Page 1

Page 2

INSTRUCTIONS PW220/PW230 1

INDEX

Warnings 2

1. Product Description 3

1.1 Applications ...............................................................................................................................................3

1.2 Description of The Automation .................................................................................................................3

1.3 Description of Devices ...............................................................................................................................3

1.3.1 PW220/PW230 Electromechanical Gear Motors ..........................................................................4

1.3.2 PC160 Control Box ........................................................................................................................4

1.3.3 PH-1 Photocells .............................................................................................................................4

1.3.4 PKS-1 Key Selector .......................................................................................................................5

1.3.5 PPB-1 Push Button ........................................................................................................................5

1.3.6 PF-1 Flashing Light .......................................................................................................................5

1.3.7 PR-1 Radio Transmitter .................................................................................................................5

1.3.8 PEL-1 Electric Latch and PS-1 Stopper ........................................................................................6

2. Installation 6

2.1 Notes of Motors in Operation .....................................................................................................................6

2.1.1 Tools in Installing ..........................................................................................................................6

2.1.2 Motors, Components and Its Installation in Illustration……........................................................7

2.2 Power Connection .....................................................................................................................................7

2.2.1 Notes for Power Connection ..........................................................................................................7

2.3 Installation ..................................................................................................................................................8

2.3.1 Preparation for Motor Installation .................................................................................................8

2.3.2 Installation of The Gear Motors ...................................................................................................10

2.3.3 PKS-1 Key Selector .....................................................................................................................12

2.3.4 PPB-1 Push Button ......................................................................................................................13

2.3.5 PF-1 Flashing Light .....................................................................................................................14

2.3.6 PH-1 Photocells ...........................................................................................................................15

2.3.7 PEL-1 Electric Latch and PS-1 Stopper ......................................................................................16

2.3.8 PC160 Control Box ......................................................................................................................18

3. Dip Switch Setting 21

3.1 Functional Switch and LED lights Introduction........................................................................................22

3.2 Transmitter Memorizing and Erasing Process...........................................................................................23

3.3 System Learning Process……………………….......................................................................................24

3.4 Gate Operation…………..........................................................................................................................24

3.5 Gate-moving Logic....................................................................................................................................24

4. Trouble Shooting 25

5. Technical Characteristics 25

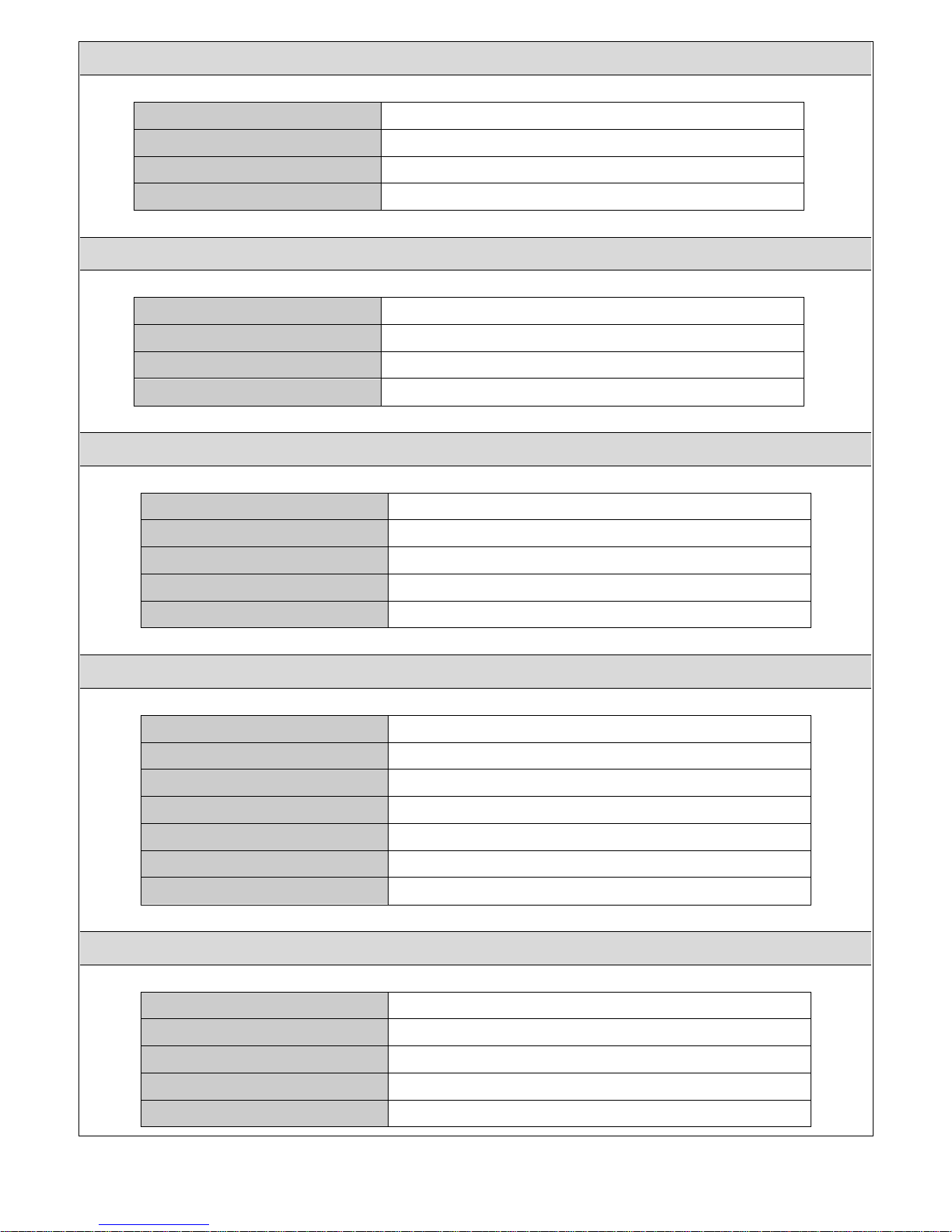

5.1 PW220 ......................................................................................................................................................25

