869-894 MHz

G3S-800-180-29

Installation & Service Manual

Multi-Carrier Power Amplifier

869 – 894 MHz

180 Watts Average Power (210 W Max.)

-60 dBc Intermodulation Distortion

044-05112 Rev. A April 2002

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

G3S-800-180-029 Installation & Service Manual

© 2002 Powerwave Technologies Incorporated. All rights reserved.

Powerwave Technologies, and the Powerwave logo are registered trademarks

Powerwave Technologies, Inc. reserves the right to make changes to the documentation and

equipment, including but not limited to component substitution and circuitry changes. Changes

that impact this manual may subsequently be incorporated in a later revision of this manual.

April 2002

Powerwave Technologies, Inc. Tel: (714) 466-1000

1801 East St. Andrew Place (888) 797-9283

Santa Ana, CA 92705 Fax: (714) 466-5800

Web Site: www.powerwave.com

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A ii April 2002

G3S-800-180-029 Installation & Service Manual

Table Of Contents

Par. Section 1 Page

No.

1-1 Introduction.......................................................................................................................................................... 1-1

1-2 General Description.......................................................................................................................................... 1-1

1-3 Functional And Physical Specifications .......................................................................................................1-1

1-4 Equipment Changes............................................................................................................................................ 1-1

1-5 Ordering Information.......................................................................................................................................... 1-2

2-1 Introduction.......................................................................................................................................................... 2-1

2-2 Electrical Service Recommendations............................................................................................................2-1

2-3 Air Conditioning.................................................................................................................................................. 2-2

2-4 Unpacking and Inspection................................................................................................................................ 2-2

2-5 Installation Instructions....................................................................................................................................2-3

2-6 Amplifier Module Connectors.......................................................................................................................... 2-4

2-6.1 Amplifier Module Status, Alarm, Control, and Power Connector............................................................ 2-4

2-6.2 Amplifier Module RF Connector......................................................................................................................2-5

General Description No.

Section 2

Installation

Section 3

Operating Instructions

3-1 Introduction.......................................................................................................................................................... 3-1

3-2 Location and Function of Amplifier Module Controls and Indicators..................................................... 3-1

3-2.1 Voltage Indicators and On/Off /Reset Switch...............................................................................................3-1

3-2.1.1 On Off Switch....................................................................................................................................................... 3-1

3-2.1.2 RF On Switch....................................................................................................................................................... 3-1

3-2.1.3 +27VDC Indicator................................................................................................................................................ 3-2

3-2.1.4 +15VDC Indicator................................................................................................................................................ 3-2

3-2.1.5 +5VDC Indicator.................................................................................................................................................. 3-2

3-2.1.6 -5VDC Indicator................................................................................................................................................... 3-2

3-2.2 Alarm Indicators................................................................................................................................................. 3-2

3-3 Initial Start-Up and Operating Procedures ...................................................................................................3-4

Section 4

Principles of Operation

4-1 Introduction.......................................................................................................................................................... 4-1

4-2 RF Input Signal.................................................................................................................................................... 4-1

4-3 RF Output Load..................................................................................................................................................... 4-1

4-4 G3S-800-180-029 Amplifier Module................................................................................................................4-1

4-4.1 Main Amplifier.................................................................................................................................................... 4-2

4-4.2 Error Amplifier.....................................................................................................................................................4-2

4-4.3 Amplifier Monitoring......................................................................................................................................... 4-2

4-4.4 Amplifier Module Cooling ................................................................................................................................4-3

4-5 Power Distribution............................................................................................................................................. 4-3

4-6 Intermodulation................................................................................................................................................... 4-3

4-7 Alarms................................................................................................................................................................... 4-3

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A iii April 2002

G3S-800-180-029 Installation & Service Manual

Section 5

Maintenance

5-1 Introduction.......................................................................................................................................................... 5-1

5-2 Periodic Maintenance....................................................................................................................................... 5-1

5-3 Test Equipment Required For Test ..................................................................................................................5-1

5-4 Clean Air Inlets/Outlets.....................................................................................................................................5-2

5-5 Performance Test ...............................................................................................................................................5-2

5-5.1 Amplifier System Performance Test............................................................................................................... 5-2

5-5.1.1 Amplifier IMD Test..............................................................................................................................................5.3

5-5.1.2 Gain Test...............................................................................................................................................................5-3

5-5.1.3 Harmonic Test ..................................................................................................................................................... 5-3

5-5.1.4 Spurious Emissions Test................................................................................................................................... 5-4

5-5.1.5 Input Return Loss................................................................................................................................................ 5-4

5-6 Field Replacement Parts and Modules.......................................................................................................... 5-5

5-6.1 G3S-800-180-029 Power Amplifier Module................................................................................................... 5-5

5-6.2 Cooling Fans ........................................................................................................................................................5-6

Section 6

Troubleshooting

6-1 Introduction.......................................................................................................................................................... 6-1

6-2

Troubleshooting..................................................................................................................................................6-1

6-2.1

DC Voltage Indicators Not Illuminated.......................................................................................................... 6-1

6-2.2

OVER PWR Illuminated or Blinking................................................................................................................ 6-1

6-2.3

HIGH TEMP Illuminated ....................................................................................................................................6-2

6-2.4

VSWR Illuminated .............................................................................................................................................. 6-2

6-2.5

DC FAIL Illuminated............................................................................................................................................ 6-3

6-2.6

FAN FAIL Illuminated......................................................................................................................................... 6-3

6-2.7

LOOP FAIL Illuminated....................................................................................................................................... 6-3

6-2.8

LOW PWR Illuminated....................................................................................................................................... 6-3

6-2.9

LPA DISABLE Illumunated................................................................................................................................ 6-3

6-3

Return for Service Procedures ........................................................................................................................6-4

6-3.1

Obtaining an RMA ..............................................................................................................................................6-4

6-3.2

Repackaging for Shipment............................................................................................................................... 6-4

List of Illustrations

Figure

No.

1-1 G3S-800-180-029 Front and Side View ........................................................................................................... 1-3

2-1 G3S-800-180-029 Rear View ............................................................................................................................. 2-4

2-2 DC and Logic Connector.................................................................................................................................... 2-4

2-3 Amplifier RF Connector..................................................................................................................................... 2-5

3-1 G3S-800-180-029 Amplifier Module RF Control Indicators........................................................................ 3-1

4-1 G3S-800-180-029 Power Amplifier Module Functional Block Diagram .................................................4-2

5-1 Amplifier System Test Setup Diagram........................................................................................................... 5-3

5-2 Amplifier Spring Clip Location ........................................................................................................................ 5-5

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A iv April 2002

G3S-800-180-029 Installation & Service Manual

List Of Tables

Table

No.

1-1 Major Amplifier Components........................................................................................................................... 1-2

1-2 G3S-800-180-029 MCPA Functional Specifications ....................................................................................1-2

2-1 Sample of DC Cable Ratings.............................................................................................................................2-1

2-2 Averaged DC Current Load ............................................................................................................................... 2-2

2-3 Averaged Heat Loading..................................................................................................................................... 2-3

2-4 Amplifier Module DC and Logic Connector Definition............................................................................... 2-5

2-5 Amplifier RF Connector Definition.................................................................................................................. 2-4

3-2 Amplifier Module Alarm Indicators Definition ............................................................................................3-3

5-1 Periodic Maintenance....................................................................................................................................... 5-1

5-2 Test Equipment Required..................................................................................................................................5-2

5-3 MCPA Test Data Sheet...................................................................................................................................... 5-5

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A v April 2002

G3S-800-180-029 Installation & Service Manual

Section 1 General Description

1-1 Introduction

This manual contains information and procedures for installation, operation, and maintenance of

Powerwave’s G3S-800-180-029 multicarrier cellular amplifier. The manual is organized into six

sections as follows:

