Page 1

Draft RX 1850-1910 MHz; TX 1930-1945 MHz

System Integration Manual

Radio Frequency Front End

Multi-Carrier Power Amplifier System

044-05082 Rev. A March 2001

Page 2

Draft RF Front End System Integraton Manual

®

© 2001 Powerwave Technologies Incorporated. All rights reserved.

Powerwave Technologies, and the Powerwave logo are registered trademarks

Powerwave Technologies, Inc. reserves the right to make changes to the documentation and

equipment, including but not limited to component substitution and circuitry changes. Changes

that impact this manual may subsequently be incorporated in a later revision of this manual.

March 2001

Powerwave Technologies, Inc. Tel: (714) 466-1000

1801 E. St Andrew Place Fax: (714) 466-5800

Santa Ana, CA 92705 Web Site: www.powerwave.com

044-05082 Rev. A

ii

March 2001

Page 3

DRAFT RF Front End System Integration Manual

Section 1 General Discription

1-1 Introduction

This manual contains information and procedures for installation, operation, and maintenance of

the Radio Frequency Front End (RFFE) Multi-Carrier Power Amplifier (MCPA) System. This

manual is organized into sections as follows:

Section 1.General Description Appendix B: Amplifier Power Setting Procedure

Section 2. Installation Appendix C: General Site Survey Form

Section 3. Operating Instructions

Section 4. Principles of Operation

Section 5. Maintenance

Section 6. Troubleshooting

1-2 General Discription

Designed to compensate for cable loss due to long cable runs, the RFFE uses an AB amplifier

that utilizes a pre-distortion technique for linearization (see figure 4-3 for the amplifier block diagram). Designed as a two unit system and equipped with a space diversity path to reduce fading,

the RFFE operates in the PCS frequency range of: 1850MHz to 1910MHz (receive) and 1930MHz

to 1945MHz (transmit): The system consists of.

• The Masthead Unit (MHU)

• The Masthead Unit Interface (MHUI)

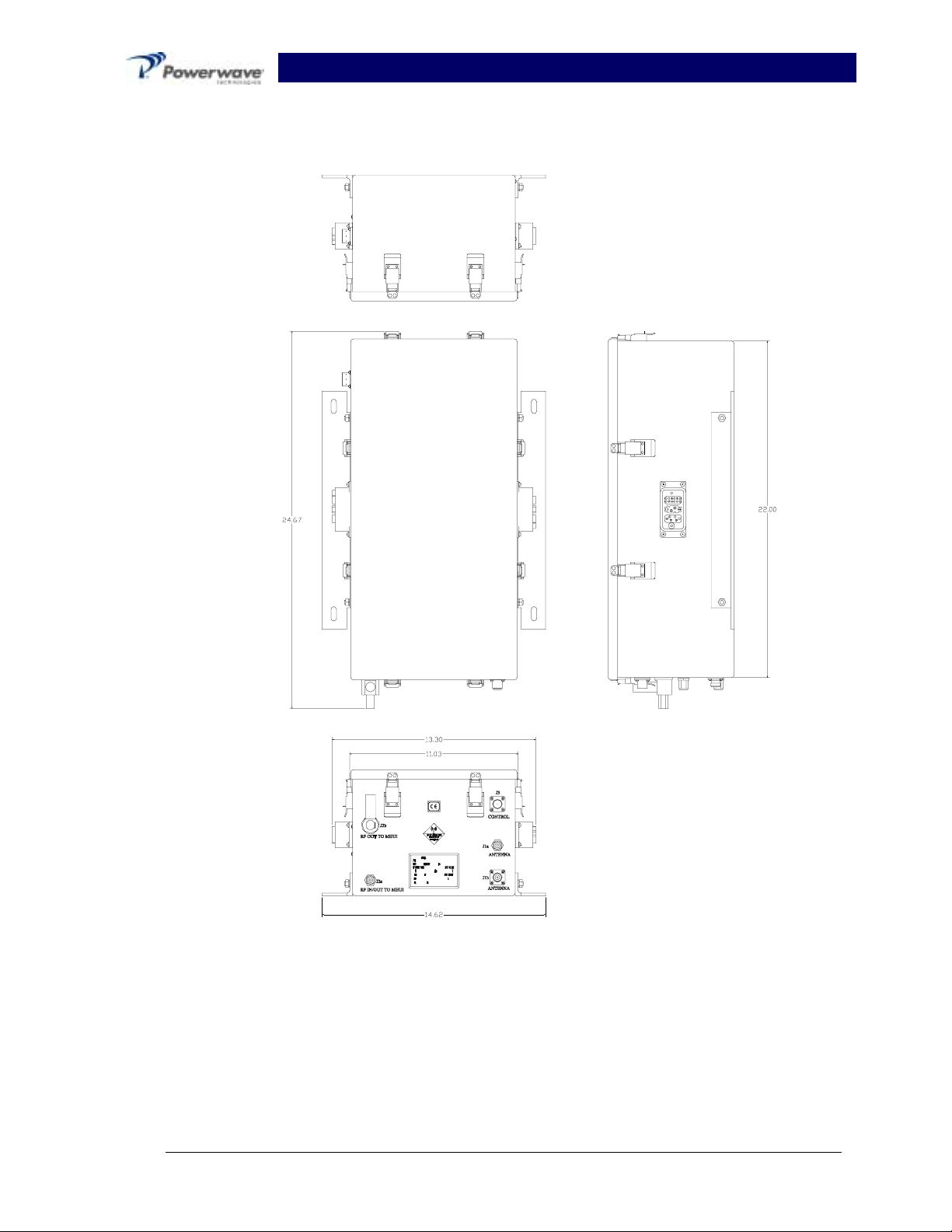

1-2.1 The Masthead Unit

The primary function of the MHU is to provide maximum RF output power (not to exceed 100

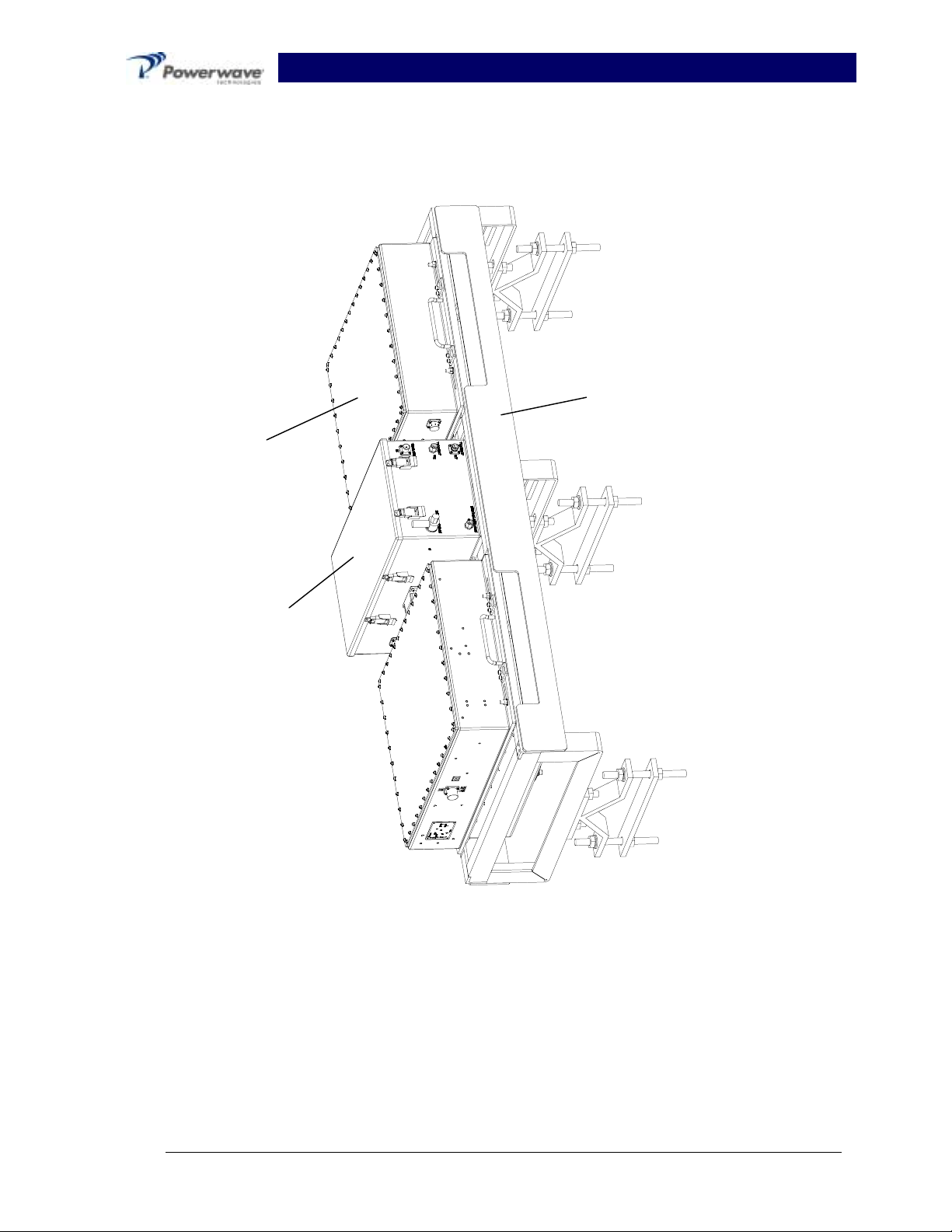

Watts) with multiple CDMA carries into a matched 50 Ohm load while maintaining the spectral regrowth and spurious requirements (see table 1-2). Supported by a mounting frame (see figure

