Page 1

ARTICULATED ARM OPENERS

FOR RESIDENTIAL

USER MANUAL

24V DC GEAR MOTOR

PA250 USER MANUAL

Page 2

INDEX

1.1 Warnings

1.2 Installation

1.2.1 Standard Installation

1.2.2 Dimension Chart

1.2.3 Components of Installation

1.2.4 Installation of Articulated Arm Opener

1.2.5 Emergency Release

1.2.6 Photocell Installation

1.2.7 Green Box Installation

1.2.8 Power Supply Connections

2.1 Wiring Connection

2.1.1 Master Motor is installed at right side

2.1.2 Master Motor is installed at left side

2.2 LED Indication

2.3 Transmitter Memorizing and Erasing Process

2.4 System Learning Process

2.5 Gate Operation

2.6 Gate-moving Logic

2.7 Checking the Gate Movement

3. Function Setting

3.1 Function of the Led Display

3.2 Photocell Adjustment

3.3 Operations for Function Settings

3.4 Function Settings

4. Trouble Shooting

5. Technical Features

5.1 Dimension

5.2 Technical Feature

6. Maintenance

1

1

1

2

2

4

4

6

6

7

8

9

10

10

10

12

12

12

12

12

13

14

15

17

17

17

18

18

1.1 Warnings

Please read this instruction manual carefully before the installation of

gate-automated system.

This manual is exclusively for qualified installation personnel.

Manufacturer is not responsible for improper installation and failure to

comply with local electrical and building regulations.

Keep all the components of system and this manual for further

consultation.

In this manual, please pay extra attention to the contents marked by the

symbol:

Be aware of the hazards that may exist in the procedures of installation

and operation of the gate-automated system. Besides, the installation

must be carried out in conformity with local standards and regulations.

If the system is correctly installed and used following all the standards

and regulations, it will ensure a high degree of safety.

Make sure that the gates works properly before installing the

gate-automated system and confirm the gates are appropriate for the

application.

Do not let children operate or play with the gate-automated system.

Do not cross the path of the gate-automated system when operating.

Please keep all the control devices and any other pulse generator away

from children to avoid the gate-automated system being activated

accidentally.

Do not make any modifications to any components except that it is

mentioned in this manual.

Do not try to manually open or close the gates before you release the

gear motor.

If there is a failure that cannot be solved and is not mentioned in this

manual, please contact qualified installation personnel.

Do not use the gate-automated system before all the procedures and

instructions have been carried out and thoroughly read.

Test the gate-automated system weekly and have qualified installation

personnel to check and maintain the system at least every 6-month.

Install warning signs (if necessary) on the both sides of the gate to warn

the people in the area of potential hazards.

Page 3

ARTICULATED ARM OPENERS USER MANUAL

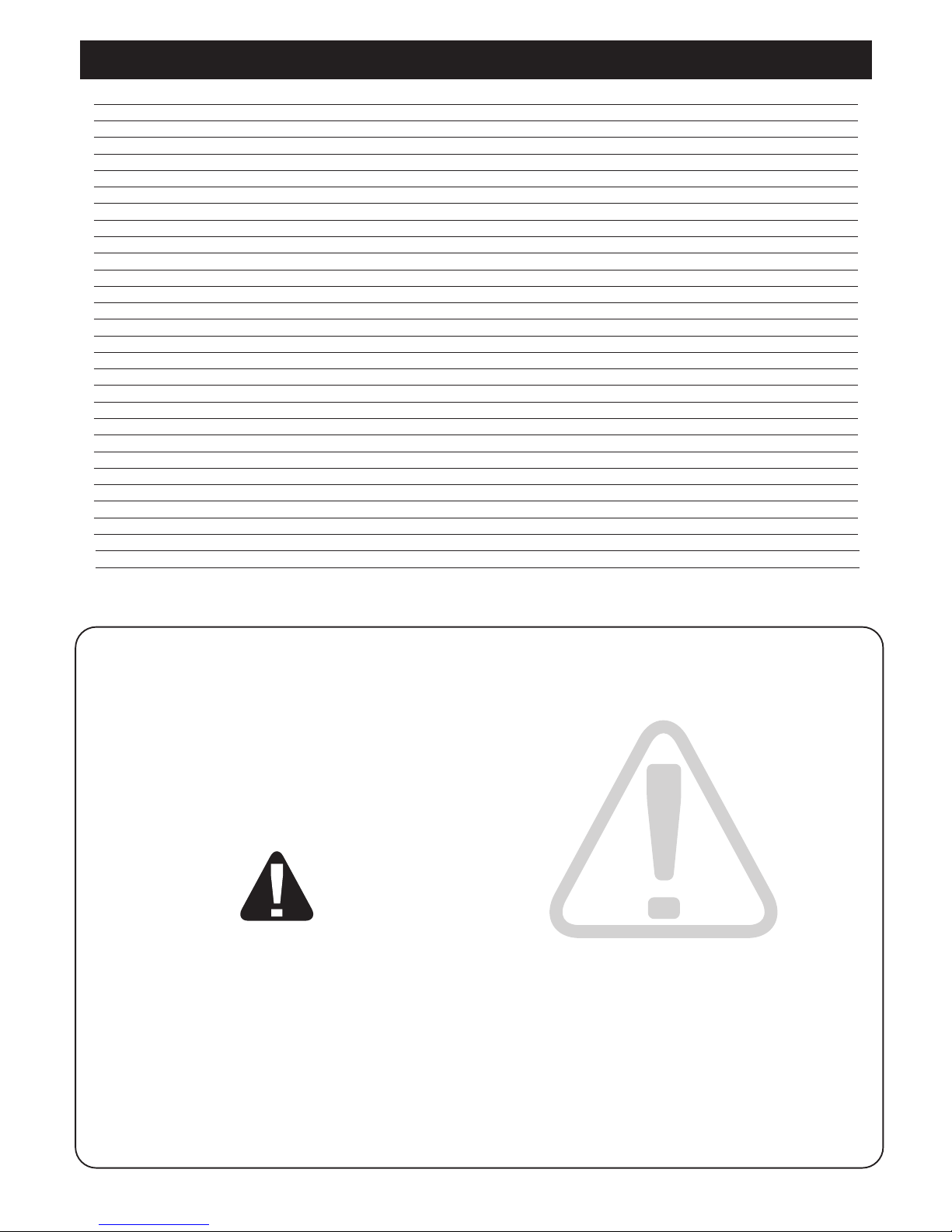

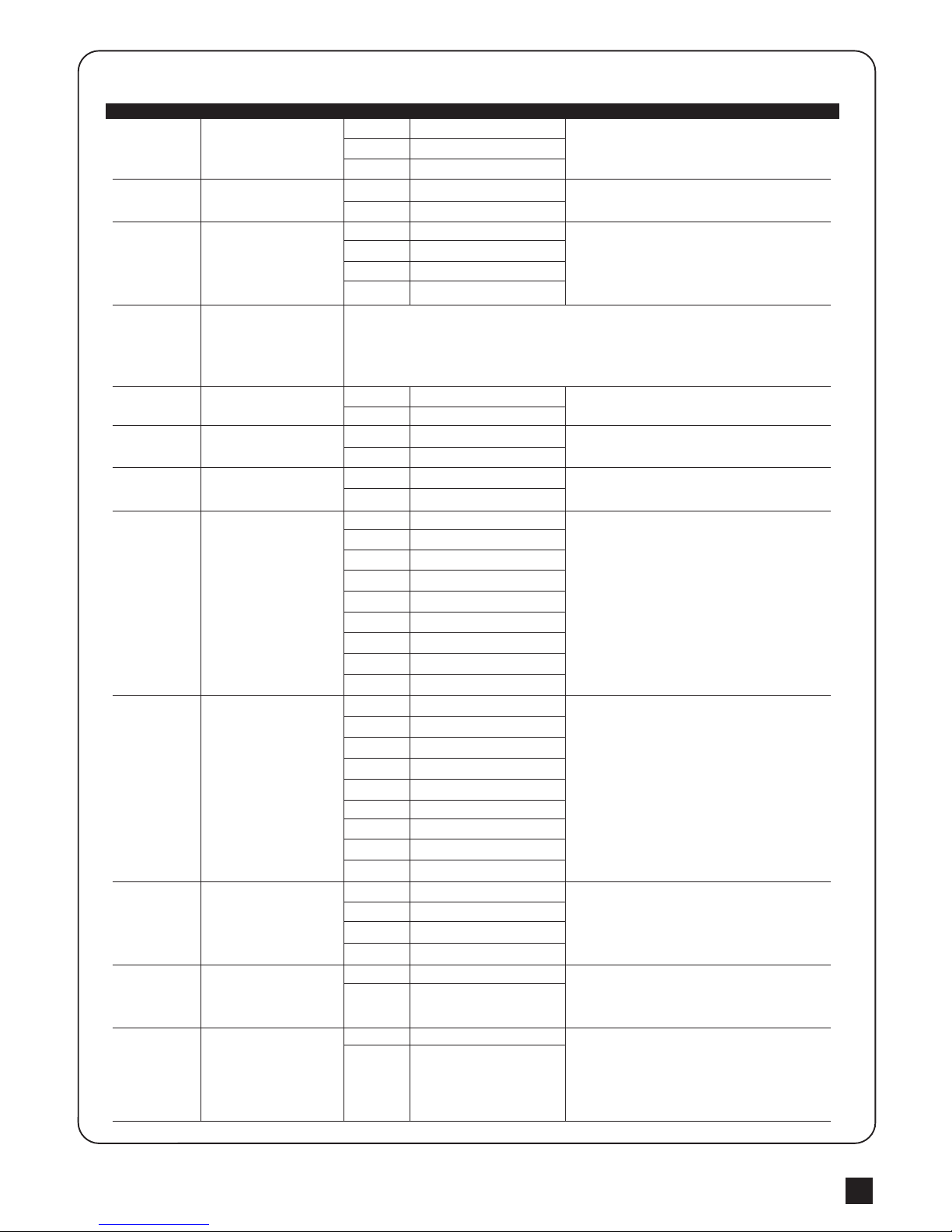

1.2.1 Standard Installation

1.2.2 Dimension Chart

1

1.2 Installation

2x1.5 mm

2

4x0.5 mm

2

TX - 4x0.5 mm

2

RX - 4x0.5 mm

2

2x1.5 mm

2

2x1.5 mm

2

4 4

2

33

1

5

1. 24V DC blinker with integrated antenna

2. Push Button

3. Photocells

4. 24V DC articulated arm opener

5. PR-1 Transmitter

Please comply with the measures shown on the chart for proper installation. If necessary,

please adjust the gate structure to the best operation.

