®

INSTALLATION & SERVICE

MANUAL

SINGLE CHANNEL

POWER AMPLIFIER

NTGS86AA

869-894 MHz

25 WATTS AVERAGE POWER

12 August 1998

Powerwave Technologies, Inc. Tel: 949-757-0530

2026 McGaw Avenue Fax: 949-757-0941

Irvine, CA 92614 Web Site: www.pwav.com

TABLE OF CONTENTS

044-05045 Rev. A

Par. Section 1 Page

No. General Description No.

1-1 Introduction ............................................................................................ 1-1

1-2 General Description .............................................................................. 1-1

1-3 Functional and Physical Specifications .................................................. 1-1

Section 2

Installation

2-1 Introduction ............................................................................................ 2-1

2-2 Electrical Service Recommendations..................................................... 2-1

2-3 Unpacking and Inspection...................................................................... 2-1

2-4 Installation Instructions........................................................................... 2-2

2-5 Amplifier Module Power, Alarm, and Control Connector........................ 2-2

2-6 RS485 Connector................................................................................... 2-3

Section 3

Operating Instructions

3-1 Introduction ............................................................................................ 3-1

3-2 Initial Start-Up and Operating Procedures ............................................. 3-1

Section 4

Principles of Operation

4-1 Introduction ............................................................................................ 4-1

4-2 RF Input Signal ...................................................................................... 4-1

4-3 RF Output Load...................................................................................... 4-1

4-4 Amplifier Functional Description............................................................. 4-1

4-4.1 Main Amplifier ........................................................................................ 4-2

4-4.2 Amplifier Monitoring ............................................................................... 4-3

4-4.3 Amplifier Module Cooling ....................................................................... 4-3

4-5 Power Distribution .................................................................................. 4-3

Section 5

Maintenance

5-1 Introduction ............................................................................................ 5-1

5-2 Periodic Maintenance............................................................................. 5-1

5-3 Test Equipment Required For Test ........................................................ 5-1

5-4 Performance Test................................................................................... 5-2

5-4.1 Amplifier Performance Test.................................................................... 5-2

5-5 Field Replacement of the Module .......................................................... 5-7

2

TABLE OF CONTENTS (Continued)

Par. Section 6 Page

No. Troubleshooting No.

6-1 Introduction .............................................................................................6-1

6-2 Troubleshooting ......................................................................................6-1

6-3 Return for Service Procedures................................................................6-1

6-3.1 Obtaining an RMA...................................................................................6-1

6-3.2 Repackaging for Shipment......................................................................6-1

LIST OF ILLUSTRATIONS

Figure Page

No. No.

