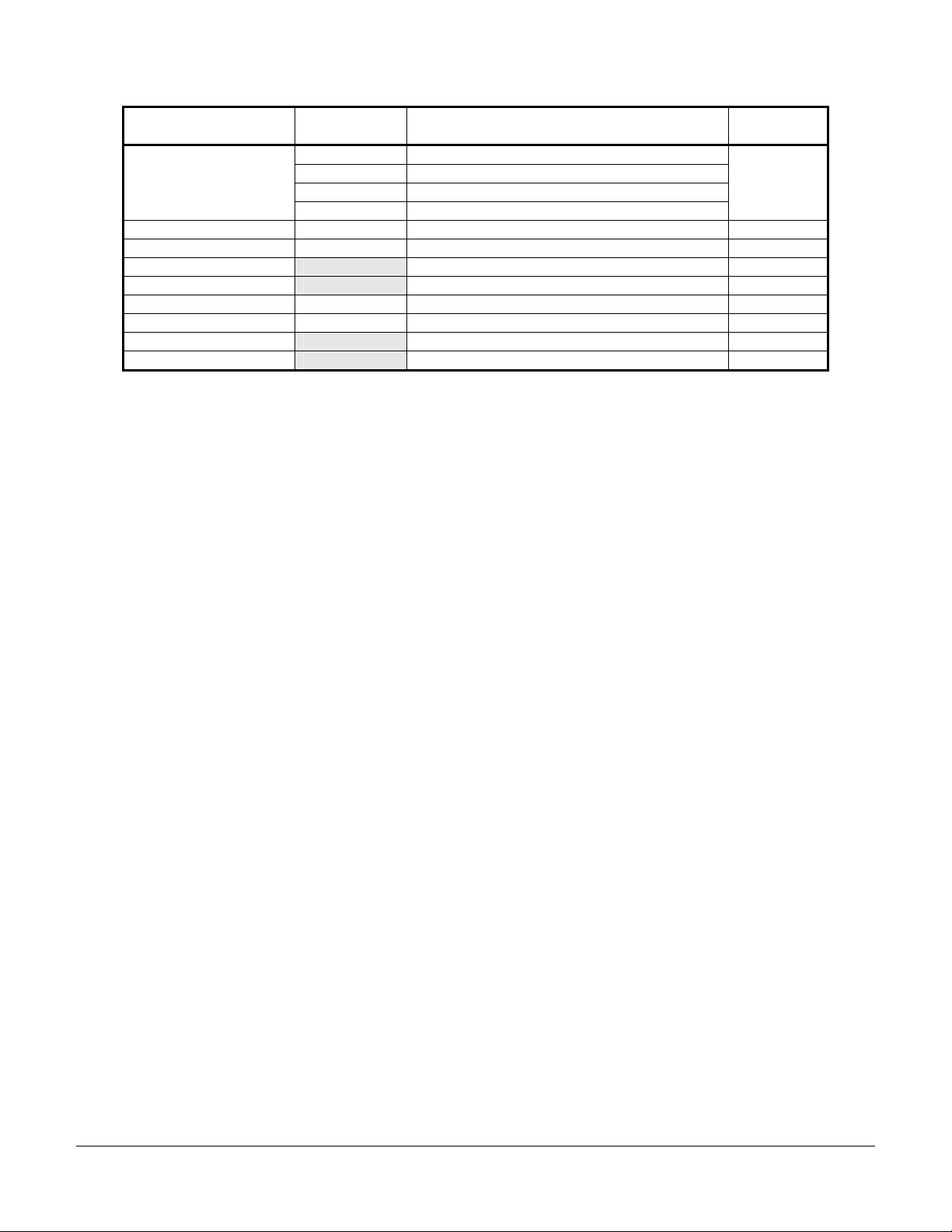

3.3 System Components and Documents

The table lists the model numbers and descriptions of the major components that comprise the OPAF system and

the document number of the manual related to each component.

044-05156 Rev C 5

Major System Components

Model Manual Description

Quantity

per system

044-05156 Reference Manual

OPAF-1923-P07C01

044-05162 Maintenance & Troubleshooting Manual

044-05163 Site Preparation & Installation Manual

1

044-05164 Field Replaceable Units Manual

G3S-1900-125 044-05122 MCPA 6

MCR21929-1-2 044-05121 Subrack 3

800-08824-001 System Interface Module 1

800-09088-001 Fan Interface Module 1

930-00018-005 * 148-Amp Rectifier 3

920-00360-002 * Low Voltage Disconnect 1

920-00337-003 Back-Up Battery 4

TPL-CZ ** Fuse, 600A, 170 VDC or less 2

* Manufactured by Cherokee International

** Manufactured by Bussmann

®

Telpower®, Cooper Bussmann, Inc. St. Louis, MO

4. System Functional Description

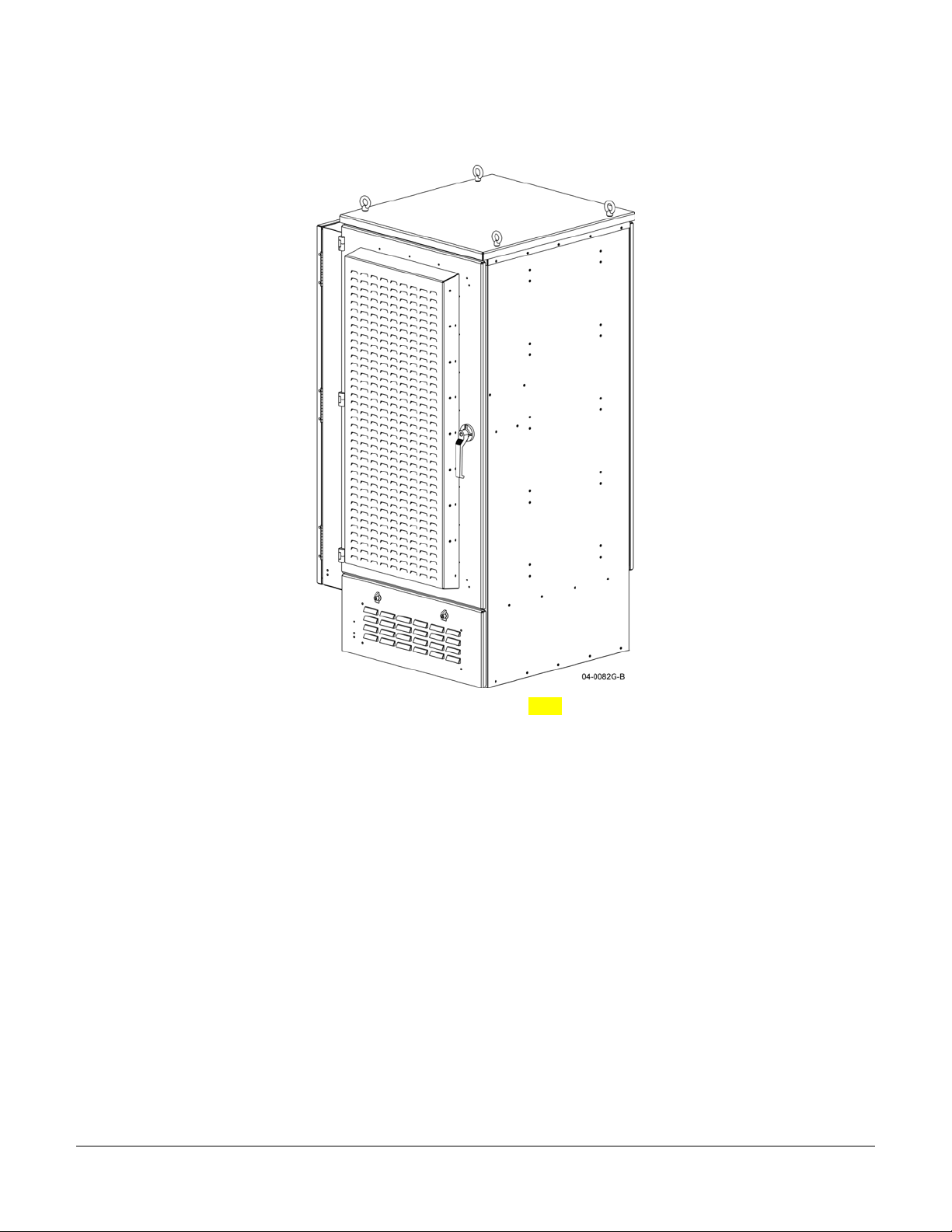

The OPAF-1923-P07C01 is an AC powered, linear, feed-forward multicarrier power amplifier system that operates

in the 60 MHz frequency band from 1930 MHz to 1990 MHz with an instantaneous bandwidth of 25 MHz. It consists

of:

• One outdoor enclosure assembly.

• Up to six model G3S-1900-125 amplifiers (two per sector, each mounted in an MCR21929-1-2 two-way subrack).

• Six

• Four 930-00018-005, 148-amp rectifiers.

• One Low Voltage Disconnect system.

Duplexer Low Noise Amplifier modules

• Four 12 Vdc 105 AH Batteries .

• System Interface Module

Designed for outdoor use, the IP54 rated enclosure is a sturdy aluminum cabinet with front and rear locking

ventilating doors. Access to the RF, and alarm cabling is located at the lower sides and rear of the enclosure.

Access to the AC power cabling is located at the left side AC panel of the enclosure

The enclosure protects the Powerwave equipment from the outdoor elements as well as housing the System

Interface Module (SIM) and the electrical interface for the 148-amp rectifiers and G3S-1900-125 MCPAs

(Multicarrier Power Amplifiers).

The all solid-state G3S-1900-125 plug-in amplifier module MCPAs, , are designed to produce high-peak power

output. The modular construction and unique and highly effective Light Emitting Diode (LED)-based operation and

fault indicators always display the current operating status of the amplifiers. The turn-on and turn-off sequence of

voltages are fully automatic, as is overload protection and recycling. A nominal 52-Amps of current is required for

the G3S-1900-125 amplifier at rated output power.

Each of the three MCR21929-1-2 subracks, contain up to two MCPAs. The MCPA outputs are combined to provide

one composite output per subrack. Each subrack is equipped with an Automatic Power Control (APC) circuit and an

RF GAIN ADJUST potentiometer. The APC indicator and GAIN ADJUST potentiometer are located on the upperright front of the subrack. Each subrack provides two RS-485 alarm interface ports, a preamp alarm interface port,

a Form-C alarm interface port and an RS-232 maintenance port, as well as, RF IN, RF OUT and a –50dB RF

sample port.

The 148-amp rectifiers and associated subracks require primary input power between 176 to 264 Vac. The rectifier

converts the AC input power to the +27 VDC for use by the system. The system design provides 12 minutes of

battery backup time with P/N 920-00337-003

Low Voltage Disconnect (LVD) monitors the output voltage of the battery system and disconnects the batteries from the circuit

batteries under a full operational load (3 hrs 30 mins. under a light load). A

044-05156 Rev C 6

when the battery voltage drops below 21 VDC. The LVD also provides the trickle charge path for the batteries during recovery

and normal operation.

The System Interface Module (SIM) monitors the performance and alarm state of the rectifiers, amplifier subracks,

and Duplexer Low Noise Amplifier (DLNA) modules.

