Page 1

Owner’s Manual

Model No. HP1005

4-3/8" Portable Hand Planer

You will need this manual for safety instructions, operating procedures, and warranty.

Put it and the original sales invoice in a safe, dry place for future reference.

Visit us on the web at www.southerntechllc.com

15-1006

QUESTION...

1•847•780•6120

Page 2

PRODUCT

SPECIFICATIONS

Power .................................... 950 W

Voltage ....................................120 V

Hertz ......................................60 Hz

Amperage .....................................8A

Operating Speed ........................16,000 RPM

Cutting Capacity Width ................4-3/8" (110 mm)

Cutting Capacity Depth ................... 1/8" (3 mm)

Rabbeting Depth ........................ 1/3" (8 mm)

TABLE OF CONTENTS

SAFETY RULES 1

ASSEMBLY 3

Unpacking

Attaching Dust Extraction

Adjusting The Depth Of Cutting

Parallel Fence

Power Source

Grounding Instructions

Guidelines For Using Extension Cords

OPERATIONS 5

Switching On And Off

Tool Park Rest

Planing

Chamfering

MAINTENANCE 6

Removing Or Installing Planer Blades

Replacing The Drive Belt

Lubrication

Carbon Brushes

Bearings

Cleaning

TROUBLESHOOTING 8

PARTS ILLUSTRATION 10

& LIST

WARRANTY 12

SECTION PAGE

Page 3

GENERAL SAFETY RULES

1

WARNING

For your own safety, read and understand all warnings

and operating instructions before using any tool or

equipment.

WARNING

Your Powertec planer is designed and engineered to

plane wood or wood products. Planing of steel or other

ferrous materials is a fire hazard and could damage your

planer.

WARNING

Some dust created by operation of power tool contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm. To

reduce your exposure to these chemicals, work in a well

ventilated area and work with approved safety equipment.

Always wear OSHA/NIOSH approved, properly fitting face

mask or respirator when using such tools.

WARNING

Failure to follow these rules may result in serious personal

injury. Remember that being careless for even a fraction

of a second can result in severe personal injury.

WORK PREPARATION

• Wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets or other jewelry which

may get caught in moving parts of the tool.

• Nonslip protective footwear is recommended. Wear

protective hair covering to contain long hair.

• Wear eye and hearing protection. Always use safety

glasses. Eye protection equipment should comply with

ANSI Z87.1 standards. Hearing equipment should

comply with ANSI S3.19 standards.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools

when tired, intoxicated or when taking medications that

cause drowsiness.

WORK AREA PREPARATION

• Keep work area clean. Cluttered work areas and

benches invite accidents.

• Work area should be properly lit.

• Do not use the machine in a dangerous environment.

The use of power tools in damp or wet locations or in

rain can cause shock or electrocution.

• Three-prong plug should be plugged directly into

properly grounded, three-prong receptacle.

• Use the proper extension cord. Make sure your

extension cord is in good condition. It should have

grounding prong and should be of the correct gauge.

1

SAFETY RULES

• Keep children and visitors away. Your shop is a

potentially dangerous environment. Children and visitors

can be injured.

• Make your workshop childproof with padlocks, master

switches or remove switch keys to prevent any

unintentional use of power tools.

• It should have a grounding prong and should be of the

correct gauge.

TOOL MAINTENANCE

• Turn the machine "OFF", and disconnect the machine

from the power source prior to inspection.

• Maintain all tools and machines in peak condition. Keep

tools sharp and clean for best and safest performance.

• Follow instructions for lubricating and changing

accessories.

• Check for damaged parts. Check for alignment of

moving parts, binding, breakage, mounting and any

other condition that may affect tool's operation.

• Poorly maintained tools and machines can further

damage the tool or machine and/or cause injury.

• A guard or any other part that is damaged should be

repaired or replaced. Do not perform makeshift repairs.

TOOL OPERATION

• Avoid accidental start-up. Make sure that the tool is in

the “OFF” position before plugging in.

• Use the right tool for your job. Do not force your tool or

attachment to do a job for which it was not designed.