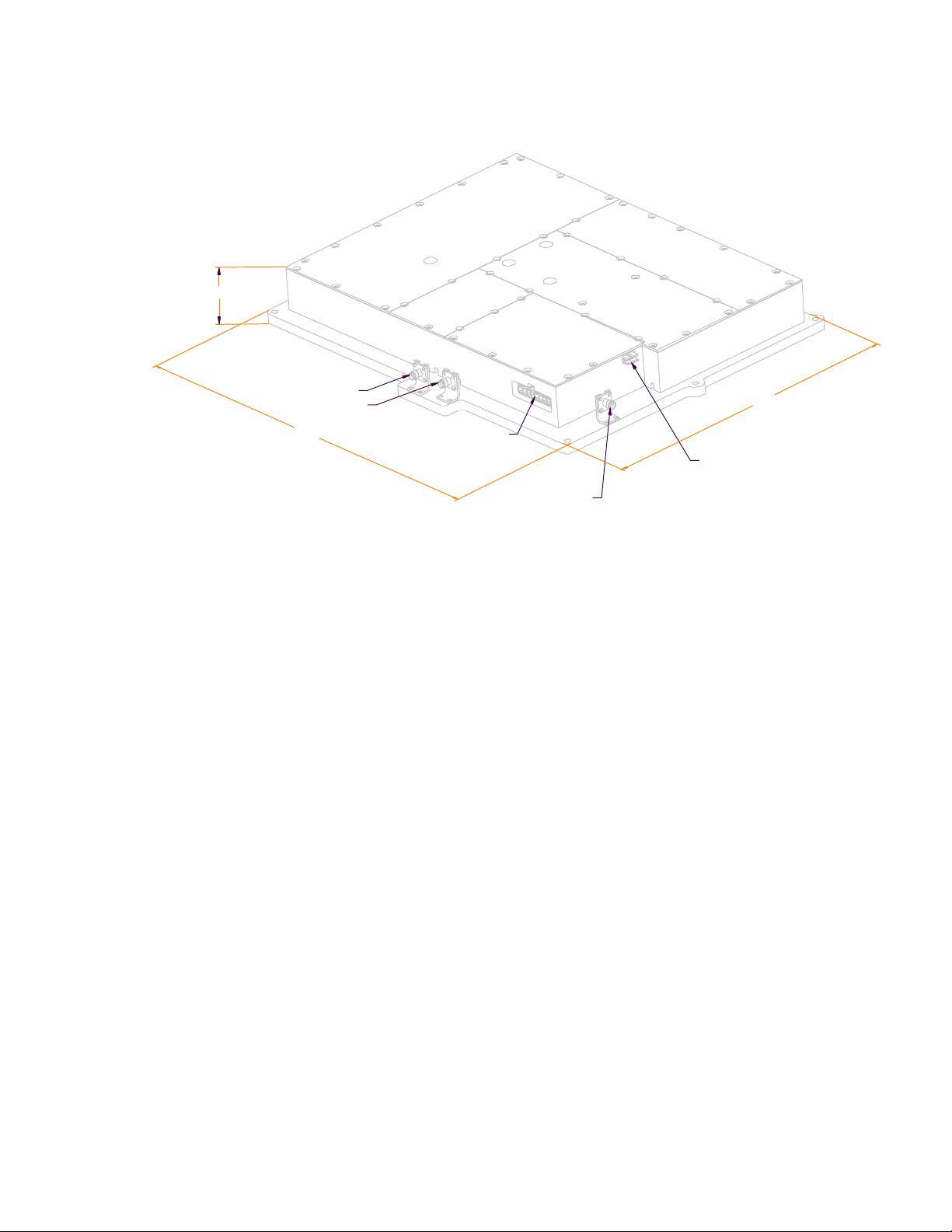

1-1 NTGS86AA Single Channel Power Amplifier ......................................... 1-3

2-1 Power, Alarm, and Control Connector (18-Pin Molex) ........................... 2-2

2-2 RS485 Connector................................................................................... 2-3

4-1 NTGS86AA Single Channel Power Amplifier Functional Block Diagram 4-2

5-1 NTGS86AA Amplifier Test Setup Diagram ............................................ 5-3

5-2 RF Input (CDMA Source) ....................................................................... 5-3

LIST OF TABLES

Table Page

No. No.

1-1 NTGS86AA Single Channel Power Amplifier Functional Specifications.....

1-2

2-1 18-Pin Molex Alarm, Control, and Power Connections .......................... 2-3

2-2 RS485 Pin Definition.............................................................................. 2-3

5-1 Periodic Maintenance............................................................................. 5-1

5-2 Test Equipment Required ...................................................................... 5-2

5-3 Single Channel Power Amplifier Test Data Sheet.................................. 5-4

6-1 Troubleshooting ..................................................................................... 6-1

3

Section

1

GENERAL DESCRIPTION

1-1. INTRODUCTION

This manual contains information and procedures for installation, operation, and maintenance of

Powerwave’s model NTGS86AA single channel power amplifier (SCPA). The manual is organized

into six sections as follows:

Section 1. General Description

Section 2. Installation

Section 3. Operating Instructions

Section 4. Principles of Operation

Section 5. Maintenance

Section 6: Troubleshooting

1-2. GENERAL DESCRIPTION

The NTGS86AA is a linear, single-channel power amplifier that operates in the 25 MHz frequency

band from 869 MHz to 894 MHz. It is designed as a self-contained module with EMI containment

for use in both an indoor and outdoor North American Cellular Base Stations. Its flat base plate

allows for mounting on a flat thermal-absorbing surface to provide adequate heat dissipation,

thereby avoiding the use of any built-in fans.

