Page 1

EN

U

ser manual

POWERWALKER

INVERTER 3000 PSW

EN, RU

Page 2

EN

Page 3

EN

CONTENTS

ABOUT THIS MANUAL ...................................................................................................................................... 1

Purpose ............................................................................................................................................................ 1

Scope ............................................................................................................................................................... 1

IMPORTANT SAFETY INSTRUCTIONS ............................................................................................................ 1

General Precautions ........................................................................................................................................ 1

Personal Precautions ....................................................................................................................................... 2

INSTALLATION ................................................................................................................................................... 3

Unpacking and Inspection................................................................................................................................ 3

Basic Configuration .......................................................................................................................................... 3

Batteries ........................................................................................................................................................... 5

Battery Cable Size ........................................................................................................................................... 5

DC Disconnect and Over-Current Protection .................................................................................................. 5

Battery Cable Connection ................................................................................................................................ 6

AC Cable Size .................................................................................................................................................. 6

AC Connections ............................................................................................................................................... 7

OPERATION ........................................................................................................................................................ 8

Front Panel and Configuration Switch ............................................................................................................. 8

Indicator & Alarm .............................................................................................................................................. 9

Operating Indicators ....................................................................................................................................... 10

Setting Indicators ........................................................................................................................................... 11

SPECIFICATIONS ............................................................................................................................................. 12

Table 5 Line Mode Specifications .................................................................................................................. 12

Table 6 Invert Mode Specifications ................................................................................................................ 13

Table 7 Charge Mode Specifications ............................................................................................................. 14

Table 8 Approximate Back-up Times ............................................................................................................. 15

Table 9 General Specifications ...................................................................................................................... 15

Table 10 Fault code/ Audible alarm ................................................................................................................ 16

TROUBLE SHOOTING ..................................................................................................................................... 17

Page 4

1

EN

ABOUT THIS MANUAL

Purpose

The purpose of this manual is to provide explanations and procedures for installing, operating and

troubleshooting for the unit. This manual should be read carefully before installations and operations.

Please retain this manual for future reference.

Scope

This document defines the functional requirements of the unit, intended for worldwide use in electronic

processing equipment. All manuals are applicable under all operating conditions when installed in the End

Use system, unless otherwise stated.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: This chapter contains important safety and operating instructions. Read and keep

this User Guide for future reference.

General Precautions

1. Before using the unit, read all instructions and cautionary markings on:

(1) The unit (2) the batteries (3) all appropriate sections of this manual.

2. CAUTION --To reduce risk of injury, charge only deep-cycle lead acid type rechargeable batteries.

Other types of batteries may burst, causing personal injury and damage.

3. Do not expose the unit to rain, snow or liquids of any type. The unit is designed for indoor use only.

Protect the unit from splashing if used in vehicle applications.

4. Do not disassemble the unit. Take it to a qualified service center when service or repair is required.

Incorrect re-assembly may result in a risk of electric shock or fire.

5. To reduce risk of electric shock, disconnect all wiring before attempting any maintenance or cleaning.

Turning off the unit will not reduce this risk.

6. CAUTION --Battery are not already installed by the supplier only a qualified professional (e.g. service

person) may install the Inverter.

7. WARNING: WORKING IN VICINITY OF A LEAD ACID BATTERY IS DANGEROUS.

BATTERIES GENERATE EXPLOSIVE GASES DURING NORMAL OPERATION. Provide ventilation

to outdoors from the battery compartment. The battery enclosure should be designed to prevent

accumulation and concentration of hydrogen gas in “pockets” at the top of the compartment. Vent the

battery compartment from the highest point. A sloped lid can also be used to direct the flow to the vent

opening location.

8. NEVER charge a frozen battery.

9. No terminals or lugs are required for hook-up of the AC wiring. AC wiring must be no less than 12 AWG

gauge copper wire and rated for 75oC or higher. Battery cables must be rated for 75oC or higher and

should be no less than table 1. Crimped and sealed copper ring terminal lugs with a 5/16 hole should

be used to connect the battery cables to the DC terminals of the unit. Soldered cable lugs are also

acceptable.

10. Be extra cautious when working with metal tools on, or around batteries. The potential exists to drop a

Page 5

2

EN

tool and short-circuit the batteries or other electrical parts resulting in sparks that could cause an

explosion.

11. No AC or DC disconnects are provided as an integral part of this unit. Both AC and DC disconnects

must be provided as part of the system installation. See INSTALLATION section of this manual.

12. Fuses (F40AL, 32VDC*6) are provided as the over current protection of the battery supply.

13. GROUNDING INSTRUCTIONS -This battery charger should be connected to a grounded permanent

wiring system. For most installations, the Ground Lug should be bonded to the grounding system at one

(and only one point) in the system. All installations should comply with all national and local codes and

ordinances.

14. AVOID AC output short-circuit; avoid DC input short-circuit and do not connect the mains while DC

input short-circuit

15. Warning: The maintenance information is only to service persons

Personal Precautions

1. Someone should be within range of your voice to come to your aid when you work near batteries.

2. Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

3. Wear complete eye protection and clothing protection. Avoid touching eyes while working near

batteries. Wash your hands when done.

4. If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters eyes,

immediately flood eyes with running cool water for at least 15 minutes and get medical attention

immediately.

5. Baking soda neutralizes lead acid battery electrolyte. Keep a supply on hand in the area of the

batteries.

6. NEVER smoke or allow a spark or flame in vicinity of a battery or generator.

7. Be extra cautious when working with metal tools on, and around batteries. Potential exists to

short-circuit the batteries or other electrical parts which may result in a spark which could cause an

explosion.

8. Remove personal metal items such as rings, bracelets, necklaces, and watches when working with

battery. Battery can produce short-circuit current high enough to weld a ring, or the like, to metal

causing severe burns.

9. If a remote or automatic generator start system is used, disable the automatic starting circuit and/or

disconnect the generator from its starting battery while servicing to prevent accidental starting during

servicing.

Page 6

3

EN

INSTALLATION

Unpacking and Inspection

Carefully unpack the inverter/charger from its shipping carton.

Verify all of items list below are present. Please call customer service if any items are missing.

The unit

1 user’s manual

Basic Configuration

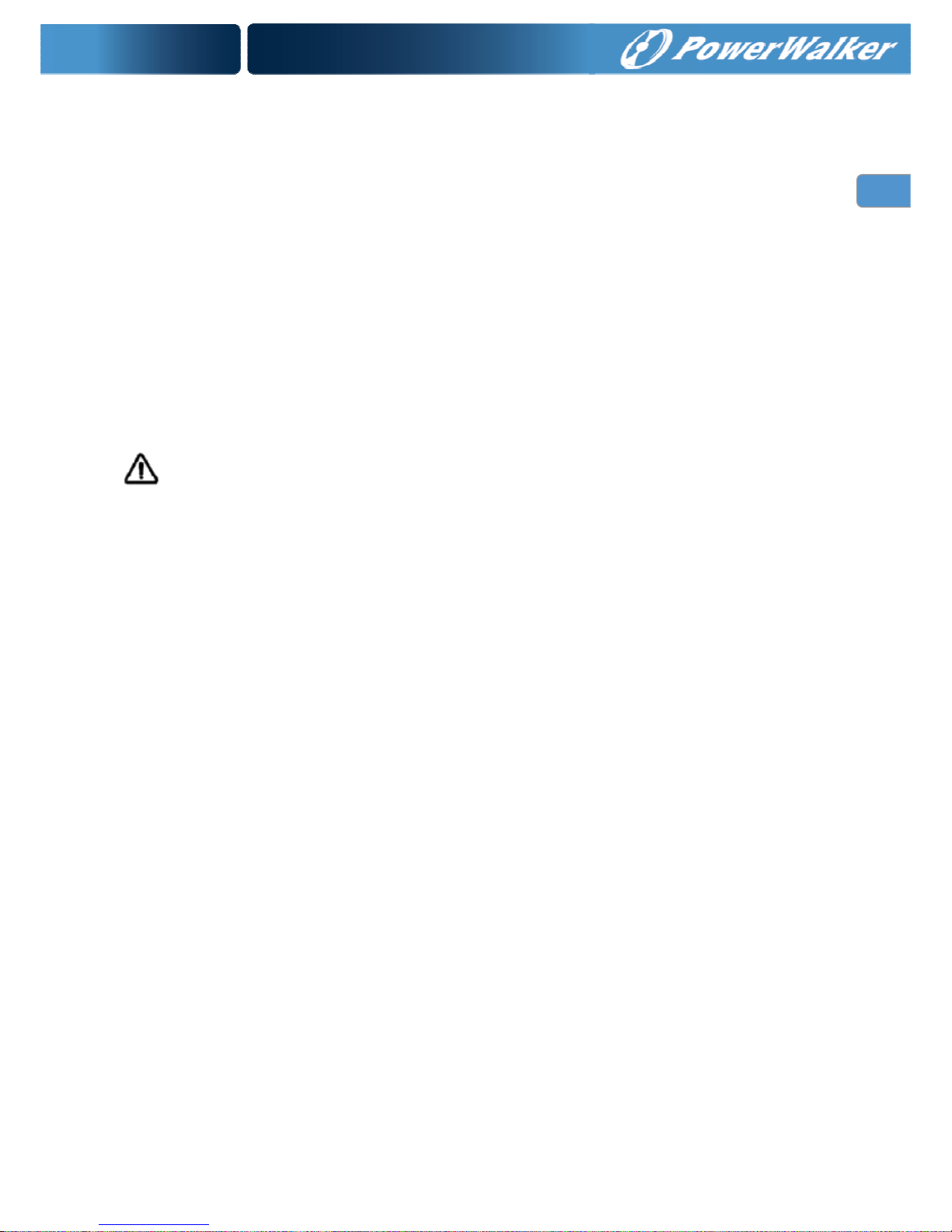

The following illustrations show basic applications for PowerWalker Inverter 3000 PSW.

