Powertronix Quasar, 10kVA, 15kVA, 20kVA, 30kVA Service Manual

Manual Registration

Prelim Page i3x3 UPS Preliminary Pages

Issue 2 - November 2001

Manual Registration

S THIS MANUAL IS A CONTROLLED DOCUMENT AND WILL BE PERIODICALLY UPĆ

DATED.

S IN ORDER TO ENSURE THAT YOU RECEIVE ANY AMMENDMENT PLEASE REGĆ

ISTER THIS MANUAL WITH THE TECHNICAL SUPPORT DEPARTMENT BY REĆ

TURNING A COPY OF THIS FORM TO:

Manual Registration

Number

Name of Registered Holder

Address of

Holder

Company

Name/Building

Street/Road

Area/region

Town/City

County/State

Post/Zip Code

Country

Telephone Number

FAX Number

E Mail Address

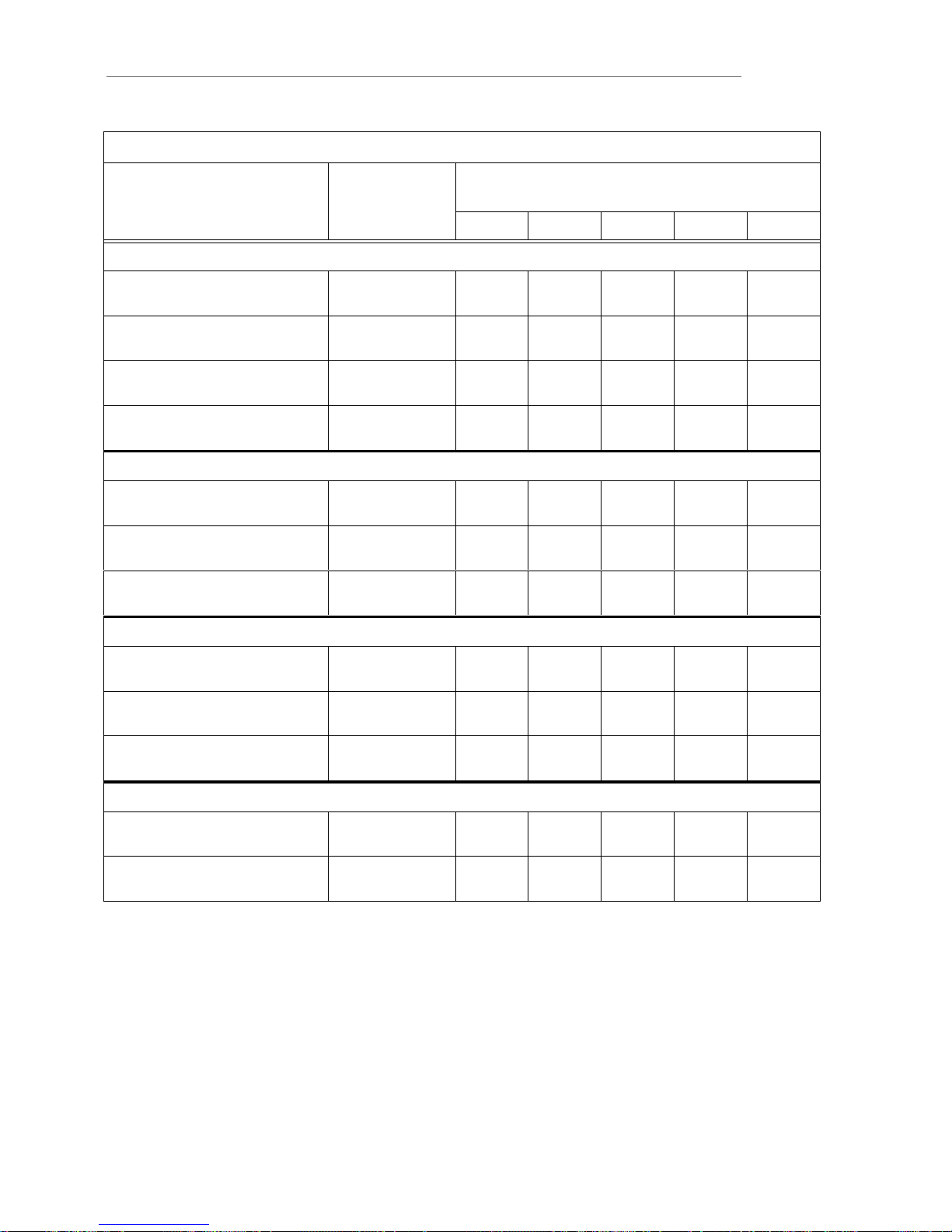

Amendment Record

Amendment Record

Service Manual

Manual Serial

Number:

Please enter the Manual Serial Nº

for future record

Issue

Nº

Issue

Date

Amendment Amended By Date

1

Initial issue

ć ć

Service Manual

Amendment Record

Prelim Page iii 3x3 UPS Preliminary Pages

This Service manual contains information concerning the installation operation and service of the folĆ

lowing UPS

EQUIPMENT PART NUMBER

With battery Without battery

10 kVA UPS

15 kVA UPS

20 kVA UPS

30 kVA UPS

UTILITY

SUPPLY

WARNING

PLEASE

NOTE

Service Manual

Limitations of Use

Prelim Page iv 3x3 UPS Preliminary Pages

Issue 2 - November 2001

Limitations of Use

ELECTROMAGNETIC COMPATABILITY

The equipment covered by this manual complies with the requirements of the EMC DirecĆ

tive 89/336/EEC and the published technical standards. Continued compliance requires

installation in accordance with these instructions and use of manufacturer approved accesĆ

sories only.

WARNINGThe UPS is a Class A product.

When used in a domestic environment a unit may cause radio interference,

If this is the case the user may be required to take additional measures

WARNING HIGH EARTH LEAKAGE CURRENT.

Earth connection is essential before connecting the utility supply.

This equipment must be earthed in accordance with local electrical codes.

WARNING This UPS does not incorporate automatic backĆfeed protection. A warning label must be

fitted to all external primary power isolators stating:

ISOLATE THE UNINTERRUPTIBLE POWER SYSTEM BEFORE WORKING ON THIS CIRCUIT.

The UPS should not be supplied from electrical power systems of the `IT'

(Impédance à Terre) type.

(IEC 364 Ć ELECTRICAL INSTALLATION OF BUILDINGS)

Note: Where use on `IT' systems is required an optional input isolation transformer should

be fitted.

CAUTION This equipment is fitted with RFI suppression filters

Earth leakage exceeds 3.5mA but is less than 300mA.

Transient and steadyĆstate earth leakage currents, which occur when starting the equipĆ

ment, should be taken into account when selecting instantaneous RCCB or RCCD devices.

Note also that the earth leakage currents of the load will be carried by this RCCB or RCCD.

These products are intended for Commercial/Industrial use only, and are not suitable for

use in any life support applications.

Service Manual

Important Instructions for safe use

Prelim Page v 3x3 UPS Preliminary Pages

Important Instructions for safe use

GENERALThe UPS must be approved engineer before it is put into serĆ

vice. Failure to observe this condition will invalidate any implied warranty.

In common with other types of high power equipment, dangerous voltages are present with

the UPS and battery enclosure. The risk of contact with these voltages is minimised as the

live component parts are housed behind a hinged lockable door.

Further internal safety screens make the equipment protected to IP20 standards.

No risk exists to any personnel when operating the equipment in the normal manner, followĆ

ing the recommended operating procedures.

All equipment maintenance and servicing procedures involving internal access, should be

carried out by trained personnel.

The UPS is for indoor use only. It must be protected from rain or excessive moisture and

installed in a clean environment, free from flammable liquids, gasses, or corrosive subĆ

stances. Do not put drinks, plants, or any other containers holding liquids, on top of the unit.

BATTERIES Battery manufacturers supply details of the necessary precautions to be observed when

working on, or in the vicinity of, a large bank of battery cells. These precautions should be

followed at all times.

Particular attention should be paid to the recommendations concerning local environĆ

mental conditions and the provision of protective clothing, first aid and fireĆfighting facilities.

TEST EQUIPMENT

When the battery is under charge it is earthĆreferenced about its midĆpoint e.g. if the battery

is being charged at 460V the battery extremities will be =230V and Ć230V with respect to

neutral (earth). When using mains powered test equipment such as oscilloscopes in the

UPS high voltage area, always use a differential mode of operation to avoid the need to disĆ

connect the oscilloscope frame earth.

PERSONNEL

When working inside the UPS (trained personnel only) is recommended that protection be

worn to prevent eye damage, should an electric arc be struck by mishandling or severe

electrical fault.

Some of the power components are very heavy. If their removal is necessary ensure that

sufficient manpower is available, otherwise use adequate mechanical handling equipment.

When working in the general area of the UPS where high voltages are present, a second

person should be standingĆby to assist and summon help in case of accident.

Service Manual

Personnel Categorisation

Prelim Page vi3x3 UPS Preliminary Pages

Issue 2 - November 2001

Personnel Categorisation

The following definitions are given to categorise the scope, and use of this service

manual:

Operator/User

This service manual is outside the scope for use by personnel who have received instrucĆ

tion on the correct operation of the UPS controls; limited to operation of the unit circuit

breakers and the Front Control Panel; operator/users are not permitted to remove any panĆ

els which are retained by screws.

Competent Personnel

The Troubleshooting section, and Service procedures contained in this manual are norĆ

mally outside the scope of personnel categorised competent; though they may be aware

of the dangers appropriate to working with hazardous voltages. A Competent engineer is

deemed to have sufficient technical skills/training to make electrical connections, install

batteries, close and open circuit breakers/fuses etc. (i.e. a qualified electrician) he is not

categorised as service personnel.

Service Personnel

This

etraining and are password authorised.

Service manual is designed for use by engineers who have received the relevant

Important Symbols

The warning triangle shown above indicate personal safety instructions.

Follow these instructions carefully to avoid injury.

