Page 1

INSTALLATION & SERVICE

MANUAL

MODEL K-10

CONTINUOUS DUTY

POWER AMPLIFIER

850-870 MHz

25 June 1998

Powerwave Technologies, Inc. Tel: 949-757-0530

2026 McGaw Avenue Fax: 949-757-0941

Irvine, CA 92614 Web Site: www.pwav.com

044-05040 Rev. A

Page 2

TABLE OF CONTENTS

Par. Section 1 Page

No. General Description No.

1-1 Introduction...................................................................................................................... 1-1

1-2 General Description......................................................................................................... 1-1

1-3 Functional and Physical Specifications............................................................................ 1-1

1-4 Equipment Changes........................................................................................................ 1-1

1-5 Ordering Information........................................................................................................ 1-2

Section 2

Installation

2-1 Introduction...................................................................................................................... 2-1

2-2 Electrical Service Recommendations.............................................................................. 2-1

2-3 Unpacking and Inspection ............................................................................................... 2-1

2-4 Installation Instructions.................................................................................................... 2-2

2-5 Amplifier Module Alarm and Control Connector .............................................................. 2-2

Section 3

Operating Instructions

3-1 Introduction...................................................................................................................... 3-1

3-2 Location and Function of Amplifier Module Control and Indicators................................. 3-1

3-3 Initial Start-Up and Operating Procedures.......................................................................3-3

3-4 Variable Input Switch....................................................................................................... 3-3

Section 4

Principles of Operation

4-1 Introduction...................................................................................................................... 4-1

4-2 RF Input Signal................................................................................................................ 4-1

4-3 RF Output Load............................................................................................................... 4-1

4-4 Functional Description..................................................................................................... 4-1

4-5 K10 Amplifier Module....................................................................................................... 4-3

4-5.1 Main Amplifier.................................................................................................................. 4-3

4-5.2 Loop Control.................................................................................................................... 4-3

4-5.3 Amplifier Monitoring......................................................................................................... 4-3

4-5.4 Amplifier Module Cooling.................................................................................................4-3

4-6 Power Distribution............................................................................................................ 4-4

044-05040 Rev. A

ii

Page 3

TABLE OF CONTENTS (Continued)

Section 5

Maintenance

5-1 Introduction...................................................................................................................... 5-1

5-2 Periodic Maintenance...................................................................................................... 5-1

5-3 Test Equipment Required for Test................................................................................... 5-1

5-4 Cleaning air Inlets/Outlets................................................................................................ 5-2

5-5 Performance Test............................................................................................................ 5-2

5-5.1 Amplifier Performance Test.............................................................................................5-2

5-6 Field Replaceable Parts and Modules............................................................................. 5-4

5-6.1 K10 Power Amplifier Module ........................................................................................... 5-4

5-6.2 Cooling Fans.................................................................................................................... 5-4

5-6.3 Fuse................................................................................................................................. 5-4

Section 6

Troubleshooting

6-1 Introduction...................................................................................................................... 6-1

6-2 Troubleshooting............................................................................................................... 6-1

6-3 Return for Service Procedure.......................................................................................... 6-2

6-3.1 Obtaining an RMA ........................................................................................................... 6-2

6-3.2 Repackaging for Shipment.............................................................................................. 6-2

LIST OF ILLUSTRATIONS

Figure Page

No. No.

1-1 Five K10 Amplifiers in Subrack........................................................................................ 1-3

2-1 Alarm and Control Connector (on Rear of K10 Module).................................................. 2-2

2-2 K10 Amplifier, Rear view ................................................................................................. 2-4

3-1 K10 Amplifier Module Control and Indicators .................................................................. 3-1

3-2 Terminal Block TB1......................................................................................................... 3-3

4-1 Variable Input Switch....................................................................................................... 4-1

4-2 K10 Block Diagram.......................................................................................................... 4-2

5-1 Amplifier Test Setup diagram .......................................................................................... 5-3

LIST OF TABLES

Table Page

No. No.

