Page 1

Owner’s Manual

Model No. MT4008

MITER SAW STAND

You will need this manual for safety instructions, operating procedures, and warranty.

Put it and the original sales invoice in a safe, dry place for future reference.

Visit us on the web at www.southerntechllc.com

17-1109

QUESTION...

1•847•780•6120

Page 2

PRODUCT

SPECIFICATIONS

Height .......................... 33-1/4" (846 mm)

Extended Width ...........42–65-1/4 (1067–1657 mm)

Maximum Load Capacity ..............330 lbs (150 kg)

Net Weight .......................29.3 lbs. (13.3 kg)

Gross Weight .....................33.7 lbs. (15.3 kg)

TABLE OF CONTENTS

SAFETY RULES 1

ASSEMBLY 2

Unpacking

Tools Needed

Assemble Handle

Unfold the Work Legs

Assemble Wheels

Assemble Roller Bar/ Extension Bar

Locking Knobs

Mounting the Miter Saw

OPERATIONS 4

Roller Bars/Extension Bars Adjustment

Material Supports

Transportation

MAINTENANCE 5

General Maintenance

Adjust Quick Release Bracket

PARTS ILLUSTRATION 6

& LIST

WARRANTY 8

SECTION PAGE

Page 3

SAFETY RULES

1

1

SAFETY RULES

WARNING

For your own safety, read all of the rules and precautions

before operating tool.

WARNING

Always follow proper operating procedures as defined in

this manual even if you are familiar with use of this miter

saw stand or any tool used with this stand. Remember

that being careless for even a fraction of a second can

result in severe personal injury.

You must be familiar with the use of any tool or accessory

used with this miter saw stand. The supplier cannot

be held responsible for any accident, injury or damage

incurred while using this stand with any tool.

WARNING

Some dust created by operation of power tool contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm. To

reduce your exposure to these chemicals, work in a well

ventilated area and work with approved safety equipment.

Always wear OSHA/NIOSH approved, properly fitting face

mask or respirator when using such tools.

CAUTION

Do not modify or use this stand for any application other

than that for which it was designed.

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

grounded power tools. Unmodified plugs and matching

outlets will reduce the risk of electric shock.

• Avoid body contact with grounded surfaces, such as

pipes, radiators, ranges, and refrigerators. There is an

increased risk of electric shock if your body is grounded.

• Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

• Do not abuse the cord. Never use the cord for carrying,

pulling, or unplugging the power tool. Keep the cord

away from heat, oil, sharp edges, or moving parts.

Damaged or entangled cords increase the risk of

electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock. If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter (GFCl}

protected supply. Use of a GFCI reduces the risk of

electric shock.

SAFETY FOR WORK STAND

• Do not attempt to assemble or operate your miter saw

stand until you have read the safety instructions in this

section.

• Only use your miter saw stand on a hard, dry and flat

surface.

• Keep your work area clean and well lit. Cluttered or dark

areas invite accidents.

• Do not overreach. Keep proper footing and balance at

all times.

• Do not load the miter saw stand with more than 330 Ibs

(150 kg).

• Store properly. Do not store the miter saw stand

outdoors or in a damp location.

• Do not stand or climb on miter saw stand. It could tip

over, causing serious injury.

• Do not permit children to use the miter saw stand

unsupervised. It is not a toy.

• Be sure all locking pins are in the set-up position holes

before using your miter saw and miter saw miter saw

stand.

• Take care when moving the stand, especially when a

miter saw is mounted.

• Dress properly. Do not wear loose clothing or jewelry.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair can be caught

in moving parts. Always wear non-slip footwear. Tie

back long hair. Roll long sleeves above the elbow.

• Always firmly attach the miter saw used with this stand.

Do not attempt to use the miter saw on the miter saw

stand until the miter saw is fastened firmly.

• Be aware of tipping. When a large piece is cut from one

end of a job, the remaining piece may be heavy enough

to tip the miter saw stand. Always ensure the workpiece

is well supported.

• Always keep all guards in place. Be sure all power tool

guards are in good working order and are in proper

adjustment and alignment.

• Always keep your hands away from the cutting area.

CAUTION

Think safety! Safety is a combination of operator common

sense and alertness at all times when tool is being used.