Before starting the installation, please make sure that the gate moves freely and that :

1) Hinges are properly positioned and greased.

2) No any obstacle in the moving area.

3) No frictions between two gate leafs or and on the ground while moving.

4) Installation reference: to open the gate with 90 degree, please refer the data table below:

A: Distance between the gate hinge and the wall bracket.

B: Distance between the gate hinge and side face of the motor.

C: Distance between the gate hinge and the fixing point of the arm.

A

To open 90 degree.

C

B

C

50

100

150

200

250

300

unit: mm

A

B

50

625

615

600

585

565

540

100

575

565

550

535

515

/

150

545

540

/

/

/

/

M1 Master

Motor

M2 Slave

Motor

Page 4

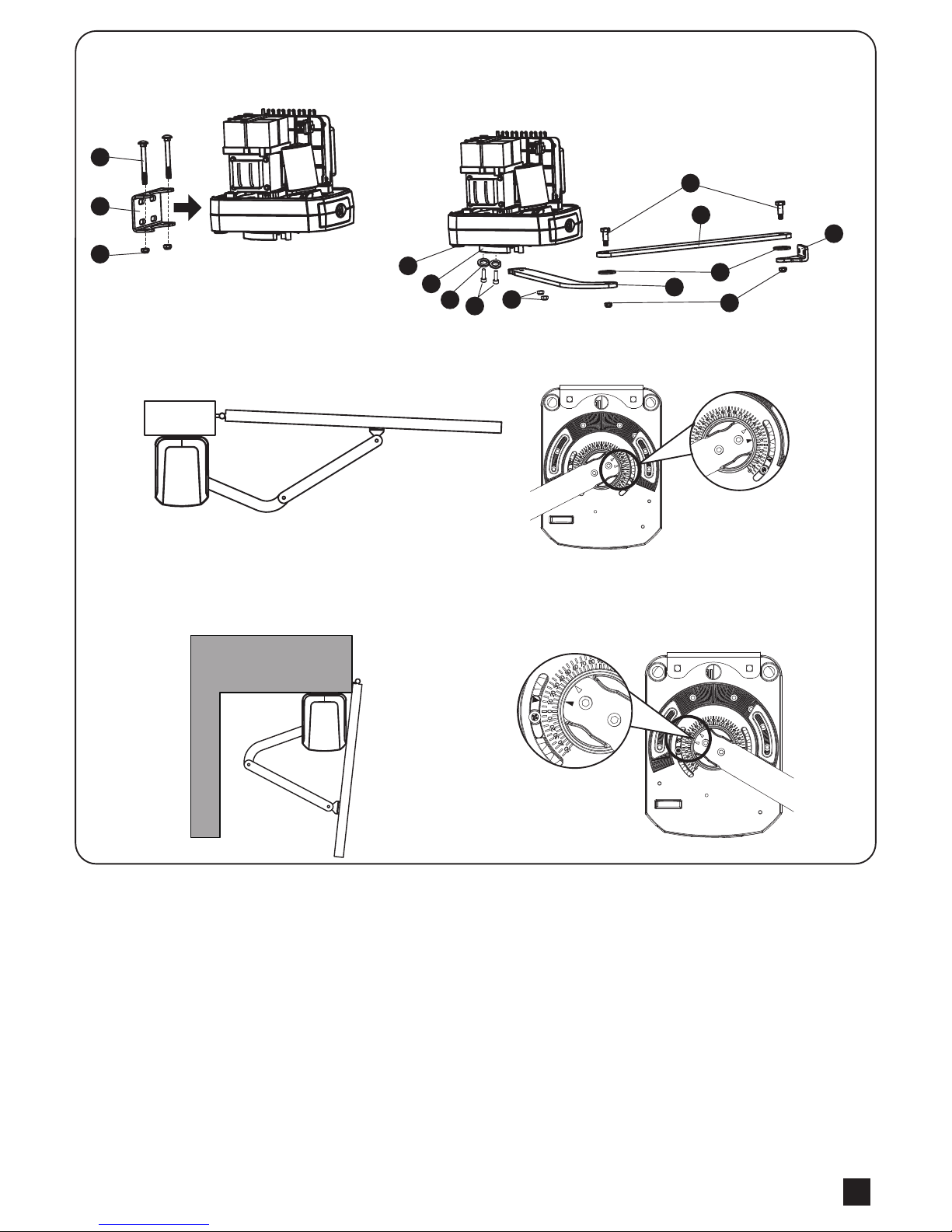

1.2.3 Components of Installation

1.2.4 Installation of Articulated Arm Opener

ARTICULATED ARM OPENERS USER MANUAL

2

1

2

3

4

5

6

7

8

9

10

11

12

13

Straight arm

Curved arm

U-shaped fixing plate

Mechanical stopper

Front-end fixing bracket

Screw

Nut Ø10

Screw

Gasket

Screw

Spring washer

Nut Ø8

Cable gland

1 pce

1 pce

1 pce

2 pcs

1 pce

4 pcs

2 pcs

2 pcs

2 pcs

2 pcs

4 pcs

4 pcs

1 pce

2

3 4 5

6

7

8

13 12 11 10 9

1

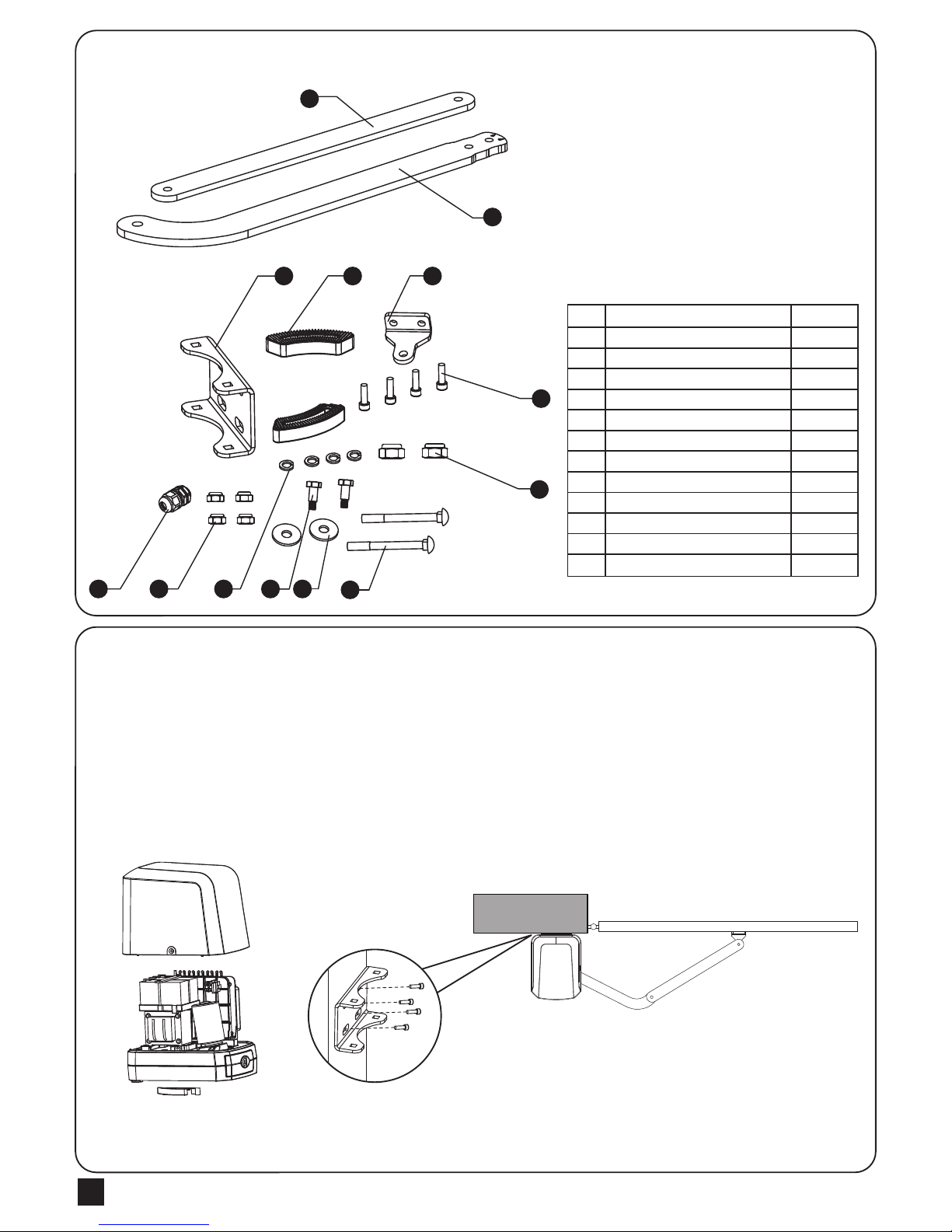

1. Refer to the Dimension Chart to choose the correct dimensions of the motors and

position to be installed.

