®

INSTALLATION & SERVICE

MANUAL

MULTICHANNEL

POWER AMPLIFIER

NTGY81AC

1930-1990 MHz

50 WATTS AVERAGE POWER

04 April 2002

Powerwave Technologies, Inc. Tel: (714) 466-1000

1801 E. St. Andrew Place Fax: (714) 466-5800

Santa Ana, CA 92705 Web Site: www.powerwave.com

044-xxxxx Rev. x

TABLE OF CONTENTS

Par. Section 1 Page

No. General Description No.

1-1 Introduction.....................................................................................................................1-1

1-2 General Description....................................................................................................... 1-1

1-3 Functional and Physical Specifications........................................................................... 1-1

Section 2

Installation

2-1 Introduction.....................................................................................................................2-1

2-2 Electrical Service Recommendations.............................................................................2-1

2-3 Unpacking and Inspection .............................................................................................. 2-1

2-4 Installation Instructions................................................................................................... 2-2

2-5 +26 VDC Power and Ground Connector P1...................................................................2-2

2-6 Alarms and Sensing Connector P2 ................................................................................ 2-3

2-7 Differential IIC Clock, Receive, and Transmit Connector P3.......................................... 2-4

2-8 IIC, Power, Alarms,and Controls Connector P4 ............................................................. 2-4

2-9 IIC, RS485, Power, and Other Signals Connector P5.................................................... 2-6

Section 3

Operating Instructions

3-1 Introduction.....................................................................................................................3-1

3-2 Initial Start-Up and Operating Procedures......................................................................3-1

Section 4

Principles of Operation

4-1 Introduction.....................................................................................................................4-1

4-2 RF Input Signal...............................................................................................................4-1

4-3 RF Output Load.............................................................................................................. 4-1

4-4 Amplifier Functional Description.....................................................................................4-1

4-4.1 Input Amplifier.................................................................................................................4-1

4-4.2 Predistortion Amplifier ....................................................................................................4-1

4-4.3 Driver Amplifier............................................................................................................... 4-2

4-4.4 Main Amplifier................................................................................................................. 4-2

4-4.5 Multifunction Board.........................................................................................................4-2

4-5 Amplifier Module Cooling................................................................................................4-2

4-5 Power Distribution...........................................................................................................4-2

044-xxxxx Rev. x

ii

TABLE OF CONTENTS (Continued)

Par. Section 5 Page

No. Maintenance No.

5-1 Introduction.....................................................................................................................5-1

5-2 Periodic Maintenance..................................................................................................... 5-1

5-3 Test Equipment Required For Test................................................................................ 5-1

5-4 Performance Test........................................................................................................... 5-2

5-4.1 Amplifier Performance Test............................................................................................ 5-2

5-5 Field Replacement of the Module................................................................................... 5-5

Section 6

Troubleshooting

6-1 Introduction.......................................................................................................................6-1

6-2 Troubleshooting................................................................................................................6-1

6-3 Return for Service Procedures .........................................................................................6-1

6-3.1 Obtaining an RMA ............................................................................................................6-1

6-3.2 Repackaging for Shipment...............................................................................................6-1

LIST OF ILLUSTRATIONS

Figure Page

No. No.

1-1 NTGY81AC Multichannel Power Amplifier ..................................................................... 1-3

