Powervar ABCE702-11R, ABCE702-11RMED, ABCE702-22R, ABCE702-22RMED, ABCE1002-11R Instruction Manual

...

Security II Rackmount Series

Uninterruptible Power Manager

For use with 700VA, 1000VA, 1440VA, 2200VA and 3000VA

2

A01-00071 Rev Fwww.powervar.com

1.0 - Introduction .................................................................... 6

2.0 - Safety Instructions ......................................................... 8

3.0 - Installation ..................................................................... 12

4.0 - Operation ....................................................................... 17

5.0 - Maintenance .................................................................. 22

6.0 - Troubleshooting ............................................................. 27

7.0 - Warranty ........................................................................ 29

8.0 - Specications ................................................................ 30

TABLE OF CONTENTS

3

A01-00071 Rev F www.powervar.com

IMPORTANT NOTICE ON BATTERY WARRANTY

The warranty policy stated in Section 8 is not valid for applications in

which the UPM is regularly and intentionally disconnected from AC

mains power. AMETEK Powervar’s two year battery warranty applies

only to products that are properly installed and consistently connected

to AC mains power, except during utility outages.

Products regularly and intentionally disconnected from AC mains

power will experience substantially reduced battery life. AMETEK

Powervar’s standard warranty term does not apply in these cases

and is supplanted by a 90-day warranty from time of shipment from

AMETEK Powervar. The warranty provided by AMETEK Powervar

provides for the replacement of the battery or battery systems in the

event that the batteries do not meet performance specications as

determined by AMETEK Powervar exclusively.

4

A01-00071 Rev Fwww.powervar.com

Danger- The danger symbol is used to indicate

imminently hazardous situations, locations, and

conditions which, if not avoided, WILL result in death,

serious injury, and/or severe property damage.

Caution- The caution symbol is used to indicate potentially hazardous situations and

conditions which, if not avoided, may result in

injury. Equipment damage may also occur.

Warning- The warning symbol is used to indicate

potentially hazardous situations and conditions which,

if not avoided, COULD result in serious injury or

death. Severe property damage COULD also occur.

Attention- The attention warning symbol is used to

indicate situations and conditions that can cause

operator injury and/or equipment damage.

Other warning symbols may appear along with the

Danger and Caution symbol and are used to specify

special hazards. These warnings describe particular areas where special care and/or procedures are required

in order to prevent serious injury and possible death.

Electrical warnings- The electrical warning symbol is a

lightning bolt mark enclosed in a triangle. The electrical

warning symbol is used to indicate high voltage locations and conditions may cause serious injury or death.

Explosion warnings- The explosion warning

symbol is an explosion mark enclosed in a triangle. The explosion warning symbol is used to

indicate locations and conditions where molten,

exploding parts may cause serious injury or death

if the proper precautions are not observed.