1-1 Major Amplifier Components........................................................................................... 1-2

1-2 K10 Amplifier Functional Specifications........................................................................... 1-2

1-3 Load Mismatch Tolerance............................................................................................... 1-2

2-1 Amplifier Module Alarm and Control Connections........................................................... 2-3

3-1 Amplifier Module Control and Indicators.......................................................................... 3-2

5-1 Periodic Maintenance...................................................................................................... 5-1

5-2 Test Equipment Required................................................................................................ 5-2

6-1 Troubleshooting............................................................................................................... 6-1

044-05040 Rev. A

iii

Page 4

Section

1

GENERAL DESCRIPTION

1-1. INTRODUCTION

This manual contains information and procedures for installation, operation, and maintenance of

Powerwave’s K10 Continuous Duty Power Amplifier. The manual is organized into five sections

as follows:

Section 1. General Description

Section 2. Installation

Section 3. Operating Instructions

Section 4. Principles of Operation

Section 5. Maintenance

Section 6: Troubleshooting

1-2. GENERAL DESCRIPTION

The K10 amplifier is designed for trunking and conventional repeater applications requiring high

duty cycles. The K10 amplifier operates from RF power sources of 250 milliwatts up to 25 watts.

The amplifier consists of an input attenuator, a predriver amplifier, a microprocessor control

circuit, and two stages of amplification followed by a 7-pole distributed low-pass filter and

associated control circuitry. The K10 amplifier has a microprocessor control board that maintains

a constant output power under varying signal input and output load conditions. A system

functional block diagram of the Model K10 amplifier is contained in section 4 of this manual.

1-3. FUNCTIONAL AND PHYSICAL SPECIFICATIONS

Functional and physical specifications for the K10 amplifier are listed in tables 1-2 and 1-3.

1-4. EQUIPMENT CHANGES

Powerwave Technologies, Inc. reserves the right to make minor changes to the equipment

without notice, including but not necessarily limited to component substitution and circuitry

changes. Such changes may or may not be incorporated in this manual, although it is our

intention to keep each manual as up-to-date as possible. To that end, we ask that you, our

customer, share with us information acquired in field situations which might be of assistance to

another user. If you share it with us, we'll pass it around.