They include the following configurations:

Utility Backup. see figure 1

Renewable Energy Source And a Generator, see figure 2

Consult with your system design for other possible configurations depending on site or code

requirements.

Figure 1 Utility Backup

PowerWalker Inverter 3000 PSW

Page 7

4

EN

Figure 2 Renewable Energy Source

PowerWalker Inverter 3000 PSW can feeds almost all kinds of appliances from home to office

environment, including motor characteristic appliances like tube light, fan, refrigerator and Air conditioner.

Note: Appliances like Air conditioner needs at least 3 minutes to restart in case of a power shortage

occurs in a way that the power turns off then back on again rapidly (time is required to balance the

refrigerant gas in inside circuit); so in order to protect your Air conditioner, please consult the Air

conditioner manufacturer whether they have already provided time delay function before installing.

Otherwise, Inverter will trig overload fault and shut off its output to protect your appliance but

sometimes it is not enough and your Air conditioner can be damaged internally beyond repair.

PowerWalker Inverter 3000 PSW

Page 8

5

EN

Batteries

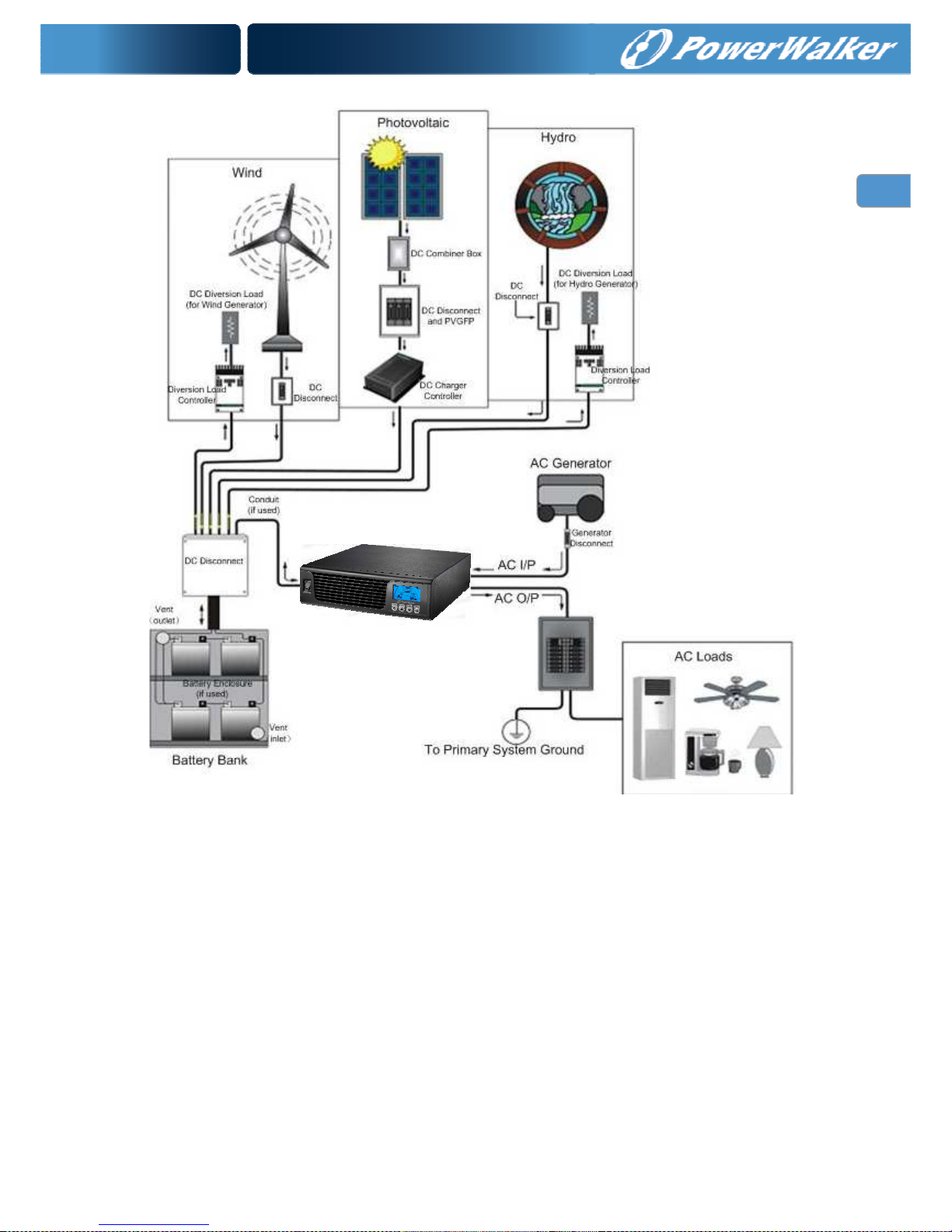

The unit support 24volt battery bank. Please refer to figure 3 to wiring battery correctly. Before

proceeding, ensure you have appropriate size batteries for this inverter. The unit can use flooded

lead-acid, or sealed GEL/AGM lead-acid batteries so ensure that your batteries are in one of these

categories.

The battery must be wired to match the units DC input voltage specifications. Suggest battery capacity

not smaller than 100AH.

Figure 3 PowerWalker Inverter 3000 PSW batteries string wiring

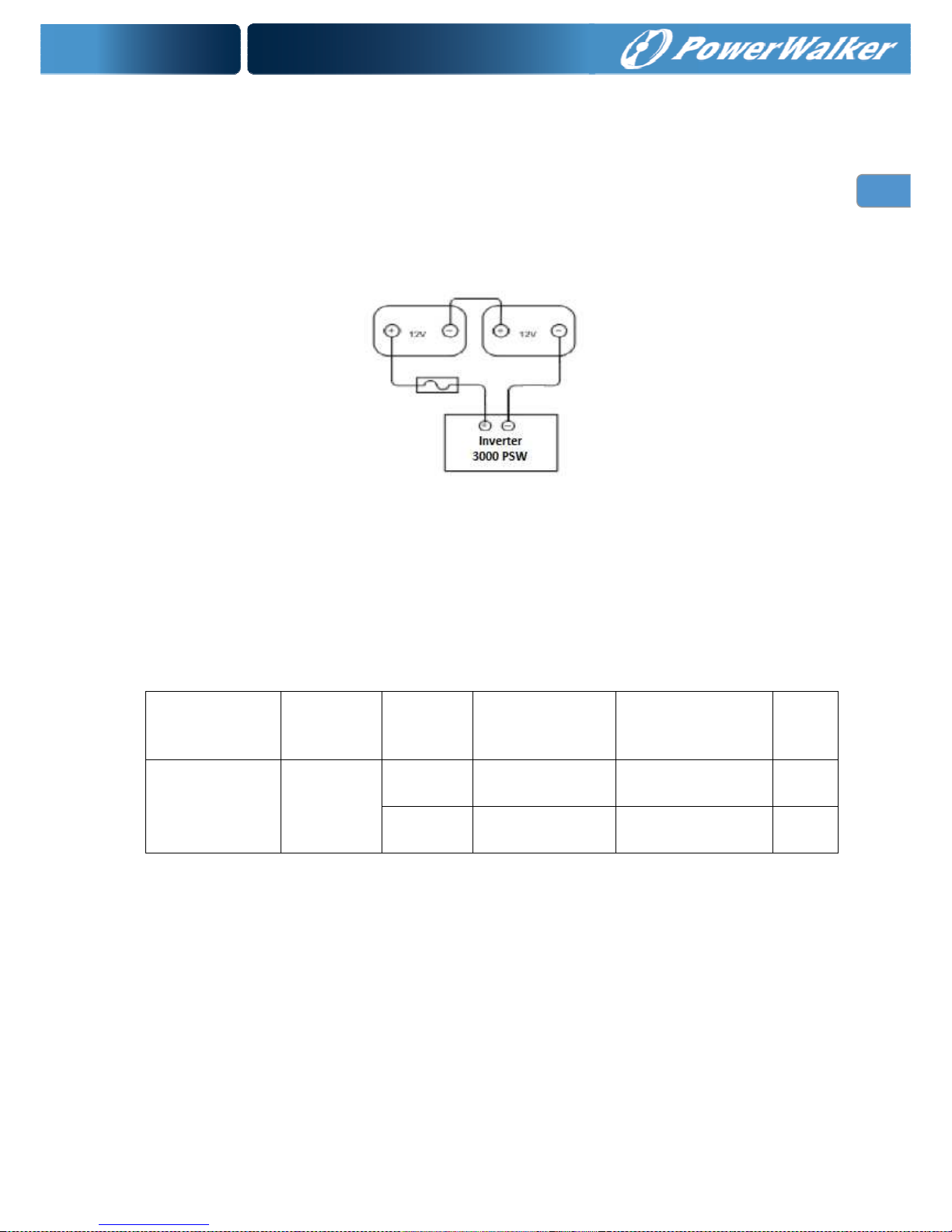

Battery Cable Size

Below table 1 you can find information for recommended battery cable and terminal.