DANGER

CAUTION

WARNING

ATTENTION

5

A01-00071 Rev F www.powervar.com

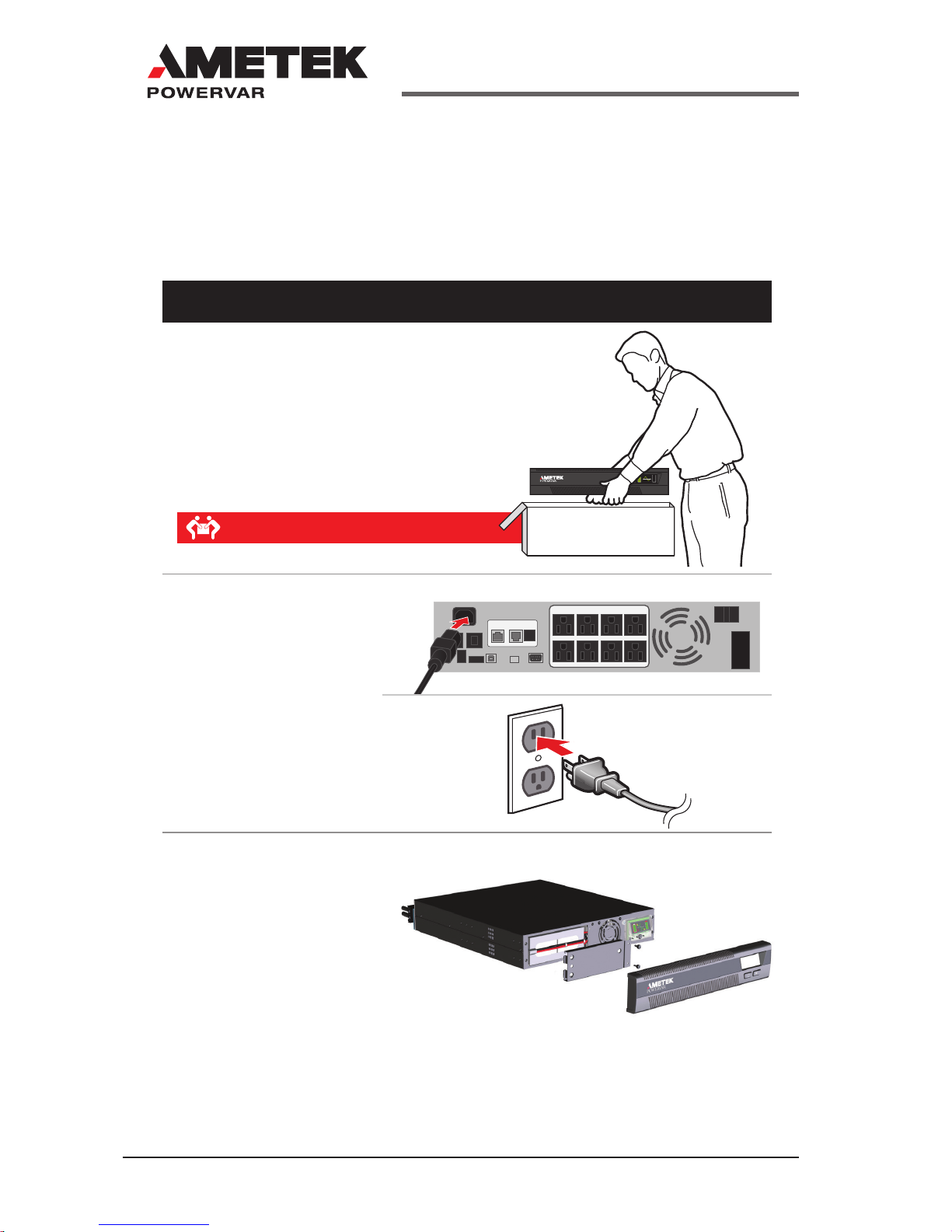

Alternating Current

Refer to instruction manual/booklet.

Two person lift.

6

A01-00071 Rev Fwww.powervar.com

1.0 INTRODUCTION

Thank you for your purchase of the AMETEK Powervar Security II Series

Rackmount UPM ( hereafter referred to as “UPM”). AMETEK Powervar man-

ufactures two versions of the UPM – a standard version, and a medical version listed to UL60601-1 and cUL C22.2 No. 60601.1. In addition, all models

are compatible with International electrical distribution systems. International

versions are UL listed (Medical listed to IEC60601-1 and EN60601) and car-

ry the CE Mark. We’ve prepared this document to help familiarize you with

the functions and controls of this product. If, after reviewing this manual, you

have any questions at all, please feel free to contact our technical support

team by phone (1-800-369-7179) or email us at service.powervar@ametek.

com.

AMETEK Powervar is a global provider of power management solutions,

headquartered in Waukegan, Illinois, with international sales and distribution

ofces in Swindon, United Kingdom, Toronto, Canada, Mexico City, Mexico

and Germany. All AMETEK Powervar solutions incorporate a high energy

surge diverter, a noise lter and a low impedance isolation transformer.

Together these components prevent power disturbances from destroying,

degrading or disrupting system operations.

Registering you AMETEK Powervar Product

Please take a few moments to register your product purchase. Registration

is easy and quick via the product registration page found on our website at

www.powervar.com.

7

A01-00071 Rev F www.powervar.com

General

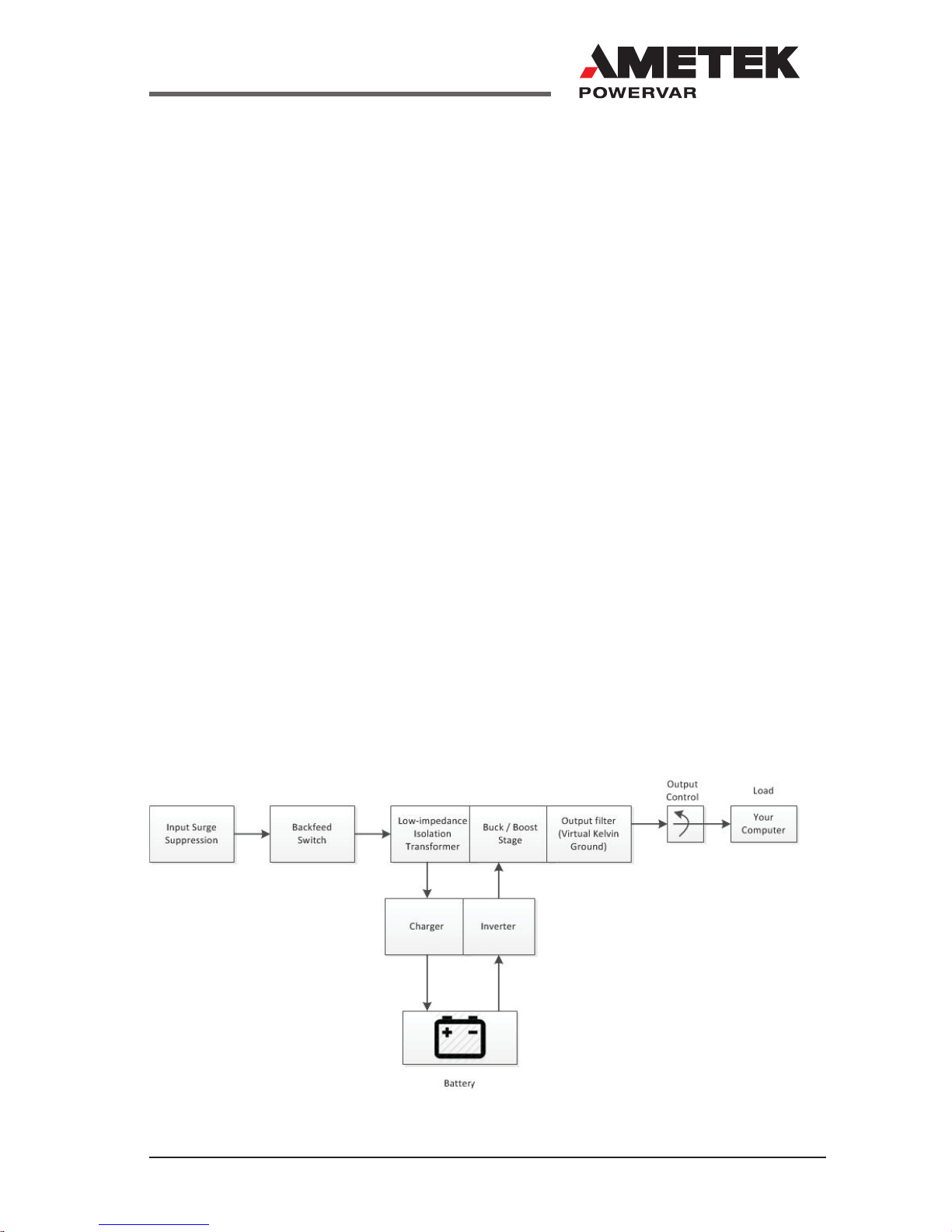

The AMETEK-Powervar Security II UPM (hereafter refered to as “UPM”)

