Powertec Pro BD6900 Owner's Manual

Model No. BD6900

QUESTION...

1•877•393•7121

Owner’s Manual

6”x 9” DISC/BELT SANDER

WITH BUILT-IN DUST COLLECTION

Visit us on the web at www.southerntechllc.com

You will need this manual for safety instructions, operating procedures, and warranty.

Put it and the original sales invoice in a safe, dry place for future reference.

10-0419

TABLE OF CONTENTS

PRODUCTION

SECTION PAGE

SAFETY RULES 1

Work Preparation

Work Area Preparation

Tool Maintenance

Tool Operation

ASSEMBLY 2

Unpackaging

Tool Needed

Mount Sander

Attach Abrasive Disc

Attach the Table Assembly to Use with Sanding Disc

Attach the Table Assembly to Use with Sanding Belt

Attach Dust Collection Bag

Power Source

Grounding Instructions

Extension Cords

Motor

Electrical Connections

OPERATION 6

SPECIFICATIONS

Horsepower (Peak HP).................................................. 1.2

Voltage...........................................................................120

Amp................................................................................7.5

Hertz................................................................................60

Phase.........................................................................Single

RPM.............................................................................3450

Belt size...................................................................6” x 48”

Belt speed...........................................................2400 FPM

Disc diameter....................................................................9”

Disc speed..........................................................3100 RPM

Table dimensions....................................................7” x 10”

Table tilts...............................................................0° to 45°

Dust port diameter............................................................2”

Base dimensions...................................................12” x 19”

ON/OFF Switch

Adjust Belt Tracking Mechanism

Adjust Belt Assembly Position

Adjust Table Tilt Angle

Belt Sanding in Horizontal Position

Operate Sanding Belt

Operate Sanding Disc

Set Up the Miter Gauge

Replace Sanding Belt

Replace Sanding Disc Abrasive

MAINTENANCE 9

General Maintenance

Cleaning

Lubrication

Keep Tool in Repair

TROUBLESHOOTING 10

PARTS ILLUSTRATION & 11

LIST

WARRANTY 14

SAFETY RULES

1

WARNING

For your own safety, read and understand all warnings

and operating instructions before using any tool or

equipment.

WARNING

Some dust created by operation of power tool contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

To reduce your exposure to these chemicals: work in a

well ventilated area and work with approved safety

equipment. Always wear OSHA/NIOSH approved,

properly fitting face mask or respirator when using such

tools.

WARNING

Failure to follow these rules may result in serious personal

injury. Remember that being careless for even a fraction

of a second can result in severe personal injury.

WORK PREPARATION

• Wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets or other jewelry which

may get caught in moving parts of the tool.

• Nonslip protective footwear is recommended.

• Wear protective hair covering to contain long hair.

• Wear eye and hearing protection. Always use safety

glasses. Eye protection equipment should comply with

ANSI Z87.1 standards. Hearing equipment should

comply with ANSI S3.19 standards.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools

when tired, intoxicated or when taking medications that

cause drowsiness.

WORK AREA PREPARATION

• Keep work area clean. Cluttered work areas and

benches invite accidents.

• Work area should be properly lighted.

• Do not use the machine in a dangerous environment.

The use of power tools in damp or wet locations or in

rain can cause shock or electrocution.

• Three-prong plug should be plugged directly into

properly grounded, three-prong receptacle.

• Use the proper extension cord. Make sure your

extension cord is in good condition and should have a

grounding prong and the three wires of

extension cord should be of the correct gauge.

• Keep children and visitors away. Your shop is a poten tially dangerous environment. Children and visitors can

be injured.

• Make your workshop childproof with padlocks, master

switches or remove switch keys to prevent any uninten tional use of power tools.

TOOL MAINTENANCE

• Turn the machine "OFF", and disconnect the machine

from the power source prior to inspection.

• Maintain all tools and machines in peak condition. Keep

tools sharp and clean for best and safest performance.

• Follow instructions for lubricating and changing

accessories.