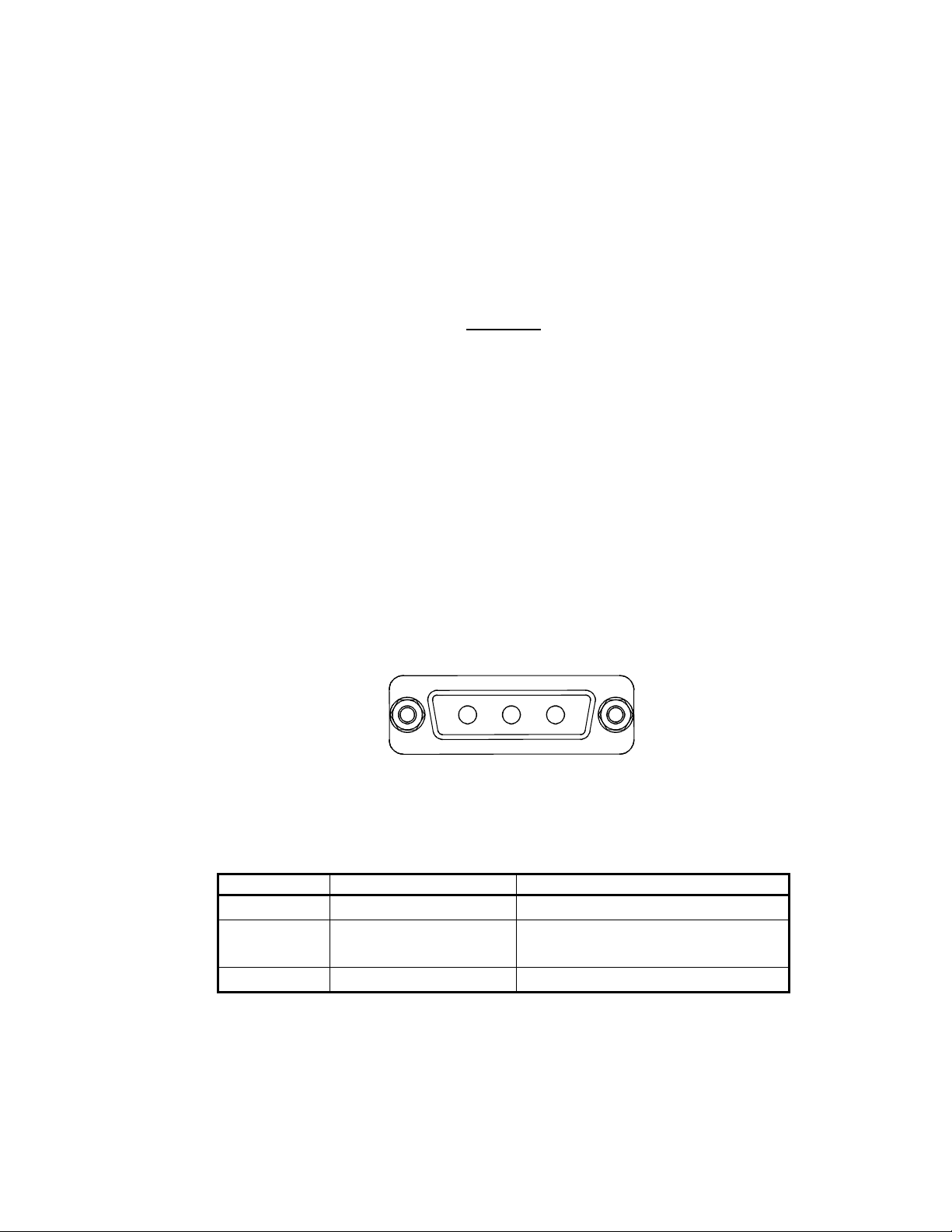

2-1 +26 Vdc Power and Ground Connector P1....................................................................2-2

2-2 Alarms and Sensing Connector P2 ................................................................................ 2-3