5.2 PW230 ......................................................................................................................................................26

5.3 PC160 Control Box .................................................................................................................................26

5.4 PH-1 Photocells .......................................................................................................................................26

5.5 PKS-1 Key Selector ................................................................................................................................27

5.6 PPB-1 Push Button .................................................................................................................................27

5.7 PF-1 Flashing Light .................................................................................................................................27

5.8 PR-1 Transmitter .....................................................................................................................................27

5.9 PEL-1 Electric Latch ...............................................................................................................................27

6. Annexes 28

6.1 CE Declaration of Conformity .................................................................................................................28

Page 3

2 INSTRUCTIONS PW220/PW230

Warnings

Please read this instruction manual carefully before the

installation of gate-automated system.

This manual is exclusively for qualified installation

personnel. Powertech Electronics Inc. is not responsible for

improper installation and failure to comply with local electrical

and building regulations.

Keep all the components of PW220/PW230 system and this

manual for further consultation.

In this manual, please pay extra attention to the contents

marked by the symbol:

Be aware of the hazards that may exist in the procedures of

installation and operation of the gate-automated system.

Also, the installation must be carried out in conformity with

local standards and regulations.

If the system is correctly installed and used following all

the standards and regulations, it will ensure a high degree of

safety.

Make sure that the gates works properly before installing

the gate-automated system and confirm the gates are

appropriate for the application.

Do not let children operate or play with the gate-automated

system.

Do not cross the path of the gate-automated system when

operating.

Please keep all the control devices and any other pulse

generator away from children to avoid the gate-automated

system being activated accidentally.

Do not make any modifications to any components except

that it is mentioned in this manual.

Do not try to manually open or close the gates before you

release the gear motors.

If there is a failure that cannot be solved and is not

mentioned in this manual, please contact qualified

installation personnel.

Do not use the gate-automated system before all the

procedures and instructions have been carried out and

thoroughly read.

Test the gate-automated system weekly and have qualified

installation personnel to check and maintain the system at

least every 6-month.

Install warning signs (if necessary) on the both sides of the

gate to warn the people in the area of potential hazards.

Page 4

INSTRUCTIONS PW220/PW230 3

1 Product Description

1.1 Applications

PW220/PW230 is applied for residential automation of single or dual leaf gate. PW220/PW230 has to be operated with electricity and it’s

forbidden to be operated by back-up batteries for normal use. Back-up batteries are only allowed for emergent operation when there is a

power failure, and the gear motors can be released by special keys to move the gate manually.

1.2 Description of the Automation

The following diagram of PW220/PW230 typical installation describes some terms and accessories of a gate automation system:

Figure 1

1.3 Description of Devices

PW220/PW230 includes the accessories shown in Figure 2.

Please check the accessories the same as the package provided.

Attention: Some accessories of PW220/PW230 are not

included due to local regulations or customized order.

A) 2 PW220/PW230 electromechanical gear motors with

mounting brackets.

B) 2 release keys.

C) 1 pair of PH-1photocells.(one TX and one RX)

D) 2 PR-1 radio transmitters.

E) 1 PKS-1 key selector with two keys.

F) 1 PPB-1 push button switch.

G) 1 PF-1 flashing light.

H) 1 PC160 control box

I) 1 PEL-1 electric latch.

J) 1 PS-1 stopper.

K) Various small parts: bolts, nuts, etc.

See Tables 1, 2, 3, 4, 5, 6.

Figure 2

Page 5

4 INSTRUCTIONS PW220/PW230

1.3.1 PW220/PW230 Electromechanical Gear Motors

1.3.2 PC160 Control Box

1.3.3 PH-1 Photocells

Figure 3

1)PW220 2)PW230 3)Release Key

Figure 4

Table 2: List of small parts for PC160 Quantity

5*30 Screw 4pcs

Nylon screw anchor 4pcs

Figure 5

The pair of PH-1 photocells has to be installed on the wall and

connected to the control panel. The function of the photocells

is to detect the obstacles found on the optical axis between the

transmitter (TX) and the receiver (RX).

PC160 control box consists of one control panel with incorporated receiver,

one transformer and two back-up batteries.

PC160 provides the complete automation of the gear motors and other

accessories of PW220/PW230 kit.

To connect separate terminals on the control panel and activate the gear

motors and other accessories, the installation manual has to be carefully read

beforehand.

PW220/PW

2

30 cons

ists of a worm screw reduction gear and a 24V

direct current motor. The gear motor could be released manually by

special release keys when there is a power failure.

The gear motor is installed with two post brackets, one rear plate and

one front plate for the installation.