• Check for damaged parts. Check for alignment of

moving parts, binding, breakage, mounting and any

other condition that may affect tool's operation.

• Poorly maintained tools and machines can further

damage the tool or machine and/or cause injury.

• A guard or any other part that is damaged should be

repaired or replaced. Do not perform makeshift repairs.

TOOL OPERATION

• Avoid accidental start-up. Make sure that the tool is in

the “OFF” position before plugging in.

• Use the right tool for your job. Do not force your

tool or attachment to do a job for which it was not

designed.

• Disconnect tool when changing parts.

• Don't force the workpiece on the machine. Damage to

the machine and/or injury may result.

• Never leave tool running unattended. Turn the power off

and do not leave tool until it comes to a complete stop.

• Do not overreach. Loss of balance can make you fall

into a working machine, causing injury.

• Never stand on tool. Injury could occur if the tool tips, or

if you accidentally contact the cutting tool.

• Know your tool. Learn the tool’s operation, application

and specific limitations before using it.

• Use recommended accessories. Use of improper

accessories may cause damage to the machine or injury

to the user.

• Handle workpiece correctly. Keep hands away from

moving parts.

• Turn tool off if it jams.

• Always feed workpiece against the direction of the

sanding rotation. To maintain control, properly support

long or wide work-pieces.

CAUTION: Think safety! Safety is a combination of operator common sense and alertness at all times when tool is

being used.

WARNING

Do not attempt to operate tool until it is completely

assembled according to the instructions.