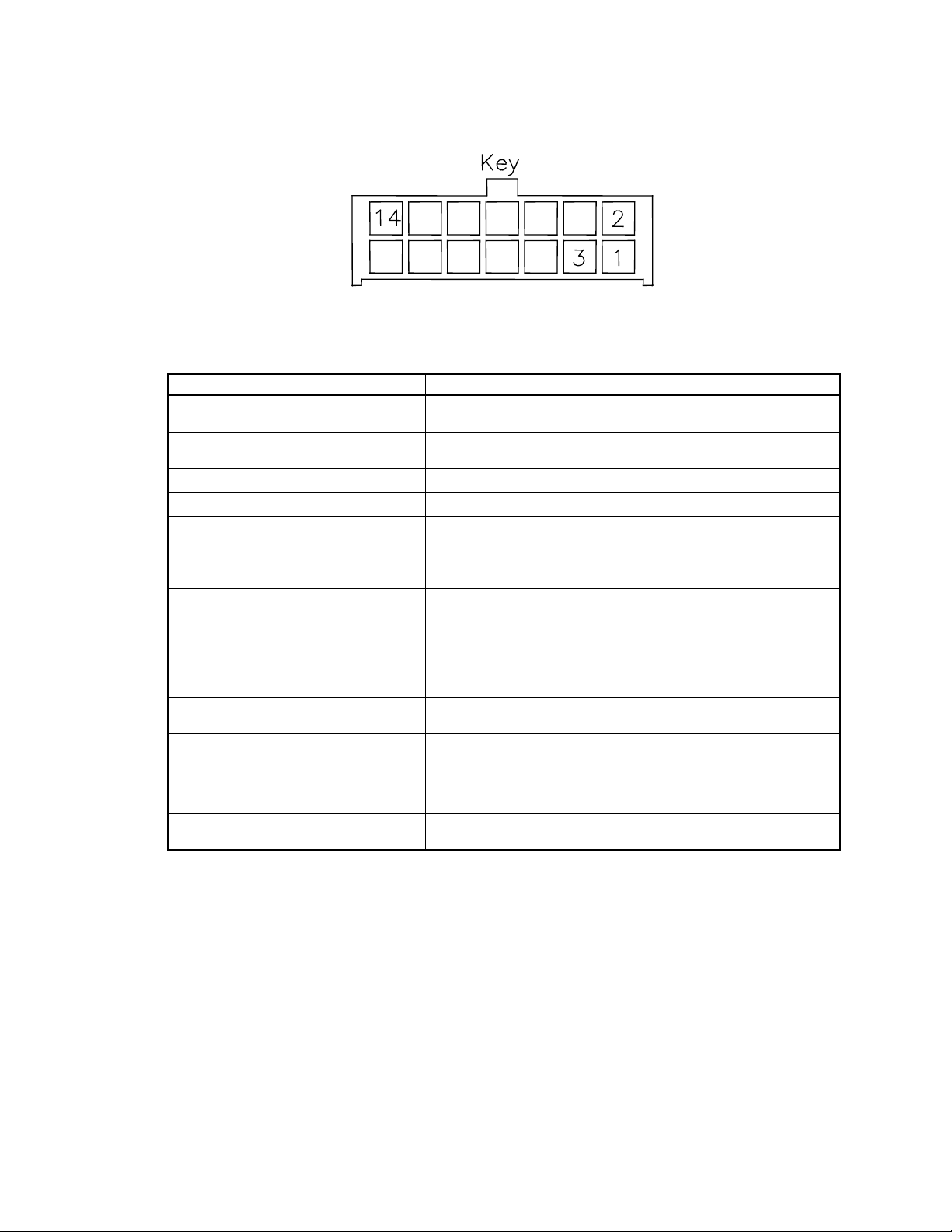

2-3 Differential IIC Clock, Receive, and Transmit Connector P3.......................................... 2-4

2-4 IIC, Power, Alarms, and Controls Connector P4 ............................................................ 2-4

2-5 IIC, RS485, Power and Other Connector P5..................................................................2-6

4-1 NTGY81AC Multichannel Power Amplifier Functional Block Diagram........................... 4-2

5-1 NTGY81AC Amplifier Test Setup Diagram .................................................................... 5-3

LIST OF TABLES

Table Page

No. No.

1-1 NTGY81AC Multichannel Power Amplifier Functional Specifications..... ....................... 1-2

2-1 +26 Vdc Power and Ground Connector P1 Definition.................................................... 2-2

2-2 Alarms and Sensing Connector P2 Definition ................................................................ 2-3

2-3 Differential IIC Clock, Receive, and Transmit Connector P3 Definition.......................... 2-4

2-4 IIC, Power, Alarms, and Controls Connector P4 Definition............................................ 2-5

2-5 IIC, RS485, Power and Other Connector P5 Definition.................................................. 2-6

5-1 Periodic Maintenance..................................................................................................... 5-1

5-2 Test Equipment Required............................................................................................... 5-2

5-3 Multichannel Power Amplifier NTGY81AC Test Data Sheet.......................................... 5-4

6-1 Troubleshooting..............................................................................................................6-1

044-xxxxx Rev. x

iii

Section

1

GENERAL DESCRIPTION

1-1. INTRODUCTION

This manual contains information and procedures f or installation, operation, and maintenance of

Powerwave’s model NTGY81AC multic hannel power amplif ier (MCPA). T he m anual is organized

into six sections as follows:

Section 1. General Description

Section 2. Installation

Section 3. Operating Instructions

Section 4. Principles of Operation

Section 5. Maintenance

Section 6: Troubleshooting

1-2. GENERAL DESCRIPTION

The NTGY81AC is a linear, multichannel power amplif ier that operates in the 60 MHz frequency

band from 1930 MHz to 1990 MHz. It is designed to be mounted in an enclosure with EMI

containment. Its flat base plate allows f or mounting on a flat thermal-absorbing s urf ac e to pr ovide

adequate heat dissipation.

Each amplifier m odule has a power, alarm, and control c onnector that allows the host s ystem to

monitor the amplifier module performance. Primary power for the amplifier is +26 Vdc.

1-3. FUNCTIONAL AND PHYSICAL SPECIFICATIONS

Functional and physical specifications for the amplifier are listed in table 1-1.

044-xxxxx Rev. x 1-1

Table 1-1. NTGY81AC Multichannel Power Amplifier Functional Specifications

Frequency Range 1930-1990 MHz (60 MHz Bandwidth)

Maximum Average Input Power 13 dBm

Continuous Average Output Power 50 Watts

Spurious Emissions @ Maximum

Rated Output Power

(50 W / 47 dBm)

Frequency Offset Requirement Meas. Bandwidth

Max. Min.

0.885-1.25 MHz -47 dBc 30 kHz

1.25-1.98 MHz -16.5 dBm 37.5 kHz

1.98-2.25 MHz -58 dBc 30 kHz

>2.25 MHz -15 dBm 1 MHz

RF Gain 47 ±2 dB

Gain Flatness:

± 0.2 dB for any 1.25-MHz band within frequency range.

Output Protection: Mismatch Protected

Input Port Return Loss: VSWR 2:1 Max.

Out of Band Spurious: Less than -15 dBm / 1 MHz

DC Input Power:

+26 ± 0.5 Vdc, 260 mV p-p max. ripple, ≤500 watts

Operating Temperature: -15 ºC. to +85 ºC. (heatsink temperature)

Storage Temperature: -40 ºC. to +85 ºC.