Table 1: Lis

t of

small parts PW220 PW230

Front plate

2pcs 2pcs

Rear plate

2pcs 2pcs

Post bracket

4pcs 4pcs

M8*25L hex bolt

4pcs 4pcs

M8 self-locking nut

4pcs 4pcs

M12 *25L hex bolt

0 2pcs

M12 self-locking nut

2pcs 2pcs

Release key

2pcs 2pcs

Front

Rear

Page 6

INSTRUCTIONS PW220/PW230 5

1.3.4 PKS-1 Key Selector

Table 3: List of small parts for PKS-1 Quantity

3*20 Screw 3pcs

Nylon screw anchor 3pcs

Key 2pcs

1.3.5 PPB-1 Push Button

Table 4: List of small parts for PPB-1 Quantity

3*20 Screw 3pcs

Nylon screw anchor 3pcs

1.3.6 PF-1 Flashing Light

Table 5: List of small parts for PF-1 Quantity

3*20 Screw 3pcs

Nylon screw anchor 3pcs

1.3.7 PR-1 Radio Transmitter

Figure 6

Figure 7

Figure 8

Figure 9

PR-1 radio transmitter is used for the remote control of the gate

movement.

To use the transmitter, press and hold the button for 1 second.

There are two buttons on the transmitter for operating dual-gate (A)

or single-gate (B) opening and closing.

PF-1 flashing light is controlled by PC160 control box and blinks

when the gate is moving. The flashing light stops blinking when the

gates finish opening or closing.

The PPB-1 push button is used for opening the gate indoors

without the radio transmitter.

The PKS-1 key selector is used for opening the gate outdoors

without the radio transmitter. PKS-1 key selector is supplied

with two keys

Page 7

6 INSTRUCTIONS PW220/PW230

1.3.8 PEL-1 Electric Latch and PS-1 Stopper

Table 6: List of small parts for PEL-1 and PS-1 Quantity

M8*25L hex bolt 3pcs

M8 self-locking nut 3pcs

Key 2pcs

2. Installation:

2.1 Notes of Motors in Operation

The PW220/PW230 gate openers are applicable to per leaf of 2.5/3.5 meters in width and 200/300 kg in weight which can be opened up

to 110 degrees primarily for residential use; where the performance shall be influenced by the factors such as gate dimension, weight and

climate that the driven torque is necessarily to be adjusted properly.

2.1.1 Tools in Installing

Please make sure all tools and cables are ready and conform to the industrial safety standard before installation. Please refer to

Figure 11.

Figure 11

Figure

10

PEL-1 electric latch is used to lock the gate and it has to be

used with PS-1 stopper and installed on the master gate.

Page 8

INSTRUCTIONS PW220/PW230 7

2.1.2 Motors, Components and Its Installation in Illustration

The installation procedure of PW220/PW230 may be changed due to various accessories and quantities installed. The basic wiring

diagram is shown in Figure 12.

No wiring cables for accessories are supplied with KIT PW220/PW230.

Figure 12

2.2 Power Connection

PW220/PW230 is required to connect two cores wires, which requires very low voltage that no professionally trained personnel is

required in installation; however, the users are advised to read the installation manual carefully before going for it. After getting to know

all accessories and their positions, suggest starting from cable conduit arrangement to prevent the cables from being broken or damaged.

2.2.1 Notes for Power Connection

1. The installation of power supply cable to the motor should be carried out by a qualified professional electrician.

2. The power supply cable of the motor should be equipped with short circuit protection and leakage protection. Please make

sure to shut off the power before going installation or maintenance.

Page 9

8 INSTRUCTIONS PW220/PW230

2.3 Installation

2.3.1 Preparation for Motor Installation

PW220/PW230 is not applicable to a gate which is inefficient or unsafe, neither to solve the defects due to incorrect installation nor

poor maintenance.

Check the following items before going for installation:

1. Make sure the weight and dimensions of the gate conform to the operation range of PW220/PW230. Don’t

use PW220/PW230 if the gate specifications do not meet the requirements.

2. Make sure the gate structure conform to the criteria of automatic operation and force regulations.

3. Make sure there is no serious friction existing in the opening or closing travel of the gate leaves.

4. Make sure the gate is at horizontal level that the gate will not move aside at any position.

5. Make sure the gate can bear the impact of the motor torque when it is installed on any hole of the bracket which the surface

is sufficiently sturdy.

6. Make sure the photo sensors are installed on flat surfaces to ensure the two ends of receiving and transmitting corresponded

to each other.

7. Check the dimensions of the motors as below.

Figure 13

(1) Dimension of PW220 (2) Dimension of PW230

8. Make sure to leave enough space when the gate is opening.

Figure 14 (aerial view)

(1)PW220 (2)PW230

Page 10

INSTRUCTIONS PW220/PW230 9

9. If the gate is OPENED OUTWARD, please leave at least 70mm between the post brackets and the gate.

Figure 15 (aerial view)

(1)PW220 (2)PW230

10. Using the leaf-opening angle as criteria to make sure all criteria in Figure 17 can be met.

Figure

16

(aerial view)

(1) PW220 (2) PW230

Figure 1

7

(1) PW220 (2) PW230

Model:PW220 Model:PW230

11. “C” value is 139mm.