2

B

A

C

D

E

F

G

H

ASSEMBLY

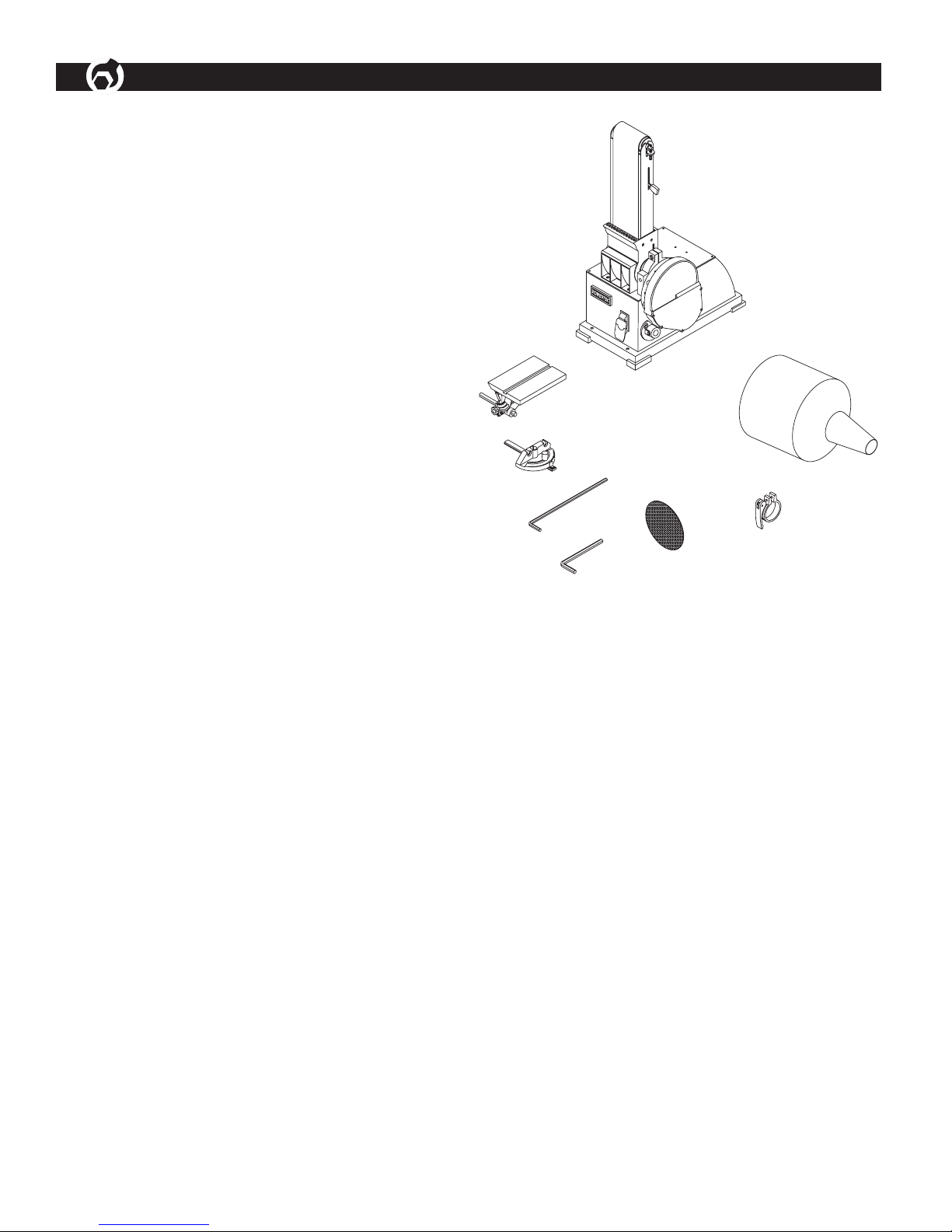

UNPACKING

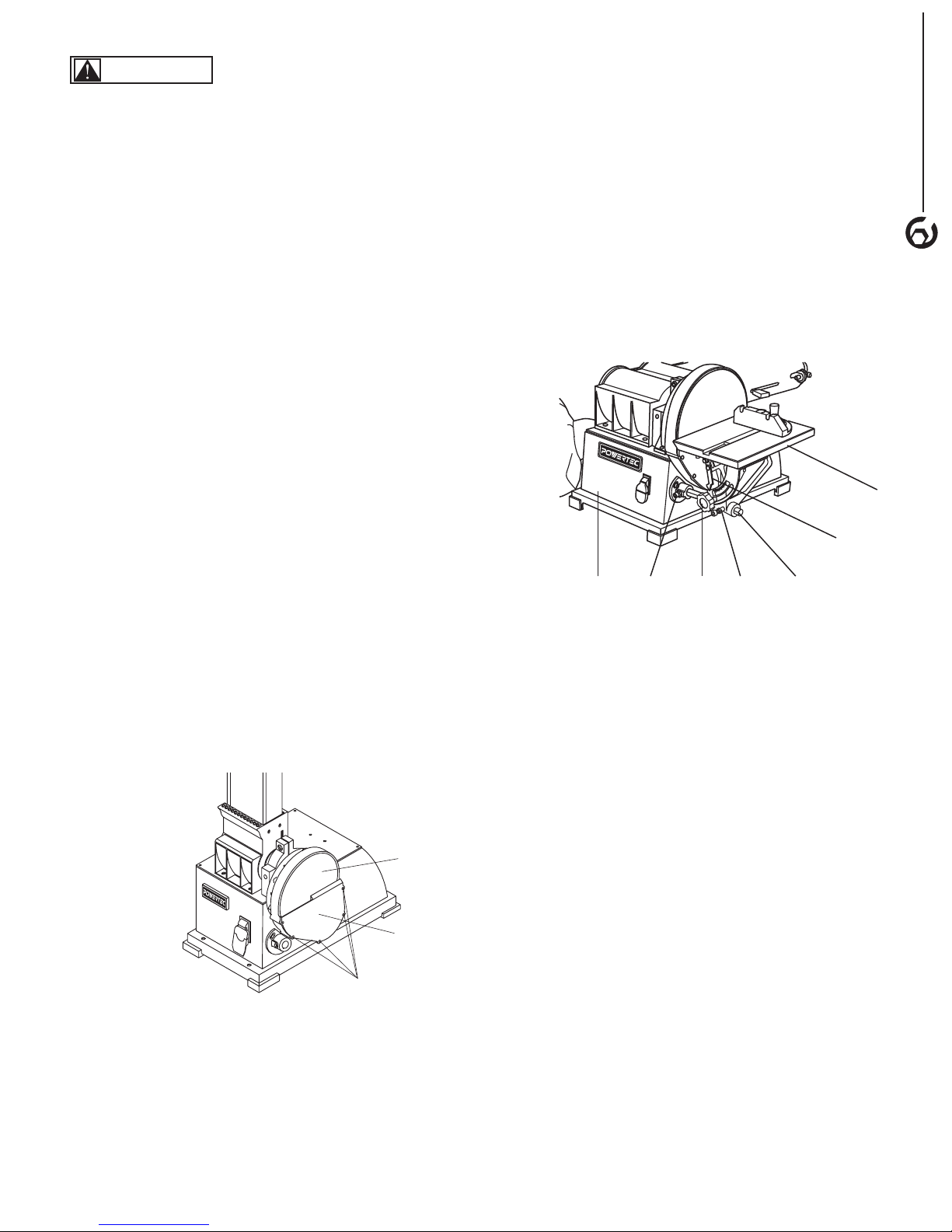

Refer to Figure 1.

Check for shipping damage. Check immediately whether

all parts and accessories are included.

The sander comes assembled as one unit. Additional

parts which need to be fastened to sander, should be

located and accounted for before assembling.

ITEM DESCRIPTION QUANTITY

A Sander 1

B Dust Collection Bag 1

C Bag Clamp 1

D Mitre Gauge Assembly 1

E Table Assembly 1

F Disc 1

G Wrench (4 mm) 1

H Wrench (6 mm) 1

Figure 1

WARNING

c

a

b

j h dli

g

k

Do not use the machine until it is completely assembled

and you have read and understood the entire operating

manuals.

TOOLS NEEDED

You will need the following tools to assemble and adjust

the machine. (The tools are not included.)

• 10mm Wrench

• 5 and 6mm Hex Wrenches

• Combination Square

• Phillips Screwdriver

MOUNT SANDER

• The machine must be installed in a well-lighted area

with correct power supply.

• The machine can be installed on either a workbench or

a tool stand by using bolts, lock washers, and hex nuts.

• The machine must be bolted to a firm and level surface.

• There must be enough clearance for the moving

workpiece during operation. There must be enough

room for safety operation of the machine.

• Slide the Table Assembly (g) onto the Supporting Rod

(d) and position the table platform in level position.

• Adjust the distance between the table platform and