2. Check if the mounting surface of the brackets to be installed is smooth, vertical and rigid.

3. Arrange the cables for power supply cable of the motors.

4. Motor installation and setting for mechanical stopper in opened and closed position.

2) Place the gate in the full closed position and

fix the U-shaped fixing plate on the wall.

1) Remove the upper cover and mechanical

stoppers on the bottom of motor.

Page 5

ARTICULATED ARM OPENERS USER MANUAL

3

4) After positioning the front of curved arm on the bottom of motor,

release the motor and position the minor arm on the end of

curved arm and mounting bracket with corresponding screws

and nuts.

5) Closed position adjustment :

4.1 After the full closed position decided, fix the corresponding mechanical stopper at the position.

4.2 After the full closed position decided, make the pointer on limit switch aligned with the pointer on the curved arm.

(Red points shown on the figure below indicate the pointers)

6) Opened position adjustment :

5.1 Adjust the gate to full opened position and after the position decided, fixed with corresponding mechanical stopper.

5.2 Adjust the gate to full opened position and after the position decided, make the pointer on the electromechanical

limit switch aligned with the pointer on the curved arm. (Red points shown on the figure below indicate the pointers)

1

5

2

7

6

3

8

12

3) Install the motor on the U-shaped fixing

plate with corresponding screws and nuts.

12

9

10

4

13

11

Page 6

ARTICULATED ARM OPENERS USER MANUAL

4

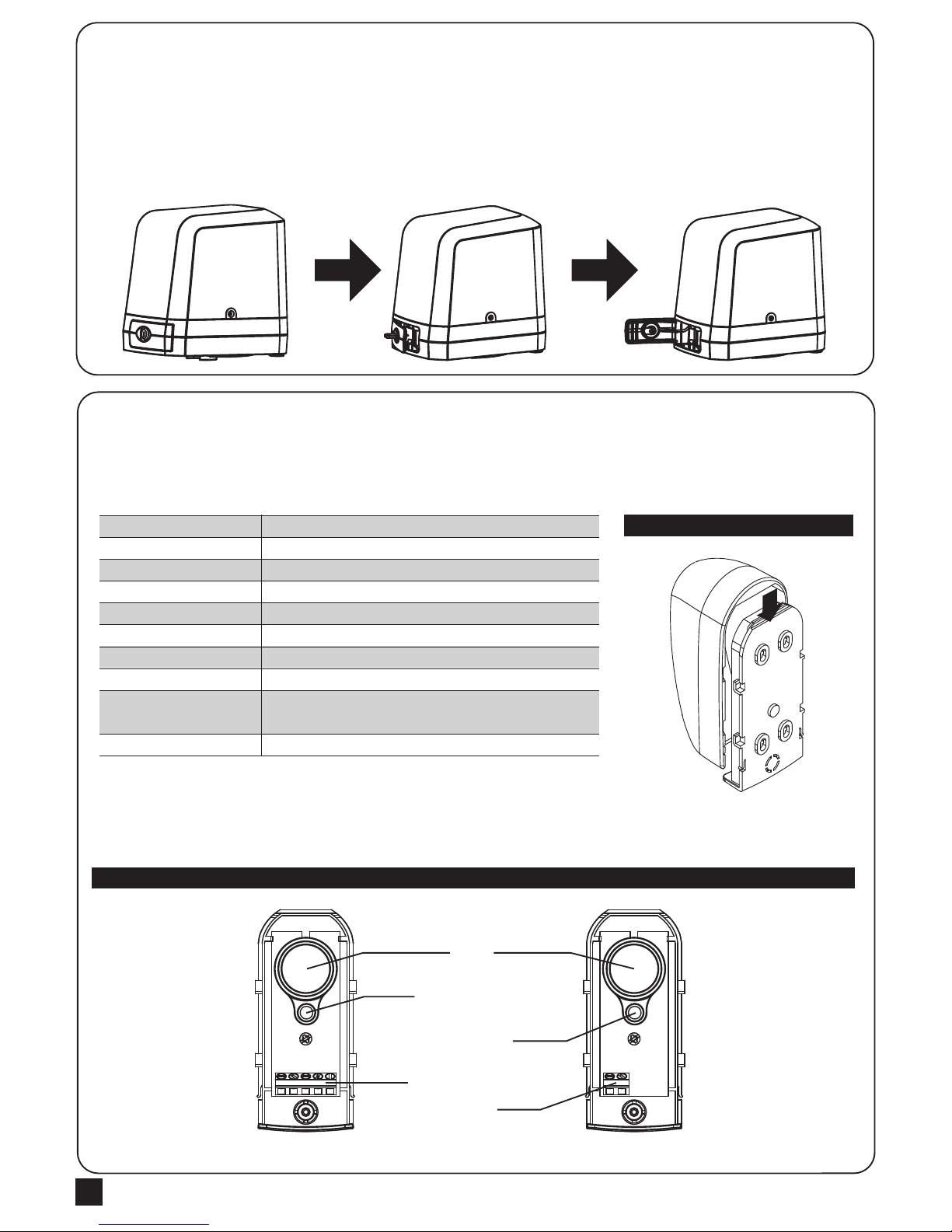

1.2.5 Emergency Release

1) Insert the release key to the release slot

2) Turn the release key anti-clockwise

3) Pull out the release bar

4) Turn the release key clockwise to fix the release bar, the release bar has to be in pulled out position when turning

the release key clockwise

The safety photocells are security devices for control automatic gates. Consist of one transmitter and one receiver

based in waterproof covers; it is triggered while breaking the path of the beams.

INSTALLATION:

Wire Connection of Photocells

TX: Connect terminals 1 and 2 on the transmitter with the terminals GND and PhVcc on the PC190 PCB.

RX: Connect terminals 1,2 and 4 on the receiver with the terminals GND, PhVcc, and Ph1/Ph2 on the PC190 PCB.

And use an extra wire to connect terminals 2 and 5 on the receiver as a bridge.

Detection Method

Sensing Range

Input Voltage

Response Time

Emitting Element

Operation Indicator

Dimensions

Output Method

Current Consumption Max

Water Proof

Through Beam

25M

AC/DC 12~24V

100MS

IR LED

Red LED(RX): ON(When Beam is Broken), Green(TX):ON

96*45*43mm

Relay Output

TX: 35MA/Rx: 38MA (When beam aligned properly);

TX: 35MA/ Rx: 20MA (When beam is broken)

IP54

SPECIFICATION:

Figure 1(2)

Figure 1(1)

1.2.6 Photocell Installation

RX

Lens

Beam Alignmnet

Indicator

Power Led

Indicator

Terminal Block

Power

Terminal Block

TX

1 2 3 4 5 1 2

Page 7

ARTICULATED ARM OPENERS USER MANUAL

5

Figure 1(3)

SKey Ph2Ph1 PhVcc PhVccDKey GND GND

19 20 21 22 23 24 25 26

1 2 3 4 5

COMNCNO+

-

+

-

1 2

RX1TX1

1 2 3 4 5

COMNCNO+

-

+

-

1 2

RX2 TX2

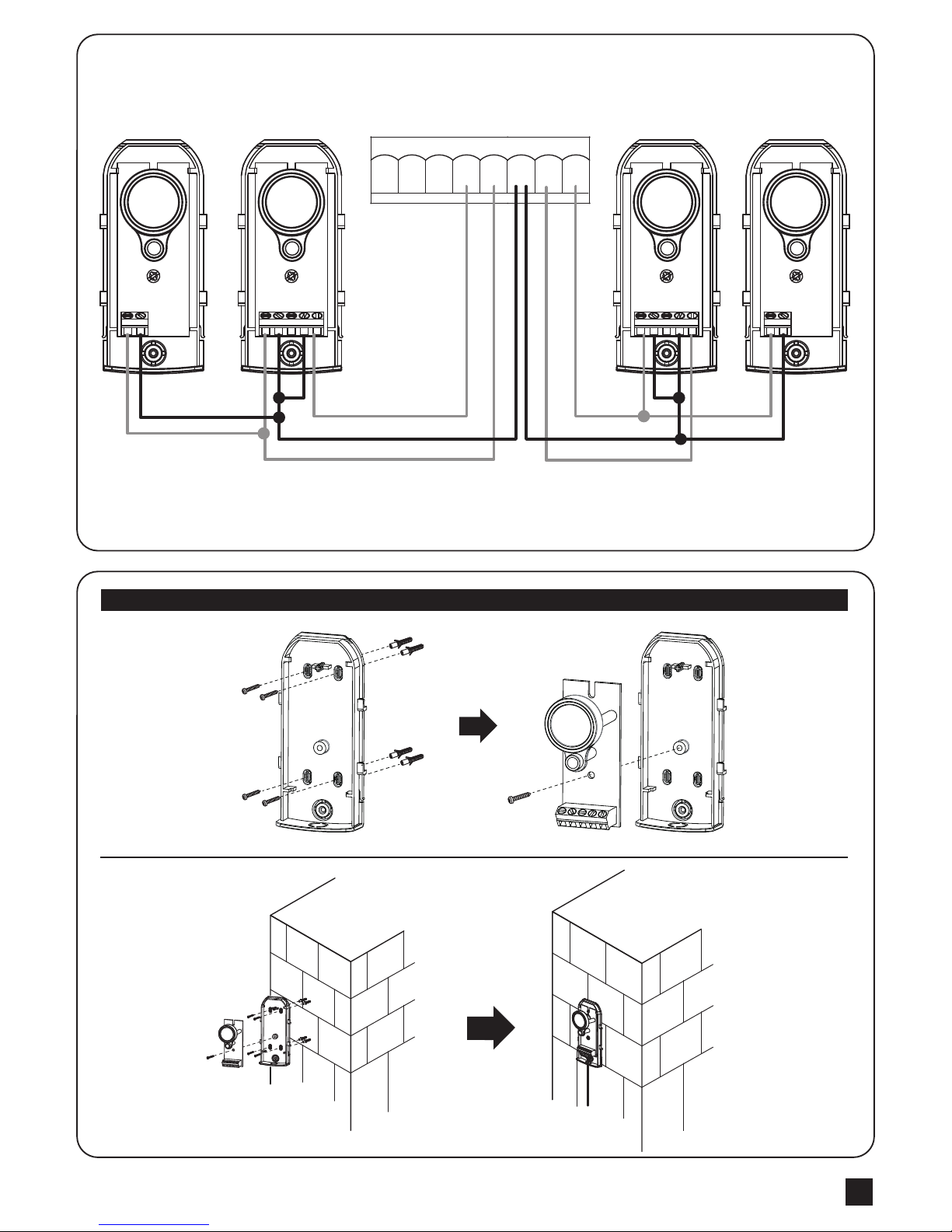

Page 8

ARTICULATED ARM OPENERS USER MANUAL

6

Please kindly notice that the operation of power connection should be carried out by a qualified electrician with

following steps:

1). Make sure the gearmotor is not connected to the power supply before the installation is done.