1-2), the Mast Head Unit (MHU) is mounted on the antenna tower near the antenna and consists

of three modular components; the common box and two RF transmit (Tx) modules. each module

is encased in a weatherproof (NEMA 4) housing (refer to table 1-2 for environmental specifications).

1-2.1.1 The Common Box

The common box (see figure 1-4) connects to both Tx modules via blind mate connectors (refer to

figure 1-1 and table 1-1). It houses a redundant LNA path, two input duplexers, two output duplexers, two 27VDC (scalable up to 1200Watts) power supplies, and a control board.

1-2.1.2 The Transmitt Modules

Powered by 220VAC from the host breaker panel, the two RF transmit modules are used for redundancy in the system. Each module houses one MPA9505-55 MCPA and a rectifier circuit that

reduces the 220VAC to the 27VDC required to operated the amplifier. To aid in maintaining the

system’s operating temperature, each amplifier is mounted on a heat sink and is equipped with a

220VAC variable speed fan. Refer to figure 1-5.

The MHU connects to the Masthead Unit Interface (MHUI) by two RF cables, and one CONTROL

cable. Refer to figure 2-6.

044-05082 Rev. A

1-1

March 2001

Page 4

DRAFT RF Front End System Integration Manual

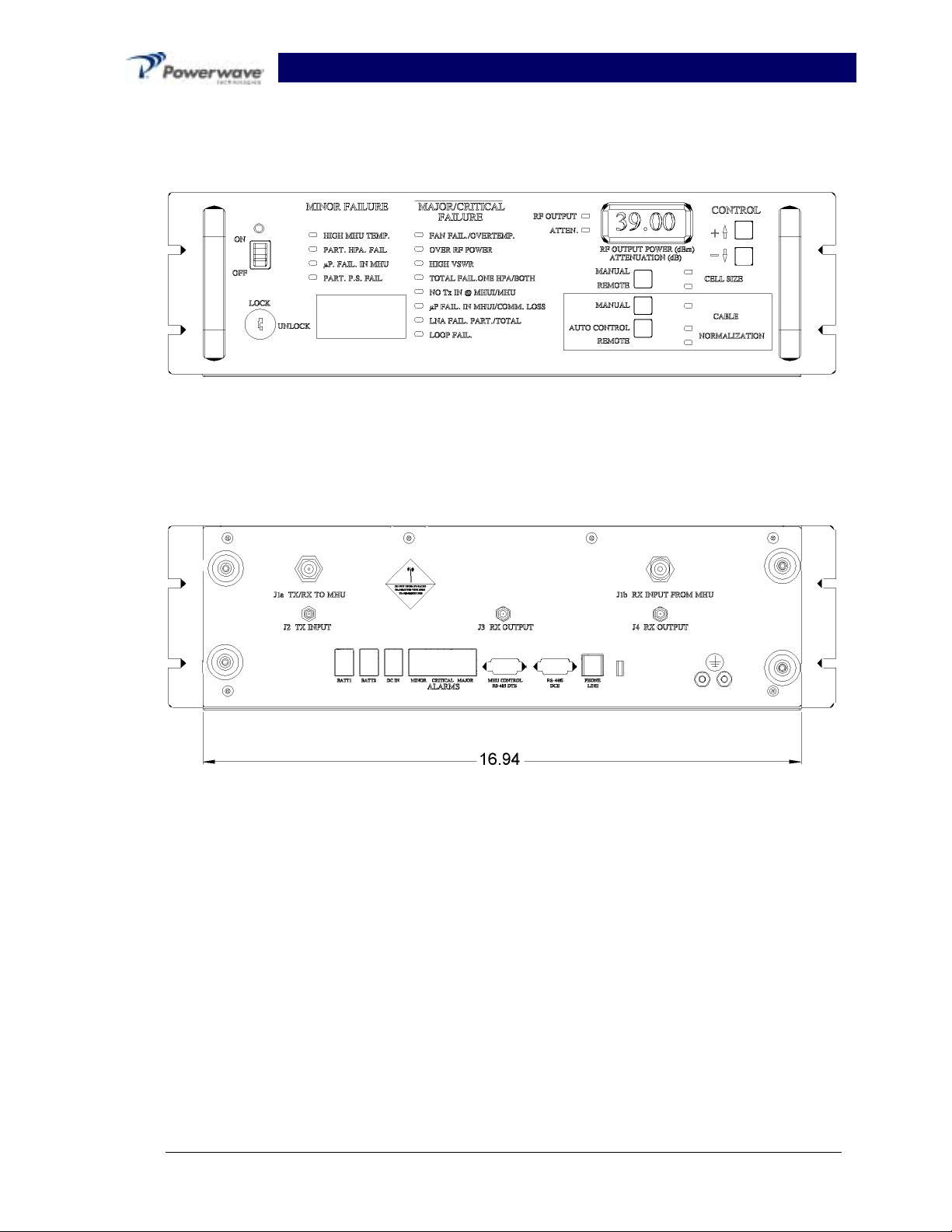

1-2.1.3 Masthead Unit Interface

The Masthead Unit Interface (MHUI) interfaces the MHU to the host base station. It provides a

user friendly control panel for power level adjustment and display. The control panel is key

activated and displays major, critical and minor alarm conditions via LED displays. Refer to section 2 for a more detailed description of the MHUI controls.

The enclosure houses a low power duplexer, a control board, the control panel, cell size variable

attenuators (both Rx and Tx) and a preamp. The system reports and displays alarm faults to the

external summary module via an RS-485 bus or form C dry contact relays. Refer to figure 4-4 for

the MHUI functional block diagram.

The MHU-MHUI pair operates between 1dB and 16dB of cable loss in the transmit/receive coaxial

cable. Therefore, the maximum distance between the MHU and MUI depends on the cable type

used (e.g. 7/8”, 1/2” or 1/4” foam-dielectric coaxial cable).