WARNING

Do not attempt to operate tool until it is completely

assembled according to the instructions.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

Page 4

2

ASSEMBLY

ASSEMBLY

2

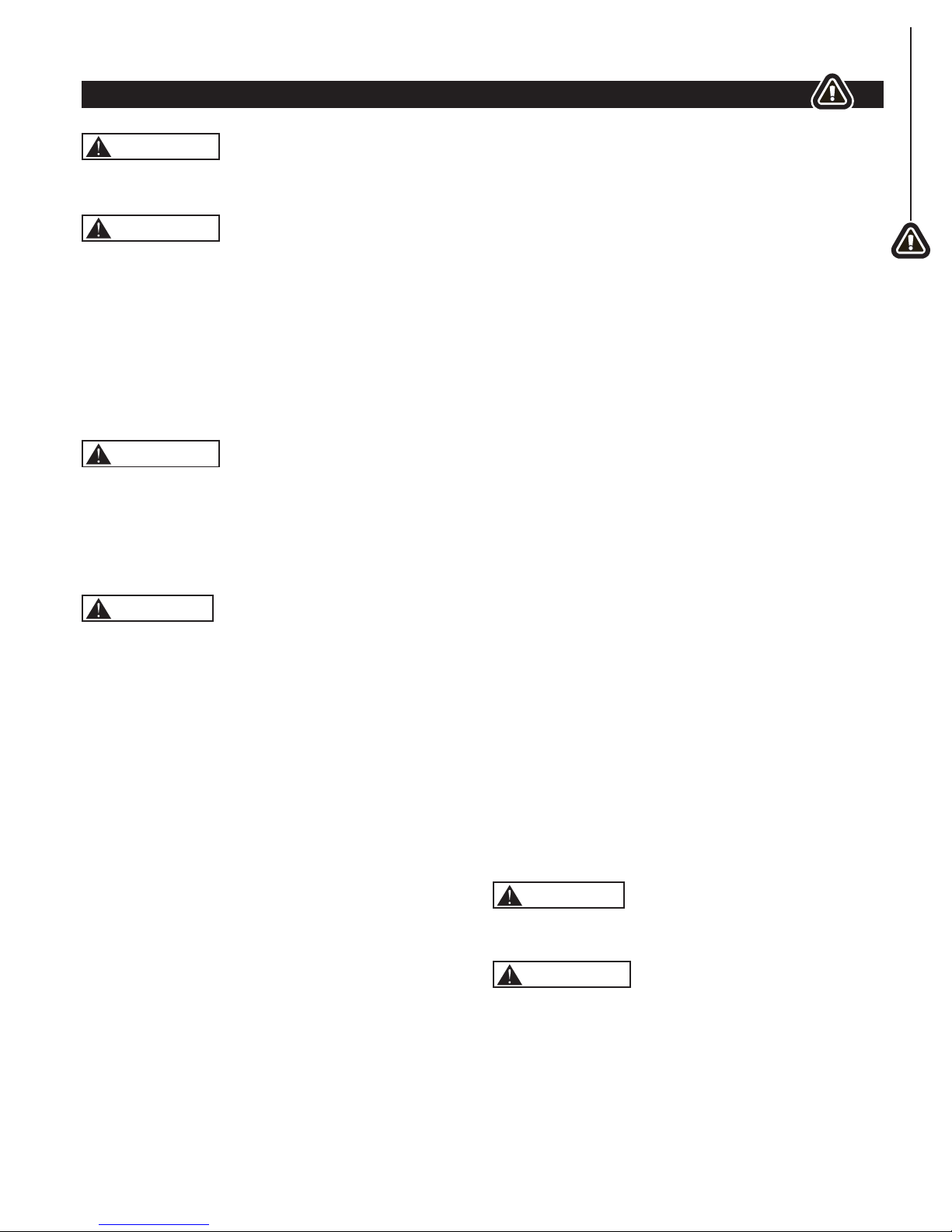

UNPACKING

Refer to Figure 1

Check for shipping damage. Check immediately whether

all parts and accessories are included.