Operating Humidity: 5 % - 95 % Relative Humidity (Noncondensing)

Storage Humidity: 5 % - 95 % Relative Humidity (Noncondensing)

Interface Connectors:

RF Input----------------------------------RF Output -------------------------------+26 Vdc Power and Ground --------Alarms and Sensing ------------------Differential IIC Clock, Rcv., Xmit.--IIC, Power, Alarms, Controls--------IIC, RS485, Power, Other Signals--

SMA Female

SMA Female

3W3 D-Sub (Connector P1)

14-Position Micro-Fit 3.0 (Connector P2)

6-Position Micro-Fit 3.0 (Connector P3)

26-Position High Density D-Sub (Connector P4)

18-Position Micro-Fit 3.0 (Connector P5)

Dimensions (inches): 11.00 x 14.50; height: 1.70

044-xxxxx Rev. x 1-2

RF OUT RF IN

P1

P4

P5

P3

P2

Figure 1-1. NTGY81AC Multichannel Power Amplifier

044-xxxxx Rev. x 1-3

Section

2

INSTALLATION

2-1. INTRODUCTION

This section contains unpacking, inspection, and installation instructions and recommendations

for the Model NTGY81AC Multi Channel Power Amplifier. Carefully read all material in this

section prior to equipment unpacking or installation. Also read and review the operating

procedures in Section 3 prior to installing the equipm ent. It is im portant that the licens ee perf orm

these tasks corr ectly and in good faith. If applicable, carefully read the appropr iate parts of the

Federal Communications Commission (FCC) rules to determine how they apply to your

installation. DON'T TAKE CHANCES WITH YOUR LICENSE.

2-2. ELECTRICAL SERVICE RECOMMENDATIONS

Powerwave Technologies recomm ends that proper AC line conditioning and surge suppression

be provided on the primary AC input to the +26 Vdc power source. All electric al s ervic e s hould be

installed in accordance with the National Electrical Code, any applicable state or local codes, and

good engineering practice. Special consideration should be given to lightning protection of all

systems in view of the vulnerability of most transm itter sites to lightning. Lightning arrestors are

recommended in the service entrance. Straight, short ground runs are recommended. The

electrical service must be well grounded.

Each amplifier system should have its own circ uit br eak er , s o a f ailur e in one does not s hut of f the

whole installation. Circuit breakers should be thermal type, capable of handling the maximum

anticipated inrush current, in a load center with a master switch.

2-3. UNPACKING AND INSPECTION

This equipment has been operated, tested and calibrated at the factory. Carefully open the

container(s) and remove the amplifier module(s). Retain all packing material that can be

reassembled in the event that the unit must be returned to the factory.

CAUTION

Exercise care in handling equipment

during inspection to prevent damage

caused by rough or careless handling.

Visually inspect the amplifier module for damage that may have occurred during shipment. Check

for evidence of water damage, bent or warped chassis, loose screws or nuts, or extraneous

packing material in the connec tor. If the equipment is dam aged, a claim s hould be filed with the

carrier once the extent of any damage is assessed. We cannot stress too strongly the importance

of IMMEDIATE careful inspection of the equipment and the subsequent IMMEDIATE f iling of the

necessary claims against the carrier if necessary. If possible, inspect the equipment in the

presence of the delivery person. If the equipment is damaged, the carrier is your first area of

recourse. If the equipment is damaged and must be retur ned to the factory, write or phone for a

return authorization. Powerwave may not accept returns without a return authorization. Claims

for loss or damage m ay not be withheld from any payment to Powerwave, nor m ay any payment

due be withheld pending the outcome thereof. WE CANNOT GUARANTEE THE FREIGHT

CARRIER'S PERFORMANCE

044-xxxxx Rev. x 2-1

2-4. INSTALLATION INSTRUCTIONS (Refer to figure 1-1)

The NTGY81AC amplif ier m odule is des igned for ins tallation on a heats ink that per m its acces s to

the module for connection of RF cables and the power, alarm, and control connector.

To install the amplifier proceed as follows:

1. Install amplifier on heatsink with thermally conductive material inserted between amplifier

module and heatsink, and secure in place with appropriate mounting screws.

2. Connect the antenna cable to RF OUT female SMA connector.

3. Connect the transceiver output cable to RF IN frmale SMA connector.

WARNING

Turn off external primary DC pow er

before connecting any cables.

4. Connect power, alarm, and control cables to m atching P1 through P5 connec tors. Refer to

paragraphs 2-5 through 2-9 following.

6. Chec k your work before applying DC voltage to the system . Make cer tain all connections are

tight and correct.

7. Measure primary DC input voltage. DC input voltage should be +26 ±0.5 Vdc. If the DC input

voltage is above or below the limits, call and consult Powerwave before you turn on your

amplifier system.

8. Refer to section 3 for initial turn-on and checkout procedures.

2-5. +26 VDC POWER AND GROUND CONNECTOR P1

The +26 Vdc power and ground connections on the am plifier are made through an 3-pin f emale

D-Sub connector (figure 2-1) and are listed and described in table 2-1.

321

Figure 2-1. +26 Vdc Power and Ground Connector P1

Table 2-1. +26 Vdc Power and Ground Connector P1 Definition

PIN SIGNAL DESCRIPTION

1 +26V +26 Vdc for MCPA

2 +26V_RTN

+26 Vdc return, grounded to MCPA

chassis ground.

3 Chassis Gnd. Chassis Ground

044-xxxxx Rev. x 2-2

2-6. ALARMS AND SENSING CONNECTOR P2

The alarms and sensing connections on the amplifier are made through a 14-pin micro-fit

connector (figure 2-2) and are listed and described in table 2-2.