• Disconnect tool when changing parts.

• Don't force the workpiece on the machine. Damage to

the machine and/or injury may result.

• Never leave tool running unattended. Turn the power off

and do not leave tool until it comes to a complete stop.

• Do not overreach. Loss of balance can make you fall

into a working machine, causing injury.

• Never stand on tool. Injury could occur if the tool tips, or

if you accidentally contact the cutting tool.

• Know your tool. Learn the tool’s operation, application

and specific limitations before using it.

• Use a proper extension cord of the correct gauge. Your

extension cord should have a grounding prong, and

should be in good condition.

• Handle workpiece correctly. Keep hands away from

moving parts.

CAUTION

Think safety! Safety is a combination of operator common

sense and alertness at all times when tool is being used.

WARNING

Do not attempt to operate tool until it is completely

assembled according to the instructions.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

Page 4

SPECIFIC SAFETY RULES FOR PLANER

2

Be aware of general power tool safety. Make sure all the

safety rules are understood.

• Wait for the cutter to stop before setting the tool down.

An exposed rotating cutter may engage the surface,

leading to possible loss of control and serious injury.

• Hold power tool by insulated gripping surfaces, when

performing an operation where the cutting accessory

may contact hidden wiring or its own cord. Cutting

accessory contacting a “live” wire may make exposed

metal parts of the powert tool “live” and could give the

operator an electric shock.

• Secure the workpiece to a stable platform using clamps

or another practical method. Holding the work by hand

or against the body leaves it unstable and may lead to a

loss of control.

• Secure the material being planed. Never hold it in your

hand or across your legs. Small workpieces must be

adequately secured so that the rotating planer blades

don’t pick them up during the forward motion of the

planer. Unstable support causes the blades to bind,

resulting in a loss of control and possible injury.

• Always start the planer before allowing the blade to

contact with the workpiece. Let the blade reach full

speed before using the tool. The planer can vibrate or

chatter and possibly kickback if the speed while cutting

is too slow.

• Check the workpiece for nails. If there are nails, either

remove them or set them well below intended finished

surface. If the planer blades strike objects like nails it

may cause serious personal injury from kickback.

• Only use this planer with wood and wood products.

• Unplug the planer before changing accessories.

Accidental start-ups may occur if the planer is plugged

in during an accessory change. Before plugging the tool

back in, check that the trigger lock is OFF.

2

SPECIFIC SAFETY RULES

• After changing blades, rotate the cutter drum to ensure

the blades do not hit any part of the blade head housing

and the blade locking screws are tight. Loose or

misaligned blades can strike tool housing and damage

the tool and cause possible injury.

• Always hold the tool firmly with both hands for maximum

control.

• Never pull the planer backwards over the workpiece.

Loss of control may occur.

• Do not put fingers or any objects into the chip ejector.

Do not clean out chips while the tool is running. Contact

with the cutter drum will cause injury.

• Remove the plug from power source before removing

chips. The blades are hidden from view and you may be

cut if the blade is contacted.

• GFCI and personal protection devices such as

electrician’s rubber gloves and footwear will increase

personal safety.

• Keep handles and hands dry, clean and free from oil

and grease. Slippery surfaces cannot safely maintain

control of the power tool.

• Develop a periodic maintenance schedule for your tool.

When cleaning a tool be careful not to disassemble

any portion of the tool. Internal wires may be misplaced

or pinched and safety guard return springs may be

improperly mounted.

• Certain cleaning agents such as gasoline, carbon

tetrachloride, ammonia, etc. may damage plastic parts.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