2). Make sure all the wires are firmly connected.

3). Supply the gearmotor with the power.

OFF ON

Green Box

5+

Cable

AC out

AC in

Green Box is for purpose when gate opener is in standby mode to allow it enter the power saving mode.

Installation manner:

AC IN: connect the electricity

AC OUT: connect the power of gate opener, and connect the transformer

5V CABLE: connect 3 pins white socket of control board

Please make sure the switch of Green Box is off before proceeding the system learning and installation of device.

Wait for the system learning and installation of device to be completed, power on the Green Box

Gate opener will enter power saving mode without receiving any instruction in 1 min, and red LED light on Green Box

will be activated. Gate opener start the operation, red LED light and power saving mode will turn off.

CAUTION:

In case of loop or installation of photocell which need power consumption anytime, please do not install Green Box.

1.2.7 GREEN BOX INSTALLATION

1.2.8 POWER SUPPLY CONNECTIONS

Page 9

ARTICULATED ARM OPENERS USER MANUAL

7

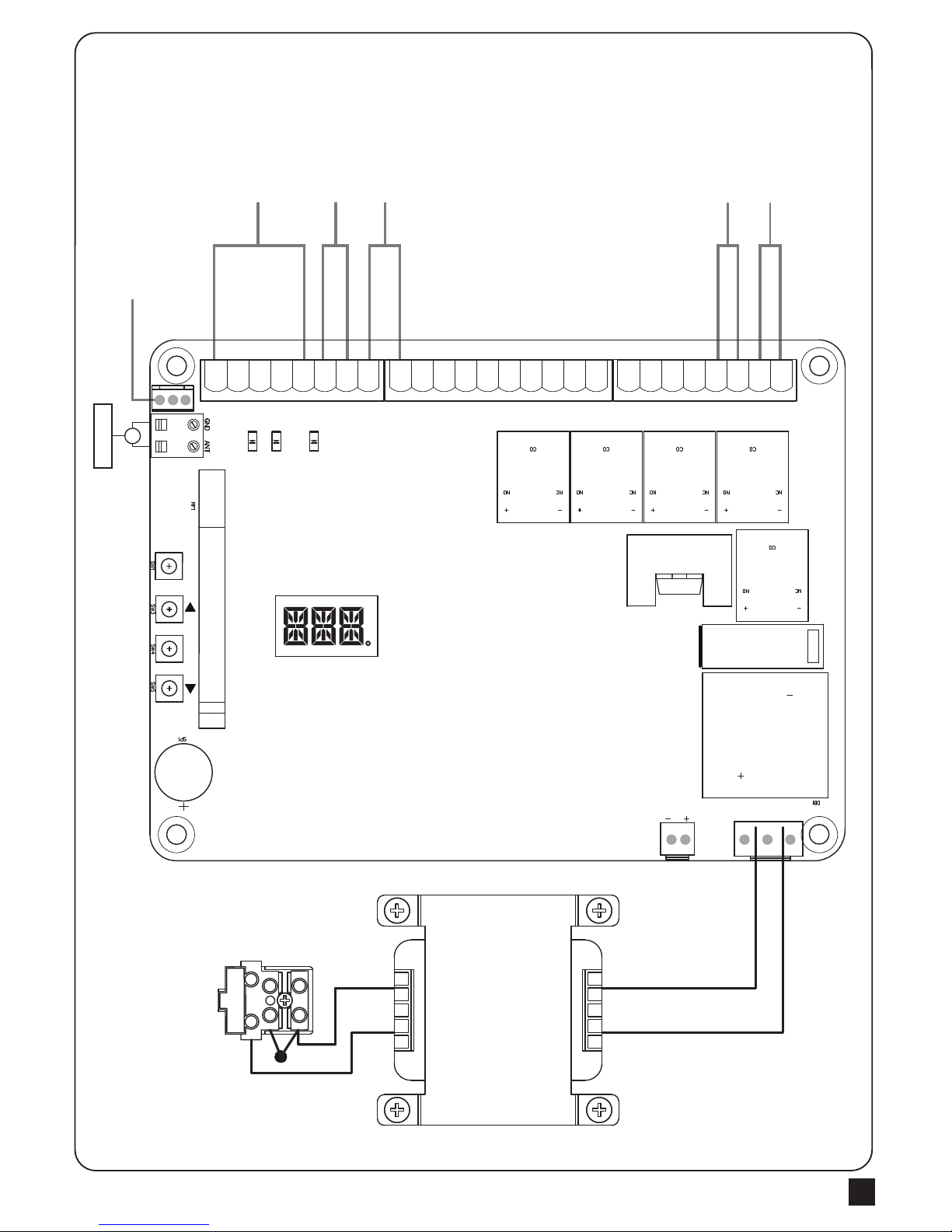

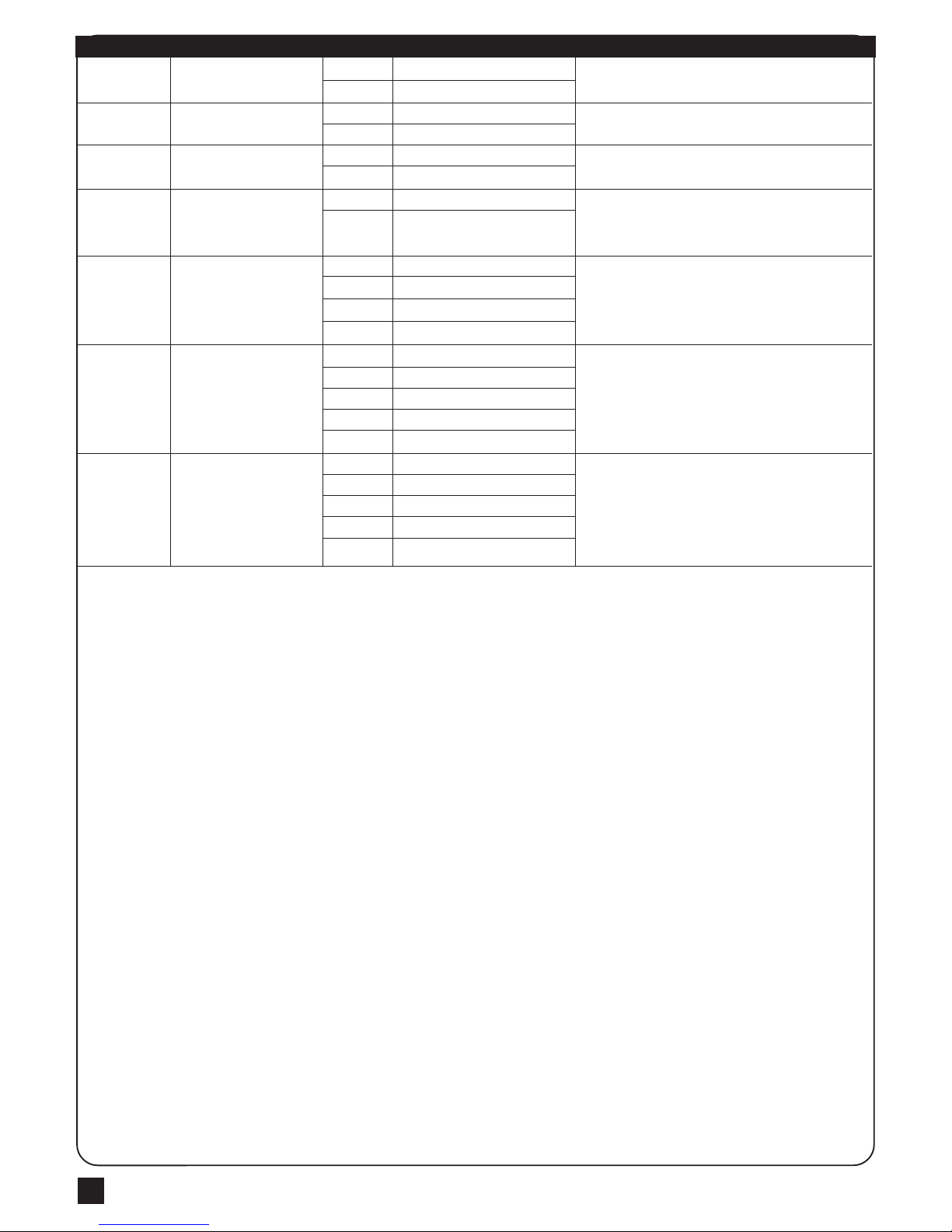

2.1 Wiring Connection

Figure 2(1)