12. “D” can be measured from the gate easily.

Page 11

10 INSTRUCTIONS PW220/PW230

13. “A” = “C” + “D”

14. The value of “B” can be calculated from the value of “A” and the leaves opening angle. Ex. If “A”=160mm with the leaves

opening angle of 100 degrees, then the value of “B” is approximate 190mm.

**Please make sure “B” and “A” are similar or the same in value that the leaves can be operated smoothly, also to reduce the

burden of the motor.

2.3.2 Installation of The Gear Motors

1. Choose the correct dimensions of the motors and

position to be installed.

2. Check if the mounting surface the brackets to be

installed is smooth, vertical and rigid.

3. Arrange the cable conduit for power supply cable of the

motors.

4. In order to obtain the optimal supporting from the rear

plate, please assemble two post brackets and one rear

metal plate according to Figure 18.

Figure 18

5. Loosen the two screws and remove the back cover of the

motor as shown in Figure19.

Figure 19

6. Place the leaves in the closed position.

7. Refer to the distance of “B” in Figure 17, place the rear

plate in the correct position on the mounting surface.

Inspect if the distance is proper as shown in Figure 23

i.e. the position the front plate of the motor to be

installed.

Figure 20

8. Place two post brackets on the surface to be installed and

mark the drilling points, then drill minimum diameter of

8mm holes by four on the mounting surface to be

installed and fasten up the brackets with screws and

washers.

Figure 21

9. Please make sure the front plate is completely installed

horizontally.

Figure 22

PW230

Page 12

INSTRUCTIONS PW220/PW230 11

10. Refer to Figure 23, the distance between front plate of

the motor and rear plate is 735mm (PW220) / 798mm

(PW230), the difference in height is 18.3mm (PW220) /

22.5mm (PW230).

Figure 23

(1) PW220

(2) PW230

11. Clamp and fix the motor front plate on the door

temporarily.

Figure 24

(1) PW220

(2) PW230

12. Lift up the motor and insert the screws into the front

plate.

13. Lift the motor overhead and push the gate to the end until the

screw holes of the motor end matches the holes on the rear plate.

Fasten the motor to the rear plate with the bolt as shown in

Figure25.

Figure 25

14. Fasten the nut tightly and loosen it for half round for

motor supporting in rotating.

15. Fasten the motor front end to the front plate with the bolt (A)

and nut (B) tightly. Fully tighten the screw.

Figure 26

(1) PW220

(2) PW230

16. Use appropriate release key to release the gear motor.

17. Try to push the released gate and make sure the motor can be

manually moved easily.

18. Make sure the motor front plate can be fastened on the gate

to be installed permanently.

19. Use the appropriate release key to fasten the gear motor

again.

20. Loosen the plastic nut under the power cable of the motor

end, and penetrate the power cable through the nut and screw

it up.

21. Connect the motor power cable as shown in Figure 27.

Figure 27

22. Close the gear motor cover by tightening the two screws

as shown in Figure28.

Figure 28

Page 13

12 INSTRUCTIONS PW220/PW230

23. Gear Motor Release

1) Turn the round plate on the release part to “OPEN” position.

See Figure 29.

Figure 29

2) Push out the release part to the end. See Figure 30.

Figure 30

3) Use the release key to turn the pin anti-clockwise

to the end. See Figure 31.