Page 5

ASSEMBLY

3

ASSEMBLY

3

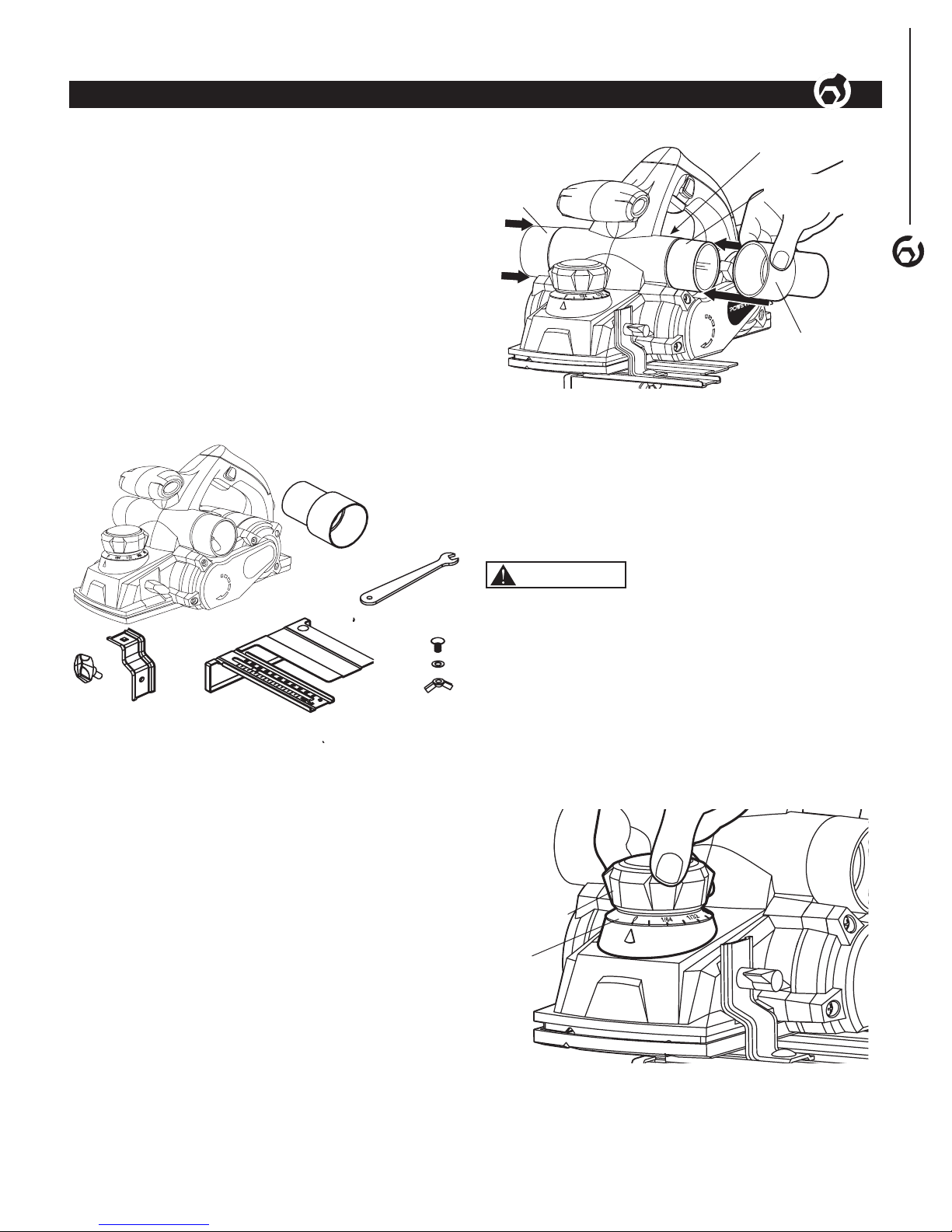

UNPACKING

Refer to Figure 1

• Examine shipping carton for freight damage before

opening. If shipping carton is damaged file a claim with

the carrier immediately.

• Carefully remove all contents from shipping carton. The

shipping carton contains:

1 - Planer

1 - Parallel Fence (bracket, bolt, washer, wingnut)

1 - Dust Extraction Adapter

1 - Locking Knobs

1 - Wrench

1 - Owner's Manual (not shown)

Planer

Parallel

Fence

Bolt

Washer

Wingnut

Locking

Knob

Figure 1

Dust Extraction

Adapter

Parallel

Bracket

Wrench

NOTE: Contact the customer service center if any of these

parts are missing.