Section 1. General Description

Section 2. Installation

Section 3. Operating Instructions

Section 4. Principles of Operation

Section 5. Maintenance

Section 6. Troubleshooting

1-2 General Description

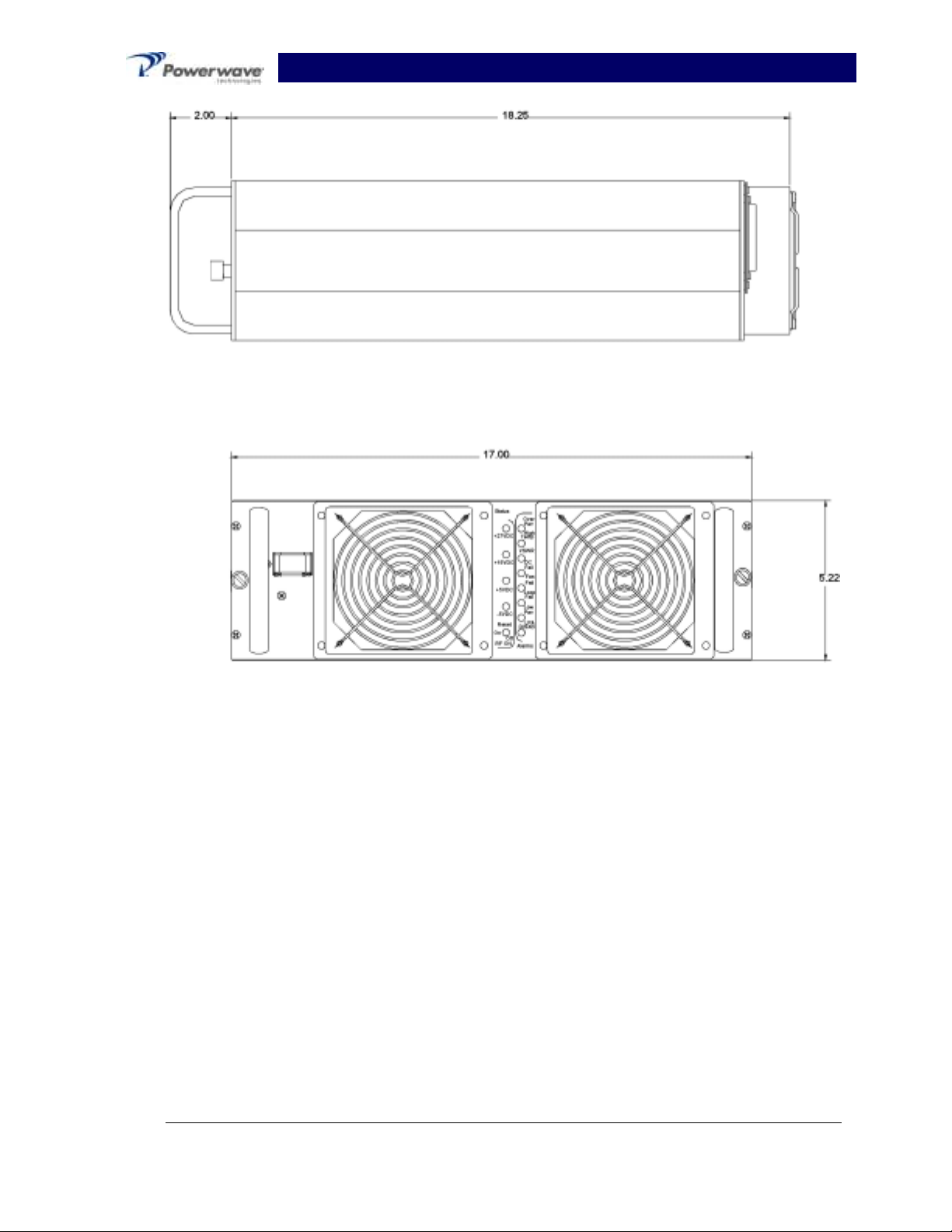

The G3S-800-180-029 (see figure 1-1) is a linear, feed-forward power amplifier that operates in

the 25 MHz frequency band from 869 MHz to 894 MHz. The amplifier can simultaneously transmit

multiple frequencies, with better than -60 dBc third order intermodulation distortion (IMD). It is designed for use in an amplifier system that is modular in design, and is ideally suited for use in

AMPS/TDMA/CDMA/CDPD/W-CDMA base stations. The plug-in Model G3S-800-180-029 amplifier modules can each provide 180 watts of power nominally (210 W max.) and function completely independently of each other. The amplifier modules are designed for parallel operation to

produce high peak power output and system redundancy for remote applications, when installed

in multi-module amplifier subracks manufactured by Powerwave. All solid-state, the system is designed to provide trouble-free operation with minimum maintenance. The system's modular construction and unique and highly effective LED-based operational status and fault indicators help

minimize downtime. The turn-on and turn-off sequences of voltages are fully automatic, as is

overload protection and recycling. Inadvertent operator damage from front panel manipulation is

virtually impossible.

The amplifier module has a status connector that allows the host system to monitor the amplifier

module’s status. The front panel of each amplifier module has unit level status/fault indicators and

an RF on/off/reset switch. Primary power for the amplifier is +27 Vdc. Cooling for each plug-in

amplifier module is provided by four fans, two mounted on the front and two on the rear of the

module. The fans draw outside air through the front of the module and exhaust hot air out

through the rear of the module.

1-3 Functional And Physical Specifications

Functional and physical specifications for the amplifier are listed in table 1-2.

1-4 Equipment Changes

Powerwave Technologies, Inc. reserves the right to make minor changes to the equipment, including but not necessarily limited to component substitution and circuitry changes. Changes that

impact this manual may subsequently be incorporated in a later revision of this manual.

All specificat i ons are subject to change without noti ce. Contact the fact ory for complete perform ance data.

044-05112 Rev. A

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

1-1 April 2002

G3S-800-180-029 Installation & Service Manual

1-5 Ordering Information

Table 1-1 following gives the part numbers and descriptions to be used when ordering either an

entire amplifier or replacement fans.

Table 1-1 Major Amplifier Components

Model Number Description

G3S-800-180-029 180 W 869-894 MHz MCPA Module

800-01075-003 Front fan assembly

800-00972-002 Rear fan assembly.

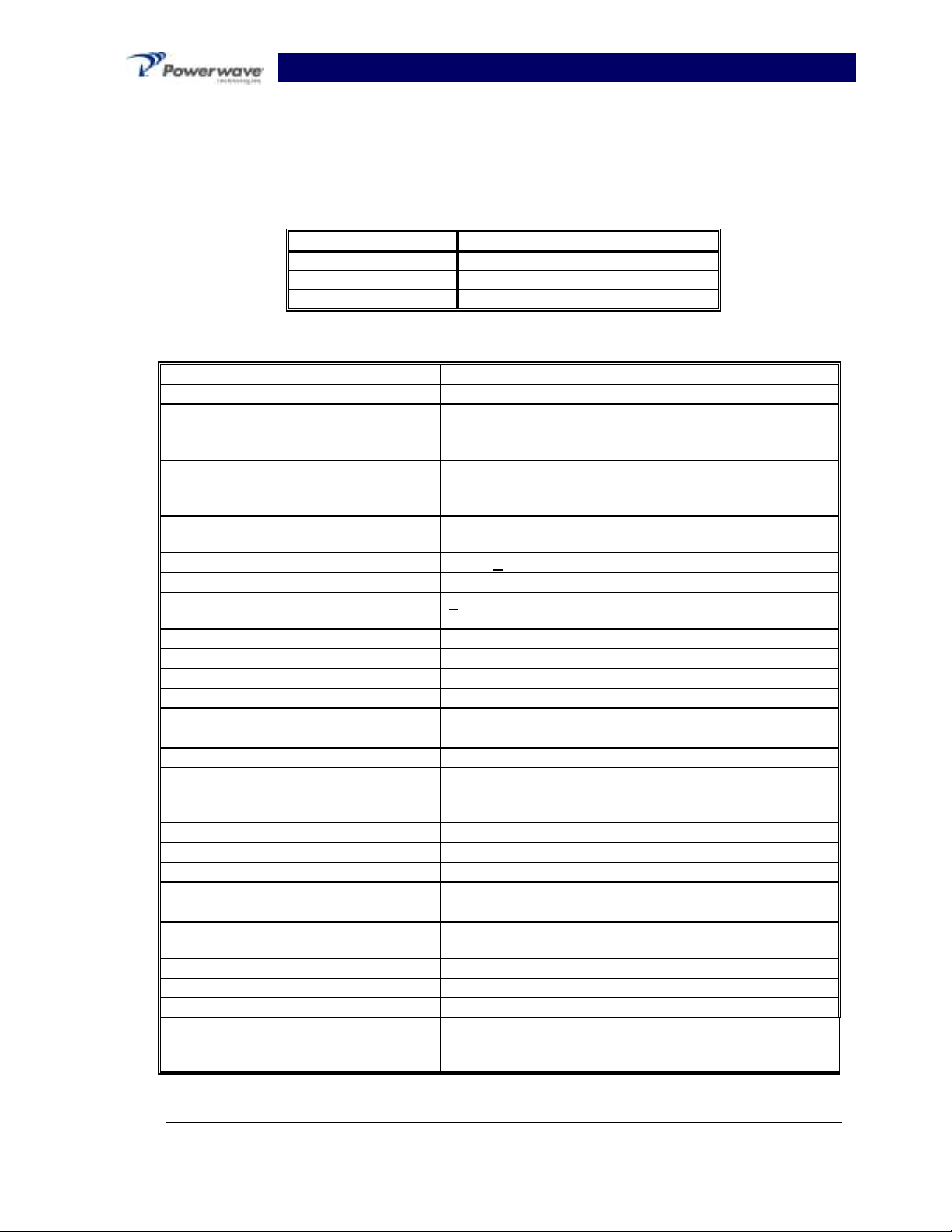

Table 1-2 G3S-800-180-029 Multicarrier Cellular Amplifier Functional Specifications