Figure 31

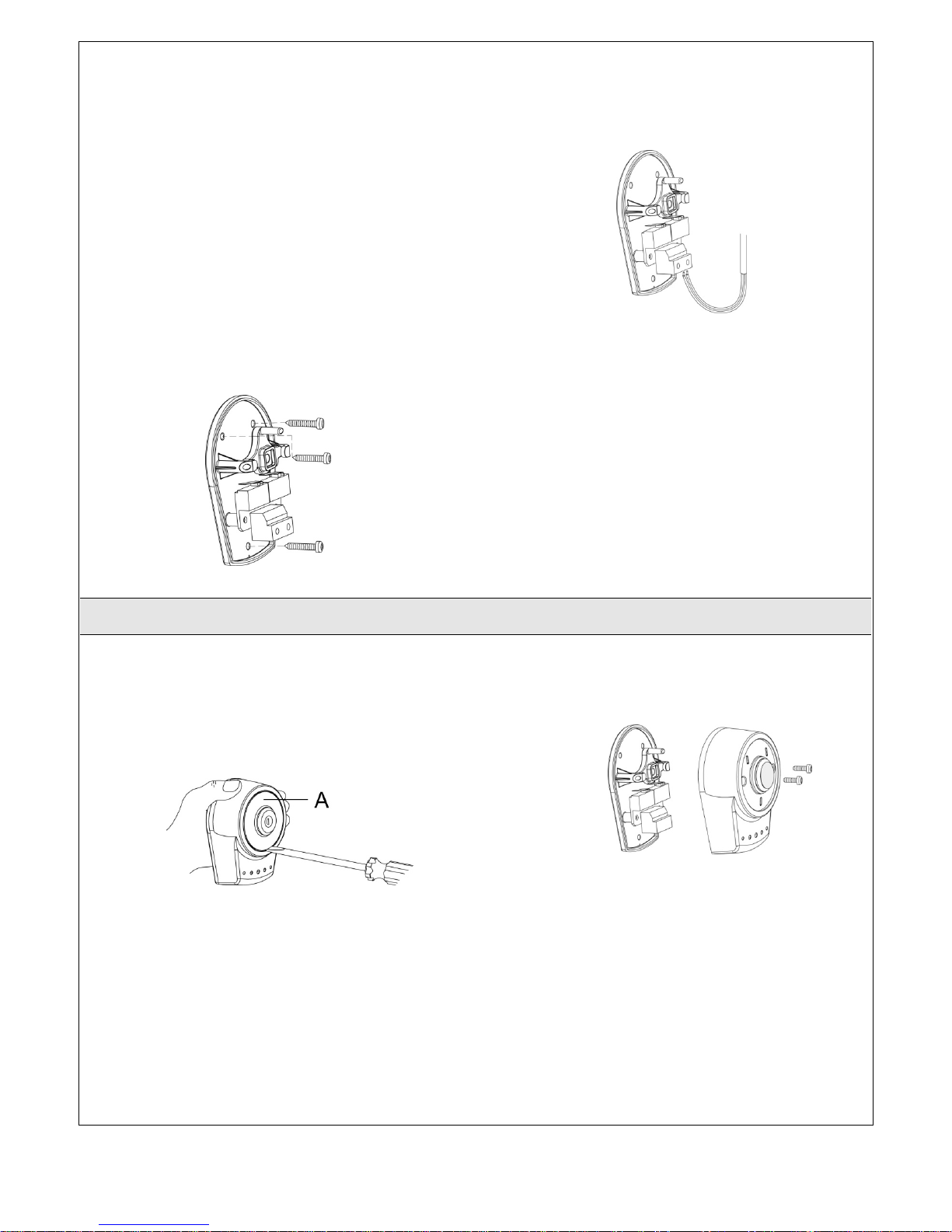

2.3.3 PKS-1 Key-Selector

1. PKS-1 key selector is installed outside and close to

the gate at the height of about 100cm, so that it

could be used by most people. Decide the

installation position of PKS-1 first. See Figure

2.3.3 (1).

Figure 2.3.3 (1)

2. Remove the round cover (A) by prizing it out with

the tip of a screwdriver. See Figure 2.3.3 (2).

Figure 2.3.3 (2)

3. Unscrew the two screws beside the lock body.

See Figure 2.3.3 (3).

Figure 2.3.3 (3)

Page 14

INSTRUCTIONS PW220/PW230 13

4. Turn the key and separate the bottom of the shell

with the lock body. See Figure 2.3.3 (4).

Figure 2.3.3 (4)

5. Breach the three holes at the bottom and mark the

points by the holes as reference.

6. Drill the holes in the wall and fix the bottom to the wall

by three screws. See Figure 2.3.3 (5).

Figure 2.3.3 (5)

7. Connect the electric wires to the terminals as

shown in Figure 2.3.3(6), and it’s not required to

distinguish any polarity. The terminals can be

removed for connecting the wires easily.

Figure 2.3.3 (6)

8. Turn the key and insert the shell on the bottom.

Turn the key back to the center position and the

shell will be fixed to the bottom.

9. Tighten the lock body with the two screws and

insert the round cover by pressing it to attach to the

whole unit.

2.3.4 PPB-1 Push Button

1. PPB-1 push button is installed indoors at the height of

about 100cm, so that it could be used by most people.

2. Remove the round cover (A) by prizing it out with the

tip of a screwdriver. See Figure 2.3.4 (1).

Figure 2.3.4 (1)

3. Unscrew the two screws beside the button.

Figure 2.3.4 (2)

4. Separate the upper shell with the bottom. See Figure

2.3.4 (2).

5. Breach the three holes at the bottom and mark the points

by the holes as reference.

Page 15

14 INSTRUCTIONS PW220/PW230

6. Drill the holes in the wall and fix the bottom to the wall

by three screws. See Figure 2.3.4 (3).

Figure 2.3.4 (3)

7. Connect the electric wires to the terminals as shown in

Figure 2.3.4 (4), and it’s not required to distinguish any

polarity. The terminals can be removed for connecting the

wires easily.

Figure 2.3.4 (4)

8. Attach the upper shell to the bottom and screw them up by

two screws and insert the round cover by pressing it to attach

to the whole unit.

2.3.5 PF-1 Flashing Light

1. Decide the installation position of the flashing light. The

flashing light has to be installed near the gate and easy to

be seen by users and passersby. The flashing light can be

installed horizontally or vertically. See Figure 2.3.5 (1).

Figure 2.3.5 (1)

2. Unscrew the four screws on the light base and separate

the base with the bottom as shown in Figure 2.3.5 (2).

Figure 2.3.5 (2)

3. Connect the wires and penetrate the wires into the hole of

the base.

Figure 2.3.5 (3)

4. Drill the holes in the wall and fix the bottom to the wall

by three screws.

Figure 2.3.5 (4)

Page 16

INSTRUCTIONS PW220/PW230 15

5. Connect the four wires of the light and the antenna to

the PCB terminals and place the wires into the conduit if

necessary.

Figure 2.3.5 (5)

6. Tighten the four screws back on the light base.

Figure 2.3.5 (6)

7. Replacing the bulb set. See Figure 2.3.5 (7)

1) Unscrew the flashing light wires from the PCB terminals

and make sure the power of the light is off.

