Page 1

Owner’s Manual

Wall Mount Dust Collector

QUESTION...

1•847•780•6120

Model No. DC5370

Visit us on the web at www.southerntechllc.com

You will need this manual for safety instructions, operating procedures, and warranty.

Put it and the original sales invoice in a safe, dry place for future reference.

26-0416

Page 2

TABLE OF CONTENTS

PRODUCT

SECTION PAGE

SAFETY RULES 1

Work Preparation

Work Area Preparation

Tool Maintenance

Tool Operation

ASSEMBLY 2

Unpacking

Installation

Test

Power Source

Grounding Instructions

Extension Cords

Motor

Electrical Connections

OPERATION 5

Basic Operations

SPECIFICATIONS

Motor ................................ 1-HP, 120/240 V, 60-Hz, 1PH

Motor Speed ..................................................... 3450 RPM

Bearings ...................... Sealed & Permanently Lubricated

Cord Length ............................................................. 6 Feet

Air Suction Capacity ........................................... 537 CFM

Max. Static Pressure ................................7.2" (182.8 mm)

Main Inlet Size ............................................ 4" (101.6 mm)

Impeller Type ..................................................... Radial Fin

Impeller Size ................................................ 10" (254 mm)

Collection Bag

(with a clear window and bottom zipper) ......... 2.5 micron

Overall Dimensions .................................... 20" x 18" x 45"

............................................. (508 x457 x 1143 mm)

Weight ...................................................... 52 lbs (23.6 kg)

MAINTENANCE 6

General Maintenance

Cleaning

Lubrication

Machine Storage

Tool Repairs

TROUBLESHOOTING 7

PARTS ILLUSTRATION & 8

LIST

WARRANTY 9

Page 3

SAFETY RULES

WARNING

For your own safety, read and understand all warnings

and operating instructions before using any tool or

equipment.

WARNING

Some dust created by power sanding, sawing, grinding,

drilling and other construction activities contains chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other

masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area and work

with approved safety equipment. Always wear OSHA/

NIOSH approved, properly fitting face mask or respirator

when using such tools.

WARNING

Always follow proper operating procedures as defined in

this manual even if you are familiar with the use of this or

similar tools. Remember that being careless for even a

fraction of a second can result in severe personal injury.

WORK PREPARATION

• Wear proper apparel. Do not wear loose clothing, gloves,

neckties, rings, bracelets or other jewelry which may get

caught in moving parts of the tool.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States ANSI

Z87.1. Everyday glasses have only impact resistant

lenses. They are NOT safety glasses.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools

when tired, intoxicated or when taking medications that

cause drowsiness.

WORK AREA PREPARATION

• Keep work area clean. Cluttered work areas invite

accidents.

• Do not use power tools in dangerous environments. Do

not use power tools in damp or wet locations. Do not

expose power tools to rain.

• Work area should be properly lit.

• Proper electrical receptacle should be available for

tool. Three-prong plug should be plugged directly into

properly grounded, three-prong receptacle.

• Extension cords should have a grounding prong and

the three wires of the extension cord should be of the

correct gauge.

• Keep visitors at a safe distance from work area.

1

• Keep children out of the work area. Ensure your work

shop is child-proof. Use padlocks, master switches or

remove switch keys to prevent any unintentional use of

power tools.

TOOL MAINTENANCE

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining and adjusting

procedures.

• Keep tool lubricated and clean for a safe operation.

• Remove adjusting tools. Form habit of checking to

see adjusting tools or accessories are removed before

switching tool on.

• Keep all parts in working order. Check to determine that

guard or other parts will operate properly and perform

their intended function.

• Check for damaged parts. Check for alignment of

moving parts, binding, breakage, mounting and any

other condition that may affect tool’s operation.

• A guard or any other part that is damaged should be

properly repaired or replaced. Do not perform makeshift

repairs.

TOOL OPERATION

• Use the right tool for your job. Do not force your tool or

attachment to do a job for which it was not designed.

• Avoid accidental start-up. Make sure that the tool is in

the “OFF" position before plugging in.

• Never leave tool running unattended.

• Know your tool. Learn the tool’s operation, application

and specific limitations before using it.

CAUTION

Think safety! Safety is a combination of operator common

sense and alertness at all times when tool is being used.