Table 1 Recommended battery cable and terminal size

Model

Number

Typical

Amperage

BATTARY

CAPACITY

1~3 m one-way CABLE TERMINAL Torque

value

PowerWalker

Inverter 3000PSW

130A

100 AH 4 AWG

or 2*8AWG

KST:RNBS22-6

(RING TYPE)

5~8

Nm

200 AH 2* 6 AWG KST:RNBS38-6

(RING TYPE)

5~8

Nm

DC Disconnect and Over-Current Protection

For safety and to comply with regulations, battery over-current protection and disconnect devices are

required. Fuses and disconnects must be sized to protect the DC cable size used, and must be rated for

DC operation. Do not use devices rated only for AC service – they will not function properly.

Note that some installation requirements may not require a disconnect device, although over-current

protection is still required.

Page 9

6

EN

Battery Cable Connection

Observe Battery Polarity! Place the ring terminal of DC cable over the bolt and directly against the unit’s

battery terminal. Tighten the M6 screw with 5-8 Nm. Do not place anything between the flat part of the

Backup System terminal and the battery cable ring terminal or overheating may occur.

DO NOT APPLY ANY TYPE OF ANTI-OXIDANT PASTE TO TERMINALS UNTIL AFTER THE

BATTERY CABLE WIRING IS TORQUED!!

Figure 5 illustrates the proper method to connect the battery cables to the unit terminals.

WARNING: Shock Hazard

Installation must be performed with care for the high battery voltage in series.

Caution!! Do NOT place anything between battery cable ring terminals and terminals on the

inverter. The terminal screw is not designed to carry current.

Apply Anti-oxidant paste to terminals AFTER terminals have been screwed.

Verify that cable lugs are flush with the battery terminals. Tighten battery cables to terminals (5-8 Nm).

Figure 4 Battery Cable Connect to unit

AC Cable Size

Before wiring the input and output of inverter, refer to table 2 for minimum recommended cable size and

torque value

Table 2 Recommended cable size and torque value for AC wire

Model Number AC Input AC Output Torque value

PowerWalker

Inverter 3000 PSW

12AWG 12 AWG 1.2~1.8 Nm

Page 10

7

EN

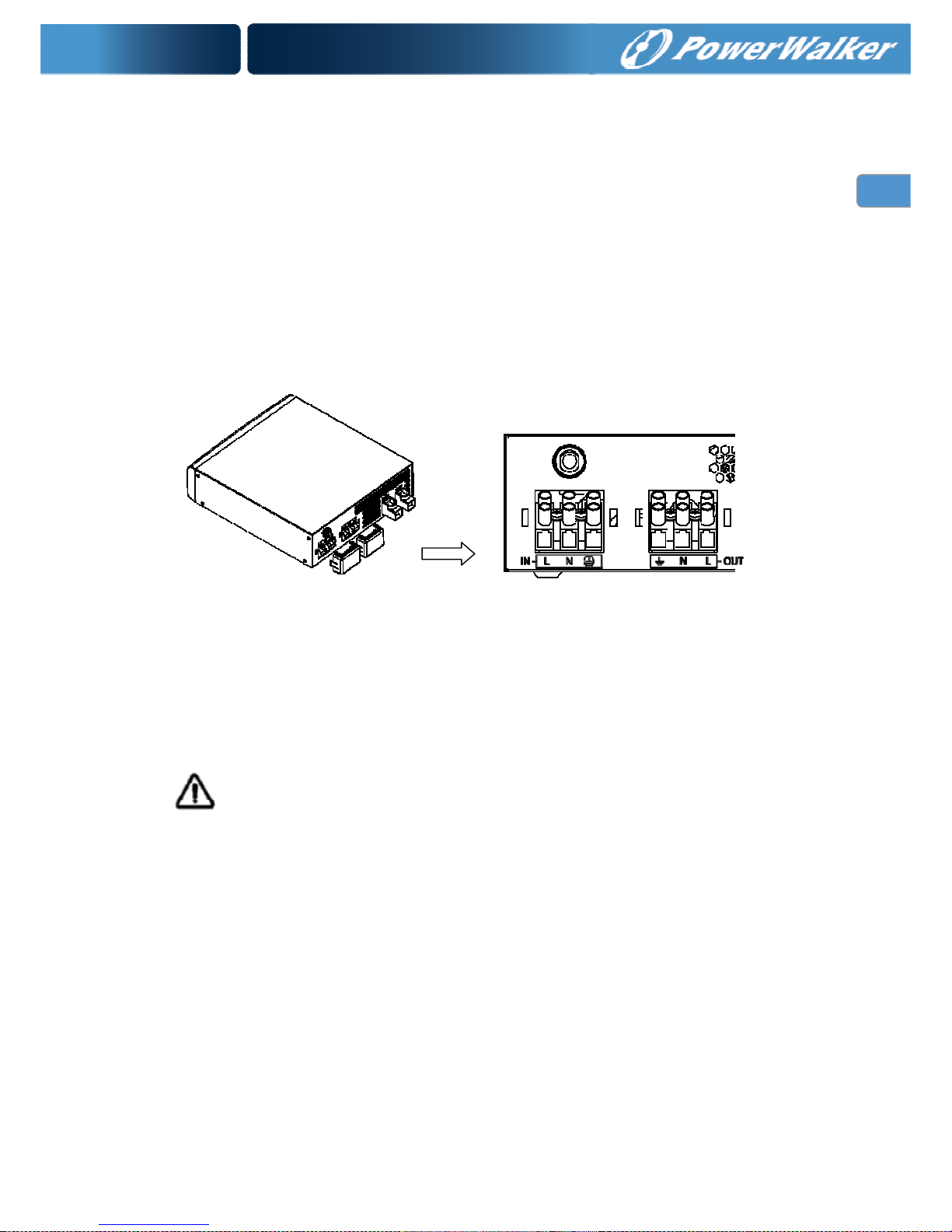

AC Connections

Installation should be done by a qualified electrician. Consult local code for the proper wire sizes,

connectors and conduit requirements.

On the left of rear chassis is the AC hardwire cover. Two three-station terminal block is provided to make

the AC connections. The terminal block is used to hardwire the AC input, AC output, and ground. The

National Electrical Code requires that an external disconnect switch be used in the AC input wiring circuit.

The AC breakers in a sub panel will meet this requirement.

Step 1: Disconnect the unit from the battery by removing the battery cables from the battery. Turning off

the unit does not constitute disconnecting from the battery.

Figure 5 AC Cable Connect to unit

Step 2: Following the wiring guide located in the AC input wiring compartment as figure 5, connect the

GND (green/yellow), Line (brown), and neutral (blue) wires from the AC input (utility, generator,

etc) to the terminal block.

Caution!! Be sure that AC source is disconnected before attempting to hardwire it to the unit.

Step 3: Connect the AC Line output wiring to the terminal marked AC Line (output), following the wiring

guide inside the compartment. Torque the wires into the terminal block.

Step 4: Lock the AC covers.