Figure 2-2. Alarms and Sensing Connector P2

Table 2-2. Alarms and Sensing Connector P2 Definition

PIN SIGNAL DESCRIPTION

1 +5V_AIM

2 +5V_AIM_RTN

3 +26V_ALARM 26V HPCA alarm input

4 +15V_ALARM 15V HPCA alarm input

5 REMOTE_SENSE

6 REMOTE_SENSE_RTN

7 +5V_ALARM 5V HPCA alarm input

8 NC Not connected

9 26ARTN 26V alarm return connected to 26V return on the MCPA

10 ARTN

11 +26V_FAN

12 +26V_FAN_RTN

13 +26V_FAN

14 +26V_FAN_RTN

5-volt supply for the AIM; routed directly to the fan

assembly / AIM connector

5-volt supply return for the AIM; routed directly to the fan

assembly / AIM connector

Remote sense for HPCA; connected directly to 26V

supply

Remote sense return for HPCA; connected directly to 26V

supply return

5V and 15V alarm return connected to 26V return on the

MCPA

26V supply for the fans; routed to fan assembly / AIM

connector

26V supply return for the fans; routed to fan assembly /

AIM connector

26V supply for the fans; routed to fan assembly

/ AIM connector

26V supply return for the fans; routed to fan assembly /

AIM connector

044-xxxxx Rev. x 2-3

2-7. DIFFERENTIAL IIC CLOCK, RECEIVE, AND TRANSMIT CONNECTOR P3

The alarms and sensing connections on the amplifier are made through a 6-pin micro-fit

connector (figure 2-3) and are listed and described in table 2-3.

Figure 2-3. Differential IIC Clock, Receive, and Transmit Connector P3

Table 2-3. Differential IIC Clock, Receive, and Transmit Connector P3 Definition

PIN SIGNAL DESCRIPTION

1 IIC_CLK+ Differential IIC Clock to the DPM

2 IIC_CLK- Differential IIC Clock to the DPM

3 IIC_RX_DATA+ Differential IIC Receive Data (from DPM)

4 IIC_RX_DATA- Differential IIC Receive Data (from DPM)

5 IIC_TX_DATA+ Differential IIC Transmit Data (to DPM)

6 IIC_TX_DATA- Differential IIC Transmit Data (to DPM)

2-8. IIC, POWER, ALARMS, AND CONTROLS CONNECTOR P4

The alarms and sensing connections on the amplifier are made through a 26-pin high density

D-Sub connector (figure 2-4) and are listed and described in table 2-4.

Figure 2-4. IIC, Power, Alarms, and Controls Connector P4

044-xxxxx Rev. x 2-4

Table 2-4. IIC, Power, Alarms, and Controls Connector P4 Definition

PIN SIGNAL DESCRIPTION

1 +26_FAN

2 +26_FAN_RTN

26V supply to the fans; routed from 12-position HPCA

connector

26V supply returnto the fans; routed from 12-position

HPCA connector

Alarm for one of three fans in fan assembly / AIM.

3 FAN_ALARM1

Generated by the fan assembly / AIM and sent to the

MFRM via the MCPA’s RS485 link.

Alarm for one of three fans in fan assembly / AIM.

4 FAN_ALARM2

Generated by the fan assembly / AIM and sent to the

MFRM via the MCPA’s RS485 link.

Alarm for one of three fans in fan assembly / AIM.

5 FAN_ALARM3

Generated by the fan assembly / AIM and sent to the

MFRM via the MCPA’s RS485 link.

Analog voltage signal that is generated from either an

6 AUX_ALARM+

external power combiner or an intrusion alarm

mechanism, passed to the MFRM through the RS485.

Analog voltage signal that is generated from either an

7 AUX_ALARM-

external power combiner or an intrusion alarm

mechanism, passed to the MFRM through the RS485.

Contact closure switch on the MCPA but controlled by the

8 AUX_CTRL1

MFRM software. Default status is OPEN upon power up

and CLOSED on power down conditions.

Contact closure switch on the MCPA but controlled by the

9 AUX_CTRL2

MFRM software. Default status is OPEN upon power up

and CLOSED on power down conditions.

10 +5V_AIM_RTN

11 +5V_AIM

5V supply return for the AIM. Comes from the HPCA via

connector P2 and routed through MCPA.

55VV ssuuppppllyy ffoorr tthhee AAIIMM.. CCoommeess ffrroomm tthhee HHPPCCAA vviia

ccoonnnneeccttoorr PP22 aanndd rroouutteedd tthhrroouugghh MMCCPPA

A

a

12 IIC_CLK+ Differential IIC clock to the fan assembly / AIM

13 IIC_CLK- Differential IIC clock to the fan assembly / AIM

14 IIC_RX_DATA+ Differential IIC receive data (from fan assembly / AIM)

15 IIC_RX_DATA- Differential IIC receive data (from fan assembly / AIM)

16 IIC_TX_DATA+ Differential IIC transmit data (to fan assembly / AIM)

17 IIC_TX_DATA- Differential IIC transmit data (to fan assembly / AIM)

18 FORCE_ON+

19 FORCE_ON-

Routed directly from MTRM connector; turns on LEDs (in

the AIM) during power-up sequence.