systems are the most advanced, line interactive, true sinewave UPS products available for your application. Each model is designed to provide total

protection for your system from a complete range of power quality problems.

UPM systems will protect your installation from normal mode voltage impulses, electrical noise, sags, surges, brownouts, and blackouts. Each UPM

contains a low impedance isolation transformer, it completely eliminates

common-mode (neutral-to-ground) voltages that are a constant threat to

the reliable operation of microprocessor-based systems. When AC power is

present, UPM constantly lters and conditions the power supply. When AC

power fails, the UPM uses its internal, maintenance-free battery to supply

reserved power to your computer system. Regardless of whether or not

commercial power is present, the UPM is consistently on the job. Ensuring a

fully conditioned, safely managed interface between your computer system

and its electrical power supply. Figure 1 illustrates the basic operation of the

UPM.

Figure 1

8

A01-00071 Rev Fwww.powervar.com

2.0 SAFETY INSTRUCTIONS

IMPORTANT - SAVE THESE INSTRUCTIONS

THIS MANUAL CONTAINS IMPORTANT SAFETY INSTRUCTIONS.

KEEP THIS MANUAL HANDY FOR REFERENCE.

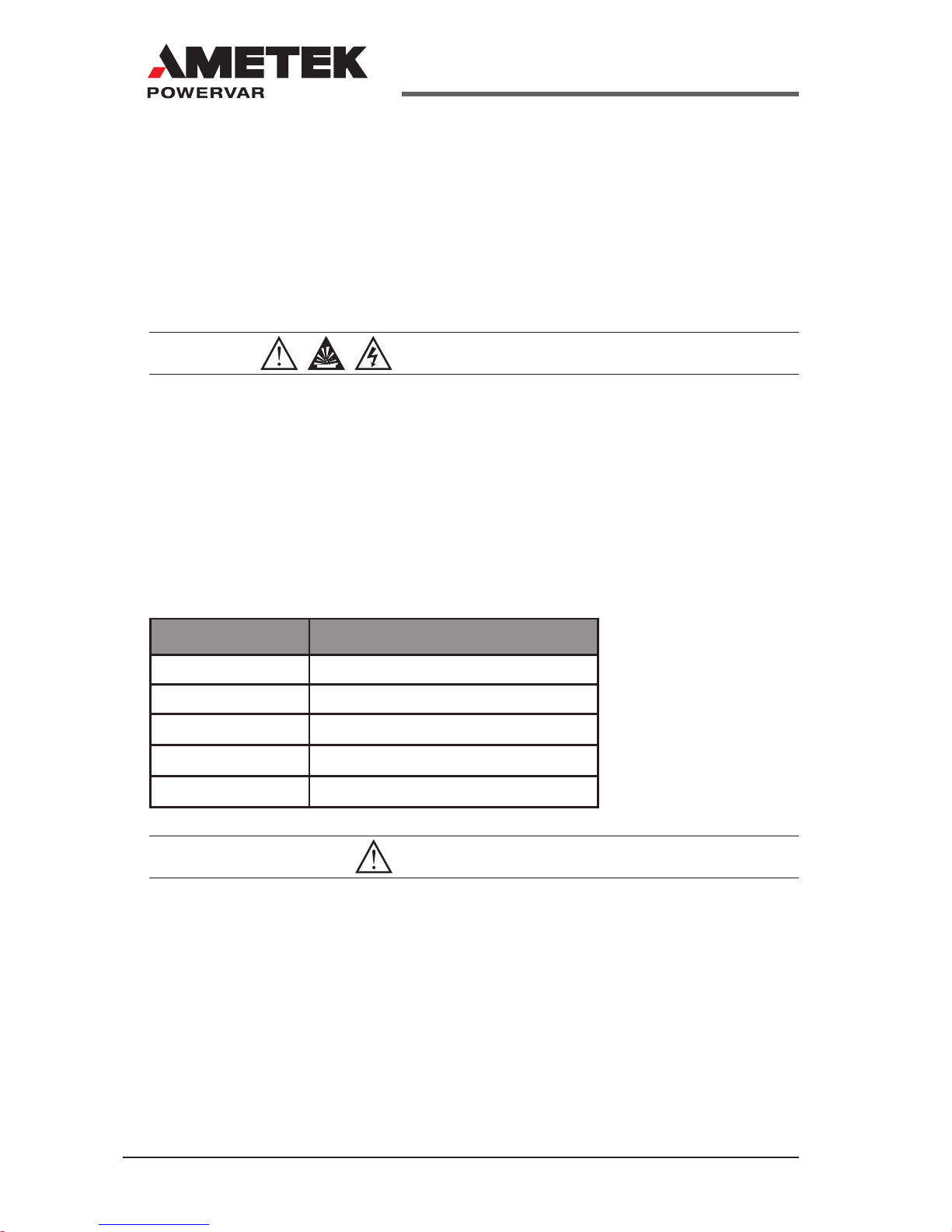

CAUTION

A battery can present a risk of electrical shock. Short-circuit currents can

be extremely high and can create severe burns as well as the risk of re or

explosion from vented gases. Always observe proper precautions.