Each amplifier module has a power, alarm, and control connector that allows the host system to

monitor the amplifier module performance. Primary power for the amplifier is +26 Vdc.

1-3. FUNCTIONAL AND PHYSICAL SPECIFICATIONS

Functional and physical specifications for the amplifier are listed in table 1-1.

4

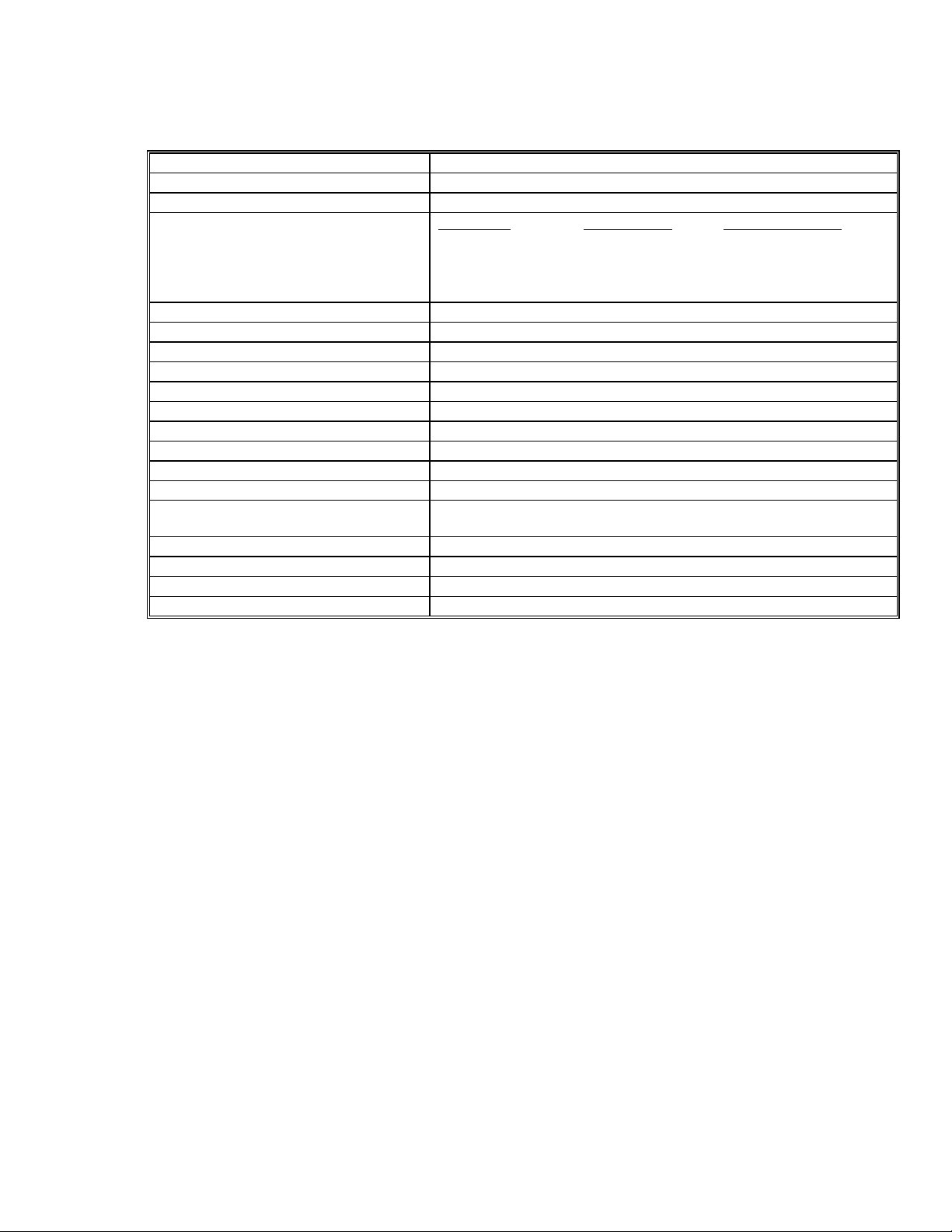

Table 1-1. NTGS86AA Single Channel Power Amplifier Functional Specifications

Frequency Range 869-894 MHz (25 MHz Bandwidth)