044-05040 Rev. A 1-1

Page 5

1-5. ORDERING INFORMATION

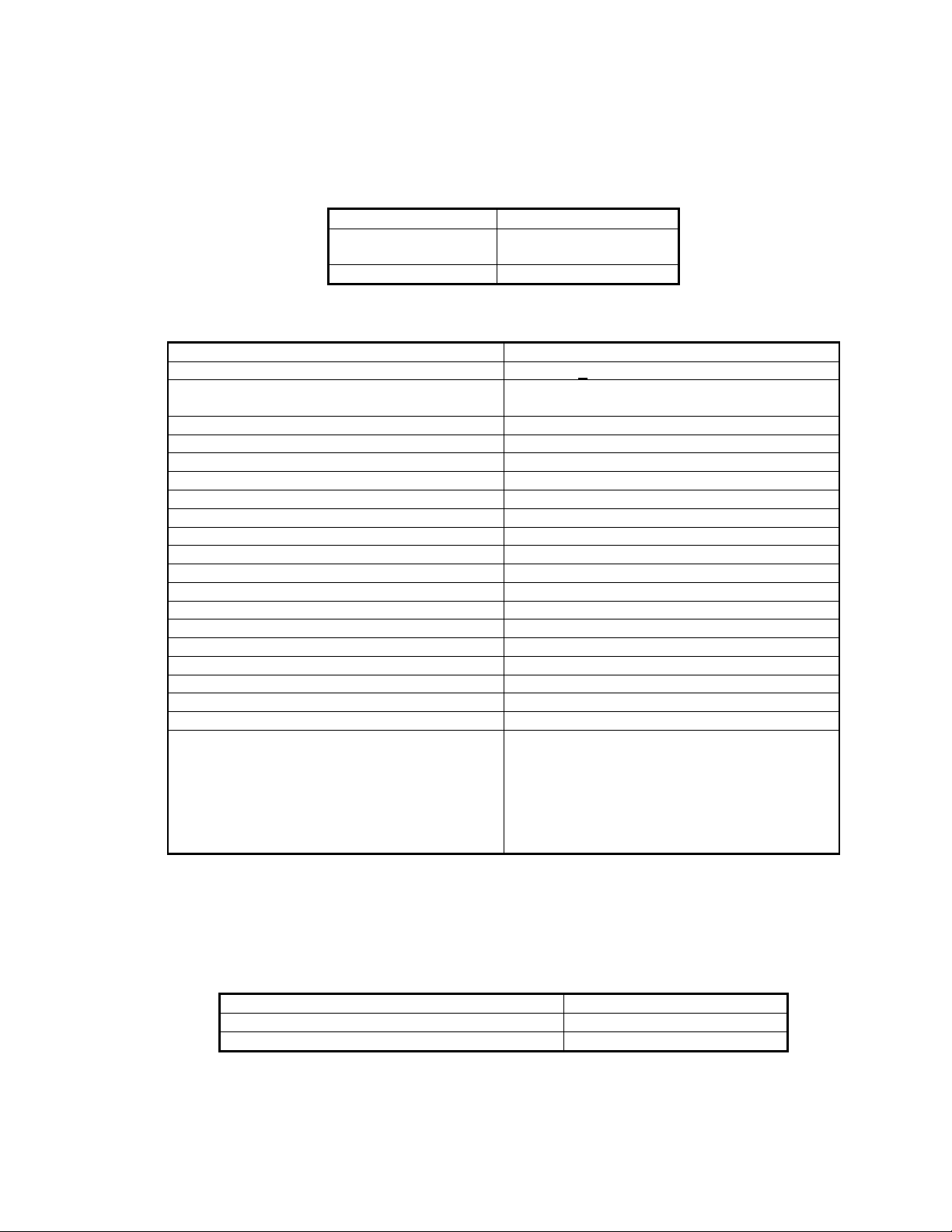

Table 1-1 following gives the part numbers and descriptions to be used when ordering either an

entire amplifier or replacement fans.

Table 1-1. Major Amplifier Components

MODEL NUMBER DESCRIPTION

K10

250 mW - 25 W 850-870

MHz Amplifier.

800-00889-001 Fan Assembly.

Table 1-2. K10 Amplifier Functional Specifications

Frequency Range: 850-870 MHz.

Operating Voltage: +28 Vdc (+1.0 Vdc)

Current Draw

9 Amperes Typical

11 Amperes Maximum

Duty Cycle: 100%

Power Input: 250 mW – 25 W.

Power Output: 100 Watts

Spurious & Harmonics: -70 dBc (Minimum)

Input/Output Impedance 50 ohms (Nominal)

Load VSWR Tolerance: See Chart

Input/Output Connector: Type 'N' Female

Vertical Mounting: 10.47"

Horizontal Mounting: 3.38"

Depth: 17.0"

Weight: 20 Pounds Nominal

Cooling Method: Fan Forced Air Over Heatsink

Operating Temp. Range: 0 °C. to +60 °C.

Storage & Transport: -10 °C. to +70 °C.

Humidity: 80% at +40 °C. (Noncondensing)

Altitude: 10,000 Feet Maximum

OPTIONS

INDICATORS

DC PWR ON, LOW OUTPUT, LOW INPUT,

HIGH INPUT, HIGH VSWR, OVER TEMP.,

Remote Control/Display Panel

L.E.D. POWER BAR METER

CONTROLS

PWR CONTROL (-10 dB)

NOTES: Manufacturer's Rated Output Power of this Equipment is for Single Carrier

Operation.

All specifications apply at +28 Vdc operating voltage.

Table 1-3. Load Mismatch Tolerance

Full Power, Sustained Operation 2:1 Maximum

Sustained Operation at Reduced Power 3:1

Microprocessor Shutdown 10:1

044-05040 Rev. A 1-2

Page 6

044-05040 Rev. A 1-3

Page 7

Section

2

INSTALLATION

2-1. INTRODUCTION

This section contains installation recommendations, unpacking, inspection, and installation

instructions for the K10 amplifier. Carefully read all material in this section prior to equipment

unpacking or installation. Also read and review the operating procedures in Section 3 prior to

installing the equipment. It is important that the licensee perform these tasks correctly and in

good faith. If applicable, carefully read Parts 73 and 74 of the Federal Communications

Commission (FCC) rules to determine how they apply to your installation. DON'T TAKE

CHANCES WITH YOUR LICENSE.

