Page 1

!

GB Instruconforuse

DE Bedienungsanleitung

POWERTEX Round Slings / Webbing Slings

20180830DE

UMPRS/PWE/PWS-

Page 2

POWERTEX Roundslings and Webbing Slings

Instruction for use (GB) (Original instructions)

serious loss of strength.

WARNING

• Failure to follow the regulations of this instruction for use may cause

serious consequences such as risk of injury.

• Read and understand these instructions before use.

1 Use of roundslings and webbing slings (sling) in adverse conditions or hazardous applications

1.1 The material from which slings are manufactured has selective

resistance to chemicals. Polyester (PES) is resistant to most mineral

acids but is damaged by alkalis;

Solutions of acids or alkalis which are harmless can become suciently concentrated by evaporation to cause damage. Contaminated slings

should be taken out of service at once, soaked in cold water, dried

naturally and referred to a competent person for examination.

Slings with grade 8 ttings and multi-leg slings with grade 8 master

links should not be used in acidic conditions. Contact with acids or

acidic fumes causes hydrogen embrittlement to grade 8 materials.

If exposure to chemicals is likely, the manufacturer or supplier should

be consulted.

1.2 Slings are suitable for use and storage in the following temperature

ranges:

a) polyester: -40°C to 100°C.

At low temperatures ice formation will take place if moisture is present.

This may act as a cutting agent and an abrasive causing internal

damage to the sling. Further, ice will lessen the exibility of the sling, in

extreme cases rendering it unserviceable for use.

These ranges vary in a chemical environment, in which case the advice of the manufacturer or supplier should be sought.

Limited indirect ambient heating, within these ranges, is acceptable for

drying.

1.3 The man-made bres from which the slings is produced are sus-

ceptible to degradation if exposed to ultra-violet radiation.

Slings should not be stored in direct sunlight or sources of ultra-violet

radiation.

2 Inspection of roundslings and webbing slings in service

2.1 Before rst use of the sling it should be ensured that:

a) the sling corresponds precisely to that specied on the order;

b) the manufacturer’s certicate is to hand;

c) the identication and WLL marked on the sling correspond with the

information on the certicate.

2.2 Before each use, the sling should be inspected for defects and to

ensure that the identication and specication are correct. A sling that

is unidentied or defective should never be used, but should be refer-

red to a competent person for examination.

EC-Declaration is available.

2.3 During the period of use, frequent checks should be made for

defects or damage, including damage concealed by soiling, which

might aect the continued safe use of the sling. These checks should

extend to any ttings and lifting accessories used in association with

the sling. If any doubt exists as to the tness for use, or if any of the

required markings have been lost or become illegible, the sling should

be removed from service for examination by a competent person.

Any damage evident in the cover (roundsling) indicates potential damage to the loadbearing core.

The following are examples of defects or damage likely to aect the

tness of slings for continued safe use:

a) Surface chafe. In normal use, some chang will occur to the surface

bres of the cover (roundsling). This is normal and has little eect. Any

substantial chafe, particularly localized, should be viewed critically.

Local abrasion, as distinct from general wear, can be caused by sharp

edges whilst the sling is under tension,

and can lead to the cover (roundsling) becoming cut, or/and cause

b) Roundsling: Cuts. Cross or longitudinal cuts in the cover, or any

damage to the stitching, raise serious doubts as to the integrity of the

core. Webbing sling: Cross or longitudinal cuts, cuts or chafe damage

to selvedges, cuts to stitching or eyes.

c) Exposed core (roundsling).

d) Chemical attack. Chemical attack results in local weakening and

softening of the material. This is indicated by aking of the cover/sur-

face which may be plucked or rubbed o. Any signs of chemical attack

to the cover (roundsling) raise serious doubts as to the integrity of the

core (roundsling).

e) Heat or friction damage. This is indicated by the bres of the cover/

surface material taking on a glazed appearance and in extreme cases,

fusion of the bres can occur, indicating a weakening of the core

(roundsling).

f) Damaged or deformed ttings.

3 Correct selection and use of roundslings and webbing slings

(slings)

3.1 When selecting and specifying slings, consideration should be

given to the required working load limit, taking into account the mode of

use and the nature of the load to be lifted. The size, shape and weight

of the load, together with the intended method of use, working environ-

ment and nature of the load, all aect the correct selection.

The selected sling should be both strong enough and of the correct

length for the mode of use. If more than one sling is used to lift a load,

these slings should be identical. The material from which the slings is

made should not be aected adversely by the environment or the load.

Consideration should also be given to ancillary ttings and lifting de-

vices which should be compatible with the sling(s).

Webbing slings: The termination of the sling should also be considered

i.e. whether ttings or soft eyes are required.

3.2

Webbing slings: When using slings with soft eyes, the minimum

eye length for a sling for use with a hook should be not less than 3,5

times the maximum thickness of the hook and in any event the angle

formed in the eye of the sling should not exceed 20°.