ITEM DESCRIPTION QTY

A Miter Saw Stand 1

B Quick Release Mounting Brackets 2

C Roller Bars 2

D Locking Knobs, plain threads (roller bars) 2

E Locking Knobs, threads with plastic cap

(extension bar)

2

F Wheels 2

G Axle 2

H Locking Nut M8 (wheels) 4

I Washer Ø8 [wheels (4), handle (2)] 6

J Washer Ø12 (wheels) 2

K Handle 1

L Bolt (handle) 2

M Lock Washer (handle) 2

N Miter Saw Mounting Hardware

(mounting bolt, washer, lock washers

and nut)

4

A

B

M

F

C

H

D

E

G

N

I

K

L

J

Figure 1

I

WARNING

Do not use the miter saw stand until it is completely

assembled and you have read and understood this entire

operating manual and the operating manual of the tool

being used with this miter saw stand.

WARNING

Do not use the miter saw stand for scaffolding or as a

ladder. Make sure to securely tighten all fasteners before

using. Maximum capacity is 330 lbs (150 kg). Power tools

on the miter saw stand should not exceed a combined

overall height of 60" (152.4 cm) from the floor.

TOOLS NEEDED

The following tools (not included) are needed to assemble

the miter saw stand:

Phillips screwdriver

13 mm wrench or socket

ASSEMBLE HANDLE

Refer to Figure 2

• Secure handle to frame with hardware supplied.

Figure 2

Bolt

Handle

Lock

Washer

Washer (Ø8)

UNFOLD THE WORK LEGS

Refer to Figure 3

• Place the miter saw stand on a flat surface with the

folded legs facing up.

• Depress the release lever and rotate the leg until it

clicks and locks into the open position. Repeat for

each leg.

Figure 3

• Place the miter saw stand in the upright position on a

flat surface.