2-2. ELECTRICAL SERVICE RECOMMENDATIONS

Powerwave Technologies recommends that proper AC line conditioning and surge suppression

be provided on the primary AC input to the +28 Vdc power source. All electrical service should be

installed in accordance with the National Electrical Code, any applicable state or local codes, and

good engineering practice. Special consideration should be given to lightning protection of all

systems in view of the vulnerability of most transmitter sites to lightning. Lightning arrestors are

recommended in the service entrance. Straight, short ground runs are recommended. The

electrical service must be well grounded.

Each amplifier system should have its own circuit breaker, so a failure in one does not shut off the

whole installation. Circuit breakers should be thermal type, capable of handling an inrush current

of 90 Amps, in a load center with a master switch.

2-3. UNPACKING AND INSPECTION

This equipment has been operated, tested and calibrated at the factory. Only in the event of

severe shocks or other mistreatment should any substantial readjustment be required. Carefully

open the container(s) and remove the amplifier module(s). Retain all packing material that can be

reassembled in the event that the unit must be returned to the factory.

CAUTION

Exercise care in handling equipment

during inspection to prevent damage

Visually inspect the amplifier module for damage that may have occurred during shipment. Check

for evidence of water damage, bent or warped chassis, loose screws or nuts, or extraneous

packing material in the connector or fans. Inspect the rear panel connector for bent connector

pins. If the equipment is damaged, a claim should be filed with the carrier once the extent of any

damage is assessed. We cannot stress too strongly the importance of IMMEDIATE careful

inspection of the equipment and the subsequent IMMEDIATE filing of the necessary claims

against the carrier if necessary. If possible, inspect the equipment in the presence of the delivery

person. If the equipment is damaged, the carrier is your first area of recourse. If the equipment is

damaged and must be returned to the factory, write or phone for a return authorization.

Powerwave may not accept returns without a return authorization. Claims for loss or damage may

not be withheld from any payment to Powerwave, nor may any payment due be withheld pending

the outcome thereof. WE CANNOT GUARANTEE THE FREIGHT CARRIER'S PERFORMANCE.

caused by rough or careless handling.

044-05040 Rev. A 2-1

Page 8

2-4. INSTALLATION INSTRUCTIONS (Refer to figures 1-1 and 2-2)

The K10 amplifier module is designed for installation in a subrack that permits access to the rear

of the subrack for connection of DC power, RF, and monitor cables.

To install the amplifier proceed as follows:

1. Install subrack in equipment rack and secure in place.

2. Install the plug-in K10 amplifier module(s) in the subrack. Tighten top and bottom

thumbscrews.

3. Connect 50-ohm antenna cable to RF OUT connector on rear of amplifier module.

4. Connect the transceiver/exciter output to RF IN connector on rear of amplifier module.

5. Connect alarm and control cable to 9-pin D-sub connector on rear of amplifier module. Refer

to paragraph 2-5 for connector definition.

WARNING

Turn off external primary DC power before

connecting DC power cables.

6. Connect positive primary power to +28V terminal and negative primary power to GND terminal

on rear of amplifier module. Tighten the power connections.

7. Check your work before applying DC voltage to the system. Make certain all connections are

tight and correct.

8. Measure primary DC input voltage. DC input voltage should be +28 Vdc ±1.0 Vdc. If the DC

input voltage is above or below the limits, call and consult Powerwave before you turn on your

amplifier system.

9. Refer to section 3 for initial turn-on and checkout procedures.

2-5. AMPLIFIER MODULE ALARM AND CONTROL CONNECTOR

The alarm and control connections on the amplifier are made through a female 9-pin D-sub

connector (figure 2-1) and are listed and described in table 2-1.

Figure 2-1. Alarm and Control Connector (on Rear of K10 Module)

044-05040 Rev. A 2-2

Page 9

Table 2-1. Amplifier Module Alarm and Control Connections

PIN NUMBER FUNCTION DESCRIPTION

1 Low Input Power

Indicates alarm when input drive is approximately 2.5 dB below

specified range.

2 GND System Ground

3 Over Temperature

4 VSWR

5

Fwd Detect V

dc

Indicates alarm if junction temperature exceeds 60 °C

Indicates alarm for VSWR >3:1

Input drive range set

6 External Reset Resets microprocessor after alarm condition is set

7 DC Power

Indicates alarm condition when 24 Vdc > power supply > 30 Vdc

8 RF Output Status Indicates alarm if an output transistor fails

9 Not used No connection

044-05040 Rev. A 2-3

Page 10

Figure 2-2. K10 Amplifier, Rear View

044-05040 Rev. A 2-4

Page 11

Section

3

OPERATING INSTRUCTIONS

3-1. INTRODUCTION

This section contains operating instructions for the K10 Amplifier.