Service Manual

Specification

Prelim Page vii UPS Preliminary Pages

Issue 2 - November 2001

Specification

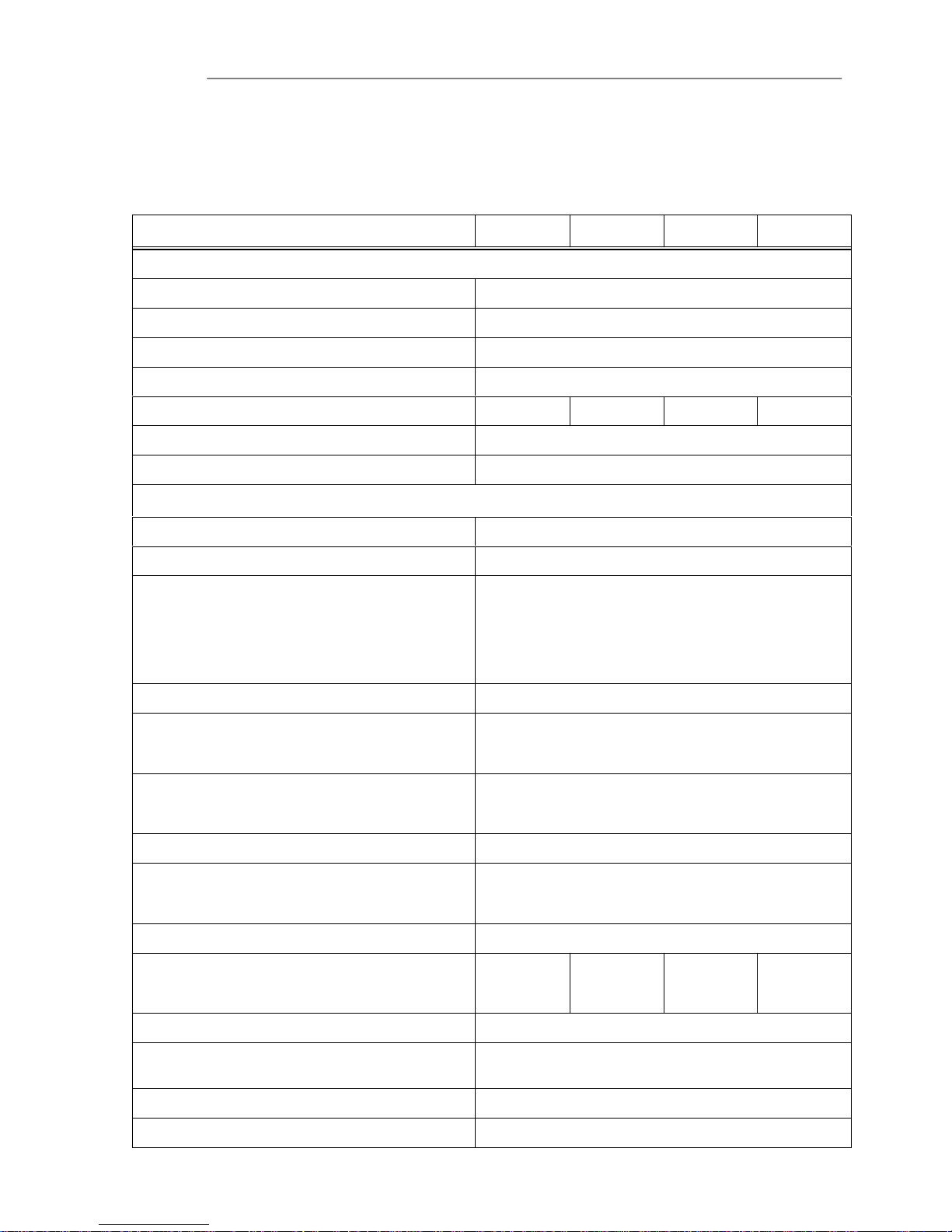

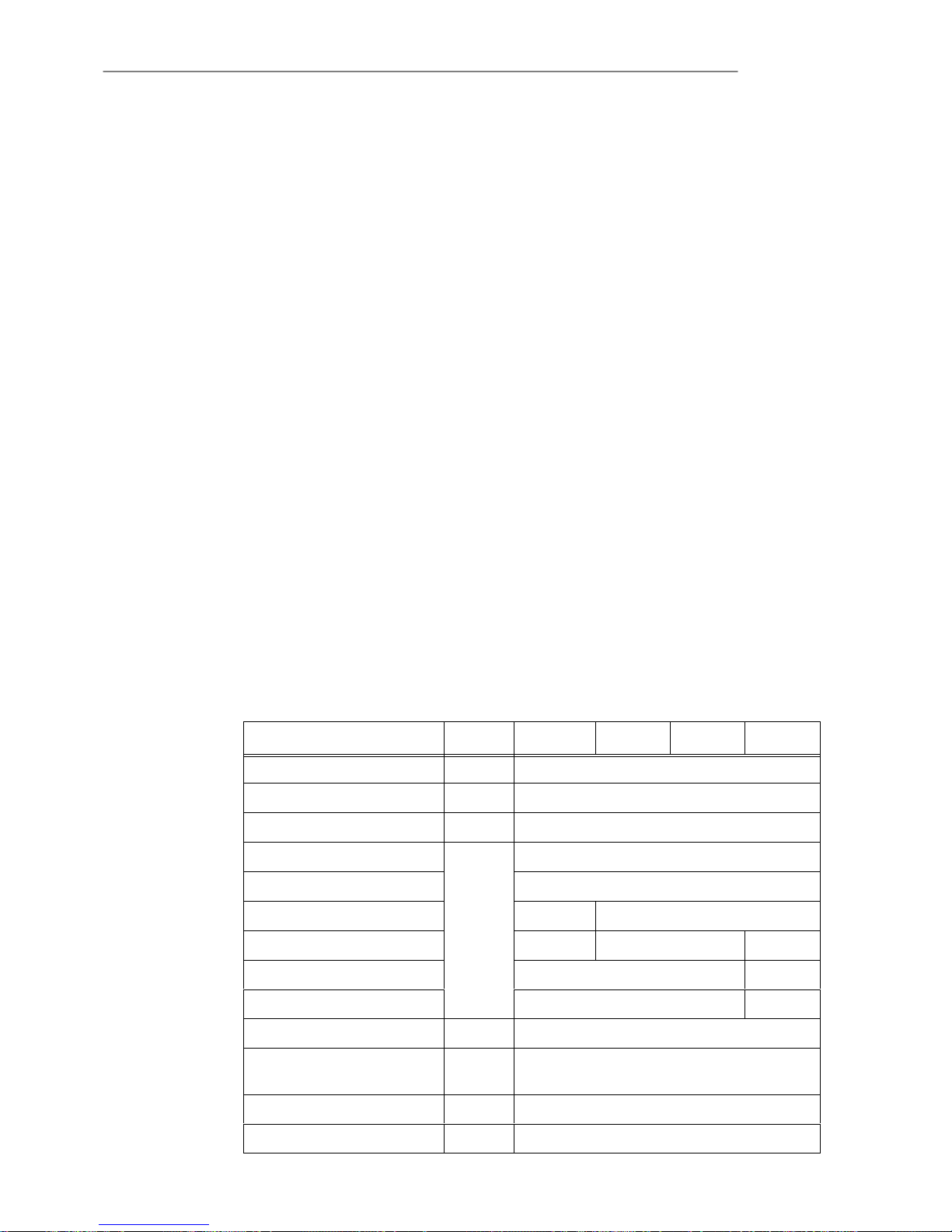

10kVA 15kVA 20kVA 30kVA

Input Data

Nominal Input Voltage 400V 3 phase, neutral and earth

Input Voltage Range 300 ć 480Vac (330 ć 480Vac full charging capability)

Nominal Input Frequency 50/60Hz

Input Frequency Range 40 ć 70Hz

Maximum Input Current at Nominal Input Voltage 18.5A 25.3A 31.7A 45.0A

Input Current Harmonic Distortion (THD) <30% (without filter)

Input Power Factor 0.95 (over specified load and voltage ranges)

Output Data

Nominal Output Voltage 380, 400 or 415Vac selectable

Output Voltage Adjustment Range 360 ć 415Vac

Output Voltage Stability

Static Balanced Load

Static 50% Unbalanced Load

Static 100% Unbalanced Load

Dynamic 50% Load Step

Dynamic 100% Load Step

±1%

±3%

±5%

±3%

±5%

Output Voltage Transient Recovery Time <30ms (to 3% RMS)

Output Voltage Distortion (THD)

Linear Load

Non Linear Load (100% 3:1 Crest Factor Load)

<3%

<5%

Output Voltage Phase Displacement

Balanced Load

100% Unbalanced Load

120° ±1%

120° ±3%

Nominal Output Frequency 50 or 60Hz

Output Frequency Regulation

Synchronised With Input

Free Running

±1% or ±4%, selectable

±0.005%

Maximum Slew Rate 1Hz/sec

Nominal Output Power Rating

kVA

kW

10

8

15

12

20

16

30

24

Output Nominal Power Factor 0.8

Overload Capability on Inverter (Load Will Transfer to

Static Bypass if Times are Exceeded)

125% for 10 minutes, 150% for 10 seconds

Output Short Circuit Current 300% of nominal current for 100ms

Maximum Load Crest Factor 3:1 (at full load without deĆrating)