Frequency Range 869-894 MHz (25 MHz Bandwidth)

Instantaneous Bandwidth 25 MHz

Total Typical / Maximum Input Power -5.44 / -5.0 dBm

Total Output Power 180 W (52.55 dBm) Nominal, 210 W (53.22 dBm) Max.

(1 Module)

IMD and In-band Spurious, mean

measurement, 30 KHz bandwidth@

+26 to +28Vdc, 25°C

Out of Band Spurious & Noise,

measured in 30 KHz BW

RF Gain 58 dB +0.5 dB

Gain Flatness:

Gain Variation w/ Voltage and

Frequency

Gain Variation Over Temperature:

Noise Figure 28 dB max

Output Protection: Mismatch Protected

Input Port Return Loss: 16 dB min

Harmonics: Better than -50 dBc

Out of Band Spurious: Better than -60 dBc

Duty Cycle: Continuous

DC Input Power:

DC Circuit Breaker Rating 100 Amps

Operating Temperature: 0 ºC to +40 ºC

Storage Temperature: -40 ºC to +85 ºC

Operating Humidity: 0 % to 80 % Relative Humidity (noncondensing)

Storage Humidity: 0 % to 100 % Relative Humidity (noncondensing)

DC Input, Summary Alarm, and RF

Input / Output Connectors:

Heat Generation 4852 BTUs @ 26 VDC, Po = 180 W (1 Amplifier)

Weight 50 lbs.

Dimensions: 5.20” High, 17.00” Wide, 20.00” Deep

Electrical Service Recommendations

Circuit Breakers

-60 dBc or -16 dBm max @ up to 16 equal power CW

tones with a combined maximum power of P

max single carrier power of P

/16.

0

with a

0

-60 dBc max @ +26 to +28 Vdc

±0.5 dB @ 27 Vdc ±1 Vdc

+ 0.5 dB; 26 to 28 Vdc

±0.5 dB

+27 Vdc ±1 Vdc, 62 amps typical (70 amps max)

Operational +21.7 Vdc to 30 Vdc (Po derated outside

normal operating range)

21-Pin D-Subminiature Combo Connector plus single-

pin D-Sub connector for additional DC capability.

Capable of handling anticipated inrush current (nor-

mally 25% over equipment maximum current draw), in

a load center with a master switch.

All specificat i ons are subject to change without noti ce. Contact the fact ory for complete perform ance data.

044-05112 Rev. A

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

1-2 April 2002

G3S-800-180-029 Installation & Service Manual

Figure 1-1 G3S-800-180-029

All specificat i ons are subject to change without noti ce. Contact the fact ory for complete perform ance data.

044-05112 Rev. A

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

1-3 April 2002

G3S-800-180-029 Installation & Service Manual

Section 2 Installation

2-1 Introduction

This section contains installation recommendations, unpacking, inspection, and installation instructions for the Multicarrier Cellular Amplifier. Carefully read all material in this section prior to

equipment unpacking or installation. Also read and review the operating procedures in Section 3

prior to installing the equipment. It is important that the licensee perform these tasks correctly and

in good faith. If applicable, carefully review the Federal Communications Commission (FCC) rules

as they apply to your installation. DON'T TAKE CHANCES WITH YOUR LICENSE.

2-2 Electrical Service Recommendations

Powerwave Technologies recommends that proper AC line conditioning and surge suppression

be provided on the primary AC input to the +27 Vdc power source. All electrical service should be

installed in accordance with the National Electrical Code, any applicable state or local codes, and

good engineering practice. Special consideration should be given to lightning protection of all

systems in view of the vulnerability of most transmitter sites to lightning. Lightning arrestors are

recommended in the service entrance. Straight, short ground runs are recommended. The electrical service must be well grounded.

Each amplifier system should have its own circuit breaker, so a failure in one does not shut off the

whole installation. Circuit breakers should be capable of handling the anticipated inrush current, in

a load center with a master switch. Powerwave recommends that a 100 amp circuit breaker be

installed in the power distribution unit for each amplifier. DC wire smaller than 2 AWG 90°C copper DC should not be installed. Each amplifier should have its own DC cable pair. See table 2-1.

CAUTION

This table and the foregoing are provided as guidelines. Follow the appropriate NEC

standards in your area and the cable manufacturer’s recommendation for proper cable

selection.

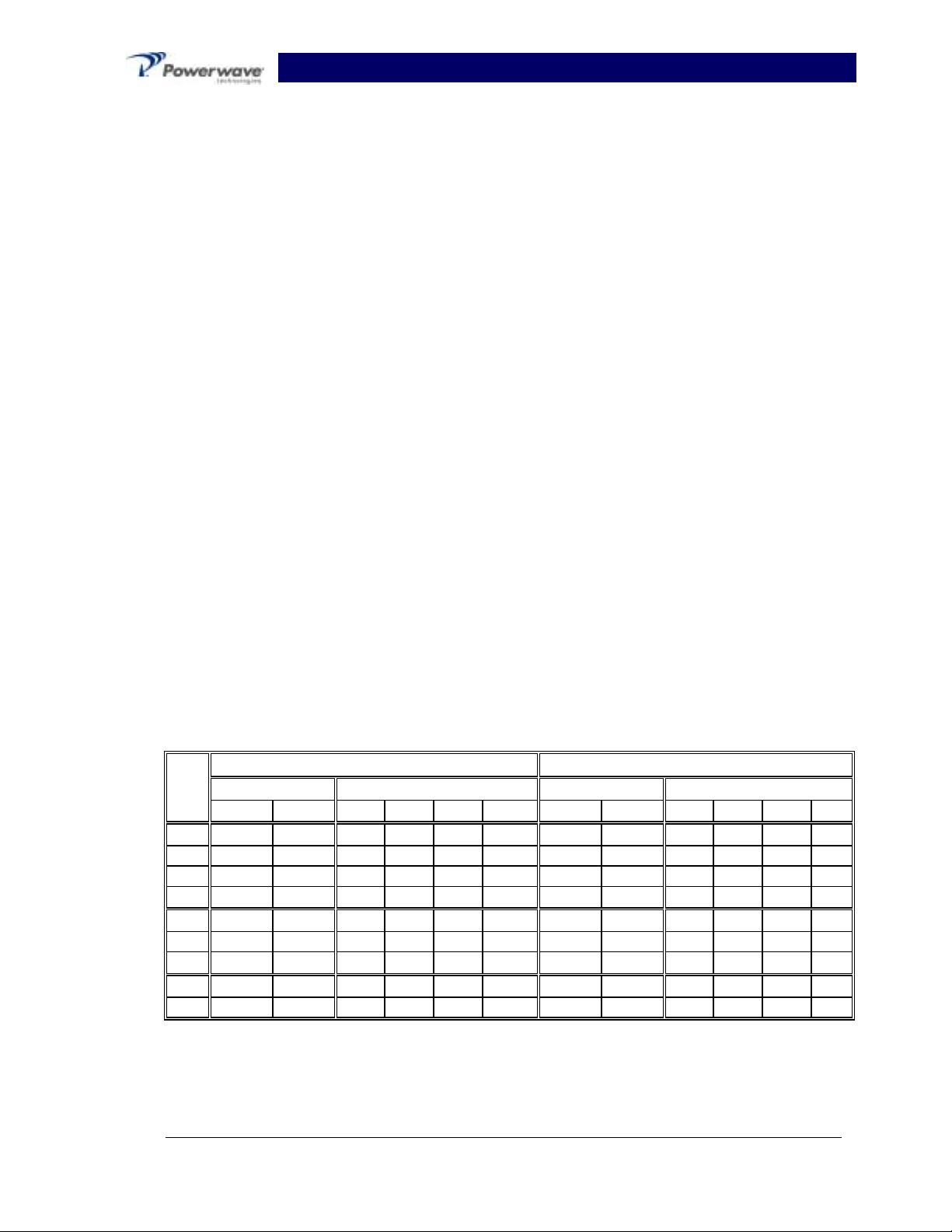

Table 2-1 Sample of DC Cable Ratings

AWG Copper Aluminum

or 3 Cond. In Raceway Single Conductor In Free Air 3 Cond. In Raceway Single Conductor In Free Air