When connecting a sling with soft eyes to a lifting appliance, the part

of the lifting appliance which bears on the sling should be essentially

straight, unless the bearing width of the sling is not more than 75 mm

in which case the radius of curvature of the lifting appliance attachment

should be at least 0,75 times the bearing width of the sling.

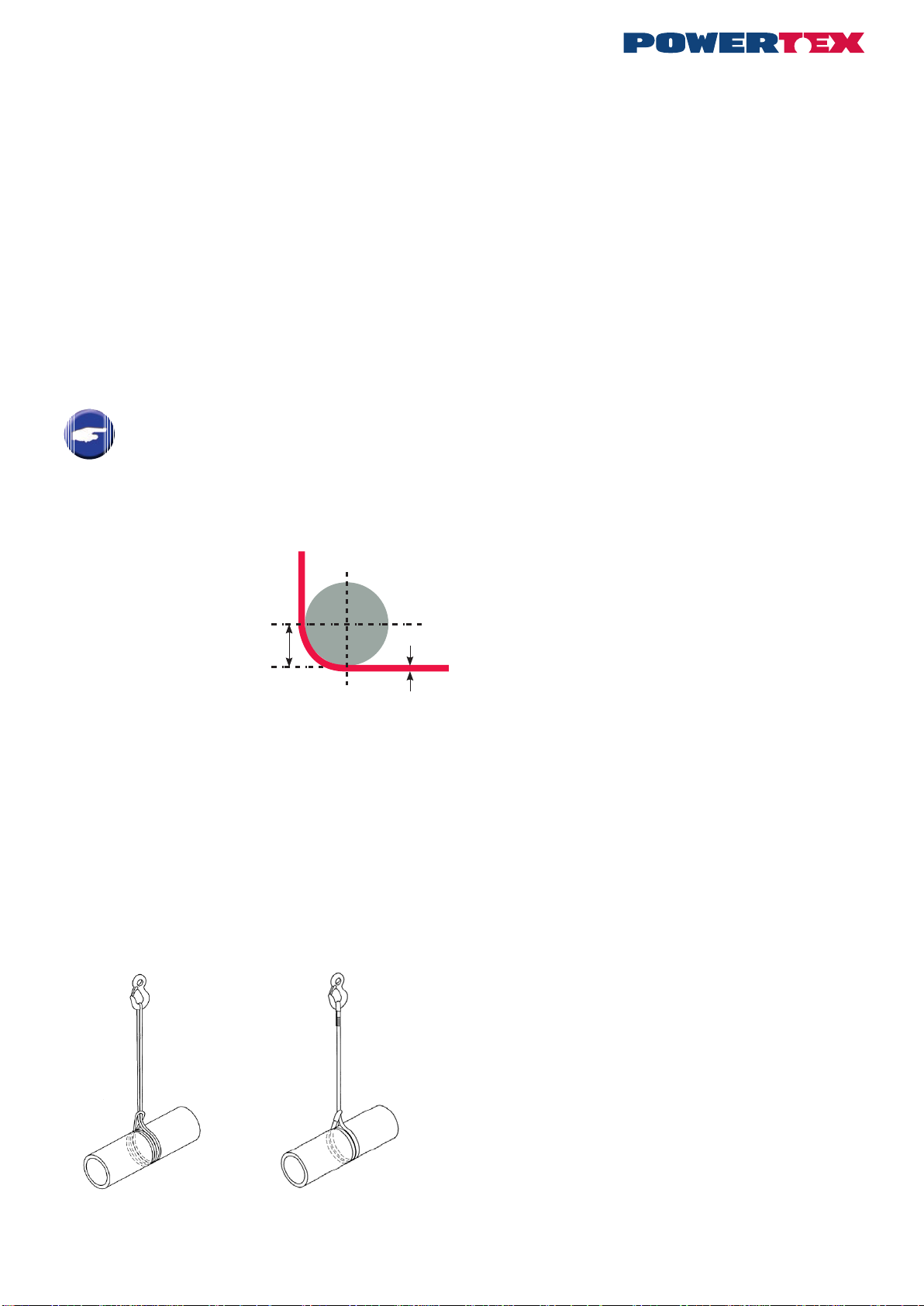

Figure D1 illustrates the problem of accommodating

webbing on a hook of radius less than 0,75 times the

bearing width of the sling.

Wide webbings may be aected by the radius of the

inside of the hook as a result of the curvature of the

hook preventing uniform loading across the width of the

webbing.

Figure D1 inadequate accommodation of a webbing

eye on a hook of too small radius

3.3 Slings should not be overloaded: the correct mode factor should be

used (see table 1).

