Page 1

Repair Center for Powertec Drives and Motors

460 Milford Parkway

Milford, OH . 45150

www.motorsystems.com

513-576-1725

Page 2

ADVANCED

MICROPROCESSOR CONTROLLED

DIGITAL SPEED / RATIO CONTROLLER

INSTALLATION AND OPERATION

MADE IN USA

This manual is fully implemented with software version (SFWVER)

93271 and later. See page 10 to find the software version of your

unit

INSTRUCTION MANUAL

Revision 2A

October 6, 1993

POWERTEC Publication # DGMAX4IM

Page 3

Page ii © copyright 1992-1996 by Powertec Industrial Motors

Page 4

DIGIMAX® Manual

Table of Contents

INTRODUCTION ....................................................................................................... 1

1.0 INSTALLATION ......................................................................................................... 3

1.1 CUSTOMER CONNECTIONS................................................................................... 3

2.0 ORIENTATION .......................................................................................................... 9

3.0 SET UP PARAMETERS .......................................................................................... 13

#1 Maximum Motor Speed............................................................................................ 15

#2 Maximum Display Value .......................................................................................... 15

#3 Decimal Places ........................................................................................................ 16

#4 Slave Ratio Setting .................................................................................................. 16

#5 Feedback PPR......................................................................................................... 16

#6 Acceleration Time.................................................................................................... 16

#7 Deceleration Time ................................................................................................... 17

#8 Master/Slave............................................................................................................ 17

#9 Preset Speed ........................................................................................................... 17

#10 Jump UP Change .................................................................................................... 17

#11 Jump Down Change ................................................................................................ 18

#12 Up-to-Speed Tolerance ........................................................................................... 18

#13 M.O.P./Jump ............................................................................................................ 18

#14 Freeze/Float ............................................................................................................ 18

#15 Display Sample Rate ............................................................................................... 18

#16 Setup During Run .................................................................................................... 18

#17 Unit I.D.....................................................................................................................19

#18 Baud Rate................................................................................................................ 1 9

#19 Local/Remote/Keylock............................................................................................. 1 9

#20 Speed/Ratio SETPOINT........................................................................................ 1 9

#21 Operator Security Code........................................................................................... 19

#22 A to D Low Engineering Units ................................................................................. 19

#23 A to D High Engineering Units ................................................................................ 2 0

#24 A to D Display Mode................................................................................................ 2 0

#25 A to D Sample Rate ................................................................................................. 20

#26 A to D Trim Enable .................................................................................................. 20

#27 Communications Protocol........................................................................................ 21

#28 D to A Source .......................................................................................................... 21

#29 D to A Low Engineering Units ................................................................................. 21

#30 D to A High Engineering Units ................................................................................ 2 1

#31 Maximum Ratio ........................................................................................................ 21

#32 PRESET Input Mode ............................................................................................... 21

#33 REVERSE Input mode............................................................................................. 22

#34 UP Input Mode......................................................................................................... 22

#35 DN Input Mode......................................................................................................... 22

#36 Installed Option Enable ........................................................................................... 22

#37 Command Ratio Setpoint......................................................................................... 22

#38 Maximum Command Ratio....................................................................................... 22

#39 Debounce Value ...................................................................................................... 22

#40 AT SPEED Source................................................................................................... 22

#41 Communications Turn Around Time........................................................................ 22

®®

®

®®

Manual

Revised 10/06/93

Page iiiDIGIMAX

Page 5

TABLE OF CONTENTS (continued)

4.0 SETUP AND OPERATION ...................................................................................... 23

LOCAL OR REMOTE .............................................................................................. 23

COMMAND OR ACTUAL ........................................................................................ 25

SETUP OR NORMAL .............................................................................................. 25

ERROR CODES ...................................................................................................... 27

JUMP OR MOP........................................................................................................ 30

FREEZE OR FLOAT................................................................................................ 3 1

MASTER OR SLAVE ............................................................................................... 31

Basic Master Mode setup ................................................................................... 31

Basic Slave Mode setup..................................................................................... 32