MCM

14 25 30 30 40 40 45 -- -- -- -- -- -12 30 35 40 50 50 55 25 25 30 40 40 45

10 40 45 55 65 70 75 30 35 45 50 55 60

Based on ambient temperature of 30°C (86°F) 100% Load Factor

Source: Industrial Electric Wire & Cable Inc., Technical Guide Vol. 4M 11/ 99, Table III Suggested Ampacities - All Types

of Insulations; B ased on National Electric Code

90°C 110°C90°C 110°C 125°C 200°C90°C 110°C90°C 110°C 125°C 200°C

8 55 60 75 85 90 100 40 45 55 65 70 80

6 70 80 100 120 125 135 55 60 80 95 100 105

4 95 105 135 160 170 180 75 80 105 125 135 140

2 125 135 185 210 225 240 100 105 140 165 175 185

1 145 160 215 245 265 280 110 125 165 190 205 220

0 165 190 250 285 305 325 130 150 190 220 240 255

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 2-1 April 2002

G3S-800-180-029 Installation & Service Manual

According to the laws of probability used to formulate Erlang tables, rarely are all channels transmitting at the same time. We can use Erlang tables to predict typical maximum current usage.

Table 2-2 describes the current load for a 3 sector (70%), 2 sector (80%) and omni (90%) site.

Based on this table, an 800 amp power plant may suffice.

Battery backup or UPS systems should be installed in remote sites or in sites which experience

brownout conditions or generator switchovers. Adding this equipment should eliminate the need

for site visits by technicians after brownouts or power outages. Battery backup systems also provide excellent DC filtering as a side benefit.

Table 2-2 Averaged DC Current Load (Amperes)

(typical, based on % of output power)

Amplifier

Power

180 9

180 6

180 3

180 1

No. Of

Amplifiers

3 Sector (70%)

Averaged Current

484 554

323 334 370

161 167 176 185

54 56 59 62

2 Sector (80%)

Averaged Current

1 Sector (90%)

Averaged Current

100%

Typical

2-3 Air Conditioning

Each G3S-800-180-029 amplifier generates 4852 BTUs of heat at full power. A fully populated

MCR30829-1-3

sector site employing three fully populated MCR30829-1-3 subracks will generate 52,510 BTUs of

heat at full power (500W per subrack, 70A, 27VDC). A five-ton air conditioner is needed to cool

this Powerwave equipment. A full three-sector site probably needs at least a five-ton air conditioner to cool all of the site's equipment, based on heat load averaging as described in table 2-2.

In keeping with section 2-3, table 2-3 describes the heat load for a 3 sector (70%), 2 sector (80%)

and omni (90%) site. Perform a site survey to determine actual air conditioning needs.

Amplifier

Power

180 9

180 6

180 3

180 1

subrack operating at full power will generate 14,556 BTUs of heat. A full three-

Table 2-3 Averaged Heat Loading (British Thermal Units/hr)

(typical, based on % of output power)

No. Of

Amplifiers

3 Sector (70%)

Averaged BTU's

38,973 43,666

25,982 26,735 29,111

12,991 13,368 13,961 14,555

4,330 4,456 4,654 4852

2 Sector (80%)

Averaged BTU's

1 Sector (90%)

Averaged BTU's

100%

Typical

2-4 Unpacking And Inspection

This equipment has been operated, tested and calibrated at the factory. Only in the event of severe shocks or other mistreatment should any substantial readjustment be required. Carefully

open the container(s) and remove the amplifier module(s). Retain all packing material that can be

reassembled in the event that the unit must be returned to the factory.

CAUTION

Exercise care in handling equipment during inspection to prevent damage caused by

rough or careless handling.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 2-2 April 2002

G3S-800-180-029 Installation & Service Manual

Visually inspect the amplifier module for damage that may have occurred during shipment. Check

for evidence of water damage, bent or warped chassis, loose screws or nuts, or extraneous

packing material in the connector or fans. Inspect the rear panel connector for bent connector

pins. If the equipment is damaged, a claim should be filed with the carrier once the extent of any

damage is assessed. We cannot stress too strongly the importance of IMMEDIATE careful inspection of the equipment and the subsequent IMMEDIATE filing of the necessary claims against

the carrier if necessary. If possible, inspect the equipment in the presence of the delivery person.

If the equipment is damaged, the carrier is your first area of recourse. If the equipment is damaged and must be returned to the factory, write or phone for a return authorization. Powerwave

may not accept returns without a return authorization. Claims for loss or damage may not be

withheld from any payment to Powerwave, nor may any payment due be withheld pending the

outcome thereof. WE CANNOT GUARANTEE THE FREIGHT CARRIER'S PERFORMANCE.

2-5 Installation Instructions (refer to figures 1-1 and 2-1)

The G3S-800-180-029 amplifier module is designed for installation in a subrack for connection of

DC power, RF, and monitor cables.

To install the amplifier proceed as follows:

1. Install the subrack in an equipment rack and secure in place, based on the installation in-

structions from the appropriate manual for the subrack being installed.

2. Connect the subrack RF output to a high quality transmit filter. Powerwave recommends that

a 800W average power / 14KW instantaneous peak power rated filter be used in most applications.

3. Connect the combined transceiver output(s) to the RF Input port of subrack.

4. Connect the alarm cable(s) to the alarm port of subrack.

WARNING

Verify that all circuit breaker switches on the power distribution panel are in the OFF

position. Turn off external primary DC power before connecting DC power cables.

5. Connect positive primary power and negative primary power to the subrack. Tighten the

subrack power connections.

6. Verify that the plug-in amplifier’s front panel On/Off switch is in the Off position.

7. Inspect the 21-pin D-Sub male combo connector on the rear of each amplifier before install-

ing the amplifier in the amplifier subrack. Verify that all pins are straight, no pins are recessed, that the alignment shield is not bent, and no packing material is embedded in the

connector.

CAUTION

Forcing the amplifier into the subrack at too fast a rate may cause the pins on the 21-pin

D-sub connector of the amplifier to become recessed or broken.

8. Install the plug-in amplifier module(s) in the subrack. Tighten left and right thumbscrews until

finger tight. Tighten the thumbscrews with a slotted screw driver about 1/8 of a turn past finger tight.

9. Check your work before applying DC voltage to the system. Make certain all connections are

tight and correct.

10. Turn the power distribution circuit breakers back on.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 2-3 April 2002

G3S-800-180-029 Installation & Service Manual

11. Measure primary DC input voltage. DC input voltage should be +27 Vdc ±1.0 Vdc. If the DC

input voltage is above or below the limits, call and consult Powerwave before you turn on

your amplifier system.

12. Refer to section 3 for initial turn-on and checkout procedures.

2-6 Amplifier Module Connectors

The amplifier has three connectors on the right rear of the module. The larger is a 21-pin male

D-Sub combo, which provides the status, alarm, control, and power connections. The smaller

BMA coaxial female connectors provide the RF connections. Refer to figure 2-1.

Figure 2-1 G3S-800-180-029 Amplifier, Rear View

2-6.1 Amplifier Module Status, Alarm, Control, And Power Connector

The amplifier has a separate remote alarm and control connector, which may be used by the host

system to monitor and control the individual amplifier modules. The status, alarm, control, and

power connections on the amplifier connector are made through a 21-pin male D-Sub combo

connector (figure 2-2) and are listed and described in table 2-4.