When replacing batteries, use the same quantity, rating and type of batteries used by AMETEK Powervar. The batteries used in this UPM are sealed

lead-acid and are maintenance free. Proper disposal of batteries is required.

Refer to your local codes for disposal of batteries.

UPM Rating Quantity and Battery Rating

700 VA 4 X 23W @ 12 VOLT

1000 VA 4 X 23W @ 12 VOLT

1440 VA 4 X 23W @ 12 VOLT

2200 VA 8 X 23W @ 12 VOLT

3000 VA 8 X 23W @ 12 VOLT

CAUTION

• This UPM contains voltages which are potentially hazardous. All re-

pairs should be performed by qualied service personnel.

• To reduce the risk of re, connect only to a circuit provided with 20 am-

peres maximum branch circuit over-current protection in accordance

with the National Electric Code, ANSI/NFPA 70.

• The UPM has its own internal energy source (battery). The output receptacles of the UPM may be live even when the UPM is not connected to an AC Supply.

9

A01-00071 Rev F www.powervar.com

STATEMENT OF INTENDED USE

The medical UPMs are intended to protect medical, non-medical computer

equipment and medical devices that need battery backup, surge protection,

voltage regulation and line noise ltering in and around patient care areas.

Safe and continuous operation of the UPM depends partially on the care taken by users. Please observe the following precautions. Not following these

could result in warranty being voided.

NOTE:

• The UPM is intended for stationary use.

• UPM is not intended for patient contact or for installation that will cause

accidental contact of patients.

• Do not use this UPM for life support applications in which a malfunction

or failure of the UPM system could cause failure or signicantly alter

the performance of a life-support device.

• Do not use this UPM near or around ammable gases. Do not use this

UPM within oxygen-enriched atmospheres.

• Do not disassemble the UPM.

• UPM is CLASS 1 equipment.

• Do not attempt to power the UPM from any receptacle except a properly grounded receptacle that matches the input plug provided with the

UPM.

• Do not place the UPM near water or in environments of excessive

humidity.

• Do not allow liquid or any foreign object to get inside the UPM.

• Do not block air vents on the front of the UPM.

• Do not plug appliances such as hair dryers, fans, heaters, etc. into the

UPM.

• Do not place the UPM under direct sunshine or close to heat emitting

sources (excessively warm temperatures will shorten battery life).

• This UPM is intended for installation in a temperature controlled, indoor

area free of conductive contaminants.

• The AC power source for the UPM should be conveniently near the

UPM and easily accessible – avoid extension cords or temporary power strips to power the UPM.

10

A01-00071 Rev Fwww.powervar.com

• The total leakage current of the UPM and consumer connected equipment should not exceed 3.5 mA for non-medical units.

• Not for use in a computer room as dened in the Standard for the

Protection of Electronic Computer/Data Processing Equipment, ANSI/

NFPA 75.

• The socket-outlet shall be installed near the equipment and shall be

easily accessible.

• The battery should be disconnected from the UPM by unplugging at its

quick connectors when maintenance or service work inside the UPM is

necessary.

• Do not dispose of batteries in a re – batteries may explode.

• Do not open or mutilate batteries. Doing so may release electrolyte or

other toxic substances, which may be harmful to the skin, eyes, or the

environment.

A battery can present a risk of electric shock and high short circuit current.

The following precautions should be observed when working with batteries:

• Remove watches, rings, or any other metal jewelry or objects which

may make contact with the battery.

• Use tools with insulated handles.

Unit is suitable for IT applications.

11

A01-00071 Rev F www.powervar.com

FCC ISSUES

Attention

This UPM has been tested and found to comply with the limits for a Class A

digital devices (Class B compliance optional), pursuant to Part 15 of the FCC

rules. These limits are designed to provide reasonable protection against

harmful interference in both residential and commercial environments.

This equipment generates, uses and can radiate radio frequency energy

and if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio and/or television reception, which

can be determined by turning the UPM equipment on and off, the user is

encouraged to try to correct the interference by one or more of the following

measures:

Relocate the UPM

Relocate the load.

This device complies to Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference

and (2) this device must accept interference received, including interference

that may cause undesired operation.

12

A01-00071 Rev Fwww.powervar.com

3.0 INSTALLATION

Some units may require 2 people to lift.

Security II Rackmount Quick Start Guide

This unit is shipped with the internal batteries disconnected.

Before starting the UPM, please follow these battery connection instructions.

1. Remove UPM from the box

2. Attached included

outlet cord and plug

UPM into wall.

Continued on side 2

3. Remove the UPM

front plastic cover and

metal battery cover

by removing the screws.

13

A01-00071 Rev F www.powervar.com

14

A01-00071 Rev Fwww.powervar.com

UNPACKING THE UPM

CAUTION

• Unpacking the unit in a low-temperature environment may cause

condensation to occur in and on the unit. Do not install the unit until

the inside and outside of the unit are absolutely dry {hazard of electric

shock}.

• The unit is heavy. Use caution when unpacking and moving the unit.

Use care when moving and opening the carton. Leave the components packaged until ready to install.

To unpack the unit and accessories:

1. Open the outer carton and remove the accessories packaged with

the unit.

2. Carefully lift the unit out of the outer carton.

3. Store the carton for future use.

Place the unit in a protected area that has adequate airow and is free of

humidity, ammable gas and corrosion.