ADVANCED FUNCTIONS ....................................................................................... 33

List of Illustrations

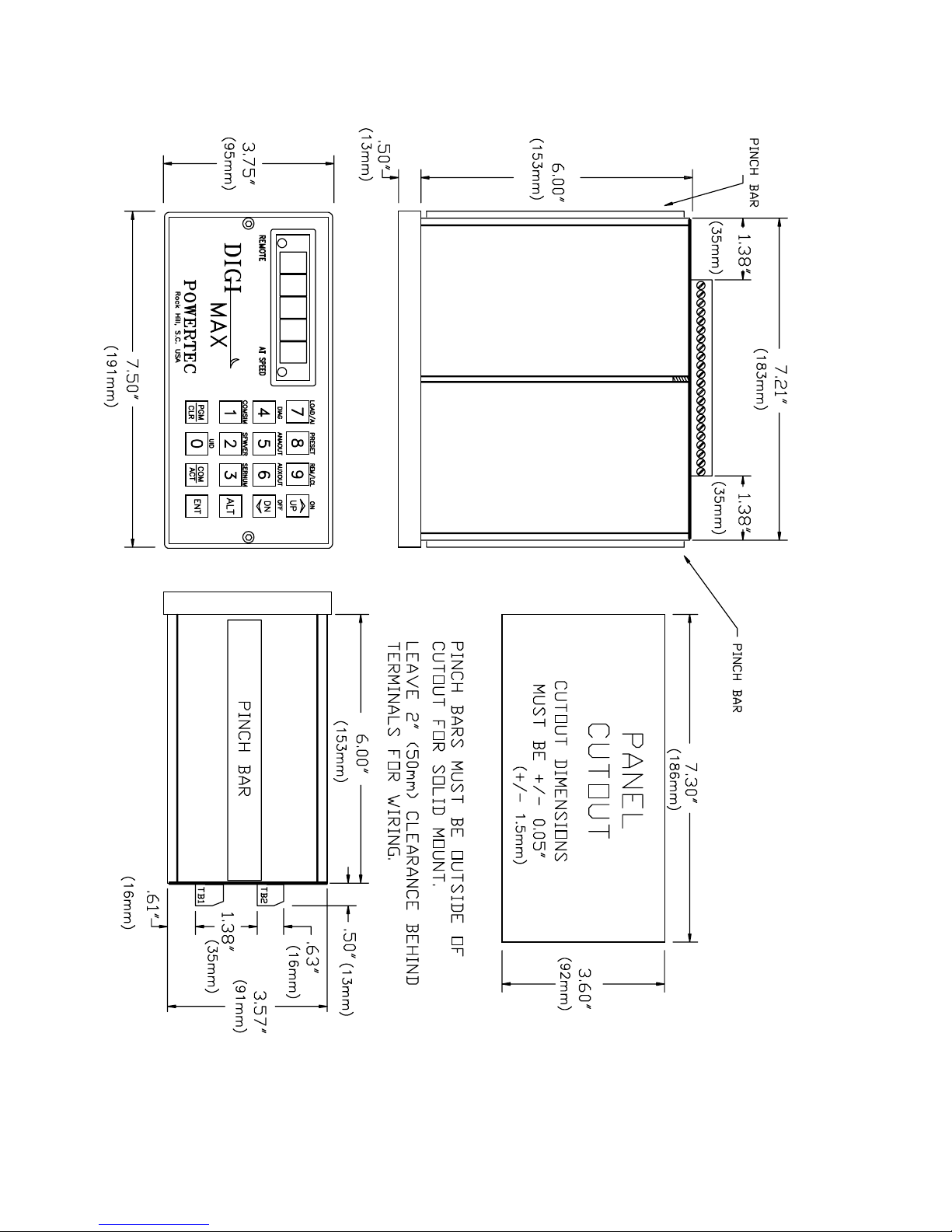

1. Physical Dimensions ................................................................................................. 2

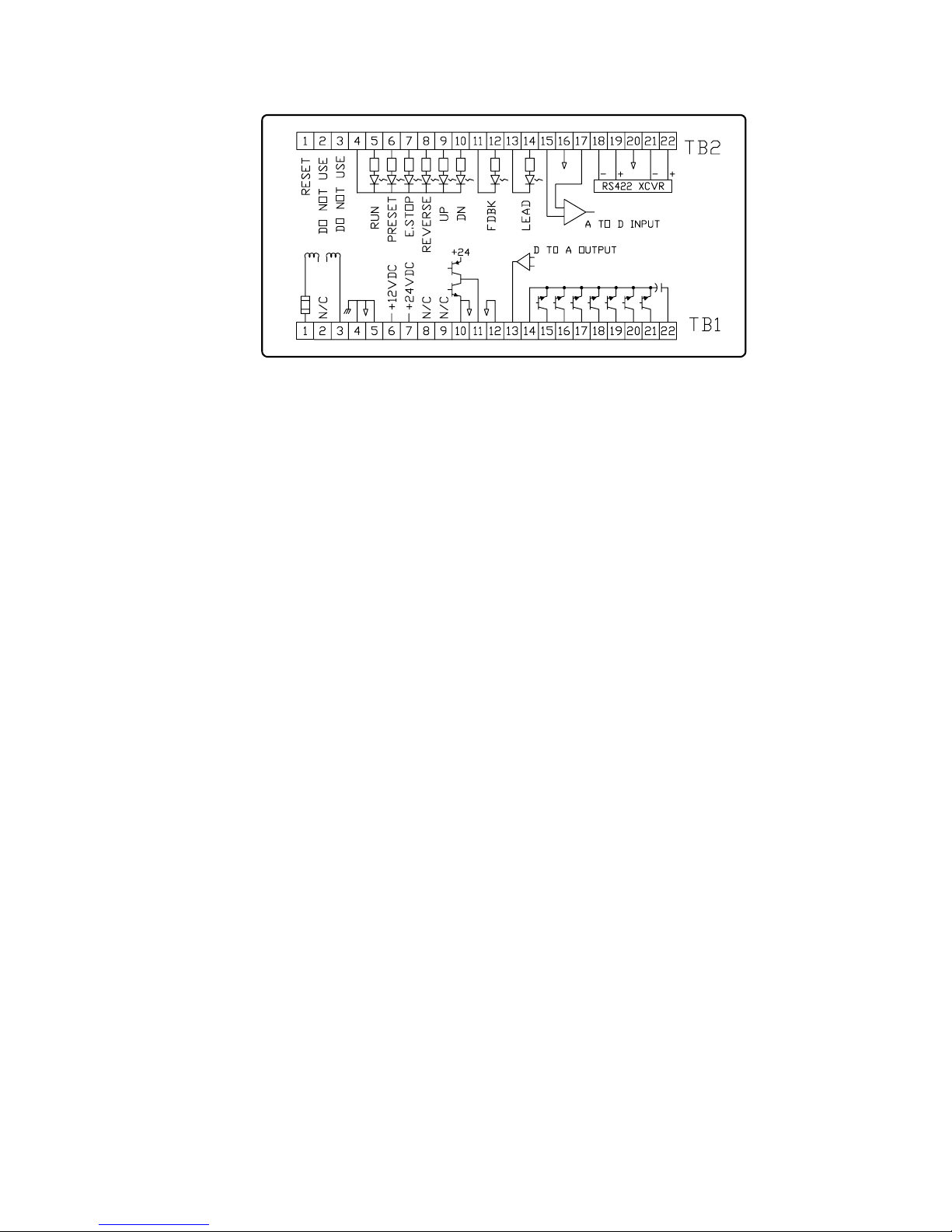

2. Rear Terminal Strip connections ............................................................................... 5

3. Connections to the

DIGIMAXDIGIMAX

DIGIMAX

DIGIMAXDIGIMAX

®

......................................................................................................................

4. Front panel Display. .................................................................................................. 9

5. Typical connections to Model 500........................................................................... 24

6. Typical connections to Non-regenerative control .................................................... 26

7. Standard connections to Regenerative control ....................................................... 28

8. Standard Connections to the MILLENNIUM® drive ................................................. 30

8

List of TABLES

1 Basic Parameters Table (1 to 21)............................................................................ 1 4

1A Extended Parameters Table (22 to 36) ................................................................... 2 0

2 Error Codes ............................................................................................................ 27

Page iv © copyright 1992-1996 by Powertec Industrial Motors

Page 6

WARNING!