Angle of

inclination

Load factor 1 2 0,8 1,4 1 1,4 1 2,1 1,5

Colour WLL ton

Green 2,0 4,0 1,6 2,8 2,0 2,8 2,0 4,2 3,0

Yellow 3,0 6,0 2,4 4,2 3,0 4,2 3,0 6,3 4,5

Brown 6,0 12,0 4,8 8,4 6,0 8,4 6,0 12,6 9,0

Orange 10,0 20,0 8,0 14,0 10,0 14,0 10,0 21,0 15,0

1-leg

U-lift Laced 1-leg angle 2-leg sling 3-, 4-leg sling

Lila 1,0 2,0 0,8 1,4 1,0 1,4 1,0 2,1 1,5

Grey 4,0 8,0 3,2 5,6 4,0 5,6 4,0 8,4 6,0

Red 5,0 10,0 4,0 7,0 5,0 7,0 5,0 10,5 7,5

Blue 8,0 16,0 6,4 11,2 8,0 11,2 8,0 16,8 12,0

Figure D1

0°- 45° 45°- 60° 0°- 45° 45°- 60°0°- 45°45°- 60°

2

Page 3

Working load limits for some modes may be given on the label. In the

case of multi-leg slings the maximum angle to the vertical should not

be exceeded.

3.4 Good slinging practices should be followed: the slinging, lifting and

lowering operations should be planned before commencing the lift.

3.5 Slings be should correctly positioned and attached to the load in a

safe manner. Slings should be placed on the load such that they are

able to adopt the attened form and the loading is uniform across

their width. They should never be knotted or twisted.

Damage to labels should be prevented by keeping them away from the

load, the hook and the angle of choke.

3.6 In the case of multi-leg slings, the WLL values have been determined on the basis that the loading of the sling assembly is symmetrical.

This means that when a load is lifted the sling legs are symmetrically

disposed in plan and subtended at the same angle to the vertical.

In the case of 3 leg slings, if the legs are not symmetrically disposed in

plan the greatest tension is in the leg where the sum of the plan angles

to the adjacent legs is greatest. The same eect occurs in 4 leg slings

except that the rigidity of the load should also be taken into account.

3.7 Slings should be protected from edges, friction and abrasion,

whether from the load or the lifting appliance. Where protection against

damage from edges and/or abrasion is supplied as part of the sling,

this should be correctly positioned. It may be necessary to supplement

this with additional protection.

Denition of a sharp edge:

Radius r (edge) < thickness d of the

lifting gear.

3.8 The load should be secured by the sling(s) in such a manner that it

cannot topple or fall out of the sling(s) during the lift. Sling(s) should be

arranged so that the point of lift is directly above the centre of gravity

and the load is balanced and stable. Movement of the sling over the

lifting point is possible if the centre of gravity of the load is not below

the lifting point.

When using basket hitch, the load should be secure since there is no

gripping action as with choke hitch and the sling can roll through the

lifting point. For slings which are used in pairs, the use of a spreader is

recommended so that the sling legs hang as vertically as possible and

to ensure that the load is equally divided between the legs.

When a sling is used in choke hitch, it should be positioned so as to

allow the natural (120°) angle to form and avoid heat being generated

by friction. A sling should never be forced into position nor an attempt

made to tighten the bite. The correct method of securing a load in a

double choke hitch is illustrated in gure 3.A (roundsling) and 3.B (webbing slings) double choke hitch provides greater security and helps to

prevent the load sliding through the sling.

Figure 3.A Figure 3.B

NOTE With a rigid load the majority of the weight may be

taken by only three, or even two, of the legs, with the

remaining legs only serving to balance the load.

r

d

3.9 Care should be taken to ensure the safety of personnel during the

lift. Persons in the danger area should be warned that the operation is

to take place and, if necessary, evacuated from the immediate area.

Hands and other parts of the body should be kept away from the sling

to prevent injury as the slack is taken up.

The work with lifting devices and equipment’s must be planned, organized and executed in order to prevent hazardous situations.

In accordance with national statutory regulations lifting devices and

equipment’s must only be used by someone well familiar with the work

and having theoretical and practical knowledge of safe use.

Apart from the instruction manual we refer to existing national regulations on each work place.

3.10 A trial lift should be made. The slack should be taken up until the

sling is taut. The load should be raised slightly and a check made that

it is secure and assumes the position intended. This is especially

important with basket or other loose hitches where friction retains the

load.

If the load tends to tilt, it should be lowered and attachments re-positioned. The trial lift should be repeated until the stability of the load is

ensured.

3.11 Care should be taken when making the lift to ensure that the load

is controlled, e.g. to prevent accidental rotation or collision with other

objects.

Snatch or shock loading should be avoided as this will increase the

forces acting on the sling.

A load in the sling or the sling itself should not be dragged over the

ground or rough surfaces.

3.12 The load should be lowered in an equally controlled manner as

when lifted.

Trapping the sling when lowering the load should be avoided. The load

should not rest on the sling, if this could cause damage and pulling the

sling from beneath the load when the load is resting on it should not be

attempted.

3.13 On completion of the lifting operation the sling should be returned

to proper storage.

When not in use, slings should be stored in clean, dry and well ventilated conditions, at ambient temperature and on a rack, away from

any heat sources, contact with chemicals, fumes, corrodible surfaces,

direct sunlight or other sources of ultra-violet radiation.