NOTE:

Before installation, please read and understand the following

instructions. Carefully examine the carton for damage. Notify the

carrier immediately if damage is observed. Be sure to save the carton

should you ever need to ship the UPM for repair or maintenance.

This UPM is intended for indoor use only. Although your

UPM is very rugged, its internal components are not sealed

from the environment. The UPM must be installed in a

protected environment away from heat producing appliances such as furnaces, radiators, and heaters. Protect the

UPM from exposure to dripping or standing water and high

humidity or condensing air conditions.

15

A01-00071 Rev F www.powervar.com

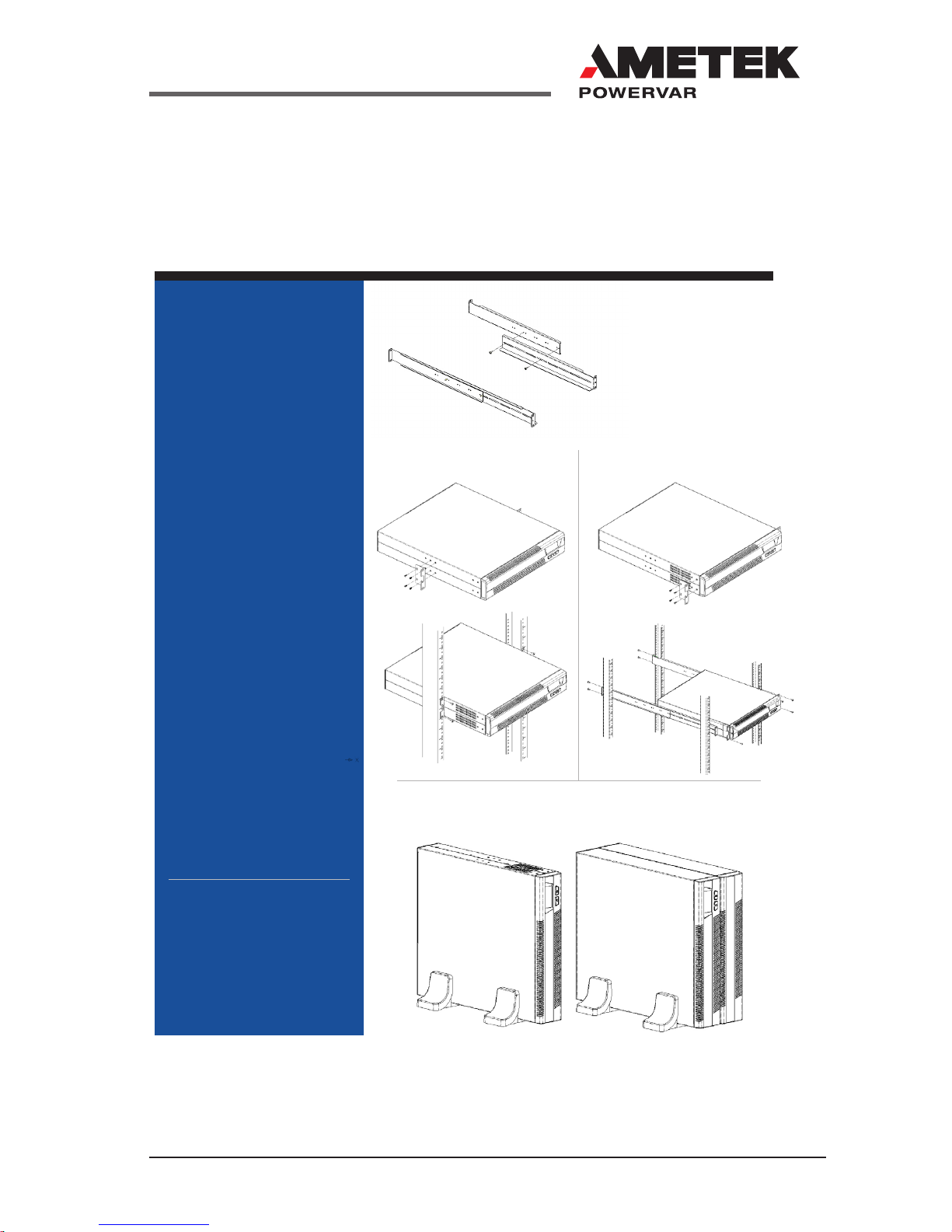

Rackmount Installation Guide

** Example of 4U unit* Example of a 2U unit

1. Assemble the side rails and

secure each with (2) screws.

DO NOT TIGHTEN.

2. Attach front of the rails to

front of rack with (1) fastener

for each side in the upper

mounting hole.

3. Attach rear of rails to rear of

rack with the (2) fasteners for

each side.

4. Tighten the (2) screws used to

assemble each rail in step 1.

5. For 2U

*

UPMs and battery

cabinets, attach (1) angled

mounting bracket to each side

of the UPM and/or each side

of the battery cabinet using

the (8) screws provided.

6. For 4U

**

UPMs - attach (2)

angled mounting brackets to

each side of the UPM using

the (16) screws provided.

7. Lift the battery cabinets and

UPM onto the mounting rails

and slide each into position.

8. Secure the 2U UPM and

battery cabinet with (4)

fasteners and the 4U UPMs

with (8) fasteners provided.

Rackmount UPM and the

external battery cabinet are

designed to be floor standing as

an alternative to rack mounting.

The UPM and external battery

cabinets use identical mounting

hardware and the procedure for

mounting is the same for both.

Each unit and each battery

cabinet must be mounted

to their own rail kits that

are included.