NOTE: After unit is assembled dispose of all packaging

material in an environmentally safe way.

ATTACHING DUST EXTRACTION

(optional)

Refer to Figure 2

NOTE: A dust extraction adapter can be fitted to the

appropriate port to allow a dust extraction system or a

suitable vacuum cleaner to be connected to the tool for a

cleaner and safer work area.

• Rotate the extraction guide switch to the desired dust

extraction port.

• Attach the dust extraction adapter to the desired dust

extraction port

Attach the dust extraction system or a suitable vacuum

cleaner hose to the adapter.

Figure 2

Extraction

Guide Switch

Dust Extraction Port

Dust

Extraction

Port

Dust Extraction

Adapter

NOTICE: Shavings may jam the dust extraction port. DO

NOT place fingers inside the dust extraction port. Switch

off and unplug the planer from the power supply, wait for

the cutter to come to a complete stop before cleaning out

the dust extraction port.

ADJUSTING THE DEPTH OF CUTTING

Refer to Figure 3

WARNING

Turn switch OFF, remove the plug from the power source

outlet and wait until the blades have come to a complete

standstill before making any adjustments or removing or

installing accessories.

• Rotate the depth adjustment knob clockwise for a

deeper cut or counterclockwise for a shallower cut.

• The numbers on the depth adjustment scale indicate the

depth of cut. The minimum cutting increment is 1/128”

(0.2 mm).

Figure 3

Depth

Adjustment

Knob

Depth

Adjustment

Scale

NOTE: It is recommended to make test cuts into a scrap

piece of wood after each adjustment to ensure the desired

amount of wood is being removed. Making several shallow

cuts instead of one deep cut will create a smoother finish.

Page 6

ASSEMBLY

4

PARALLEL FENCE

Refer to Figure 4

WARNING

Turn switch OFF, remove the plug from the power source

outlet and wait until the blades have come to a complete

standstill before making any adjustments or removing or

installing accessories.

• Assemble the parallel fence to the bracket using

the bolt, washer and wingnut. The washer is placed

between the wing nut and parallel fence.

• Secure the parallel fence bracket to the left-hand side of

the planer with the locking knob.

• Loosen the wing nut and slide the parallel fence in or

out to the desired width. Tighten the wing nut.

Figure 4

Fence

Fence Bracket

Wing Nut

Bolt

Washer

Locking Knob

POWER SOURCE

WARNING

Do not connect to the power source until the machine is

completely assembled.

The machine is wired for 120 volts, 60 Hz alternating

current. Before connecting the machine to the power

source, make sure the switch is in the “OFF” position.

Running the unit on voltages which are not within range

may cause overheating and motor burn-out. Heavy loads

require that voltage at motor terminals be no less than the

voltage specified on nameplate.

GROUNDING INSTRUCTIONS

IN THE EVENT OF A MALFUNCTION OR BREAKDOWN,

grounding provides the path of least resistance for an

electric current and reduces the risk of electric shock.

This tool is equipped with an electric cord that has an

equipment grounding conductor and a grounding plug.

The plug MUST be plugged into a matching outlet that is

properly installed and grounded in accordance with ALL

local codes and ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not fit

the outlet, have the proper outlet installed by a licensed

electrician.

IMPROPER CONNECTION of the equipment grounding

conductor can result in electric shock. The conductor with

the green insulation (with or without yellow stripes) is the

equipment grounding conductor. If repair or replacement

of the electric cord or plug is necessary, DO NOT connect

the equipment grounding conductor to a live terminal.

CHECK with a licensed electrician or service personnel

if you do not completely understand the grounding

instructions or whether the tool is properly grounded.

CAUTION

In all cases, make certain the outlet in question is properly

grounded. If you are not sure, have a licensed electrician

check the outlet.

WARNING

This tool is for indoor use only. Do not expose to rain or

use in damp locations.

Guidelines for using extension cords

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting

in loss of power and overheating. The table below shows

the correct size to be used according to cord length and

nameplate ampere rating. When in doubt, use a heavier

cord. The smaller the gauge number, the heavier the cord.