1 2 3 4 5 6 7 8 9

A1

A2

10 11 12 13 14 15 16 17

Figure 2-2 DC and Logic Connector (on Rear of G3S-800-180-029 Amplifier Module)

A3

A4

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 2-4 April 2002

G3S-800-180-029 Installation & Service Manual

Table 2-4 Amplifier Module DC and Logic Connector Definition

Pin Function Description

A1 Power Input +27 Vdc (Power Contact)

A2 Power Input +27 Vdc (Power Contact)

A3 Ground Ground (Power Contact)

A4 Ground Ground (Power Contact)

1 RS485 +TxD Serial Communication Data Out

2 RS485 +RxD Serial Communication Data In

3 Service Loop TTL input to Amp. Gnd. for special test mode (Note 1)

4 MCPA Disabled

(Summary Fault)

5 Mod Addr 0 TTL input to Amp. Gnd. supplied by shelf to identify slot.

6 Mod Addr 1 TTL input to Amp. Gnd. supplied by shelf to identify slot.

7 TP1 TTL output. Future test point.

8 Manual Download GND to download manually

9 DC on stat TTL output. High indicates Amp is powered on.

10 RS485 –TxD Serial Communication Data Out

11 RS485 –RxD Serial Communication Data In

12 SCL7 No connection

13 SDA7 No connection

14 FP Disable Output Output, GND if the front panel switch is in the OFF position; +5 volts

15 FP RST Output, GND if the front panel switch is in the RESET position; +5 volts

16 GND Ground

17 Module Detect Ground potential. Informs the subrack that an MCPA is plugged in.

Note 1: Service loop grounded allows the MCPA to be enabled or disabled by the front panel

switch when not mounted in the shelf.

TTL signal normally low indicates MCPA enabled. A high level indi-

cates that the MCPA has been disabled. Over Power, Over Voltage

takes one second to activate the signal.

indicates the front panel switch is in the ON position.

otherwise.

2-6.2 Amplifier Module RF Connector

The amplifier has separate RF connectors, which are used for the RF signal input and output.

The RF connections on the amplifier connector are made through two BMA female coaxial connectors (figure 2-3) and are listed and described in table 2-5.

A1

A2

Figure 2-3 Amplifier RF Connector

Table 2-5 Amplifier RF Connector Definition

Pin Function Description

A1 RF Input BMA Coaxial Female, Radiall

A2 RF Output BMA Coaxial Female, Radiall

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 2-5 April 2002

G3S-800-180-029 Installation & Service Manual

Section 3 Operating Instructions

3-1 Introduction

This section contains operating instructions for the Multicarrier Cellular Amplifier System.

3-2 Location And Function Of Amplifier Module Controls And Indicators

Primary +27 Vdc power is applied to the amplifier via a 100-amp circuit breaker (ON-OFF) located

on the left side of the amplifier front panel.

The plug-in amplifier module RF control and indicators, located in the center of the amplifier front

panel between the cooling fans, are shown in figure 3-1. The status and RF control functions and

alarms are described in detail in the subsequent paragraphs.

Figure 3-1 G3S-800-180-029 Amplifier Module RF Control and Indicators

3-2.1 Voltage Indicators And On/Off/Reset Switch

3-2.1.1 On Off Switch

This is the DC power switch for the amplifier module. The On/Off switch is a circuit breaker rated

for the inrush current and maximum current draw allowable with this amplifier module. This switch

should be in the Off position whenever the amplifier is inserted or removed from an amplifier

subrack.

3-2.1.2 RF ON Switch

Three position switch:

Off (down position) - Turns off RF section of amplifier module.

On (center position) - Normal amplifier on position.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 3-1 April 2002

G3S-800-180-029 Installation & Service Manual

Reset (up position) - When toggled to reset position, all the red LED indicators will turn on

one at a time in sequence followed by all the green indicators one at a time in sequence; this

will also reset the fault latches. If the switch is held in the reset position, a microcontroller reset will occur. This will be verified by the LEDs toggling state again. The switch is spring

loaded to return to the normal ON position when released. If a fault occurs and the MCPA is

disabled, the alarms can be cleared and the MCPA enabled by this reset position. The functions of the switch are disabled for five seconds after a power-up condition.

3-2.1.3 +27VDC Indicator

Green LED. When lit, indicates that the +27 Vdc supply is greater than +21 Vdc and less than

+31 Vdc. If the +27 Vdc indicator goes out, the DC FAIL indicator will illuminate. This indicates

that the +27 Vdc voltage dropped below +21 Vdc.

3-2.1.4 +15VDC Indicator

Green LED. When lit, indicates that the +15 Vdc supply is greater than +12 Vdc and less than

+17 Vdc. If the +15 Vdc indicator goes out, the DC FAIL indicator will illuminate. This indicates

that the +15 Vdc voltage dropped below +12 Vdc or increased above +17 Vdc.

3-2.1.5 +5VDC Indicator

Green LED. When lit, indicates that the +5 Vdc supply is greater than +2 Vdc and less than +7

Vdc. If the +5 Vdc indicator goes out, the DC FAIL indicator will illuminate. This indicates that the

+5 Vdc voltage dropped below +2 Vdc or increased above +7 Vdc.

3-2.1.6 -5VDC Indicator

Green LED. When lit, indicates that the -5 Vdc supply is greater than -7 Vdc and less than -2 Vdc.

If the -5 Vdc indicator goes out, the DC FAIL indicator will illuminate. This indicates that the -5

Vdc voltage dropped below -7 Vdc or increased above -2 Vdc.

3-2.2 Alarm Indicators

The alarm modes described here are indicative of amplifier alarm modes made to the amplifier

subrack. The amplifier subrack interprets these alarms and may subsequently deliver a different

alarm indication to the host equipment. Refer to the amplifier subrack manual to determine host

equipment level alarms.

Refer to section 6 to interpret and correct the various alarm states.

Refer to table 3-1.

A ‘Minor Alarm’ indicates a potential fatal amplifier problem via the amplifier front panel LEDs. and

the MCPA fault will be in evaluation.

A ‘Major Alarm’ indicates a major problem but the MCPA module will not be disabled.

A ‘Critical Alarm’ is indicative of a fatal problem. The fault indicator will latch on and the MCPA

module will be disabled.

Both ‘Major Alarm’ and ‘Critical Alarm’ will be sent to the host system via the MCPA subrack.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 3-2 April 2002

G3S-800-180-029 Installation & Service Manual

Table 3-1 Amplifier Module Alarm Indicators Definition

Alarm Mode LED

MCPA

Module

Over Pwr Critical Red Disable High

MCPA

Disable signal

(pin 4 inTable 2-1)

Condition

MCPA module output power >220

watts (Note 4)

Over Pwr Critical Red Disable High Input power >-3 dBm

High Temp Minor Red Enable Low High temperature detected

High Temp Critical Red Disable High

High temperature detected for longer

than two minutes

VSWR Minor Red Enable Low 14.5 W < Reflected Power < 38W

VSWR Critical Red Disable High

60W < Reflected power detected at

output longer than approx. two min.

One of the internal DC voltages

DC Fail Minor Red Enable Low

dropped below or exceeded the safe

threshold level

DC Fail Critical Red Disable High

DC Fail

(Over

Critical Red Disable High

voltage)

Fan Fail

(one)

Major Red Enable Low Any fan failure

Voltage out of range for longer than

approx. two minutes (Note 2)

+27 Vdc input >30 V for longer than

one sec. after initial detection of DC

input >31 V (Note 3)

Loop Fail Minor Red Enable Low Loop failure detected

Loop Fail Critical Red Disable High

Loop failure detected longer than 2

minutes

Rack controller detected MCPA out-

Low Pwr Minor Red Enable Low

put is 3 dB below that of the other

MCPA in the system.

Rack controller detected low power

Low Pwr Critical Red Disable High

condition for more than approx. two

minutes

Unit is manually switched off using

LPA

DISAB.

Critical Red Disable High

the front panel RF ON switch, or disabled by a serial command or auto

shutdown by an alarm condition.

NOTES:

1. RS-485 serial alarm will follow LED status.

2. The appropriate status LED shall turn off indicating which voltage is out of its range.

3. When overvoltage is detected:

a) MCPA shall shut down (disable)

b) Turn on red DC Fail LED

c) Set flag for DC Fail alarm

4. When overpower is detected:

a) MCPA shall shut down (disable)

b) Turn on Over Pwr LED

c) Set flag for Over Pwr alarm

d) The MCPA module uses an RMS power detector to determine the overpower fault.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 3-3 April 2002

G3S-800-180-029 Installation & Service Manual

3-3 Initial Start-Up And Operating Procedures

The amplifier module has two operating controls, both located on the front face of the module: the

power ON - OFF switch and the RF ON - ON/OFF/RESET switch (refer to figures 1-1 and 3-1).