the Sanding Disc so it is 1/16” or less. Do not allow the

Sanding Disc to touch any part of the Table Assembly

(g).

• Secure the Table Assembly (g) in position with the Bolt

(h). Tighten the Bolt (h) against the flat surface of the

Supporting Rod (d). Check that Table Assembly (g) is

stable.

• Set the table 90 degree (Perpendicular) to the Sanding

Disc with a Combination Square. Secure the table in

position by tightening the knob (j) on the tilt angle scale

under the table platform.

• Zero the angle indicator: set the pointer (k) to 0 degree.

Figure 3

ASSEMBLY

3

ATTACH ABRASIVE DISC

Refer to Figure 2

• Remove all screws (b) and remove the Disc Cover (a).

• Clean the surface of the aluminum disc.

• Peel off the protective paper on the back of the Abrasive

Disc (c).

• With the adhesive side facing the aluminum disc,

carefully place the Abrasive Disc (c) onto the center of

aluminum disc.

• Confirm the position is satisfactory before press the

Abrasive Disc (c) firmly and evenly against the

aluminum disc in the entire area.

• Replace the Disc Cover (a) and tighten with screws (b).

Figure 2

ATTACH THE TABLE ASSENBLY TO USE

WITH SANDING DISC

Refer to Figure 3

• Insert the Supporting Rod (d) into the mount on the side

of base (i), to the left lower corner of the Sanding Disc.

• Secure the Supporting Rod (d) onto the base (i) by

tightening the Bolt (l) against the flat surface of the

Supporting Rod (d). Check that Supporting Rod (d) is

stable and will not roll.