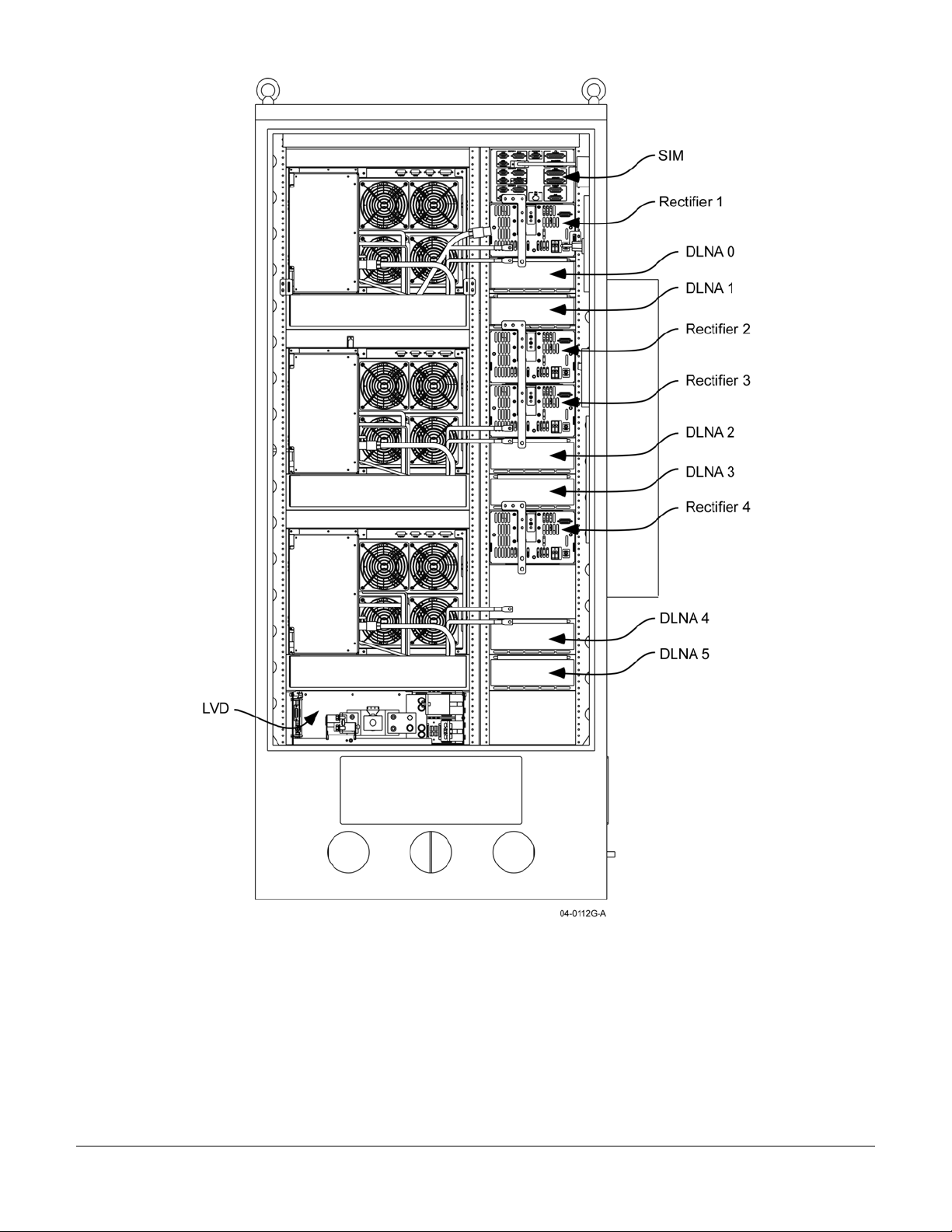

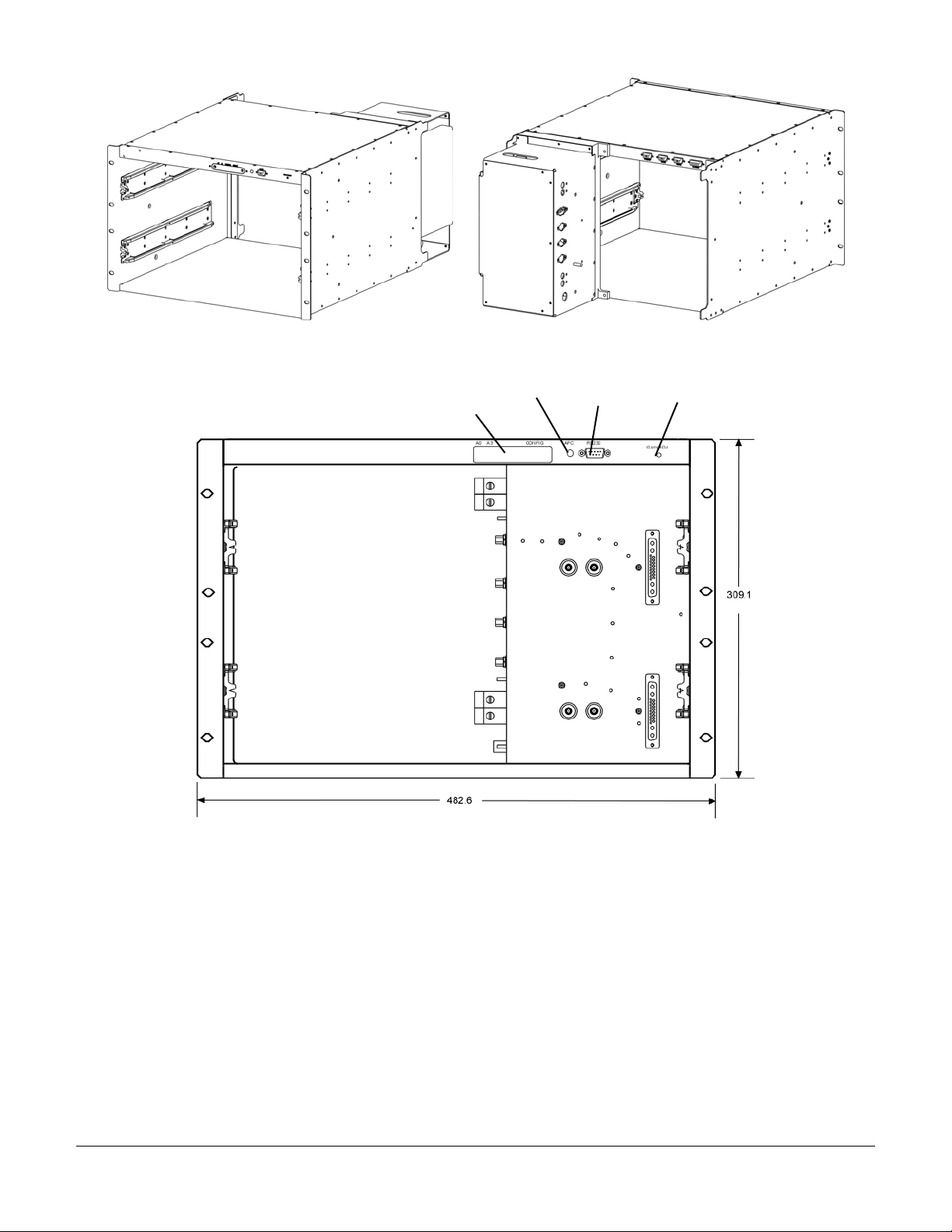

OPAF Front Isometric View and Rear Isometric View

044-05156 Rev C 7

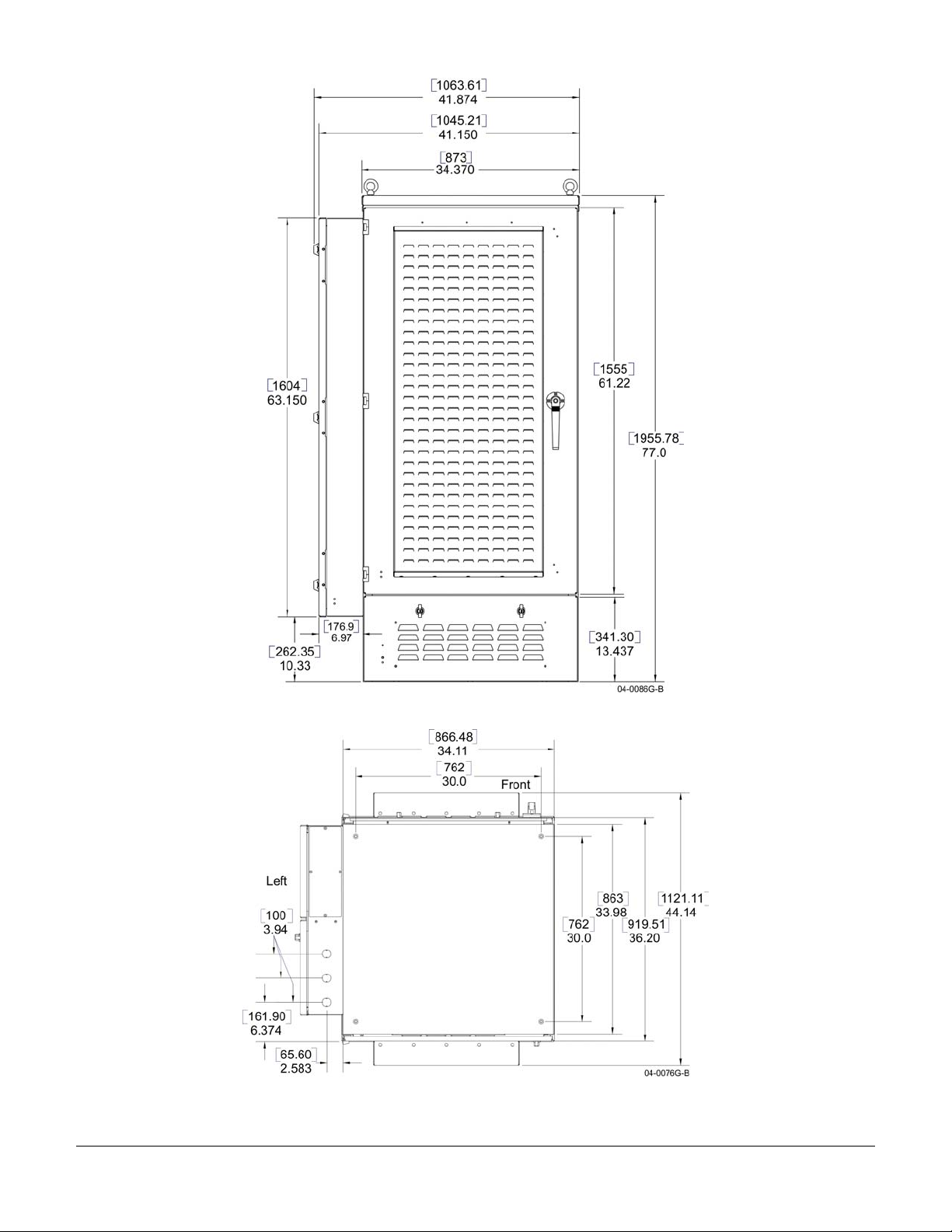

OPAF Front View with Dimensions

OPAF Bottom View with Dimensions

044-05156 Rev C 8

OPAF Left Side View and Right Side with Dimensions

044-05156 Rev C 9