3-2. LOCATION AND FUNCTION OF AMPLIFIER MODULE CONTROL AND INDICATORS.

The location and function of the K10 amplifier module control and indicators is shown in figure 3-1

and is described in detail in table 3-1.

Figure 3-1. K10 Amplifier Module Control and Indicators

044-05040 Rev. A 3-1

Page 12

Table 3-1. Amplifier Module Control and Indicators

NO. NAME FUNCTION

1 DC PWR ON

Indicator

Green LED. Continuous illumination at voltages from 26-29.9 Vdc (this

is the acceptable operating range for the K10 amplifier). At DC voltages from 24-25.9 Vdc, the LED will flash and the output power will

remain at its specified level. At voltages less than 24 and greater than

30 Vdc, the K10 will shut down, and the DC POWER ON LED will

flash.

2 LOW OUTPUT

Indicator

Red LED. Activates when:

1. The op amp in the automatic gain control becomes saturated at its

rails, or

2. One of the finals in the amplifier becomes faulty.

3 LOW INPUT

Indicator

(Refer to figure

3-2)

4 HIGH INPUT

Indicator

(Refer to figure

3-2)

5 HIGH VSWR

Indicator

Red LED. Activates when input drive to the K10 drops by 1.5 dB from

its rated input drive. At this point, the led will flash, but the output will

remain at its rated power. Should the RF input drive drop by another

1 dB, the LED will illuminate continuously and there will be no output

from the K10 amplifier.

Red LED. Activates when input drive to the K10 is increased by 1.5 dB

from its rated input drive. At this point, the led will flash, but the output

will remain at its rated power. Should the RF input drive increase by

another 1 dB, the LED will iilllluummiinnaattee ccoonnttiinnuuoouussllyy and there will be no

output from the K10 amplifier.

Red LED. Activates at loads greater than 3:1. At this point, the amplifier output will drop by -3dB. Should the output load open (VSWR

>10:1) the indicator will still be lit and there will be no output from the

amplifier.

6 OVER TEMP

Indicator

Red LED. Activates when the heatsink of the amplifier exceed 63 degrees Celsius. At this point, the K10 amplifier will shut down, and there

will be no output. When the amplifier has sufficiently cooled, the K10

will resume normal operation.

7 PWR CONTROL

Adjustment

8 POWER

Indicator

Allows user to reduce the power output by more than 10 dB below the

factory-set 100 watts.

Output LED bar level indicator. Each bar represents 10 watts of output

power.

044-05040 Rev. A 3-2

Page 13

044-05040 Rev. A 3-3

Page 14

3-3. INITIAL START-UP AND OPERATING PROCEDURES

To perform the initial start-up, proceed as follows:

1. Double-check to ensure that all input and output cables are properly connected.

CAUTION

Before applying power, make sure that the input and output of the

amplifier are properly terminated at 50 ohms. Do not operate the

amplifier without a load attached. Refer to table 1-2 for input power

requirements. Excessive input power may damage the amplifier

NOTE

The output coaxial cable between the amplifier and the antenna must

be 50 ohm coaxial cable. Use of any other cable will distort the output.

2. Verify that power supply measures 28 ±1 Vdc. Apply power to the amplifier(s). Do not apply

an RF signal to the amplifier system.

3. Visually check the indicators on each amplifier module, and verify the following:

a. The DC PWR ON indicator (green) on all amplifier modules should be on.

b. The LOW INPUT indicator (red) on all amplifier modules should be on.

4. Turn on external exciter/transceiver and apply RF input signals. All red LEDs should turn off

within 2.5 seconds.

3-4. VARIABLE INPUT SWITCH

If the RF input to the K10 amplifier should change, figure 4-1 shows which DIP switch to activate

for various inputs. This should only be performed by a trained technician, and with prior approval

and instructions from Powerwave’s service department. Failure to receive prior permission to

open the amplifier could void the warranty.