AMPERAGE

REQUIRED GAUGE

FOR EXTENSION CORDS

25 ft. 50 ft. 100 ft. 150 ft.

6 A 18

gauge

16

gauge

14

gauge

12

gauge

Make sure your extension cord is properly wired and in

good condition. Always replace a damaged extension cord

or have it repaired by a qualified person before using it.

Protect your extension cords from sharp objects,

excessive heat and damp/wet areas.

Use a separate electrical circuit for your tools. This circuit

must not be less than a #12 wire and should be protected

with a 15 A time-delayed fuse. Before connecting the

motor to the power line, make sure the switch is in the

OFF position and the electric current is rated the same as

the current stamped on the motor nameplate. Running at

a lower voltage will damage the motor.

WARNING

This tool must be grounded while in use to protect the

operator from electric shock.

Page 7

OPERATION

5

SWITCHING ON AND OFF

Refer to Figure 5

CAUTION

Before connecting to the power supply, always make sure

the trigger switch and trigger lock work properly. The tool

is equipped with a trigger lock to avoid unintentional startups.

To turn the planer on, press the trigger lock and then

squeeze the trigger switch.

To switch off, release the trigger switch.

Figure 5

Trigger Lock

Trigger

TOOL PARK REST

Refer to Figure 6

When the planer is lifted from the workpiece the park rest

swings down to rest on the workpiece. This keeps the

blade from coming into contact with the work surface.

The tool park rest will swing up and out of the way when

the back of the planer crosses the edge of the workpiece.

Figure 6

Tool Park

Rest Up

Tool Park

Rest Down

Depth Adjustment

Knob/ Front Handle

Main Handle

CAUTION

DO NOT lock the trigger switch on when resting the

tool on the park rest. The vibration of the running motor

will cause the planer to move and possibly fall from the

workpiece.

PLANING

Refer to Figure 6

CAUTION

Always start the planer and allow it to reach full speed

before touching it to the the workpiece. Lift the tool from

the workpiece before releasing the trigger and turning

it off. Wait until the cutter has come to a complete stop

before setting the planer down.

• Ensure the workpiece is held securely in place on the

work surface.

• Hold the planer firmly with both hands, with one hand

on the depth adjustement knob/front handle and one

hand on the main handle. Rest the front shoe flat on the

workpiece surface, make sure the blades do not make

contact with the workpiece.

• Switch the tool on and wait for the blades to reach full

speed.

• Move the tool gently forward, applying downward

pressure to the front of the tool at the beginning of

planing and at the rear of the tool toward the end of the

planing stroke.

• Push the planer beyond the edge of the workpiece

without tilting it downwards. Do not stop the planer until

it clears the workpiece completely.

NOTICE: Planing is easier if you incline the workpiece

slightly away from you so that you plane “downhill”.

The rate of planing and the depth of the cut determine the

quality of the finish. For rough cutting, you can increase

the depth of cut. To achieve a good finish, you will need to

reduce the depth of the cut while advancing the tool more

slowly.

NOTICE: Moving the machine too fast may cause a poor

quality of cut and can damage the blades or the motor.

Moving the machine too slowly may burn or mar the cut.

The proper feed rate will depend on the type of material

being cut and the depth of the cut. Practice on a scrap

piece of material to gauge the correct feed rate and cutting

dimensions.

CAUTION

The motor may stall if improperly used or overloaded.

Reduce the pressure (feed rate) or depth of cut to prevent

possible damage to the tool if the motor labors.

OPERATION

5

Page 8

CHAMFERING

Refer to Figure 7

To make a chamfered cut, align the “V” grooves in the

front shoe of the planer with the corner edge of the

workpiece.

• Adjust to desired depth of cut.

• Place the “V” groove on the front adjustable shoe over

the edge being beveled. Place weight on the depth

adjustment knob so that the “V” groove is flat on the

edge to be beveled.

• Grasp the tool firmly with both hands. Turn the tool on

and push the plane forward with steady pressure on the

front adjustable shoe.