Routed directly from MTRM connector; turns on LEDs (in

the AIM) during power-up sequence.

20 +26V_FAN 26V supply for the fans from (HPCA) connector P2

21 +26V_FAN_RTN 26V supply return for the fans from (HPCA) connector P2

22-26 NC Not connected

044-xxxxx Rev. x 2-5

2-9. IIC, RS485, POWER, AND OTHER SIGNALS CONNECTOR P5

The alarms and sensing connections on the amplifier are made through a 18-pin micro-fit

connector (figure 2-5) and are listed and described in table 2-5.

Figure 2-5. IIC, RS485, Power, and Other Signals Connector P5

Table 2-5. IIC, RS485, Power, and Other Signals Connector P5 Definition

PIN SIGNAL DESCRIPTION

Turns on LEDs (in the AIM) during power up sequence;

1 FORCE_ON+

routed directly from MTRM connector to fan assembly /

AIM connector

Turns on LEDs (in the AIM) during power up sequence;

2 FORCE_ON-

routed directly from MTRM connector to fan assembly /

AIM connector

Enables MCPA when high. Requires enable command

3 +ALLOW_HPA_ENABLE

via RS485 and HW_ENABLE high impedance to ground

and no shutdown conditions exist.

Enables MCPA when high. Requires enable command

4 -ALLOW_HPA_ENABLE

via RS485 and HW_ENABLE high impedance to ground

and no shutdown conditions exist.

5 MCPA_TX+ Differential RS485 link to MTRM

6 MCPA_TX- Differential RS485 link to MTRM

7 MCPA_RX+ Differential RS485 link from MTRM

8 MCPA_RX- Differential RS485 link from MTRM

9 IIC_CLK+ Differential IIC clock from MTRM

10 IIC_CLK11 IIC_RX_DATA+

12 IIC_RX_DATA13 IIC_TX_DATA+

14 IIC_TX_DATA-

15 +5V_DC_IN

16 +5V_DC_RTN

DDiiffffeerreennttiiaall IIIICC cclloocckk ffrroomm MMTTRRM

DDiiffffeerreennttiiaall IIIICC rreecceeiivvee ddaattaa ((ffrroomm MMTTRRMM)

DDiiffffeerreennttiiaall IIIICC rreecceeiivvee ddaattaa ((ffrroomm MMTTRRMM)

DDiiffffeerreennttiiaall IIIICC ttrraannssmmiitt ddaattaa ((ttoo MMTTRRMM)

DDiiffffeerreennttiiaall IIIICC ttrraannssmmiitt ddaattaa ((ttoo MMTTRRMM)

+5V supply voltage for the IIC circuit on MCPA; not used

in any other circuits.

+5V supply voltage return for the IIC circuit on MCPA; not

used in any other circuits.

M

)

)

)

)

Cable detect line connected to GPI/O port of MTRM

17 CABLE_DETECT

microprocessor. Pulled high via +5V_DC_IN; connected

to reset pin on microcontroller to allow MTRM reset if

necessary.

18 HW_ENABLE

Hardware enable signal. MCPA enabled when shorted to

chassis ground.

044-xxxxx Rev. x 2-6

Section

OPERATING INSTRUCTIONS

3

3-1. INTRODUCTION

This section contains operating instructions for the Multicarrier Cellular Amplifier.

3-2. INITIAL START-UP AND OPERATING PROCEDURES

There are no operating controls or indicators on the NTGY81AC amplifier module. To perform the

initial start-up, proceed as follows:

1. Double check to ensure that all input and output cables are properly connected.

CAUTION

Before applying power, make sure that the input and output of the

amplifier are properly term inated at 50 ohms. Do not operate the

amplifier without a load attached. Refer to table 1-1 for input power

requirements. Excessive input power may damage the amplifier

NOTE

The output coaxial cable between the amplifier and the antenna must

be 50 ohm coaxial cable. Use of any other cable will distort the output.

2. Turn on supply that provides +26 Vdc to the amplifier system.

3. Turn on external exciter/transceiver and apply RF input signals.

044-xxxxx Rev. x 3-1

Section

4

PRINCIPLES OF OPERATION

4-1. INTRODUCTION

This section contains a functional description of the multichannel power amplifier (MCPA).

4-2. RF INPUT SIGNAL

The maximum input power should not exceed the limits specified in table 1-1.

4-3. RF OUTPUT LOAD

The load impedance should be as good as possible (1.5:1 or better) in the working band f or good

power transfer to the load.

4-4. AMPLIFIER FUNCTIONAL DESCRIPTION

The NTGY81AC amplifier (figures 1-1 and 4-1) is a linear, multichannel power amplifier that

operates in the 60 MHz frequency band from 1930 MHz to 1990 MHz at an output power of 50

watts. Each amplifier is a self-contained module and is functionally independent of any other

amplifier modules in the system . Each amplifier module has an alarm board that m onitors the

amplifier perfor mance. If a failure or f ault occurs in an amplifier m odule, it is transm itted to the

host system via an RS485 interface.