1

7

6

12 12

AB

1

1

2

3

4

7

6

C

Note: The Connector Identification (A,B and C) is for reference only

and not necessarily labled on the actual connector

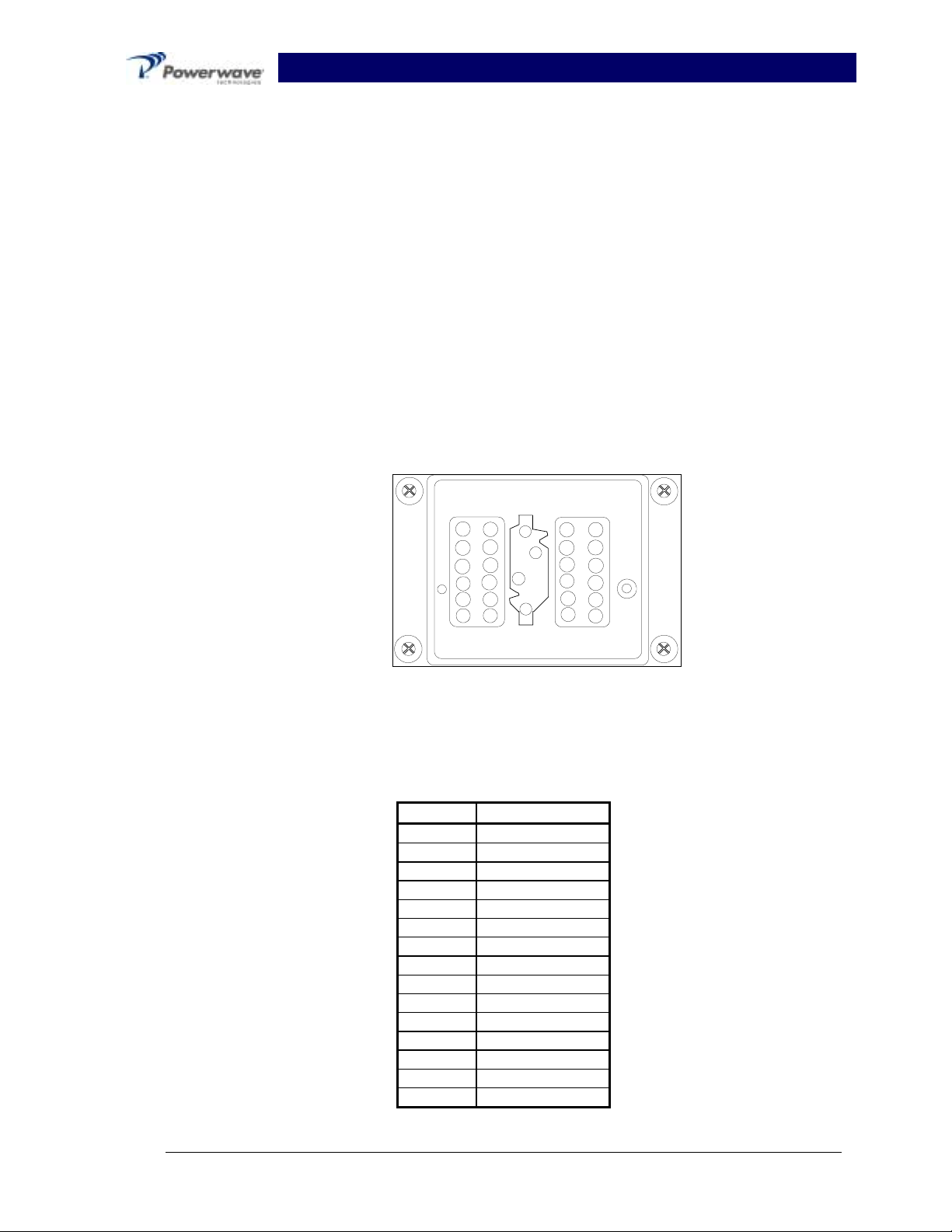

Figure 1-1 Masthead Unit Blind mate Connector Interface

Table 1-1 Blindmate Connector Pin Designation

Pin Function

1A +26 VDC

2A +12 VDC

3A -8 VDC

4A COM

5A-12A Not used

1B Not used

2B TX IN

3B TX OUT

4B Not used

1C Mute

2C-4C Not used

5C RS-485H

6C RS-485L

7C COM

8C-12C Not used

044-05082 Rev. A

1-2

March 2001

Page 5

DRAFT RF Front End System Integration Manual

Table 1-2 System Specifications with the MPA9505-55 MCPA

Frequency:

Receive

Transmit

RF Input Power 3dBm (2 milliWatts)

RF Output Power: 55 Watts (47.40 dBm) Max./ 7carriers

1850-1910 MHz

1930-1945 Mhz

Nominal Gain

Typical Gain Flatness

40 dB ±1.0 dB

±0.2 dB (over any 2.0 MHz in band)

Gain Variation Over Temperature 1.0 dB @ -20 to 80 ºC Base Plate

IMD Spurious Emissions @ 7 carriers

(Room Temperature):

Frequency Off-Set ± 885 KHz

Frequency Off-Set ± 1.25 MHz

Frequency Off-Set ± 2.25 MHz

-47 dBc max (30 KHz BW)

-13 dBm max (12.5 KHz BW)

-40 dBc (marker to marker)

IMD Spurious of MCPA in MHU @ Antenna Port:

885 KHz, 30 KHz BW

1.98 MHz, 30 KHz BW

2.25 MHz, 1 MHz BW

-47 dBc

-57 dBc

-15 dBm

Spectrum Regrowth of MCPA in MHU @

Antenna Port:

885 KHz

1250 MHz

2250 KHz

-47 dBc

-13 dBm

-13 dBm

Tx Noise in Rx Band @ MCPA Output: -122 dBm/Hz (max.)

Tx Power in Rx Band @ MHUI Rx Output -110 dBm @ Rated Output Power

Input/Output VSWR 1.3 : 1

Output Protection Mismatch Protected

DC Power

27 VDC ± 1.0 VDC @ 24 Amps max.

Sample Port -40 dB ±1.0 dB

Operating Temperature

Storage Temperature

-20 °C to 85 °C Base Plate

-40 ºC to 85 °C Base Plate

Operating Humidity 0-95% (Non Condensed)

Operating Vibration 1.0 GHz from 10 Hz to 150 Hz

Wind Load 125 mph (min.)

NEMA Rating 4

Remote Alarm Reporting RS-485, Form-C

Receive Band Noise @ MCPA Output -122 dB

Tx-Rx Rejection >75 dB

Dimensions 10(H)x24(W)x48(D) inches

Weight (Fully assembled) 29 lbs (13kg)

044-05082 Rev. A

1-3

March 2001

Page 6

DRAFT RF Front End System Integration Manual

Mounting

Frame

Transmit

Module

(typ. 2 plcs.)

Common

Box

Figure 1-2 The Mast Head Unit with Two Transmit Modules

044-05082 Rev. A

1-4

March 2001

Page 7

DRAFT RF Front End System Integration Manual

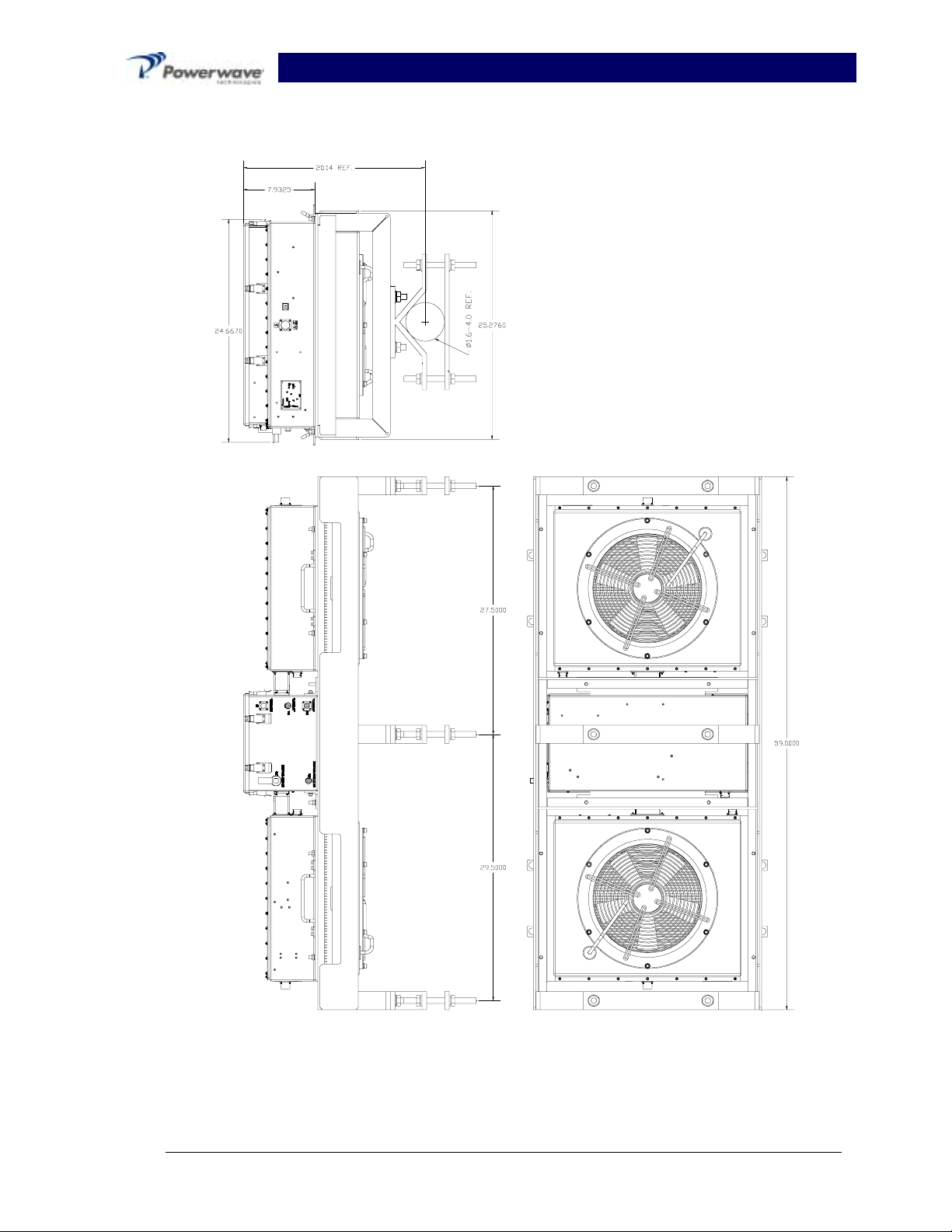

044-05082 Rev. A

Figure 1-3 Masthead Unit Assembly

1-5

March 2001

Page 8

DRAFT RF Front End System Integration Manual

044-05082 Rev. A

Figure 1-4 The Common Box

Figure 1-5

Figure 1-6 The Common Box Assembly

1-6

March 2001

Page 9

DRAFT RF Front End System Integration Manual

Blind-mate

Connector

Figure 1-7 The Transmit Module Assembly

Breather

Vent.