Key

Selector

Push

Button

Photocells connection is

detailed on page 5

Flashing

LightLatch

Transformer

Antenna

Green Box

LED Display

Blue LED – RF Learning

LED2 Push button or Key selector

LED3 Photocell 1

LED 4 Photocell 2

UP

SET

SET

DOWN

RF-LEARN

RF-LEARN

LED2LED4LED3

11

Lit+Lit-Lat+Lat-M1+M1-M2+M2-5VS1S2GNDLmt1Lmt2GNDLmt3Lmt4GNDGND Ph1Ph2 PhVccPhVcc GND DKeySKey

26 2425 23 2122 1920 18 1617 15 1314 11 1012 9 8 67 5 34 12

Page 10

ARTICULATED ARM OPENERS USER MANUAL

8

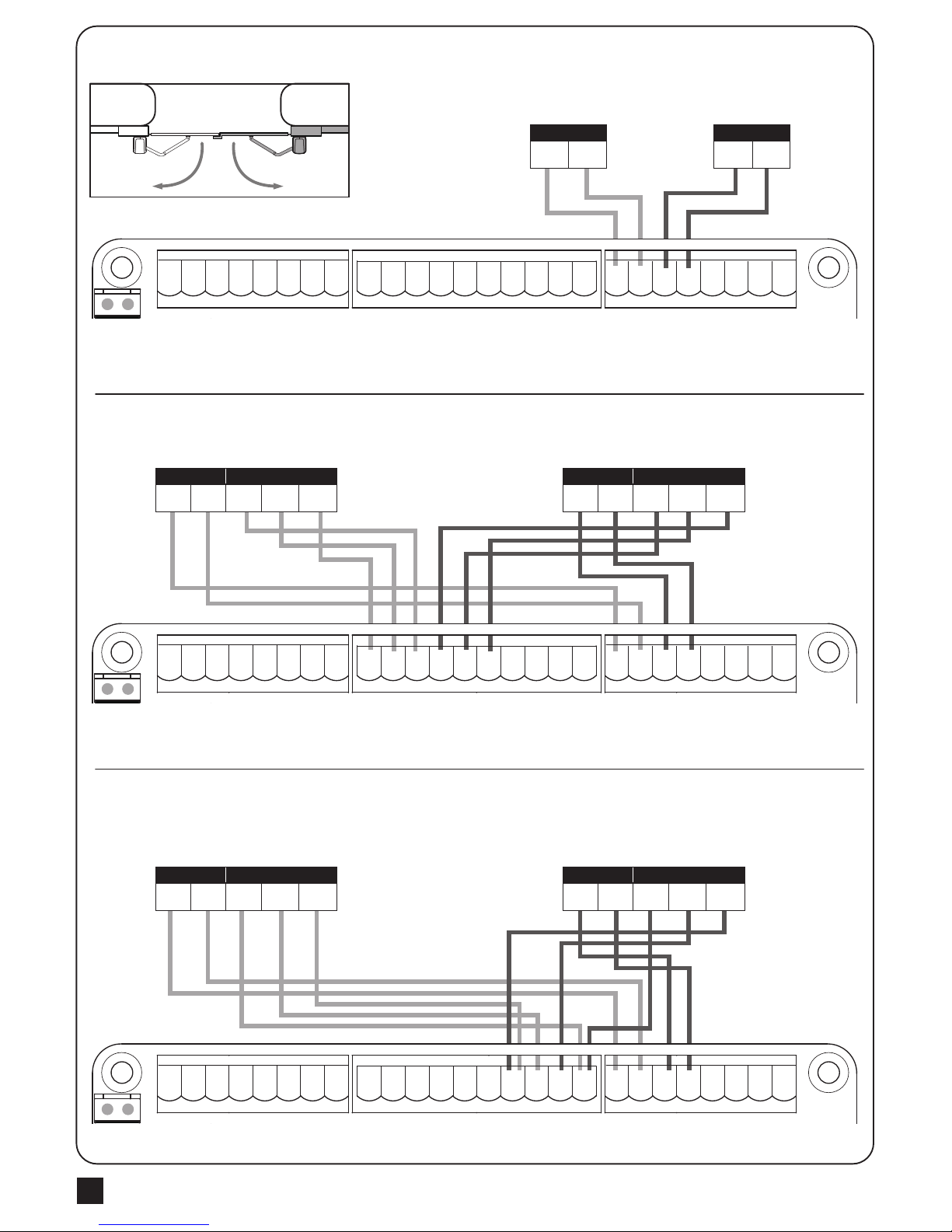

M1+ M1-

Motor1 Power

2.1.1 Master Motor is installed at right side

Motor with Hall sensor

M2-M1-

Lat-

Lit-

Lmt4Lmt3

Lmt2

Lit+ SKey

S1

M2+

M1+Lat+ Ph2Ph1 PhVcc PhVcc

S25V

ANT

GND

DKey GND

GND

GND

GND

Lmt1

GND

J5

J4 J3

J8

CO

CO

CO

CO

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

LED2

LED3

LED4

M2+ M2-

Motor2 Power

Motor with Limit switch

M2-M1-

Lat-

Lit-

Lmt4Lmt3

Lmt2

Lit+ SKey

S1

M2+

M1+Lat+ Ph2Ph1 PhVcc PhVcc

S25V

DKey GND

GND

GND

GND

Lmt1

GND

J5

J4 J3

J8

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

M1- Limit1 Limit2 GNDM1+

Motor1 Power Limit Switch

M2- Limit4 Limit3 GNDM2+

Motor2 Power Limit Switch

M2-M1-

Lat-

Lit-

Lmt4Lmt3

Lmt2

Lit+ SKey

S1

M2+

M1+Lat+ Ph2Ph1 PhVcc PhVcc

S25V

DKey GND

GND

GND

GND

Lmt1

GND

J5

J4 J3

J8

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

M1- 5V S1 GNDM1+

Motor1 Power Hall sensor

M2- 5V S2 GNDM2+

Motor2 Power Hall sensor

Figure 2(2)

Figure 2(3)

Figure 2(4)

Remark:

Limit1, Limit3 (Open limit)

Limit2, Limit4 (Close limit)

M1 M2

Page 11

ARTICULATED ARM OPENERS USER MANUAL

9

M2+ M2-

Motor2 Power

M1+ M1-

Motor1 Power

M2- Limit4 Limit3 GNDM2+

Motor2 Power Limit Switch

M2- 5V S2 GNDM2+

Motor2 Power Hall sensor

M2-M1-

Lat-

Lit-

Lmt4Lmt3

Lmt2

Lit+ SKey

S1

M2+

M1+Lat+ Ph2Ph1 PhVcc PhVcc

S25V

DKey GND

GND

GND

GND

Lmt1

GND

J5

J4 J3

J8

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

M2-M1-

Lat-

Lit-

Lmt4Lmt3

Lmt2

Lit+ SKey

S1

M2+

M1+Lat+ Ph2Ph1 PhVcc PhVcc

S25V

DKey GND

GND

GND

GND

Lmt1

GND

J5

J4 J3

J8

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

M1- Limit1 Limit2 GNDM1+

Motor1 Power Limit Switch

M2-M1-

Lat-

Lit-

Lmt4Lmt3

Lmt2

Lit+ SKey

S1

M2+

M1+Lat+ Ph2Ph1 PhVcc PhVcc

S25V

DKey GND

GND

GND

GND

Lmt1

GND

J5

J4 J3

J8

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

M1- 5V S1 GNDM1+

Motor1 Power Hall sensor

Figure 2(5)

Figure 2(6)

Figure 2(7)

Remark:

Limit1, Limit3 (Close limit)

Limit2, Limit4 (Open limit)