THE DIGIMAX®AS SHIPPED FROM THE FACTORY OPERATES ON

115VAC POWER INPUT ONLY AT TB1 TERMINALS 1 AND 3.

230 VAC UNITS MAY BE OBTAINED BY SPECIAL ORDER, IN WHICH

CASE IT WILL HAVE A 230VAC NAMEPLATE AND STICKER.

DO NOT APPLY 230 VAC TO THE DIGIMAX® UNLESS YOU HAVE

CHECKED FOR THE PROPER CONNECTIONS.

NOTICE!

If you are replacing a DIGIMAX III with a

DIGIMAXDIGIMAX

DIGIMAX®, check TB2

DIGIMAXDIGIMAX

terminals 1,2, and 3 to be sure that there are no connections to these

terminals! These terminals weren't used on the DIGIMAX III, but they

are used internally on the

TIONS on TB2 terminals 1,2, and 3 when the

DIGIMAXDIGIMAX

DIGIMAX®. There should be NO CONNEC-

DIGIMAXDIGIMAX

DIGIMAXDIGIMAX

DIGIMAX® is used.

DIGIMAXDIGIMAX

®®

®

®®

Manual

Page vDIGIMAX

Page 7

SUMMARY OF WARRANTY AND DISCLAIMER

POWERTEC Industrial Motors, warrants the

DIGIMAXDIGIMAX

DIGIMAX® to be free from defects in materials and

DIGIMAXDIGIMAX

workmanship for a period of one year from the date of shipment from the factory, or, if purchased from an

authorized distributor or Original Equipment Manufacturer, not more than 18 months from the date of shipment

from the factory. Upon written notification to the factory of a possible defect in materials or workmanship,

POWERTEC will, at its sole option, repair or replace, at the factory, such defective parts as it deems necessary

to restore the unit to its original specifications.

There is no other warranty, express or implied, including fitness of purpose for the application intended.

This warranty does not cover accidental or intentional damage; physical or electrical misuse or abuse;

defective or incorrect installation; effects of the

DIGIMAXDIGIMAX

DIGIMAX® on other equipment or effects on the

DIGIMAXDIGIMAX

DIGIMAXDIGIMAX

DIGIMAX

DIGIMAXDIGIMAX

caused by other equipment; attempted use outside of specified ranges; or any other situation which is deemed

to be outside of the control of POWERTEC.

The user is responsible for the application of the product and/or the programming thereof.

Programs which attempt to use the communications capability of the

DIGIMAXDIGIMAX

DIGIMAX® are the responsibility

DIGIMAXDIGIMAX

of the user.

This warranty does not encompass any other claims, including, but not limited to, special, incidental, or

consequential damages.

This instruction manual has been assembled as a guide to the use of a POWERTEC product. It represents

the best efforts to compile and present the information herein. Such errors as may appear in no way affect the

above stated warranty. If mistakes of fact are found or suspected in this manual, please notify the factory or

your distributor at once.

®

Page vi © copyright 1992-1996 by Powertec Industrial Motors

Page 8

®®

®

®®

Manual

Page viiDIGIMAX

Page 9

INTRODUCTIONINTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

DIGIMAXDIGIMAX

The

DIGIMAX® is an advanced, micro-processor based, digital speed reference

DIGIMAXDIGIMAX

designed for use with POWERTEC Brushless motors and controls. It is a reliable and

repeatable pulse train source with features designed for the needs of computer controlled

process lines. It may be used for master speed setting or as an extremely accurate ratio

setting device.

DIGIMAXDIGIMAX

The

DIGIMAX® is an "open loop" type of control, i.e., speed feedback information

DIGIMAXDIGIMAX

to this speed setting device is not necessary to maintain the speed regulation of the

system. The nature of the permanent magnet based Brushless motor and control system

is that it will maintain zero percent speed regulation from no load to full load over its entire

speed range. Closing the speed loop for speed regulation is unnecessary. Speeds

generated by the

operating conditions. The Brushless motor will run at exactly the speed at which it is told

to run, and the next time that same speed is commanded, it will be repeated exactly.

DIGIMAXDIGIMAX

The

DIGIMAX® is as much at home in the ratio mode as it is in the speed mode,

DIGIMAXDIGIMAX

and it can switch between the two on the fly. This consistent speed control is invaluable

in setting up processes which vary from day to day, but must be duplicated from order

to order.

DIGIMAXDIGIMAX

The

DIGIMAX® is also easy to apply and use. It can be installed in locations where

DIGIMAXDIGIMAX

it is easily accessible to operators, which may be remote from the location of the motor

control. Control inputs and outputs are isolated, for flexibility and immunity to interactions

between units.

Speed or ratio setpoints and operating parameters are entered via a 16-key keypad

on the face of the

entered by remote connection to an industry standard RS-422 or RS-485 communications link with a variety of protocols.

The five place digital readout may be set for motor RPM, process speed, or other

useful engineering units, from the motor or from another source besides the motor being

controlled. Indicators show when the speed is attained and whether the unit's control is

local or remote.

DIGIMAXDIGIMAX

The

DIGIMAX® has six programmable output switches (open collector transistors),

DIGIMAXDIGIMAX

offering the possibility of operation completely through the communications link.

There is a position registration function (temporary increase or decrease in speed)

which may be alternatively programmed as a motor operated potentiometer. There are

UP and DOWN controls are on the front panel, and there are remote inputs for these

functions as well. The MOP function may be programmed to stay at its former speed after

a stop, or to return to zero speed when stopped.

DIGIMAXDIGIMAX

DIGIMAX® represents a high level of sophistication for users of POWERTEC

DIGIMAXDIGIMAX

Brushless motors and controls. It is very effective in operator controlled or computer

controlled systems when precision, repeatability, flexibility, and ease of interface to the

host unit are required.