(Typ. 2 Plcs)

220 VAC

Connector

(Typ. 2 Plcs)

044-05082 Rev. A

1-7

March 2001

Page 10

DRAFT RF Front End System Integration Manual

044-05082 Rev. A

Figure 1-8 Masthead Unit Interface Front and Rear Views.

1-8

March 2001

Page 11

DRAFT RF Front End System Integration Manual

Section 2 Installation Instructions

2-1 Introduction

This section contains unpacking, inspection, installation instructions and recommendations for the

RF Front End (RFFE) System. It is important that the licensee perform the following tasks correctly and in good faith:

1. Carefully read all material in this section prior to equipment unpacking or installation.

2. Also, read and review the operating procedures in section 3 prior to installing the equipment.

3. If applicable, carefully review the Federal Communications Com mission (FCC) rules as they

apply to your installation. DON'T TAKE CHANCES WITH YOUR LICENSE.

2-2 Site Survey

Powerwave Technologies recom mends that site surveys be perform ed by qualified individuals or

firms prior to equipment or dering or installation. Performing a detailed s ite survey will reduce or

eliminate installation and turn-up delays caused by oversights. A general site sur vey form is provided in appendix B. This form is commonly used by Powerwave field engineers and may be

used as a guide. Pay particular attention to power plant capacity, air conditioning needs, RF and

AC/DC cabling/breaker requirements.

2-3 Electrical Service Recommendations

Powerwave recommends that:

• Proper AC line conditioning and surge suppression be provided on the primary AC input to the

+27 VDC power source.

• All electrical service should be installed in accordance with the National Electrical Code, any

applicable state or local codes, and good engineering practice.

• Straight, short ground runs be used.

• The electrical service must be well grounded.

Circuit breakers should be c apable of handling the antic ipated inru sh c ur rent, in a load center with

a master switch.

2-4 Air Conditioning

An air-conditioning unit is not required for this Powerwave Equipment.

2-5 Unpacking And Inspection

This equipment (as applic able) has been operated, tes ted and calibrated at the f actory. Caref ully

open and remove the Masthead Unit (MHU) components (2 transmit modules, 1 common box and

1 mounting frame assembly with associated mounting hardware) and Masthead Unit Interface

(MHUI) from their r espective containers. Retain all pack ing material that can be reas sembled in

the event that the unit must be returned to the factory. Please perform the following steps:

Exercise care in handling equipment during inspection to prevent damage caused by

rough or car eless handling.

044-05082 Rev. A

AUTION

C

2-1

March 2001

Page 12

DRAFT RF Front End System Integration Manual

1. Visually inspect the MHU components and the MHUI for damage that may have occurred

during shipment.

2. Chec k for evidence of water damage, bent or warped chassis, loos e screws or nuts , or extraneous packing material in the connector(s).

AUTION

C

Before applying power, make sure that all connectors to the Units are secure. Make

sure that the input and output of the units are properly terminated at 50 ohms. Do not

operate the system without a load attached. Refer to section 1, table 1-1 for input

power requirements. Excessive input power may damage the equipment.

If possible, inspect the equipment in the presence of the delivery person.

If the equipment is damaged:

• The carrier is your first area of recourse.

• A claim should be filed with the carrier once the extent of any damage is assessed.

We c annot stress too s trongly the importance of IMMEDIATE car eful ins pection of the equipm ent

and the subsequent IMMEDIATE filing of the necessary claims against the carrier if necessary.

If the equipment is damaged and must be returned to the factory:

• Please write or phone for return authorization. Refer to section 6-3.1 for instructions.

• Powerwave may not accept returns without a return authorization.

Claims for loss or damage m ay not be withheld from any payment to Powerwave nor may any

payment due be withheld pending the outcome thereof. WE CANNOT GUARANTEE THE

FREIGHT CARRIER'S PERFORMANCE

2-6 Installation Instructions

The RFFE Mast Head Unit (MHU) is designed for installation on the antenna tower. The host

equipment must permit acces s to the MHU for AC, monitor and RF cables. Proper ventilation is

also required. Powerwave recomm ends that the MHU be clamped directly to the antenna pole

(see figure 1-3 for mounting fram e dimensions). A pole extension may be necessary for some

cell sites. However, if the MHU is mounted to a surfac e, ensure that there is a minimum clearance of six inches between the mounting surface and the fans to allow for proper air circulation.

The RFFE Mast Head Interface (MHUI) is mounted in the host base s tation cabinet or rack . The

base station enclosure mus t permit access to the MHUI for; DC power, RF and m onitor cables.

Proceed with the installation instructions as follows:

ARNING

W

Verify that the ON/OFF switch on the MHUI is in the OFF position. Turn off external

primary AC and DC power before connecting power cables.

1. Install the MHUI into the host base station and secure it into place using #10x32x1/2 Phillips

screws and #10 flat washers.

2. Before assembling the MHU, inspect the blind mate connector on the common box and

transmit modules. Verify that the pins are straight, and that the alignment shield is not bent.

3. Turn off the 220 VAC circuit breaker that feeds the transmit modules.

ARNING

W

Do not slam the transmit modules into the common box. Forcing the modules into the

housing at too fast a rate may cause inproper connection or damage to the connector.

044-05082 Rev. A

2-2

March 2001

Page 13

DRAFT RF Front End System Integration Manual

4. Clamp the MHU frame to the antenna tower (see figure 1-4 for frame dimensions).

5. Place the common box into it’s location on the MHU frame (see fiqure 1-1). Secure in place

with the supplied screws.

6. Place a transmit module on the MHU frame. Slide the module toward the common box until it

locks into place with the blind mate connector on the common box. Tightened down with the

supplied screws.

7. Repeat step 5 for the second transmit module.

8. Connect the RF cables to the MHU.

9. Connect the 220 VAC power cable from the host base station’s AC power breaker panel to

the MHU. Refer to figure 2-1 and xx and table 2-1 for pin designations.

10. Connect the TX/RX TO MHU (J1a) on the MHUI to the RF IN/OUT TO MHUI (J2a) port on the

common box.

11. Connect the RX INPUT FROM MHU (J1b) port on the MHUI to the RF OUT TO MHUI (J2b)

port on the MHU.

12. Connect the TX INPUT (J2) port on the MHUI to the TX IN port of the host base station.

13. Connect the RX OUTPUT (J3) on the MHUI to the Rx OUT port of the host base station.

14. Connect the J4 RX OUTPUT on the MHUI to the Rx DIVERSITY OUT on the host base

station.

15. Connect the MHU CONTROL cable on the MHUI to the CONTROL (J3) port on the MHU.

Refer to figures 2-1 and 2-2 and tables 2-2 and 2-5 for pin locations and pin designations.

16. Lift the safety cover on the MHUI DC IN terminal board and connect the dc power cable.

There is no polarity on the terminal board, therefore it doesn’t matter which pin you connect

to. Refer to figure 2-5 and table 2-6. Replace the safety cover.

17. Remove the safety cover from the BATT1 terminal board and connect the host battery backup cable. There is no polarity on the terminal board, therefore it doesn’t matter which pin you

connect to. Refer to figure 2-1 and table 2-1. Replace the safety cover.

18. Repeat step 17 for the BATT2 connection.

19. Remove the plastic cover from the alarms terminal board. Connect the alarm cables to their

appropriate terminal. See figure 4-4 for pin locations designation.

ARNING

W

Check your work before applying AC and DC voltage to the system. Make certain all

connections are tight and correct.

Measure primary DC input voltage. DC input voltage should be +26 VDC ±1.0 Vdc. If the DC input voltage is above or below the limits, call and consult Powerwave before you turn on your amplifier system.

Refer to section 3 for initial turn-on and checkout procedures.