Service Manual

Specification

Prelim Page viiiUPS Preliminary Pages

Issue 2 - November 2001

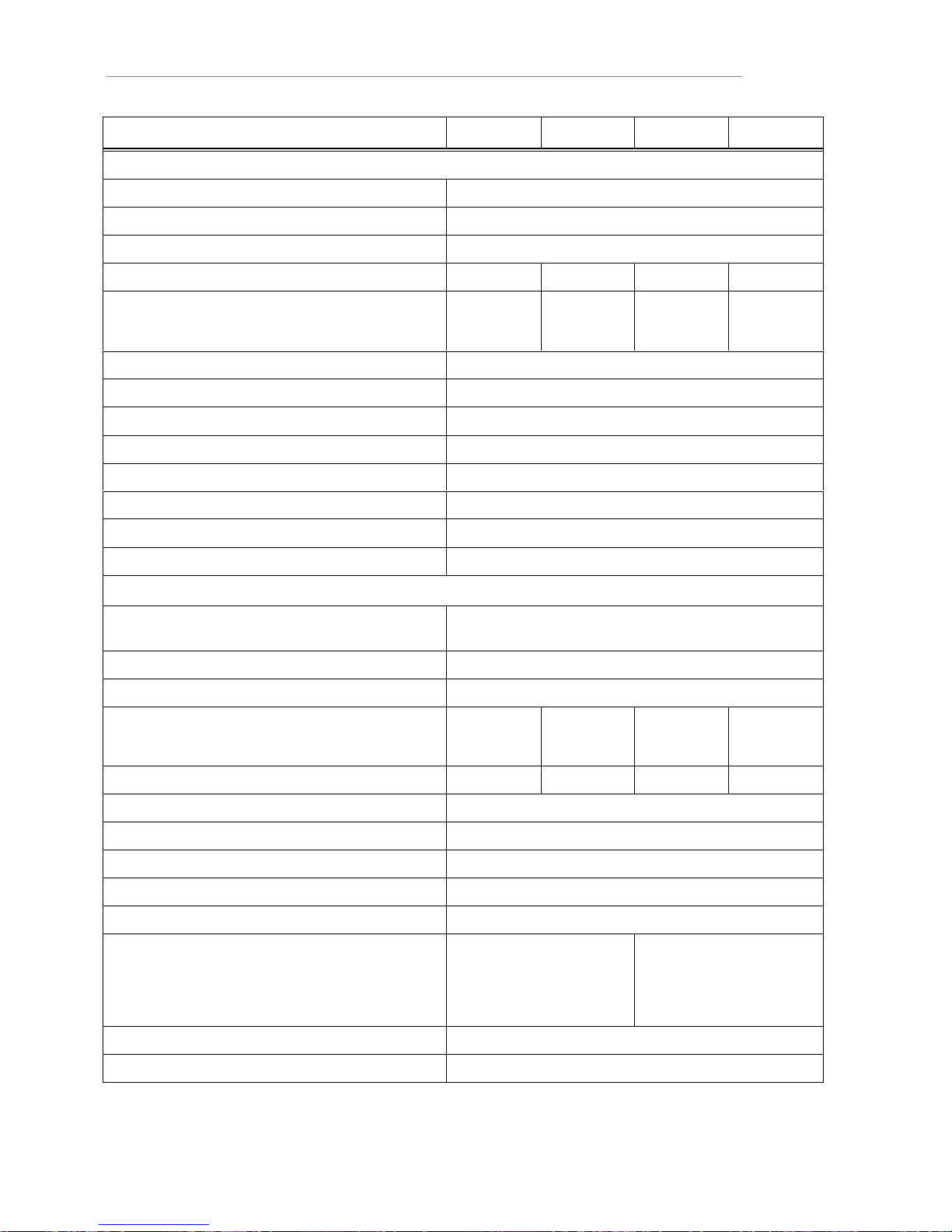

10kVA 15kVA 20kVA 30kVA

Intermediate DC Circuit Data

Internal Battery Type valve regulated, sealed, lead acid cells

Number of Battery Cells 192

Nominal Battery Voltage 384Vdc

Internal Battery Rating 7.2Ahr 2 x 7.2Ahr 2 x 7.2Ahr 3 x 7.2Ahr

Full Load Autonomy Time With Standard Internal Battery

(For part load and battery configuration Autonomy times

refer to the table on page Ćxiii)

6 minutes 9 minutes 6 minutes 6 minutes

DC Bus Overvoltage Trip 500Vdc

End of Battery Discharge Voltage 320Vdc

Battery PreĆalarm Discharge Voltage Level 350Vdc

Battery Charger Nominal Float Voltage at 20°C 432Vdc

Battery Charger Voltage Stability ±1%

Battery Charger Output Voltage Ripple <1%

Maximum Battery Recharging Current 1, 3, 5 or 7A (Selectable)

Automatic Battery Test 12, 24 or 48 hour impedance test

System Data

Topology

True OnĆline double conversion, high frequency,

transformerless design

Power Upgrade Yes ć up to a maximum rating of 30kVA

StartĆup On Battery Yes

System Efficiency (Excluding Battery Charging)

50% Linear Load

100% Linear Load

88%

90%

88%

90%

89%

91%

90%

91%

Full Load Inverter Efficiency 94% 94% 94% 94%

Operating Temperature Range 0° Ć 40°C (20°C for optimal battery lifetime)

Storage Temperature Range Ć20° to 70°C (excluding battery)

Operating Relative Humidity Range <95% (nonĆcondensing)

Maximum Altitude Above Sea Level 1000m before deĆrating

Audible Noise Level At 1 Metre <52dBA

Relay Communications Card

Alarm Contacts

DB9 connector

On Battery

Low Battery

Internal Terminals

On Battery

Low Battery

On Bypass

UPS On

Remote Stop Contacts Open to disable inverter and static bypass

Cable Entry Bottom entry at rear of unit

Service Manual

Specification

Prelim Page ixUPS Preliminary Pages

Issue 2 - November 2001

10kVA 15kVA 20kVA 30kVA

Bypass Data

Input Voltage Range For Bypass Switching Nominal ±10%

Overload Capability on Static Bypass 150% for 30 minutes, 1000% for 100 m seconds

Mechanical Data

Unit Dimensions (w x h x d) 530 x 1220 x 950 mm

Unit Weight Without Battery 185kg

Unit Weight With Standard Battery 275kg 365kg 365kg 455kg

Shipping Dimensions (w x h x d) 545 x 1260 x 965 mm

Unit Shipping Weight Without Battery 215kg

Unit Shipping Weight With Standard Battery 305kg 395Kg 395kg 485kg

Enclosure Rating IP20

Colour

RAL 7035 Metal Covers

RAL 7042 Plastic Door

Design Standards

Safety

Radio Frequency Interference (RFI)

Electromagnetic Compatibility (EMC)

European Directive

Quality

EN50091Ć1Ć1

EN50091Ć2 Class A

CE marked compliance LVD / EMC

ISO9001

Service Manual

Specification

Prelim Page xUPS Preliminary Pages

Issue 2 - November 2001

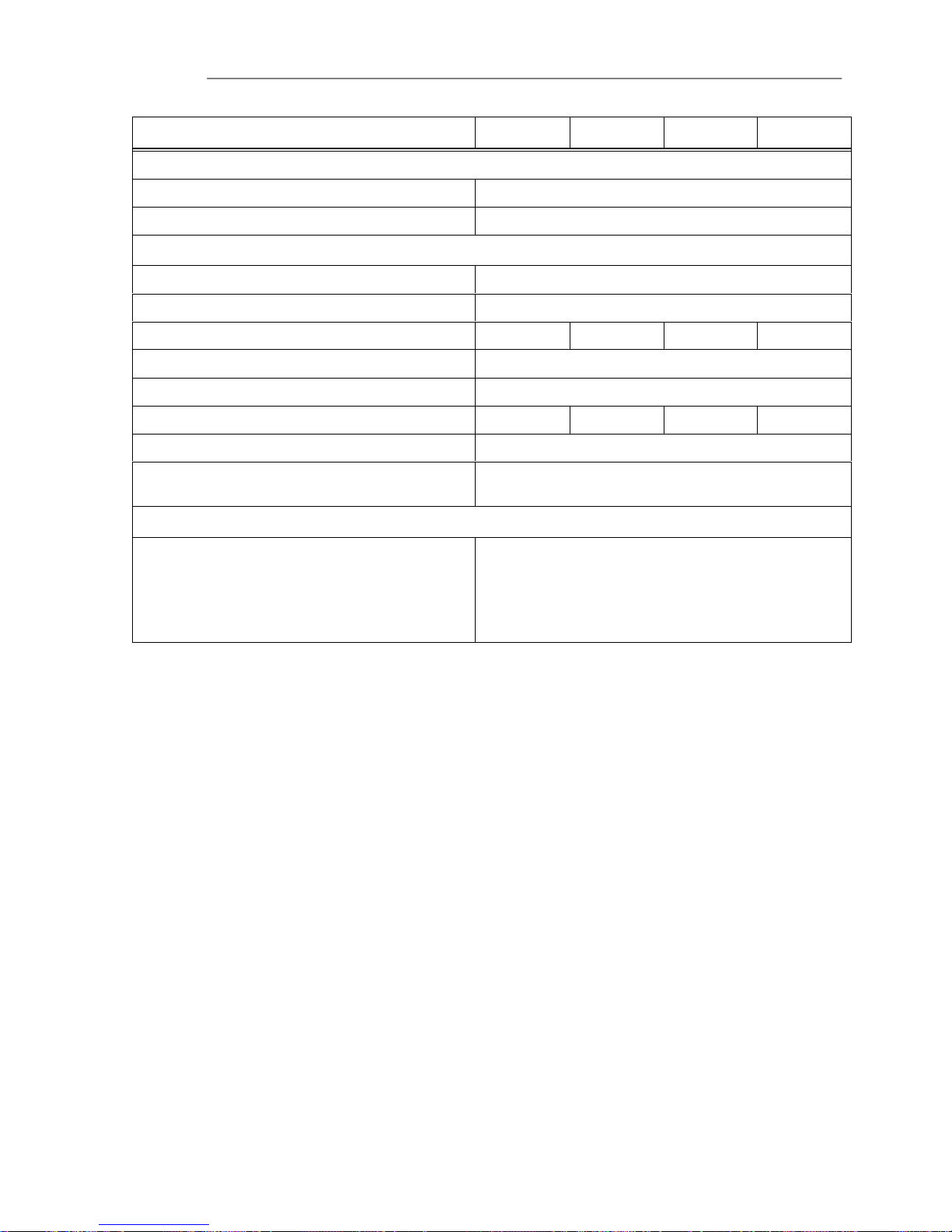

BATTERY AUTONOMY TIMES

Configuration Part Nº

Approximate Autonomy Time in Minutes at

Stated Load and 25°C

Configuration

Part N

100% 75% 50% 25% 10%

3 Phase 10kVA

UPS with 1 internal set of batteries

(Standard configuration)

6 9 17 35 115

UPS with 2 internal sets of batteries

+ 1 x BATT

17 24 40 82 282

UPS with 3 internal sets of batteries

+ 2 x BATT

28 41 66 133 486

UPS with 4 internal sets of batteries

+ 3 BATT

41 57 94 191 600

3 Phase 15kVA

UPS with 2 internal sets of batteries

(Standard configuration)

9 14 24 55 157

UPS with 3 internal sets of batteries

+ 1 x BATT

17 24 40 91 269

UPS with 4 internal sets of batteries

+ 2 x BATT

24 35 56 128 398

3 Phase 20kVA

UPS with 2 internal sets of batteries

(Standard configuration)

6 9 17 39 108

UPS with 3 internal sets of batteries

+ 1 x BATT

11 17 28 64 178

UPS with 4 internal sets of batteries

+ 2 xBATT

17 24 40 91 263

3 Phase 30kVA

UPS with 3 internal sets of batteries

(Standard configuration)

6 9 17 40 110

UPS with 4 internal sets of batteries

+ 1 x BATT

9 14 24 56 157

Service Manual

Table of Contents

Prelim Page i3x3 UPS Preliminary Pages

Issue 1 - May 2001

Table of Contents

Manual Registration i. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Amendment Record ii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limitations of Use iv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Important Instructions for safe use v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Personnel Categorisation vi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specification vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1 - Overview 1 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 - Introduction 1 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 - Equipment Construction 1 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 - Principle of operation 1 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 - UPS Power Configuration 1 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 - Battery fuses switch 1 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 - Installation 2 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 - Installation (Mechanical) 2 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 - Preliminary Checks 2 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 - Installation (Electrical) 2 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 - Power Cabling 2 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 - Power Cable connections 2 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 - Safety Earth 2 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4 - Protective devices 2 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 - Battery Installation 2 - 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 - Battery Safety 2 - 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 - Battery Installation Check 2 - 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3 -Installing the Battery Upgrade Kit (BATTCABLE)2 - 9. . . . . . . . . . . . . .