Page 11

8

EN

OPERATION

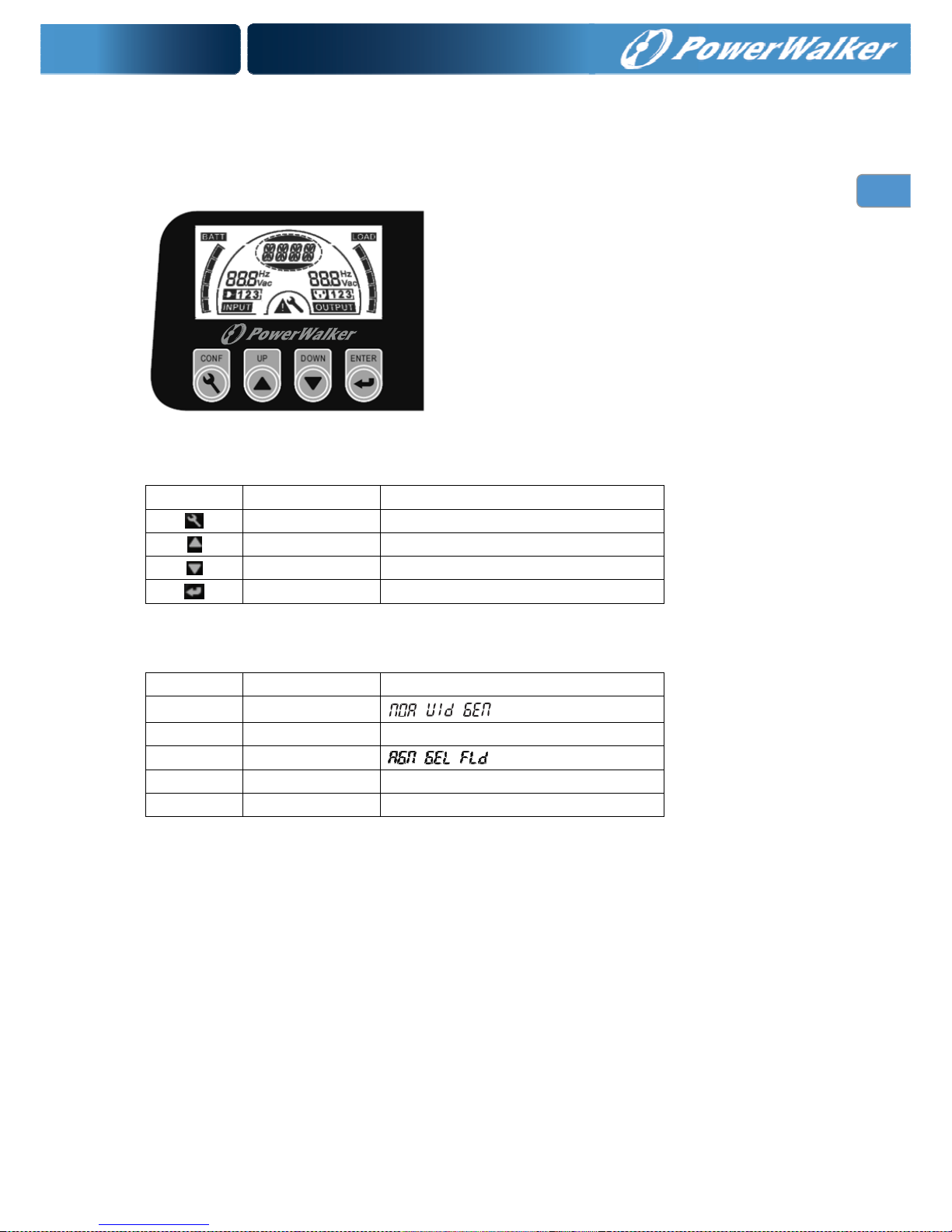

Front Panel and Configuration Switch

Table 3 configuration button function

Switch Function Description

config Enter config mode, and turn page

up Move up to pre-select

down Move down to pre-select

enter Enter to confirm

Table 4 configuration pages option

Page Description Selectable option

1 Input range

2 Output range 230V

3 Battery type

4 Charger current

20A/10A

5 Saver mode ON/OFF

Note: There are 5 configuration pages totally, change only active by enter

button pressed within current page.

Page 12

9

EN

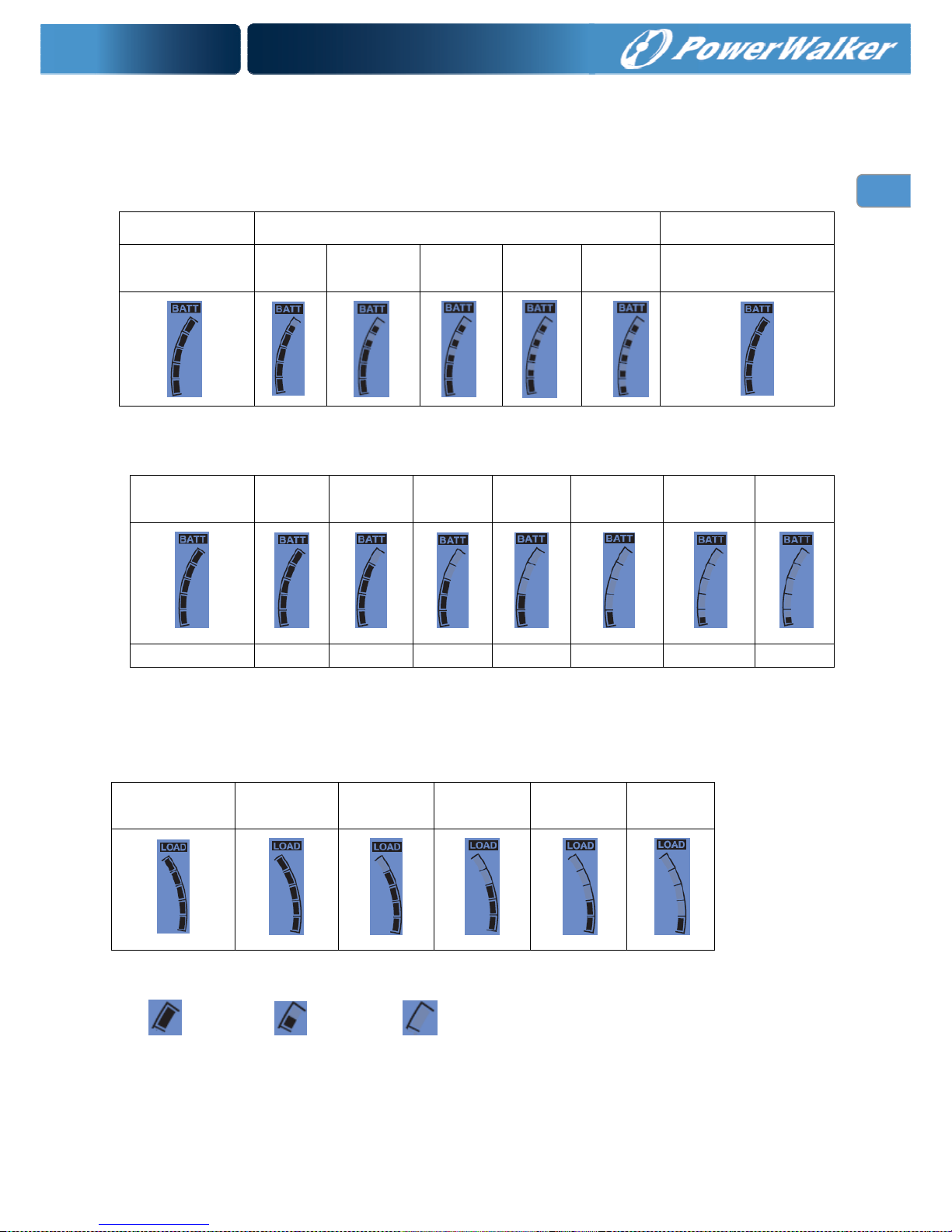

Indicator & Alarm

Charger mode battery indicator

Battery capacity segment will lighting to comply with battery voltage

Status CC/CV Floating

Battery

voltage(+/-0.6V)

>26V 25V~26V 24V~25V 21V~24V <21V

Any battery voltage

Inverter mode battery indicator:

Battery

voltage(+/-0.6V)

>26V 25V~26V 24V~25V 23V~24V 21.6V~23V 20V~21.6V <20V

ALARM -- -- -- -- -- 1beep/2s continue

Load indicator:

The load indicate the load percentage comply with load VA or W (show the bigger value), the overload label

will flash when overload.

Load (±4%) >85% 65%~85% 45%~65% 25%~45% 0%~25%

Note:

Solid on; On to off; Off.

Page 13

10

EN

Operating Indicators

Standby Mode: Inverter Mode:

Voltage and Frequency exchanged every 5 seconds Voltage and Frequency exchanged every 5 seconds

Line Mode: Warning Mode:

Voltage and Frequency exchanged every 5 seconds Red back light flash every 1 second

Fault Mode:

Red back light Keep on

Page 14

11

EN

Setting Indicators

Page 15

12

EN

SPECIFICATIONS

Table 5 Line Mode Specifications

MODEL PowerWalker Inverter 3000 PSW

Input Voltage Waveform

Sinusoidal (utility or generator)

Nominal Input Voltage

230Vac

Low Line Disconnect

170Vac±4%(NOR)

90Vac±4%(GEN/WID)

Low Line Re-connect

180Vac±4% (NOR)

100Vac±4% (GEN/WID)

Note:

1.NOR setting can be used for general electrical appliance

2. WID setting can be used only for some special load, such as lamp, fan.

High Line Disconnect

280Vac±4%

High Line Re-connect

270Vac±4%

Max AC Input Voltage

300Vac rms

Nominal Input Frequency

50Hz / 60Hz (Auto detection)

Low Line Frequency Disconnect

40±1Hz

Low Line Frequency

Re-connect

42±1Hz

High Line Frequency Disconnect

65±1Hz

High Line Frequency Re-connect

63±1Hz

Output Voltage Waveform

As same as Input Waveform

Output Short Circuit Protection

30A Circuit Breaker

Efficiency (Line Mode)

>95% ( Rated R load, battery full charged )

Transfer Switch Rating

30A

Transfer Time

10ms (typical) 15ms max(NOR)

20ms (typical) 40ms max(GEN/WID)

Bypass charger enable in off mode

Yes

Power Limitation

Page 16

13

EN

Table 6 Invert Mode Specifications

MODEL PowerWalker Inverter 3000 PSW

Output Voltage Waveform

Pure Sine Wave

Rated Output Power

3000VA

Power Factor

0.8

Nominal Output voltage

230Vac

Minimum Peak Output Voltage at

Rated Power

>200V

Output Frequency(Hz)

50Hz / 60Hz ± 1Hz (follow first connect to grid)

Output Voltage Regulation

±10% Vrms

Nominal Efficiency

>90% (@Normal DC Input; >60% R load)

Over-Load Protection

fault after 5s@≥150% load,<=200% load

fault after 10s@110%~150% load,

Surge rating

6000VA

Capable of starting electric motor

1.5HP

Output Short Circuit Protection

Current limit (Fault after 4 cycles max)