3.14 Prior to placing in storage, slings should be inspected for any

damage which may have occurred during use. Slings should never be

returned damaged to storage.

3.15 Where lifting slings have come into contact with acids and/or alkalis, dilution with water or neutralization with suitable media is recommended prior to storage.

Depending on the material of the lifting sling and on the chemicals referred to in 1, 1.1, it may be necessary in some cases to request from

the supplier additional recommendations on the cleaning procedure to

be followed after the sling has been used in the presence of chemicals.

3.16 Slings which have become wet in use, or as the result of cleaning,

should be hung up and allowed to dry naturally, not near a heat source.

4 Examination and repair

Examination periods should be determined by a competent person,

taking into account the application, environment, frequency of use and

similar matters, but in any event, slings should be visually examined at

least annually by a competent person to establish their tness for

continued use.

Records of such examinations should be maintained.

Damaged slings should be withdrawn from service. Never attempt to

carry out repairs to the slings yourself.

Page 4

5 Information

We recommend a maximum life span of 10 years, eective from the

date of production. This may be extended, but depends on a more

detailed examination.

Before rst use:

Mark up the date for rst use by year and month the example shown.

End of use/Disposal

Powertex liftingslings shall always be sorted / scrapped as polyester

scrap.

Main material is polyester.

We will assist you with the disposal, if required.

Disclaimer

We reserve the right to modify product design, materials, specications

or instructions without prior notice and without obligation to others.

If the product is modied in any way, or if it is combined with a

non-compatible product/component, we take no responsibility for the

consequences in regard to the safety of the product.

SCM Citra OY

Juvan Teollisuuskatu 25 C

FI-02920 Espoo

Finland

www.powertex-products.com

hereby declares that Powertex roundslings and textile slings as described above is in com pliance with EC Machinery Directive 2006/42/EC

and amendments and EN 1492-1, -2.

4

Page 5

POWERTEX Rundschlingen und Hebebänder

Bedienungsanleitung (DE)

gen könnten. Diese Kontrollen sollten sich auch auf alle Beschläge

WARNUNG

• Die Nichtbeachtung der in dieser Gebrauchsanweisung enthaltenen

Vorschriften kann schwerwiegende Folgen nach sich ziehen und unter

anderem die Verletzungsgefahr erhöhen.

• Lesen und verinnerlichen Sie diese Anweisungen vor dem Gebrauch.

1 Nutzung von Rundschlingen und Hebebändern (Anschlagmittel)

unter widrigen Bedingungen oder in gefährlichen Anwendungen

1.1 Das Material aus dem die Anschlagmittel hergestellt werden, hat

eine hohe Beständigkeit gegenüber Chemikalien. Polyester (PES) ist

gegen die meisten Mineralsäuren beständig, wird jedoch durch Laugen

beschädigt;

Unschädliche Lösungen von Säuren oder Laugen können durch

Verdunstung eine entsprechende Konzentration erreichen, die Schäden verursachen kann. Verunreinigte Anschlagmittel sind umgehend

von der weiteren Benutzung auszuschließen und müssen in kaltem

Wasser eingeweicht, an der Luft getrocknet und durch eine fachkundige Person überprüft werden.

Anschlagmittel mit Beschlägen der Güteklasslasse 8 und mehrsträngige Anschlagmittel mit Aufhängegliedern der Güteklasse 8 sollten nicht

unter sauren Bedingungen eingesetzt werden. Der Kontakt mit Säuren

oder sauren Dämpfen verursacht bei Güteklasse 8 oder

Materialien höherer Güteklassen Wasserstoversprödung.

Falls eine Exposition gegenüber Chemikalien wahrscheinlich ist,

empehlt es sich, Rücksprache mit dem Hersteller oder Lieferanten zu

nehmen.

1.2 Die Nutzung und Aufbewahrung der Anschlagmittel innerhalb der

folgenden Temperaturbereiche ist zulässig:

a) Polyester: -40°C bis 100°C.

Bei niedrigen Temperaturen kann es zu Eisbildung kommen, falls

Feuchtigkeit vorhanden ist. Das Eis kann wie ein Schneid- und

Schleifmittel wirken und Schäden im Inneren des Anschlagmittels

verursachen. Darüber hinaus verringert das Eis die Flexibilität des

Anschlagmittels und macht dieses im Extremfall sogar für den Einsatz

unbrauchbar.

Diese Temperaturbereiche variieren in chemischen Umgebungen, in

diesem Fall sollte eine Empfehlung des Herstellers oder Lieferanten

eingeholt werden.

Zum Trocknen ist eine begrenzte indirekte Umgebungsheizung innerhalb dieser Bereiche zulässig.

1.3 Die künstlichen Fasern, aus denen die Anschlagmittel hergestellt

werden, sind anfällig für Schäden durch ultraviolette Strahlung.

Die Anschlagmittel sollten nicht in direktem Sonnenlicht oder in der

Nähe von UV-Strahlungsquellen aufbewahrt werden.