2.1.2 Master Motor is installed at left side

Motor with Hall sensor

Motor with Limit switch

M1M2

Page 12

ARTICULATED ARM OPENERS USER MANUAL

10

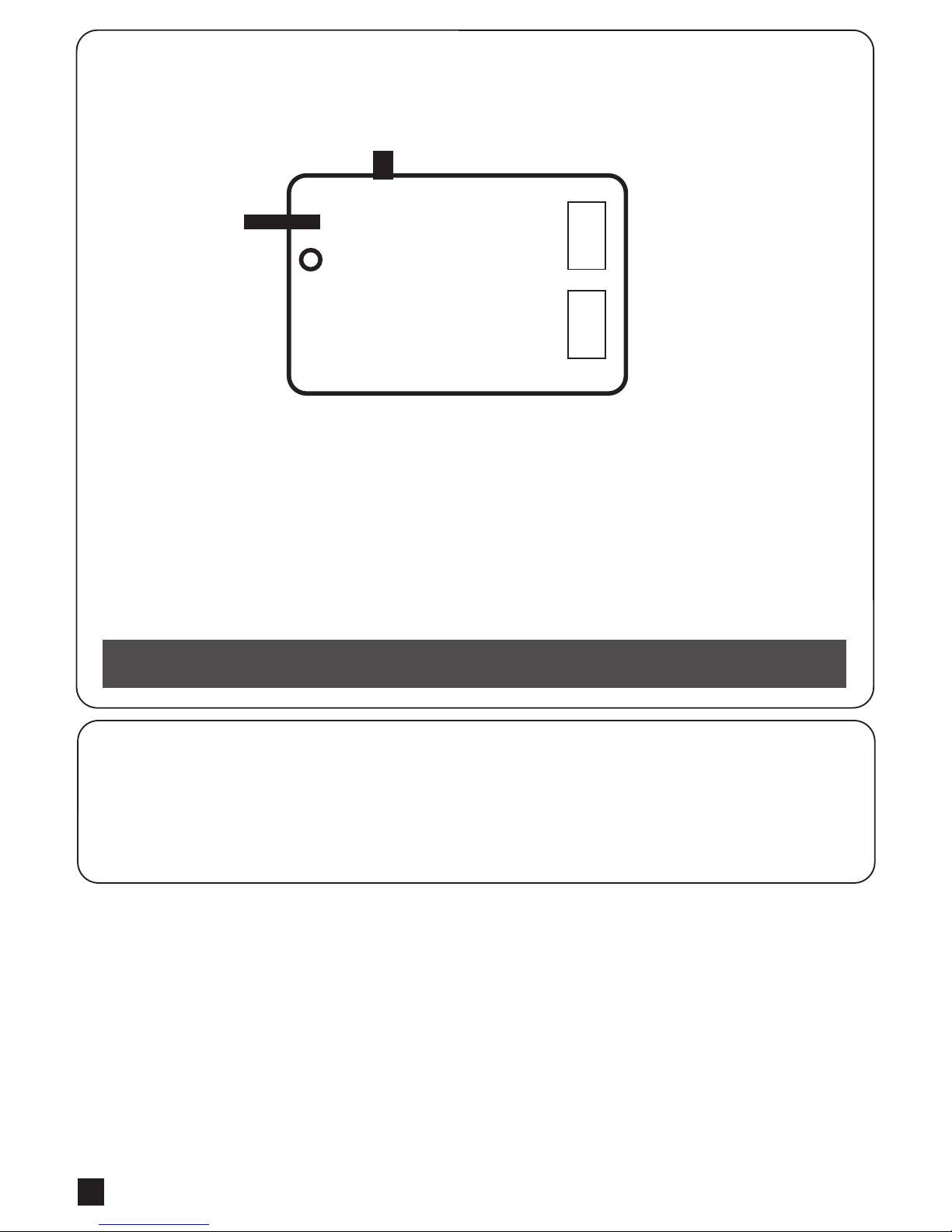

2.4 System Learning Process

2.3 Transmitter Memorizing and Erasing Process

(A) Transmitter Memorizing: Press and hold the “RF-LEARN” button on the PCB for 1 second and then the blue LED

indicator on the RF board will be “ON”. Press A button for dual-gate installation ; press B button for single-gate

installation on the transmitter within 5 seconds. The transmitter learning is completed

when the blue indicator is “OFF”.

(B) Transmitter Memory Erasing: Press and hold the “RF-LEARN” button on the PCB for 10 seconds until blue LED off.

(C) One radio receiver can be memorized with 200pcs of transmitters.

Blue LED on receiver board: Blinks three times when remote learning is completed.

LED2 External device : If the switch of the key selector, or the push button is activated, LED2 will be on.

LED3 Photocells 1 : LED3 will be on when the first pair of the photocells are activated.

LED4 Photocells 2 : LED4 will be on when the second pair of the photocells are activated.

Antenna

M2-M1-

Lat-

Lit-

Lmt4Lmt3

Lmt2

Lit+ SKey

S1

M2+

M1+Lat+ Ph2Ph1 PhVcc PhVcc

S25V

ANT

GND

DKey GND

GND

GND

GND

Lmt1

GND

PC190-PCB1

40121-377-A1

+ -

T4

SW3

UP

Q17

J5

SW1

RF-LEARN

RF1

K5

K3

K2K1

J4 J3

J7

F1

DB1

J8

SW4

SET

SW5

DOWN

NC NO

CO

+-

NC NO

CO

+-- +

CO

NONC

- +

CO

NONC

NC NO

CO

+-

-

+

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

LED2

LED3

LED4

2.2 LED Indication

Step1: Connect the master motor wires to M1 terminals and the slave motor wires to M2 terminals correctly.

If only one gate is installed, the motor wires have to be connected to M1 terminals.

Step2: Set the function F2-1 for dual gate learning; or set the function F2-2 for single gate learning.

Step3: To start dual gate system learning.

To start dual gate system learning.

Press and hold the “UP+SET+DOWN” button on the PCB for 3 seconds. The LED display will show “LEA” and

“D-G”. Press the button (A) on the transmitter within 10 seconds to activate the system learning automatically.

LED display will show “ARN”, do not interrupt this procedure by pressing the transmitter or stop the gate. In

system learning mode, the gates will proceed with the following procedures figure 2(8). LED display will show

“RUN” once system learning completed.

To start single gate system learning.

Press and hold the “UP+SET+DOWN” button on the PCB for 3 seconds. The LED display will show “LEA” and

“S-G”. Press the button (B) on the transmitter within 10 seconds to activate the system learning automatically.

LED display will show “ARN”, do not interrupt this procedure by pressing the transmitter or stop the gate. In

system learning mode, the gates will proceed with the following procedures figure 2(8). LED display will show

“RUN” once system learning completed.

Page 13

ARTICULATED ARM OPENERS USER MANUAL

11

A. Dual Gate:

Slave Gate Close → Master Gate Close → Master Gate Open → Slave Gate Open →

Slave Gate Close → Master Gate Close

B. Single Gate :

Master Gate Close → Master Gate Open → Master Gate Close

1

1

5

2 3

1 2 3

4

6

2 3

1 2 3

4 5 6

Notes:

(A) System learning fails and needs to be learned again when an unpredictable interruption occurs.

(B) Once the system learning is completed, there is no need to proceed with the learning process again when there isa

power failure.

(C) The slave gate opens 3 seconds after the master gate opens and the master gate closes 3 seconds after the slave

gate closes.

(D) While using limit switch mode, please make sure the motor hit limit switch when it’s in deceleration speed.

figure 2(8)

Page 14

ARTICULATED ARM OPENERS USER MANUAL

12

2.5 Gate Operation

Press the button “A” on the transmitter for dual-gate operation.

Press the button “B” on the transmitter for single-gate

operation in either single-gate or dual-gate installation.

2.6 Gate-moving Logic

(A) In gate-opening phase: The gates stop if the transmitter/push button/key selector is activated, and close when

the transmitter/push button/key selector is reactivated.

(B) In gate-closing phase: The gates stop if the transmitter/push button/key selector is activated, and open when

the transmitter/push button/key selector is reactivated.

(C) In gate-opening or gate-closing phase: For safety purpose, the gates stop if encountering obstacles.

2.7 Checking the Gate Movement

1). Release the gearmotor with the release key and move the gate to the middle so that it is free to move in both

opening and closing directions; then lock the gearmotor.

2). Perform the gate opening and closing several times and make sure the gates reaches the limit switch at least

2~3 centimeters before the mechanical stop.

3.1 Function Of The Led Display

3. Function Setting

LED Display Programmable Functions

“N-L”: The system learning is not done.

“RUN”: The system is in normal performing.

“CLN” The memory of the system is all cleaned/deleted. Press and hold “UP+DOWN” for

5 seconds.

“STP”: The motor stop in the middle of the operating process.

“ME”: Motor operation error

“LEA”: Enter learning mode and then wait for learning instructions.

The operation of gate learning:

(1). Press “SET” + “DOWN” + “UP” for 3seconds, and the LED display shows “LEA” +”DG”;

and then press the transmitter (A) button one time. After 1~3seconds, the LED display shows

the current value during learning mode, it shows 10 for 1A.