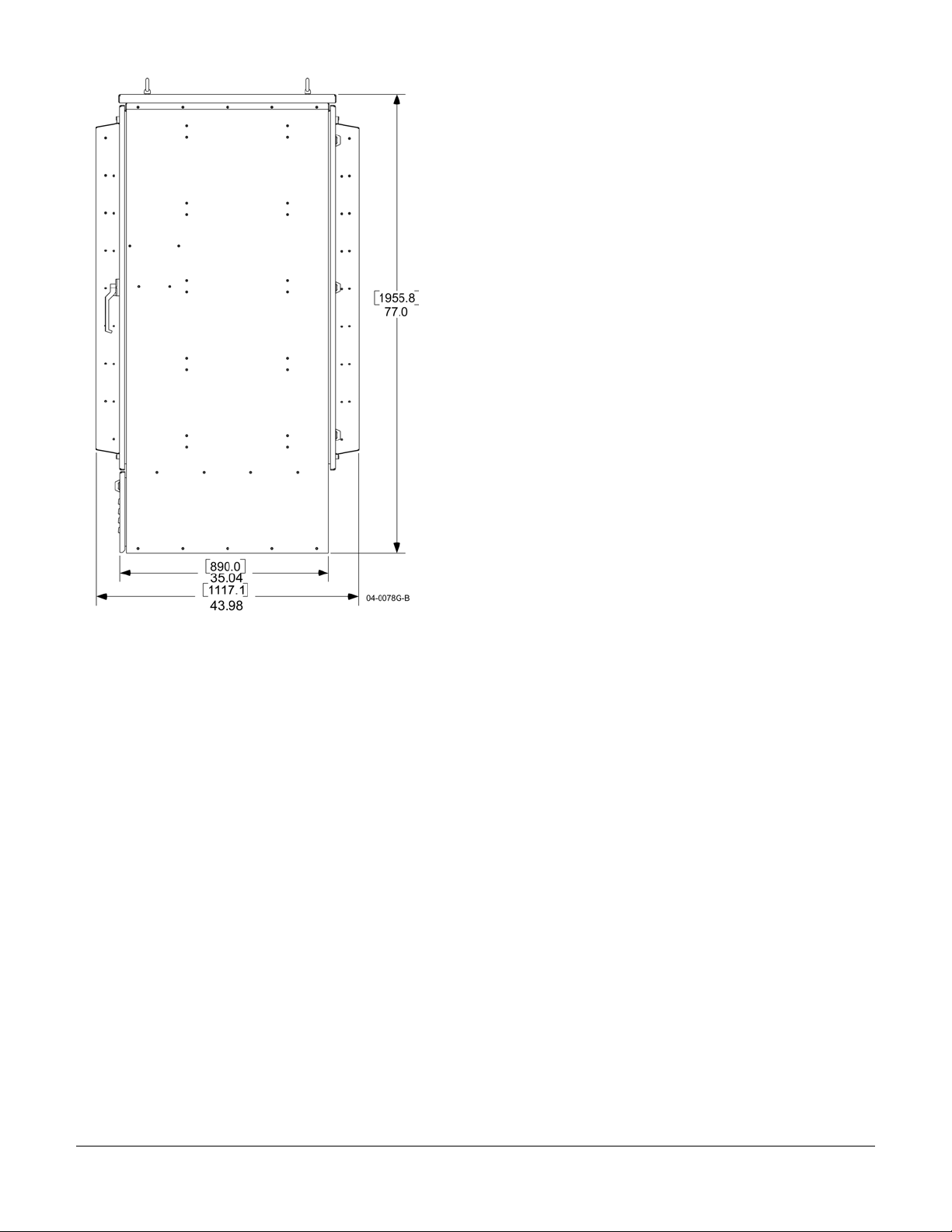

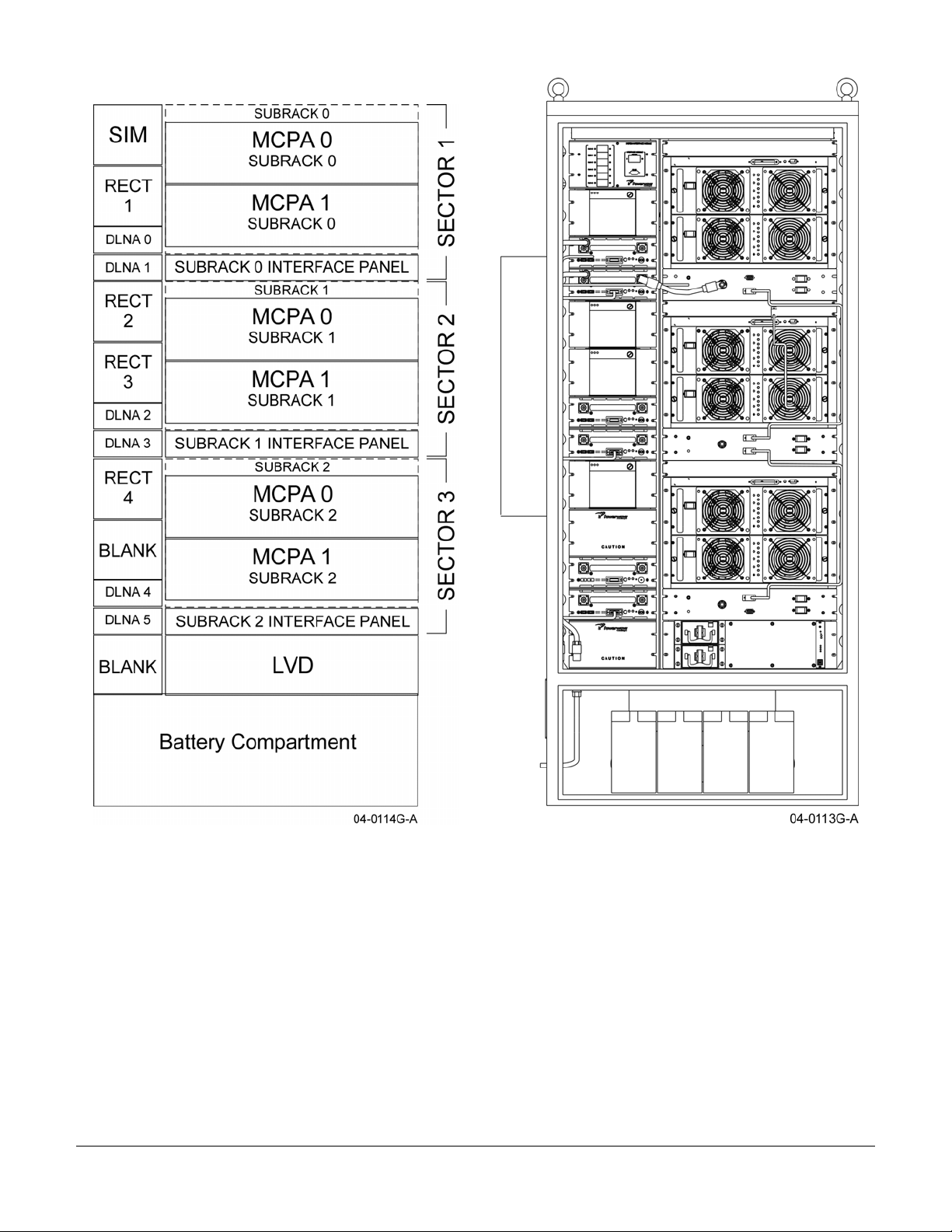

OPAF Front View with Door Removed

044-05156 Rev C 10

OPAF Rear View with Door Removed

044-05156 Rev C 11

A

r

A

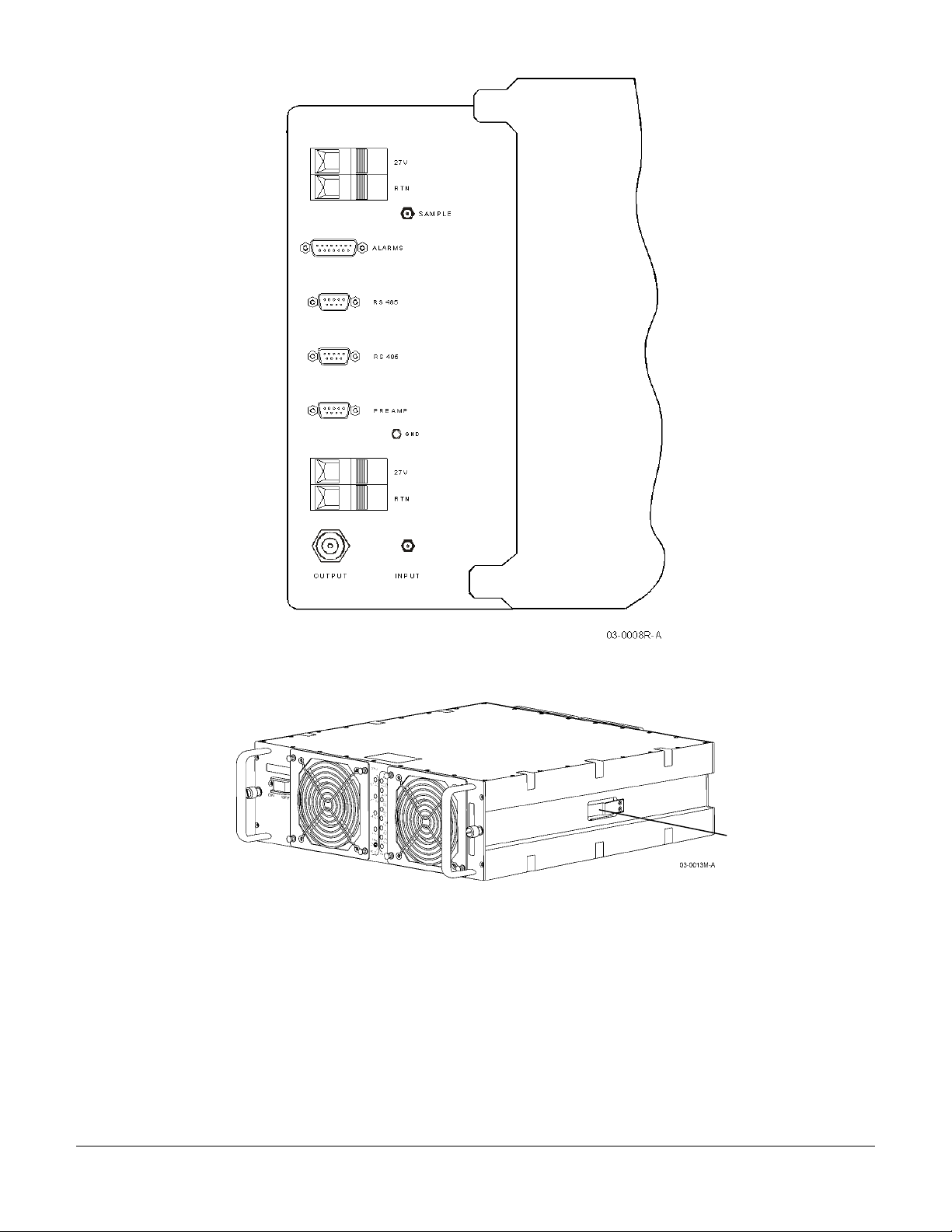

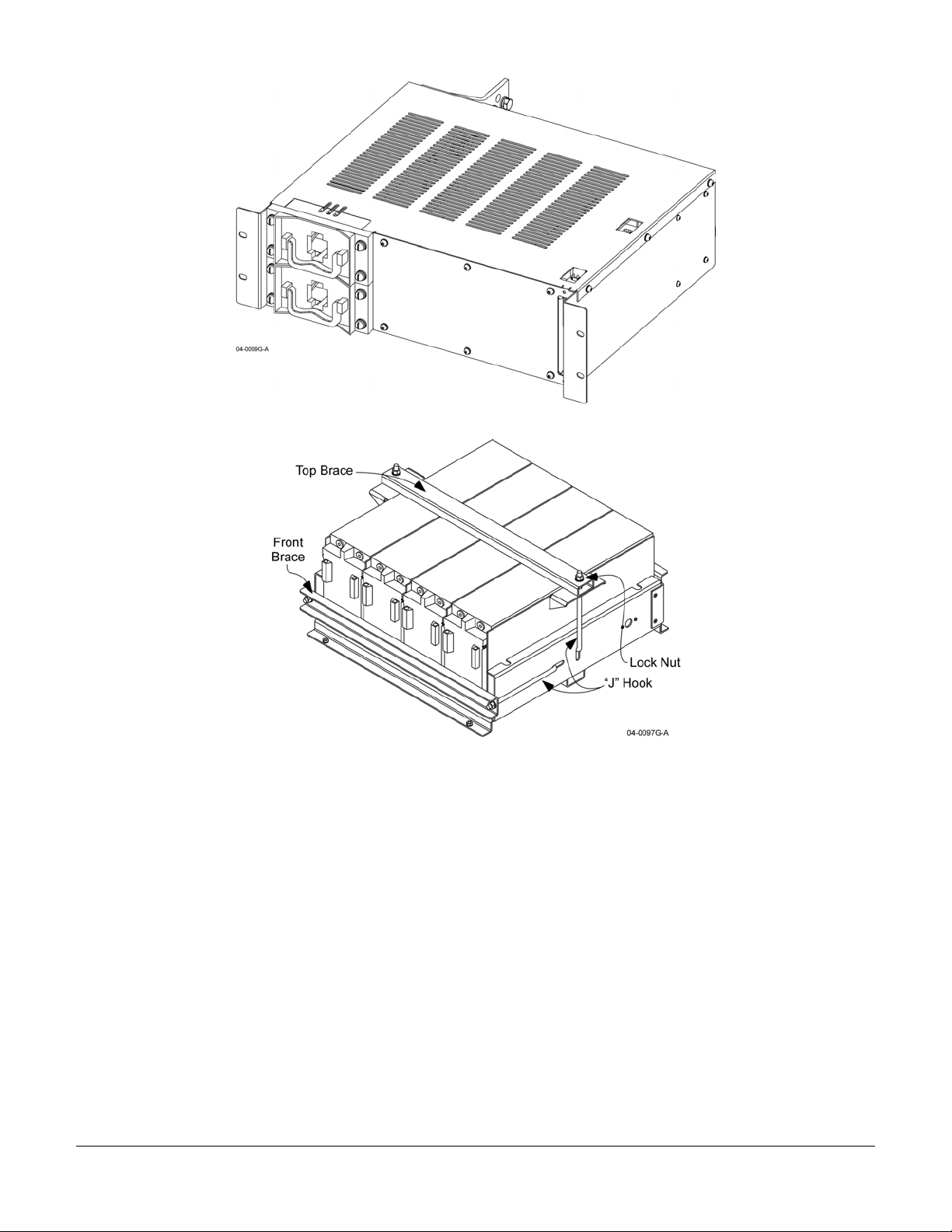

MCR21929-1-2 Subrack Front and Rear Isometric View

Host Address and

Configuration

Switches (Covered)