Nominal DC Input Voltage

24V

Min DC start voltage

20V

Low DC Alarm

21.0 ± 0.6Vdc

Low DC Alarm Recovery

21.6 ± 0.6Vdc

Low DC Shut-down

20.0 ± 0.6Vdc

Low DC Shut-down Recovery

22.0 ± 0.6Vdc

High DC Shut-down

30.0 ± 0.6Vdc

High DC Shut-down Recovery

29.0 ± 0.6Vdc

DC component of output

<100mV

Power Limitation

Page 17

14

EN

Table 7 Charge Mode Specifications

Nominal Input Voltage

230Vac

Input Voltage Range

180V - 270Vac(NOR)

100V - 270Vac(GEN/WID)

High Voltage Disconnect

280Vac±4%

High Line Re-connect

270Vac±4%

Low Voltage Disconnect

170Vac(NOR)

90Vac(GEN/WID)

Low Line Re-connect

180Vac±4% (NOR)

100Vac±4% (GEN/WID)

Nominal Output Voltage

Refer to Charge Algorithm/ Battery Type Setting

Nominal Charge Current

10A @Vi/p<170Vac

20A@Vi/p=230Vac

10A @Vi/p>280Vac

Charge current tolerance

±10%

Over Charge Protection

Bat. V ≥30Vdc, Fault, Buzzer alarm

Charge Algorithm

Three stage:

Boost CC (constant current stage) → Boost CV

(constant voltage

stage) → Float (constant voltage stage)

Battery Type Setting(+/-0.3v/bat)

Battery Type

Boost CC/CV Float

Voltage(V) Voltage(V)

24 24

Flooded 29.2 27.0

AGM / Gel 28.2 27.0

Charger current (+/-10%)

Charge(A)

20

Note: NOR – Normal range; GEN-Generator range; WID-Wide range

Page 18

15

EN

Table 8 Approximate Back-up Times

Load(VA)

100Ah 24VDC(min) 200AH 24VDC(min)

300 457.5 972.2

600 208.1 499.5

900 140.6 262.3

1200 103 178.1

1500 77.8 138.3

1800 57.6 113.2

2100 49.5 100.5

2400 41.4 87.9

2700 33.2 75.3

3000 28.4 62.6

Note: Back-up times depend on the quality of the battery, age of battery and type of battery.

Specifications of batteries vary from one manufacturer to another.

Table 9 General Specifications

Safety Standard

EN60950-1:2006+A1: 2010

EN62040-1-1: 2008

EMC Standard

EN62040-2 : 2006 C2

Operating

Temperature Range

0°C to 45°C

Storage temperature

-15°C~ 60°C

Altitude, operational

Elevation: 0 – 1500 Meters

Relative humidity

5% to 95% non-condensing

Audible Noise

60dB max

Cooling

Forced air

Dimension(L*W*H)

330mm*268mm*76mm

Net Weight

4.9KG

DC wiring

Double 6 AWG cable for each polarity

AC input/output

L/N/G:12AWG

Page 19

16

EN

Table 10 Fault code/ Audible alarm

Operate Condition

--

Low DC

Voltage

Alarm

Inverter DC voltage<Low DC Alarm 1beep/2s -- -- --

0

Low DC

Voltage

Protection

Inverter

DC Voltage<Low DC Shutdown

--

Beep

continuous

Auto

Mains is

normal

1

Over

Charge

Protection

Line

DC Voltage>High DC input

Shut-down

Beep

continuous

-- Manual --

1

Over

Voltage

Protection

Standby

DC Voltage>High DC input

Shut-down

--

Beep

continuous

Auto

DC

Voltage<High

DC input

Shut-down

Recovery

Line/

Inverter

110%~150% load

1beep/0.5s,and

continuous 10s

Beep

continuous

Manual --

Line/

Inverter

>150% load

1beep/0.5s,and

continuous 5s

Beep

continuous

Manual --

3

Output

Short

Circuit

Protection

Inverter

1)Output Voltage<20Vrms

2)TX temperature>102

℃

--

Beep

continuous

Manual --

4

Fan Fault

Protection

Line/

Inverter

Fan Locked

Fan Defected

2beep/2s, and

continous 1min

Beep

continuous

Manual --

5

Over

Temp

Protection

Line/

Inverter

HEAT SINK Temp≥100℃

--

Beep

continuous

Auto

HEAT SINK

Temp≤ 55℃

6

Output

Abnormal

Inverter

1)Output Voltage<170Vrms

or Output Voltage>250Vrms

2)TX temperature>102℃

--

Beep

continuous

Manual --

Fault

(O/P=OFF)

Restart

2

Over Load

Protection

Active

Mode

Condition

Warning

(O/P=ON)

Fault

Code

Protect

Function

Page 20

17

EN

TROUBLE SHOOTING

Problem Possible Causes Remedy

No LCD display

1. Battery Weak 1. Re-charge battery

2. Battery defective (can't be

charged)

2. Battery replacement

3. Power switch is not pressed 3. Press and hold power switch

4. Battery polarity reversed, can’t

start up the unit

4. Sent back for repair

Mains normal but

works in inverter

mode

1. AC Input missing 1. Check AC input connection

2. Input protector is effective 2. Reset the input protector

Mains normal but

can’t works in

inverter mode

1. Battery disconnected 1. Connect batteries

2. Low batteries 2. Recharge batteries or change new batteries

Alarm buzzer

beeps

continuously

1. Overload(fault code: F2)

1. Verify that the load matches the capability

specified in the specs

2. Output short circuit(fault code: F3) 2. Check wiring or remove abnormal load

3. Over temp(fault code: F5) 3. Move away barrier in front of airflow inlet

4. Over charger(fault code: F1) 4. Restart the unit

5. Over voltage(fault code: F1)

5. Turn down the DC input voltage below the high

DC input shut-down recovery

6. Fan fault(fault code: F4)

6. Check if something block the fan, if not replace

the fan

7. DC voltage under the low DC

shut-down(fault code: F0)

7. Make sure mains is normal to recharger the

battery if not switch the power off until mains is

normal

8. Output abnormal(fault code: F6) 8. Send back for repair

Back up time is

shortened

1. Overload 1. Remove some non-critical load

2. Battery voltage is too low 2. Charge battery for 8 hours or more

3. Battery bank is too small 3. Increase battery bank capacity

Page 21

RU

Руководство

пользователя

Инвертор POWERWALKER

3000 PSW

RU

Page 22

0

RU

Содержание

Кратко о руководстве ...................................................................................................................................... 1

Цель ................................................................................................................................................................. 1

Сфера действия ............................................................................................................................................. 1

ВАЖНЫЕ ИНСТРУКЦИИ ПО БЕЗОПАСНОСТИ ............................................................................................ 1

Основные предостережения ......................................................................................................................... 1

Личные меры предосторожности .................................................................................................................. 2

УСТАНОВКА ....................................................................................................................................................... 3

Распаковка и осмотр ...................................................................................................................................... 3

Базовая конфигурация .................................................................................................................................. 3

Батареи ........................................................................................................................................................... 5

Размер батарейных кабелей ......................................................................................................................... 5

Отсоединение постоянного тока и защита от скачков тока ........................................................................ 5

Подсоединение батарейного кабеля ............................................................................................................ 6

Размер кабеля переменного тока ................................................................................................................. 6

Подсоединения переменного тока ............................................................................................................... 7

РАБОЧИЕ ОПЕРАЦИИ ...................................................................................................................................... 8

Передняя панель и конфигурации коммутатора ......................................................................................... 8

Индикаторы & Сигналы тревоги.................................................................................................................... 9

Индикаторы операций ................................................................................................................................. 10

Индикация настроек ..................................................................................................................................... 11

ХАРАКТЕРИСТИКИ ......................................................................................................................................... 12

Таблица 5 Характеристики - режим питания от сети .............................................................................. 12

Таблица 6 Характеристики – режим инвертора ......................................................................................... 13

Таблица 7 Характеристики – режим зарядки ............................................................................................. 14

Таблица 8 Примерное время автономной работы .................................................................................... 15

Таблица 9 Общие характеристики .............................................................................................................. 15

Таблица 10 Коды ошибок/ Звуковой сигнал ............................................................................................... 16

УСТРАНЕНИЕ НЕИСПРАВНОСТЕЙ ........................................................................................................... 17

Page 23

1

RU

Кратко о руководстве

Цель

Целью этого руководства является формулировка описаний и формирование процедур по

установке, функционированию и устранению неисправностей устройства. Рекомендуем тщательно

изучить данное руководство, и держать в доступном месте для будущего использования.

Сфера действия

Этот документ определяет функциональные требования к устройству, и предназначен для

использования во всем мире в сфере электронных устройств для обработки информации. Все

руководства применимы при любых условиях эксплуатации при установке их в системах для

конечного использования, если только не сказано иное.

ВАЖНЫЕ ИНСТРУКЦИИ ПО БЕЗОПАСНОСТИ

ВНИМАНИЕ!: Эта глава содержит важные инструкции по эксплуатации и безопасности.

Ознакомьтесь и храните данное руководство для будущего использования.

Основные предостережения

1. Перед использованием устройства прочитайте все инструкции и предупреждающие надписи:

(1) На устройстве (2) На батареях (3) и все соответствующие разделы данного руководства.