WARNING

Do not attempt to operate tool until it is completely

assembled according to the instructions.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

SAFETY RULES

1

Page 4

2

SAFETY RULES

WARNING

Read and understand the instruction manual before

operating the dust collector. Basic precautions listed

below should always be followed when using your dust

collector to reduce the risk of injury, electrical shock

or fire.

• This dust collector is designed to collect sawdust only.

• Never attempt to use this dust collector to vacuum water

2

or any other liquids.

• Never try to use this dust collector to collect large

wood pieces.

• Never attempt to use this dust collector to collect metal

materials such as screws, nails or other metal parts.

• Always wear approved eye protection and respirator

when emptying collection/filter bags.

SPECIFIC SAFETY INSTRUCTIONS

• Never operate the dust collector with all blast

gates closed.

• Turn machine off, disconnect power cord and ensure all

moving parts have stopped completely before changing

or emptying the bags.

• ALWAYS ensure collection/filter bags are secured

in place.

• Do not place your hand or tools near the open inlet

while operating. Serious personal injury or damage to

the machine can happen.

• Always connect dust collector to the matched

power source.

IMPORTANT : Always consider safety first as it applies

to your individual working conditions, the environment in

every shop is different.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

2

UNPACKING

Refer to Figure 1.

Check for shipping damage. Check immediately whether all

parts and accessories are included. If anything is missing or

broken, contact your retailer or call 847-780-6120.

• Carefully remove all contents from shipping carton. The

shipping carton contains:

ITEM DESCRIPTION QUANTITY

A Motor Housing

2

B Dust Collection Bag 1

C Motor Bracket 1

D Wall Mounting Bracket 1

E Quick Release Bag Clamp 1

F Foam Strip 1

G Hardware Bag

(contains four flange bolts) 1

H 12-10 mm Wrench 1

Owner's Manual (not shown)

ASSEMBLY

Figure 1

INSTALLATION

Refer to Figures 2 - 3

CAUTION

Do not attempt assembly if parts are missing.

Call the Customer service line to obtain replacement

parts.

WARNING

Do not operate dust collector until completely assembled.

Do not operate this tool until you have completely read

and understood this manual.

NOTE: After unit is assembled dispose of all packaging

material in an environmentally safe way.

Tools required for assembly:

• 10 mm Wrench

1. Align holes in motor bracket with holes in motor housing,

secure bracket in place with four bolts supplied.

Page 5

all Mount Bracket

Figure 2

Flange Bolt

A

W

Motor Bracket

• If mounting to a framed wall attach the mounting

bracket to a support board. Attach the support board

with lag screws (not supplied).

4. Hang the dust collector onto the wall mounting bracket.

5. Place the adhesive foam strip (supplied) around the

dust collector outlet port.

6. Place the dust collector bag onto the outlet port and

secure in place with the quick release bag clamp

(supplied).

TEST

ASSEMBLY

Adhesive Foam Strip

Quick Release Clamp

2. Wall mounting bracket placement:

NOTE: The mounting bracket must be placed a minimum

of 44" (1117.6 mm) from the floor and a minimum of 6"

(152.4 mm) from the corner or adjoining wall so the motor

has sufficient cooling space.

NOTE: Place the mounting bracket near an existing power

source. Make sure all power cords will be protected from

traffic, material handling, moisture, chemicals or other

hazards. Ensure the power source is easy to access.

Figure 3

WARNING

Before starting the dust collector, make sure you have

read and understood the manual and you are familiar with

the functions and safety features on the machine. Failure

to do so may cause serious personal injury.

Run a test to ensure the dust collector operates properly.

1. Ensure all tools are removed from the work area and the

wall mounting bracket is secure.

2. Plug the power cord into the correct receptacle. (Refer

to Power Source paragraph in this section of the

manual.)

3. Turn the dust collector ON. (Refer to On/Off Switch

paragraph in Operation section of the manual.)

4. If unusual noise or excessive vibration is noticed, shut

off the machine immediately and disconnect the cord

from the power source. Check all the assembled parts

once again and investigate to find the problem.

5. If the dust collector operates correctly, turn the machine

OFF and remove the safety key on the switch. Once the

safety key is removed, turn the switch ON. The machine

should not run with the safety key removed.