2) Release the three screws (A)、(B)、(C) of the flashing light

cover.

3) Separate the flashing light cover and replace the bulb set

with a new one.

4) Tighten the three screws (A)、(B)、(C) of the flashing light

cover.

Figure 2.3.5 (7)

2.3.6 PH-1 Photocells

1. Decide the installation position of the photocells. See

Figure 2.3.6 (1)

Figure 2.3.6 (1)

2. Unscrew the screws and secure the photocells on the post

A, B or C.

Figure 2.3.6 (2) Figure 2.3.6 (3)

3. Wiring connection:

TX: Connect terminals 1(+) and 2(-)on the transmitter with

the terminals 12V and GND on the PC160 PCB.

RX: Connect terminals 1, 2 and 4 on the receiver with the

terminals 12V, GND and SAFE on the PC160 PCB.

And use an extra wire to connect terminals 2 and 5 on the

receiver as a bridge.

See Figure 2.3.6 (4) Figure 2.3.6 (5) and Figure 2.3.8 (4)

Page 17

16 INSTRUCTIONS PW220/PW230

Figure 2.3.6 (4)

Figure 2.3.6 (5)

2.3.7 PEL-1 Electric Latch and PS-1 Stopper

1. Stopper:

1) Before installing the stopper, please make sure the gates are

in close positions and the surface to be installed is flat.

2) Place the stopper on the ground using the bottom as

reference, and mark the 3 drilling points.

See Figure 2.3.7 (1) For the gate opened inward.

See Figure 2.3.7 (2) For the gate opened outward.

Figure 2.3.7(1)

Note: If the gate is opened outward, place the stopper in

opposite direction.

Figure 2.3.7(2)

3) Drill the 3 marked points, and then securely attach the

stopper to the ground with screws and washers.

See Figure 2.3.7 (3)

Figure 2.3.7(3)

Page 18

INSTRUCTIONS PW220/PW230 17

2. Electric Latch:

(If the gate is opened outward)

1) If the gate is opened outward, please change the spring

inside and screw it in the different place.

See Figure 2.3.7 (4), Figure 2.3.7 (5),

Figure 2.3.7 (6) & Figure 2.3.7 (7)

Figure 2.3.7(4) Unscrew the screws.

Figure 2.3.7(5) Take the casing off.

Figure 2.3.7(6) The location of the spring.

Figure 2.3.7(7)

Change the spring and screw it in the different place.

(Installation)

2) Weld the back plate of the electric latch to the surface on

the master gate. See Figure 2.3.7 (8).

Please avoid melting the wires by the heat of the fixed

plate.

Figure 2.3.7(8) For the gate opened inward.

Figure 2.3.7(9) For the gate opened Outward.

Page 19

18 INSTRUCTIONS PW220/PW230

3) The gap between the bottom of electric latch and the

stopper should be less than 7mm. See Figure 2.3.7 (10)

Figure 2.3.7(10) For the gate opened inward.

Figure 2.3.7(11) for the gate opened Outward.

4) Connect the wires of the electric latch to the

terminal LATCH and GND on the PCB.

See Figure 2.3.8 (5)

2.3.8 PC160 Control Box

1. Decide the installation position of PC160 control box

first, it is suggested to be installed near the gate and

should be protected from possible damage. Be aware of

the motor cable length before deciding the installation

position.

2. Remove the cover by unscrewing the four screws on the

cover. See Figure 2.3.8 (1).

Figure 2.3.8 (1)

3. Use a screwdriver to puncture the holes beneath the

bottom of the control box. See Figure 2.3.8 (2).

Figure 2.3.8 (2)

4. Secure it on the wall. See Figure 2.3.8 (3).

Figure 2.3.8 (3)

Page 20

INSTRUCTIONS PW220/PW230 19

5. Wiring Connection:

Prepare all the wires of the accessories beforehand and connect the wires to the gear motors and accessories on the PCB as shown

in Figure 2.3.8 (4). All of the wiring connections of the accessories are not requested to distinguish the positive (+) and the

negative (-) polarity.

1) PF-1 Flashing light:

Connect the two wires from the flashing light to the terminal LIGHT and GND on the PCB.

2) PEL-1 Electric Latch:

Connect the two wires from the electric latch to the terminal LATCH and GND on the PCB.

3) PW220/PW230 Gear Motors:

Refer to Figure 2.3.8 (5) and connect the wires separately to the terminals on the PCB.

M1: Connect the motor wire (White +) to the terminals M1 (+), and (Yellow -) to the M1 (-).

M2: Connect the motor wire (White +) to the terminals M2 (+), and (Yellow -) to the M2 (-).

Notes:

For gates opened outward,

M1: Connect the motor wire (Yellow -) to the terminals M1 (+), and (White +) to the terminals M1 (-).

M2: Connect the motor wire (Yellow -) to the terminals M2 (+), and (White +) to the terminals M2 (-).

4) PH-1 Photocells:

Please remove the cover of JP1 and connect the wires to proper terminals.

5) PKS-1 Key Selector:

For Single leaf operationRefer to Figure 2.3.8 (4) and connect the two wires from the key selector to the terminal BUTT1

and GND (J7) on the PCB.

For Dual leaf operationRefer to Figure 2.3.8 (4) and connect the two wires from the key selector to the terminal BUTT2

and GND (J7) on the PCB.