Floor Standing Installtion

Middle Rack Installation Standard Rack Installation

16

A01-00071 Rev Fwww.powervar.com

Rackmount Installation Guide

INSPECTING THE UPM

If any equipment has been damaged during shipment, keep the shipping cartons and packing materials

for the carrier or place of purchase and file a claim for shipping damage:

1. File with the carrier within 15 days of receipt of the equipment;

2. Send a copy of the damage claim within 15 days to your service representative.

WARNINGS

Use all supplied mounting hardware on each UPM and External Battery Cabinet.

NEVER depend on devices installed on lower levels to support other devices.

Two people are recommended for safe installation.

Never attempt to mount the UPM or external battery cabinet with the from mount ears

only. Continuous support is required throughout the mounting procedure to prevent

damage or injury.

17

A01-00071 Rev F www.powervar.com

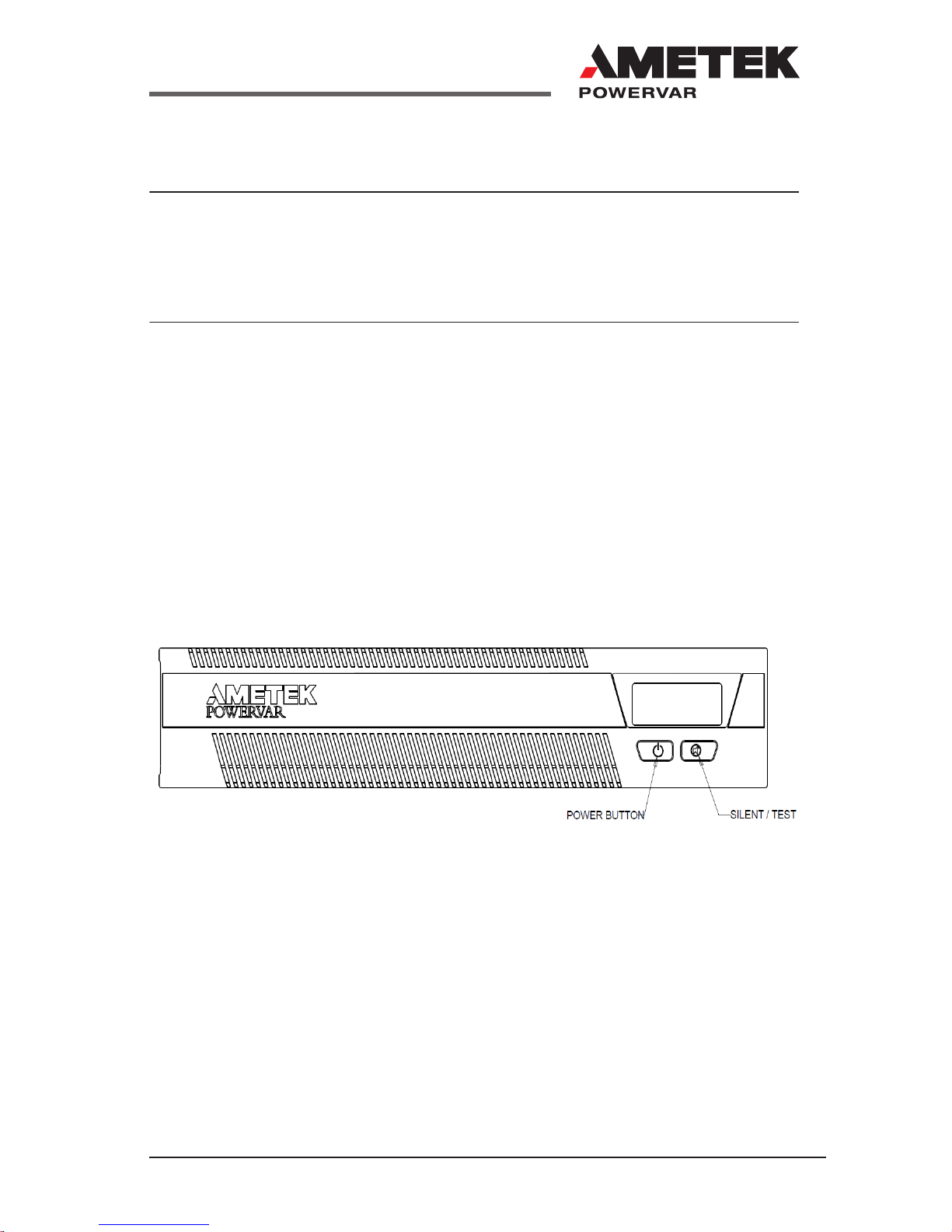

4.0 OPERATION

NOTE:

In order to operate the UPM, you must rst plug the battery enable

plug(s) into the battery enable socket(s) behind the front panel of the

UPM.

On/Off Button

The On/Off button is a dual function control:

• When the UPM is off and AC power is present to the UPM input,

pressing the On/Off button for more than 2 seconds will turn the UPM

output on.

• If battery is connected, pressing the On/Off switch for 2 seconds or

more will “cold-start” the UPM on its internal battery with no incoming

AC present.

• When the UPM is on, pressing the On/Off button for more than 2

seconds will turn off the UPM output power.

Test/Silence Button

The Test/Silence button is a dual function control:

• Pressing the Test/Silence button when AC power is present and the

UPM is operating causes the UPM to enter a self test mode in which

it tests both battery and inverter for a few seconds before returning to

the AC supply. We recommend you close all open les before initiating

self-test.

• When AC power fails, the UPM warns you with an audible alarm. The

Test/Silence button is used to silence the alarm. When battery power

begins to run low, the audible alarm will automatically return and beep

at a faster rate.