2.4 -Setting Standard Relay Interface PCB2 - 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 - Setting Options on the standard Relay Interface 2 - 12. . . . . . . . . . . . . . . . .

2.4.2 - Relay Interface Connections 2 - 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.3 - Remote EPO (Emergency Power Off) 2 - 14. . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.4 - Emergency Power Off (E.P.O.) pushĆbutton connection 2 - 14. . . . . . . . . . .

2.4.5 - Connection to Personal Computer 2 - 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.6 - UPS Monitoring 2 - 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 - Commissioning 3 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 - PreĆpower Checks 3 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 - Validating the Installation 3 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 - Positioning 3 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 - Preliminary checks 3 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 - Setting UPS Parameters 3 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 - Control Logic PCB CS0072. 3 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 - Driver Interface PCB CS0071 Settings 3 - 2. . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 - Auxiliary DC-DC PSU Converter PCB CS0070 Settings 3 - 3. . . . . . . . . .

3.3.4 - Battery Charger PCB CS0074 Setting 3 - 3. . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.5 - LCD Display Monitor Board CS0077 Settings 3 - 3. . . . . . . . . . . . . . . . . . .

Service Manual

Table of Contents

Prelim Page iiUPS Preliminary Pages

Issue 1 - May 2001

3.4 - Initial UPS Start-up. 3 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 - Converter and Inverter Output Calibration. 3 - 4. . . . . . . . . . . . . . . . . . . . . .

3.4.2 - Inverter to Bypass Synchronisation Check. 3 - 6. . . . . . . . . . . . . . . . . . . . .

3.4.3 - Battery Charger Output Calibration. 3 - 6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 - Power Checks 3 - 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 - Bupass Failure Test 3 - 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 - Mains Failure Checks 3 - 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 - Test Transfer to the Reserve Line (Automatic Bypass). 3 - 8. . . . . . . . . . . .

3.5.4 - Manual Bypass Operation Check 3 - 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.5 - Local EPO 3 - 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.6 - External EPO 3 - 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 - Normal UPS Start-Up Instructions 3 - 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.1 - LCD Messages and LED status after starting the UPS. 3 - 12. . . . . . . . . . .

3.7 - Normal Shutdown to Manual Bypass 3 - 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 - Setting Options 3 - 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8.1 - Setting options on the Relay card 3 - 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 - Operation and control4 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 - Operator Control Panel 4 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 - Functional description 5 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 - Control Logic PCB CS0072 5 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 - Potentiometer adjustment 5 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 - Link and Jumper functions 5 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 - Auxiliary Supply PCB CS0070 5 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 - Battery Threshold settings 5 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 - Driver Interface PCB CS007I 5 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 - Bypass Voltage Threshold Adjustment 5 - 3. . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 - Link and Jumper functions 5 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 - Battery Charger CS0074 5 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 - Battery Charger Voltage Adjustment 5 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 - Link and Jumper Functions 5 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.3 - Battery test 5 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 - UPS monitor board PCB CS0077 5 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 - Relay Interface PCB CS0082 5 - 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.1 - EPO Connections. 5 - 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.2 - Optional Second Relay Interface PCB 5 - 6. . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 - LCD MIMIC DISPLAY CS0075 5 - 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.1 - Control panel indicator LEDs 5 - 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 - Maintenance 6 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 - Scheduled Maintenance 6 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 - Daily Checks 6 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 - Weekly Checks 6 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.3 - Annual Maintenance 6 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 - Battery Maintenance 6 - 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 - Factors Effecting Battery Use 6 - 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 - Battery Testing 6 - 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Manual

Table of Contents

Prelim Page iii3x3 UPS Preliminary Pages

Issue 1 - May 2001

6.2.3 - Battery capacity testing. 6 - 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 - Battery Replacement 6 - 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 - UPS Storage 6 - 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7 - Troubleshooting 7 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 - Introduction 7 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 - General Fault Identification Procedure 7 - 1. . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 - Special Tools. 7 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 - Removing the UPS Covers 7 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 - Component Location 7 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 - Fault Identification 7 - 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 -Typical Voltage Values7

7.7 -Fuse Check List7 - 12

- 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8 -Test Procedures7 - 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8.1 - DC Bus Discharge Routine, Shutdown to Maintenance Bypass. 7 - 13. . .

7.8.2 -DC offset7 - 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8.3 - IGBT Replacement 7 - 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8.4 -IGBT testing7 - 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8.5 - SCR Testing 7 - 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8.6 - Inverter Drive Signal Testing 7 - 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8.7 -Checking power circuit capacitors.7 - 27. . . . . . . . . . . . . . . . . . . .

7.9 -PCB Replacement Procedures7 - 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.9.1 - Auxiliary DC Ć DC Converter Part Nº OSDE0070 (PCB Label: CS0070 Exx) 7 - 28

7.9.2 - LCD UPS Monitor Board OSDE0077 (PCB Label: CS0077 Exx) 7 - 29. . . .

7.9.3 - Inverter Driver/Feedback Interface Part Nº OSDE0071 7 - 30. . . . . . . . . . . .

7.9.4 - 3ph TL Control Logic Part Nº OSDE0072 * (PCB Label: CS0072 Exx) 7 - 32. . .

7.9.5 - Battery Charger Part Nº OSDE0074 (PCB Label: CS0074) 7 - 34. . . . . . . .

7.9.6 - Input Filter Part Nº OSDE0079 (PCB Label: CS0079 Exx) 7 - 36. . . . . . . . .

7.9.7 - Operator Control Panel (LDC) Part Nº OSDE0075 (PCB Label: CS0075 Exx)7 - 36

Chapter 8 - Optional Equipment 8 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 - Second Relay card (Optional) 8 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 - Remote Alarm Panel 8 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 - Remote Alarm Panel connection 8 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 - Upgrade Kit 8 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 - Isolation Transformer 8 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 - Internal Extended Battery Kit 8 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 - Battery Connecting Kit 8 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 9 - Spare Parts 9 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 10 - Schematic Diagrams 10 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 - 13x3 UPS Overview

Issue 2 - November 2001

Chapter 1 - Overview

1.1 - Introduction

The aim of this chapter is to give a general overview of the, control principles and construction of the

series onĆline Uninterruptible Power Supply (UPS).

The UPS is a standĆalone, single module, system designed to furnish a well regulated 3 phase

power supply to a critical load, such as a computer, under all rated load and input supply conditions.

The unit is of a category known as an `onĆline' UPS and is therefore permanently connected between

the utility 3Ćphase supply and the load equipment and operational at all times

A battery provides the standĆby power source for the UPS when the input utility supply fails.

The system offers the user the following advantages:

Increased power quality. The UPS has its own internal voltage and frequency regulator circuits

which ensure that its output is maintained within close tolerances independent of voltage and frequency

variations on the utility power lines.

Increased noise rejection. By rectifying the input AC power to DC power, and then converting it

back to AC, any electrical noise present on the input utility supply line is effectively isolated from the UPS

output, therefore the critical load sees only clean power.

Powewr blackout protection. If the utility power fails, the UPS continues to power the critical load

from its backĆup battery source, leaving the load immune from power disturbances ć even complete

power blackouts.