6) PPB-1 Push Button:

For Single leaf operationRefer to Figure 2.3.8 (4) and connect the two wires from the key selector to the terminal BUTT1

and GND (J7) on the PCB.

For Dual leaf operationRefer to Figure 2.3.8 (4) and connect the two wires from the key selector to the terminal BUTT2

and GND (J7) on the PCB.

Page 21

20 INSTRUCTIONS PW220/PW230

Figure 2.3.8 (4)

Page 22

INSTRUCTIONS PW220/PW230 21

Figure 2.3.8 (5)

3. Dip Switch Setting

LIGHT DELAY:

ON: The flashing light blinks for 5 seconds before the gate moves.

OFF: The flashing light blinks and the gate moves simultaneously.

OPENING PHOTO:

When the gate moves in the opening phase, t

he photo sensor can be selected as

active or inactive.

ON:

In the opening phase, the gate will stop when the photo sensor is activated.

In the closing

phase, the gate will stop and open to the end when the photo

sensor is activated.

OFF:

In the opening phase, the gate will not stop when the photo sensor is

activated.

In the closing phase, the gate will stop and open to the end when the photo

sensor is activated.

Page 23

22 INSTRUCTIONS PW220/PW230

SLOW DOWN SPEED:

The final speed can be set when the gate is moving at slow-down speed

ON: The final speed = 55% normal speed.

OFF: The final speed = 70% normal speed.

AUTO CLOSE1:

The function of auto close or without auto close can be selected

AUTO CLOSE2:

The function of auto close or without auto close can be selected

DIP4 (Auto close1) DIP5 (Auto close2) Function

OFF OFF Without auto close function

OFF ON Auto close On, waiting time 50 seconds

ON OFF Auto close On, waiting time 25 seconds

ON ON Auto close On, waiting time 12 seconds

3.1 Functional Switch and LED lights Introduction

SW2

The button of transmitter memorizing and erasing.

VR1

Over-current limit can be adjusted from min 0.8Amp to Max 4.2 Amp.

VR2

The over-current sensitivity of Master Gate (M1) could be adjusted from 1.8 second to 3.8 second.

VR3

The over-current sensitivity of Master Gate (M1) could be adjusted from 1.8 second to 3.8 second.

VR4

Close delay of two leaves can be adjusted from min 0 second to Max. 7 second.

LED1(Red)

LED1 is ON when AC input is in. And LED1 blinks quickly when the gate is in slow-down speed.

LED2(Yellow)

When the photocells are triggered, LED2 will be on.

LED3(Green)

When the transmitter/push button/key selector is triggered, LED3 will be on.

NC: No Connection

Page 24

INSTRUCTIONS PW220/PW230 23

3.2 Transmitter Memorizing and Erasing Process

RF Transmitter Memorizing & Erasing

1.1.1 Press button SW2 for 1 second, the blue LED light on the receiver board will be on and receiver module will be

changed to “Learning Mode” for 10 seconds. During the period of learning mode, press the left button on the

transmitter, then the transmitter can be memorized by receiver module. (Up to 200 different transmitter can be

memorized) The blue light on the receiver board will blink twice after pressing the button on the transmitter. The

blue light on the receiver board will go off when the transmitter memorizing is done.

1.1.2 The memory can be cleared completely if the SW2 (code learning) is pressed continuously for 10 seconds after the

blue light.

Self-Learning mode for gate operation systems

Step1:

Connect the wires of two motors with terminal M1+/M1- & M2+/M2-

Step2:

Connect 230VAC with terminal J1 and battery with J2.

Setp3:

In single leaf installation, just connect the motor wires with terminal M1+/M1-

Step4:

Press SW2 button for more than 1 second and the blue light on the receiver board

is on. Press the left

button on the transmitter to m

emorize the transmitter with the receiver board. The blue light will be off

after the transmitter memorizing is done.

Step5:

In Single or Dual leaf installation, please press the left button of the remote control for system learning.

After pressing the left button, system learning will be executed step by step as follows:

1. Dual Gate:

Slave Gate Close → Master Gate Close → Master Gate Open → Slave Gate Open →

Slave

Gate Close → Master Gate Close

2. Single Mode :

Master Gate Close → Master Gate Open → Master Gate Close

Step 6:

If motor stops during the learning mode, please adjust the over current switch to proper position.

Page 25

24 INSTRUCTIONS PW220/PW230

3.3 System Learning Process

Connect the master motor wires to M1 terminals and the slave motor wires to M2 terminals correctly. If only one gate is installed,

the motor wires have to be connected to M1 terminals.

In system learning mode, the gates will proceed with the following procedures.

(A) Dual-Gate Mode: Slave Gate closes→ Master Gate closes→ Master Gate opens →Slave Gate opens →Slave Gate closes→

Master Gate closes.

(B) Single-Gate Mode: Master Gate closes→ Master Gate opens→ Master Gate closes.

Notes: System learning fails and needs to be learned again when an unpredictable interruption occurs.

3.4 Gate Operation

Figure 34

3.5 Gate-moving Logic

(A) In gate-opening phase: The gates stop if the transmitter/push button/key selector is activated, and close when the

transmitter/push button/key selector is reactivated.

(B) In gate-closing phase: The gates stop if the transmitter/push button/key selector is activated, and open when the

transmitter/push button/key selector is reactivated.