18

A01-00071 Rev Fwww.powervar.com

Load Monitor

The Load Monitor is a six-segment LED display that shows the current load

percentage. The rst 5 LED’s each indicate approximately 20% load, with the

6th red LED showing the UPM is overloaded.

Battery Charge Monitor

The Battery Charge Monitor is a ve-segment LED display that shows the

charge capacity of the internal battery from zero to 100%. Each LED indicates

approximately 20% of full charge.

Site Wiring Fault Indicator – (120 VAC models only)

The “SF” symbol will be displayed on the front panel of the UPM if it is

connected to an improperly wired AC receptacle. This is to indicate a missing

safety ground wire or a reversal in phase and neutral wiring. If the “SF”

is displayed on the front panel you should contact a qualied electrician

immediately.

NOTE:

Do not operate the UPM if the Site Wiring Fault LED is illuminated.

When lit, the LED is indicating a wiring condition, which may represent

a hazard of re or electrocution. In addition, improper wiring may create

reliability problems for both the UPM and the connected system. Never

use a 3-blade to 2-blade adapter (often called a “cheater”) to power UPM.

These devices remove the safety ground connection to the UPM and will

cause the Site Wiring Fault LED to illuminate.

19

A01-00071 Rev F www.powervar.com

Display Functionality

The location should provide adequate airflow around the UPM. Provide a minimum 3” clearance on all sides for proper ventilation.

Applying Power to the UPM

Connect the power cord to a verified grounded 3 wire receptacle. Verify

that the Site Wiring Fault “SF” is off (120 VAC models only). Once properly

connected and initially checked, turn on the UPM by pressing and holding the

front panel On/Off switch for 3 seconds.

Operational Tests

Observe the front panel of the UPM. The following table shows system status

behavior.