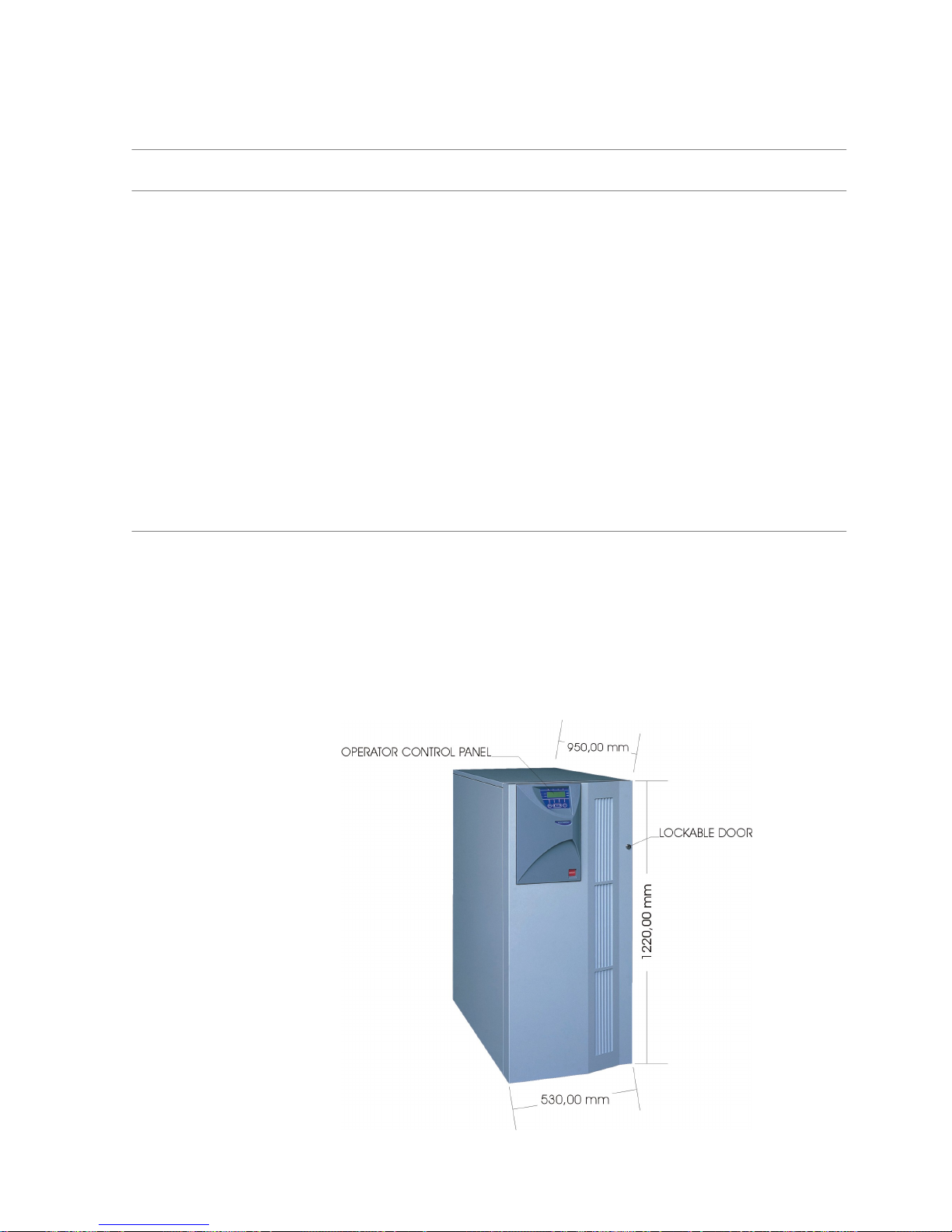

1.2 - Equipment Construction

The equipment is constructed around a steel frame with removable panels. The door which can be seĆ

cured with a key is opened to give easy access to the input, bypass, output, reserve line circuit breakers

and battery C.B. fused switch, protecting them from accidental operation.

A string LED and control panel on the front of the cabinet permits the operator to monitor the UPS.

The cabinet houses both the power components and the batteries.

It is carried on four wheels. Jacking feet help to support the UPS, and also prevent it from moving once

it has been wheeled into its final position. These feet are also used to secure the equipment to its shipĆ

ping pallet during transit.

Cooling is by internal fan. Air is drawn in from beneath the UPS and exhausted through ventilation grills

of the front panel. These areas must be kept free of anything that may avoid the air flow into and out of

the unit.

Figure 1-1Front view of cabinet.

Service ManualChapter 1 - Overview

Equipment Construction

1 - 23x3 UPS Overview

Issue 2 - November 2001

1.2.1 - Principle of operation

Normal operation

During normal operation, i.e. when the UPS input supply is present and within specification, both the

converter and inverter sections are active and the automatic byĆpass is turned on to connect the inverter

output to the critical load terminals. The battery fuseĆholder switch is also closed and the battery is thereĆ

fore permanently float charged at the d.c. terminals voltage level.

Mains Failure

If the mains has a failure or is out of tolerance the converter will be supplied from the battery, while the

Inverter will continue to operate for a period of time which depends on the load and the capacity of the

battery. If the mains supply has not returned within this time, the Inverter will go off automatically and

an alarm condition will appear on the UPS operator control panel.

Critical load will not be interrupted in the event of a drop or return of the AC power mains.

Return of power mains

When the mains returns within the required tolerance, the converter will be automatically supplied from

mains, supplying power to the Inverter and recharging the battery at the same time. There will be no

interruption of the critical load.

UPS fault

In the event of an inverter failure, the automatic byĆpass will automatically transfer the load onto the

mains with no interruption. In such an event, request qualified technical assistance.

The load will be transferred with no interruption if the inverter is synchronised with the mains; if this is

not the case, there will be an interruption of some milliseconds.

The intervention of the automatic byĆpass line is shown on the front panel by the yellow led on.

WARNING CAUTION: When the load is being supplied from the bypass line through the automatic byĆ

pass, it is connected directly to the mains supply and is therefore no longer protected

against mains faults.

Maintenance Bypass

A second bypass circuit contained in the UPS cabinet, identified as the 'Maintenance Bypass' line is

included to enable the reserve supply to be made available to the load while facilitating a safe working

environment for carrying out scheduled UPS system maintenance or trouble shooting. The circuit is

manually selected by the Manual Bypass Switch (3) which can be padlocked in the OFF position.

WARNING CAUTION CAUTION: If an automatic circuit breaker device is not present in the input disĆ

tribution panel, there remains a dangerous voltage at the output terminals and also on the

input terminals of the UPS module that is switched off.

Note: The load is not protected from mains aberrations when operating on the

maintenance bypass mode.

Service Manual Chapter 1 - Overview

Equipment Construction

1 - 33x3 UPS Overview

Issue 2 - November 2001

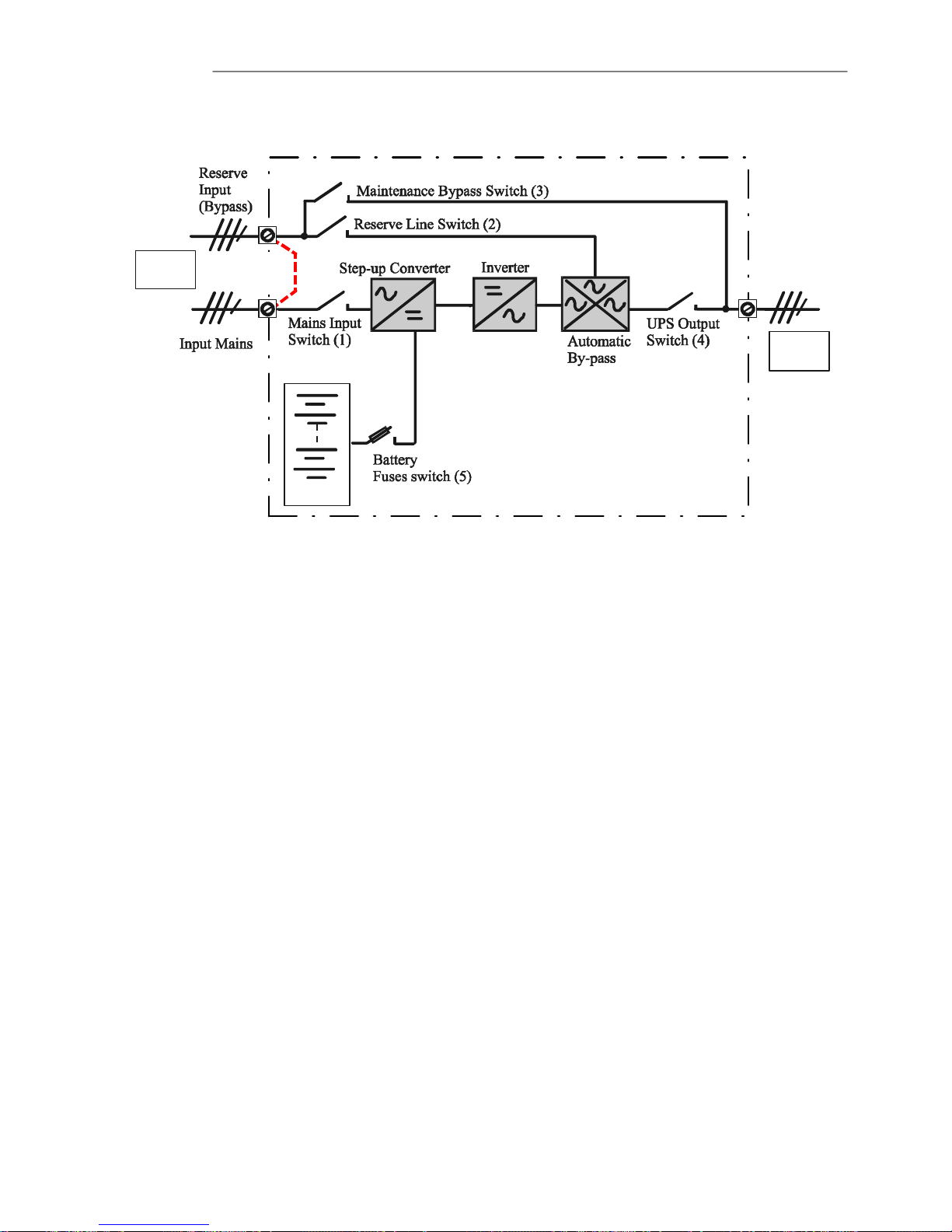

Figure 1-2Split Bypass" configuration

UPS

Output

UPS

Input

Battery

UPS

Split

Bypass

Link

1.2.2 - UPS Power Configuration

Common Bypass

The UPS is factory set to operate in the Common Bypass" configuration. Split Bypass links shown

in Figure 1-2 connect the Input Mains supply to the Reserve Input (Bypass) line creating a common

input. A separate Reserve Input is therefore not required.

Split Bypass

To configure the with a Split Bypass input, the Split Bypass links shown in Figure 1-2 are removed

by the commissioning engineer. In the Split Bypass" configuration the static bypass line is connected

by a separate power switch to a dedicated `bypass' power source which also feeds the maintenance

bypass line. Where a separate power source is not available the Reserve and Converter input supply

connections would be linked together.

With the exception of the maintenance bypass switch (3), all the isolators shown must be closed during

normal UPS operation.

1.2.3 - Battery fuses switch

The battery is connected to the d.c. bus through a battery fuses switch (5) fitted inside the UPS cabinet

2 - 13x3 UPS Installation

Issue 2 - November 2001

Chapter 2 - Installation

2.1 - Installation (Mechanical)

2.1.1 - Preliminary Checks

Before installing the UPS hardware the following preliminary checks must be carried out:

1. Verify that the UPS room satisfies the environmental conditions stipulated in the equipment

specification, paying particular attention to the ambient temperature and air exchange

system.

Material admittance

1. Remove any packaging debris, then visually examine the UPS and battery equipment for

transit damage, both internally and externally.

Report any such damage to the shipper immediately.

2. Ascertain that the material supplied corresponds with that on the freight bill.

Identification

The equipment supplied is provided with an adhesive identification label placed on the UPS rear panel

reporting type of UPS model and power.

The cases used to transport the equipment must be unpacked as specified by the procedure stated

below.

Packing material removal

During this operation observe the indications (FRAGILE, UP) printed on the case to avoid damaging the

UPS

To remove the packing material proceed in the following manner:

1. Place the equipment on the floor as instructed on the outer case (UP, DOWN).

2. Cut the tape and open the flaps at the top of the cardĆboard box.

3. Remove the extruded elements used as protective packing.

4. Position the forks of the lifting truck under the UPS taking care not to damage the UPS

castors and lift it a few centimetres from the floor. Back up the forklift and position the UPS.