044-05082 Rev. A

2-3

March 2001

Page 14

DRAFT RF Front End System Integration Manual

Figure 2-1 DC IN, BATT1, BATT2 Terminal Board Layout

Table 2-1 DC IN, BATT1, BATT2 Terminal Designations

Terminal Point Designation

No Polarity 27VDC

No Polarity 27VDC RTN

2-7 MHU Power, Alarm, Control, and RF Connector

2-7.1 MHU Power

The system 220VAC power is routed to the MHU via the host circuit breaker panel then to the J5

connector on the Tx module (refer to figure 1-5 for the connector location and figure 2-1 and table

2-1 for the connector pin location and designation. The 220VAC is internally routed to the fans

and the module’s rectifier (power supply) circuit that reduces the 220VAC signal to the 27VDC

needed to power the amplifier. The power supply circuit also generates the +12VDC and –8VDC

used to power the MHU internal components.

The amplifier alarm system from the MHU to the MHUI is routed by way of the common box assembly. Connections on the amplifier ar e m ade through the blind m ate connector . Refer to table

2-3 for a description of the alarms and controls.

J5

A

C

B

220VAC IN

Figure 2-2 220VAC Input Connector

044-05082 Rev. A

Table 2-2 220VAC Pin Designation

Pin Designation

ALine

BLine

C Neutral

2-4

March 2001

Page 15

DRAFT RF Front End System Integration Manual

Table 2-3 MCPA Alarms & Controls

Items Specifications Remarks

Alarms & Controls TTL Level; +5 Volts

Buffer: 74ABT244 (5V) - recommended

Deletion Alarm When unit does not exist (HEAR_PAU)

Equipped: GND Deletion OPEN

Function Fail Alarm When unit does not exist (HEAR_PAU)

Normal: High Abnormal GND

VSWR Alarm

3:1 (6dB ± 1dB) @ 35dBm-48dBm Output Power. PAU

remains normal operation when this alarm condition

disappears (NOT shutdown)

High Temp. Alarm This alarm only at +75ºC. +5 ºC//-0 ºC RS-485

Over Power Output

Alarm

@output power is greater than +48.5 dBm ±0.5dB.

MCPA will recover when the alarm condition disap-

pears. (NOT shutdown).

DC Fail Alarm

@ +20.5 Vdc ± 0.5V or +29 Vdc ± 0.5V. When this

alarm occurs the MCPA shall shut-down

Loop Fail Alarm When an alarm occurs on the feed forward path. RS-485

EN/DISABLE Reserved RS-485

The Alarm Interf ace connector on the back of the MHUI is a 9-pin female D-sub connector that

permits serial interfac e with the external alarm monitor. Refer to figur e 2-3 and table 2-3 for c onnector pin definition.

D-Line

D-Line

RS-485

RS-485

RS-485

Figure 2-3 MHU Control, RS-485 DTE Connector

Table 2-4 MHU CONTROL Connector Pin Designations

2-8 Remote Control and Status

2-8.1 RS-485 Physical Layer

51

96

Pin Designation

1 RS-485H

2 RS-485L

3 Common

The MHUI supports an RS-485 differential serial asynchronous communications link operation at

9600 baud, 1 bit start, 8 bit data, 1 bit parity, 1 bit stop bit, no parity. The MHUI port supports

redundant RS-485 drivers and receivers; the active driver and receiver pair shall be selected by

the state of the supplied RS_485_SEL lines available at the MHUI alarm terminal board. The

MHUI serves Addreses 10h to 13h. The MHUI terminates the RS-485 differential receive and

044-05082 Rev. A

2-5

March 2001

Page 16

DRAFT RF Front End System Integration Manual

transmit lines with 120 ohms. Because this communications bus is also shared with other system

resources, the MCPA supports the following asynchronous packet format communications

protocol.

The Low Speed Bus (LSB) 1 and 2 are selected by the following truth table:

Table 2-5 The LSB 1 and LSB 2 Selection Truth Table

LSB RS_485_SEL_H RS_485_SEL_L

110

201

2-8.2

Asynchonous Packet Protocol

The following protocol or similar to support duplex operations of two antennas. The packet format

used for both commands and responses is as follows:

Table 2-6 Asychronous Packet Protocol

Byte Field Description

0 Source ID Address of Source

1 Destination ID Address of Destination

2 CMD/ECHO Command/Echo field

3 LEN Length of transparent binary Data field bytes

4 ADDITIVE CSUM Checksum of all preceding and Data bytes

5 to 4+ LEN Data LEN data bytes for LEN>0, LEN<256

J3

A

C

B

044-05082 Rev. A

CONTROL

Figure 2-4 J3 CONTROL Connector

Table 2-7 J3 CONTROL Connector Pin Designation

Pin Designation

A RS-485H

B RS-485L

C Common

2-6

March 2001

Page 17

DRAFT RF Front End System Integration Manual

2-9 Commands to the MHUI

The CMND/ECHO byte is used to send commands from the host to the MHUI as follow:

Table 2-8 CMND/ECHO comands from the Host to the MHUI

Byte Command

LEN=00H;

CMND/ECHO=

00H Report base status

01H Enable HPA in MHU and report and report base status

02H Disable HPA in MHU and report base status

03H Report extended status

04H Interrogation of temperature in MHU at HPA heat sink

05H Interrogation of RF-output power at MHU HPA output

06H Interrogation of RF-input power at the MHU HPA input

07H Interrogation of RF-input power in the MHUI at TX path after the cell size

attenuator

08H Interrogation of current cable normalization attenuator settings in MHUI

09H Interrogation of current cell cell size attenuator settings in the MHUI

0AH Interrogation of current MHUI attenuator control status for cell size and cable

normalization

0BH Interrogation of (last) manual adjustment value for the cable normalization

0CH Interrogation of (last) manual adjustment value for the cell size attenuator

0DH Switch off remote control of cable normalization attenuators, switch on manual mode

and and report ext. status. The LED for remote control shall be switched off and the

LED for manual controll shall be switched on. Use last stored manual adjustment

value.

0EH Switched off remote control of cable normalization attenuators, switch on automatic

mode and report ext. status. The LED for remote control shall be switched off and

the LED for auto control shall be switched on. Use last stored value calculated by

the automatic control alogorithm.

0FH Switch off remote control of cable normalization attenuators, switch on mode, which

was valid before switching to remote control and report ext. status. The LED for re-

mote control shall be switched off and the LED for automatic control or manual con-

tol shall be switched on. Use last stored manual adjustment value.

10H Switch Cell Size control to manual and report ext. status. Illuminate front panel LED

for manual cell size setting, switch off front panel LED for remote cell size setting.

Use last stored manual adjustment value.

11H Report extended Status and then rest MHUI and MHU. Restart with default settings.

LEN=01H

CMD/ECH=

12H Remote control of cable normalization attenuator: Stop automatic or manual setting

of the attenuator and use fixed value in data byte. Illustratie front panel LED for re-

mote cable normalization. Store current attenuator value for later usage.

13H Remote control of cell size attenuator: Stop manual control of cell size

attenuator use value in data byte. Illuminate front panel LED for remote cell size

setting Store current attenuator value for later usage.

CMD/ECH=

14h-FFH

Reserved

044-05082 Rev. A

2-7

March 2001

Page 18

DRAFT RF Front End System Integration Manual

2-9.1 Responses from the MHUI

The MHUI responses always echo the received CMND byte as the ECHO byte of the response

packet. Amplifier base status is reported by setting the LEN field to 01H and reporting the following bit mapped byte in the data field of the response packet for CMD==00h, 01h, 02h base status.

Table 2-9 Bit Mapped Byte in the Data Field fo Response Packet for

CMD==00h, 01h, 02h Base Status

Byte Specification

b0 1=High VSWR shutdown/0=normal

b1 1=High Temperature condition/0=normal

b2 1=Over-temperature shutdown/0=normal

b3 1=Partial Power supply fail at MHU/0=normal

b4 1=Fan fail at MHUI, if fan is implemented/0=normal

b5 1=Over Power shutdown/0=normal

b6 1=Fan ON/0=Fan OFF (if fan is implemented in the MHUI, else 0)

b7 1=Amplifier Enable/0=Amplifier Disabled

OTE

N

In case of RF overpower and high VSWR the shutdown condition will be alarmed

only after three unsuccessful attempts of self recovery.

Table 2-10 Bit Mapped Byte in the Data Field for Response Packet for

CMD==03H, 0DH, 0EH, 0FH, 10H or 11H Report Extended Status

Byte Specification

b0 1=partial failure HPA/0=normal

b1 1=partial failure LNA/0=normal

b2 1=total failure HPA/0=normal

b3 1=total failure LNA/0=normal

b4 1=Loss of communication between the MHUI and MHU/0=normal

b5 1=High VSWR warning (>3:1)/0=normal

b6 1=No TX input signal at MHUI/0=normal

b7 1=No TX input signal at MHU/0=normal

For CMD=04…0CH the data field contains the according value with the least significant bit at b0.