2 Inspektion von Rundschlingen und Hebebändern im Einsatz

2.1 Vor der ersten Verwendung des Anschlagmittels ist sicherzustellen,

dass:

a) das Anschlagmittel präzise den Angaben auf dem Bestellschein

entspricht;

b) ein Zertikat des Herstellers vorhanden ist;

c) die auf dem Anschlagmittel angegebene Kennzeichnung und WLL

mit den Angaben des Zertikats übereinstimmt.

und Hebezeuge erstrecken, die in Verbindung mit dem Anschlagmittel

verwendet werden. Falls Zweifel an der Gebrauchstauglichkeit bestehen oder eine der erforderlichen Kennzeichnungen verloren gegangen

oder unleserlich geworden ist, muss das Anschlagmittel zur Überprüfung durch eine befähigte Person außer Betrieb genommen werden.

Oenkundige Schäden in der Ummantelung (Rundschlinge) weisen auf

eine mögliche Beschädigung des tragenden Kerns hin.

Im Folgenden nden Sie Beispiele für Mängel oder Schäden, welche die Eignung des Anschlagmittels für eine kontinuierliche sichere

Nutzung beeinträchtigen könnten:

a) Oberächlicher Verschleiß. Bei normalem Gebrauch tritt ein gewisser Verschleiß der Oberächenfasern der Ummantelung auf (Rund-

schlinge). Dies ist vollkommen normal und wirkt sich nur geringfügig

aus. Starker Verschleiß, insbesondere punktuell, sollte jedoch kritisch

betrachtet werden. Punktuelle Abnutzungen, können – anders als

allgemeiner Verschleiß – durch scharfe Kanten verursacht werden,

während das Anschlagmittel unter Spannung steht,

und können dazu führen, dass die Ummantelung (Rundschlinge) eingeschnitten wird und/oder an Festigkeit verliert.

b) Schnittverletzungen: Einschnitte. Kreuz- oder Längsschnitte in der

Ummantelung oder beschädigte Nahtstellen bieten Anlass für ernste

Zweifel an der Unversehrtheit des Kerns. Hebeband: Kreuz- oder

Längsschnitte, Einschnitte oder beschädigte Webkanten, beschädigte

Nähte oder bis in die Ösen reichende Einkerbungen.

c) Freiliegender Kern (Rundschlinge).

d) Chemische Einwirkung. Eine chemische Einwirkung führt zu punk-

tueller Schwächung und Aufweichung des Materials. Dies zeigt sich

durch Abblättern der Ummantelung/Oberäche, die sich abzupfen oder

abreiben lässt. Alle Anzeichen einer chemischen Beschädigung der

Ummantelung (Rundschlinge) bieten Anlass für Zweifel an der

Unversehrtheits des Kerns (Rundschlinge).

e) Schäden durch Hitze oder Abrieb. Diese zeigen sich in den Fasern

der Ummantelung/des Oberächenmaterials, die ein glasig glänzendes

Aussehen annehmen, in extremen Fällen können Fasern miteinander

verschmelzen, was wiederum eine Schwächung des Kerns (Rundschlinge) zur Folge hat.

f) Beschädigte oder verformte Beschläge.

3 Die richtige Auswahl und Verwendung von Rundschlingen und

Hebebändern (Anschlagmittel)

3.1 Bei der Auswahl und Bestimmung von Anschlagmitteln ist stets die

erforderliche Betriebslastgrenze zu beachten, des Weiteren sind die

Betriebsart sowie die Art der anzuhebenden Ladung zu berücksichtigen. Faktoren wie die Größe, die Form und das Gewicht der Ladung in

Kombination mit der beabsichtigten Verwendungsmethode, der Arbeit-

sumgebung und der Art der Ladung beeinussten die richtige Auswahl.

Das ausgewählte Anschlagmittel muss sowohl stark genug als auch

ausreichend lang für die beabsichtigte Verwendung sein. Wird mehr

als ein Anschlagmittel zum Anheben einer Ladung verwendet, sollten

diese Anschlagmittel identisch sein. Das Material aus dem diese Anschlagmittel bestehen,

darf weder durch die Umgebung noch durch die Ladung negativ beeinträchtigt werden.

Darüber hinaus sind zusätzliche Beschläge und Hebevorrichtungen zu

berücksichtigen, die ihrerseits mit der/den Anschlagmittel(n) kompatibel

sein müssen.

Hebebänder: Die Ausführung der Endausführung ist ebenfalls zu

berücksichtigen, d. h. ob Beschläge oder Schlaufen erforderlich sind.

2.2 Das Anschlagmittel muss vor jeder Nutzung auf Mängel kontrolliert werden, zudem ist sicherzustellen, dass die Kennzeichnung und

Spezikation korrekt sind. Ein nicht gekennzeichnetes oder mangelhaftes Anschlagmittel darf nicht verwendet werden, sollte jedoch einer

befähigten Person zur Überprüfung vorgelegt werden.

Eine EG-Konformitätserklärung ist verfügbar.