Page 5

3

ASSEMBLY

ASSEMBLY

3

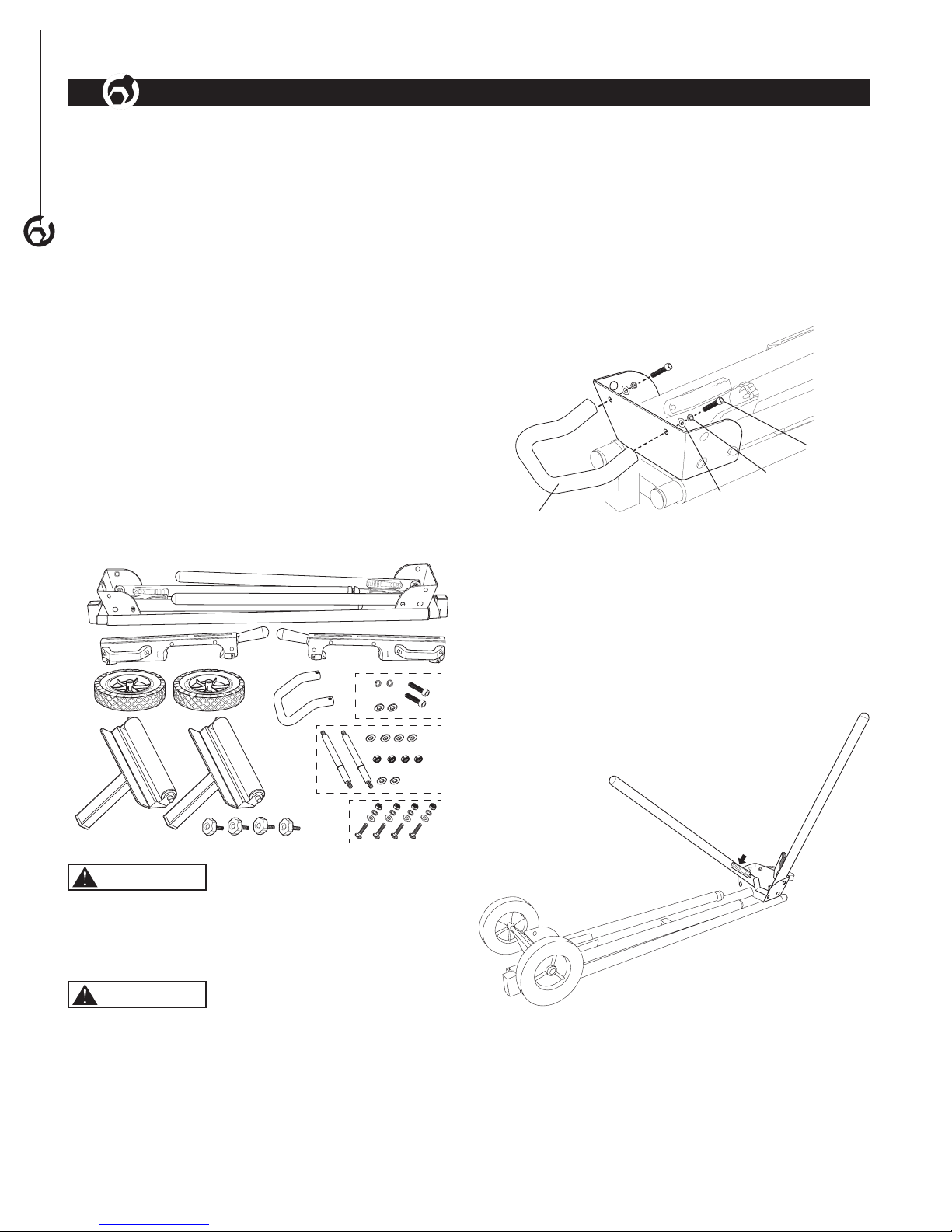

ASSEMBLE WHEELS

Refer to Figure 4

• Slide the axle through the axle bracket, turn the axle

until the machined end fits into the inside bracket

hole. Place one small (Ø8) washer and nut onto axle.

Tighten nut.

NOTE: The axle has a retaining ring on one end and is

machined to fit the axle bracket hole on the other end,

make sure the machined end is inserted into the axle

bracket first.

• Slide one larger (Ø12) washer and the wheel on the

axle. Secure in place with the small (Ø8) washer and

nut. Tighten nut. NOTE: Raised hub goes to the inside.

• Repeat with other wheel.

Figure 4

Axle

Wheel

Nut

Washer

(Ø8)

Washer

(Ø8)

Nut

Washer

(Ø12)

Axle Bracket

Retaining

Ring

ASSEMBLE ROLLER BAR/ EXTENSION BAR

LOCKING KNOBS

Refer to Figure 5

• Place the roller arms into the roller bar supports, slide

up and down to desired location and secure in place

with locking knobs (plain threads).

• Assemble locking knobs (threads with plastic cap) to the

bottom of the frame as shown.

Figure 5

Roller Bar

Locking Knob

Locking

Knob

MOUNTING THE MITER SAW

Refer to Figure 6-7

WARNING

Risk of accidental starting and serious personal injury.

Unplug the miter saw before attaching it to the miter saw

stand.

WARNING

Risk of serious personal injury. Always make sure the

miter saw is fully supported and securely attached to

a level work surface. Make sure the miter saw stand is

located on a flat surface.

WARNING

Do not mount a table saw on this miter saw stand.

Aggressive feeding of sheet materials into a table saw

could cause the stand to tip over.

NOTE: This miter saws stand is to be used with miter

saws with four mounting holes in a rectangular pattern

• Mount the miter saw to the quick-release mounting

brackets using the supplied hardware (mounting bolt,

washer, lock washers and nut) as shown.

Figure 6

Bolt

Lock Washer

Nut

Flat Washer

Page 6

• The quick release mounting brackets hook onto the

miter saw stand frame. Using the handles on the

quick release mounting brackets, lift the miter saw and

position the quick release mounting brackets onto the

miter saw stand as shown in Figure 7 (SAW IS NOT

SHOWN TO ALLOW VISIBILITY OF THE RAILS AND

BRACKETS).

Figure 7

• Lower the saw into place and press the locking levers

down to lock the mounting brackets into place.

OPERATION

4

WARNING

Do not use the miter saw stand for scaffolding or as a

ladder. Make sure to securely tighten all fasteners before

using. Maximum capacity is 330 lbs (150 kg). Power tools

on the miter saw stand should not exceed a combined

overall height of 60" (152.4 cm) from the floor.

NOTE: For your convenience this stand is equipped with

tool trays and a mesh bottom to help prevent accidental

dropping of tools.

ROLLERS BARS/EXTENSION BAR

ADJUSTMENT

Refer to Figure 8

The extension bars move in and out to properly support

the workpiece.

The roller bars are used as directional rollers or with the

extension bars as stationary stop guides.

• Loosen the locking knobs, slide the extension bar in or

out to the required position, tighten the locking knobs.

• Loosen the locking knobs, slide the roller bars up and

down to desired location, tighten the locking knobs.