2. ВНИМАНИЕ! Для снижения риска повреждений заряжайте только аккумуляторы

свинцово-кислотного типа глубокого цикла. Другие типы батарей могут взрываться и причинять

персональные травмы и повреждения.

3. Не подвергайте устройство действию дождя, снега и других жидкостей любого типа. Устройство

разработано для использования только внутри помещений. Защищайте устройство от брызг,

если оно используется в транспортных средствах.

4. Не разбирайте устройство. При необходимости обслуживания или ремонта предоставьте

устройство в квалифицированный сервисный центр. Неправильный демонтаж может являть

собой риск удара тока или ожога от огня.

5. Чтобы снизить риск удара током, отсоедините все провода перед попыткой любого действия по

обслуживанию или чистке. Просто выключенное устройство не снижает такой риск.

6. ВНИМАНИЕ –Если батарея не установлена поставщиком, только квалифицированный персонал

(например, представитель сервисного центра) может производить запуск Инвертора.

7. ПРЕДУПРЕЖДЕНИЕ: РАБОТА В КОНТАКТЕ СО СВИНЦОВО-КИСЛОТНЫМИ БАТАРЕЯМИ

ОПАСНА. БАТАРЕИ ГЕНЕРИРУЮТ ВЗРЫВООПАСНЫЕ ГАЗЫ ДАЖЕ ПРИ НОРМАЛЬНОМ

ФУНКЦИОНИРОВАНИИ. Обеспечьте вентиляцию батарейного отделения воздухом извне.

Батарейное приложение должно быть разработано без возможности скопления водорода в

«карманах» верхней части отделения. Батарейное отделение должно проветриваться с самой

его высокой точки. Крышка с наклоном может также использоваться для направления потока

обдува к вентиляционным отверстиям.

8. НИКОГДА НЕ заряжайте замороженную батарею.

9. Никакие клеммы или наконечники не требуются монтирования проводки переменного тока.

Проводка переменного тока должна быть сделана из медного провода не менее чем 12 AWG,

которые рассчитаны на 75oC или более. Батарейные кабели должны быть рассчитаны на 75oC

Page 24

2

RU

или более, и должны иметь параметры не менее чем в Таблице 1. Нарезные и герметичные

наконечники медного кольца с отверстием 5-16 предназначены для подсоединения батарейных

кабелей к терминалам выхода постоянного тока устройства. Припаянные кабельные

наконечники также пригодны к использованию.

10. Будьте особенно осторожны, когда работаете металлическим инструментом поблизости батарей.

Существует потенциал, который может через проводящий инструмент спровоцировать короткое

замыкание между батареями или другими электрическими деталями, что создаст искрение, что в

свою очередь может стать причиной взрыва.

11. Прерыватели цепи переменного и постоянного тока не являются частями комплекта поставки

устройства. Эти прерыватели должны быть обеспечены в качестве материалов для монтажа

при установке системы. См. раздел УСТАНОВКА данного руководства.

12. Предохранители (F40AL, 32VDC*6) необходимы как защита питания батарей от всплесков тока.

13. ИНСТРУКЦИИ ПО ЗАЗЕМЛЕНИЮ Зарядное устройство батареи должно подключаться к

системе проводов, которая надежно заземлена. Для большинства инсталляций наконечник

заземления должен быть соединен с системой заземления в одной и только одной точке системы.

Все установки должны соответствовать всем национальным и местным нормам и правилам.

14. ИЗБЕГАЙТЕ короткого замыкания на выходе переменного тока; избегайте короткого замыкания

на входе постоянного тока и не производите подсоединение к сети питания при коротком

замыкании на входе постоянного тока

15. Внимание!: Информация по обслуживанию – только для сервисного персонала

Личные меры предосторожности

1. Кто-то должен присутствовать на расстоянии вашего голоса, чтобы в случае необходимости

прийти к вам на помощь, когда вы работаете с(около) батареями.

2. Имейте рядом достаточно свежей воды и мыло на случай контакта кислоты из батарей с кожей,

одеждой или глазами.

3. Носите защитные средства для глаз и одежды. Избегайте касания к глазам при работе вблизи

батарей. После работы мойте руки.

4. Если кислота из батареи попала на кожу или одежду, промойте это место немедленно с водой и

мылом. Если кислота попала в глаза, немедленно промойте глаза прохладной проточной водой

в течение не менее 15минут и обратитесь за медицинской помощью.

5. Пищевая сода нейтрализует электролит из свинцово-кислотных батарей. Держите ее под рукой

вблизи расположения батарей.

6. НИКОГДА НЕ курите и не позволяйте возникновения искр или пламени в непосредственной

близости от батарей или генератора.

7. Будьте особенно осторожны, когда работаете металлическим инструментом с или поблизости

батарей. Существует потенциал, который может через проводящий инструмент спровоцировать

короткое замыкание между батареями или другими электрическими деталями, что создаст

искрение, что в свою очередь может стать причиной взрыва.

8. Снимите личные вещи из металла: кольца, браслеты, ожерелья, часы при работе с батареями.

Батарея может давать ток короткого замыкания, который является достаточно высоким для

плавки металла кольца, что может повлечь серьезные ожоги.

9. Если используется система удаленного или автоматического запуска от генератора, отключите

цепь автоматического запуска и/или отсоедините генератор от его стартовой батареи, пока

производите сервисное обслуживание для предотвращения случайного запуска во время работ.

Page 25

3

RU

УСТАНОВКА

Распаковка и осмотр

Внимательно распакуйте инвертор/зарядное устройство и выньте его из транспортной коробки.

Убедитесь, что нижеуказанное есть в наличии. Обратитесь в службу поддержки, если какие-либо

элементы отсутствуют.

Устройство

1 руководство пользователя

Базовая конфигурация

Ниже приведен пример базового применения Инвертора PowerWalker 3000 PSW.

Изображены следующие конфигурации:

Автономная работа от устройства – Рис. 1

Пополняющиеся источники энергии и генератор - Рис. 2

Проконсультируйтесь с вашими разработчиками системы для других возможных конфигураций в

зависимости от требований местности или кодировок.

Рис. 1 Автономная работа от устройства

Инвертор PowerWalker 3000 PSW

Page 26

4

RU

Figure 2 Renewable Energy Source

Инвертор PowerWalker 3000 PSW может питать почти все виды приложений в домашней и

офисной среде, в том числе приложения с моторизованными характеристиками, такие как

трубкообразное освещение, вентиляторы, холодильники и кондиционеры.

Примечание: Такие приложения, как кондиционер, требуют как минимум 3 минуты для перезапуска

в случае, если падение сети питания происходит таким образом: питание пропадает в сети,

и возобновляется очень быстро (кондиционеру требуется время для балансировки

газа-хладагента внутри его канала циркуляции). Поэтому для защиты кондиционера воздуха

проконсультируйтесь у его производителя, реализуется ли функция обеспечения временной

отсрочки повторного запуска перед установкой кондиционера. В противном случае, инвертор

воспримет такой сбой как перегрузку, и заблокирует этот выход питания для защиты

Инвертор PowerWalker 3000 PSW

Page 27

5

RU

приложения, но иногда эта мера является недостаточной, и кондиционер получит внутренние

повреждения, не подлежащие ремонту.

Батареи

Устройство поддерживает батарейный комплект 24Вольт. См. Рис. 3 для корректного соединения

батарей. Перед работой убедитесь, что батареи соответствуют данному инвертору. Устройство

может использовать жидкие(доливаемые) свинцово-кислотные аккумуляторы, или герметичные

свинцово-кислотные гелевые или с поглощающим стекловолокном. Поэтому проверьте, относятся

ли аккумуляторы к одной из этих категорий.

Батареи соединяются таким образом, чтобы соответствовать параметру устройства по значению

входного напряжения постоянного тока. Емкость батареи рекомендована не менее 100Ач.

Рис. 3 Подключение батарей гирляндой к Инвертору PowerWalker 3000 PSW

Размер батарейных кабелей

Ниже в Таблице 1 содержатся рекомендации по выбору батарейных кабелей и их наконечников.

Таблица 1 Рекомендованные батарейные кабели и их наконечники

Номер модели

Типичная

амперность

Емкость

батареи

1~3 метра в

одну

сторону

Кабельный

наконечник

Крутящий

момент

Инвертор

PowerWalker

3000PSW

130A

100 Ач

4 AWG

или 2*8AWG

KST:RNBS22-6

(типа кольцо)

5~8 Нм

200 Ач

2* 6 AWG

KST:RNBS38-6

(типа кольцо)

5~8 Нм

Отсоединение постоянного тока и защита от скачков тока

Для соблюдения правил безопасности, батарее требуется защита от скачков, а также возможность

отключения устройств. Предохранители и прерыватели должны быть рассчитаны для защиты

выбранных размеров кабелей постоянного тока, и должны быть рассчитаны на работу с

постоянным током. Не используйте устройства, рассчитанные на работу только с переменным

током – они не будут работать должным образом.

Имейте в виду, что некоторые требования по установке могут не требовать отсоединения

устройства, однако все же требуют наличие защиты от скачков тока.

Page 28

6

RU

Подсоединение батарейного кабеля

Соблюдайте полярность батарей! Расположите кольцо наконечника кабеля постоянного тока над

болтом и прямо напротив клеммы батареи устройства. Затяните винт M6 с 5-8 Нм. Не размещайте

ничего между плоской частью терминала системы резервного копирования и кольцом

наконечника батарейного кабеля во избежание перегрева.