Maximum Average Input Power 13 dBm

Continuous Average Output Power 25 Watts

Spurious Emissions @ Maximum

Rated Output Power (44 dBm)

RF Gain 43 ±2 dB

Gain Flatness:

Output Protection: Mismatch Protected

Input Port Return Loss: VSWR 2:1 Max.

Out of Band Spurious: Less than -14 dBm

DC Input Power:

Operating Temperature: -15 ºC. to +85 ºC. (heatsink temperature)

Storage Temperature: -40 ºC. to +70 ºC.

Operating Humidity: 5 % - 95 % Relative Humidity (Noncondensing)

Storage Humidity: 5 % - 95 % Relative Humidity (Noncondensing)

DC Input, Alarm, and Control

Connector:

RF Input Connector: SMA Female

RF Output Connector: SMA Female

RF Sample Connector:

Dimensions (inches): Width: 12.515; depth: 9.900; height: 1.670

Frequency Requirement Meas. Bandwidth

750 kHz offset -46 dBc 30 kHz

1.23 MHz offset -61 dBc 30 kHz

1.5 MHz offset -61 dBc 30 kHz

1.98 MHz offset -61 dBc 30 kHz

±

0.15 dB for any 2-MHz band within frequency range.

+26 ± 0.5 Vdc, 260 mV p-p max. ripple, ≤350 watts

18-Pin Molex

SMA Female (27±1 dB below RF Output)

5

RF OUTPUT

RF INPUT

9.900

12.515

18 PIN MO LEX CONNE CTOR

RS485 CONNECTOR

Figure 1-1. NTGS86AA Single Channel Power Amplifier

6

Section

2

INSTALLATION

2-1. INTRODUCTION

This section contains unpacking, inspection, and installation instructions and recommendations for

the Model NTGS86AA Single Channel Power Amplifier. Carefully read all material in this section

prior to equipment unpacking or installation. Also read and review the operating procedures in

Section 3 prior to installing the equipment. It is important that the licensee perform these tasks

correctly and in good faith. If applicable, carefully read Parts 73 and 74 of the Federal

Communications Commission (FCC) rules to determine how they apply to your installation. DON'T

TAKE CHANCES WITH YOUR LICENSE.

2-2. ELECTRICAL SERVICE RECOMMENDATIONS

Powerwave Technologies recommends that proper AC line conditioning and surge suppression be

provided on the primary AC input to the +26 Vdc power source. All electrical service should be

installed in accordance with the National Electrical Code, any applicable state or local codes, and

good engineering practice. Special consideration should be given to lightning protection of all

systems in view of the vulnerability of most transmitter sites to lightning. Lightning arrestors are

recommended in the service entrance. Straight, short ground runs are recommended. The

electrical service must be well grounded.

Each amplifier system should have its own circuit breaker, so a failure in one does not shut off the

whole installation. Circuit breakers should be thermal type, capable of handling the maximum

anticipated inrush current, in a load center with a master switch.

2-3. UNPACKING AND INSPECTION

This equipment has been operated, tested and calibrated at the factory. Carefully open the

container(s) and remove the amplifier module(s). Retain all packing material that can be

reassembled in the event that the unit must be returned to the factory.

CAUTION

Exercise care in handling equipment

during inspection to prevent damage

caused by rough or careless handling.