1. Verify that no DC or RF is applied to the K10.

2. If necessary, remove K10 from subrack.

3. Remove the lid from the K10.

4. Locate the variable toggle switch (S1) on the 500-00800-001 driver PCB.

5. Refer to figure 4-1 for various switch settings.

044-05040 Rev. A 3-4

Page 15

Section

4

PRINCIPLES OF OPERATION

4-1. INTRODUCTION

This section contains a functional description of the K10 Amplifier.

4-2. RF INPUT SIGNAL

K10 amplifiers are equipped with an input variable switch that ranges from 250mW to 25W (see

figure 4-1). They have a predriver module that consists of an input attenuator pad, variable input

attenuator, and a power amplifier module that provides up to 13dB of gain. The microprocessor

uses detector circuitry to maintain a constant output level by sensing RF input, output, VSWR,

temperature, and driver/final failures. Input VSWR to the K10 should not exceed 2:1 for best

performance.

Figure 4-1. Variable Input Switch

4-3. RF OUTPUT LOAD

The load impedance should be as good as possible (2:1 or better) in the working band for good

power transfer to the load.

4-4. FUNCTIONAL DESCRIPTION

The K10 amplifier (see block diagram figure 4-2) is a linear, single channel amplifier that operates

in the frequency band from 850 MHz to 870 MHz. The amplifier specifications are listed in table

1-2. Each amplifier is a self-contained plug-in module and is functionally independent of other

amplifier modules. The amplifier modules are designed for parallel operation to achieve high

peak power output, and for redundancy in unmanned remote locations. Each amplifier in the

system can simultaneously transmit carrier frequencies, at an average total power output of 100

watts.

044-05040 Rev. A 4-1

Page 16

044-05040 Rev. A 4-2

Page 17

4-5. K10 AMPLIFIER MODULE

The amplifier module has an output of 100 watts power with all harmonics suppressed to better

than -70 dBc below carrier level. The amplifier module is comprised of:

Microprocessor board/alarm monitoring

Pre-driver board/splitter

Two final gain stages

Alarm monitoring, control, and display panel

Distributed low pass filter board/ combiner board

4-5.1. MAIN AMPLIFIER

The input and output of the amplifier employ three-stage, class AB amplifiers which provide

approximately 54 dB of gain in the 20 MHz frequency band from 850 MHz to 870 MHz. The

amplifier operates on +28 Vdc, and a bias voltage of +6 Vdc, and is mounted directly on a heat

sink. The alarm logic controls the +6 Vdc bias voltage which shuts down the amplifier.

4-5.2. LOOP CONTROL

The loop control circuitry consists of a microprocessor (see paragraph 4-2), which prevents the

RF output and input power from exceeding the safe operating maximum power levels.

The RF output power from the model K10 amplifier is controlled by the microprocessor. A

coupled detector on the low-pass filter PCB monitors the final RF output level and generates a DC

voltage (VFWD) proportional to the RF output level. VFWD is fed back to the microprocessor.

The microprocessor compares this voltage to a reference voltage, and varies the output gain of

the driver module to maintain a constant 100-watt output. The microprocessor also provides

over-temperature protection for the amplifier. All RF modules in the amplifier are mounted on a

common heatsink. The modules all have temperature-sensing lCs mounted on them which

constantly monitor heat and convert it to a DC voltage. This voltage is sent to the microprocessor

which shuts down the amplifier should temperatures exceed 63 degrees Celsius. When the

amplifier has sufficiently cooled down, the microprocessor re-enables the amplifier.

The output of the driver amplifier, approximately five watts of power, is fed to a 2-way power

splitter, amplified by the two parallel final amplifier modules, then combined and fed to the 7-pole

distributed low-pass filter. The filter attenuates any spurious and harmonic signals that may have

been produced by the various gain stages, for a final RF output of 100 watts. Double shielded

Teflon cable is used for all high power RF interconnections.

4-5.3. AMPLIFIER MONITORING

In the main amplifier modules, all normal variations are automatically compensated for by the

microprocessor. However, when large variations occur beyond the adjustment range of the loop

control, a low output alarm will occur. The alarms are displayed in the front panel indicators.