45°

Figure 7

Depth

Adjustment

Knob

"V" Groove

OPERATION

6

Otherwise, the resulting imbalance can cause vibration

and poor planing action while shortening the life of the

blade and the tool.

The planer blades are reversible. When one of the

cutting edges becomes dull or chipped the blade can be

reversed. When both cutting edges have been used the

blades should be discarded.

Do not attempt to sharpen or use resharpened blades of

any kind. Use only blades designated for use with this

model, as other blades may not clamp securely in blade

holder, causing vibration and a decrease in performance.

• Use the wrench supplied to loosen all clamping screws.

Figure 8

Clamping

Screws

• Clean chips and foreign matter from the cutter drum and

blade.

• If one blade edge is dull, reverse the blade. If both blade

edges are dull, remove the blade and replace it with a

new blade.

• Slide the good blade face up into the blade holder of the

cutter drum until it stops. The ridge along the blade goes

on the opposite side of the clamping screws.

Align Blade

• Loosely tighten the two outside clamping screws, the

blade must be adjusted to align with the outside edge

of the front and rear shoes.

MAINTENANCE

6

MAINTENANCE

6

WARNING

Any attempt to repair or replace electrical parts on this

tool may be hazardous. Repairs not listed here should be

performed by a qualified service technician.

WARNING

Always turn switch OFF, remove the plug from the power

source outlet and wait until the blades have come to a

complete standstill before making any adjustments or

removing or installing accessories.

• Replace any damaged or missing parts. Use parts list

to order parts. Any attempt to repair motor may create

a hazard unless repair is done by a qualified service

technician. Call the customer service line at 847-780-6120

for assistance.

REMOVING OR INSTALLING PLANER

BLADES

Refer to Figure 8–9

WARNING

Turn switch OFF, remove the plug from the power source

outlet and wait until the blades have come to a complete

standstill before making any adjustments or removing or

installing accessories.

WARNING

These blades cannot and should not be resharpened.

WARNING

The planer blades are sharp and fragile and must be

handled carefully to avoid injury to the user and damage

to the blades.

NOTICE: Always change both blades at the same

time. Use blades of the same dimensions and weight.

Page 9

times to make sure the belt is even on both pulleys.

• Replace the drive belt cover and secure in place with

the four screws. Tighten screws.

• Connect to the power supply and switch the planer on,

run for one minute to make sure the motor and new belt

work properly.

Figure 10

Drive Belt Cover

LUBRICATION

Your tool has been properly lubricated and is ready to use.

It is recommended that tools with gears be re-lubricated

with a special gear lubricant at every brush change.

CARBON BRUSHES

The brushes in your tool have been engineered for many

hours of dependable service. To maintain peak efficiency

of the motor, we recommend examining the brushes every

two to six months. Only genuine replacement brushes

designed specifically for your tool should be used.

BEARINGS

Bearings that become noisy (due to heavy load or

abrasive material cutting) should be replaced as soon as

possible to avoid overheating or motor failure.

CLEANING

Ventilation openings must be kept clean and free of

foreign matter. Do not attempt to clean these components

by inserting pointed objects through openings.

WARNING

The tool may be cleaned most effectively with compressed

dry air. Always wear safety goggles when cleaning tools

with compressed air.

WARNING

Certain cleaning agents and solvents damage plastic

parts. Some of these are: gasoline, carbon tetrachloride,

chlorinated cleaning solvents, ammonia and household

detergents that contain ammonia.

MAINTENANCE

7

MAINTENANCE

7

• Place a straight edge along the outside surface of the

front and rear shoes.

Figure 9

Front Shoe

Rear

Shoe

Blade

• Slide the blade until it contacts the straight edge.

• Make sure the blade sits correctly in the blade holder

groove of the cutter drum.

• Tighten the clamping screws.

CAUTION

Tighten all clamping screws carefully. A loose clamping

screw can be extremely dangerous. Check regularly to

ensure they are tightened securely.

NOTICE: Your planed surface will end up rough and

uneven unless the blades are properly and securely

set. The blades must be mounted so the cutting edge is

absolutely level (parallel to the surface of the rear shoe).