The amplifier is com pliant to the requirem ents of FCC Part 24 with respect to spurious em issions

(see table 1-1). Constant gain is m aintained by continuously compar ing ac tive paths with pass ive

references, and correcting for small variations through the RF feedback controls. All gain

variations, for example thos e due to temperature, are reduced to the passive referenc e variations .

The amplifier module is comprised of:

An input amplifier

A predistortion amplifier

A driver amplifier

A main amplifier

A multifunction board

4-4.1. INPUT AMPLIFIER

RF is fed to the input amplifier, which consists of an isolator at the input, bandpass filter, VVAs,

and phase shifters for gain control and phase sweeping functions. They are controlled by a

microprocessor on the multifunction board. At its output, the input amplifier splits the signal to the

predistortion amplifier and carrier cancellation circuits.

4-4.2. PREDISTORTION AMPLIFIER

The predistortion amplifier predistorts the input signal in a way that it linearizes the output of the

main amp at 50 watts. It also contains the main loop VVAs and phase shifters. All the predistortion

voltages and loop voltages are controlled by a microprocessor.

044-xxxxx Rev. x 4-1

4-4.3. DRIVER AMPLIFIER

The driver amplifier consis ts of two stages of c lass AB amplific ation which provide approximately

40 dB of gain in the 60 MHz frequency band from 1930 MHz to 1990 MHz. The amplifier operates

on +26 Vdc, and a safe bias voltage which is controlled by microprocessors.

4-4.4. MAIN AMPLIFIER

The main am plifier em ploys two class AB amplif ication s tages f or m ax im um eff iciency. It pr ovides

approximately 25 dB of gain in the 60 MHz frequency band. The output from the m ain am plif ier is

typically 48.6 dBm. The amplifier operates on +26 Vdc, and gate bias voltages controlled by

microprocessors.

4-4.5. MULTIFUNCTION BOARD

The multifunction board consists of control and alarm circuits. The MCPA communicates to the

host system through the multifunction board which gathers the status information of the amplifier

and reports to the host system via the RS485 interface when instructed. It also protects the MCPA

from adverse conditions such as overpower, input overdrive, overvoltage, etc. A microprocessor

on the multifunction board also controls two loops in the feed-forward system.

RF

IN

INPUT

AMPLIFIER

PREDISTORTION

AMPLIFIER

MULTIFUNCTION BOARD

(ALARMS AND LOOP CONTROLS)

DRIVER

AMPLIFIER

MAIN

AMPLIFIER

OUT

Figure 4-1. NTGY81AC Multichannel Power Amplifier Functional Block Diagram

4-5. AMPLIFIER MODULE COOLING

Each amplifier m odule is contained within a thermally conductive chassis which, when properly

mounted on an adequate thermal surface, will provide sufficient c ooling to maintain the amplifier

within the specified operating temperature range.

4-6. POWER DISTRIBUTION

Primary DC power for the amplifier is provided by the host system. The amplifier generates all the

required voltages internally from the main source.

RF

044-xxxxx Rev. x 4-2

Section

5

MAINTENANCE

5-1. INTRODUCTION

This section contains per iodic maintenance and performance test pr ocedur es f or the multichannel

power amplifier. It also contains a list of test equipment required to perform the identified tasks.

NOTE

Check your sales order and equipment warranty

before attempting to service or repair the unit. Do

not break the seals on equipm ent under warranty or

the warranty will be null and void. Do not return

equipment for warranty or repair service until proper

shipping instructions are received from the factory.

5-2. PERIODIC MAINTENANCE

Periodic maintenance requirem ents are listed in Table 5-1. Table 5-1 also lists the inter vals at

which the tasks should be performed.

Table 5-1. Periodic Maintenance

TASK INTERVAL ACTION

Inspection

Cables and

Connectors

Performance Tests

5-3. TEST EQUIPMENT REQUIRED FOR TEST

Test equipment required to test the amplifier is listed in Table 5-2. Equivalent test equipment may

be substituted for any item, keeping in mind that a thermistor type power meter is required.

All RF test equipment must be calibrated to 0.05

dB resolution. Any deviation from the nominal

attenuation must be accounted for and f actored

into all output readings.

12 Months Inspect signal and power cables for

frayed insulation. Check RF connectors

to be sure that they are tight.

12 Months Perform annual test per paragraph 5-5.

NOTE

044-xxxxx Rev. x 5-1

Table 5-2. Test Equipment Required

MENCLATURE MANUFACTURER MODEL

Signal Generator Agilent (H.P.) ESG4433B

30 dB Attenuator, 250 Watt Tenuline

Spectrum Analyzer H.P. 8562E

Coax Directional Coupler H.P. 778D

Power Meter / Sensor H.P. 437B / 8481A

Network Analyzer H.P. 8753D

Current Probe

Source Diskette Powerwave

Driver PA (1930-1990 MHz) 12 dB gain, P

= 29 dBm (min)

1dB

5-4. PERFORMANCE TEST

Performance testing should be conducted every 12 months to ensure that the amplifier system

meets the operational specif ications listed in table 5-3. Also verify system perf ormanc e after any

amplifier m odule is replaced in the field. The test equipment required to perform the testing is

listed in table 5-2, and the test setup is shown in figure 5-1.