2.3 Während des Nutzungszeitraums sollten regelmäßige Kontrollen

auf Mängel oder Beschädigungen durchgeführt werden, einschließlich

etwaiger durch Verschmutzung verborgenen Beschädigungen, welche

die weitere kontinuierliche Nutzung des Anschlagmittels beeinträchti-

3.2 Hebebänder: Bei Verwendung von Schlaufenhebebändern sollte

die Mindestschlaufenlänge bei einem mit einem Haken genutzten

Anschlagmittel nicht weniger als die 3,5-fache maximale Dicke des

Hakens betragen und in jedem Fall sollte der von der Schlaufe des

Anschlagmittels geformte Winkel 20° nicht überschreiten.

Beim Anbringen eines Schlaufenhebebandes an Hebezeugen, sollte

der Teil des Hebezeuges, der auf dem Anschlagmittel auiegt, im

Wesentlichen gerade sein, es sei denn die Auageäche des An-

schlagmittels beträgt nicht mehr als 75 mm, in diesem Fall muss der

Krümmungsradius der Hebevorrichtung mindestens das 0,75-fache der

Auagebreite des Anschlagmittels betragen.

Page 6

Abbildung D1 zeigt das Problem der Aufnahme eines

Hebebandes an einem Haken mit einem Krümmungsra-

dius von weniger als der 0,75-fachen Auagebreite des

Anschlagmittels.

Breite Gurte können durch den Innenradius des Hakens

infolge der Hakenkrümmung beeinusst werden, wodurch eine gleichmäßige Belastung über die gesamte

Breite des Gurtes verhindert wird.

Abbildung D1 Nicht sachgemäße Aufnahme eines Hebebandes miteinem Haken mit zu kleinem Radius.

Abbildung D1

3.3 Anschlagmittel dürfen nicht überlastet werden: es ist der korrekte

Lastanschlagfaktor zu verwenden (siehe Tabelle 1).

1-Strang

U-Gehänge Geschnürt 1-Strang Winkel 2-Strang Schlaufe 3-, 4-Strang Schlaufe

Neigungs-

winkel

Lastanschlagfaktor 1 2 0,8 1,4 1 1,4 1 2,1 1,5

Farbe WLL t

Lila 1,0 2,0 0,8 1,4 1,0 1,4 1,0 2,1 1,5

Grün 2,0 4,0 1,6 2,8 2,0 2,8 2,0 4,2 3,0

Gelb 3,0 6,0 2,4 4,2 3,0 4,2 3,0 6,3 4,5

Grau 4,0 8,0 3,2 5,6 4,0 5,6 4,0 8,4 6,0

Rot 5,0 10,0 4,0 7,0 5,0 7,0 5,0 10,5 7,5

Braun 6,0 12,0 4,8 8,4 6,0 8,4 6,0 12,6 9,0

Blau 8,0 16,0 6,4 11,2 8,0 11,2 8,0 16,8 12,0

Orange 10,0 20,0 8,0 14,0 10,0 14,0 10,0 21,0 15,0

Betriebslastgrenzen für bestimmte Lastanschlagfaktoren können auf

dem Etikett angegeben sein. Im Fall von mehrsträngigen Anschlagmitteln sollte der maximale Winkel zur Vertikalen nicht überschritten

werden.

0°- 45° 45°- 60° 0°- 45° 45°- 60° 0°- 45° 45°- 60°

Denition einer scharfen Kante:

Radius r (Kante) < Dicke d des Hebezeugs

r

d

3.8 Die Ladung sollte durch Anschlagmittel so gesichert sein, dass sie beim Anheben nicht kippen oder

herausfallen kann. Anschlagmittel müssen so angeordnet sein, dass

sich der Haken des Hebezeuges direkt über dem Schwerpunkt der

Last bendet und die Ladung ausgeglichen und stabil auiegt. Wenn

der Lasthaken sich nicht direkt über dem Schwerpunkt bendet, ist

ein Verrutschen des Anschlagmittels möglich. Für paarweise genutzte

Anschlagmittel empehlt sich der Einsatz einer Spreiztraverse, damit

die Anschlagmittel möglichst senkrecht hängen und um sicherzugehen,

dass die Last gleichmäßig zwischen den Strängen verteilt ist.

Wird ein Anschlagmittel im doppelten Schnürgang verwendet, sollte

es so positioniert werden, dass sich ein Schnürwinkel von 120° bildet.

Wärmeentwicklung durch Reibung ist zu verhindern. Anschlagmittel

dürfen auf keinen Fall in eine bestimmte Position gezwungen werden,

ein Nachspannen der Schnürung ist ebenfalls zu vermeiden. Die korrekte Methode zur Sicherung einer Ladung im doppelten Schnürgang

ist in Abbildung 3.A (Rundschlinge) und 3.B (Hebebänder) beschrieben. Der doppelte Schnürgang bietet erhöhte Sicherheit und verhindert, dass die Ladung durch das Anschlagmittel abrutscht.