НЕ НАНОСИТЕ АНТИОКСИДАНТНУЮ ПАСТУ НИКАКОГО ТИПА НА ТЕРМИНАЛЫ ДО ТОГО,

ПОКА БАТАРЕЙНЫЙ КАБЕЛЬ ЕЩЕ НЕ ПРИКРУЧЕН !!

Рис 4 показывает правильный способ присоединения батарейного кабеля к терминалам

устройства.

ВНИМАНИЕ: Опасность поражения электрическим током

Установка должна выполняться с осторожностью из-за высокого напряжения батареи и

последовательно.

Предупреждение!! Ничего не располагайте между кольцом наконечника батарейного

кабеля и терминалами инвертора. Винт терминала не предназначен для проводки тока.

Применяйте антиоксидантную пасту к терминалам ПОСЛЕ соединения терминалов кабеля и

инвертора.

Убедитесь, что наконечники кабелей расположены на одном уровне, вровень с батарейными

терминалами. Прикрутите батарейные кабели к терминалам (5-8 Нм).

Рис 4 Батарейный кабель, подсоединенный к устройству

Размер кабеля переменного тока

Перед подключением входа и выхода инвертора ознакомьтесь с указанными в Таблице 2

минимальными рекомендованными размерами кабеля и крутящего момента

Таблица 2 Рекомендованные размеры кабеля и крутящего момента для проводки переменного

тока

Номер модели

Вход переменного

тока

Выход

переменного тока

Крутящий

момент

Инвертор PowerWalker

3000 PSW

12 AWG

12 AWG

1.2~1.8 Нм

Page 29

7

RU

Подсоединения переменного тока

Установка должна выполняться квалифицированным электриком. Уточните местную кодировку и

требования к надлежащему сечению проводов, коннекторам и кабель-каналам.

Слева на заднем шасси расположена крышка клемм разводки кабелей переменного тока. Два

блока клемм, каждый с тремя контактами, предназначен для подключения переменного тока.

Клеммный блок используется для разводки с жестким креплением входного переменного тока,

выходного переменного тока, и заземления. Национальный кодекс безопасности электромонтажа

требует наличие внешнего рычага прерывателя для электрической цепи переменного тока.

Прерыватели переменного тока, размещенные на дополнительной панели, соответствуют этим

требованиям.

Шаг 1: Отсоедините устройство от батареи путем отсоединения батарейного кабеля от батареи.

Просто выключенное устройство не означает отсутствие контакта с батареей.

Рис 5 Кабель переменного тока подсоединен к устройству

Шаг 2: Следуйте обозначениям по разводке, расположенным на блоке подсоединения входа

переменного тока, как показано на Рис 5, подсоедините GND (зеленый/желтый), Line

(коричневый), и нейтраль(N) (синий) провода входного кабеля переменного тока (от сети

здания, генератора, и прочее) к входному блоку клемм.

Внимание!! Убедитесь, что источник переменного тока отсоединен перед попытками

приступить к жесткому подсоединению его к устройству.

Шаг 3: Подсоедините провод Line выходного кабеля переменного тока к клемме на выходном

блоке переменного тока, обозначенной АC Line (output), следуя маркировке проводов

внутри отсека. Прикрепите провода к клеммам блока.

Шаг 4: Закройте крышку панели переменного тока.

Page 30

8

RU

РАБОЧИЕ ОПЕРАЦИИ

Передняя панель и конфигурации коммутатора

Таблица 3 Функции конфигурационных кнопок

кнопка

функция

Описание

config

Ввод конфигурационного режима,

перемотка страниц

up

Движение вверх для выбора

down

Движение вниз для выбора

enter

Ввод как подтверждение

Таблица 4 Значение страниц конфигурирования

Страница

Описание

Опции для выбора

1

Входной диапазон

2

Выходной диапазон

230V 3 Тип батареи

4

Ток зарядки

20A/10A

5

Режим экономии

ON/OFF

Примечание: Всего есть 5 страниц конфигурации, изменение страницы считается внесенным,

только если нажата кнопка enter, когда находимся на текущей странице

Page 31

9

RU

Индикаторы & Сигналы тревоги

Индикатор режима зарядки батареи

Шкала емкости батарей подсвечивается по сегментам в соответствии с напряжением батарей

Статус ЗАРЯДКИ

CONSTANT CURRENT/CONSTANT VOLTAGE(постоянный

ток/постоянное напряжение)

Скользящий режим

Напряжение

батареи(+/-0.6В)

>26В

25В~26В

24В~25В

21В~24В

<21В

Любое напряжение

батареи

Индикатор батареи в режиме инвертора:

Напряжение

батареи

(+/-0.6В)

>26В

25В~26В

24В~25В

23В~24В

21.6В~23В

20В~21.6В

<20В

Сигнал тревоги

--

--

--

--

--

1сигнал/

2секунды

Продолжительный

Индикатор нагрузки:

Нагрузка указывает процент нагрузки в соответствии с ВА или Вт нагрузки (показывает большее

значение), метка перегрузки будет мигать, если перегрузка есть.

Нагрузка (±4%)

>85%

65%~85%

45%~65%

25%~45%

0%~25%

Примечание:

Точно еще есть; Есть но исчезает; Отсутствует полностью.

Page 32

10

RU

Индикаторы операций

Режим ожидания: Режим инвертора:

Значение напряжения и частоты выводятся Значение напряжения и частоты выводятся

по очереди каждые 5 секунд по очереди каждые 5 секунд

Режим от сети: Режим предупреждения:

Значение напряжения и частоты выводятся Красная подсветка мигает каждую секунду

по очереди каждые 5 секунд

“1”: Normal

“3”: Wide

“2”: Generator

“OVLD”: Overload Warning

“FAN”: Fan Abnormal Warning

“BATT”: Battery Low Warning

1 – Нормальный 2 – Генератор 3- - Широкий OVLD - Перегрузка BATT – низкий заряд батарей

FAN – сбой вентилятора

Режим сбоя:

Красная подсветка горит непрерывно

“F 0”: Low DC Voltage

“F 1”: Over Charge

“F 3”: Output Short

“F 4”: Fan Fault

“F 6”: Output Abnormal“F 2”: Over load

“F 5”: Over Temperature

F0 – низкое напряжение постоянного тока F1 – Перезарядка F2 – Перенагрузка F3 – Выходное

питание отсутствует F4 – сбой вентилятора F5 – превышение температуры F6 - выходное

питание недопустимой величины

Page 33

11

RU

Индикация настроек

Настройка входного диапазона

Нормальный режим Режим от генератора Широкий режим

Настройка типа батарей

С абсорбированным электролитом (AGM) Гелевые Доливаемые

Настройка тока зарядки

Высокий ток (20А) Низкий ток(10А)

Настройка режима экономии

Режим экономии выключен Режим экономии включен

Page 34

12

RU

ХАРАКТЕРИСТИКИ

Таблица 5 Характеристики - режим питания от сети

МОДЕЛЬ

Инвертор PowerWalker 3000 PSW

Форма входного напряжения

Синусоида (сеть питания или генератор)

Номинальное входное напряжение

230В

Порог отключения при понижении напряжения сети

170В±4%(NOR)

90В±4%(GEN/WID)

Порог обратного подключения при сниженном

напряжении сети

180В±4% (NOR)

100В±4% (GEN/WID)

Примечание:

1.NOR используется для обычных приложенийe

2. WID используется только для специфической

нагрузки, такой как лампы, вентиляторы.

Порог отключения при повышении напряжения сети

280В±4%

Порог обратного подключения при повышенном

напряжении сети

270В±4%

Максимальное входное напряжение переменного тока

300В rms

Номинальная входная частота

50Гц / 60Гц (Авто определение)

Отключение – низкий предел частоты

40±1Гц

Обратное подключение – низкий предел частоты

42±1Гц

Отключение – высокий предел частоты

65±1Гц

Обратное подключение – высокий предел частоты

63±1Гц

Форма выходного напряжения

Такая же как и входного

Защита от короткого замыкания на выходе

30A прерыватель цепи

Эффективность (режим от сети)

>95% ( Номинальная нагрузка, полный заряд

батареи )

Предел для автоматического перехода

30A

Время перехода

10мс (типичное) 15мс макс(NOR)

20мс (типичное) 40мс макс(GEN/WID)

Панель обходного режима при отключении

Да

Ограничение по мощности

Input Voltage

Output Power

3KVA/2.4KW

1.5KVA/1.2KW

90V 180V

280V

Page 35

13

RU

Таблица 6 Характеристики – режим инвертора

МОДЕЛЬ

Инвертор PowerWalker 3000 PSW

Форма выходного напряжения

Чистая синусоида

Номинальная выходная мощность

3000ВA

Коэффициент мощности

0.8

Номинальное выходное напряжение

230В

Нижний порог выходного напряжения при номинальной

мощности

>200В

Выходная частота (Гц)

50Гц / 60Гц ± 1Гц (следуем первому

подключению к сети)

Регулировка выходного напряжения

±10% В rms

Номинальная эффективность

>90% (при нормальном входном

постоянном токе;