5-4.1. AMPLIFIER PERFORMANCE TEST.

To perform the test, proceed as follows:

1. Connect test equipment as shown in figure 5-1.

NOTE

Do not apply any RF signals at this time.

AMPLIFIER SPURIOUS EMISSIONS TEST:

2. Load the MFRM waveform on the ESG (signal generator). Apply this signal through a

driver amplifier to the MCPA so that the RF signal going into the MCPA is approximately 0

dBm (adjust the input RF signal level to get 47 dBm output power). Measure spurious

emissions. Verify that it is within specification.

GAIN TEST:

3. Set input power level to power amplifier at 0 dBm (1932, 1960, and 1987 MHz).

4. Measure the output power in dBm.

5. Subtract input power (in dBm) from output power (in dBm) to get gain.

6. Check the amplifier gain across the band from 1930 MHz to 1990 MHz. Gain s hould be

47 ±2 dB. Record test data in table 5-3.

INPUT RETURN LOSS TEST:

7. Read and record the S

return loss measurement on network analyzer. Record test data

11

in table 5-3.

044-xxxxx Rev. x 5-2

Figure 5-1. NTGY81AC Amplifier Test Setup Diagram

044-xxxxx Rev. x 5-3

Table 5-3. Multichannel Power Amplifier NTGY81AC Test Data Sheet

Tested By: ___________________ Serial No: ________________

Pass/Fail: ____________________ Date: ____________________

50W MCPA Test

Test Conditions: Load and source impedance: 50 ohms, VSWR < 1.2:1

Supply voltage: +26 Vdc ±±±± 0.4 Vdc (unless otherwise noted).

Network Analyzer Span: 60 MHz

Marker #1 = 1930 MHz, #2 = 1960 MHz, #3 = 1990 MHz

TEST

1.00 NETWORK ANALYZER 1930 1960 1990

1.01 Gain

1.02 Gain Flatness

1.03 I nput Return Loss, worst case In band

1.04 Output Return Loss, worst case in band

2.00 CDMA TESTS (Spurious Emissions)

3 TONE: W-CDMA @ 50W out

RBW= 3KHz; VBW=10KHz

2.01

2.02

2.03 2nd Harmonic

2.04 Pilot

CONDITION MIN MAX FREQUENCY (MHz)

45.0 dB 49.0 dB

0 dB

∆ @ +2.25 Mhz

∆ @ –2.25 Mhz

0.4 dB/

1.25 MHz

-10 dB

-15 dB

-16 dBm/

1 MHz

-16 dBm/

1 MHz

3860 3920 3980

-16 dBm/

1 MHz

1925 1945 1965

16 dBm/

1 MHz

2.05 Current @ 50 W out

044-xxxxx Rev. x 5-4

19 A

5-5. FIELD REPLACEMENT OF THE MODULE

The NTGY81AC multichannel power am plifier module can be replaced in the field on site by a

qualified technician with adequate ESD protection and experience maintaining RF power

amplifiers and similar equipment.

To replace a power amplifier module, proceed as follows:

1. Turn off 26 Vdc power to that specific module.

2. Disconnect the two RF cables and connectors P1 through P5.

3. Remove 13 screws that secure amplifier module to heat sink.

4. Carefully remove amplifier module from heat sink.

5. Add Thermstrate ther mal interface pad to surface of replacement amplifier which

mates with heatsink.

6. Install replacement in reverse order of steps 1 through 4 above.

044-xxxxx Rev. x 5-5

Section

6

TROUBLESHOOTING

6-1 INTRODUCTION

This section contains a list of problems which users have encountered and a few suggested

actions that may correct the problem . If the suggested corrective action does not elim inate the

problem, please contact your Powerwave field representative or the factory for further instructions.

NOTE

Check your sales order and equipment warranty

before attempting to service or repair the unit. Do

not break the seals on equipm ent under warranty or

the warranty will be null and void. Do not return

equipment for warranty or repair service until proper

shipping instructions are received from the factory.

6-2 TROUBLESHOOTING

Refer to table 6-1 for troubleshooting suggestions.

Table 6-1. Troubleshooting.

SYMPTOM SUGGESTED ACTION

MCPA Inoperative 1. Check for proper power supply voltage.

MCPA Not Enabled 1. Verify HPA-Allow-Enable line is high.

Alarm Output is (RS 422) High Verify input RF is within specified power and frequency limits

6-3 RETURN FOR SERVICE PROCEDURES

When returning products to Powerwave, the following procedures will ensure optimum response.

6-3.1 Obtaining an RMA

A Return Material Authorization (RMA) number must be obtained prior to returning

equipment to the factory for service. Please contact our Repair Department at (888) 7979283 or (714) 466-1000 to obtain this number, or FAX your request to (714) 466-5816.

Failure to obtain this RMA number may result in delays in receiving repair service.

6-3.2 Repackaging for Shipment

To ensure safe shipment of the amplifier, it is recommended that the package designed

for the amplifier be used. The original packaging material is reusable. If it is not

available, contact Powerwave’s Customer Service Department for packing materials and

information.

044-xxxxx Rev. x 6-1

Loading...

Loading...