Abbildung 3.A Abbildung 3.B

3.4 Eine gute Anschlagpraxis ist einzuhalten: die Anschlag-, Hub- und

Absenkarbeiten sollten vor Beginn der Hubarbeiten geplant werden.

3.5 Anschlagmittel müssen korrekt positioniert und sicher an der

Ladung befestigt werden. Anschlagmittel müssen so an der Ladung

platziert werden, dass sie ach auiegen und sich die Last

gleichmäßig über die gesamte Breite verteilen kann. Sie dürfen auf

keinen Fall verknotet oder verdreht sein.

Beschädigungen an Etiketten sollten verhindert werden, indem sie

von der Ladung, dem Haken und einer eventuellen Schnürgang-Stelle

ferngehalten werden.

3.6 Im Fall von mehrsträngigen Anschlagmitteln wurden die

Tragfähigkeiten (WLL-Werte) auf Grundlage einer symmetrischen

Belastung der Anschlagmittelgruppe bestimmt. Das bedeutet, dass die

Anschlagmittelstränge beim Anheben einer Ladung symmetrisch in

einer Ebene angeordnet sind und sich im selben Winkel zur Vertikalen

gegenüberliegen.

Im Fall von 3 Strängen ist zu beachten, dass - sofern die Stränge nicht

symmetrisch in einer Ebene angeordnet sind - die größte Spannung in

dem Strang auftritt, bei dem der Winkel zu den angrenzenden Strängen am größten ist. Der gleiche Eekt tritt bei 4-strängigen Anschlagmitteln auf, allerdings ist hier die Biegefestigkeit der Ladung ebenfalls

zu berücksichtigen..

HINWEIS: Bei einer ausreichend steifen Ladung kann ein

Großteil des Gewichts von nur drei oder sogar zwei der

Stränge aufgenommen werden, während die restlichen

Stränge nur die Ladung ausbalancieren.

3.7 Die Anschlagmittel müssen vor Kanten, Reibung und Abrieb durch

Ladung und Hebezeug geschützt werden. Wenn ein Kanten- und/oder

Abriebschutz gemeinsam mit dem Anschlagmittel geliefert wird, muss

dieser korrekt positioniert werden. Möglicherweise ist es notwendig,

diesen mit zusätzlichen Schutzmaßnahmen zu ergänzen.

3.9 Es ist darauf zu achten, dass die Sicherheit des Personals

während des gesamten Hebevorgangs gewährleistet ist. Personen, die

sich im Gefahrenbereich aufhalten, müssen gewarnt werden, dass der

Hebevorgang kurz bevor steht, und gegebenenfalls aus der unmittelbaren Umgebung verwiesen werden.

Hände oder andere Körperteile müssen von der Anschlagmittel

ferngehalten werden, um Verletzungen zu vermeiden, wenn sich der

Durchhang plötzlich spannt.

Die Arbeit mit Lastaufnehmeeinrichtungen und Hebezeugen muss gut

geplant, organisiert und ausgeführt werden, um Gefahrensituationen

zu vermeiden.

In Einklang mit den nationalen gesetzlichen Vorschriften dürfen Lastaufnahmeeinrichtungen und Hebezeuge nur von Personen verwendet werden, die mit der Arbeit vertraut sind und theoretische und

praktische Kenntnisse einer sicheren Anwendung haben.

Abgesehen von der jeweiligen Bedienungsanleitung verweisen wir auf

die bestehenden nationalen Vorschriften an jedem Arbeitsplatz.

3.10 Ein Hebetest ist durchzuführen. Der Lasthaken sollte so weit

angehoben werden, bis das Anschlagmittel stra gespannt ist. Die

Ladung wird dann vorsichtig angehoben und es wird überprüft, ob sie

sicher hängt und die gewünschte Position einnimmt. Dies ist vor allem

beim Hängegang oder anderen losen Anschlagtechniken wichtig, bei

denen die Ladung nur durch Reibung festgehalten wird.

Falls sich die Ladung neigt, muss sie wieder abgesenkt werden und

die Anschlagmittel müssen neu positioniert werden. Der Hebetest sollte

so oft wiederholt werden, bis die Stabilität der Ladung gewährleistet ist.

3.11 Während des Anhebens ist sicherzustellen, dass die Ladung

kontrolliert wird, z. B. um eine versehentliche Rotation oder Kollision

mit anderen Objekten zu verhindern.

6

Page 7

Ruck- oder stoßartige Belastungen sind zu vermeiden, da hier weit

größere Kräfte als das eigentliche Gewicht der Ladung auf das Anschlagmittel wirken.

Eine in einer Schlaufe hängende Ladung bzw. das Anschlagmittel

selbst niemals über den Boden oder raue, unebene Flächen ziehen.

3.12 Die Ladung sollte ebenso gleichmäßig abgesenkt wie angehoben

werden.

Ein Verhaken des Anschlagmittels beim Absenken der Ladung sollte

vermieden werden. Die Ladung darf nicht auf dem Anschlagmittel

abgestellt werden, dies könnte Beschädigungen verursachen. Darüber

hinaus sollte niemals versucht werden, das

Anschlagmittel gewaltsam unter einer Ladung herauszuziehen, wenn

diese darauf steht.