Lower to the floor.

Hinet is provided with wheels to allow ease of movement.

5. Retain the packing material.

The original transit packing should be used if the equipment is be returned to the

maintenance centre, or moved to another position.

6. Check that the equipment has not been damaged.

Any damage should immediately be reported to the Sales Representative.

7. Locate the four battery fuses. Do not fit at this point.

8. Locate the door key and panel bolt spanner secured on the rear of the UPS. Retain for future

use.

9. The operator manual and communication cable are located behind the hinged front door.

Moving the cabinets

WARNING Ensure that any lifting equipment used for moving the UPS cabinet has sufficient lifting caĆ

pacity.

Ensure that the UPS weight is within the designated surface weight loading (Kg/cm2) of any

handling equipment. See the UPS specification for weight details.

The UPS can be lifted using a fork lift. Take care when using either method not to damage

the UPS castors located on the bottom of the unit.

Service ManualChapter 2 - Installation

Installation (Mechanical)

2 - 23x3 UPS Installation

Issue 2 - November 2001

Locating the unit in the operating position

The UPS cabinets are fitted with castors on the base to allow ease of movement and positioning. When

the equipment has been finally positioned ensure the adjustable feet are set so that the UPS will remain

stationary and stable

Ensure the following considerations are observed when locating the equipment:

a) Easy connection.

b) Enough space to ensure good access when servicing the UPS.

c) Exchange of air sufficient enough to dispel heat produced by UPS.

d) Protection against atmospheric agents.

e) Protection against excessive humidity and very high heat sources.

f) Protection against dust.

g) Compliance with the current fire prevention regulations.

h) Operating environment temperature is within +20° C and +25° C.

The batteries are at maximum efficiency in this temperature range.

Clearances

Cooling air enters the module through ventilation grills located at the bottom of the cabinet and is exĆ

hausted through the fan grills located on the front panel; you must therefore allow for a minimum gap

of 170 mm behind the unit to allow adequate air flow. Clearance around the front of the equipment

should be sufficient to enable free passage of personnel with the door fully opened.

Raised floor installation

If the equipment is to be located on a raised floor it must be mounted on a pedestal suitably designed

to accept the equipment point loading.

Refer to the base view to design this pedestal.

Cable entry

Cables enter the UPS cabinet from the rear.

UPS Mechanical Characteristics

Rated power kVA 10 15 20 30

Height mm 1220

Width mm 530

Depth mm 950

Weight:

Hinet cabinet 185

with 1 battery strings

275

with 2 battery strings

Kg

365

with 3 battery strings 455

with 4 battery strings 545

Ventilation Ć forced

Airflow full speed

Air flow half speed

m3/h

600

300

Protection grade Ć IP 20

Cable entry Ć Bottom

Service Manual Chapter 2 - Installation

Installation (Electrical)

2 - 33x3 UPS Installation

Issue 2 - November 2001

2.2 - Installation (Electrical)

The UPS requires connection of the power cables once it has been mechanically installed. All auxiliary

cables, whether screened or not, should be run separate from the power cables in metal conduits, or

metal ducts electrically bonded to the cabinet metalwork to which they are connected.

2.2.1 - Power Cabling

WARNING BEFORE CABLINGĆUP THE UPS, ENSURE THAT YOU ARE AWARE OF THE LOCATION AND

OPERATION OF THE EXTERNAL ISOLATORS THAT CONNECT THE UPS INPUT/BYPASS

SUPPLY TO THE MAINS DISTRIBUTION PANEL.

CHECK THAT THESE SUPPLIES ARE ELECTRICALLY ISOLATED, AND POST ANY NECESSĆ

ARY WARNING SIGNS TO PREVENT THEIR INADVERTENT OPERATION.

2.2.2 - Power Cable connections

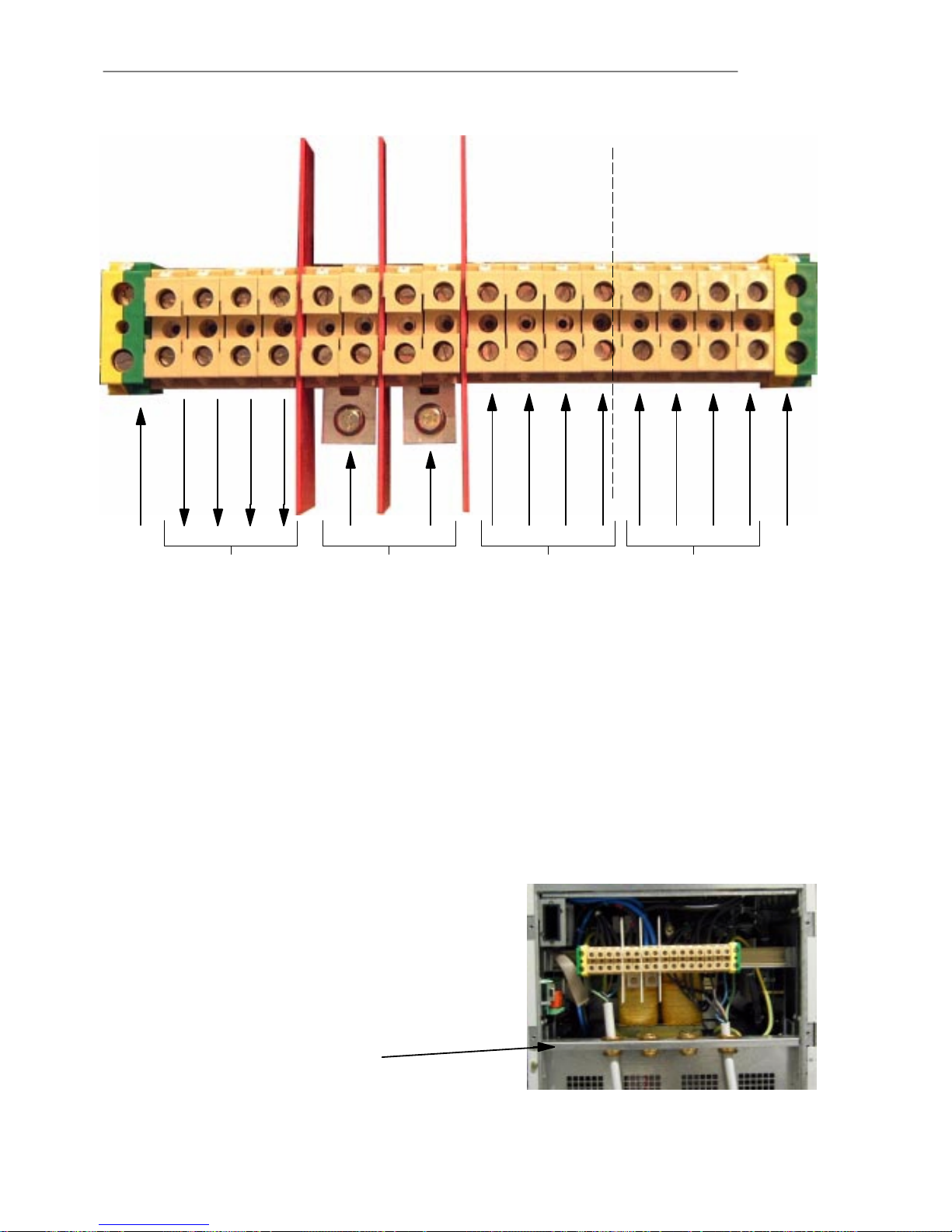

The cable connection terminal block shown in Figure 2Ć1 is located at the rear of the cabinet.

1. Prepare the power cable ends and locate in the lower terminals of the terminal block.

2. Connect Input Mains to terminals 14 (U1), 15 (V1), 16 (W1) & 17 (N1).

Caution When preparing the power cables for connection, provide sufficient spare cable to allow

the UPS to be moved if necessary from it's normal operating position for servicing access.

Spare cable can be coiled beneath the unit.

3. Tighten the terminal block lower securing screws and check that each cable is secure.

4. Connected the UPS Output power cables to terminals 1 (U2), 2 (V2), 3 (W2) & 4 (N2) as

shown in Figure 2Ć1.

5. Secure the cables to the cable securing bar adjacent to the terminal block using appropriate

cable clamps.

Note: If connecting a battery to the External Battery input connections ensure

that connections are made with the correct polarity.

Split Bypass Configuration

If the UPS is to operate with a separate Reserve Input (Bypass) supply.

1. Connect the power connections for the Bypass to terminals 10 (U3), 11 (V3), 12 (W3) & 13

(N3)

2. Connect the Input Mains to terminals to 14 (U1), 15 (V1), 16 (W1) & 17 (N1) as shown in

Figure 2Ć1.

Caution When the UPS is to be operated in the Split Bypass" configuration, the Split Bypass shortĆ

ing links must first be removed by the Commissioning Engineer before Power is applied

to the unit.

Note: The maximum cable size that can be connected to the UPS power

terminal block is 25mm

2

Service ManualChapter 2 - Installation

Installation (Electrical)

2 - 43x3 UPS Installation

Issue 2 - November 2001

Figure 2-1Connections to distribution Terminal Block.

PE1U22V23W24N25+6+7ć8ć9U310V311W312N313U114V115W116N117PE

18

Ground

Ground

UPS Output Ext. Battery Input Reserve Input (Bypass) Input Mains

1.. Ground (ground lead for load connection) 2.. Input reserve (Bypass) phase U3

3.. Output phase U2 4.. Input reserve (Bypass) phase V3

5.. Output phase V2 6.. Input reserve (Bypass) phase W3

7.. Output phase W2 8.. Input Reserve (Bypass) Neutral N3

9.. Output Neutral N2 10.. Input Mains phase U1

11.. Battery Positive (ext. Battery input) 12.. Input Mains phase V1

13.. Battery Positive (ext. Battery input) 14.. Input Mains phase W1

15.. Battery Negative (ext. Battery input) 16.. Input Mains Neutral N1

17.. Battery Negative (ext. Battery input) 18.. Ground (Incoming ground wire from UPS

input mains connected to this terminal)

Figure 2-2 Cable Securing Bar

Cable Securing Bar

Service Manual Chapter 2 - Installation

Installation (Electrical)

2 - 53x3 UPS Installation

Issue 2 - November 2001

2.2.3 - Safety Earth

The safety earth busĆbar is located near the UPS output terminals. The safety earth cable must be conĆ

nected to the earth terminal and bonded to each cabinet in the system.