Status indicators on the front panel include DC PWR ON, LOW OUTPUT, LOW INPUT, HIGH

INPUT, HIGH VSWR, and OVER-TEMP. AN RF power-level adjustment potentiometer is also

provided on the front panel. The power adjustment allows the user to reduce the power output by

more than 10 dB below the factory-set 100-watt output. An output LED bar level indicator is also

provided on the K10. Each bar represents 10 watts of output power.

4-5.4. AMPLIFIER MODULE COOLING

Although each amplifier module contains its own heat sink, It is cooled with forced air. Two fans

are used for forced air cooling and redundancy. The fans, located on the rear of the amplifier

module and operating continuous duty from applied DC, draw ambient air in through the front of

the amplifier and exhaust hot air out the rear of the module. The fans are field replaceable.

4-6. POWER DISTRIBUTION

Primary DC power for the system is provided by the host system. This system supplies each

amplifier module with +28 Vdc directly via a 15-amp fuse located on the rear panel of the

044-05040 Rev. A 4-3

Page 18

amplifier. The amplifier module has a DC/DC converter that converts the +28 Vdc to +6 Vdc to

provide bias.

044-05040 Rev. A 4-4

Page 19

Section

5

MAINTENANCE

5-1. INTRODUCTION

This section contains periodic maintenance and performance test procedures for the K10. It also

contains a list of test equipment required to perform the identified tasks.

NOTE

Check your sales order and equipment warranty

before attempting to service or repair the unit. Do

not break the seals on equipment under warranty or

the warranty will be null and void. Do not return

equipment for warranty or repair service until proper

shipping instructions are received from the factory.

5-2. PERIODIC MAINTENANCE

Periodic maintenance requirements are listed in Table 5-1. Table 5-1 also lists the intervals at

which the tasks should be performed.

WARNING

Wear proper eye protection to avoid eye injury

when using compressed air.

Table 5-1. Periodic Maintenance

TASK INTERVAL ACTION

Cleaning

Air Vents 30 Days Inspect and clean per paragraph 5-4

Inspection

Cables and

Connectors

Performance Tests

5-3. TEST EQUIPMENT REQUIRED FOR TEST

Test equipment required to test the amplifier system is listed in Table 5-2. Equivalent test

equipment may be substituted for any item.

12 Months Inspect signal and power cables for

frayed insulation. Check RF connectors

to be sure that they are tight.

12 Months Perform annual test per paragraph 5-5.

NOTE

All RF test equipment must be calibrated to 0.05

dB resolution. Any deviation from the nominal

attenuation must be accounted for and factored

into all output readings.

044-05040 Rev. A 5-1

Page 20

Table 5-2. Test Equipment Required

NOMENCLATURE MANUFACTURER MODEL

Signal Generator H.P. 8648B

40 dB Attenuator, 250 Watt Tenuline

DC power supply H.P 6269B

Spectrum Analyzer H.P. 8560E

Dual Directional Coupler Narda

Power Meter / Sensor H.P. 437B / 8481A

Linear Discreet Amplifier

Digital Multi-Meter Fluke 73

Current Probe

5-4. CLEANING AIR INLETS/OUTLETS

The air inlets and outlets should be cleaned every 30 days. If the equipment is operated in a

severe dust environment, they should be cleaned more often as necessary. Turn off DC power

source before removing fans. If dust and dirt are allowed to accumulate, the cooling efficiency

may be diminished. Using either compressed air or a brush with soft bristles, loosen and remove

accumulated dust and dirt from the air inlet panels.

5-5. PERFORMANCE TEST

Performance testing should be conducted every 12 months to ensure that the amplifier system

meets the operational specifications listed in table 1-2. Also verify system performance after any

amplifier module is replaced in the field. The test equipment required to perform the testing is

listed in table 5-2, and the test setup is shown in figure 5-1.

NOTE

The frequencies used in this test are typical for an

amplifier with a band from 850 MHz to 870 MHz.

5-5.1. AMPLIFIER PERFORMANCE TEST.

This test is applicable to a subrack equipped with one to five plug-in K10 amplifier modules.

Perform the tests applicable to your system. To perform the test, proceed as follows:

1. Connect test equipment as shown in figure 5-1.

NOTE

Do not apply any RF signals at this time.

2. Turn on DC (28 V). Turn on signal generator and set frequency to 860 MHz.

HARMONICS TEST

3. With the power amplifier set at 100 watts power output, use the spectrum analyzer and

check the frequency band from 850 MHz to 870 MHz for harmonics. Harmonics should

be -70 dBc maximum.