To perform the initial start-up, proceed as follows:

1. Verify that all input and output cables are properly connected.

CAUTION

Before applying power, make sure that the input and output of the amplifier are

properly terminated at 50 ohms. Do not operate the amplifier without a load attached.

Refer to table 1-2 for input power requirements. Excessive input power may damage

the amplifier

WARNING

Ensure the amplifier is turned off while disconnecting and reconnecting cables

between the antenna interface and power measurement equipment. Failure to do so

may cause damage to the equipment or personal injury.

NOTE

The output coaxial cable between the amplifier and the antenna must be 50 ohm coaxial

cable. Use of any other cable will distort the output.

2. Verify that the amplifier front panel switches are in the OFF position.

3. Turn on supply that provides +27 Vdc to the amplifier system. Do not apply an RF signal to

the amplifier system

4. Place the ON - OFF circuit breaker on the amplifier in the ON position. Visually check the

indicators on the amplifier module, and verify that the following indicators are on:

A. LPA DISAB. indicator (red) should be on.

B. The +27VDC, +15VDC, +5VDC and -5VDC indicators (green) on the amplifier module

should be on.

5. Set the RF ON switch to the ON (center) position. All red LEDs should turn off after six seconds.

6. Follow the power setting procedure set forth in the amplifier subrack or system integration

manual. Turn on external exciter/transceiver and apply RF input signals.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 3-4 April 2002

G3S-800-180-029 Installation & Service Manual

Section 4 Principles of Operation

4-1 Introduction

This section contains a functional description of the Multicarrier Cellular Amplifier.

4-2 RF Input Signal

This amplifier may be installed in a base station system as either a stand-alone module (i.e. in a

micro-cell application), or combined with multiple amplifiers in a combining subrack product available from Powerwave. In either case, the maximum input power for all carrier frequencies should

not exceed the limits specified in table 1-2. For proper amplifier loop balance and to ensure compliance with FCC rules, the out of band components of the input signals should not exceed -40

dBc. The input VSWR presented to the amplifier should be 2:1 (or better) to maximize the transfer

of input power to the amplifier; this is particularly important when the amplifier is not installed in a

Powerwave manufactured combining subrack.

4-3 RF Output Load

The load impedance should be as good as possible (1.5:1 or better) in the working band for good

power transfer to the load. If the amplifier is operated into a filter, it will maintain its distortion

characteristics outside the signal band.

4-4 G3S-800-180-029 Amplifier Module

The G3S-800-180-029 amplifier is a linear, feed-forward power amplifier that operates in the 25

MHz frequency band from 869 MHz to 894 MHz. The amplifier modules are designed for parallel

operation to achieve high peak power output, and provide system redundancy when installed in

multi-module amplifier subracks manufactured by Powerwave. The Powerwave amplifier system

is ideally suited for unmanned remote locations.

The amplifier module, figure 4-1, has an average output of 180 watts nominal power (1800 watts

peak power) with intermodulation products suppressed to better than -60 dBc below carrier levels.

The amplifier provides an amplified output signal with constant gain and phase. Constant gain and

phase is maintained by continuously comparing active paths with passive references, and correcting for small variations through the RF feedback controls. All gain and phase variations, for

example those due to temperature, are reduced to the passive reference variations. Each amplifier module has an alarm and display board that monitors the amplifier performance. If a failure or

fault occurs in an amplifier module, it is displayed on the individual amplifier front panel.

The amplifier module is comprised of:

Predistorter

Pre-amplifiers

Main amplifier

Error amplifier

Two feed-forward loops with phase-shift and gain controls

DC/DC power regulator

Alarm monitoring, control and display panel

The main amplifier employs class AB amplification for maximum efficiency. The error amplifier

and feed forward loops are employed to correct signal nonlinearities introduced by the class AB

main amplifier. The error amplifier operates in class AB mode. The RF input signals are ampli-

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 4-1 April 2002

G3S-800-180-029 Installation & Service Manual

fied by a preamp and coupled to an attenuator and phase shifter in the first feed-forward loop.

The main signal is phase shifted by 180 degrees and amplified in the premain amplifier. The output from the premain amplifier is fed to the class AB main amplifier. The output from the main

amplifier is typically 220 watts. The signal is output to several couplers and a delay structure.

The signal output from the main amplifier is sampled using a coupler, and the sample signal is

combined with the main input signal and input to the second feed-forward loop. The error signal is

attenuated, phase shifted 180 degrees, then fed to the error amplifier where it is amplified to a

level identical to the sampled output from the main amplifier. The output from the error amplifier

is then coupled back and added to the output from the main amplifier. The control loops continuously make adjustments to cancel out any distortion in the final output signals.

RF Out

RFL

PWR

Pre

Amp

1st Loop

Phase & Gain

+15 +5 -5

Power Supply

+27VDC

Smart Rack

Pre

Main

2nd Loop

Phase & Gain

Alarms & Display

Pre

Dist

Delay

Feed Forward Loop control

Main

Amp

FWD

PWR

Error

Amp

-30dB

Front Panel

Delay

-10dB

Figure 4-1 G3S-800-180-029 Power Amplifier Module Functional Block Diagram

4-4.1 Main Amplifier

The input and output of the amplifier employ two-stage, class AB amplifiers which provide approximately 32 dB of gain in the 25 MHz frequency band from 869 to 894 MHz. The amplifier operates on +27 Vdc, and a bias voltage of +5 Vdc, and is mounted directly on a heat sink that is

temperature monitored by a thermostat. If the heat sink temperature exceeds 90° C, a high temperature fault occurs. The alarm logic controls the +5 Vdc bias voltage that shuts down the amplifier.

4-4.2 Error Amplifier

The main function of the error amplifier is to amplify the distortion signal generated by the 1

Loop, to a level that cancels out the distortion and IMD when the error signal is coupled onto the

main signal at the amplifier output. The error amplifier is a balanced multistage, class AB amplifier.

st

4-4.3 Amplifier Monitoring

In the main and error amplifier modules, all normal variations are automatically compensated for

by the feedforward loop control. However, when large variations occur beyond the adjustment

range of the loop control, a loop fault will occur. The alarms are displayed on the front panel indicators and output via a 21-pin connector on the rear of the module to the subrack summary board

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 4-2 April 2002

G3S-800-180-029 Installation & Service Manual

for subsequent remote monitoring via the ALARMS connector. Refer to paragraph 2-6 as well as

figure 2-2 and table 2-3 for a description of the ALARMS connector.

4-4.4 Amplifier Module Cooling

Although each amplifier module contains its own heat sink, it is cooled with forced air. Four fans

are used for forced air-cooling and redundancy. The fans, located on the front and rear of the

amplifier module, draw air in through the front of the amplifier and exhaust hot air out the back of

the module. The fans are field replaceable.

4-5 Power Distribution

Primary DC power for the system is provided by the host system to the MCR30829-1-3 Series or

compatible subrack. The subrack supplies each amplifier module with +27 Vdc directly and via

the RF power splitter/combiner. The amplifier module has a DC/DC converter that converts the

+27 Vdc to +15 Vdc, +5 Vdc and -5 Vdc.

4-6 Intermodulation

The G3S-800-180-029 amplifier is designed to deliver a 180-watt nominal composite average

power (210 W max.), multi-carrier signal, occupying a bandwidth less than or equal to 25 MHz, in

the band from 869 to 894 MHz. The maximum average power for linear operation, and thus the

amplifier efficiency, will depend on the type of signal amplified.

Three or more CW tones of equal input power will lower individual intermodulation products. If the

frequencies are not equally spaced, the level of intermodulation products gets very low. When the

frequencies are equally spaced, those products fall on top of each other on the same frequency

grid. The average power of all intermodulation beats falling on the same frequency is called the

composite intermodulation; it is -60 dBc or better.

4-7 Alarms

The presence of several plug-in amplifier alarms can be detected at the DC and logic connector

on the amplifier rear panel. Refer to table 2-3 and figure 2-2 for a description of the connector.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 4-3 April 2002

G3S-800-180-029 Installation & Service Manual

Section 5 Maintenance

5-1 Introduction

This section contains periodic maintenance and performance test procedures for the Multicarrier

Cellular Amplifier. It also contains a list of test equipment required to perform the identified tasks.