A

B

C

D

Page 15

ARTICULATED ARM OPENERS USER MANUAL

13

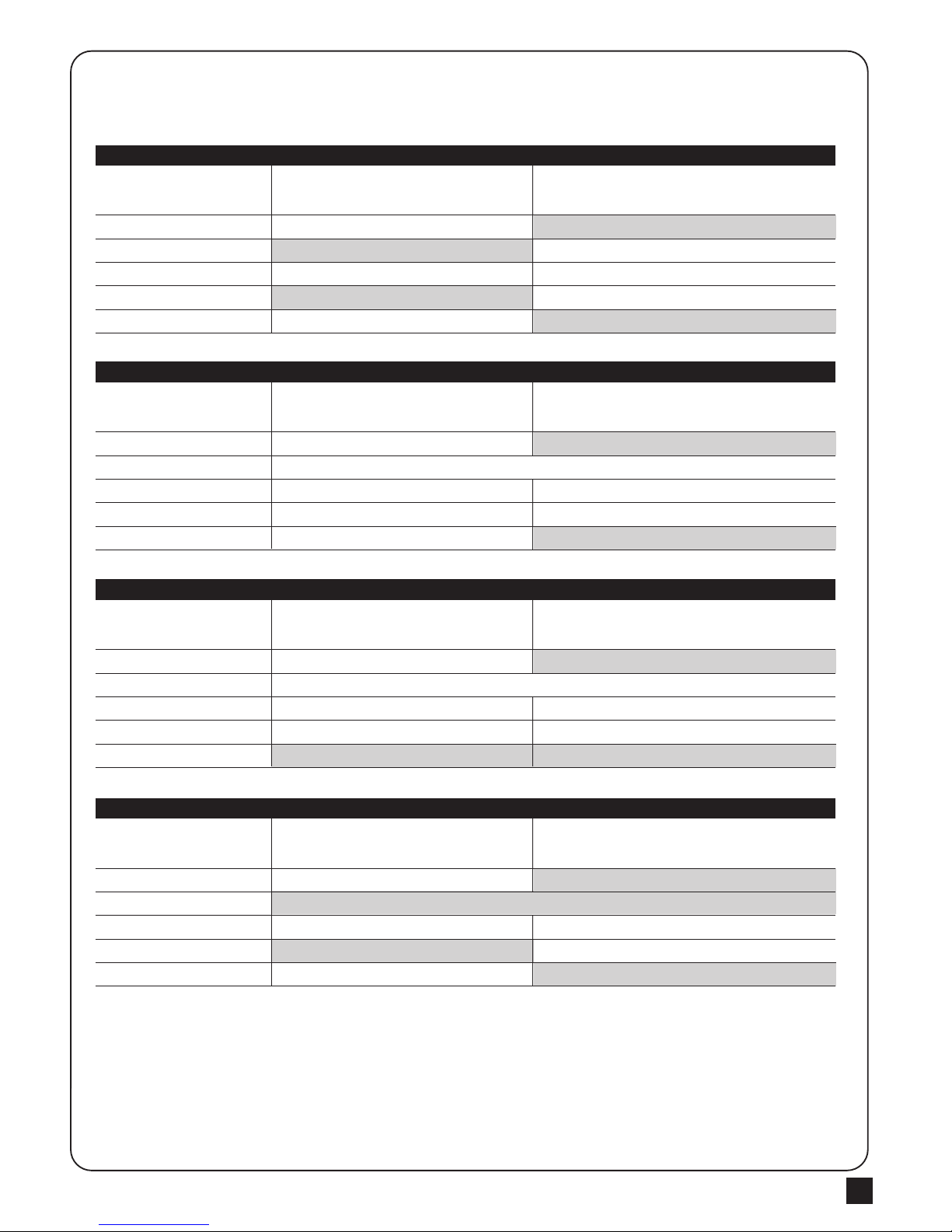

1. F9-1

Type of Safety Device

FULLY CLOSED

FULLY OPENED

STOP DURING MOVING

CLOSING

OPENING

Safety Device2 :

Photocell-OPEN

Open not allowed

No effect

Open not allowed

No effect

Close

Safety Device1 :

Photocell-CLOSE

No effect

Reload automatic closing time

Reload automatic closing time

Open

No effect

Position of Gate When safety devices are activated

2. F9-2

Type of Safety Device

FULLY CLOSED

FULLY OPENED

STOP DURING MOVING

CLOSING

OPENING

Safety Device2 :

Safety Edge

Open not allowed

Locks

Reverse to open for 2 seconds

Reverse to clsoe for 2 seconds

Reload automatic closing time

Safety Device1 :

Photocell-CLOSE

No effect

Reload automatic closing time

Open

No effect

Position of Gate When safety devices are activated

3. F9-3

Type of Safety Device

FULLY CLOSED

FULLY OPENED

STOP DURING MOVING

CLOSING

OPENING

Safety Device2 :

Opening Device

Open

Open

Open

No effect

Reload automatic closing time

Safety Device1 :

Photocell-CLOSE

No effect

Reload automatic closing time

Open

No effect

Position of Gate When safety devices are activated

4. F9-4

Type of Safety Device

FULLY CLOSED

FULLY OPENED

STOP DURING MOVING

CLOSING

OPENING

Safety Device2 :

Photocell-OPEN/CLOSE

Open not allowed

Locks

Stop

Stop

Close not allowed, Open for 2 seconds when auto closing is ON

Safety Device1 :

Photocell-CLOSE

No effect

Close not allowed

Open

No effect

Position of Gate When safety devices are activated

3.2 Photocell Adjustment

The actions of the photocells safety edge loop detector when they detecting obstacles.

Page 16

ARTICULATED ARM OPENERS USER MANUAL

14

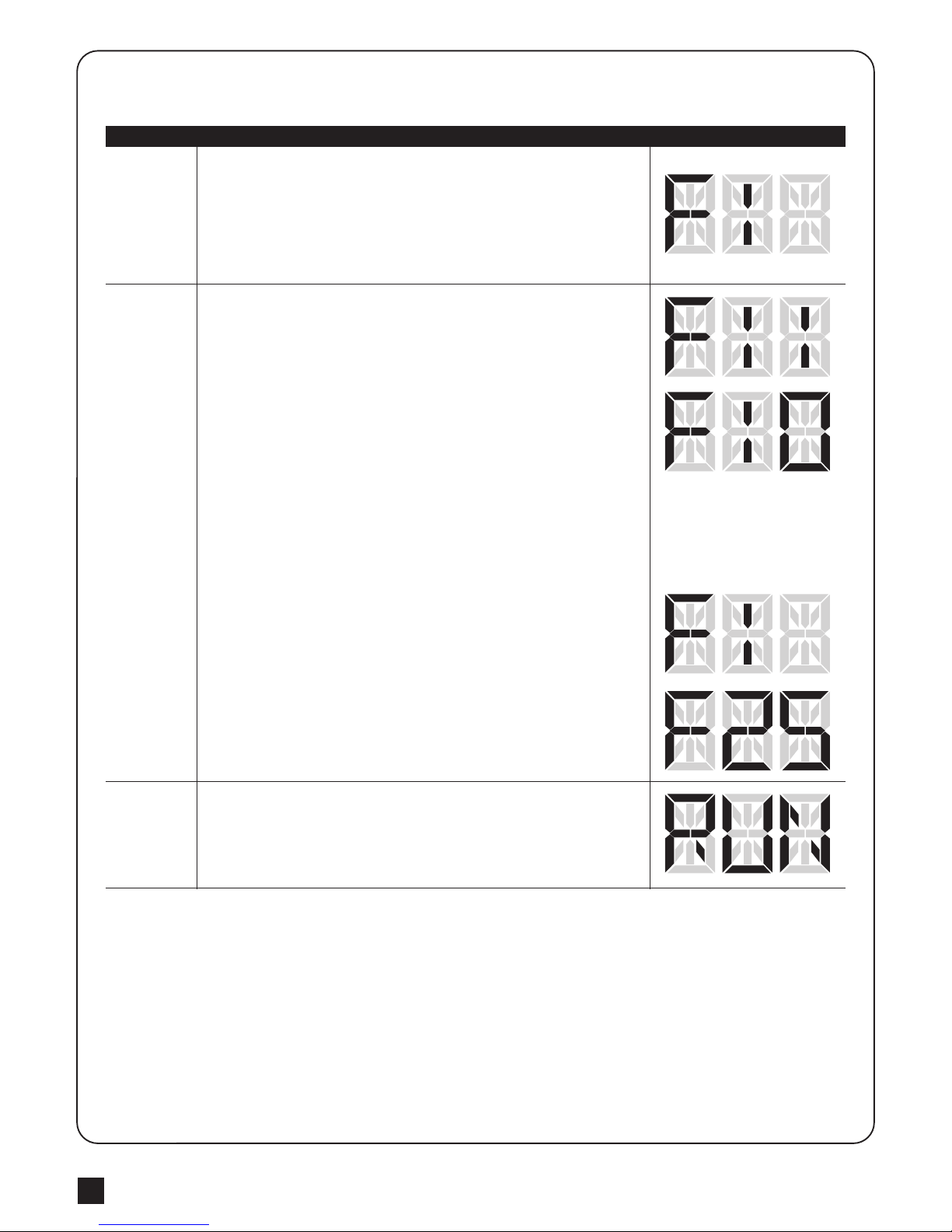

For exmple: How to set the function “F1-0”; the steps are following:

(1) Press the “SET” button for 3seconds then releases it, and the

system enters the first option. The LED will display “F1” (*) as the

right hand-side picture.

(*) If you would like to enter “F2” function or others as the first option,

please press the “UP” button to adjust F2~F8 until you get “F2”.

1.

3.3 Operations for Function Settings

Step Operations LED Display after the Step

(2) After completing the operation (1), then press the “SET” button

again, you will enter the second option as the right hand-side picture.

And you will see the third number for the second option.

(3) Continually press the “Down” button until you search the function

“0” (**) of F1 as the right hand-side picture. “F1-0” is set completely.

(**) If you would like to set one of functions “0 ~ 8” as the second

option, please press the “UP” or “Down” button to adjust it.

(4) If you would continue setting up the next functions, please press

“SET” to return the first option, like F1 or F2 or F3…or F8.

For example, after complete “F1-0” setting. You would continue

setting “F2-5”, please press “SET” to return the formal option. The

LED display shows the first two numbers as as the first option as the

right hand-side picture, “F1”. And then follow the operation (*) and (2)

~ (3) until you get “F2-5” as the right hand-side picture. “F2-5” is set

completely.

After setting all functions you need, then wait for 10seconds, the LED

will display “RUN”. And you can use transmitter to operate the gate.

2.

3.