DIGIMAXDIGIMAX

DIGIMAX® are accurate within 50 parts per million under all specified

DIGIMAXDIGIMAX

DIGIMAXDIGIMAX

DIGIMAX®. Speed or ratio setpoints and parameters may also be

DIGIMAXDIGIMAX

DIGIMAX® is a registered trademark of POWERTEC Industrial Corporation

®®

®

®®

Manual

Page 1DIGIMAX

Page 10

Figure 1: Physical dimensions of the DIGIMAX®.

Page 2 © copyright 1992-1996 by Powertec Industrial Motors

Page 11

1.0 INST1.0 INST

1.0 INST

1.0 INST1.0 INST

DIGIMAXDIGIMAX

The

DIGIMAX® may be installed in any orientation in a clean, dry location. Care should

DIGIMAXDIGIMAX

be exercised in making the cutout in the mounting panel, since the pinch bars must be placed

firmly against the mounting panel just outside of the cutout section to hold the unit in place.

The front panel has sealed membrane switches, but the front panel should be protected

against moisture falling directly onto it and seeping into the box around the faceplate.

The front panel should be protected against physical damage, but accidental casual

contact with the front panel is not likely to cause a problem.

The customer connection terminals at the rear of the box require at least 2" (50mm) of

free space behind the box for installation, removal and wiring. It is advisable to not install

high energy switches or electro-magnetic devices next to the

to run wires carrying high energy in the same groupings as the wires to and from it.

1.1 CUSTOMER CONNECTIONS1.1 CUSTOMER CONNECTIONS

1.1 CUSTOMER CONNECTIONS

1.1 CUSTOMER CONNECTIONS1.1 CUSTOMER CONNECTIONS

DIGIMAXDIGIMAX

The

DIGIMAX® has two terminal strips on the back of the unit for customer connections

DIGIMAXDIGIMAX

(see figure 2 on page 5). These terminal strips are removable for ease of wiring and to

facilitate the replacement of the unit, should that become necessary for any reason. The

terminal strips are keyed differently to prevent mix-ups.

All connections except the AC input power are low voltage, low current, DC circuits

which may be susceptible to system electrical noise interference. Directions for wiring and

shielding must be followed exactly for best results (see figure 3 on page 8).

Wires to and from the

All relays used in conjunction with, or in the vicinity of, the DIGIMAX® must have arc

suppressors (if they have AC coils) or free wheeling diodes (if they are DC). Keep high power

switching relays and contactors away from the

interference from arcing and magnetic field fluxes.

ALLAALLA

ALLA

ALLAALLA

DIGIMAXDIGIMAX

DIGIMAX

DIGIMAXDIGIMAX

TIONTION

TION

TIONTION

DIGIMAXDIGIMAX

DIGIMAX®, nor is it advisable

DIGIMAXDIGIMAX

®®

®

®®

must be kept away from power wiring.

DIGIMAXDIGIMAX

DIGIMAX® and its wiring to prevent

DIGIMAXDIGIMAX

BOTTOM TERMINAL STRIP TB1BOTTOM TERMINAL STRIP TB1

BOTTOM TERMINAL STRIP TB1

BOTTOM TERMINAL STRIP TB1BOTTOM TERMINAL STRIP TB1

1 115 VAC HOT line

2 unconnected pin

3 115 VAC NEUTRAL

4 CASE GROUND

5 EARTH GROUND

The DIGIMAX® must be operated on 115VAC, single phase. Tolerance is +/- 10%.

Frequency range is 48 to 62 hertz. If one side of the supply is grounded, the hot side of the

supply should be connected to terminal 1. The other wire is connected to terminal 3.

230VAC

of 230VAC power is discouraged due to the noisy nature of this type of power.

Terminal 2 is not connected to anything. It is used for voltage separation on the

terminals. Do not make connections of low-voltage, noise sensitive signals on terminal 2.

Terminal 4 is used for grounding the metal case of the

mounting screws, and terminal 5 should be solidly grounded to an earth ground. The earth

ground must be tied to a system ground which is tied into the system power ground at a

central location. Where long and (electrically) noisy runs are involved, an earth ground rod

in the vicinity of the drive cabinet is recommended.

The AC supply should not have excessive line noise. The input power to the unit is

filtered, but excessive line gaps or spikes could cause erratic power supplies.

®®

®

®®

Manual

DIGIMAXDIGIMAX

DIGIMAX® units may be obtained on special order from the factory. The use

DIGIMAXDIGIMAX

DIGIMAXDIGIMAX

DIGIMAX® with one of the case

DIGIMAXDIGIMAX

Page 3DIGIMAX

Page 12

6 10 -> 12 VDC output, unregulated, 100 mA

7 24 VDC output, unregulated, 100 mA

8 NO CONNECTION

9 NO CONNECTION

If you have an application where you wish to use DC power to power a

DIGIMAXDIGIMAX

DIGIMAX®,

DIGIMAXDIGIMAX

you must either use a UPS or contact POWERTEC for a special unit.

Terminal 6 may be used for small 12VDC loads up to 100 mA.

Terminal 7 can supply up to 50 mA at 20 to 24 VDC, unregulated. Terminal 7 is most

often used to turn on the DIGITAL mode in the Model 1000 series and larger drives (using

the 141-108 series Current Controller board), and this is, in fact, recommended.

The output level of these two terminals is dependent on the AC supply voltage.Other

loads on the unit and the load on each of these terminals will also affect the voltage level.

If either of these terminals are overloaded, the accuracy of the

DIGIMAXDIGIMAX

DIGIMAX® will be degraded.

DIGIMAXDIGIMAX

Terminal 4 or 5 may be used as a common for these terminals.

Voltage levels on terminals 6 and 7 ARE NOT GUARANTEED. These outputs are

for convenience only for small loads associated with the

DIGIMAXDIGIMAX

DIGIMAX®. If stable and/or

DIGIMAXDIGIMAX

regulated voltages are needed for external relays and devices used for system purposes,

the user should incorporate in the system a separate power supply for them.

10 - FREQUENCY OUTPUT

11 + FREQUENCY OUTPUT

This is the output frequency to the controlled drive or drives. It is capable of driving up

to ten inputs of motor controls or ten other

DIGIMAXDIGIMAX

DIGIMAX® inputs or a combination of the two

DIGIMAXDIGIMAX

adding up to ten inputs. Output from these terminals is a square wave from a "totem-pole"

driver with a +24 VDC peak and an off value less than 0.5 VDC. The duty cycle may vary.