Depending on the length not used higher bits are filled with0.

Reply for command 0H4 (data field):

00H= -40 ºC, 1 ºC steps, 88H = +90 ºC

FEH< -40 ºC , FFH > +90 ºC

Reply for commands 05H, 06H and 7H (data field):

00H= -10 dBm, ¼ dB steps, FFH = 53 ¾ dBm

044-05082 Rev. A

2-8

March 2001

Page 19

DRAFT RF Front End System Integration Manual

Reply for commands 08H, 09H, 0BH and 0CH (data field):

Cell size attenuator:

00H= full attenuation 20dB, FFH= no attenuation 0dB, step size 20/255 dB

Cable normalization attenuator:

00H= full attenuation 20 dB, FFH= no attenuation 0dB, step size 20/255 dB

For commands 12H and 13H the value in the data byte is defined in the same way as above for

cell size and cable normalization respectively.

Table 2-11 MHUI Attenuator Control Status for: CMD==0AH

Byte Specification

b0 1=manual cell size control on/0=normal

b1 1=remote cell size control on/0=normal

b2 0=normal

b3 1=remote manual cable normalization on/0=normal

b4 1=automatic cable normalization algorithm on/0normal

b5 1=remote cable normalization on/0 =normal

b6 0=normal

b7 0=normal

For RF output power, temperature and attenuator values the MHUI shall submitt a rounded value

as long as the exact value is not available.

MHUI responses MUST commence within 50 ms (0.050 sec.) of reception of a valid command

(poll).

2-9.2 Hardware Reset

Reset both MHU and MHUI and restart with default settings. Refer to table 2-12.

Table 2-12 Default Settings

Reset Default Setting

Power Recovery Last known status

Hardware Reset Last known status

Manual Reset by Front Panel

Bottons

Software Reset via RS-485 Last known status

Initial Factory Preset

Press manual buttons for cell size adjustment, manual

button for cable loss normalization and the button for automatic

control simultaneously

Reset to initial factory preset

Cell Size Attenuator and Cable loss normalization attenuator at

max. attenuation (20dB for cable normalization attenuator,

20dB for cell size attenuator)

044-05082 Rev. A

Set front panel display to FFF

No LED is illuminated

2-9

March 2001

Page 20

DRAFT RF Front End System Integration Manual

p

p

J3

CONTROL

J2b

RF OUT TO MHUI

RF IN/OUT TO MHUI

To Rx

J1a

ANTENNA

Diversity

Antenna

To Rx/Tx

J2a

J1b

ANTENNA

Antenna

Battery

Backu

1

Battery

Backu

2

+27VDC

Rx OUT Rx DIVERSITY OUT Tx IN

ALARMS RS-485

HOST RADIO BASE STATION

Figure 2-5 System Interconnect Diagram

044-05082 Rev. A

2-10

March 2001

Page 21

DRAFT RF Front End System Integration Manual

Section 3 Operating Instructions

3-1 Introduction

This section contains operating instructions for Powerwave’s RF Front End system.

3-2 Location and Function of the MH U and MHUI Controls and Indicators

The Masthead Unit (MHU) is not equipped with controls or indicators. Instead, the MHU interfaces with the host base station by way of the Masthead Unit Interface (MHUI). The location of

the controls and indicators for the MHUI are shown in figure 3-1. And described in detail below.

Figure 3-1 MHUI Control Panel

3-2.1 Main Power

The MHUI has a main power switch/circuit breaker and a +24 VDC power indicator (LED) to indicate the power is cycled on the MHUI:

• The MHU amplifier alarm signal enters the amplifier in the DISABLED state and reports the

status as amplifier disabled.

• Except when the service loop shows continuity, in which case the MHU alarm signal will enter

the amplifier in the ENABLED state, unless faults or alarms would prohibit entry to such state.

3-2.2 Enable/Disable of Front Panel Functions

The front panel functions of the MHUI are key protected with the exception of the output power

display, monitoring alarms and main power switch.

3-2.3 MHUI Cell Size Attenuator Settings

The MHUI cell size setting is performed either manually or by remote control. This is indicated by

one of two LEDs illuminated.

At the front of the MHUI a push-button switch is used to enable RF power adjustments for cell

size. If the cell size is controlled by remote and if there is any manual adjustment via the frontpanel, the mode will be manual until a new RS-485 command is received. The attenuator adjustment range is between 0 and 20dB.

044-05082 Rev. A

3-1

March 2001

Page 22

DRAFT RF Front End System Integration Manual

3-2.4 MHUI Cable-Normaliztion-Attenuators Settings/Cable-Normalization-Mode Selection

Buttons

The MHUI cable normalization attenuator setting is performed either manually or by remote control or by an automatic control algorithm. This is indicated by one of three LEDs illuminated.

At the front of the MHUI a push-button switch is used to enable the manual setting of the cable

loss normalization attenuators, which are adjusted together with the same push-button switch as

used for manual cell size adjustment.

At the front of the MHUI a push-button switch is used, which enables the automatic control algorithm for cable normalization. If the cable normalization attenuator is being controlled by remote

and if there is any manual adjustment via the front-panel or a manual switch to the automatic

control algorithm, then the mode will be manual or automatic control until a new RS485 command

is received.

If the mode is manual and if the front-panel push-button switch for automatic control is pressed,

the new mode will be automatic control. If the mode is automatic control and if the front-panel

push button for manual adjustment is pressed, the new mode will be manual.

3-2.5 MHUI Alarm Indicators

Front-panel LED’s at the MHUI front-panel will show the alarms of MHU and MHUI. All of these

alarms can be interrogated via RS-485. There are three types of alarms indicated by contact closures; Minor, Major, and Critical

The alarm types are identified by their associated LED color. They are:

• Minor Alarm (Yellow)

• Major Alarm ( Flashing Red)

• Critical Alarm (Solid Red)

The following table identifies the alarm number and its related function.

Table 3-1 Alarms and Rela ted Function

Alarm Function

1

2

3

4

5

6

• High temperature condition at the MHU

• Fan fail at MHU

• Over-temperature shutdown at MHU

•

• Over RF power shutdown

• High VSWR shutdown at antenna port of MHU

• Partial fail of one MCPA in MHU

• Total fail of one MCPA in MHU

• Total Fail of both MCPA in MHU

•

• No TX input signal at MHUI

• No TX input signal at MHU

• Microprocessor in MHU not working

• Microprocessor in MHUI not working

• Loss of communication between MHUI and MHU

• Partial power supply failure at MHU

• Partial fail of LNA in MHU

• Total fail of LNA in MHU

044-05082 Rev. A

3-2

March 2001

Page 23

DRAFT RF Front End System Integration Manual

The alarm indicators show the instantaneous condition of the MHU and MHUI.

3-2.5.1 RF overpower

• The MHU-MHUI-system waits 500ms,

• then it will reduce the gain by 3 dB and then

• makes 3 attempts to recover the gain at 500ms intervals without submitting an alarm via

RS485 until (if not successful) it holds the current gain setting and reports an RF overpower

shutdown. The unit will still be transmitting.

3-2.5.2 RF Overpower

• The MHU-MHUI-system will wait 500ms until it shuts down.

• Three attempts are made to recover from shutdown at 500ms intervals without submitting an

alarm via RS-485

• If not successful, it makes a final shutdown and reports final status via the RS-485.

(with reduced gain)

3-2.5.3 High VSWR (> 5:1)

• The MHU-MHUI-system will wait 500ms until it shuts down

• Three attempts are made to recover from shutdown at 500ms intervals without submitting an

alarm via RS-485.

• If not successful, it makes a final shutdown and reports final status via the RS-485.

3-2.5.4 Loss of communication between MHU and MHUI (5 seconds without communication)

• The MHUI will switch off the MHU and turn it on later again for resetting the MHU controller.

• If the MHU responds, no alarms have to be submitted via RS-485 but an internal count must

be incremented.

• If this count exceeds 3, an alarm will be submitted via RS-485.

• The MHU will resume at previous status. The incremental count will then return to 0.

• If the MHU does not respond, an alarm will be activated via the RS-485 at the MHUI. The

MHU will then shut itself down.

3-2.6 The Digital Display

A digital display consisting of three seven segment LEDs is used to display the RF output power

of the MHU in dBm.