All cabinets and cable trunking must be earthed in accordance with local regulations.

WARNING FAILURE TO FOLLOW ADEQUATE EARTHING PROCEDURES CAN RESULT IN ELECTRIC

SHOCK HAZARD TO PERSONNEL, OR THE RISK OF FIRE, SHOULD AN EARTH FAULT

OCCUR.

BEFORE ANY OTHER CABLE CONNECTION THE PE SAFETY CONDUCTOR SHALL BE

CONNECTED

2.2.4 - Protective devices

Protection against earth faults (RCD devices):

In the event of a differential (RCD) device being installed upstream of the input supply, the transient and

steady state earth leakage currents that are produced during startĆup of the UPS must be taken into acĆ

count.

The presence of an RFI suppression filter inside the UPS, determines a residual earth current no greater

than 500 mA.

Residual current circuit breakers (RCCB) must be sensitive to d.c. unidirectional pulse (class A) in the

mains and insensitive to transient current pulses.

Service ManualChapter 2 - Installation

Battery Installation

2 - 63x3 UPS Installation

Issue 2 - November 2001

2.3 - Battery Installation

All UPS models are normally shipped with an internal battery fitted, therefore a thorough check

of the battery installation is required before applying power to the unit. The battery capacity, number of

cells and installation is dependent on the unit power rating and autonomy option ordered. A full break

down of the different battery configurations can be found in the Specification on preliminary page Ćxiii.

In addition to the standard battery fitted to the UPS extra strings may be added (to a maximum of 4) to

upgrade the battery autonomy. Full fitting instructions for the battery upgrade are included with each

kit, however this information has been also included in this section of the manual for continuity.

The UPS may also have an extended battery option to be fitted either in a separate or atĆ

tached cabinet, therefore the same basic checks apply.

Before

2.3.1 - Battery Safety

WARNING THE BATTERY CHAIN IS A HIGH VOLTAGE ENERGY SOURCE. WHICH CAN BE VERY DANĆ

GEROUS GIVING A POTENTIAL RISK OF SHOCK OR BURNS.

GREAT CARE SHOULD BE EXERCISED AT ALL TIMES WHEN WORKING WITH BATTERIES.

S Special care should be taken when working with the batteries associated with this

equipment.

S When connected together, the battery terminal voltage will exceed 380Vdc and is

potentially lethal.

S Eye protection should be worn to prevent injury from accidental electrical arcs.

S If a battery leaks electrolyte, or is otherwise physically damaged, it should be

placed in a container resistant to sulphuric acid and disposed of in accordance with

local regulations.

S If electrolyte comes into contact with the skin the affected area should be washed

immediately.

2.3.2 - Battery Installation Check

1. Gain access to the battery safety cover by first opening the front hinged door.

a) Disconnect the Earth bonding cable from the safety cover.

b) Remove the two top M6 retaining bolts.

c) Release the two bottom retaining bolts and lift the cover from the UPS.

2. Remove the Main Switch Cover held by four M6 retaining bolts.

3. Carefully ease the cover away from the control switches.

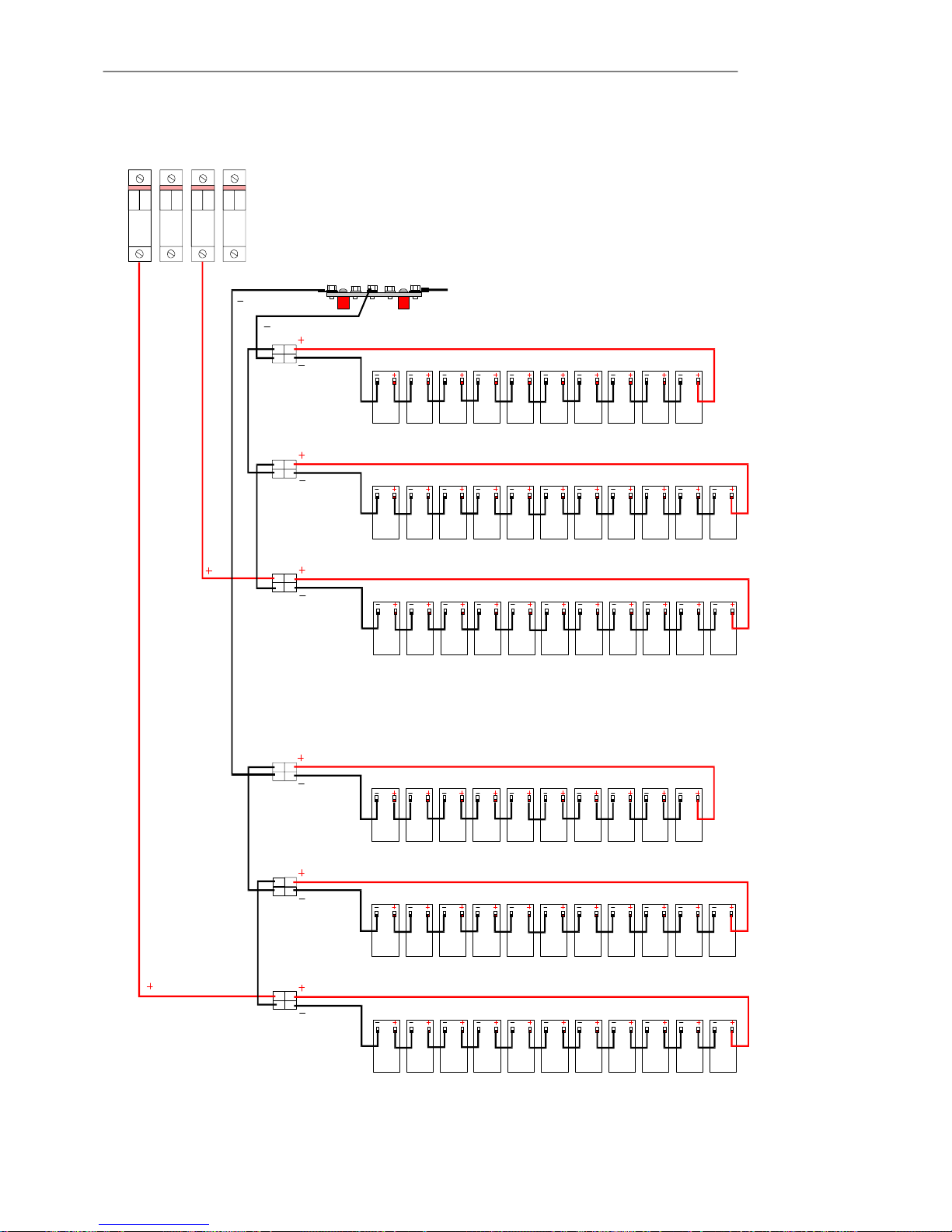

Note:Each battery string are held in 3 trays positioned as

shown in Figure 2Ć3, up to four strings can be fitted dependent on model.

4. Check the battery security in each tray.

5. Check that the FastĆon connecters to each battery are secure and that each connector is

correctly positioned on the battery terminals.

6. Check that the battery linking connectors are correct for each tray.

7. Check that the +ve cable from lower battery tray connector is connected to the correct

battery fuse, as shown in Figure 2Ć4

8. Check that the ćve battery from the top battery tray connector is secured to the common

battery ćve connection bar.

Service Manual Chapter 2 - Installation

Battery Installation

2 - 73x3 UPS Installation

Issue 2 - November 2001

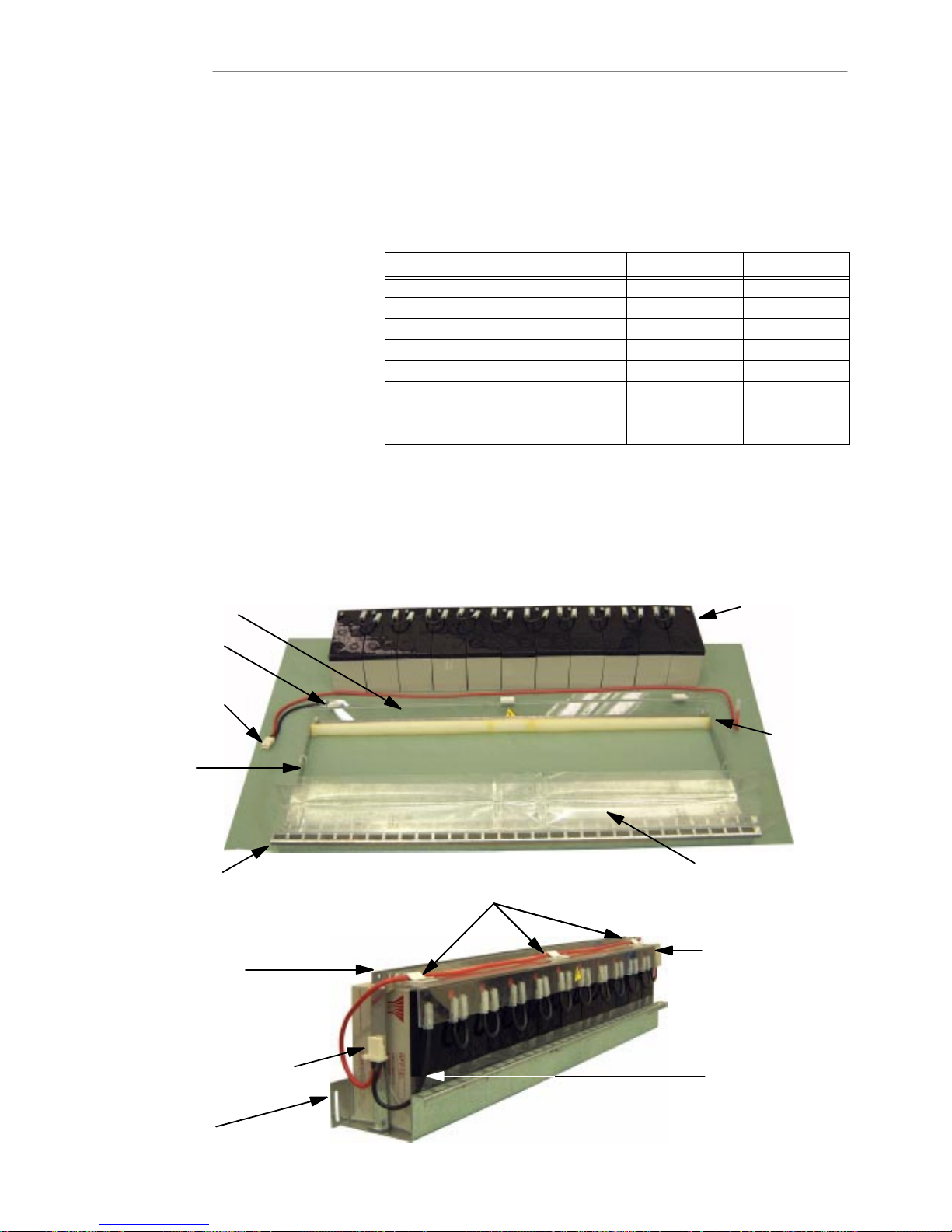

Figure 2-3 Battery Tray Installation for one battery string

Battery Fuses (shown removed)

Battery Earth Bar

Battery String Voltage Check

Note: Battery fuses are removed for transit and should only be fitted by the

commissioning engineer. The fuses can be found with the User manual, in

the document pocket on the battery safety cover.