PC LED

Indicato

RS232

Port

Gain

djust

MCR21929-1-2 Front View without Amplifiers

044-05156 Rev C 12

MCR21929-1-2 Subrack Interface Connectors

G3S-1900-125 Multi-Carrier Power Amplifier Isometric View

Release

Latch

044-05156 Rev C 13

G3S-1900-125 Multi-Carrier Power Amplifier- Front, Side and Rear Views

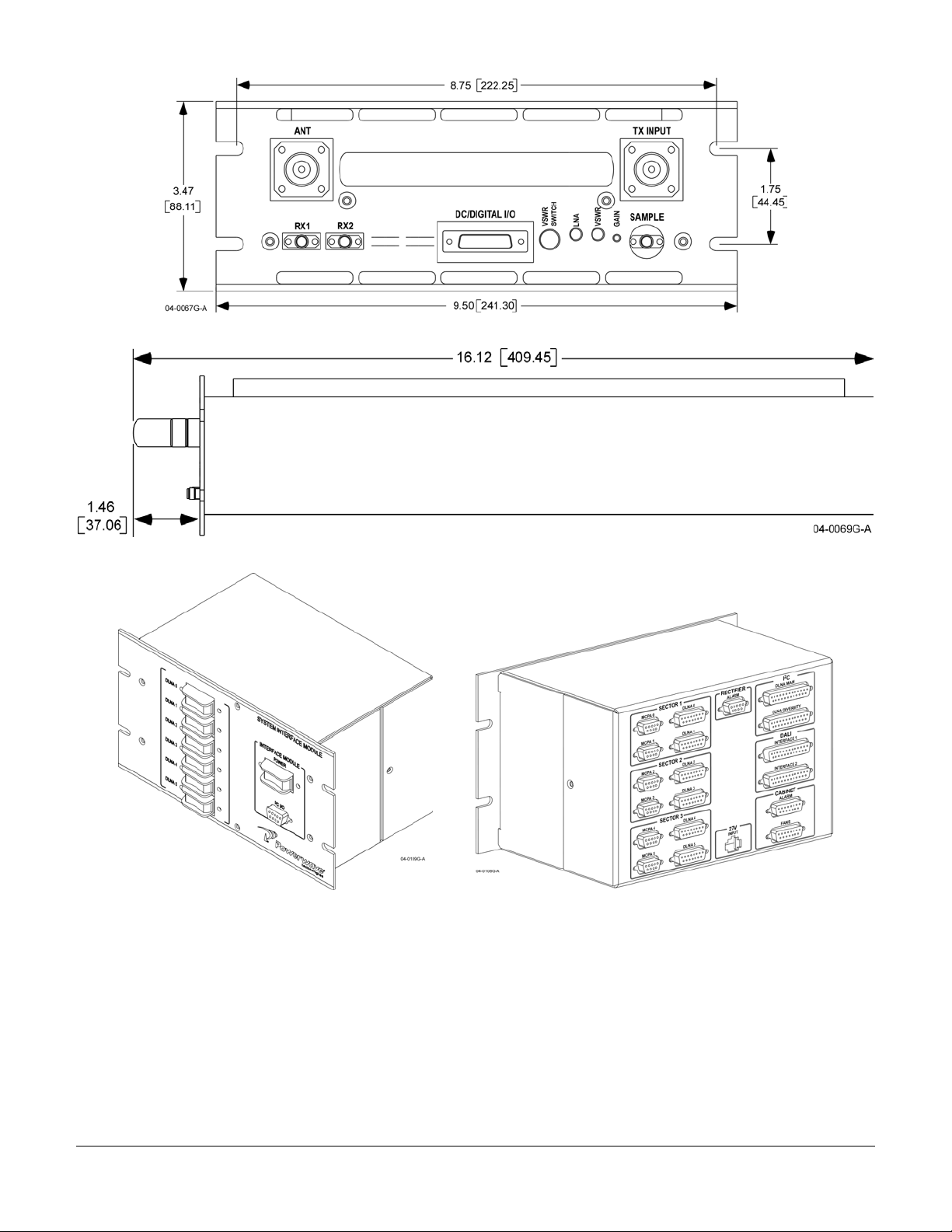

DLNA Dimetric View

044-05156 Rev C 14

DLNA Front Panel

DLNA Side View Panel

System Interface Module

044-05156 Rev C 15

Front

r

Rea

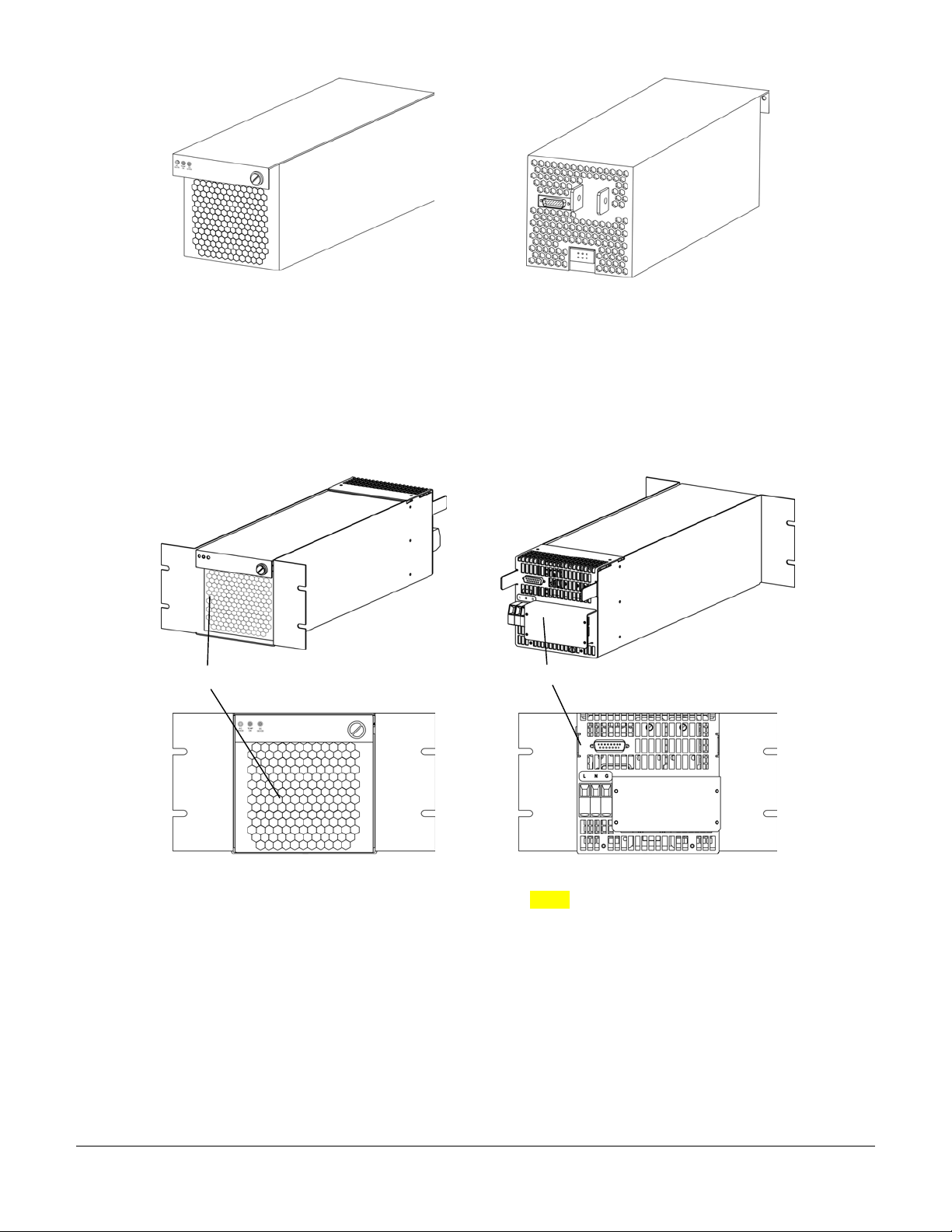

148-Amp Rectifier Isometric Views

Front

Rear

148-Amp Rectifier Tray and Panel Views

044-05156 Rev C 16

Low Voltage Disconnect (LVD) Module

P/N 920-00337-003 Back-Up Battery

4.1 Cabinet Overview

This section contains a functional description of the Powerwave OPAF Outdoor Multi-Carrier Power Amplifier

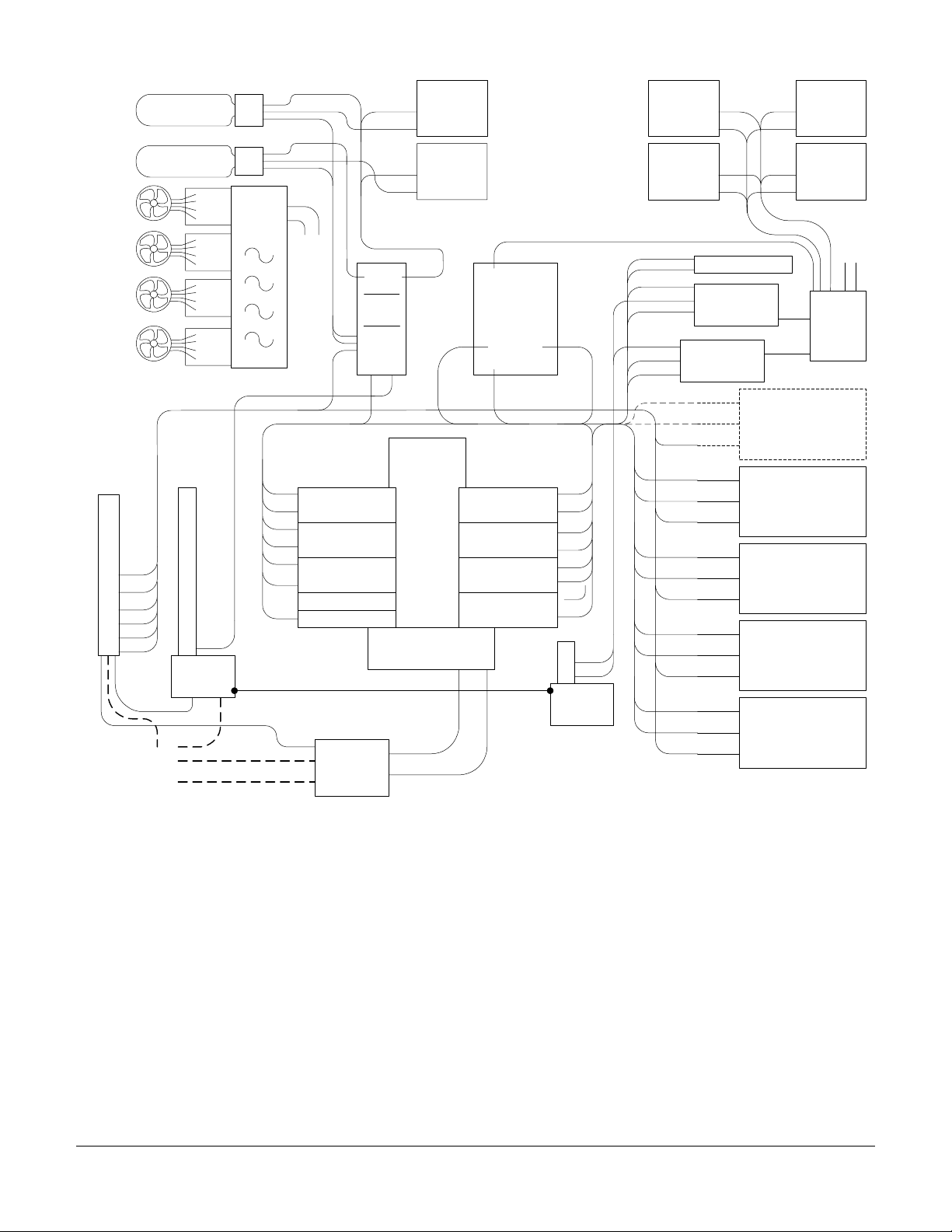

(MCPA) System. Refer to the system block diagrams below.