• Repeat for the second blade, making sure both blades

are set to the same cutting level and positioned in the

center of the cutter drum.

REPLACING THE DRIVE BELT

Refer to Figure 10

WARNING

Turn switch OFF, remove the plug from the power source

outlet and wait until the blades have come to a complete

standstill before making any adjustments or removing or

installing accessories.

• Remove the four screws from the drive belt cover.

• Remove the old drive belt. Pull the belt from the top

pulley while turning the bottom pulley by hand.

• Use a soft brush to clean the pulleys.

• Place the new belt on the bottom pulley first, align the

V grooves on the new belt with the grooves on the

bottom pulley. Place the other side of the belt onto the

top pulley, turn the top pulley by hand until the belt is

in place on both pulleys. Turn the pulley by hand a few

Page 10

5

TROUBLESHOOTING

8

8

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Motor does not run 1. Machine not plugged in 1. Plug power cord into electrical receptacle

2. Blown fuse or tripped circuit breaker 2. Replace fuse or reset the circuit breaker

3. Motor does not work 3. Replace motor

Motor stalls or

does not have full

power

1. Incorrect line voltage 1. Have a qualified electrician check circuit for proper voltage

Fuse blows or

circuit breaker trips

1. Overloaded electrical circuit breaker 1. Reduce the amount of items on circuit

2. Wrong fuse or circuit breaker 2. Replace with correct fuse or circuit breaker

3. Undersized or excessive length of

extension cord

3. Use correct size extension cord

Page 11

NOTE

Page 12

PLANER PARTS ILLUSTRATION

10

PARTS LIST

10

Page 13

PLANER PARTS LIST

11

Key No. Part No. Description Qty Specification Key No. Part No. Description Qty Specification