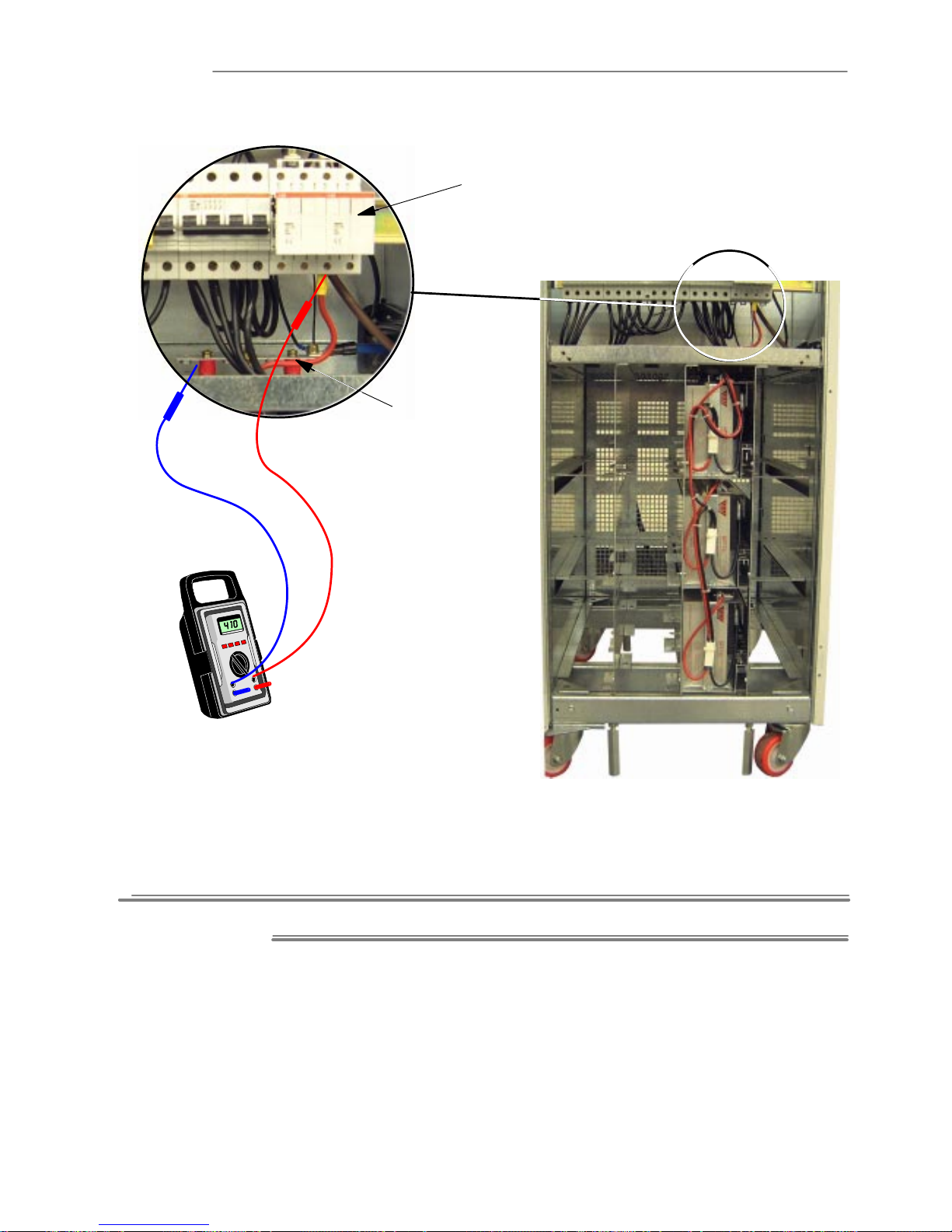

Battery String Voltage check

1. Ensure the battery fuses are removed from the switched fuse holders.

Warning Do not fit the battery fuses into the fuse holders or close the fuse holders.

2. With a DVM set to a DC range of above 450V, check for each individual battery string

voltage. This voltage for a serviceable battery should be between +385V and +416V DC.

3. Measure the battery string voltage from the lower connecting screw of the appropriate fuse

holder and the battery ćve connection bar. As shown in Figure 2-3

4. If a voltage of less than +385V is recorded reĆcheck the battery connections and reĆtest the

string voltage.

Note: A measured voltage substantially less then +385V DC may point to a

defective battery block this can be further isolated by disconnecting each

individual tray and carry out a further check of each tray voltage. This

should be grater than 132V for trays of 11 battery blocks and 120V for 10

blocks.

F1 F2 F3 F4

Battery Fuses

Battery ćve Connection Bar

Battery String 3 Top Battery Tray (10)

Battery String 3 Middle Battery Tray (11)

Battery String 3 Bottom Battery Tray (11)

CN1

CN2

CN3

Note: Battery strings 1 & 3 shown connected

Battery String 1 Top Battery Tray (10)

Battery String 1 Middle Battery Tray (11)

Battery String 1 Bottom Battery Tray (11)

CN1

CN2

CN3

Service ManualChapter 2 - Installation

Battery Installation

2 - 83x3 UPS Installation

Issue 2 - November 2001

Figure 2-4 Battery Cable Connections for one string

Service Manual Chapter 2 - Installation

Battery Installation

2 - 93x3 UPS Installation

Issue 2 - November 2001

2.3.3 -Installing the Battery Upgrade Kit

Note: Installation of a battery upgrade kit must only be carried out by a suitably

qualified, manufacturer approved engineer.

Kit Contents

Prior to installing the battery upgrade kit thoroughly check the items for damage and ensure that they

are in a serviceable condition.

Check that the battery kit contains the following items:

Item Description Part Nº Quantity

Mylar insulating sheet CM 0319 3

Battery tray CM 0470 3

Battery retaining bracket CM 0743 3

Lexan protection CM 0101 3

Battery cable harness OS 001 1

Adhesive foam strip ? ć

Cable holder self adhesive ? 9

Label `High Voltage' ? 3

Note: The 32 battery blocks are not included in the upgrade kit Part Nº

BATTCABLE, but are supplied separately as Battery Kit Part Nº

INTBATT.

Figure 2-5 Battery Tray Assembly

Mylar Insulating Sheet

Battery Blocks

(links fitted)

Lexan protection strip

Cable Holder

Battery Tray

Battery Cable

Retaining

Bracket

Foam Strip

Battery Tray

Mylar Insulating Sheet

(fold to fit batteries)

Battery Cable Connector

(Secure to retaining

bracket with cable tie)

Retaining Bracket

Cable Holder

Lexan protection strip

Service ManualChapter 2 - Installation

Battery Installation

2 - 103x3 UPS Installation

Issue 2 - November 2001

Battery Tray Assembly

1. Place the Mylar insulation strip on to the battery tray.

2. With a DVM check each individual battery block terminal voltage is within 12.5V to 13.0V.

Voltages measured below this may indicate a defective battery block. Refer to `Battery

Maintenance' on Page 6Ć5 Chapter 6 `Maintenance' for information on battery testing.

3. Fold the mylar insulation to fit the batteries and place the 11 battery blocks on to the battery

tray, as shown in Figure 2-5

(Note 10 battery blocks are fitted to the top battery tray.

4. Stick the adhesive foam strip to the battery fixing bracket.

5. Screw the battery retaining bracket to the battery tray.

Connect the batteries using the short battery interconnecting links.

6. Fit the lexan protection to the battery fixing bracket.

7. Place the three adhesive cable retaining clips to the lexan insulating strip, one in the middle

and one at each end.

8. Identify the cable Anderson type connecter supplied with a red and black interconnecting

cable and connect the red cable to the remaining +ve battery connection and the black

cable to the ćve battery connection.

9. Secure the cables in the cable retaining clips.

10. Secure the red cable to the battery retaining bracket at the rear of the assembled battery tray

using a cable tie supplied.

11. Stick the `High Voltage' label to the lexan insulating strip.

Repeat the above procedure for the remaining two battery trays.

Note: The upper battery tray is fitted with 10 batteries.

Battery String Connection

1. Ensure that the UPS has been powered down.

Note: When positioning the battery trays in the UPS, slight downward pressure

may be required on the front of the tray to clear the chassis metalwork at

the rear.

2. Fit the lower battery tray of 11 batteries to the lower position and secure using the battery

tray retaining bolt.

3. Fit the second battery tray of 11 batteries to the middle position and secure using the battery

tray retaining bolt.

4. Fit the upper battery tray of 10 batteries to the top position and secure using the battery tray

retaining bolt.

5. Refer to the schematic diagram (Figure ) locate the battery string interconnecting links from

the battery cable set.

6. Thread the Red +ve wire of the lower Anderson type cable connector through the

appropriate access hole and connect it to the battery fuse lower cable terminal.

Note: Fuse F1 is used for the first battery string, F2 for the second etc.

7. Thread the Black ćve wire of the top Anderson type cable connector through the appropriate

access hole and connect it to the ćve battery connection bar cable stud.

8. Connect the wiring harness connectors to the battery tray Anderson connectors.

a) CN1 to the top battery tray.

b) CN2 to the middle battery tray.

c) CN3 to the lower battery tray.

9. Secure the Anderson type battery connectors to the battery retaining bracket using the cable

ties supplied with the kit.

Loading...

Loading...