MATERIAL SUPPORTS

Refer to Figure 8

Fold the material supports out to stack extra material for

easy excess.

Roller Bar

Locking

Knob

Material

Support

Extension

Bar

Locking

Knob

Tool Trays

Locking

Knob

Roller Bar

Material

Support

Locking

Knob

Figure 8

Tool Trays

Release

Levers

4

ASSEMBLY

OPERATION

4

Page 7

OPERATION

5

GENERAL MAINTENANCE

WARNING

When servicing, use only identical replacement parts. Use

of any other parts may create a hazard or cause product

damage. To ensure safety and reliability, all repairs

should be performed by a qualified service technician.

WARNING

Keep the miter saw stand dry, clean, and free from oil and

grease. Always use a clean cloth when cleaning. Never

use brake fluids, gasoline, petroleum based products

or any strong solvent to clean the miter saw stand .

Chemicals can damage, weaken or destroy plastic which

may result in serious personal injury

MAINTENANCE

5

MAINTENANCE

5

ADJUST QUICK RELEASE BRACKET

Refer to Figure 10

The quick release mounting brackets must be secure on

the miter saw stand. If adjustment is needed:

Turn the adjusting nut on the adjustment screw clockwise

to tighten the clamping tension.

Turn the adjusting nut on the adjustment screw

counterclockwise to loosen the clamping tension.

Adjustable

Nut

Figure 10

TRANSPORTATION

Refer to Figure 8, 9

WARNING

Risk of unsafe operation. Ensure proper footing and use

caution when rolling the miter saw stand to prevent tipping

or loss of balance.

• Lift up on the end of the miter saw stand with wheels.

• While holding the stand with one hand, squeeze the

release levers and fold up the two suspended legs. The

legs will lock into place.

• Lower the stand until the wheels rest on a flat surface.

• Using the handle, tilt the other end of the miter saw

stand up and transfer the weight to the wheels.

• Squeeze the release levers and fold up the remaining

two legs. The legs will lock into place.

• Holding the handle, carefully lower the stand to the

ground.

• To move the stand, use handle to lift and tilt the miter

saw stand onto the wheels. Move miter saw stand as

shown.