ATTACH THE TABLE ASSEMBLY TO USE

WITH SANDING BELT

Refer to Figure 4

• With the Sanding Belt Assembly in upright position,

locate the Mount (e) of side of Sanding Belt Assembly.

• Insert the Support Rod (d) into the Mount (e). Secure

the Supporting Rod (d) onto the Mount (e) by tightening

the Bolt (f) against the flat surface of the Supporting Rod

(d). Check that Supporting Rod (d) is stable and will not

roll.

• Slide the Table Assembly (g) onto the Supporting Rod

(d) and position the table platform in level position.

• Adjust the distance between the table platform and the

Sanding Belt so it is 1/16” or less. Do not allow the

Sanding Belt to touch any part of the Table Assembly

(g).

• Secure the Table Assembly (g) in position with the Bolt

(h). Tighten the Bolt (h) against the flat surface of the

Supporting Rod (d). Check that Table Assembly (g) is

stable.

• Set the table 90 degree (Perpendicular) to the Sanding

Belt with a Combination Square. Secure the table in

position by tightening the knob (j) on the tilt angle scale

under the table platform.

• Zero the angle indicator: by setting the pointer (k) to 0

degree.

ASSEMBLY

j

h

k

g

d

n

m

f

e

Grounded outlet Box

3 - Prong Plug

Grounding Prong

Grounding

Means

Grounded outlet Box

Adapter

4

Figure 4

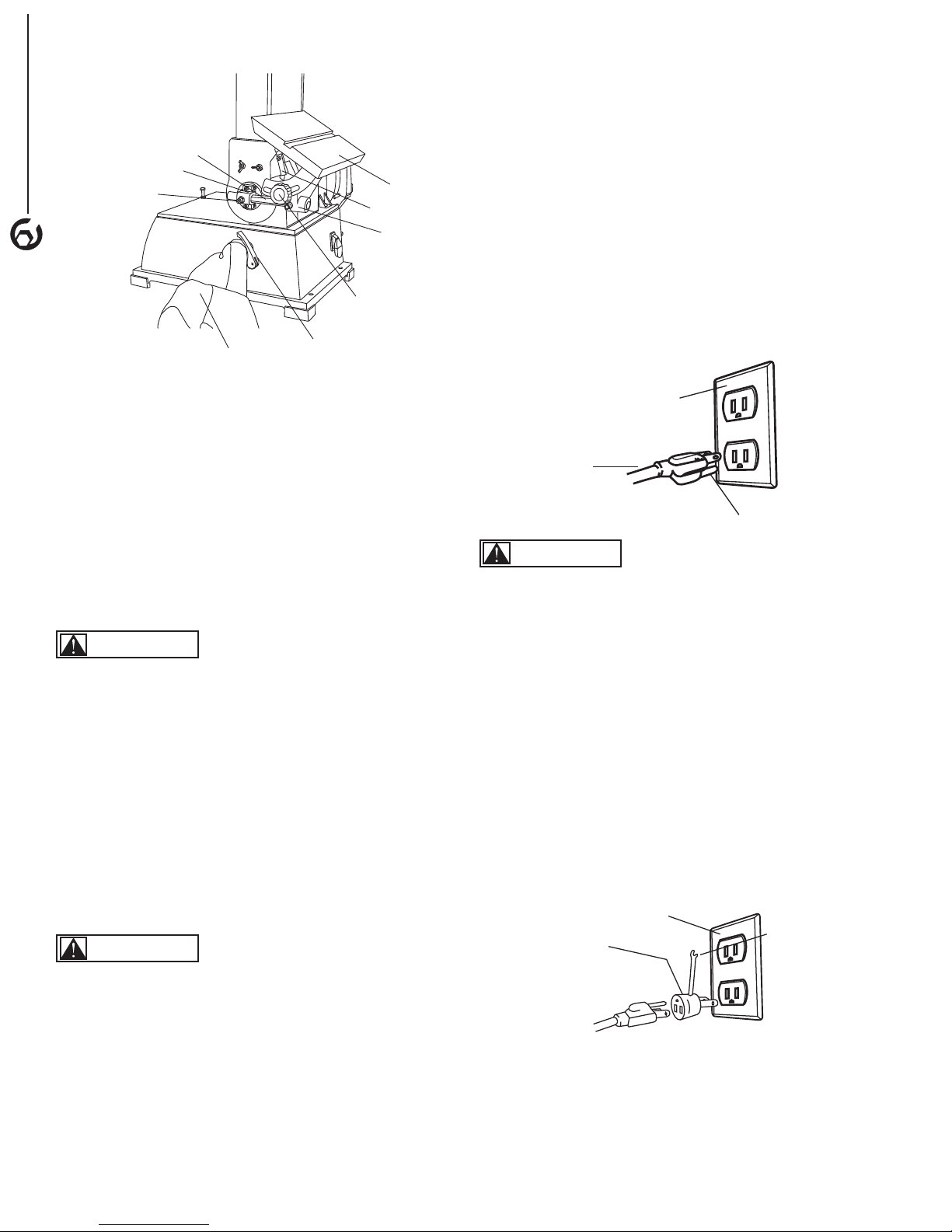

• Grounding plug should be plugged directly into a

properly installed and grounded 3-prong grounding-type

receptacle, as shown (Figure 5)

• The plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

• Check with a qualified electrician or service personnel if

these instructions are not completely understood or if in

doubt as to whether the tool is properly grounded.

• Do not modify plug provided. If it will not fit in outlet,

have proper outlet installed by a qualified electrician.

Use only 3-wire extension cords, that have 3-prong

grounding type plugs and matching 3-conductor

receptacles that accept the machine's plug, as show in

Figure 5

ATTACH THE DUST COLLECTION BAG

Refer to Figure 3

• Slide the Clamp (m) over the Sleeve of Dust Collection

Bag (n).

• Locate the Dust Port on the side of the Base.

• Place the Dust Collection bag (n) and Clamp over the

Dust Port. If necessary, adjust the size of the Clamp (m)

opening by rotating the handle on the Clamp (m).