The display is also used for manual adjustment of the cell size and the cable normalization

attenuators. When the corresponding front panel push-buttons for manual adjustment are

pressed, the current attenuation value in dB is displayed with a minimum resolution of 1dB.

Th same digital display shows temperature in degrees C when a temperature push-button is

pressed. When released, the display reverts to output power.

044-05082 Rev. A

3-3

March 2001

Page 24

DRAFT RF Front End System Integration Manual

3-3 Initial Start-Up and O perating Procedures

To perform the initial start-up, proceed as follows:

• Double check to ensure that all input and output cables are properly connected.

AUTION

C

Before applying power, make sure that the input and output of the amplifiers are properly terminated at 50 ohms. Do not operate the amplifier without a load attached. Refer to Table 1-1 for input power requirements. Excessive input power may damage

the MCPA.

OTE

N

The output coaxial cable between the amplifier and the antenna must be 50 ohm coaxial cable. Use of any other cable will distort the output.

• Place the power ON/OFF switch on the MHUI front panel in the “ON” position.

• Allow the amplifiers to warm up for at least 5 minutes before taking power readings.

• Refer to Appendix A for the power setting procedure.

044-05082 Rev. A

3-4

March 2001

Page 25

DRAFT RF Front End System Integration Manual

Section 4 Principles of Operations

4-1 Introduction

This section contains a functional description of the Powerwave RFFE MCPA System. Refer to

figure 4-1 and figure 4-3 for the system and amplifier functional block diagrams respectively.

4-2 RF INPUT Signal

The maximum input power for all carrier f r equenc ies s hould not ex c eed the limits specified in sec tion 1, table 1-1 of this manual. For proper amplif ier loop balanc e, the out of band c om ponents of

the input signals should not exceed -60 dBc. T he input VSWR should be 2:1 maxim um (or better).

4-3 RF OUTPUT Load

The load impedance should be as good as possible (1.5:1 or better) in the working band f or good

power transfer to the load. If the am plifier is operated into a filter, it will m aintain its distortion

characteristics outside the signal band even if the VSW R is inf inite, provided the ref lected power

does not exceed one W att. A paras itic s ignal of less than one Watt incident on the output will not

cause distortion at a higher level than the normal forward distortion (i.e. -60 dBc).

4-4 System Functional Description

A two unit configuration, the RFFE is comprised of a weatherproof (NEMA 4 rating) outdoor Masthead Unit (MHU) booster system and an indoor rack mount Masthead Unit Interface (MHUI). The

MCPA system operates in the PCS frequency range of: 1850MHz to 1910MHz (receive) and

1930MHz to 1945MHz (transmit).

4-4.1 The MHU

The MHU has two solid-state power amplifiers for the transmit signals and low noise amplifiers for

the receive function. Both transmit and receive systems are redundancy protected, and in addition, there is space diversity provided for the receive system (see figure 1-1). The MHU employs

a common box unit that interfaces the two transmit modules to the MHUI. Signals to and from the

MHU interconnect to the base station transceivers through the indoor MHUI control.

4-4.2 The MHUI

The MHUI is the interface between the MHU system and the host base station. The MHUI reports

alarms via the RS-485 bus or form-C interface (see figures 2-3, 2-4, 4-4 and tables 2-3 and

2-6) and displays alarms using an LED display (see figure 1-1 and 3- 1). The MHUI hous es a low

power duplexer, control board, the system control panel, a pr eamp, and the cell size variable attenuators (both transmit and receive).

The composite RF signals from the base station radios are applied to the J1a (TX/RX TO MHU)

connector at the rear of the MHUI. From there the signal passes through a combiner a voltage

variable attenuator (VVA) for cell size setting, a second attenuator for cable loss normalization a

diplexer, a third VVA for cable loss normalization, then out through a two-way splitter. Each leg of

the splitter passes through an isolator, then the blind-mate connector to interface with the MCPA.

The signal returns to the MHUI via the blind-mate connector after being amplified by the MCPA

modules. The active power combiner combines the two high-power signals. The active power

combiner has the capability of switching MCPA channels off-line by the use of RF switches. If an

MCPA is not present, turned off, or faulted, the switch will open in that channel and physically disconnect that MCPA. The combiner maintains its low insertion characteristics when used in the

044-05082 Rev. A

4-1

March 2001

Page 26

DRAFT RF Front End System Integration Manual

single path configuration. Note that the splitter is not switched, therefore the power is automatically reduced by 3 dB, thus eliminating an output overdrive condition. The output of the combiner

is fed through a coupler, then a receive-band filter. The amplified RF signal is available for use at

the output of the receive-band filter (J2). The coupler is used to sample the output power to the

true RMS detector. The true RMS detector will supply the micro controller with an accurate average power regardless of the signal modulation type. The dynamic range is 25 dB. The power

reading is used during the gain initialization phase when deploying the system or monitoring to

detect excessive output power. In both cases the VVA will be adjusted accordingly.

RX Path RX Path RX Path

VVA Box

Dr.

Dr.

DiplexerDiplexer

Cable

Cable run from

base station to

masthead

PD

PD

HPA

HPA

MHUMHUI

Diplexer

Figure 4-1 RF Front End System Functional Block Diagram

4-4.3 Transmit Modules

Power output specifications for a two module system is listed in section 1, table 1-1. Each module

houses an MPA9505-55 MCPA and one 27VDC 1200 Watt power supply. It is a self-contained

plug-in unit and is functionally independent of the other transmit module. The transmit modules

are designed for parallel operation to achieve high peak power output, and for redundancy in unmanned remote locations.

4-4.3.1 MPA9505-55 MCPA

The MCPA is an AB amplifier that utilizes pre-distortion technology for linearization. The predistortion technique is effective because it compensates for the non-linear amplification characteristics of the power amplifier. The amplifier module, figure 1-6, has an average power output of

55 Watts maximum with intermodulation products suppressed to better than -40 dBc (at ±2.25

MHz from Fc) below carrier levels. The amplifier provides an amplified output signal with constant

gain and phase by adding approximately 30 dB of distortion cancellation on the output signal.

Constant gain and phase is maintained by continuously comparing active paths with passive references, and correcting for small variations through the RF feedback controls (refer to figure 4-3

for the amplifier’s functional block diagram). All gain and phase variations, for example those due

to temperature, are reduced to the passive reference variations

044-05082 Rev. A

4-2

March 2001

Page 27

DRAFT RF Front End System Integration Manual

Main Section

BLF2047s

BLF2047s

BLF2047s

BLF2047s

BLF2047s

BLF2047s

BLF2047s

BLF2047s

Combiner

Section

-30dB

SAMPLE

RF-OUT

VSWR

RF-IN

SYSTEM

DRIVER

(35dB)

MULTIFUNCTION

BOARD

uProcessor

GAIN

AGC

PHASE

Driver Section

VG3

VG2

VG1

OUTPUT DETECTOR

BLF2045s

BLF2045s

MRF284

2WPRE-D

30W.125W

BLF2045s

BLF2045s

Figure 4-2 MPA9505-55 MCPA Functional Block Diagram

4-4.4 Power Distribution

Primary AC and DC power for the RFFE system is provided by the host system. Each Tx module

on the MHU has its own +27VDC power supply, powered by 220VAC from the host circuit breaker

panel. The Tx power supply also produces the ±20VDC, +12VDC, and -8VDC for the systems

internal components.

4-4.5

Alarms

The presence of the two plug-in amplifier alarms can be detected at the ALARMS terminal board

at the rear of the MHUI control panel. Refer to figure 4-3 for a description of the connector and

pin designations.