If everything operates correctly the dust collector is ready

for use.

POWER SOURCE

WARNING

Do not connect dust collector to the power source until all

assembly steps have been completed.

The motor is designed for operation on the voltage and

frequency specified. Normal loads will be handled safely

on voltages not more than 10% above or below specified

voltage. Running the unit on voltages which are not within

the range may cause overheating and motor burn-out.

Heavy loads require that the voltage at motor terminals be

no less than the voltage specified on nameplate.

• Power supply to the motor is controlled by a single

pole locking rocker switch. Remove the key to prevent

unauthorized use.

3

3. Use the wall mounting bracket as a template to mark

mounting holes.

• If mounting on a masonry wall use lag screws with lag

shield anchor studs (not supplied).

Page 6

GROUNDING INSTRUCTIONS

ASSEMBLY

WARNING

Improper connection of equipment grounding conductor

can result in the risk of electrical shock. Equipment

should be grounded while in use to protect operator from

electrical shock.

• Check with a qualified electrician if you do not

understand grounding instructions or if you are in doubt

as to whether the tool is properly grounded.

• This tool is equipped with an approved cord rated at

4

120V and a 3-prong grounding type plug (see Figure 4)

for your protection against shock hazards.

• Grounding plug should be plugged directly into a

properly installed and grounded 3-prong grounding type

receptacle, as shown (see Figure 4).

Figure 4

Properly Grounded Outlet

Grounding Prong

3-Prong Plug

• Do not remove or alter grounding prong in any manner.

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electrical shock.

WARNING

Do not allow fingers to touch the terminals of plug when

installing or removing from outlet.

• Plug must be plugged into matching outlet that is

properly installed and grounded in accordance with

all local codes and ordinances. Do not modify plug

provided. If it will not fit in outlet, have proper outlet

installed by a qualified electrician.

• Inspect tool cords periodically, and if damaged, have

repaired by an authorized service facility.

• Green (or green and yellow) conductor in cord is the

grounding wire. If repair or replacement of the electric

cord or plug is necessary, do not connect the green (or

green and yellow) wire to a live terminal.

EXTENSION CORDS

• The use of an extension cord is not recommended.

The use of any extension cord will cause some drop in

voltage and loss of power.

• Wires of the extension cord must be of sufficient size to

carry the current and maintain adequate voltage.

• Use the table to determine the minimum wire size

(A.W.G.) extension cord.

• Use only 3-wire extension cords having 3-prong

grounding type plugs and 3-pole receptacles which

accept the tool plug.

• If the extension cord is worn, cut or damaged in any

way, replace it immediately.

Extension Cord Length

Wire Size…………….. A.W.G.

Up to 50 ft…………… 14 gauge

NOTE: Using extension cords over 50 ft. long is not

recommended.

MOTOR

The dust collector is assembled with motor and wiring

installed. The electrical wiring schematic is shown in

Figure 5.

The permanently split capacitor motor has the following

specifications:

Horsepower (Peak HP) .................................................. 1

Voltage ............................................................... 120/240

Amp ......................................................................... 7/3.5

Hertz ............................................................................ 60

Phase .................................................................... Single

RPM ......................................................................... 3450

ELECTRICAL CONNECTIONS

WARNING

All electrical connections must be performed by a qualified

electrician. Make sure tool is off and disconnected

from power source while motor is mounted, connected,

reconnected or anytime wiring is inspected. Motor and

wires are installed as shown in wiring schematic (See

Figure 5). Motor is assembled with approved, 3-conductor

cord to be used at 120 volts.

Figure 5

The power lines are inserted directly into the switch. The

green ground line must remain securely fastened to the

frame to properly protect against electrical shock. The

power supply to the motor is controlled by a single pole

locking rocker switch.

• Remove the key to prevent unauthorized use.

Page 7

OPERATION

5

OPERATION

BASIC OPERATIONS

ON/OFF Switch

The keyed switch is intended to prevent unauthorized use

of the dust collector.

1. To turn the dust collector ON insert the yellow key into

the key slot in the center of the switch.

2. Push the key firmly into the slot, then push switch to the

ON position to start the dust collector.

3. To turn the dust collector OFF push the switch to the

down position.