12 - ANALOG OUTPUT

13 + ANALOG OUTPUT

The analog output at TB1 terminals 12 and 13 may be used to read a voltage signal

proportional to one of the

DIGIMAXDIGIMAX

DIGIMAX® speed sources, or from the RS-422 link, or from the

DIGIMAXDIGIMAX

keypad. This output ranges from 0 to +10 VDC. The source and level of this output is set by

parameters #28 (source of the output signal), #29 (the lowest value for the output), and #30

(the highest value for the output). See page 21.

14 EMITTERS OF AUXILIARY OUTPUTS

15 "AT SPEED" OUTPUT (open collector)

16 AUXILIARY OUTPUT #1 (open collector)

17 AUXILIARY OUTPUT #2 (open collector)

18 AUXILIARY OUTPUT #3 (open collector)

19 AUXILIARY OUTPUT #4 (open collector)

20 AUXILIARY OUTPUT #5 (open collector)

21 AUXILIARY OUTPUT #6 (open colllector)

22 OUTPUTS SUPPLY CONNECTION

An external power supply MUST be used to power any devices connected to

these outputs. These outputs are "open collector" outputs with all of the emitters brought

together at TB1 terminal 14 (see figure 2). The positive side of the supply has to be connected

to TB1 terminal 22 (this supplies the drivers on the board), and the negative side of the supply

must be connected to TB1 terminal 14. All of these outputs are isolated from the DIGIMAX

Page 4 © copyright 1992-1996 by Powertec Industrial Motors

®

Page 13

Figure 2: Rear terminal strip connections of the

DIGIMAXDIGIMAX

DIGIMAX

DIGIMAXDIGIMAX

®

common, but their emitters are all common to each other. The maximum allowable voltage

between TB1 terminals 22 (+) and 14 (-) is 30VDC. The maximum allowable current on each

of the TB1 terminals 15 thru 21 is 100 mA. Snubber diodes are built into the outputs. If the

wiring to the external relays is run more than a few feet, additional snubber diodes should

be used at the external relay coils.

Do not run any large solenoid valves or large contactors directly from these outputs.

Use interface relays connected to these outputs to run this other equipment.

The AT SPEED output operates with the AT SPEED indicator on the front panel. The

adjustment of the AT SPEED tolerance is controlled by parameter #12. The AT SPEED

output and the AT SPEED front panel LED work only in the MASTER mode. In SLAVE mode,

the AT SPEED LED and the AT SPEED output are on all of the time, except when changing

to a newly entered ratio..

The other six outputs are controllable by protocol commands through the RS-422 link.

They can also be operated from the keypad on the front (see page 11). These outputs may

be used for run, stop, man/auto, fwd/rev, or for peripheral device control.

By connecting relays to these outputs and using the relays to control the drive, it is

possible to run the

TOP TERMINAL STRIP TB2TOP TERMINAL STRIP TB2

TOP TERMINAL STRIP TB2

TOP TERMINAL STRIP TB2TOP TERMINAL STRIP TB2

DIGIMAXDIGIMAX

DIGIMAX® and motor control entirely through the communications link.

DIGIMAXDIGIMAX

1 HARDWARE RESET

2 DO NOT USE!

3 DO NOT USE!

Terminal 1 on TB2 is used for a hardware reset. When terminal 1 is connected to a

ground (such as TB1 terminal 5), the DIGIMAX® resets just as if the power to the unit were

turned off and the power was then turned back on again. The parameters are NOT cleared

by this operation.

It is NOT recommended that wires be permanently attached to these terminals

because there is a possibility that a noise pulse or accidental activation of the switch may

cause an unintentional reset, interrupting normal operation. Such noise may come from

nearby power components or a difference in potential between the case or terminals of the

DIGIMAXDIGIMAX

DIGIMAX® and ground.

DIGIMAXDIGIMAX

DO NOT MAKE ANY CONNECTIONS TO TB2 TERMINALS 2 and 3! These terminals

are used for programming functions. Connecting anything to these inputs will result in

damage to the unit.

®®

®

®®

Manual

Page 5DIGIMAX

Page 14

4 CATHODES OF CONTROL INPUTS (ground or common)

5 RUN INPUT (+24 VDC)

6 PRESET INPUT (+24 VDC)

7 EMERGENCY STOP INPUT (+24 VDC)

8 REVERSE INPUT (+24 VDC)

9 JUMP/MOP UP INPUT (+24 VDC)

10 JUMP/MOP DOWN INPUT (+24 VDC)

Power for the control inputs must be supplied from a separate source. Usually this

power comes from the Brushless drive being controlled. Nominal supply voltage is 24 VDC,

which need not be regulated, but must be filtered. The tolerance is +/- 25%.

The control inputs do not control any functions on the controlled drive. Commands

given to the

DIGIMAXDIGIMAX

DIGIMAX® must also be given to the drive at the same time.

DIGIMAXDIGIMAX

The EMERGENCY STOP input must be activate before the unit will respond to any

external input or keyboard commands. This input normally parallels the E.STOP of the drive.

Activating the RUN input starts the DIGIMAX®, and will it run until the RUN input is

removed. Usually, the run relay contact on the speed board of the drive is used for this. A

SETPOINT value should be entered prior to the first time a RUN command is entered after

power is applied; otherwise the unit will start at zero speed (or ratio) and wait for a SETPOINT

to be entered by the operator. If parameter #14 is set to 1 (see page 18), on all subsequent

RUN commands, the DIGIMAX® will start at the last speed or ratio entered.

The PRESET command changes the speed output to go to the value in parameter #9.

The REVERSE input causes the frequency output to decelerate, at the rate set into

parameter #7, to zero speed, and then to accelerate back to the setpoint at the rate set into

parameter #6. Giving a reverse command to the

DIGIMAXDIGIMAX

DIGIMAX® does NOT cause the drive to

DIGIMAXDIGIMAX

reverse. A separate, simultaneous command must be given to the drive. If the drive is given

a reverse command, it will not reverse until the

DIGIMAXDIGIMAX

DIGIMAX® is given a reverse command,

DIGIMAXDIGIMAX

because the drive input frequency must be at zero before the drive will reverse direction.