A complete OPAF system consists of a combined three-sector configuration that includes six G3S-1900-125

MCPA, 125-Watt amplifiers and three 4 KW (148-Amp), six Duplexer LNA (DLNA) assemblies, a System Interface

Module (SIM), four 220 VAC AC to +27 VDC rectifiers, a Low Voltage Disconnect (LVD) assembly, four backup

batteries and one outdoor enclosure.

The cabinet is equipped with four lifting bosses on the top panel. The lifting bosses are designed to carry six-times

the weight of the cabinet and its full contents, providing the weight is evenly distributed between the four lifting

bosses.

The cabinet provides easy cable and conduit access, to eliminate the need for external cable protective materials.

This eases the installation and maintenance of the cabinet. The cabinet is designed for ease of maintenance with

most modules and cables accessible either from the front of the cabinet, or side panel maintenance ports.

The cabinet provides 3 110 VAC GFCI courtesy outlets. 2 are incorporated in the front and rear light fixtures at the

top of the cabinet, the third is located inside the AC panel. 10 amps of service is available for these three outlets.

044-05156 Rev C 17

Rear

46

F1

44

45

43

BLK

50

GRN

49

To

SIM

14

13

11

10

8

7

4

45,

Load

46

GFCI

Outlet

44

43

G

6

4

30 A CB 5

Rectifier 3

30 A CB 4

Rectifier 2

30 A CB 3

Rectifier 1

15 A CB 2 GFCI

Line

Light 2

Light 1

GRN

1 BLU

2 RED

3 WHT

4 YEL

1 BLU

2 RED

3 WHT

4 YEL

1 BLU

2 RED

3 WHT

4 YEL

1 BLU

2 RED

3 WHT

4 YEL

Fan

Module

F2

F3

F4

WHT

Ground Bus

27

24

15

12

9

6

3

5

Neutral

Bus

*61

GND

Customer

AC Input

*Ground Warning

When connecting to the main service transformer, connect main ground and wire #61 to the Neutral bus.

When connecting to another AC panel, this becomes a sub-panel. Connect main ground to the Ground Bus and disconnect wire #61 at

the Neutral bus. Insulate the bare wires on #61 wire. Failure to disconnect wire #61 may cause a ground loop and a safety hazard,

resulting in injury or equipment damage.

Neu

Line

Line

EMI Filter

N/O

48

N/C

50

COM

N/O

47

N/C

49

COM

47, 48

NH

WHT

NH

5

WHT

Main

Bus

150 A Main

CB 1

Line

Line

S2

Front

S1

6 5 4

3 2 1

AC Relay

B A

20

9 8 7

20 A CB 6

Surge Pro.

30 A CB 7

Rectifier 4

30 A CB 8

Rectifier 5

15 A CB 9

Battery Heater

1

34

30, 31

2

RED

GRN

BLK

21

BLK

16, 20

18, 21

22

23

25

26

28

29

BLK

19

17

Neutral

Bus

WHT

BLK

AC

Door

Batt

Door

28

29

BLK

GRN

19

31

18

N/O

N/C

COM

N/O

N/C

COM

16

17

30

1

26

25

27

23

22

24

14

13

15

11

10

12

8

7

9

35 39

36 40

37

38

Battery Heater

Surge

Protector

1

Surge

Protector

GND

GND

GND

GND

GND

2

Line

Line

930-00018-005

Line

4 KW (148 Amp)

Line

930-00018-005

Line

4 KW (148 Amp)

Line

930-00018-005

Line

4 KW (148 Amp)

Line

930-00018-005

Line

4 KW (148 Amp)

Line

930-00018-005

41

42

32

2

BLK

33

BLK

4 KW (148 Amp)

Rectifier

Rectifier

Rectifier

Rectifier

Rectifier

4.2 AC Power Distribution

N/O

Front

N/C

Door

COM

N/O

Rear

N/C

Door

COM

34

SIM

04-0064W-C

To Fan

Module

Simplexed transmit RF input is provided by the BTS to the OPAF input bulkhead. The transmit signals are

combined (in the 16x16 configuration), amplified, then duplexed with the receive signals. The duplexed signals are

presented to a bulkhead connector for interface with the antenna port. The duplexer provides coupled samples of

the forward and reflected signals for BTS diagnostics.

Received signals from the duplexed antenna are separated from the transmit signals in the DLNA. The receive

signals are amplified by 45 dB through a low noise amplifier. The output signal is split into two paths, to allow for

future system expansion. Each sector has two DLNAs, one for the primary receive path and one for the diversity

receive path. The diversity DLNA only has transmit signals when the sector is expanded beyond eight carriers.

The SIM assembly monitors the MCPAs, LNAs, LVD, and rectifiers, and reports alarms via the I

2

C and DALI

interface.

044-05156 Rev C 18

+21.7dBm Max/Carrier

+30.7dBm Composite

-0.2dB

+53.3dBm

DLNA1

-0.3dB

-0.8dB

TX

RX

d

Power from S-

New Cabinet

with Ca ble

Loss

+5.2dBm

-0.5dB

Composite

8 Carriers @

-3.8dBm/Carrier

VVA Set @

-2.8dB

to achieve

max RF

output

+30.7dBm Composite

1

66

FORM-C

Max Combined Power 220W (53.4dBm)

MCR21929-1-2

+51.5 +/-0.5dB Gain Max

10 dB Dynamic Range

To

RS-485

S

p

l

i

t

VVA

RS-485

t

e

r

l

VVA_Contro

+4.7dBm

MCPA

Controller

To

2nd

Controller

2

3

6

C

A FE

99

I2C

d

System Interface Module

OPAF-1923-P07C01 RF Configuration, Single Sector Example

G3S-1900-125

G3S-1900-125

+27VDC GND

B

9

99

RS-485

D

I2C

m

Switch

Comb.

Form-C

6

1

9

+30.9dBm

-3.0dB

Ω

50

+53.4dBm

-0.1dB

+53.3dBm

Switch_ Control

-3.0dB

+30.9dBm

-0.2dB+21.7dBm Max/Carrier

Ω

50

Antenna Power Levels:

+52.0dBm (160W)

8 Carriers @ +43.0dBm/Carrier

-23.0dBm Max/Carrier

-14.0dBm Composite

+49dBm

DLNA0

-0.3dB

+49dBm

TX:

RX:

LNA

LNA

A

-0.1dB

N

T

R

X

d

-0.1dB

+12VDC

I2C

FWD

Detector

Circuit

RVS

I2C

L/A

-0.1dB

9

A

GND

+27VDC

TX/RX

m

-0.8dB

TX

A

-0.1dB

N

T

R

X

d

-0.1dB

+12VDC

I2C

FWD

Detector

Circuit

I2C

+52.1dBm

L/A

RVS

-0.1dB

9

B

GND

+27VDC

04-0065B-B

4.3 RF Input Signal

Any number of RF input signals can be applied to the transmit RF input port, providing: the signals meet

established mask requirements for any 2G or 3G wireless modulation scheme, the input signals do not cause the

amplifier to be over driven, and the gain of the system meets the appropriate base station architechural

requirements. The maximum input power for all carrier frequencies should not exceed the limits idicated in the

system specification. The input VSWR should be 2:1 maximum (or better).

4.4 RF Output Load

The load impedance should be as good as possible (1.5:1 or better) in the working band for good power transfer to

the load. The amplifier is operated into a duplexer and will maintain its distortion characteristics outside the signal

band even if the VSWR is infinite, provided the reflected power does not exceed one watt. A parasitic signal of less

than one-watt incident on the output will not cause distortion at a higher level than the normal forward distortion (i.e.

-63 dBc).

044-05156 Rev C 19

4.5 G3S-1900-125 Amplifier Module

4.5.1 Overview

The G3S-1900-125 amplifier is a linear, feed-forward power amplifier that operates in the 60 MHz frequency band

from 1930 MHz to 1990 MHz. It is designed to operate in two continuous frequency blocks in the PCS band or an

instantaneous bandwidth of 20 MHz. A typical one-sector system is illustrated above. Each amplifier is a selfcontained plug-in module and is functionally independent of the other amplifier module. The amplifier modules are

designed for parallel operation to achieve high peak power output, and for redundancy in unmanned remote

locations. Each amplifier in the system can simultaneously transmit multiple carrier frequencies at 85 watts per

sector, for a combined output power of 170 watts.

Each amplifier output is an amplified composite signal of approximately 125 watts before losses. All phase and gain

corrections are performed on the signal(s) in the individual amplifier modules. Each amplifier module has alarm and

display LEDs that display the amplifier performance. If a failure or fault occurs in an amplifier module, it is displayed

on the individual amplifier front panel.

The amplifier typically draws 52 amps of current at rated output power, and approximately 25 amps with no RF

signals applied. Be sure to turn the amplifier off before removing it from the subrack to avoid damaging the

equipment or causing personal injury.

4.5.1.1 Controls, Indicators, & Interfaces

Primary +27 Vdc power is applied to the amplifier via a 100-amp circuit breaker (ON-OFF) located on the left side of

the amplifier front panel.

The plug-in amplifier module RF control and indicators, located in the center of the amplifier front panel between

the cooling fans, are shown below. The status and RF control functions are described in detail in the Amplifier

Module DC Indicators RF Switch Definition table. The alarms are described in detail in the Amplifier Module RF

Control and Indicators Definition table.

G3S-1900-125 Amplifier Module RF Control and Indicators

044-05156 Rev C 20

Name Function

+27VDC

Indicator

+15VDC

Indicator

+5VDC

Indicator

-5VDC

Indicator

Green LED. When lit, indicates that the +27 Vdc supply is greater than +21 Vdc and less than +31

Vdc. If the +27 Vdc indicator goes out, the DC Fail indicator will illuminate. This indicates that the +27

Vdc voltage dropped below +21 Vdc.

Green LED. When lit, indicates that the +15 Vdc supply is greater than +12 Vdc and less than +17

Vdc. If the +15 Vdc indicator goes out, the DC Fail indicator will illuminate. This indicates that the +15

Vdc voltage dropped below +12 Vdc or increased above +17 Vdc.

Green LED. When lit, indicates that the +5 Vdc supply is greater than +2 Vdc and less than +7 Vdc. If

the +5 Vdc indicator goes out, the DC Fail indicator will illuminate. This indicates that the +5 Vdc

voltage dropped below +2 Vdc or increased above +7 Vdc.

Green LED. When lit, indicates that the -5 Vdc supply is greater than -7 Vdc and less than -2 Vdc. If

the -5 Vdc indicator goes out, the DC Fail indicator will illuminate. This indicates that the -5 Vdc

voltage dropped below -7 Vdc or increased above -2 Vdc.

Three position switch:

Off (down position) - Turns off amplifier module.

On (center position) - Normal amplifier on position.

Amplifier Module DC Indicators RF Switch Definition

RF ON

Switch

Reset (up position) - When toggled to reset position, all the red LED indicators will turn on one at a

time in sequence followed by all the green indicators one at a time in sequence; this will also reset the

fault latches. If the switch is held in the reset position, a microcontroller reset will occur. This will be

verified by the LEDs toggling state again. The switch is spring loaded to return to the normal ON

position when released. If a fault occurs and the MCPA is disabled, the alarms can be cleared and the

MCPA enabled by this reset position. The functions of the switch are disabled for five seconds after a

power-up condition.