Visually inspect the amplifier module for damage that may have occurred during shipment. Check

for evidence of water damage, bent or warped chassis, loose screws or nuts, or extraneous packing

material in the connector. If the equipment is damaged, a claim should be filed with the carrier

once the extent of any damage is assessed. We cannot stress too strongly the importance of

IMMEDIATE careful inspection of the equipment and the subsequent IMMEDIATE filing of the

necessary claims against the carrier if necessary. If possible, inspect the equipment in the

presence of the delivery person. If the equipment is damaged, the carrier is your first area of

recourse. If the equipment is damaged and must be returned to the factory, write or phone for a

return authorization. Powerwave may not accept returns without a return authorization. Claims for

loss or damage may not be withheld from any payment to Powerwave, nor may any payment due

be withheld pending the outcome thereof. WE CANNOT GUARANTEE THE FREIGHT

CARRIER'S PERFORMANCE

7

2-4. INSTALLATION INSTRUCTIONS

The NTGS86AA amplifier module is designed for installation on a heatsink that permits access to

the module for connection of RF cables and the power, alarm, and control connector.

To install the amplifier proceed as follows:

1. Install amplifier on heatsink with thermally conductive material inserted between amplifier

module and heatsink, and secure in place with four mounting screws.

2. Connect the antenna cable to

3. Connect the transceiver output cable to

(Refer to figure 1-1)

RF OUT

SMA connector.

RF IN

SMA connector.

4. Connect coupled RF output monitor cable to

Turn off external primary DC power before

connecting cable to 18-pin Molex connector.

5. Connect power, alarm, and control cable to 18-pin Molex connector.

6. Check your work before applying DC voltage to the system. Make certain all connections are

tight and correct.

7. Measure primary DC input voltage. DC input voltage should be +26 ±0.5 Vdc. If the DC input

voltage is above or below the limits, call and consult Powerwave before you turn on your

amplifier system.

8. Refer to section 3 for initial turn-on and checkout procedures.

2-5. AMPLIFIER MODULE POWER, ALARM, AND CONTROL CONNECTOR

The power, alarm, and control connections on the amplifier are made through an 18-pin Molex

connector (figure 2-1) and are listed and described in table 2-1.

RF SAMPLE

WARNING

SMA connector.

Figure 2-1. Power, Alarm, and Control Connector (18-Pin Molex)

8

TTaabbllee 22--11.. 1188--PPiinn MMoolleexx AAllaarrmm,, CCoonnttrrooll,, aanndd PPoowweerr CCoonnnneeccttiioonns

PIN SIGNAL DESCRIPTION SIGNAL NAME

1 Temperature Output (0-4.7 volts) TEMP_OUT

2 Reverse Power Detection (0-4.7 volts) REV_PWR

3 Forward Power Detection (0-4.7 volts) FWR_PWR

4 Ground GND

5NCNA

6

7 Ground GND

8 Ground GND

9 Ground GND

10 + Anxiety output (RS 422 level) ANX (+)

11 + Enable input (RS 422 level) ENABLE (+)

12

13 + Alarm output (RS 422 level) ALARM (+)

14

15 +26 Vdc VDD

16 +26 Vdc VDD

17 +26 Vdc VDD

18 +26 Vdc VDD

2-6. RS485 CONNECTOR

The RS485 connector (figure 2-2) allows the user to monitor the status of the amplifier, download

new firmware, and revise the amplifier attributes. The pin connections are defined in table 2-2.

−

Anxiety output (RS 422 level)

−

Enable input (RS 422 level) ENABLE (−)

−

Alarm output (RS 422 level) ALARM (−)

ANX (-)

s

1

Figure 2-2. RS485 Connector

Table 2-2. RS485 Pin Definition

PIN

1Rxd+

2

3

4Txd+

FUNCTIO

N

−

Rxd

−

Txd

4

9

Section

3

OPERATING INSTRUCTIONS

3-1. INTRODUCTION

This section contains operating instructions for the Multicarrier Cellular Amplifier.