NOTE

Check your sales order and equipment warranty before attempting to service or repair

the unit. Do not break the seals on equipment under warranty or the warranty will be

null and void. Do not return equipment for warranty or repair service until proper

shipping instructions are received from the factory.

5-2 Periodic Maintenance

Periodic maintenance requirements are listed in table 5-1. Table 5-1 also lists the intervals at

which the tasks should be performed.

WARNING

Wear proper eye protection to avoid eye injury when using compressed air.

Table 5-1 Periodic Maintenance

Task Interval Action

Cleaning

Air Vents 30 Days Inspect and clean per paragraph 5-4

Inspection

Cables and Connec-

tors

Performance Tests

12 Months Inspect signal and power cables for

frayed insulation. Check RF connectors

to be sure that they are tight.

12 Months Perform annual test per paragraph 5-5.

5-3 Test Equipment Required For Test

Test equipment required to test the amplifier system is listed in table 5-2. Equivalent test equipment may be substituted for any item, keeping in mind that a thermistor type power meter is required.

NOTE

All RF test equipment must be calibrated to 0.05 dB resolution. Any deviation from the

nominal attenuation must be accounted for and factored into all output readings.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 5-1 April 2002

G3S-800-180-029 Installation & Service Manual

Table 5-2 Test Equipment Required

Nomenclature Manufacturer Model

Signal Generator RDL IMD-801D-03A

30 dB Attenuator, 500 Watt Weinschel Corp. 53-30-34

20 dB Attenuator, 20 Watt

(2 each)

Spectrum Analyzer H.P. 8560E

Coax Directional Coupler H.P. 778D

Power Meter/Sensor H.P. 437B/8481A

Network Analyzer H.P. 8753C

Current Probe

Tenuline

5-4 Cleaning Air Inlets/Outlets

The air inlets and outlets should be cleaned every 30 days. If the equipment is operated in a severe dust environment, they should be cleaned more often as necessary. Turn off DC power

source before removing fans. If dust and dirt are allowed to accumulate, the cooling efficiency

may be diminished. Using either compressed air or a brush with soft bristles, loosen and remove

accumulated dust and dirt from the air inlet panels.

5-5 Performance Test

Performance testing should be conducted every 12 months to ensure that the amplifier system

meets the operational specifications listed in table 5-3. Also verify system performance after any

amplifier module is replaced in the field. The test equipment required to perform the testing is

listed in table 5-2, and the test setup is shown in figure 5-1.

NOTE

The frequencies used in this test are typical for an amplifier with a 25 MHz band from

869 MHz to 894 MHz. Select evenly spaced F1, F2, F3, and F4 frequencies that cover the

instantaneous bandwidth of your system.

5-5.1 Amplifier System Performance Test

This test is applicable to the G3S-800-180-029 amplifier modules. To perform the test, proceed as

follows:

1. Connect test equipment to the amplifier as shown in figure 5-1.

NOTE

Do not apply any RF signals at this time.

Turn on signal generator and set frequency F1 to 880 MHz, F2 to 883 MHz, F3 to 886 MHz,

and F4 to 889 MHz. Adjust each signal generator output so that the sum power output from

all four signal generators equals -6 dBm at the input.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 5-2 April 2002

G3S-800-180-029 Installation & Service Manual

20 dB

Unit Under Test

+27 Vdc

Gnd RF In

Generator

G3S-800-180

Plug-in

Amplifier

Module

Filter /

Isolator

Signal

Directional Coupler

RF

Out

Splitter

1:2

Figure 5-1 Amplifier System Test Setup Diagram

5-5.1.1 Amplifier IMD Test And Current Test

Sensor Head

8482A

30 dB

Attenuator

500 W

Attenuator

Spectrum Analyzer

8651E

Power Meter

20 dB

20 W

Power Meter

Sensor Head

8482A

Network Analyzer

8753C

2. Adjust attenuator for an input signal at -10 dBm. Turn on the amplifier by setting RF ON

switch of amplifier. Adjust variable attenuator to set amplifier power output on power meter to

180 watts. Measure IMD on spectrum analyzer. IMD should be -60 dBc max. Record test

data in table 5-3. Set RF ON switch to OFF.

3. With the amplifier module set at 180 watts power output, use the current probe (magnetic

field type) and measure the dc current flow from the +27 Vdc power source. Current should

be 70 amps maximum. Record test data in table 5-3.

5-5.1.2 Gain Test

4. Disconnect spectrum analyzer from test setup, and connect the network analyzer.

5. Set network analyzer as follows:

Ø Power output to -10 dBm.

Ø Frequency start to 869 MHz.

Ø Frequency stop to 894 MHz.

Ø Normalize the network analyzer for gain and return loss.

6. Check the gain across the band from 869 MHz to 894 MHz. Gain should be between 58 dB.

Record test data in table 5-3.

5-5.1.3 Harmonics Test

7. With the power set at 180 watts power output, use the spectrum analyzer and check the frequency band from 869 MHz to 894 MHz for harmonics. Harmonics should be 5 dBm maximum. Record test data in table 5-3.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 5-3 April 2002

G3S-800-180-029 Installation & Service Manual

5-5.1.4 Spurious Test

8. With the power amplifier set at 180 watts power output, use the spectrum analyzer and check

the frequency band from 869 MHz to 894 MHz for spurious signals. Spurious signals should

be -60 dBc maximum. Record test data in table 5-3.

5-5.1.5 Input Return Loss Test

9. Reset and turn on amplifier module. Read and record the S

return loss measurement on

11

network analyzer. Input return loss should be –16 dB maximum. Record test data in table

5-3.

Table 5-3 Multicarrier Cellular Amplifier Test Data Sheet

DATE _________________________________

AMPLIFIER S/N _________________________

TEST CONDITIONS:

Load and Source Impedance: 50 Ohms

VSWR: < 1.2:1

Supply Voltage: +27 Vdc ±1.0 Vdc

TEST SPECIFICATION MIN MAX DATA

4-TONE IMD

RF Gain

Gain Flatness

Harmonics

Spurious

Input Return

Loss

DC Power

Vcc = 27 Vdc

PO = 180 W

Freq.: 880, 883, 886, and 889

MHz

Vcc = 27 Vdc

PO = 180 W

Freq. = 880 MHz

Vcc = 27 Vdc ±1 Vdc

PO =180 W

869-894 MHz Band

Vcc = 27 Vdc

PO = 180 W

869-894 MHz Band

Vcc = 27 Vdc

PO =180 W

869-894 MHz Band

Vcc = 27 Vdc

PO = 180 W

869-894 MHz Band

Vcc = 27 Vdc

PO = 180 W

4 Tones

-60 dBc

57.5 dB 58.5 dB

-0.5 dB +0.5 dB

5 dBm

-60 dBc

-16 dB

70 Amps

PASS _________________________________ FAIL _______________________________

Tested by ______________________________

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 5-4 April 2002

G3S-800-180-029 Installation & Service Manual

5-6 Field Replaceable Parts And Modules

The following parts and modules can be replaced in the field on site by a qualified technician with

experience maintaining RF power amplifiers and similar equipment:

1. G3S-800-180-029 power amplifier modules

2. Cooling fans

5-6.1 G3S-800-180-029 Power Amplifier Module

To replace a power amplifier module, proceed as follows:

1. Set both the RF ON On/Off/Reset switch and the power ON/OFF switch on the front panel of

the amplifier module to OFF.

2. Loosen two screws that secure amplifier module to subrack.

CAUTION

The amplifier is equipped with a spring clip on each side panel to prevent the amplifier

from being fully removed from the subrack via the front panel handles. When removing

the amplifier from the subrack, it is very important to support the amplifier such that the

rear of the module does not suddenly drop when it disengages from the track. A drop

such as this could damage the module or cause personal injury.

Spring Clip

Figure 5-2 Amplifier Spring Clip Location

3. Use the handle on the front of the module, and with a steady even pressure, gently pull the

module about half way out of subrack until the spring-clips prevent the amplifier from being

removed (refer to figure 5-2).

4. Simultaneously press the front half of each spring clip towards the center of the amplifier and

resume removal of the amplifier.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 5-5 April 2002

G3S-800-180-029 Installation & Service Manual

5-6.2 Cooling Fans

To replace a front cooling fan, proceed as follows:

1. Loosen four snap fasteners that secure fan to amplifier module. Disconnect fan power connector from amplifier module.

To replace a rear cooling fan, proceed as follows:

1. Remove amplifier module from subrack; see paragraph 5-6.1 preceding.

1. Loosen the four Phillips head screws that secure the fan to the amplifier module. Disconnect

the fan power connector from the amplifier module.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 5-6 April 2002

G3S-800-180-029 Installation & Service Manual

Section 6 Troubleshooting

6-1 Introduction

This section contains a list of problems and a few suggested actions that may correct the problem. If the suggested corrective action does not eliminate the problem, please contact your Powerwave field representative or the factory for further instructions.