Page 17

ARTICULATED ARM OPENERS USER MANUAL

15

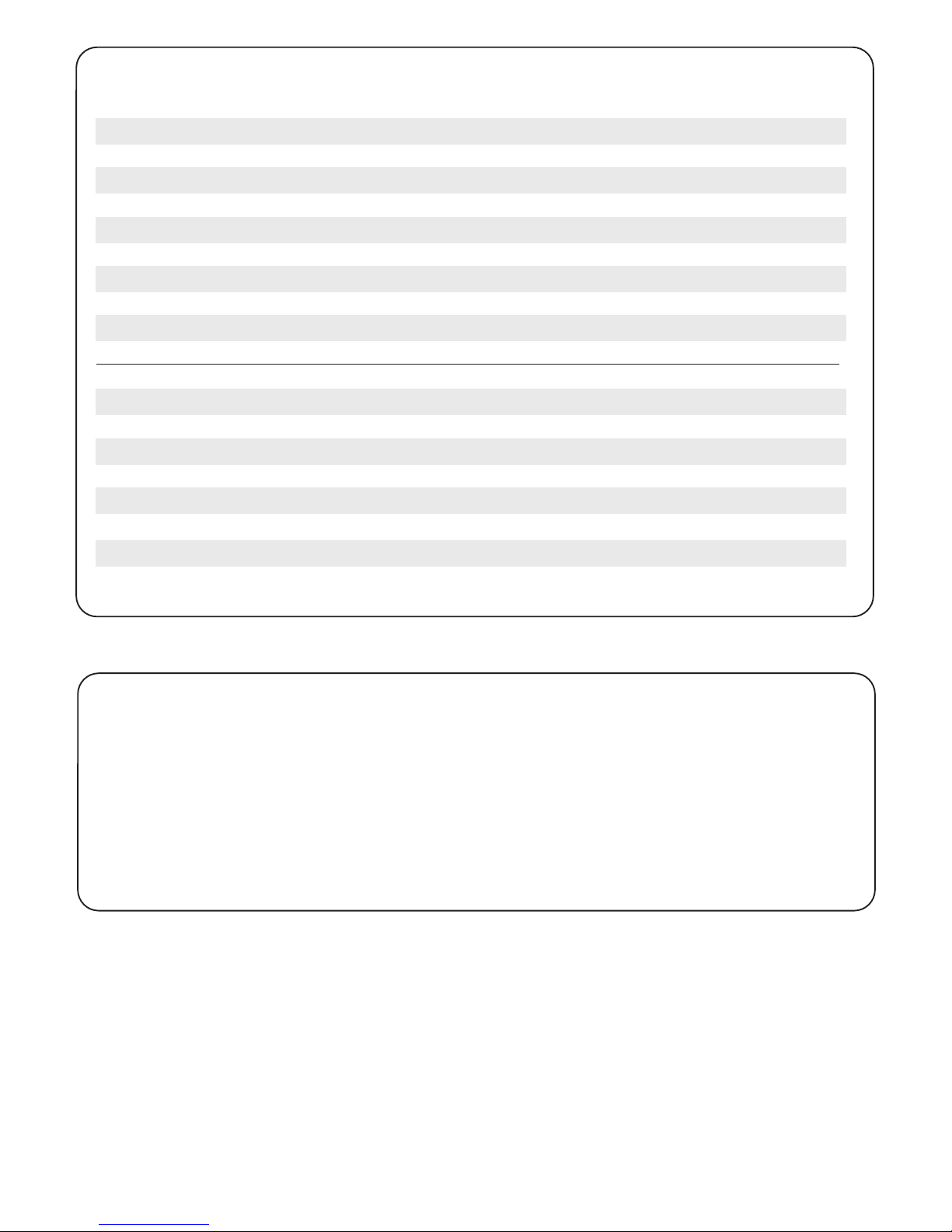

3.4 Function Settings

Note(F3 Setting is for F1-3 Motor with Hall sensor):

Only in “F1-3”Hall sensor mode, the PCB will record all the current value while learning mode. Please set F3 function

after learning mode. The LED display 10 to indicate all of the recorded values will increase 1 ampere as the over current

value. In other words, the LED shows 20 to indicate all the recorded values will increase 2 ampere as the over current

value. The value can be adjusted by pressing button UP and DOWN. The maximum value is 40(4.0A) and the minimum

value is 05(0.5A).

LED Display Definition Parameter Table Description

Motor Type

Dual or Single Gate

Over Current Setting

Over Current Setting

Operation Speed

Deceleration function

Deceleration Speed

Open/Close delay of dual

gate operation adjustment

Auto-Close adjustment

Photocell function mode

Pedestrian Mode function

Pre-Flashing function

F1

F2

F3

F3

F4

F5

F6

F7

F8

F9

FA

FB

F1-1

F1-2

F1-3

F2-1

F2-2

F3-1

F3-2

F3-3

F3-4

F4-1

F4-2

F5-1

F5-2

F6-1

F6-2

F7-1

F7-2

F7-3

F7-4

F7-5

F7-6

F7-7

F7-8

F7-9

F8-0

F8-1

F8-2

F8-3

F8-4

F8-5

F8-6

F8-7

F8-8

F9-1

F9-2

F9-3

F9-4

FA-0

FA-1

FB-0

FB-1

Motor only

Motor with Limit Switch

Motor with Hall sensor

Dual Gate

Single Gate

2A

3A

4A

5A

100% Full speed

80% Full speed

Function ON

Function OFF

70% Full speed

50% Full speed

2 sec

3 sec

4 sec

5 sec

6 sec

7 sec

8 sec

9 sec

10 sec

Function OFF

3 sec

10 sec

20 sec

40 sec

60 sec

120 sec

180 sec

300 sec

Mode 1

Mode 2

Mode 3

Mode 4

Function OFF

Function ON

Function OFF

Function ON

1. The factory setting is "F1-1".

1. The factory setting is "F2-1".

1. The factory setting is "F3-1",

2. F3 setting is for F1-1 Motor only and F1-2 Motor with

Limit Switch

1. The factory setting is "F4-1".

1. The factory setting is "F5-1".

1. The factory setting is "F6-2".

1. The factory setting is "F7-1".

1. Auto-close mode activates when the gates move to

the end position or stopped manually. If the transmitter,

push button, or the key selector is activated before the

auto-close counting, the gate will close immediately.

2. The factory setting is "F8-2".

1. The factory setting is "F9-1".

1. When funciton on and push B key in the transmitter,

one gate will open partically.

2. The factory setting is "FA-1".

1. When function ON, the light will flash before the gate

operate 3 seconds. If set OFF, the flash light will operate

with motor in the same time.

2. The factory setting is "FB-0".

Page 18

ARTICULATED ARM OPENERS USER MANUAL

16

LED Display Definition Function Table Description

Photocell 1 function

Photocell 2 function

Buzzer function

Latch release function

Open/Stop/Close/Stop

function key

Pedestrian Mode function key

Auto-Close function Key

FC

FD

FE

FF

FG

FH

FI

FC-0

FC-1

FD-0

FD-1

FE-0

FE-1

FF-0

FF-1

FG-1

FG-2

FG-3

FG-4

FH-0

FH-1

FH-2

FH-3

FH-4

FI-0

FI-1

FI-2

FI-3

FI-4

Function OFF

Function ON

Function OFF

Function ON

Function OFF

Function ON

Function OFF

Function ON

A Key

B Key

C Key

D Key

Function OFF

A Key

B Key

C Key

D Key

No key to control

A Key

B Key

C Key

D Key

1. The factory setting is "FC-0".

1. The factory setting is "FD-0".

1. The factory setting is "FE-1".

1. If the function on, the gate will move forword a little before the

gate operate for releasing the latch.

2. The factory setting is "FF-1".

1. The factory setting is "FG-1".

1. The factory setting is "FH-2".

1. The key is to turn on or off the Auto-Close function.

2. The factory setting is "FI-3".

3.When the flasher and buzzer is running, the auto closed

button has no function till flasher and buzzer finish running.

Page 19

ARTICULATED ARM OPENERS USER MANUAL

17

5. Technical Features

5.1 Dimension

Overheated Back-up Batteries

The gate doesn’t move when pressing the

button of the transmitter

The gate only moves a little distance when

pressing the button of the transmitter.

The transmitting distance is too short

The gear motors run very slowly

The Flashing light does not work

The leaves shall be closed instead of opening

The leaves suddenly stop during moving

The leaves does not move or only move toward

one direction

The master gate closes to the end first and the

slave gate stops, the flashing light blinks fast for

five seconds.

The gear motors does not run and the relay is

noisy when operating the gate opening and

closing

Check the wiring connection of the batteries.

1. Check if LED3 or 4 is “OFF”.

2. Check if the voltage of the batteries is upon 22V.

3. Make sure all the wiring connections are firmly connected to the

terminals on the PCB.

4. Make sure the fuse is workable.

Make sure the wiring connection of the hall sensor is firm.

Make sure the connecting terminals of the

Antenna is firm.

Check the dip switch setting of the speed adjustment.

Check if the wiring connection of the flashing light is correct.

Change the polarity connection of the positive (+) with the negative (-)

of the gear motors.

1. Check if the “RESET” socket is activated.

2. Make sure the wiring connection of the gear motors is firm.

3. Make sure the hall sensor wiring connection is firm.

4. The GND terminal of the photocells on the PCB must be

short-circuited if no photocells installed.

5. Make sure the fuse is workable.

1. Check if the “RESET” socket is activated.

2. Make sure the wiring connection of the gear motors is firm.

3. Make sure the hall sensor wiring connection is firm.

4. The GND terminal of the photocells on the PCB must be

short-circuited if no photocells installed.

Cut off the AC input power and the output of the batteries. Release the

master gate and slave gate manually, then open the master to the end

and close the slave gate to the end by hand, then power the whole unit

by connecting the AC and battery terminals.

Check if the fuse is burned.

4. Trouble Shooting

190mm250mm

255.2mm

Page 20

34100-124-01-C

6. Maintenance

Conduct the following operations at least every 6 months. If in high intensity of use, shorten the period in between.

Disconnect the power supply:

(1) Clean and lubricate the screws, the pins, and the hinge with grease.

(2) Check the fastening points are properly tightened.

(3) Make the wire connection are in good condition.

Connect the power supply:

(1) Check the power adjustments.

(2) Check the function of the manual release.

(3) Check the function of photocells or other safety devise.

5.2 Technical Feature:

Model

Motor

Gear type

Nominal thrust

Maximum Gate Weight

Maximum Gate Length

Operating Temperature

Dimension

Weight

PA250

24Vdc motor

Electromechanical worm gear

2500N

250 kg per leaf

2.5 meters per leaf

-20

o

C~+50oC

256 x 187 x 267mm

6 kg

Model

Main power supply

Back-up battery

Receiver board

Installation

Operating Temperature

Dimension

PC190

230Vac/110Vac, 50Hz/60Hz

2pcs of batteries for emergency operation, 1.2A each

433.92MHz; 200 transmitters memory

Built - in PCBA

-20

o

C~+50oC

275mm x 195mm x 102mm

Loading...

Loading...