044-05156 Rev C 21

Amplifier Module RF Control and Indicators Definition

Amplifier

Alarm

Over PWR

Fault

Over PWR

Fault

High

Temperature

High

Temperature

System

Latching

LED

MCPA

Module

Alarm

(From

Subrack)

Yes Red Disable Major High

No Red Disable Major High

No Red Enable None Low

No Red Disable Major High

MCPA

Disable signal

(pin 4)

VSWR No Red Enable None Low

VSWR Yes Red Disable Major High

DC Fail No Red Disable Major High

DC Fail

(Over

No Red Disable Major High

Voltage)

DC Fail

(Under

No Red Disable Major High +27VCD input < 21 V 21.5V

Voltage)

Fan Fail No Red Enable Minor Low

Loop Fail Yes Red Disable Major High

Low PWR N/A Red Enable None Low

MCPA Module Alarm Definition:

Condition

MCPA Module P

out

> 52 dBm (Note 1)

Pin > -6 dBm software; -

5 dBm hardware

Base plate

temperature >

80 C

Base plate temperature

>

85 C

Reflected and Forward

Powers both exceed

40W. Condition exist for

less than 1 minute

Alarm set after alarm

state on for more than 1

minute

Average Internal

voltage out of range.

+27V DC input

> 30.5 V

Any fan fail (<70 Hz

Speed)

Loop fail detected longer

than 2 min

Indication shown base

on rack RS 485

command.

Auto-

Recovery

None

<-12 dBm

Software

<75°C

<75°C

Reflected or

Forward Power

< 38W

None

(Note 2)

30.0V

(>100 Hz

Speed)

None

NA

Note 1: When Over Power detected at the output:

a) MCPA Module will shut down (Disable).

b) Turn on red Over Power lamp.

c) Latch Over Power alarm

d) The MCPA Module will use a RMS detector to determine the over power fault.

Note 2: The Appropriate Status lamp will turn off, indicating which voltage is out of its range.

(10% range for +15V, +5V, and -5V).

The amplifier module has an average output of 125 watts power (1250 watts peak power) with intermodulation

products suppressed to better than -63 dBc below carrier levels. The amplifier provides an amplified output signal

with constant gain and phase by adding approximately 25 dB of distortion cancellation on the output signal.

Constant gain and phase is maintained by continuously comparing active paths with passive references, and

correcting for small variations through the RF feedback controls. All gain and phase variations, for example those

due to temperature, are reduced to the passive reference variations. The amplifier module is comprised of:

Preamplifiers Two feed-forward loops with phase-shift and gain controls

Main amplifier DC/DC power regulator

Error amplifier Alarm monitoring, control, and display panel

044-05156 Rev C 22

4.5.1.2 Main Amplifier

The main amplifier employs class AB amplification for maximum efficiency. The error amplifier and feed forward

loops are employed to correct signal nonlinearities introduced by the class AB main amplifier. The error amplifier

operates in class AB mode. The RF input signals are amplified by a preamp and coupled to an attenuator and

phase shifter in the first feed-forward loop. The main signal is phase shifted by 180 degrees and amplified in the

premain amplifier. The output from the premain amplifier is fed to the class AB main amplifier. The output from the

main amplifier is typically 180 watts. The signal is output to several couplers and a delay line.

The signal output from the main amplifier is sampled using a coupler, and the sample signal is combined with the

main input signal and input to the second feed-forward loop. The error signal is attenuated, phase shifted 180

degrees, then fed to the error amplifier where it is amplified to a level identical to the sampled output from the main

amplifier. The output from the error amplifier is then coupled back and added to the output from the main amplifier.

The control loops continuously make adjustments to cancel out any distortion in the final output signals.

RF Out

RFL

PWR

Pre

Amp

1st Loop

Phase & Gain

+15 +5 -5

Power Supply

+27VDC

Smart Rack

Pre

Main

2nd Loop

Phase & Gain

Alarms & Display

Pre

Dist

Delay

Feed Forward Loop control

Main

Amp

FWD

PWR

Delay

Phase

& Gain

Error

Amp

Front Panel

G3S-1900-125 Power Amplifier Module Functional Block Diagram

The 2nd loop control section obtains a sample of the distortion added to the output signals by the main amplifiers,

phase shifts the signals by 180 degrees, then feeds it to the error amplifier. There it is amplified to the same power

level as the input sample and coupled on to the main output signal. The final output is monitored by the 2nd loop

and adjusted to ensure that the signal distortion and IMD on the final output is canceled out.

The input and output of the amplifier employ two-stage, class AB amplifiers, which provide approximately 25 dB of

gain in the 60 MHz frequency band from 1930 to 1990 MHz. The amplifier operates on +27 Vdc, and is mounted

directly on a heat sink, which is temperature monitored by a thermal sensor. If the heat sink temperature exceeds

85°C, a high temperature fault occurs. The alarm logic controls the transistor bias voltage, which shuts down the

amplifier.

4.5.1.3 Error Amplifier

The main function of the error amplifier is to sample and amplify the signal distortion level generated by the main

amplifier, to a level that cancels out the distortion and IMD when the error signal is coupled onto the main signal at

the amplifier output. The error amplifier is a balanced multistage, class AB amplifier, has 75 dB of gain, and

produces over 100-watts peak output. The amplifier operates on +27 Vdc and is mounted directly on a heat sink.

4.5.1.4 Amplifier Monitoring

In the main and error amplifier modules, all normal variations are automatically compensated for by the feedforward

loop control. However, when large variations occur beyond the adjustment range of the loop control, a loop fault

will occur. The alarms are displayed on the front panel indicators and output via a 21-pin connector on the rear of

the module to the subrack summary board for subsequent remote monitoring via the ALARMS connector.

4.5.2 Amplifier Module Cooling

044-05156 Rev C 23

Although each amplifier module contains its own heat sink, it is cooled with forced air. Four fans are used for

forced air cooling and redundancy. The fans, located on the front and rear of the amplifier module, draw air in

through the front of the amplifier and exhaust hot air out the back of the module. The fans are field replaceable.

4.5.3 Intermodulation

The G3S-1900-125 amplifier is designed to deliver a 125-watt composite average power, multicarrier signal,

occupying a bandwidth less than or equal to 20 MHz, in the bandwidth from 1930 to 1990 MHz. The maximum

average power for linear operation, and thus the amplifier efficiency, will depend on the type of signal amplified.

4.5.3.1 Two Tone Intermodulation

When measured with two equal CW tones spaced anywhere from 30 kHz to 20 MHz apart, and at any power level

up to the average power, the third order intermodulation products will be below -63 dBc

4.5.3.2 Multitone Intermodulation

Adding more tones to the signal will lower individual intermodulation products. If the frequencies are not equally

spaced, the level of intermodulation products gets very low. When the frequencies are equally spaced, those

products fall on top of each other on the same frequency grid. The average power of all intermodulation beats

falling on the same frequency is called the composite intermodulation; it is -63 dBc or better.

4.5.4 Amplifier Monitoring

The amplifier has a separate remote alarm and control connector, which may be used by the host system to

monitor and control the individual amplifier modules. The status, alarm, control, and power connections on the

amplifier connector are made through a 21-pin male D-Sub combo connector and are listed and described in the

Amplifier Module DC and Logic Connector Definition table.

1 2 3 4 5 6 7 8 9

A1

A2

10 11 12 13 14 15 16 17

A3

A4

DC and Logic Connector (Male, on Rear of G3S-1900-125 Amplifier Module]

Amplifier Module DC and Logic Connector Definition

PIN Function Description

A1 Power Input +27 Vdc (Power Contact)

A2 Power Input +27 Vdc (Power Contact)

A3 Ground Ground (Power Contact)

A4 Ground Ground (Power Contact)

1 RS485 +TxD Serial Communication Data Out

2 RS485 +RxD Serial Communication Data In

3 Service Loop TTL input to Amp. Gnd. for special test mode (Note 1)

4 MCPA Disabled

(Summary Fault)

5 Mod Addr 0 TTL input to Amp. Gnd. supplied by shelf to identify slot.

6 Mod Addr 1 TTL input to Amp. Gnd. supplied by shelf to identify slot.

7 TP1 TTL output. Future test point.

8 Manual Download GND to download manually

9 DC on stat TTL output. High indicates Amp is powered on.

10 RS485 –TxD Serial Communication Data Out

11 RS485 –RxD Serial Communication Data In

12 SCL7 No connection

13 SDA7 No connection

14 FP Disable Output Output, GND if the front panel switch is in the OFF position; +5 volts indicates the front panel

15 FP RST Output, GND if the front panel switch is in the RESET position; +5 volts otherwise.

16 GND Ground

17 Module Detect Ground potential. Informs the subrack that an MCPA is plugged in.

TTL signal normally low indicates MCPA enabled. A high level indicates that the MCPA has

been disabled. Over Power, Over Voltage takes one second to activate the signal.

switch is in the ON position.

044-05156 Rev C 24

Note 1: Service loop grounded allows the MCPA to be enabled or disabled by the front panel switch when not

mounted in the shelf.

4.5.5 Pilot Tone Control

The multi-amplifier subracks can be used to control the pilot tone frequency of the installed amplifiers. Pilot tone

frequency selection is based on the intended operational band of the amplifiers per the following table.

Pilot Frequency Setting Based on PCS Frequency Block of Operation

Block Designator

Base Station Bandwidth Pilot (MHz)

Transmit Frequency Band (MHz)

A 1930-1945 15 1945.5 (A)

D 1945-1950 5 1950.5 (D)

B 1950-1965 15 1965.5 (B)

E 1965-1970 5 1964.5 (E)

5 1965-1970 5 1970.5 (5)

F 1970-1975 5 1969.5 (F)

C 1975-1990 15 1974.5 (C)

Block Pairs

A-D 1930-1950 20 1950.5 (D)

D-B 1945-1965 20 1965.5 (B)

B-E 1950-1970 20 1970.5 (5)

E-F 1965-1975 10 1964.5 (E)

F-C 1970-1990 20 1969.5 (F)

E-C Excluding F 1965-1990 Excluding: 1970-1975 25 1974.5 (C)

Notes:

1. If the Block Designator has not been previously selected through serial communication on connector

J10M, pilot defaults to 1960.5 MHz on the G3S-1900-80 amplifier; 1964.5 on the G3S-1900-125

amplifier

2. If the Block Designator is selected through serial interface on connector J10M, pilot frequency is moved

to the appropriate spot and is stored permanently into the microprocessor until another band is

changed.

If the pilot tone is not moved and signals are transmitted in B-band, some traffic channels may transmit directly on

the pilot tone. The pilot tone requires a guard band of 60 KHz for TDMA, 270 KHz for CDMA (IS-95), and 400 KHz

for GSM. Transmitting on the pilot tone will cause the amplifier to go into Loop Fail. This will not damage the MCPA.

However, CDMA customers will experience a Loop Fail in every sector where the amplifiers are installed. TDMA

and GSM customers will experience intermittent Loop Fails in the sectors that use these frequencies.

On the other hand, if the pilot tone is not moved and signals are transmitted in A-band (1930-1945) or C-band

(1975-1990), the instantaneous bandwidth of the amplifier will be exceeded. This will cause equipment operated in

the outer bands of the PCS band to experience higher intermodulation distortion, which may in turn cause them to

exceed FCC emission limits. The lower end of the PCS band presents the farthest frequency span from the pilot

tone, which begins at 1930 MHz; 30.5 MHz away from the pilot tone of the G3S-1900-80 amplifier; 34.5 MHz away

from the pilot tone of the G3S-1900-125 amplifier.

Setting the pilot tone frequency of the amplifiers requires a laptop interface program. The laptop can be connected

to the multi-amplifier subrack’s RS-232 port. The multi-amplifier subrack provides the interface to the amplifiers to

set their pilot frequency and stores this setting in memory. If an amplifier fails, the multi-amplifier subrack programs

the pilot frequency of the replacement amplifier to that of the other installed amplifiers.