The JUMP/MOP UP and JUMP/MOP DOWN inputs duplicate the functions of the UP

and DN inputs on the front panel.

11 - TACHOMETER INPUT

12 + TACHOMETER INPUT

13 - FOLLOWER INPUT

14 + FOLLOWER INPUT

These two inputs are isolated from the

DIGIMAXDIGIMAX

DIGIMAX® electronics and from each other.

DIGIMAXDIGIMAX

Both inputs require a +24VDC nominal peak input and a low of less than 1VDC. Both inputs

will accept signals up to 50 kilohertz. Minimum pulse width for both inputs is 10 microseconds. Wider pulse widths are desireable. Rise times are not critical, but they should be less

than 5% of the duty cycle.

The tachometer input is for the

DIGIMAXDIGIMAX

DIGIMAX® display and it also supplies a zero speed

DIGIMAXDIGIMAX

signal. It normally comes from the motor control, but it may come from any frequency

reflecting the driven process. With a 1750 RPM small frame motor, a standard POWERTEC

Brushless motor control supplies a 3500 Hertz pulsed waveform to this input, but larger

motors' controls supply a 7000 hertz signal to the tachometer input and servo rated controls

may supply frequencies of up to 50 kilohertz.

The follower input is the frequency which the

DIGIMAXDIGIMAX

DIGIMAX® follows in SLAVE mode. A

DIGIMAXDIGIMAX

standard 1750 RPM low horsepower Brushless motor control operates at 3500 Hertz input

frequency. This is the ideal input frequency for the follower input if the follower motor is 1750

RPM. The

DIGIMAXDIGIMAX

DIGIMAX® can multiply by a factor of up to eight, but performance and resolution

DIGIMAXDIGIMAX

at high multiples may be degraded.

Page 6 © copyright 1992-1996 by Powertec Industrial Motors

Page 15

15 - AUXILIARY ANALOG INPUT

16 GROUND

17 + AUXILIARY ANALOG INPUT

The maximum input is +10 VDC, but the input is a differential type input, so a negative

voltage may be accepted by reversing input leads. TB2 TERMINAL 17 MUST ALWAYS BE

MORE POSITIVE (ON AN ABSOLUTE SCALE) THAN TB2 TERMINAL 15. If TB2 terminal

15 is more positive than TB2 terminal 17, the effective input will be 0.

The auxiliary analog input is for transferring an analog voltage representing a system

value (such as motor current) through the RS-422 communications link. For this type of

operation, parameter #26 must be 0. #23 is set to read out a +10 VDC input in Engineering

Units (EGU). Parameter #22 is set to low EGU, which may be zero, but doesn't have to be.

The auxiliary analog input may also be used as an analog trim or dancer (see

parameters #20 on page 19, and #26 on page 21). The input leads should be connected to

TB2 terminals 15 and 17 (not ground) and TB2 terminal 16 should be used for the shield.

If parameter #26 is 1, a 5VDC input is zero effect. Increasing voltage increases the setpoint.

If parameter #26 is 2, a 0VDC input is no effect. Increasing voltage increases the setpoint.

If parameter #26 is 3, a 0VDC input is no effect. Increasing voltage decreases the setpoint.

The maximum speed (parameter #1) may not be exceeded in speed mode.

The maximum ratio (parameter #31) may not be exceeded in slave mode.

18 RS-422 - RECEIVE

19 RS-422 + RECEIVE

20 RS-422 No connection

21 RS-422 - TRANSMIT

22 RS-422 + TRANSMIT

In order to ensure good communications, it is required that shielded cable be used in

the RS-422 communications link. The cable should have conductors no smaller than #24

AWG for distances up to 500 feet. Recommended cables are cables such as Belden® Wire

Company part #9829 or part #88102.

Connecting the link together consists of connecting all of the transmit terminals of the

DIGIMAXDIGIMAX

DIGIMAX® units in parallel (+ to +, and - to -). Then all receive terminals are connected in

DIGIMAXDIGIMAX

parallel (+ to +, and - to -).

ANSI standards apply to RS-422 communications. The RS-422 standard stipulates

that the number of stations shall be at least 10 without repeaters. (Repeaters are amplifiers

which strengthen the signal to feed more stations). The

DIGIMAXDIGIMAX

DIGIMAX® communications may

DIGIMAXDIGIMAX

operate up to 32 units on the link.

After connecting all of the RS-422 terminals together, one end of the chain is tied to the

host (a PLC, a personal computer through an RS-422 output card or an RS-232 to RS-422

converter, or an industrial computer with an RS-422 port). Normally the "transmits" of the

DIGIMAXDIGIMAX

DIGIMAX®'s will tied to the "recieve" of the host, and the "receives" to the "transmits", but

DIGIMAXDIGIMAX

check the specifications of the host to be used. The unit at the far end of the line, furthest from

the host, must have a resistor equal to the cable's impedance (120 ohms) installed across

its receive terminals. This is "terminating" the line. It prevents signal reflections from causing

spurious signals on the line. The transmit line is terminated at the host.

The RS-485 Communications standard may be used with the

DIGIMAXDIGIMAX

DIGIMAX® by tying the

DIGIMAXDIGIMAX

+Transmit to the +Receive and the -Transmit to the -Receive. Terminal 20 is for the shields.

If you are putting together a large system, it is a good idea to consult someone who is

knowledgable and experienced in the art of serial communications.

®®

®

®®

Manual

Page 7DIGIMAX

Page 16

Figure 3: Connections to the DIGIMAX® speed controller.

Page 8 © copyright 1992-1996 by Powertec Industrial Motors

Page 17

2.0 ORIENT2.0 ORIENT

2.0 ORIENT

2.0 ORIENT2.0 ORIENT

AA

TIONTION

A

TION

AA

TIONTION

The proper operation of the

panel controls. Speeds, ratios, and parameters will be set by the operator with the keypad,

which consists of numerical and action keys. The display and the LED's will supply important

information during setup and while the process is in operation.