• Tighten the Clamp (m) by pressing the handle. Check

that the Dust Collection Bag (n) is securely attached to

the Dust Port.

POWER SOURCE

WARNING

Do not connect to the power source until the machine is

completely assembled.

The machine is wired for 120 volts, 60 HZ alternating

current. Before connecting the machine to the power

source, make sure the switch is in the "OFF" position.

Running the unit on voltages which are not within range

may cause overheating and motor burn-out. Heavy loads

require that voltage at motor terminals be no less than the

voltage specified on nameplate.

• Power supply to the motor is controlled by a locking

rocker switch. Remove the key to prevent unauthorized

use.

Figure 5

WARNING

Do not permit fingers to touch the terminals of plug when

installing or removing from outlet.

• Inspect tool cords periodically, and if damaged, have

repaired by an authorized service facility.

• The conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or replacement

of the electric cord or plug is necessary, do not connect

the green (or green and yellow) wire to a live terminal.

A temporary 3-prong to 2-prong grounding adapter (see

Figure 6) may be used to connect this plug to a matching

2-conductor receptacle as shown in figure 6. The

temporary adapter should be used only until a properly

grounded outlet can be installed by a qualified electrician.

Figure 6

GROUNDING INSTRUCTIONS

WARNING

Improper connection of equipment grounding conductor

can result in the risk of electrical shock.

• The machine should be grounded while in use to protect

operator from electrical shock.

• In the event of an electrical short circuit, grounding

reduces the risk of electrical shock by providing an

escape wire for the electric current.

• This machine is equipped with an approved

3-conductor cord rated at 150V and a 3-prong

grounding type plug for your protection against shock

hazards.

In Canada, the use of temporary adapter is not permitted

by the Canadian Electric Code. Where permitted, the rigid

green tab or terminal on the side of the adapter must be

securely connected to a permanent electrical ground such

as a properly grounded water pipe, a properly grounded

outlet box or a properly grounded wire system.

Loading...

Loading...