(C) In gate-opening or gate-closing phase: For safety purpose, the gates stop if encountering obstacles.

In dual gate installation:

Press the button “A” on the transmitter for dual-gate operation.

Press the button “B” on the transmitter for single-gate

operation.

In single gate installation:

Press the button “A” on the transmitter for single-gate

operation

.

Page 26

INSTRUCTIONS PW220/PW230 25

4. Trouble Shooting

Overheated Back-up Batteries

Check the wiring connection of the batteries.

The gate doesn’t move when pressing the

button of the transmitter

1. Check if the voltage of the batteries is below 21V.

2. Check if LED1 is “ON”.

3. Make sure all the wiring connections are firmly connected to the

terminals on the PCB.

4. Make sure the fuse is workable.

The Flashing light does not work

1. Check if the wiring connection of the flashing light is correct.

2. Check if the bulb is burned.

The leaves shall be closed instead of

opening

Change the polarity connection of the positive (+) with the negative (-)

of the gear motors.

The leaves does not move or only move

toward one direction

1. Check if the “RESET” socket is activated.

2. Make sure the wiring connection of the gear motors is firm.

3. The GND terminal of the photocells on the PCB must be

short-circuited if no photocells installed.

The master gate closes to the end first

and the slave gate stops, the flashing

light blinks fast for five seconds.

Cut off the AC input power and the output of the batteries. Release the

master gate and slave gate manually, then open the master to the end

and close the slave gate to the end by hand, then power the whole unit

by connecting the AC and battery terminals.

The gear motors does not run and the

relay is noisy when operating the gate

opening and closing.

Check if the fuse is burned.

5. Technical Characteristics

5.1 PW220

Motor

24Vdc motor with mechanical release

Gear type

Worm gear

Peak thrust

2500N

Nominal thrust

2000N

Stroke length

356mm with mechanical stop/400mm without mechanical stop.

Power supply

24Vdc

Maximum operating current

4A for maximum 10 seconds.

Maximum gate weight

200 kg per leaf

Maximum gate length

2.5 meters

Duty cycle

20%

Operating Temperature

-20℃~+50℃

Dimension

819mm * 115mm * 106mm

Weight

6.0kg

Page 27

26 INSTRUCTIONS PW220/PW230

5.2 PW230

Motor

24Vdc motor with mechanical release

Gear type

Worm gear

Peak thrust

3000N

Nominal thrust

2500N

Stroke length

350mm

Power supply

24Vdc

Maximum operating current

4A for maximum 10 seconds.

Maximum gate weight

300 kg per leaf

Maximum gate length

3 meters

Duty cycle

20%

Operating Temperature

-20℃~+50℃

Dimension

844mm * 115mm * 106mm

Weight

6.25kg

5.3 PC160 Control Box

Application

For PW220/PW230 power supply

Main power supply

230Vac/110Vac, 50Hz/60Hz

Back-up battery

2pcs of batteries for emergency operation, 1.2A each

Transformer

4.2A, 24V

Receiver board

433.92MHz; 200 transmitters memory

Installation

Wall mounted vertically

Operating Temperature

-20℃~+50℃

Dimension

275mm * 195mm * 102mm

5.4 PH-1 Photocells

Detection type

Through beam

Operating distance

30 meters

Response time

100ms

Input voltage

AC/DC 12~24V

Operating Temperature

-20℃~+60℃

Protection class

IP66

Dimension

59mm * 87mm * 38mm

Page 28

INSTRUCTIONS PW220/PW230 27

5.5 PKS-1 Key Selector

Application

For outdoor use

Installation

Wall mounted vertically

Operating Temperature

-20℃~+50℃

Dimension

85mm*60.5mm*40.5mm

5.6 PPB-1 Push Button

Application

For indoor use

Installation

Wall mounted vertically

Operating Temperature

-20℃~+50℃

Dimension

85mm*60.5mm*40.0mm

5.7 PF-1 Flashing Light

Application

For warning purpose during leaves movement

Lamp

24Vdc Halogens bulb

Operating Temperature

-20℃~+50℃

Installation

horizontally or vertically installed

Dimension

205mm * 80mm * 75mm

5.8 PR-1 Transmitter

Application

Radio transmitter for remote control of PW220/PW230

Frequency

433.92Mhz

Coding

Rolling code

Buttons

2, for single-gate or dual-gate operation

Power Supply

6V with two CR2016 type lithium batteries

Operating Temperature

-20℃~+50℃

Dimension

71.5mm * 33mm * 14mm

5.9 PEL-1 Electric Latch

Application

For locking the gate.

Power Supply

24Vdc

Operating Temperature

-20℃~+50℃

Operating Current

5A

Dimension

61mm * 55mm * 120mm

Page 29

1095 Budapest, Mester utca 34.

Tel.: *218-5542, 215-9771, 215-7550,

1141 Budapest, Fogarasi út 77.

Tel.: *220-7940, 220-7814, 220-7959,

216-7017, 216-7018 Fax: 218-5542

Mobil: 30 940-1970, 20 949-2688

E-mail: delton@delton.hu W eb: www.delton.hu

www.kaputnyitunk.hu

220-8881, 364-3428 Fax: 220-7940

Mobil: 30 531-5454, 30 939-9989

Loading...

Loading...