4. Remove the yellow switch key, when the dust collector

has come to a complete stop, by gently pulling it

outward.

WARNING

Remove the switch key whenever the dust collector is not

in use.

Place it in a safe place and out of reach of children.

WARNING

ALWAYS lock the switch OFF when the dust collector is

not in use. Remove the key and keep it in a safe place.

In the event of power failure, blown fuse, or tripped

circuit breaker, turn the switch OFF and remove the key,

preventing accidental startup when power comes on.

Figure 6

On/Off Switch

Yellow Switch

Key

Operation

1. Position the tool being used close to the dust collector.

2. Connect one end of a dust collector hose to the dust

collector inlet and one end to the machine outlet. Secure

both ends with hose clamps (not included).

3. Turn the dust collector ON. (Refer to On/Off Switch

paragraph in this section of the manual.)

Figure 7

Dust Collector

Dust Collector

Inlet

Hose

5

Page 8

6

MAINTENANCE

GENERAL MAINTENANCE

WARNING

Make sure the machine is turned off and the cord is

disconnected from the power source before servicing and

removing/replacing any components on the machine.

• Check the dust collector daily for loose mounting bolts,

6

screws, damaged wires, worn switch, full collection bag

and any other unsafe condition.

• The impeller screw may loosen with use. Check the

impeller once a month to ensure the impeller screws are

tight, securing the impeller on the shaft.

To check: Make sure the machine is turned off and the

cord is disconnected from the power source. Access the

impeller screws through the inlet cover on the machine

and tighten to secure the impeller on the shaft.

CLEANING

Check and empty the collection bag on your dust collector

regularly. The machine operates at a much higher level of

efficiency when the collection bag is empty.

This collection bag has a clear window and a bottom zip.

The clear window allows operator to see the amount of

dust in the bag and the bottom zip makes bag-emptying easy.

MAINTENANCE

LUBRICATION

The sealed bearings in the motor have been permanently

lubricated at the factory. They require no further

lubrication.

MACHINE STORAGE

• When the dust collector is not in use, disconnect the

cord from the power source and store the machine in a

dry place.

• Do not expose the machine to rain.

• Ensure the cord is kept away from potential damage

sources such as; sharp objects, chemicals, heat sources

and water.

TOOL REPAIRS

• If power cord is worn, cut, or damaged in any way, have

it replaced immediately.

• Replace worn abrasives when needed.

• Replace any damaged or missing parts. Use parts list

to order parts. Any attempt to repair motor may create

a hazard unless repair is done by a qualified service

technician. Call the customer service line at

847-780-6120 for assistance.