Figure 4: Front panel display

The display is a full five digits, allowing numbers up to 99999 to be displayed. A decimal

point may be placed between any two of the five digits, allowing numbers to be displayed

or set down to 0.0001.

The display has two levels of brightness to indicate the mode in which it is operating.

The COMMAND mode is a dimmer display. In COMMAND mode the display shows the

SETPOINT value. The ACTUAL mode is a much brighter display. In ACTUAL mode the

display shows the actual speed of the motor in whatever scale is set up by the parameters.

See the explanation of the COM/ACT button below.

The AT SPEED indicator changes only in the MASTER mode, indicating that the actual

motor speed is within the programmed tolerance. In SLAVE mode the AT SPEED indicator

is on all of the time except when slewing to a newly entered ratio.

The REMOTE indicator is on when remote operation is on. In one REMOTE mode, the

keypad is locked out unless the unit's LOC/REM key is pressed. In another mode, even the

LOC/REM key is locked out.

DIGIMAXDIGIMAX

DIGIMAX® requires a complete understanding of the front

DIGIMAXDIGIMAX

The numeric display of the

while power is applied. There are, however, times at which the

display will be blank. One condition under which the display

blanks while power is on is when the PGM/CLR button is pressed

just prior to entering the access code. The access code may then

be entered. Another occasion when the display goes blank is after

the ALT key is pressed until one of the keys with a command in

small letters above it is pressed.

DIGIMAXDIGIMAX

DIGIMAX® is normally lit up

DIGIMAXDIGIMAX

THRU

The number keys on the

1. entering speeds and ratios into the unit while the unit is in operation. Speeds and

ratios may range from one to five digits, from 0.0001 to 99999;

2. entering the security code to gain access to the parameters. The security code may

vary from 1 to 5 digits. It is not necessary to enter leading zeroes;

3. entering parameter values while in setup mode. The parameter values may range

from one to five digits.

DIGIMAXDIGIMAX

The

DIGIMAX® will not accept more than five digits in a single number. When a

DIGIMAXDIGIMAX

number is pressed, the microprocessor enters the number entry mode. As numbers are

entered, they are displayed in the display (except in the entry of security codes, when dashes

are displayed). On the sixth consecutive digit a new five digit number is started. This feature

may be used to advantage when an incorrect number is pressed during an entry. Simply

keep pressing numbers until the display is full, then enter the correct number sequence.

The ENTER button must be pressed before any numerical data is entered into the

DIGIMAXDIGIMAX

DIGIMAX®. Numbers may be pressed continuously, but nothing will happen until the

DIGIMAXDIGIMAX

ENTER button is pressed. The ENTER button must be pressed after the security code, after

speed or ratio command entries, and after parameter values are entered. The ENTER button

is not used for function keys such as UP, DN, SET, COM/ACT, or LOC/REM.

The ENTER key may also be used to clear error codes (see page 27).

®®

®

®®

Manual

DIGIMAXDIGIMAX

DIGIMAX® are used for :

DIGIMAXDIGIMAX

Page 9DIGIMAX

Page 18

The UP and DN buttons are used to make changes in the speed or ratio while the

DIGIMAXDIGIMAX

DIGIMAX® is in operation. There are two control inputs on the back terminals which

DIGIMAXDIGIMAX

accomplish the same functions as the front panel buttons.

There are two modes of response to the UP and DN buttons (see page 31):

1. A "shaft position change" (JUMP) function. When the UP or DN button is pressed,

the output frequency temporarily increases or decreases (depending which one is pressed)

and returns to the SETPOINT when the button is released. The effect of this on the Brushless

motor control is to move the motor shaft forward or backward in its rotation by an amount

proportional to the extra pulses. The amount of change is determined by parameters.

2. A "motor operated potentiometer" (MOP) function. When the UP or DN button is

pressed, speed will continue to increase or decrease as long as the appropriate button is

pressed. When the button is released, speed will remain at the value which exists when the

button is released. This emulates the action of the traditional motor operated potentiometer.

The UP and DN buttons are also used during parameter entry (see page 13).

The CMD/ACT button toggles the

DIGIMAXDIGIMAX

DIGIMAX® between displaying the speed (or ratio)

DIGIMAXDIGIMAX

COMMAND value and the ACTUAL speed (or a derivative thereof). In ACTUAL mode (the

display is bright) the microprocessor displays the speed information returned by the motor.

In COMMAND mode (the display is dimmed) the display is the current SETPOINT (a speed

command in MASTER mode and a ratio command in SLAVE mode). In SLAVE mode a

decimal point appears after the first digit to show how many numbers to enter (see page 34).

The PGM/CLR key is used to enter and leave the parameter table in the SETUP mode.

It must be pressed first, followed by a security code and then the ENTER button to access

the parameters. When the PGM/CLR key is pressed, the display will blank and the numbers

of the security code, as they are entered, will be acknowledged by a dash for each number

pressed. After the ENTER button is pressed, if the code is correct, the display will show the

parameter which was displayed when the parameters were last accessed, or parameter #1

if this is the first access since the last power-up. The PGM/CLR key must be pressed to exit

the SETUP mode. If the access code is incorrect, the display returns to the mode it was in

before the PGM/CLR key was depressed.

The PGM/CLR key may also be used as a CLEAR function during value entry.

The ALT key is used for quick access to command functions which are assigned to the

number and command keys as ALTernate functions. These are functions which may not be

used as often as the dedicated keys, but to which quick access is desired. To use the

alternate functions, it is necessary to press the ALT key (the display will go blank), and then

the key with the desired function printed above it. In some cases, additional actions may be

necessary.

UID The UID function displays the Unit ID number (param #17) when the ALT key is

pressed, followed by the "0" key. After 10 seconds, the display returns to its previous state.

COMSIM COMSIM means COMmunications SIMulator. The COMSIM function sends

out a continuous string of "A" characters (hex 41) on the RS-422 port for 10 seconds. This

function is used for testing. It is accessed by pressing the ALT key followed by the "1" key.