3-2. INITIAL START-UP AND OPERATING PROCEDURES

There are no operating controls or indicators on the NTGS86AA amplifier module. To perform the

initial start-up, proceed as follows:

1. Double check to ensure that all input and output cables are properly connected.

CAUTION

Before applying power, make sure that the input and output of the

amplifier are properly terminated at 50 ohms. Do not operate the

amplifier without a load attached. Refer to table 1-1 for input power

requirements. Excessive input power may damage the amplifier

NOTE

The output coaxial cable between the amplifier and the antenna must

be 50 ohm coaxial cable. Use of any other cable will distort the output.

2. Turn on supply that provides +26 Vdc to the amplifier system.

3. Turn on external exciter/transceiver and apply RF input signals.

Section

4

PRINCIPLES OF OPERATION

4-1. INTRODUCTION

This section contains a functional description of the Single Channel Power

Amplifier (SCPA).

4-2. RF INPUT SIGNAL

The maximum input power should not exceed the limits specified in table 1-1.

10

4-3. RF OUTPUT LOAD

The load impedance should be as good as possible (1.5:1 or better) in the working

band for good power transfer to the load.

4-4. AMPLIFIER FUNCTIONAL DESCRIPTION

The NTGS86AA amplifier (figures 1-1 and 4-1) is a linear, single-channel power

amplifier that operates in the 25 MHz frequency band from 869 MHz to 894 MHz

at an output power of 25 watts. Each amplifier is a self-contained module and is

functionally independent of any other amplifier modules in the system. Each

amplifier module has an alarm board that monitors the amplifier performance. If a

failure or fault occurs in an amplifier module, it is transmitted to the host system

via an 18-pin Molex connector.

The amplifier is compliant to the requirements of FCC Part 22 and TIA/EIA IS97A

with respect to spurious emissions (see table 1-1). Constant gain is maintained by

continuously comparing active paths with passive references, and correcting for

small variations through the RF feedback controls. All gain variations, for example

those due to temperature, are reduced to the passive reference variations. The

amplifier module is comprised of:

A three-stage driver amplifier

A main amplifier

Alarm monitoring and control

A spurious emission detection DSP circuit

4-4.1. THREE-STAGE DRIVER AMPLIFIER

The input of the amplifier employs three stages of class AB amplification which

provide approximately 33 dB of gain in the 25 MHz frequency band from 869 MHz

to 894 MHz. The amplifier operates on +26 Vdc, and a bias voltage of +5 Vdc,

and is mounted directly on a heat sink. The alarm logic controls the +5 Vdc bias

voltage that shuts down the amplifier.

4-4.2. MAIN AMPLIFIER

The main amplifier employs class AB amplification for maximum efficiency. The

signal provides approximately 10 dB of gain in the 25 MHz frequency band. The

output from the main amplifier is typically 30 watts. The amplifier operates on +26

Vdc, and a bias voltage of +5 Vdc, and is mounted directly on a heat sink. The

alarm logic controls the +5 Vdc bias voltage that shuts down the amplifier.

11

Three Stage

Driver

Main Amp

RF

IN

33dB

Gain

Phase,

Gain,

and

Bias

Control

10dB

Gain

Phase,

Gain,

and

Bias

Control

SPURIOUS DETECTION

DSP CIRCUIT

ALARM CIRCUIT

Figure 4-1. NTGS86AA Single Channel Power Amplifier Functional Block

Diagram

RF

OUT

Optimize

the

spurious

emissions

mask

of the

CDMA

output

signal

4-4.3. ALARM MONITORING AND CONTROL

In the amplifier, all normal variations are automatically compensated for by the

spurious detector control. However, when large variations occur beyond the

adjustment range of the loop control, a loop fault will occur. The alarms are output

via an 18-pin Molex connector on the module for subsequent remote monitoring.

4-4.4. SPURIOUS EMISSION DETECTION DSP CIRCUIT

The primary function of the spurious detection circuit is to monitor the spurious

emissions mask of the RF signal at all amplifier stages. DSP circuitry is used to

control the phase, gain, and bias of all amplifier stages, thereby optimizing the

spurious emissions mask of the CDMA output signal.