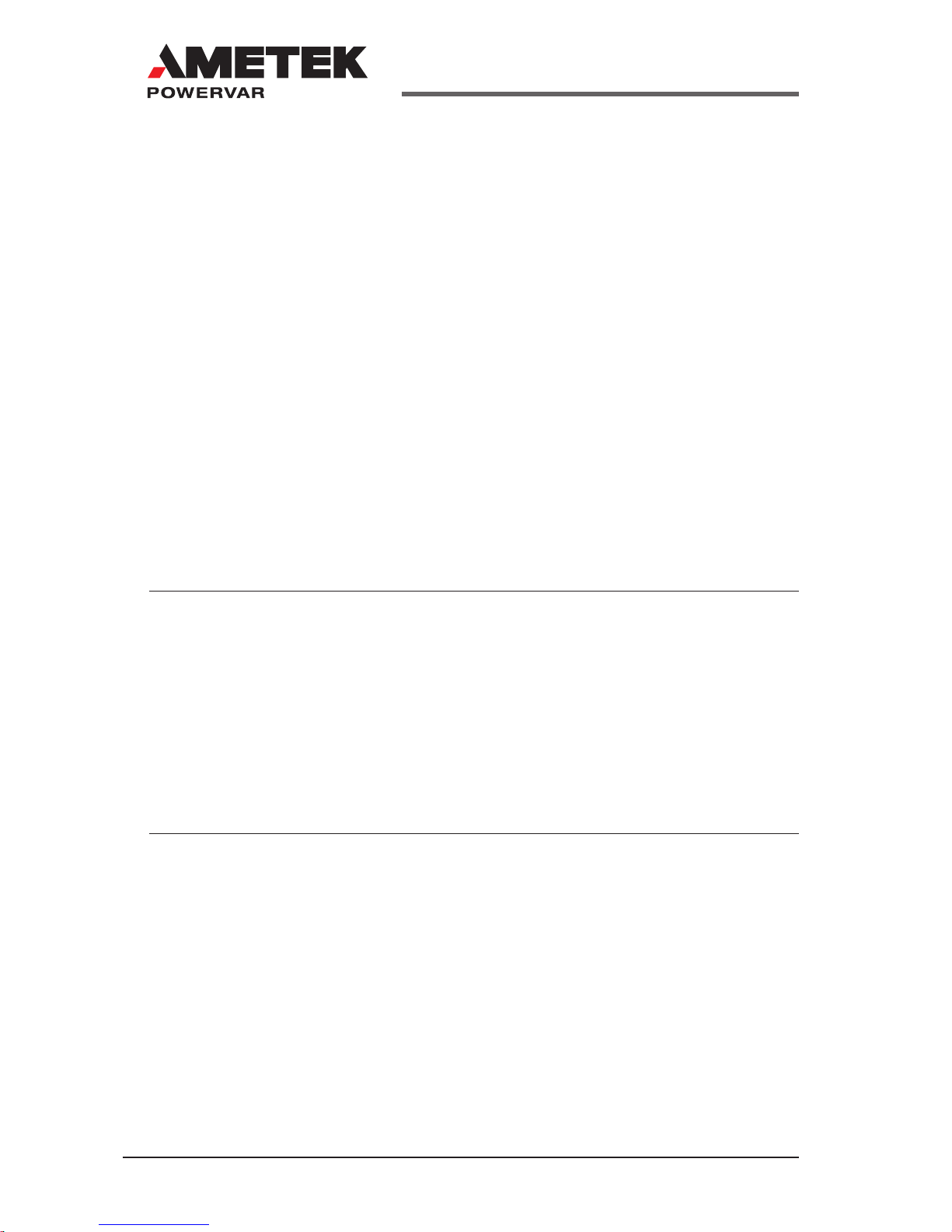

UPM LED DISPLAY UNIT STATUS

UPM output on

Battery charge status in 20% increments

UPM in battery operation due to improper incoming AC voltage

Battery fault or battery disconnected

UPM load status in 20% increments

UPM overloaded

Unit in buck operation due to high incoming AC voltage

Unit in boost operation due to low incoming AC voltage

Fault

UPM over temperature

UPM Front Panel

Output

Battery

System Status

20

A01-00071 Rev Fwww.powervar.com

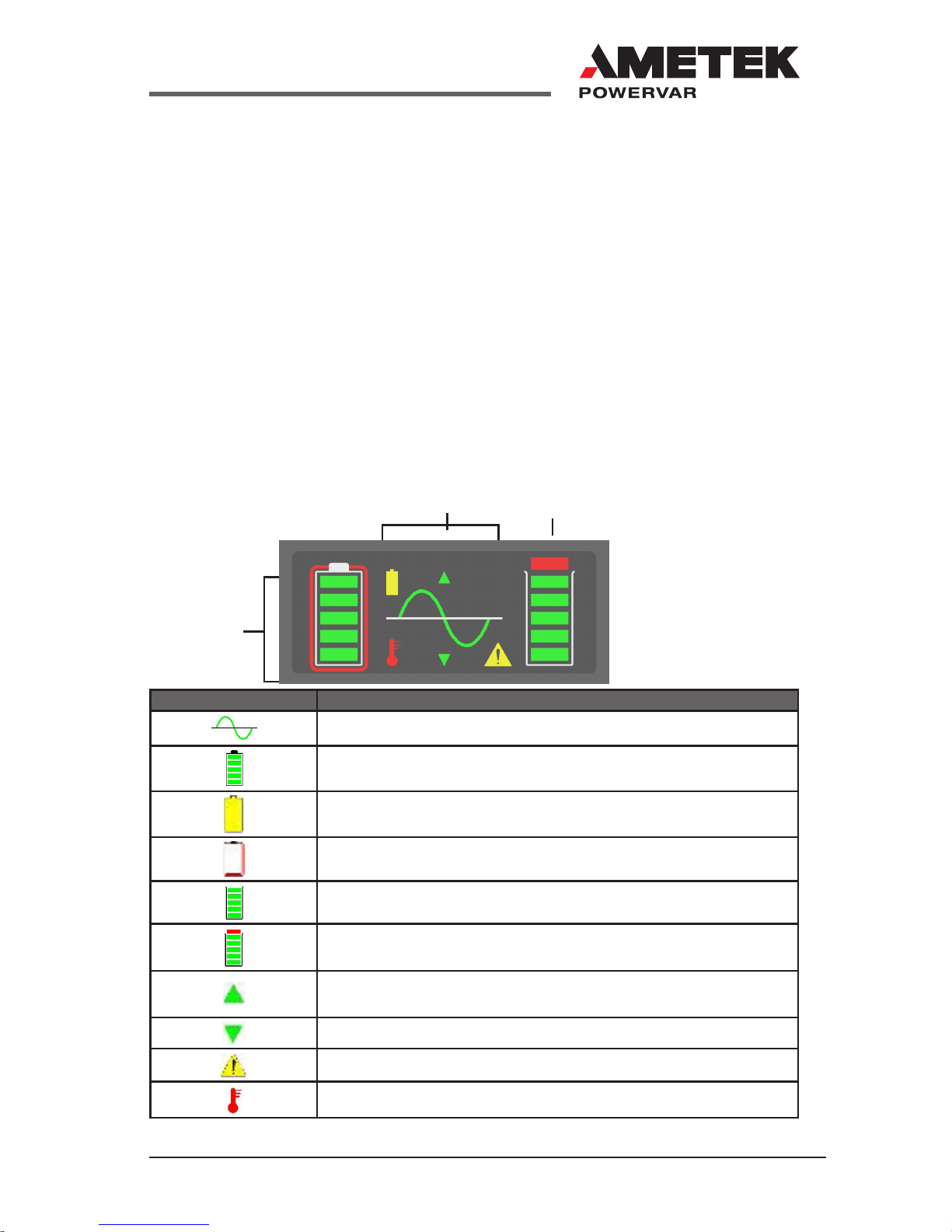

UPM Load and Battery Indicators

Example:

UPM display showing normal operation

(Fully charged batteries with 60% load shown)

UPM display showing in battery backup operation

(Batteries 80% charged with 60% load shown)

UPM display showing an overload condition (Batteries 100%

charged and greater than 100% load shown)

UPM display showing over-temperature condition

(Batteries 80% charged with 80% load shown)

UPM display showing a bad battery condition

(Inspect or replace battery unit loaded to 60%)

NOTE:

Depending on the charge state of the battery, it is possible that the

battery charge level LEDs may be ashing (this is normal).

Initial Startup

With the connected equipment powered off, perform an initial test of the

UPM backup function by pressing the Test/Silence button on the front pan-

el. During this test, the Battery LED ( ) on the front panel should briey

illuminate. It is also possible to test the backup function by unplugging the

UPM input power cord. If you choose to test the UPM in this manner, you

will note that the UPM will beep every few seconds while the power cord is

unplugged. The Battery LED ( ) will also illuminate constantly.

Once you have performed an initial test of the UPM backup function, turn on

the connected computer equipment. Verify that the unit is not overloaded. If

the unit is overloaded all load LED’s will be on the fault LED ( ) will ash,

remove the least critical devices from the UPM one by one until the overload

LED is extinguished. With the connected loads powered up, perform the

backup test once again by pressing the Test/Silence button or unplugging the

UPM. When this nal test is completed, the UPM will be ready to use.

Loading...

Loading...