NOTE

Check your sales order and equipment warranty before attempting to service or repair

the unit. Do not break the seals on equipment under warranty or the warranty will be

null and void. Do not return equipment for warranty or repair service until proper

shipping instructions are received from the factory.

6-2 Troubleshooting

The following are general guidelines established to aid Field Engineers or Cell Site Technicians in

the proper method of Powerwave equipment fault resolution by fault mode.

6-2.1 DC Voltage Indicators Not Illuminated

1. Check the front panel ON/OFF switch.

2. Check the power plant circuit breaker.

3. Check for +27 + 1.0 VDC at the amplifier subrack input.

A. If the voltage is low, verify that all DC connections between the power plant and the am-

plifier subrack are tight.

B. If the voltage is correct,

1. Remove the amplifier from the subrack slot and move the amplifier to another amplifier subrack slot.

2. Check the voltage on the power pins of the mating amplifier and amplifier subrack

connector.

3. Verify that the amplifier DC connections are not damaged.

4. Return the amplifier to the factory for repair.

6-2.2 OVER PWR Illuminated or Blinking

1. If all the amplifiers in a given amplifier subrack are in Over Pwr and the LPA Disable LED is

illuminate, then the input RF power level is too high and the amplifiers have been turned off.

RF power may be incorrectly set during equipment commissioning. This may be due to a

faulty jumper cable. Verify the amplifier subrack output cables, transmit filter, and directional

coupler are in proper working order. The loss between the amplifier subrack and the hatch

plate is typically less than 2.0 dB.

2. If all the amplifiers in a given amplifier subrack are in Over Pwr and the LPA Disable LED is

not illuminated, then the input RF power level is too high. The amplifier subrack is attempting

to maintain a safe power output level (smart subracks with True RMS power detectors and

voltage variable attenuators only). RF power may be incorrectly set during equipment commissioning. This may be due to a faulty jumper cable. Verify the amplifier subrack output ca-

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 6-1 April 2002

G3S-800-180-029 Installation & Service Manual

bles, transmit filter, and directional coupler are in proper working order. The loss between the

amplifier subrack and the hatch plate is typically less than 2.0 dB.

3. If only one or two amplifiers in a given amplifier subrack are in Over Pwr and the LPA Disable

LED is blinking, then the amplifier subrack is probably in Sleep Mode (smart subracks with

True RMS power detectors and voltage variable attenuators only).

A. Pressing the On/Off/Reset switch momentarily in the Up position or cycling DC power on

the amplifier should bring the amplifier back on-line.

B. Sleep Mode firmware may be disabled in the field with a PC interface and software

available from Powerwave.

4. Move the amplifier to another slot in a different subrack, if available. Mark the amplifier with a

sticker or place a tie wrap on the handle to identify the amplifier. Monitor for future failure.

A. If the same amplifier fails again, return the amplifier to the factory for repair.

B. If the replacement amplifier in the original subrack fails, replace the amplifier subrack.

6-2.3 HIGH TEMP Illuminated

5. If an amplifier is in HIGH TEMP and the LPA Disable LED is illuminate, then the amplifier

heat sink temperature is too high. This may be due to:

A. High ambient temperature.

B. Fan failure.

C. Insufficient air-volume capacity. Most of Powerwave’s amplifiers require a certain

amount of free-space to allow proper airflow.

6. Correct the heat problem, then reset the amplifier by momentarily pressing the Reset button

on the amplifier front panel up.

6-2.4 VSWR Illuminated

7. If all the amplifiers in a given amplifier subrack are in VSWR and the LPA Disable LED is illuminate, then the output RF reflected power level is too high and the amplifiers have been

turned off. This may be due to a faulty jumper cable or transmit filter. Verify the amplifier

subrack output cables, transmit filter, and directional coupler are in proper working order. The

loss between the amplifier subrack and the hatch plate is typically less than 2.0 dB. This fault

normally occurs during site or just following site power setting and normally takes about 10 to

15 minutes to reveal itself. This fault may not occur at low power levels (i.e. when just one or

two channels are up).

8. If one amplifier in an amplifier subrack is in VSWR and the LPA Disable LED is illuminated,

then the output RF reflected power level is too high for that amplifier. This may be due to

A. A damaged or recessed amplifier RF output connector. Return the amplifier to the fac-

tory for repair.

Mishandling of the amplifier normally causes recessed pins. Before installing an ampli-

fier, look at the D-sub connector to ensure none of the pins are recessed, bent or that

the outer connector shield is not damaged. When installing the amplifier, do not force

the amplifier into the slot. Gentle even pressure is all that is needed to properly seat the

amplifier.

B. Improper seating of the amplifier.

1. Ensure the amplifier thumbscrews are properly tightened.

2. Try seating the amplifier in another subrack slot.

3. Try seating the amplifier in a subrack in another sector.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 6-2 April 2002

G3S-800-180-029 Installation & Service Manual

6-2.5 DC FAIL Illuminated

If an amplifier is in DC FAIL and the LPA Disable LED is illuminate, then one of the four amplifier

DC voltages is either out of tolerance or not present. Return the amplifier to the factory for repair.

6-2.6 FAN FAIL Illuminated

If an amplifier is in FAN FAIL, then the one of the amplifier’s cooling fans has failed. Replace the

fan.

Fan failure does not cause the amplifier to shut down; amplifier shut down is determined by heat

sink temperature.

6-2.7 LOOP FAIL Illuminated

9. Loop Fail is always accompanied by LPA Disable LED illuminated. This may be due to

A. Inability of the amplifier to maintain a 180° phase shift between the first and second

loops.

B. A damaged error amplifier. This can be caused by

1. Out of band spurious or intermods being applied at too high of a level at the amplifier input port. An input band-pass filter may be necessary to correct this problem.

2. Disconnecting amplifier RF output cables while the amplifier is still turned on. Always turn the amplifier off when moving output RF cables from the hatch plate to

test equipment and back again.

C. Improper power balance between amplifiers in a given subrack.

1. Ensure the amplifier thumbscrews are properly tightened. Reset the amplifier by

momentarily pressing the Reset button on the amplifier front panel up.

2. Try seating the amplifier in another subrack slot.

3. Try seating the amplifier in a subrack in another sector.

6-2.8 LOW PWR Illuminated

Low Power is always accompanied by the LPA Disable LED illuminated. This is due to the gain of

either the internal preamplifier or main amplifier being 0.5 dB (typically) or more below the amplifier specification. The amplifier should be returned to the factory.

6-2.9 LPA DISABLE Illuminated

10. LPA Disable LED illuminated indicates that the amplifier RF section is turned off. This may

be due to

A. An accompanied alarm indicating a critical amplifier fault (i.e. Loop Fail fault).

B. A response to a subrack command, purposely inhibiting the amplifier (i.e. Sleep Mode

activation)

C. Improper seating of the amplifier in the subrack.

11. Ensure the amplifier thumbscrews are properly tightened. Reset the amplifier by momentarily

pressing the Reset button on the amplifier front panel up.

12. Try seating the amplifier in another subrack slot.

13. Try seating the amplifier in a subrack in another sector.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 6-3 April 2002

G3S-800-180-029 Installation & Service Manual

6-3 Return For Service Procedures

When returning products to Powerwave, the following procedures will ensure optimum response.

6-3.1 Obtaining An RMA

A Return Material Authorization (RMA) number must be obtained prior to returning equipment to

the factory for service. Please contact our Repair Department at (888) 797-9283 or (714) 4661000 to obtain this number, or FAX your request to (714) 466-5816. Failure to obtain this RMA

number may result in delays in receiving repair service.

6-3.2 Repackaging For Shipment

To ensure safe shipment of the amplifier, it is recommended that the package designed for the

amplifier be used. The original packaging material is reusable. If it is not available, contact

Powerwave’s Customer Service Department for packing materials and information.

Copyright Powerwave Technologies, Inc., April 2002. All rights reserved

044-05112 Rev. A 6-4 April 2002

Loading...

Loading...