PARTS LIST

11

1 HP1005001 Screw 27 ST4.0x16

2 HP1005002 Belt cover 1 PA6-GF30

3 HP1005003 Bearing cover 1 PA6-GF30

4 HP1005004 Screw 4 ST4.2x10

5 HP1005005 Stator 1 φ73x50

6 HP1005006 Air deflection 1 PA6-GF30

7 HP1005007 Washer 2 4

8 HP1005008 Screw 2 ST4.0x65

9 HP1005009 Left handle 1 PA6-

GF30+TPE

10 HP1005010 Dust extraction panel 1 ABS

11 HP1005011 Dust extraction knob 1 ABS

12 HP1005012 Switch 1 DZKA-5 10A

250V

13 HP1005013 Cord clip 1 PA6-GF30

14 HP1005014 Cord guard 1 PVC

15 HP1005015 Power cord 1 2x1mm²

16 HP1005016 Driving wheel 1 LY12

17 HP1005017 Bearing 3 608-2RS

18 HP1005018 Armature 1 φ41x50

19 HP1005019 Nut 4 M6

20 HP1005020 Right housing 1 PA6-

GF30+TPE

21 HP1005021 Planer head 1 φ57.5x108

22 HP1005022 Bearing 1 6200-2RS

23 HP1005023 Passive wheel 1 LY12

24 HP1005024 Belt 1 Rubber

25 HP1005025 Nameplate 1

26 HP1005026 Label 1

27 HP1005027 Foot park 1 PA6-GF30

28 HP1005028 Spring 1 65Mn

29 HP1005029 Supporting shaft 1 45#

30 HP1005030 Raffle plate 1 PA6-GF30

31 HP1005031 Base plate 1 ADC12

32 HP1005032 Guide plate 1 PA6-GF30

33 HP1005033 Spring 1 65Mn

34 HP1005034 ball 1 3.5

35 HP1005035 Screw 1 M6

36 HP1005036 Adjusting plate 1 ADC12

37 HP1005037 C-spring 1 65Mn

38 HP1005038 Regulating sleeve 1 ADC12

39 HP1005039 Adjust spring 1 65Mn

40 HP1005040 Main housing 1 PA6-GF30

41 HP1005041 Adjust nut 1 PA6-GF30

42 HP1005042 Dial 1 PA6-GF30

43 HP1005043 Adjust knob 1 ABS+TPE

44 HP1005044 Capacitor 1 2*0.22μF

45 HP1005045 Knob cover 1 ABS

46 HP1005046 Brush holder 2 H62Y2

47 HP1005047 Carbon brush 2 230V

48 HP1005048 Motor cover 1 PA6-GF30

49 HP1005049 Vacuum adapter 1 PA6-GF30

50 HP1005050

51 HP1005051 Fixing support 1 08F

52 HP1005052 Knob 1 PA6-GF30

53 HP1005053 Parallel guide 1 08F

54 HP1005054 Screw 1 M6x12

55 HP1005055 Wing nut 1 M6

56 HP1005056 Screw 2 ST4.0x30

57 HP1005057 Big washer 1 08F

58 HP1005058 Small washer 1 08F

59 HP1005059 Washer 1 6

60 HP1005060 Spanner 1 40Mn

Page 14

WARRANTY

12

WARRANTY

12

Thank you for investing in a POWERTEC power tool. This product has been designed and manufactured to meet high

quality standards and is guaranteed for domestic use against defects in workmanship or material for a period of 12

months from the date of purchase. This guarantee does not affect your statutory rights.

SOUTHERN TECHNOLOGIES LLC. BENCH TOP AND STATIONARY POWER TOOL

LIMITED 1 YEAR WARRANTY AND 30-DAY SATISFACTION GUARANTEE POLICY

POWERTEC products are designed and manufactured by Southern Technologies LLC. All warranty communications

should be directed to Southern Technologies LLC by calling 847-780-6120, 9 AM to 5 PM, Monday through Friday,

US Central Time.

30- DAY SATISFACTION GUARANTEE POLICY

During the first 30 days after the date of purchase, if you are dissatisfied with the performance of this POWERTEC tool

for any reason, you may return the tool to the retailer from which it was purchased for a full refund or exchange. You

must present proof of purchase and return all original equipment packaged with the original product. The replacement

tool will be covered by the limited warranty for the balance of the one year warranty period.

LIMITED ONE YEAR WARRANTY

This warranty covers all defects in workmanship or materials in this POWERTEC tool for a one year period from the

date of purchase. This warranty is specific to this tool. Southern Technologies, LLC reserves the right to repair or

replace the defective tool, at its discretion.

HOW TO OBTAIN SERVICE

To obtain service for this POWERTEC tool you must return it, freight prepaid, to POWERTEC. You may call

847-780-6120 for more information. When requesting warranty service, you must present the proof of purchase

documentation, which includes a date of purchase. POWERTEC will either repair or replace any defective part, at

our option at no charge to you. The repaired or replacement unit will be covered by the same limited warranty for the

balance of one year warranty period.

WHAT IS NOT COVERED

This warranty applies to the original purchaser at retailer and may not be transferred.

This warranty does not cover consumable items such as saw blades, knives, belts, discs, cooling blocks and sleeves.

This warranty does not cover required service and part replacement resulting from normal wear and tear, including

accessory wear.

This warranty does not cover any malfunction, failure or defect resulting from:

1) misuse, abuse, neglect and mishandling not in accordance with the owner’s manual.

2) damage due to accidents, natural disasters, power outage, or power overload.

3) commercial or rental use.

4) alteration, modification or repair performed by persons not recommended by POWERTEC.

DISCLAIMER

To the extent permitted by applicable law, all implied warranties, including warranties of MERCHANTABILITY or

FITNESS FOR A PARTICULAR PURPOSE, are disclaimed. Any implied warranties, that cannot be disclaimed under

state law are limited to one year from the date of purchase. Southern Technologies LLC. is not responsible for direct,

indirect, incidental or consequential damages. Some states do not allow limitations on how long an implied warranty

lasts and/or do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations may

not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state

to state. Southern Technologies LLC., makes no warranties, representations, or promises as to the quality or

performance of its power tools other than those specifically stated in this warranty.

Page 15

NOTE

Page 16

Southern Technologies, LLC

3816 Hawthron CT,

Waukegan, IL 60087

Loading...

Loading...