4-5. AMPLIFIER MODULE COOLING

Each amplifier module is contained within a thermally conductive chassis which,

when properly mounted on an adequate thermal surface, will provide sufficient

cooling to maintain the amplifier within the specified operating temperature range.

4-6. POWER DISTRIBUTION

Primary DC power for the amplifier is provided by the host system. The amplifier

module has a DC/DC converter that converts the +26 Vdc to +15 Vdc, +5 Vdc and

+8 Vdc.

12

Section

5

MAINTENANCE

5-1. INTRODUCTION

This section contains periodic maintenance and performance test procedures for the Single

Channel Power Amplifier. It also contains a list of test equipment required to perform the identified

tasks.

NOTE

Check your sales order and equipment

warranty before attempting to service or

repair the unit. Do not break the seals on

equipment under warranty or the warranty

will be null and void. Do not return

equipment for warranty or repair service

until proper shipping instructions are

received from the factory.

5-2. PERIODIC MAINTENANCE

Periodic maintenance requirements are listed in Table 5-1. Table 5-1 also lists the intervals at

which the tasks should be performed.

Table 5-1. Periodic Maintenance

TASK INTERVAL ACTION

Inspection

Cables and

Connectors

Performance Tests

5-3. TEST EQUIPMENT REQUIRED FOR TEST

Test equipment required to test the amplifier is listed in Table 5-2. Equivalent test equipment may

be substituted for any item, keeping in mind that a thermistor type power meter is required.

All RF test equipment must be calibrated to 0.05

dB resolution. Any deviation from the nominal

attenuation must be accounted for and factored

into all output readings.

12 Months

12 Months

NOTE

IInnssppeecctt ssiiggnnaall aanndd ppoowweerr ccaabbllees

ffoorr ffrraayyeedd iinnssuullaattiioonn.. CChheecckk RRF

ccoonnnneeccttoorrss ttoo bbee ssuurree tthhaatt tthheey

aarree ttiigghhtt.

PPeerrffoorrmm aannnnuuaall tteesstt ppeer

ppaarraaggrraapphh 55--55.

.

r

.

F

y

s

13

Table 5-2. Test Equipment Required

MANUFACTURER MODEL

MENCLATURE

Signal Generator H.P. 8656B

20 dB Attenuator, 250 Watt Tenuline

20 dB Attenuator, 20 Watt (2 each) Tenuline

Spectrum Analyzer H.P. 8560E

Coax Directional Coupler H.P. 778D

Power Meter / Sensor H.P. 437B / 8481A

Arbitrary Waveform Generator Sony AWG2021

Network Analyzer H.P. 8753C

Current Probe

Source Diskette Powerwave

CDMA Generator Noise Com 800-1

5-4. PERFORMANCE TEST

Performance testing should be conducted every 12 months to ensure that the amplifier system

meets the operational specifications listed in table 5-3. Also verify system performance after any

amplifier module is replaced in the field. The test equipment required to perform the testing is listed

in table 5-2, and the test setup is shown in figure 5-1.

NOTE

The frequencies used in this test are typical for an amplifier with a

25 MHz band from 869 MHz to 894 MHz. Select evenly spaced

F1, F2, F3, and F4 frequencies that cover the instantaneous

bandwidth of your system.

5-4.1. AMPLIFIER PERFORMANCE TEST.

To perform the test, proceed as follows:

1. Connect test equipment as shown in figure 5-1.

NOTE

Do not apply any RF signals at this time.

AMPLIFIER SPURIOUS EMISSIONS TEST:

2. With the RF input signal to the amplifier set to be as shown in figure 5-2, use the spectrum

analyzer to measure the spurious emissions performance. Record test data in table 5-3.

Verify that it is within the specifications shown in table 1-1. Switch tested amplifier to OFF.