SPURIOUS TEST

4. With the power amplifier set at 100 watts power output, use the spectrum analyzer and

check the frequency band from 850 MHz to 870 MHz for spurious signals. Spurious

signals should be -70 dBc maximum.

044-05040 Rev. A 5-2

Page 21

GAIN TEST:

5. Disconnect spectrum analyzer from test setup, and connect the power meter.

6. Apply the rated input RF drive to the K10. Verify that the unit delivers 100W out for rated

input.

Figure 5-1. Amplifier Test Setup Diagram

044-05040 Rev. A 5-3

Page 22

5-6. FIELD REPLACEABLE PARTS AND MODULES

The following parts and modules can be replaced in the field on site by a qualified technician with

experience maintaining RF power amplifiers and similar equipment:

1. K10 Power Amplifier Modules

2. Cooling Fans

3. 15 Amp Fuse

5-6.1. K10 POWER AMPLIFIER MODULE

To replace a K10 module, proceed as follows:

1. Loosen two thumbscrews that secure amplifier module to subrack.

CAUTION

When removing the amplifier from the subrack, it is very

important to support the amplifier such that the rear of the

module does not suddenly drop when the guide rail disengages

from the track. A drop such as this could damage the rear of the

amplifier.

2. Use the handles on the front of the module, and with a steady even pressure, pull the

module out of chassis.

5-6.2. COOLING FANS

To replace a cooling fan, proceed as follows:

1. Remove amplifier module from subrack.

2. Loosen three screws that secure fan to amplifier module. Disconnect fan power

connector from amplifier module.

3. Install replacement fan in reverse order of steps 1 and 2 above.

5-6.3. FUSE

The K10 amplifier 28 Vdc power input line contains a single fuse as follows:

Manufacturer: Littlefuse

Manufacturer’s Number: 313015

Rating: 15 amps

Style 3AG Slo-Blo

Size: 1/4 inch diameter

1-1/4 inches long

044-05040 Rev. A 5-4

Page 23

Section

6

TROUBLESHOOTING

6-1 INTRODUCTION

This section contains a list of problems which users have encountered and a few suggested

actions that may correct the problem. If the suggested corrective action does not eliminate the

problem, please contact your Powerwave field representative or the factory for further instructions.

NOTE

Check your sales order and equipment warranty

before attempting to service or repair the unit. Do

not break the seals on equipment under warranty or

the warranty will be null and void. Do not return

equipment for warranty or repair service until proper

shipping instructions are received from the factory.

6-2 TROUBLESHOOTING

Refer to table 6-1 for troubleshooting suggestions.

Table 6-1. Troubleshooting.

SYMPTOM SUGGESTED ACTION

1. Check that subrack power connection is secure.

Any voltage indicators (green)

are not lit or blinking

OVER TEMP alarm (red) is lit

HIGH/LOW INPUT alarm

(red) is lit

HIGH VSWR alarm (red) is lit

LOW OUTPUT alarm (red) is

lit

2. Check for proper power supply voltage.

3. Check fuses or circuit breakers on amplifier or subrack.

4. Verify that amplifier is fully inserted into subrack.

1. Verify fan(s) are operating properly.

2. Check ambient temperature (not to exceed spec – see

table 1-2)

Verify RF input level does not exceed spec – see table 1-2

Check output connections and cables for integrity and

tightness

Contact Powerwave field representative or factory.

044-05040 Rev. A 6-1

Page 24

6-3 RETURN FOR SERVICE PROCEDURES

When returning products to Powerwave, the following procedures will ensure optimum response.

6-3.1 Obtaining an RMA

A Return Material Authorization (RMA) number must be obtained prior to returning

equipment to the factory for service. Please contact our Customer Service Department at

(949) 757-0530 to obtain this number. Failure to obtain this RMA number will result in

considerable delays in receiving repair service.

6-3.2 Repackaging for Shipment

To ensure safe shipment of the amplifier, it is recommended that the package designed

for the amplifier be used. The original packaging material is reusable. If it is not

available, contact Powerwave’s Customer Service Department for packing materials and

information.

044-05040 Rev. A 6-2

Loading...

Loading...