>60% номинальной нагрузки

Защита от перегрузки

Сбой спустя 5с при≥150%

нагрузки,<=200% нагрузки

Сбой спустя 10с при 110%~150%

нагрузки,

Верхний порог скачка напряжения

6000ВА

Возможность запуска электродвигателя

1.5 лошадиных сил

Защита от короткого замыкания на выходе

Ограничение тока (Сбой макс после 4

циклов)

Номинал напряжения постоянного тока на входе

24В

Минимальное стартовое напряжение постоянного тока

20В

Сигнал при низком постоянном токе

21.0 ± 0.6В постоянного тока

Сигнал восстановления при низком постоянном токе

21.6 ± 0.6В постоянного тока

Завершение работы при низком постоянном токе

20.0 ± 0.6В постоянного тока

Переход к восстановлению при низком постоянном токе

22.0 ± 0.6В постоянного тока

Завершение работы при высоком постоянном токе

30.0 ± 0.6В постоянного тока

Переход к восстановлению при высоком постоянном токе

29.0 ± 0.6В постоянного тока

Составная часть постоянного тока на выходе

<100мВ

Ограничение мощности

Battery Voltage

Output power

3KVA/2.4KW

2.1KVA/1.68KW

27V26.5V 30V20V

Page 36

14

RU

Таблица 7 Характеристики – режим зарядки

Номинальное входное напряжение

230В переменного тока

Диапазон входного напряжения

180В – 270В (NOR) переменного тока

100В – 270В(GEN/WID) переменного тока

Отключение при высоком напряжении

280В переменного тока ±4%

Подключение при высоком напряжении

270В переменного тока ±4%

Отключение при низком напряжении

170 В переменного тока (NOR)

90 В переменного тока (GEN/WID)

Подключение при низком напряжении

180 В переменного тока ±4% (NOR)

100 В переменного тока ±4% (GEN/WID)

Номинальное выходное напряжение

См. алгоритм зарядки/ настройки по типу батареи

Номинальный ток зарядки

10A @Vi/p<170 В переменного тока

20A@Vi/p=230 В переменного тока

10A @Vi/p>280 В переменного тока

Колебания тока зарядки

±10%

Защита от перезарядки

Напряжение батареи ≥30В постоянного тока, Сбой,

Сигнал тревоги

Алгоритм зарядки

Три этапа:

Повышение CC (заряд стабилизированным током →

Повышение CV (заряд стабилизированным

напряжением) → компенсирующий (при снижении

напряжения до нижнего порога снова начинается заряд

стабилизированным током)

Установки по типу батареи

(+/-0.3В/Батарея)

Тип батареи

Повышение CC/CV

компенсирующий

Напряжение(В)

Напряжение (В)

24

24

доливаемая

29.2

27.0

AGM / Гель

28.2

27.0

Ток заряда (+/-10%)

170

Charge(A)

20

180 270 280

Set as 20A & NOR range

Input(Vac)

170

Charge(A)

180 270 280

Set as 10A & NOR range

Input(Vac)

90

Charge(A)

100 270 280

Set as 10A & GEN/WID range

Input(Vac)

Charge(A)

10

Set as 20A & GEN/WID range

Input(Vac)

170

10 10

20

280

90 100

230

270

Примечание: NOR – нормальный диапазон; GEN-диапазон от генератора; WID-Широкий диапазон

Page 37

15

RU

Таблица 8 Примерное время автономной работы

Нагрузка(ВА)

100Ач 24В

постоянного тока(мин)

200Ач 24В постоянного

тока(мин)

300

457.5

972.2

600

208.1

499.5

900

140.6

262.3

1200

103

178.1

1500

77.8

138.3

1800

57.6

113.2

2100

49.5

100.5

2400

41.4

87.9

2700

33.2

75.3

3000

28.4

62.6

Примечание: Время автономной работы зависит от качества батареи, ее возраста и типа.

Характеристики батарей разных производителей отличаются.

Таблица 9 Общие характеристики

Стандарт Безопасности

EN60950-1:2006+A1: 2010

EN62040-1-1: 2008

Стандарт Электромагнитной

совместимости

EN62040-2 : 2006 C2

Диапазон температур рабочего режима

0°C to 45°C

Температура хранения

-15°C~ 60°C

Высота над уровнем моря, в рабочем

режиме

Высота: 0 – 1500 метров

Относительная влажность

От 5% до 95% без конденсата

Уровень шумов

60ДБ максимум

Охлаждение

Нагнетаемым воздухом

Размеры(Д*Ш*В)

330мм*268мм*76мм

Нетто вес

4.9кг

Проводка постоянного тока

Двойной 6 AWG для каждой полярности

Вход/выход переменного тока

L/N/G:12AWG

Page 38

16

RU

Таблица 10 Коды ошибок/ Звуковой сигнал

код

оши

бки

Функция

защиты

режим

активности

Условие

Предупреждение

(О/Р=ON (ВКЛ))

Ошибка

(О/Р=OFF(ВЫКЛ))

Перезагрузка

Работ

а

Условие

--

Сигнал низкого

напряжения DC

Инвертор

Напряжение DC <

нижнего порога для

сигнала

1звучание/2сек

--

--

--

0

Защита от

низкого

напряжения DC

Инвертор

Напряжение DC <

нижнего порога

завершения работы

--

Продолжительн

ый сигнал

Авто

Сеть

питания в

норме

1

Защита от

перезарядки

Сеть питания

Напряжение DC >

верхнего входного

порога завершения

работы

Продолжительный

сигнал

--

Вручн

ую

--

1

Защита от

перенапряжен

ия

Режим

ожидания

Напряжение DC >

верхнего входного

порога для

завершения работы

--

Продолжительн

ый сигнал

Авто

Напряжени

е

DC<верхнег

о входного

порога для

восстановл

ения

завершени

я работы

2

Защита от

перенагрузки

Сеть/Инвертор

110%~150% нагрузка

1звучание/0,5сек, и

продолжается 10сек

Продолжительн

ый сигнал

Вручн

ую

--

Сеть/Инвертор

>150% нагрузка

1звучание/0,5сек, и

продолжается 5сек

Продолжительн

ый сигнал

Вручн

ую

--

3

Защита от

короткого

замыкания на

выходе

Инвертор

1) Выходное

напряжение<20B:

2)TX

температура>102гра

д C

--

Продолжительн

ый сигнал

Вручн

ую

--

4

Защита при

сбоях

вентилятора

Сеть/Инвертор

Вентилятор

заблокирован,

Вентилятор имеет

дефект

2звучания/2сек, и

продолжается 1мин

Продолжительн

ый сигнал

Вручн

ую

--

5

Защита от

перегрева

Сеть/Инвертор

температура

радиатора >100гр.C

--

Продолжительн

ый сигнал

Авто

Темп.

радиатора

<55град C

6

Неполадки на

выходах

Инвертор

1)250B<Выходное

напряжение<170B:

2)TX темп.>102гр. C

--

Продолжительн

ый сигнал

Вручн

ую

--

Примечание – условное обозначение: DC- постоянный ток

Page 39

17

RU

УСТРАНЕНИЕ НЕИСПРАВНОСТЕЙ

Проблема

Возможная причина

Исправление

Не светится

ЖК-дисплей

1. Слабая батарея

1. RЗарядите батарею

2. Батарея неисправна (не

заряжается)

2. Замените батарею

3. Кнопка вкл. Питания не

работает

3. Нажмите и удерживайте кнопку питания

4. Полярность батареи перепутана,

устройство не стартует

4. Верните для ремонта

Сеть питания в

норме, но

работает в

режиме

инвертора

1. На вход не поступает

переменный ток

1. Проверьте соединение с входным

переменным током

2. Защита входа срабатывает

2. Отключите защиту входа

Сеть питания в

норме, но нет

возможности

работы в режиме

инвертора

1. Отключена батарея

1. Подсоедините батареи

2. Низкий заряд батареи

2. Перезарядите батареи или замените их

новыми

Сигнал тревоги

звучит

непрерывно

1. Перегрузка(код ошибки: F2)

1. Убедитесь, что нагрузка соответствует

емкости, указанной в характеристиках

2. Короткое замыкание на

выходе(код ошибки: F3)

2. Проверьте проводку или отключите

замыкающую нагрузку

3. Перегрев(код ошибки: F5)

3. Уберите помеху впереди входа воздуха

4. Перезарядка(код ошибки: F1)

4. Перезагрузите устройство

5. Перенапряжение(код ошибки:

F1)

5. Снизьте входное напряжение постоянного

тока ниже верхнего предела входного

постоянного тока, при котором происходит

восстановление закрытия системы

6. Сбой вентилятора(код ошибки:

F4)

6. Проверьте, не блокирован ли вентилятор,

если нет, его нужно заменить

7. Напряжение постоянного тока

ниже порога для закрытия системы

при постоянном токе(код ошибки:

F0)

7. Убедитесь что сеть питания достаточна для

подзарядки батареи, отключите инвертор до

тех пор, пока сеть питания не нормализуется

8. Выход не в норме(код ошибки:

F6)

8. Верните для ремонта

Время

автономной

работы слишком

мало

1. Перегрузка

1. Отключите часть некритичной нагрузки

2. Напряжение батарей слишком

низкое

2. Зарядите батарею в течение 8ч или более

3. Блок батарей недостаточен

3. Увеличьте емкость блока батарей

Loading...

Loading...