Refer to the Site Preparation and Installation Manual or Field Replaceable Units manual for the pilot tone

configuration procedure. Contact Powerwave to obtain a copy of the program and related instructions.

044-05156 Rev C 25

4.6 MCR21929-1-2 Amplifier Subrack

4.6.1 Overview

The MCPA system is a linear, feed-forward power amplifier system that operates in the 60 MHz frequency band

from 1930 to 1990 MHz with an instantaneous bandwidth of 20 MHz. It consists of an amplifier subrack with up to

two 125-watt G3S-1900-125 plug-in amplifiers.

The MCR21929-1-2 houses an RF power splitter/combiner and a control module that monitors the functional status

of all plug-in amplifiers. Additionally, the subrack is equipped with an Automatic Power Control (APC) circuit and an

RF GAIN ADJUST potentiometer. The APC indicator and GAIN ADJUST potentiometer are located on the upper

front of the subrack as shown below. Each subrack provides two RS-485 alarm interface ports, a preamp alarm

interface port, a Form-C alarm interface port and an RS-232 maintenance port, as well as, RF IN, RF OUT and a

–50dB RF sample port. Only the two RS-485 alarm interface ports are used to report alarm status to the SIM.

Subrack alarms are daisy chained together and address switches on the front panel are set to identify the

appropriate sector.

When two of the same model amplifiers are used, the system offers up to 218 watts of output power (after combiner

insertion losses) using the 125-watt amplifier.

MCR21929-1-2 (Reach-through (Pseudo) Front Access) - This 19-inch flush mount subrack has front “reach

through” access to its interconnect panel located at the rear of the subrack.

4.6.1.1 Controls, Indicators, & Interfaces

The location and function of the amplifier subrack controls and indicators is depicted below and described in the

paragraphs that follow.

MCR21929-1-2 Controls and Indicators

4.6.1.1.1 AO A3 (Address) Switch

This four-position DIP switch is used for setting the external RS-485 alarm bus address.

MCR21929-1-2 Address Switches

4.6.1.1.2 Config Switch

This four-position DIP switch is used for selecting software features in the amplifier subrack. Refer to Gain Modes

later in this section for a description. Preamplifiers are not used in this system, so the second dip switch is set to

Off, as indicated below in the left two diagrams.

044-05156 Rev C 26

MCR21919-1-2 Configuration Switch

4.6.1.1.3 APC LED

The LED indicator located on the top right-hand corner of the subrack serves several functions. Under normal

conditions, the indicator is off. Anytime the APC function is engaged, either from an overdrive or voltage derating

situation, the indicator blinks. When the overdrive or voltage derating condition is removed and all the gain is

recovered, the indicator ceases to blink and remains off. During maintenance functions such as downloading

firmware and detector calibration, the indicator blinks to signify the beginning and end of those functions.

APC LED Sequence and Blink Rate

Operation Sequence Blink Rate

APC due to an overdrive On/Off 1 Hz

APC due to an over voltage On/Off/Off/On 1 Hz

APC due to an under voltage On/Off/Off/On 1 Hz

System firmware upgrade On/Off 0.1 Hz

Detector calibration On/Off 1 Hz

4.6.1.1.4 Gain Adjust

This potentiometer allows the subrack gain to be attenuated 0 to 10 dB in Normal operating mode, or 0 to 3 dB in

Constant Gain operation mode. Refer to Gain Modes later in this section.

044-05156 Rev C 27

MCR21929-1-2 Subrack Input/Output Connectors

Reference

Number

Name Function

1 DC Power Terminals Base station DC power connections.

2 GROUND Lug Subrack chassis ground.

3 RF OUTPUT Connector

4 RF INPUT Connector

Type-N female coax connector, RF output to TX filter and antenna. See

table A-1 for power output level of one to two amplifier module systems.

SMA female coax connector. RF input from combiner or TX card. See

specifications for power input level.

5 RF SAMPLE Connector SMA female coax connector. ~ –50 dB sample of the subrack RF output.

6 ALARMS Connector

7 RS-485 Connectors

8 PREAMP Connector

9 RS-232 Connector

15-pin female D-Sub connector. Permits remote monitoring of amplifier

form-C dry contact alarms.

9-pin female D-Sub connector. Permits remote monitoring of RS-485

signals.

9-pin female D-Sub connector. Permits remote monitoring of preamplifier

and DC converter signals.

9-pin female D-Sub connector. Permits downloading of software to the

subrack and/or amplifiers.

4.6.2 Automatic Power Control (APC)

The APC is a power limiting function that limits the composite output power to 0.2dB to 1.0dB greater than the rated

power for the inserted MCPA combinations. If the output power of the subrack exceeds an “engage” threshold (see

below) the gain is reduced. The LED indicator located on the top front-right of the subrack blinks when the APC is

engaged. The gain is reduced until the output power complies with the “settle” range threshold. As the input drive

reduces, the gain recovers by the amount needed to approach the nominal output power, until the original gain is

achieved. Any power level in between the nominal and the engage threshold does not warrant a gain change.

APC Limit Thresholds (Watts)(G3S-1900-125)

MCPAs Nominal Engage Settle

1 109 122 112

2 218 244 222

4.6.3 Gain Modes

The subrack can be operated in either standard gain or constant gain mode. The choice of two gain modes

provides system design flexibility. Standard gain is the mode most often selected by system designers and is the

factory default setting of the subrack. Standard gain mode changes the gain of a subrack based on the number of

installed functional modules, while constant gain restricts the gain of the subrack to that of about one module,

regardless of the number of modules installed.

When a given sector is operated at full available power to maximize call capacity or when more system gain is

needed, standard gain mode is best. At lower power level requirements or when a specific system gain value must

be maintained, the system designer may elect to use constant gain mode instead. Constant gain mode maintains a

consistent cell site coverage footprint while allowing N+1 redundancy and increased system reliability. By installing

one more amplifier than the RF power plan requires, Constant gain mode allows for a back-up amplifier, should one

of the cell site’s amplifiers become inoperable.

Standard gain or constant gain is independently selectable on a sector-by-sector basis.

Subrack Gain

Active

MCPAs Standard

Gain Mode

Constant

2 51.5 48

1 48.5 48

044-05156 Rev C 28

4.6.3.1 Standard Gain Overview and Application (Default Configuration)

In the standard gain mode, the gain of the system is dependent on the number of amplifiers operating at a given

time and the power from the amplifiers is used at or near their maximum limits. When the design of the cell site

requires full power from the amplifiers installed in the subrack in order to achieve maximum call capacity, the

standard gain mode should be used. For example, if the sector design calls for 150 watts (measured at the

directional coupler output; assuming 1.5 dB of loss from the subrack to the directional coupler), the sector should

be configured with two 125 watt amplifiers (154 watts at directional coupler; 51.5 dB subrack system gain) to take

full advantage of the available power. The trade-off here, is that if an amplifier fails, the available power drops back

to 77 watts, the overall gain drops by 3.0 dB, and all the transmit channel powers drop by 3.0 dB as well (i.e. 7.5

watts to 3.75 watts per channel).

Gain adjustment via the front panel potentiometer is available.

4.6.3.2 Constant Gain Overview and Application

In constant gain mode, the gain of the subrack remains the same, regardless of the number of amplifiers installed.

Good engineering practice requires careful planning when using constant gain mode. When the design of the cell

site requires much less than maximum power, but must maintain a specific radius of coverage, constant gain mode

is ideal. For example, if the sector design calls for 75 watts output power at the directional coupler, the sector must

be configured with two 125 watt amplifiers (87 watts; 48 dB gain) when constant gain is enabled to allow for

amplifier failure. If an amplifier fails, the available power drops back to 43 watts, the subrack gain adjusts to remain

48 dB (77 watts), and all the transmit channel powers remain at the set power (i.e. 7.5 watts per channel).

However, while in constant gain mode, if the sector power is set to maximum (i.e. 100 watts with two amplifiers

installed), and an amplifier fails, the remaining amplifier will be over-driven and likely to go into an over power

condition. Should this occur, the sector would go into APC control, the input power is attenuated (see paragraph 4-

5), the sector’s footprint shrinks and an alarm is sent to the switch.

Gain adjustment via the front panel potentiometer is available.

4.6.3.3 Gain Mode Control and Theory

The MCR21929-1-2 subrack adds 3 dB of attenuation when constant gain mode is initially activated, reducing the

system gain of the MCR21929-1-2 from a nominal of 51.5 dB to 48.5 dB. Therefore, whenever the gain mode is

changed from standard gain to constant gain or visa-versa, the cell technician must reset the overall system gain or

individual channel power.

In constant gain mode, the gain of each carrier (or the system) must remain constant to avoid reducing the cell

radius. When the subrack detects an amplifier failure, the amplifier subrack reduces input attenuation through the

Voltage Variable Attenuator (VVA) by the amount of gain lost while the amplifier is removed from the circuit. This

allows the system gain to remain constant, and allows the cell site to maintain a consistent footprint. When the

replaced MCPA is enabled, attenuation is again added to the input port of the subrack by the amount of gain

introduced by the replacement MCPA to maintain an overall subrack constant gain.

As MCPAs are disabled and enabled, system gain is recovered within a 1-second time frame. The subrack is

shipped from the factory with the configuration switch set for Standard Gain mode active.

4.6.4 Performance Derating With Lower Supply Voltage

The MCPA system will operate at full power, while meeting all spectrum requirements, over a supply voltage range

of 26 to 28 VDC. The MCPA System will meet derated spectrum requirements at derated output power levels over

a supply voltage range of 21 to 30 VDC. MCPA System power derating levels are outlined in below. The LED

indicator located on the top front right of the subrack blinks when the output power is derated.

Power Derating Versus Voltage Profile

Supply Voltage[VDC] Output Power Derating

28V ≤ V < 30V

26V ≤ V < 28V

24V ≤ V < 26V

22V ≤ V < 24V

21V ≤ V < 22V

044-05156 Rev C 29

0.5dB

0dB

0.5dB

1.0dB

1.5dB

As the voltage returns to nominal levels, the output power will return accordingly. Sufficient hysteresis of at least 0.1

V is included to eliminate 'toggling' at crossover voltage levels.

4.6.5 Amplifier Monitoring

The amplifier alarms are displayed on the front panel indicators and output via a 21-pin connector on the rear of the

module to the subrack summary board for subsequent remote monitoring via the ALARMS connector. The subrack

interprets the amplifier alarms, reacts accordingly, and provides alarm status to the base station through both the

Form-C and RS-485 alarm bus.

Amplifier alarms may be monitored through the dry contact ALARMS 15-pin female D-sub connector on the rear of

the subrack. Refer to Alarm States and ALARMS Connector Definition tables and alarm connector figures below

for pin definition of the alarms connector.

Alarm States

MCAs

Installed

MCAs

Enabled

Minor Major Critical Major Critical Minor Major Critical

Form-C RS-485

Preamp

Pre-

amp

2 2 0 0 0 0

2 1 1 0 1 0

2 0 1 1 0 1

1 1 0 0 0 0

1 0 1 1 0 1

One Fan Fault 1 1

No Fan Fault 0 0

O

No Preamp Fault 0 0 0 0

P

T

One Side Preamp Fault 1 0 1 0

I

O

N

Both Sides Preamp Fault 1 1 0 1

A

L

0 = Low (no alarm)

1 = High (alarm)

4.6.5.1 Form C Alarms (not used)

Form-C Alarms Connector

044-05156 Rev C 30

Cable is 24 AWG,

copper wire stripped

and tinned at one end.

Alarm Cable (optional), P/N 700-00649-001

ALARMS Connector Definition

Indicated state

is without DC

power applied.