Figure 4-3 Form C Dry Contacts Alarms Terminal Board

4-4.6

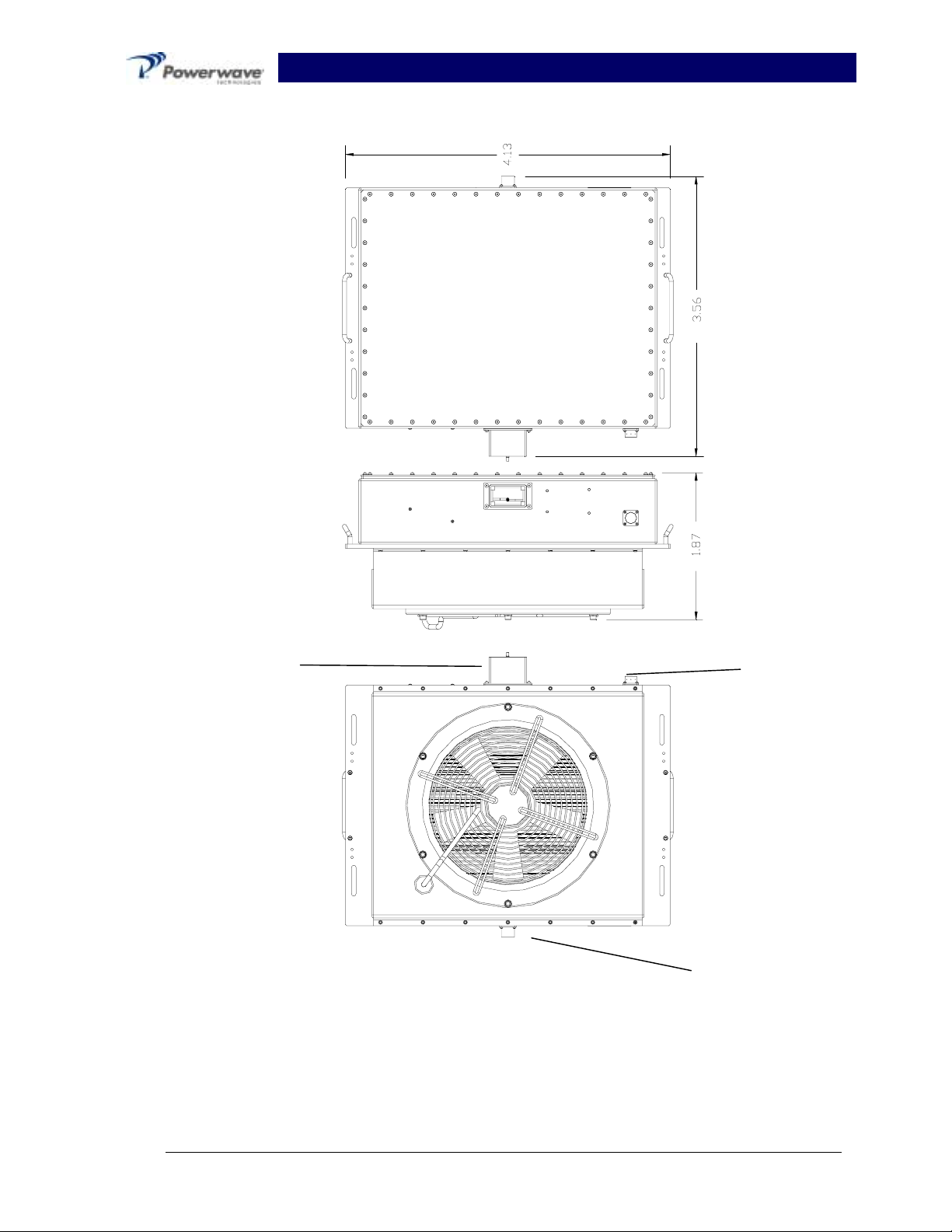

Amplifier Module Cooling

``

To maintain operating temperature, each transmit module is equipped with its own heat sink and

220 VAC cooling fan. Mounted at the back of the module (see figure 1-7), the fan forces outside

air onto the enclosure housing. The fans are field replaceable. Refer to section 5 for replacement

procedure.

044-05082 Rev. A

4-3

March 2001

Page 28

DRAFT RF Front End System Integration Manual

Section 5 Maintenance

5-1 Introduction

This section contains periodic maintenance and performance test procedures for the RF Front

End (RFFE). It also contains a list of test equipment required to perform the identified tasks.

OTE

N

Check your sales order and equipment warranty before attempting to service or repair

the unit. Do not break the seals on the equipment under warranty or the warranty will

be null and void. Do not return equipment for warranty or repair service until proper

shipping instructions are received from the factory.

5-2 Periodic Maintenance

Periodic maintenance requirem ents are listed in table 5-1. Table 5-1 also lists the intervals at

which the tasks should be performed.

ARNING

W

Wear proper eye protection to avoid eye injury when using compressed air.

Table 5-1 Periodic Maintenance

Task Interval Action

Cleaning:

Air Vents 30 Days Inspect and clean per para. 5-4.

Inspection:

Cables and

Connectors

Performance Tests:

12 Months Inspect signal and power cables for

12 Months Perform annual test per para. 5-5.

5-3 Test Equipment Required For Test

OTE

N

All RF test equipment must be calibrated to 0.05 dB resolution. Any deviation from

the nominal attenuation must be accounted for and factored into all output readings.

frayed insulation. Check RF connectors to be sure that they are

tight.

044-05082 Rev. A

5-1

March 2001

Page 29

DRAFT RF Front End System Integration Manual

Table 5-2 Test Equipment Required

Nomenclature Manufacturer Model

5-4 Clean Air Inlets/O utlets

The air inlets and outlets should be cleaned every 30 days. If the equipment is operated in a severe dust environment, they should be cleaned more often as necessary. Turn off DC power

source before rem oving fans. If dust and dirt are allowed to accumulate, the cooling eff iciency

may be diminished. Using either compressed air or a brus h with soft bristles , loosen and rem ove

accumulated dust and dirt from the air inlet panels.

5-5 Performance Test

Performance testing should be conducted every 12 months to ensure that the amplifier system

meets the operational specif ications listed in table 5-3. Also verify system perf ormanc e after any

amplifier m odule is replaced in the field. The test equipment required to perform the testing is

listed in table 5-2, and the test setup is shown in figure 5-1.

OTE

N

The frequencies used in this test are typical for an amplifier with a 15 MHz band from

1930 MHz to 1945 MHz. Select evenly spaced F1, F2, F3, and F4 frequencies that

cover the instanta neous bandwidth of your system.

044-05082 Rev. A

5-2

March 2001

Page 30

DRAFT RF Front End System Integration Manual

5-6 Field Replaceable Parts and Modules

The following parts and modules can be replaced in the f ield on site by a qualified technician with

experience maintaining RF power amplifiers and similar equipment:

• Transmit Modules

• Cooling Fans

5-6.1 Replacing a Transmit Module

The To replace a power amplifier module, proceed as follows:

1. Turn off the 220 VAC circuit breaker that feeds the MHU

2. Loosen the four screws that secure the amplifier module to the MHU chassis.

3. Carefully slide the amplifier away from the common box.

4. Install the replacement amplifier in reverse order.

AUTION

C

To avoid damage to the module and blindmate connector, care must be taken as not

to drop the module when removing it from the MHU support frame. The amplifier

weighs approximately 10 lbs.

5-6.2 Replacing the Cooling Fans

5-6.2.1 To replace a front cooling fan, proceed as follows:

1. Turn off the 220 VAC power to the MHU.

2. Unplug the power line to the fan.

3. Remove the six screws holding the fan to its chassis (you may be required to remove the

MHU from the mounting pole to gain access to the fan.

4. Pull fan out.

5. Install the replacement fan in reverse order of steps 1, 2, 3 and 4 above.

044-05082 Rev. A

5-3

March 2001

Page 31

RF Front End System Integration Manual

Section 6 Troubleshooting

6-1 Introduction

This section contains a list of problems which users have enc ountered and a few suggested actions that may correct the problem. If the suggested corrective action does not eliminate the

problem, please contact your Powerwave field representative or the factory for further instructions.

Note

Check your sales order and equipment warranty before attempting to service or repair

the unit. Do not break the seals on equipment under warranty or the warranty will be

null and void. Do not return equipment for warranty or repair service until proper

shipping instructions are received from the factory.

6-2 Troubleshooting

Refer to table 6-1 for troubleshooting suggestions.

Table 6-1 Troubleshooting

Symptom Suggested Action

The voltage indicator (green)

is not lit or blinking

1. Check that the MHU-MHUI power connectors are secure.

2. Check for proper power supply voltage.

1. Verify fan(s) are operating properly.

High Temp alarm LED is lit

Over Pwr alarm LED is lit Verify RF input level does not exceed spec. See table 1-1.

VSWR alarm LED is lit

2. Check ambient temperature (not to exceed spec. See

table 1-1).

Check output connections and cables for integrity and

tightness.

6-3 Return For Service Procedures

When returning products to Powerwave, the following procedures will ensure optimum response.

6-3.1 Obtaining an RMA

A Return Material Authorization (RMA) number must be obtained prior to returning equipment to

the factory for service. Please contact our Repair Department at (714) 466-1000 to obtain this

number, or FAX your request to (714) 466-5800. Failure to obtain this RMA number may result in

delays in receiving repair service.

6-3.2 Repackaging for Shipment

To ensure safe shipment of the amplifier, it is recommended that the package designed for the

amplifier is used. The original packaging material is reusable. If it is not available, contact our

Repair Department for packing materials and information.

044-05082 Rev. A

6-1

March 2001

Loading...

Loading...