Figure 9

Page 8

MITER SAW STAND PARTS ILLUSTRATION

6

PARTS LIST

6

Page 9

MITER SAW STAND PARTS LIST

7

PARTS LIST

7

Key# Part# Description Specifications Qty

1 MT4008001 Body Tube 2

2 MT4008002 Storage Box PP 2

3 MT4008003 Legs Fixing Housing 1

4 MT4008004 Nylon Fixing Nut M8 4

5 MT4008005 Flat Washer Φ8 10

6 MT4008006 Flat Washer Φ12 2

7 MT4008007 C Clip Φ12 2

8 MT4008008 Axle 2

9 MT4008009 Pan Head Screws M6*12 8

10 MT4008010 Square Tube End Caps PP 4

11 MT4008011 Wheels 2

12 MT4008012 Bolt M6*14 8

13 MT4008013 Legs Fixing Housing 1

14 MT4008014 PH Screw M8*16 2

15 MT4008015 Split Washer 8 2

16 MT4008016 Handle 1

17 MT4008017 Rivet 5*10 16

18 MT4008018 Locking Knob M8*15 2

19 MT4008019 Extension Tube Fixing Part PP 2

20 MT4008020 Steel Net 1

21 MT4008021 Mounting Locking Handle 2

22 MT4008022 Cam Block ABS 2

23 MT4008023 FH Shoulder Screw 7*45 2

24 MT4008024 FH Shoulder Screw M6*45 4

25 MT4008025 Hex Bolt M6*20 4

26 MT4008026 Mounting Carrying Handle 2

27 MT4008027 Spring Pin Φ5*45 4

28 MT4008028 FH Shoulder Screw M6*35 2

Key# Part# Description Specifications Qty

29 MT4008029 M6 Nut M6 10

30 MT4008030 Saw Mounting Bracket 2

31 MT4008031 Mounting Bracket End Cap PE 4

32 MT4008032 Nylon Fixing Nut M6 8

33 MT4008033 Rear Clamp Jaw PP 2

34 MT4008034 Front Clamp Jaw PA6+GF20% 2

35 MT4008035 Split Washer 6 6

36 MT4008036 Flat Washer Φ6 8

37 MT4008037 Carriage Bolt M6*60 4

38 MT4008038 Roller 2

39 MT4008039 Work Support Welding Part 2

40 MT4008040 End Cap 4

41 MT4008041 Slotted Screw 10*34.5 4

42 MT4008042 End Cap 30*30 4

43 MT4008043 Work Support Welding Part PP M8*15 2

44 MT4008044 Extension Tube 2

45 MT4008045 PH Screw M6*8 2

46 MT4008046 Hexagon Socket Button Head

Screws

M6*46 2

47 MT4008047 Material Support 2

48 MT4008048 Legs 2

49 MT4008049 C Clip 6 4

50 MT4008050 Nylon Fixing Nut M10 4

51 MT4008051 Carriage Bolt M10*45 4

52 MT4008052 Locking Pin 4

53 MT4008053 Rivet 6*44 4

54 MT4008054 Quick Release Leg Lock Lever PP 4

55 MT4008055 Legs 2

56 MT4008056 Feet End Cap 4

Page 10

Thank you for investing in a POWERTEC power tool. This product has been designed and manufactured to meet high

quality standards and is guaranteed for domestic use against defects in workmanship or material for a period of 1 year

from the date of purchase. This guarantee does not affect your statutory rights.

SOUTHERN TECHNOLOGIES LLC. BENCH TOP AND STATIONARY POWER TOOL

LIMITED ONE YEAR WARRANTY AND 30-DAY SATISFACTION GUARANTEE POLICY

POWERTEC products are designed and manufactured by Southern Technologies LLC. All warranty communications

should be directed to Southern Technologies LLC by calling 847-780-6120, 9 AM to 5 PM, Monday through Friday,

US Central Time.

30- DAY SATISFACTION GUARANTEE POLICY

During the first 30 days after the date of purchase, if you are dissatisfied with the performance of this POWERTEC tool

for any reason, you may return the tool to the retailer from which it was purchased for a full refund or exchange. You

must present proof of purchase and return all original equipment packaged with the original product. The replacement

tool will be covered by the limited warranty for the balance of the one year warranty period.

LIMITED ONE YEAR WARRANTY

This warranty covers all defects in workmanship or materials in this POWERTEC tool for a one year period from the

date of purchase. This warranty is specific to this tool. Southern Technologies, LLC reserves the right to repair or

replace the defective tool, at its discretion.

HOW TO OBTAIN SERVICE

To obtain service for this POWERTEC tool you must return it, freight prepaid, to POWERTEC. You may call (toll free)

1-847-780-6120 for more information. When requesting warranty service, you must present the proof of purchase

documentation, which includes a date of purchase. POWERTEC will either repair or replace any defective part, at

our option at no cost to you. The repaired or replacement unit will be covered by the same limited warranty for the

remainder of the one year warranty period.

WHAT IS NOT COVERED

This warranty applies to the original purchaser at retail and may not be transferred.

This warranty does not cover consumable items such as saw blades, knives, belts, discs, cooling blocks and sleeves.

This warranty does not cover required service and part replacement resulting from normal wear and tear, including

accessory wear.

This warranty does not cover any malfunction, failure or defect resulting from:

1) misuse, abuse, neglect and mishandling not in accordance with the owner's manual.

2) damage due to accidents, natural disasters, power outage, or power overload.

3) commercial or rental use.

4) alteration, modification or repair performed by persons not recommended by POWERTEC.

DISCLAIMER

To the extent permitted by applicable law, all implied warranties, including warranties of MERCHANTABILITY or

FITNESS FOR A PARTICULAR PURPOSE, are disclaimed. Any implied warranties, that cannot be disclaimed under

state law are limited to one year from the date of purchase. Southern Technologies LLC. is not responsible for direct,

indirect, incidental or consequential damages. Some states do not allow limitations on how long an implied warranty

lasts and/or do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations may

not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state

to state. Southern Technologies LLC., makes no warranties, representations, or promises as to the quality or

performance of its power tools other than those specifically stated in this warranty.

WARRANTY

8

WARRANTY

8

Page 11

NOTE

Page 12

Southern Technologies, LLC

3816 Hawthorn CT,

Waukegan, IL 60087

Loading...

Loading...