See ALARMS

Connector

Definition table

PIN Alarm Type Function

Operating

State

Alarm

State

1 Minor Continuity with common if no fan fault Closed Open

2 Minor Common Common Common

3 Minor

4 Major

Continuity with common if one or more fan

faults on any MCPA

Continuity with common if all installed

MCPAs are active

Open Closed

Closed Open

5 Major Common Common Common

6 Major

7 Critical

Continuity with common if one or more

MCPAs are disabled

Continuity with common if one or more

MCPAs are active

Open Closed

Closed Open

8 Critical Common Common Common

9 Critical

10 Preamp Major

Continuity with common if all installed

MCPAs are disabled

Continuity with common if external preamp

is functioning correctly

Open Closed

Closed Open

11 Preamp Major Common Common Common

12 Preamp Major

Continuity with common if external preamp

primary channel faults

Open Closed

Continuity with common if external preamp

13 Preamp Critical

primary and redundant channels are

Closed Open

functioning correctly

14 Preamp Critical Common Common Common

15 Preamp Critical

Continuity with common if external preamp

primary and redundant channels are faulted

Open Closed

044-05156 Rev C 31

4.6.5.2 RS-485 Connectors (J4, J5)

RS-485 signals are monitored through the RS-485 9-pin female D-sub connector on the rear of the subrack.

DB9 Connector

RS-485 and Preamp Connector Definition

PIN Description PIN Description

1 RS-485 TX data + 6 No Connection

2 RS-485 TX data - 7 No Connection

3 RS-485 RX data + 8 No Connection

4 RS-485 RX data - 9 Ground

5 Ground/Shield

4.6.5.3 Preamp Connector (J6; not used)

Alarm information from the system preamplifiers are monitored through this female 9-pin sub connector located on

the rear of the MCPA subrack. The OPAF-1923-P07C01 does not employ preamplifiers.

Preamplifier Alarm Connector Definitions

PIN Description PIN Description

1 No Connection 6 PA Major +

2 No Connection 7 PA Major 3 RS-232 TX 8 PA Critical +

4 No Connection 9 PA Critical 5 Ground/Shield

4.6.5.4 RS-232 Connector

This port is configured for RS-232 serial communications. Refer to the DB9 figure and the RS-232 Connector

Definition (J20) table for pin location and definition. The RS-232 interface is located on the front of the amplifier

subrack. The purpose of this connector is to provide a system interface for upgrading firmware, displaying output

power and system status, and configuration. These tasks are performed using a PC with interface software. The

connector is a type DB-9. The RS-232 port is only enabled if pin 8 is grounded. Grounding pin 8 disables the two

RS-485 host interface ports. Standard 8-bit, 1-stop bit, no parity, 9600 Baud provides the appropriate interface

communication setting.

RS-232 Connector Definition (J20)

PIN Description PIN Description

1 No Connection 6 No Connection

2 RS-232 RX 7 No Connection

3 RS-232 TX 8 Select = 0 (grounded)

4 No Connection 9 No Connection

5 Ground

4.6.6 Pilot Tone Control

Refer to paragraph 4.4.5 for a full description of the amplifier pilot tone. The MCR21929-1-2 subrack can be used to

control the pilot tone frequency of the installed amplifiers. Pilot tone frequency selection is based on the intended

044-05156 Rev C 32

operational band of the amplifiers and must be set during commissioning of the base station, and anytime the

MCR21929-1-2 subrack is replaced.

Setting the pilot tone frequency of the amplifiers requires a laptop interface program. The laptop can be connected

to the MCR21929-1-2’s RS-232 port. The MCR21929-1-2 provides the interface to the amplifiers to set their pilot

frequency and stores this setting in memory. If an amplifier fails, the MCR21929-1-2 programs the pilot frequency of

the replacement amplifier to that of the other installed amplifiers.

4.7 DLNA

4.7.1 Duplexer Overview

The Duplexer Low Noise Amplifier (DLNA) module provides Bandpass filtering for both the uplink (receive) and

downlink (transmit) paths, as well as gain for the receive path and alarm monitoring for receive gain and VSWR.

The DLNA presents excellent return loss on all ports with 18 dB or better. The coupled ports are accurate to +

dB; the –55 dB sample port is accurate to +

TX In

N-F

RX Main

SMA-F

45 dB

Gain

2.5 dB

Gain

Adjust

TX

RX

Vcc

Gain

Adjust

Antenna

N-F

1.0

LNA1:2

RX Div

SMA-F

TX

Sample

-55 dB

Vcc

FWD

1:2

Vcc

-40 dB

REF

-40 dB

+27 VDC

04-0066B-A

Regulator

RS-485 RX

RS-485 TX

RS-485 RX

Alarm

Temp Sensor

A:D A:D

micro-C

Vcc

1

2

3

4

VSWR

S1

VSWR Alarm

LNA Alarm

DLNA Block Diagram

4.7.2 Receive Path Overview

The receive path provides for a variable gain Low Noise Amplifier (LNA) from 43 to 45 dB. The LNA gain is

controlled from a front panel 10-turn potentiometer. The LNA is set to 45 db of gain from the factory. The output of

the LNA is further split into two paths, reducing the receive gain by approximately 3.3 dB, for input to the base

station. The noise figure of the DLNA is typically better than 2 dB at room temperature including all DLNA

components. The main receive path is used for the 8x8 configuration. The diversity receive path is used for the

16x16 configuration.

A microprocessor in the DLNA monitors the current draw of the LNA. If the LNA current draw drops below a

predetermined threshold, an LNA alarm is generated back to the SIM. In addition, a front panel LED is illuminated

when the LNA fails.

044-05156 Rev C 33

DLNA Front Panel

4.7.3 Transmit Path Overview

The transmit path receives amplified RF signals from the MCR21929-1-2 amplifier subrack. The amplified signals

are filtered and duplexed with the receive signals and presented to the antenna port. The transmit filter provides

105 dB of isolation in the receive band between the transmit and antenna ports.

4.7.4 DLNA Alarms

VSWR and LNA alarms for the DLNA are given on the front panel and sent via an alarm bus to the SIM.

Close-up View of DLNA Front Panel

Alarm indications for the DLNA are as follows:

Green (ON) Normal

Red (ON) Alarm State 1

Yellow (ON) Alarm State 2

Green/Red (OFF) Alarm State 3

Fast Flash Test Mode

Green (ON) Normal

Green (OFF) Loss of Supply voltage

044-05156 Rev C 34

VSWR LED

LNA LED

A front panel four-position rotary switch is provided to set the VSWR alarm threshold based on the length of cable

from DLNA output (typically FSJ4 or LDF4) to the antenna foam jumper (typically 1 5/8 Heliax). The switch position

is set with a jeweler’s screwdriver. As a general guide, set the switch as follows:

DLNA

Number

0

1

2

3

4

5

Alarm Thresholds (in dB; Return Loss)

Alarm

State 1

Minor

Alarm

State 2

Major

Alarm

State 3

Critical

Switch

Position

Design

Tolerance

(dB)

Internal

Cabinet

Cable Loss

External

Cabinet

Cable Loss

1 1 0.25 <0.75 6 +2 9.5 +2.5 12 +3

2 2 0.25 >0.75, <1.75 8 +2.25 11.5 +3 14 +3.5

3 3 0.25 >1.75, <2.75 10 +2.5 13.5 +3 16 +4

4 Test - - - - 1 1 0.23 <0.77 6 +2 9.5 +2.5 12 +3

2 2 0.23 >0.77, <1.77 8 +2.25 11.5 +3 14 +3.5

3 3 0.23 >1.77, <2.77 10 +2.5 13.5 +3 16 +4

4 Test - - - - 1 1 0.16 <0.84 6 +2 9.5 +2.5 12 +3

2 2 0.16 >0.84, <1.84 8 +2.25 11.5 +3 14 +3.5

3 3 0.16 >1.84, <2.84 10 +2.5 13.5 +3 16 +4

4 Test - - - - 1 1 0.14 <0.86 6 +2 9.5 +2.5 12 +3

2 2 0.14 >0.86, <1.86 8 +2.25 11.5 +3 14 +3.5

3 3 0.14 >1.86, <2.86 10 +2.5 13.5 +3 16 +4

4 Test - - - - 1 1 0.09 <0.91 6 +2 9.5 +2.5 12 +3

2 2 0.09 >0.91, <1.91 8 +2.25 11.5 +3 14 +3.5

3 3 0.09 >1.91, <2.91 10 +2.5 13.5 +3 16 +4

4 Test - - - - 1 1 0.07 <0.93 6 +2 9.5 +2.5 12 +3

2 2 0.07 >0.93, <1.93 8 +2.25 11.5 +3 14 +3.5

3 3 0.07 >1.93, <2.93 10 +2.5 13.5 +3 16 +4

4 Test - - - - -

4.7.5 DLNA Interface

The DLNA employs a DB-15 connector to communicate via the SIM and receive input DC power. Communication is

accomplished using I

2

C with the BTS signaling.

The SIM knows whether or not all DLNAs are connected by a module detect circuit provided on each DLNA

(ground on pin 9).

J6 DB15 Pin Assignments

PIN Description PIN Description

1 27V 9 Detect

2 27V 10 Temp Out

3 Ground 11 (mfg test use only)

4 Ground 12 (mfg test use only)

5 Write Protect 13 SCL_N (RX)

6 SCL_P (RX) 14 SDA_TX_N

7 SDA_TX_P 15 SDA_RX_N

8 SDA_RX_P

2

Via I

C, the alarms can be read and an EEPROM can be both read and written too. The SIM however does read

the temp sensor on the DLNA. The DLNA has an RS-232 interface that is only used during test and is not wired out

to the SIM.

044-05156 Rev C 35

The LNA alarm is sensed within the LNA for both low and high current. A single open collector output is read by the

micro-controller and passed on the to I

2

C interface.

4.8 Power Plant

The power plant incorporates EMI filtering, AC surge suppression, a series of circuit breakers, load sharing

rectifiers, battery backup, DC power monitoring, and a Low Voltage Disconnect transfer switch.

Neu

Connect when wired

as Main Panel;

Disconnect when

wired as Sub-Panel

(default)

GND

Line

Neutral

Bus

GND

Bus

EMI

Line

Filter

Line

Line

150 A

Main

CB

30 A CB

30 A CB

20 A CB

15 A CB

15 A CB

30 A

CB

30 A

CB

30 A

CB

30 A

CB

30 A

CB

Reserved

Battery Heater

Surge Pro.

AC Relay

GFCI Outlet

Line

Line

GND

Line

Line

GND

Line

Line

GND

Line

Line

GND

Line

Line

GND

4 KW

(148 amp)

Rectifier

4 KW

(148 amp)

Rectifier

4 KW

(148 amp)

Rectifier

4 KW

(148 amp)

Rectifier

4 KW

(148 amp)

Rectifier

AC / DC Power Block Diagram

System

Interface

Module

Alarm 1

Alarm 2

Alarm 3

K1 K2 K3

600A

Monitor

K4

K1

600A

600A

DLNA 0

DLNA 1

DLNA 2

DLNA 3

DLNA 4

DLNA 5

100 A

100 A

Alpha

Amplifier

Subrack

Beta

Amplifier

Subrack

Gamma

Amplifier

Subrack

LVD

T

Customer Supplied

Prewired

Prewired

04-0063B-B

4.8.1 Rectifiers

A series of four 4 KW rectifiers (PN: 930-00018-005) is employed to provide the OPAF power. The rectifiers source

592 amps of combined output DC power at +27 VDC under normal operating conditions. The rectifiers are

designed to operate on 180 to 264 VAC, single phase power, 47 to 63 Hz, and operate at 89% efficiency. They do

not require any minimum load to operate. The rectifier system is modular in design. N+1 redundancy is built into the

system, so a failure in one rectifier does not affect the performance of the base station. Each rectifier provides

performance data and alarms to the LVD controller and the SIM. In addition to the 30 amp circuit breaker installed

in the AC panel, each rectifier is protected by an internal 30 amp 3AG fuse.

The rectifier front panel provides 3 LEDs for quick fault determination

Rectifier LED Definitions

LED Indication

AC Good Green = OK

Temperature OK Green = OK

DC Good Yellow = OK

044-05156 Rev C 36

Rectifier Subrack Pin Assignments

PIN Description PIN Description

1 5 Vbs 9 AC fail

2 5 Vbs rtn 10 V prog

3 Module Detect 11 V1 sense

4 Pgood 12 I monitor

5 On/off 13 Tem OK

6 I share 14 Rtn Sense

7 Mod-Ena 15 No Connection

8 0VP tp

4.8.2 Batteries