3.13 Nach Abschluss des Hebevorgangs sind die Anschlagmittel wieder ordnungsgemäß zu lagern.

Bei Nichtgebrauch müssen die Anschlagmittel an einem sauberen,

trockenen und gut belüfteten Ort bei Raumtemperatur auf einem Regal

und weit weg von Wärmequellen, Kontakt mit Chemikalien, Rauchga-

sen, korrodierenden Oberächen, direktem Sonnenlicht oder anderen

Quellen ultravioletter Strahlung gelagert werden.

3.14 Vor der Lagerung sollten die Anschlagmittel auf eventuell während

des Gebrauchs aufgetretene Schäden untersucht werden. Anschlagmittel dürfen nicht beschädigt gelagert werden.

3.15 Falls die Anschlagmittel in Berührung mit Säuren und/oder Basen

gekommen sind, empehlt sich vor der Einlagerung eine Verdünnung

mit Wasser oder eine Neutralisation mit geeigneten Mitteln.

Abhängig vom Material des Hebebandes und den unter 1, 1.1 angeführten Chemikalien, kann es in einigen Fällen erforderlich sein,

vom Anbieter zusätzliche Empfehlungen zu den Reinigungsverfahren

einzuholen, die befolgt werden sollten, nachdem das Anschlagmittel in

Kontakt mit Chemikalien genutzt wurde.

5 Informationen

Wir empfehlen eine maximale Nutzungsdauer von 10 Jahren ab dem

Produktionsdatum. Dieser Zeitraum kann verlängert werden, bedarf

jedoch einer eingehenderen Überprüfung.

Vor der ersten Verwendung:

Markieren Sie das Datum der ersten Nutzung mit Jahr und Monat

wie im abgebildeten Beispiel.

Ende der Lebensdauer/Entsorgung

Powertex Rundschlingen und textilen Anschlagmitte sind stets als

Polyesterabfall zu entsorgen.

Das Hauptmaterial ist Polyester.

Wir stehen Ihnen bei Bedarf bei der Entsorgung zur Seite.

Haftungsausschluss

Wir behalten sich das Recht vor, die Produktgestaltung, Materialien,

Spezikationen oder Anweisungen ohne vorherige Ankündigung und

frei von Verpichtungen gegenüber anderen zu ändern.

Wird das Produkt in irgendeiner Weise modiziert oder mit einem

nicht kompatiblen Produkt oder einer nicht kompatiblen Komponente

kombiniert, übernehmen wir keine Verantwortung für die Folgen in

Hinblick auf die Produktsicherheit.

3.16 Während der Verwendung oder infolge einer Reinigung nass

gewordene Anschlagmittel sollten aufgehängt und an der Luft getrocknet werden, auf keinen Fall in der Nähe einer Wärmequelle.

4 Kontrolle und Reparatur

Die Kontrollzeiträume sind von einer befähigten Person unter Berück-

sichtigung der Anwendung, der Umgebung, der Nutzungshäugkeit

und ähnlicher Faktoren festzulegen, die Anschlagmittel sollten jedoch

in jedem Fall jährlich von einer befähigten Person auf ihre Eignung für

die weitere kontinuierliche Nutzung überprüft werden.

Im Rahmen dieser Kontrollen sind Aufzeichnungen zu führen.

Beschädigte Anschlagmittel sind unverzüglich außer Betrieb zu setzen.

Versuchen Sie niemals, die Anschlagmittel selbst zu reparieren.

SCM Citra OY

Juvan Teollisuuskatu 25 C

FI-02920 Espoo

Finland

www.powertex-products.com

erklärt hiermit, dass die Powertex Rundschlingen und textilen

Anschlagmittel wie oben beschrieben alle Anforderungen der

EG-Maschinenrichtlinie 2006/42/EG und deren Änderungen erfüllen

und EN 1492-1, -2.

Page 8

8

Page 9

CERTEX Lifting KnowHow app

!

Download The Lifting KnowHow app’en from the App Store / Google play!

The App has the following features:

- Load charts for dierent types of lifting slings

- Protractor for measuring sling angles

- Instructions for safe use of a selection of lifting gear

- Built-in gps function that nds the Lifting Solutions Group oce closest to

your position.

- And a lot more.

The Lifting KnowHow is a unique knowledge transfer programme.

CertMax+

The CertMax+ system is a unique leading edge certication management

system which is ideal for managing a single asset or large equipment portfolio across multiple sites. Designed by the Lifting Solutions Group, to deliver

optimum asset integrity, quality assurance and traceability, the system also

improves safety and risk management levels.

User Manuals

You can always nd the valid and updated User Manuals on the web.

The manual is updated continuously and valid only in the latest version.

NB! The English version is the Original instruction.

The manual is available as a download under the following link:

www.powertex-products.com/manuals

Page 10

www.powertex-products.com

Loading...

Loading...