GAIN TEST:

3. Disconnect spectrum analyzer from test setup, and connect the network analyzer.

4. Set network analyzer as follows:

a. Power output to 11 dBm.

b. Frequency start to 869 MHz.

c. Frequency stop to 894 MHz.

d. Normalize the network analyzer for gain and return loss.

5. Check the amplifier gain across the band from 869 MHz to 894 MHz. Gain should be as

specified in table 1-1 ±1 dB. Record test data in table 5-3.

14

INPUT RETURN LOSS TEST:

6. Read and record the S

table 5-3.

return loss measurement on network analyzer. Record test data in

11

Figure 5-1. NTGS86AA Amplifier Test Setup Diagram

15

Table 5-3. Single Channel Power Amplifier Test Data Sheet

DATE__________________________________

MODULE S/N ___________________________

TEST CONDITIONS:

Load and Source Impedance: 50 Ohms

VSWR: < 1.2:1

Supply Voltage: +26 Vdc ±0.1 Vdc

TEST SPECIFICATION MIN MAX

DATA

RF Gain Vcc = 26 Vdc

PO = 25 W

Freq. = 880 MHz

Spurious

Emissions

Gain Flatness Vcc = 26 Vdc

Input Return

Loss

PASS FAIL

Tested by

Vcc = 26 Vdc

PO =25 W

869 - 894 MHz Band

PO =25 W

869 - 894 MHz Band

Vcc = 26 Vdc

PO = 25 W

869-894 MHz Band

Table 1-1

-1 dB

-18 dB

Table 1-1

+1 dB

-65 dBc

±0.7 dB

16

5-5. FIELD REPLACEMENT OF THE MODULE

The NTGS86AA single channel power amplifier module can be replaced in the field on site by a

qualified technician with experience maintaining RF power amplifiers and similar equipment:

To replace a power amplifier module, proceed as follows:

1. Turn off 26 Vdc power to that specific module.

2. Disconnect the three RF cables, 18-pin Molex cable, and RS485 cable.

3. Loosen four screws that secure amplifier module to heat sink.

4. Carefully remove amplifier module from heat sink.

5. Install replacement in reverse order of steps 1 through 4 above.

Section

6

TROUBLESHOOTING

6-1 INTRODUCTION

This section contains a list of problems which users have encountered and a few suggested actions

that may correct the problem. If the suggested corrective action does not eliminate the problem,

please contact your Powerwave field representative or the factory for further instructions.

NOTE

Check your sales order and equipment

warranty before attempting to service or

repair the unit. Do not break the seals on

equipment under warranty or the warranty

will be null and void. Do not return

equipment for warranty or repair service

until proper shipping instructions are

received from the factory.

6-2 TROUBLESHOOTING

Refer to table 6-1 for troubleshooting suggestions.

Table 6-1. Troubleshooting.

SYMPTOM SUGGESTED ACTION

SCPA Inoperative 1. Check for proper power supply voltage.

SCPA Not Enabled 1. Verify RS 422 + (ENABLE signal) is high.

11.. VVeerriiffyy DDCC ssuuppppllyy iiss ≤≤2288..55±±00..2255 VVddc

Anxiety Output is RS 422

High

2. Verify TEMP_OUT <5 °C above maximum sensor temp.

3. Verify RF input <6 dBm ±0.5 dB; remove overdrive and

toggle ENABLE input.

c

17

Alarm Output is RS 422 High Verify input RF is within specified power and frequency limits

6-3 RETURN FOR SERVICE PROCEDURES

When returning products to Powerwave, the following procedures will ensure optimum response.

6-3.1 Obtaining an RMA

A Return Material Authorization (RMA) number must be obtained prior to returning

equipment to the factory for service. Please contact our Customer Service Department at

(949) 757-0530 to obtain this number. Failure to obtain this RMA number will result in

considerable delays in receiving repair service.

6-3.2 Repackaging for Shipment

To ensure safe shipment of the amplifier, it is recommended that the package designed for

the amplifier be used. The original packaging material is reusable. If it is not available,

contact Powerwave’s Customer Service Department for packing materials and information.

18

Loading...

Loading...