Page 9

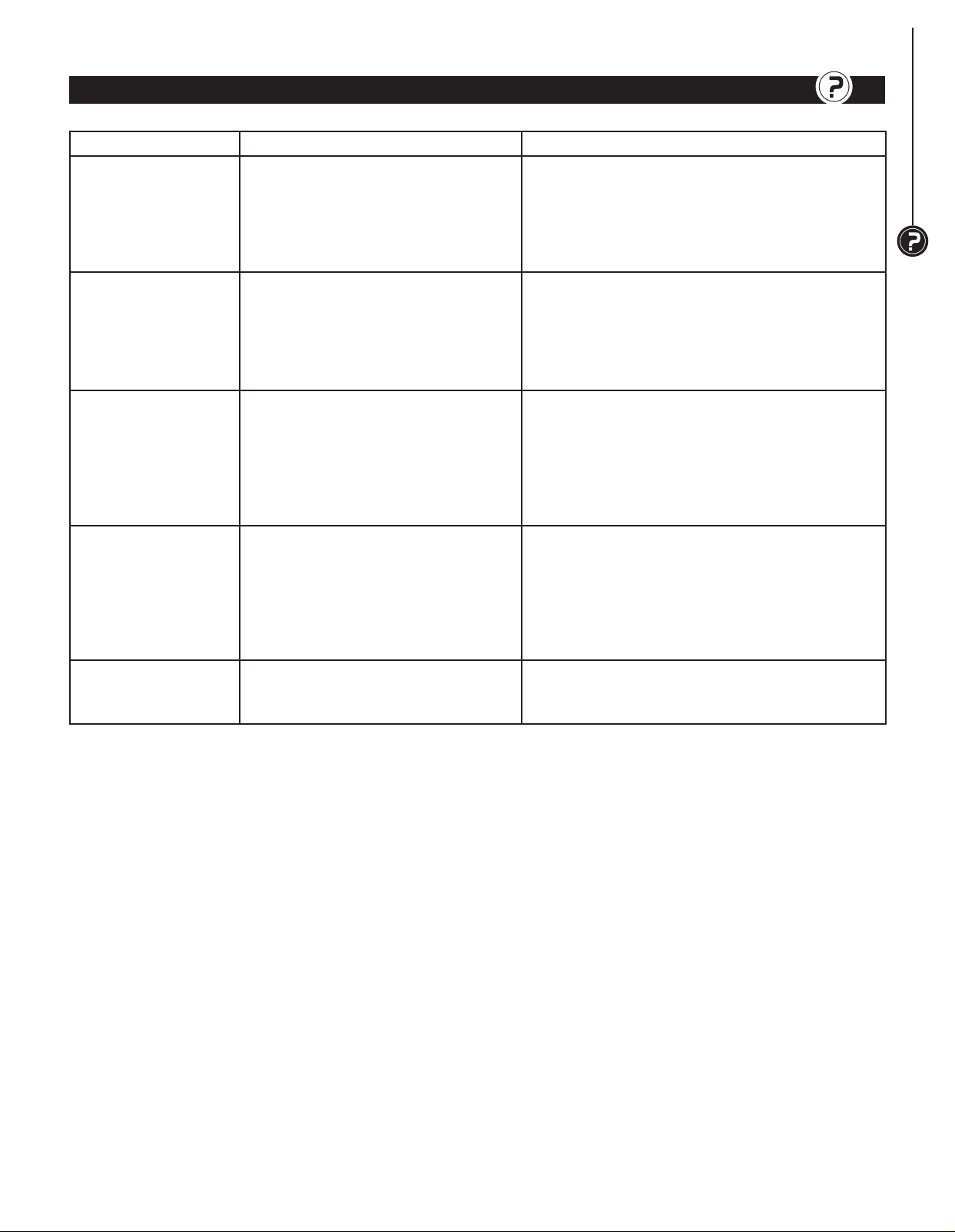

TROUBLESHOOTING

7

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Motor will not start 1. Low voltage

2. Open circuit in motor or loose

connections

3. Defective switch

4. Defective capacitor

5. Switch key is removed

Motor will not start;

fuses blown or circuit

breakers are tripped

Unit has vibration or

noisy operation

Loud, repetitious

noise or excessive

vibration coming from

dust collector

Sawdust blown into

the air from the dust

collector

1. Short circuit in line cord or plug

2. Short circuit in motor or loose

connections

3. Incorrect fuses or circuit breakers in

power line

1. Motor or components are loose

2. Motor mount is loose/broken

3. Unit is incorrectly mounted to wall

4. Motor fan is rubbing cover

5. Motor bearings faulty

1. Dust collection bag is full

2. Dust collector hose restricted

3. The lumber is wet and dust is not

flowing through the hose smoothly

4. There is a leak in the hose

Hose clamps or dust collection bag is

not properly clamped and secured.

1. Check power line for proper voltage

2. Inspect all lead connections on motor for loose or

open connection

3. Replace switch

4. Replace capacitor

5. Insert switch key

1. Inspect line cord or plug for damaged insulation

and shorted wires

2. Inspect all lead connections on motor for loose or

shorted terminals or worn insulation on wires

3. Install correct fuses or circuit breakers

1. Inspect/replace any stripped or damaged bolts/

nuts and re-tighten.

2. Tighten/replace

3. Tighten/replace mounting hardware

4. Replace fan cover; replace loose/damaged fan

5. Call the customer service line at 847-780-6120

for assistance

1. Empty collection bag.

2. Remove hose from dust collector inlet and

unblock the restriction in the hose. A plumbing

snake may be necessary.

3. Process lumber with less than 20% moisture

content.

4. Inspect and replace hose.

Check hose and dust collection bag, ensure hose

and bag clamps are tight and completely over the

hose and bag.

TROUBLESHOOTING

7

Page 10

8

PARTS LIST

8

WALL MOUNT DUST COLLECTOR PARTS ILLUSTRATION

WALL MOUNT DUST COLLECTOR PARTS LIST

Key No. Part No Description Qty

1 DC5370001 Main housing 1

2 DC5370002 Inlet cover 4" 1

3 DC5370003 Impeller 10" 1

4 DC5370004 Motor 1

5 DC5370005 Impeller washer 1

6 DC5370006 Spring washer 1/4" 1

7 DC5370007 Cap screw M6 x 30 1

8 DC5370008 Phillip HD tp screw M5 x10 12

9 DC5370009 Motor gasket 1

10 DC5370010 Flat washer 1/4" x 18 4

11 DC5370011 Hex screw 1/4" x 1/2" 4

12 DC5370012 Motor plate 1

13 DC5370013 Wall mount bracket 1

14 DC5370014 Flange bolt 1/4" x 1/2" 4

15 DC5370015 Cap 1" 1

16 DC5370016 Handle cover 1

17 DC5370017 Set screw 5/16" x 5/16" 1

18 DC5370018 Collection bag 1

19 DC5370019 Bag clamp 5" 1

Page 11

WARRANTY

Thank you for investing in a POWERTEC power tool. This product has been designed and manufactured to meet high

quality standards and is guaranteed for domestic use against defects in workmanship or material for a period of 12

months from the date of purchase. This guarantee does not affect your statutory rights.

SOUTHERN TECHNOLOGIES LLC. BENCH TOP AND STATIONARY POWER TOOL

LIMITED 1 YEAR WARRANTY AND 30-DAY SATISFACTION GUARANTEE POLICY

POWERTEC products are designed and manufactured by Southern Technologies LLC. All warranty communications

should be directed to Southern Technologies LLC by calling 847-780-6120 (toll free), 9 AM to 5 PM, Monday through

Friday, US Central Time.

30- DAY SATISFACTION GUARANTEE POLICY

During the first 30 days after the date of purchase, if you are dissatisfied with the performance of this POWERTEC tool

for any reason, you may return the tool to the retailer from which it was purchased for a full refund or exchange. You

must present proof of purchase and return all original equipment packaged with the original product. The replacement

tool will be covered by the limited warranty for the balance of the one year warranty period.

LIMITED ONE YEAR WARRANTY

This warranty covers all defects in workmanship or materials in this POWERTEC tool for a one year period from the

date of purchase. This warranty is specific to this tool. Southern Technologies, LLC reserves the right to repair or

replace the defective tool, at its discretion.

9

WARRANTY

9

HOW TO OBTAIN SERVICE

To obtain service for this POWERTEC tool you must return it, freight prepaid, to POWERTEC. You may call (toll

free) 847-780-6120 for more information. When requesting warranty service, you must present the proof of purchase

documentation, which includes a date of purchase. POWERTEC will either repair or replace any defective part, at

our option at no charge to you. The repaired or replacement unit will be covered by the same limited warranty for the

balance of one year warranty period.

WHAT IS NOT COVERED

This warranty applies to the original purchaser at retailer and may not be transferred.

This warranty does not cover consumable items such as saw blades, knives, belts, discs, cooling blocks and sleeves.

This warranty does not cover required service and part replacement resulting from normal wear and tear, including

accessory wear.

This warranty does not cover any malfunction, failure or defect resulting from:

1) misuse, abuse, neglect and mishandling not in accordance with the owner’s manual.

2) damage due to accidents, natural disasters, power outage, or power overload.

3) commercial or rental use.

4) alteration, modification or repair performed by persons not recommended by POWERTEC.

DISCLAIMER

To the extent permitted by applicable law, all implied warranties, including warranties of MERCHANTABILITY or

FITNESS FOR A PARTICULAR PURPOSE, are disclaimed. Any implied warranties, that cannot be disclaimed under

state law are limited to one year from the date of purchase. Southern Technologies LLC. is not responsible for direct,

indirect, incidental or consequential damages. Some states do not allow limitations on how long an implied warranty

lasts and/or do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations

may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state. Southern Technologies LLC., makes no warranties, representations, or promises as to the quality or

performance of its power tools other than those specifically stated in this warranty.

Page 12

Southern Technologies, LLC

3816 Hawthorn CT,

Waukegan, IL 60087

Loading...

Loading...