SFWVER To accommodate changes in function of the DIGIMAX

EEPROM may be changed. Sometimes it is necessary to refer to the specific software in the

unit. Pressing ALT followed by the "2" key makes the version date appear in the display. The

format of the date is a five digit number. The first two numbers are the year and the last three

numbers are the day of the year. For instance, April 10th is the 100th day of a non-leap year.

Page 10 © copyright 1992-1996 by Powertec Industrial Motors

®

, the software in the

Page 19

SERNUM Pressing ALT followed by the "3" key displays the serial number of the unit.

DIAG The DIAGnostics function will display a set of diagnostic aids to help to determine

the state of the

to use the diagnostic functions.

Pressing ALT followed by the "4" key causes an equals sign ("=") to appear in the left

lower corner of the display.

If the "1" button is then pressed, a two digit HEX number appears in the display which

represents the on/off states of the inputs on terminals 4 through 10 on TB2.

The number may range from "00" (all inputs off) to "3F" (all inputs on). The number "05"

in the display would tell the operator that the RUN and ESTOP inputs are on, and therefore

DIGIMAXDIGIMAX

the

DIGIMAX® should be running.

DIGIMAXDIGIMAX

This number is structured as follows:

DIGIMAXDIGIMAX

DIGIMAX®. You must have a knowledge of how to use hexadecimal numbers

DIGIMAXDIGIMAX

The first digit is bits 4-7 (7654 binary).

The second digit is bits 0-3 (3210).

bit 7 = Not used

bit 6 = Not used

bit 5 = Down input

bit 4 = Up input

bit 3 = Reverse input

bit 2 = EStop input

bit 1 = Preset input

bit 0 = Run input

If the "DOWN" input (not the front panel key) is activated while running, the number

displayed should be "23" (0010 0011).

ANAOUT Pressing the ALT key and the "5" key displays the current value of the

Analog Output at terminals 13 (+) and 12 (-) on TB1.The display shows the letter "Ao" on the

left side of the display and the current value of the Analog Output in Engineering units, which

are controlled and scaled with parameters #28 through #30. (See parameters section).

Parameter #28 determines the source of the Analog Output signal and parameters #29

and #30 determine the minimum and maximum values, respectively. If parameter #28 is set

to "3", the Analog output value is set from the keypad. Simply key in a new number between

parameter #29 (0 VDC out) and parameter #30 (10 VDC out) and press ENT. The Analog

Output will go a the new value which is proportionally between the two.

AUXOUT Pressing the ALT key and the "6" key brings up the AUXiliary OUTput menu.

The letters "Au" appear on the left side of the display. You can see the state of one of the

six auxiliary outputs by pressing the output number (1 through 6). If you then wish to change

the state of the output, you can press either the ON (UP) key or the OFF (DN) key and then

the ENT key to change the state of the output.

LOAD/AI The value in engineering units of the Analog Input (TB2 terminals 15 and 17)

is displayed by pressing the ALT key followed by the "7" key. An "Lo" is displayed followed

by the value. Scaling is handled by parameters #22 and #23 (see parameters section).

PRESET The

ALT key followed by the "8" key followed by the "UP" (ON) key. To turn the PRESET off,

press ALT, then the "8" key, then the "DN" (OFF) key.

DIGIMAXDIGIMAX

DIGIMAX® may be forced into PRESET speed mode by pressing the

DIGIMAXDIGIMAX

®®

®

®®

Manual

Page 11DIGIMAX

Page 20

REM/LCL Press the ALT key followed by the "9" key to toggle between the Remote and

Local modes of the

all keypad functions are active. In Remote mode only the REM/LCL function and the COM/

ACT key will operate. If parameter #19 is set to "2" (KEYLOCK), you must press the ALT key,

an access code, the UP key and the ENT key in sequence before the

back to the Local mode from the KEYLOCK mode.

DIGIMAXDIGIMAX

DIGIMAX®. In Local mode (REMOTE LED indicator in the display is off)

DIGIMAXDIGIMAX

DIGIMAXDIGIMAX

DIGIMAX® will switch

DIGIMAXDIGIMAX

ON The ON function (the "UP" key) will only work for the AUXOUT and the PRESET

functions. It is not necessary to press the ALT key between the PRESET key and the ON

key or after the AUXOUT number key before the ON key.

OFF The OFF function (the "UP" key) will only work for the AUXOUT and the PRESET

functions. It is not necessary to press the ALT key between the PRESET key and the OFF

key or after the AUXOUT number key before the ON key.

RESETTING PARAMETERS TO FACTORY DEFAULTS

The parameters may be reset to the factory default values by the following key

sequence (the

Page 12 © copyright 1992-1996 by Powertec Industrial Motors

DIGIMAXDIGIMAX

DIGIMAX® must be in the stopped mode):

DIGIMAXDIGIMAX

[ALT] [CMD] - The display will blank out.

[7] [9] [1] [3] [5] - A dash ("-") will appear for each number entered.

[ENT] - A "y" will appear in the display.

[UP] - the parameters should be reset to the defaults.

Page 21

3.0 SET UP P3.0 SET UP P

3.0 SET UP P

3.0 SET UP P3.0 SET UP P

DIGIMAXDIGIMAX

The

DIGIMAX® has 41 setup parameters which may be programmed for specific

DIGIMAXDIGIMAX

applications. Most of these parameters alter the operating characteristics. There are default

parameters for general purpose usage, but the actual programming of these parameters

for any application is the responsibility of the user.

The unit is shipped from the factory with the default parameters unless it is shipped as

part of a system. If it is part of a system, it will be shipped with parameters which will be set

up according to the information which POWERTEC has available about how it will be used.

If a special setup has been requested, or is required, that is how it is shipped. Table I on page

14 and Table 1A on page 20 contain a list of the default parameters, which may be entered

from the table. After a

to enter all parameter values into Tables I (page 14) and 1A (page 20) to maintain a record.

PARAMETER ACCESSPARAMETER ACCESS

PARAMETER ACCESS

PARAMETER ACCESSPARAMETER ACCESS

Access to the parameter list requires the knowledge of one of the two security codes:

a master maintenance code (printed at the end of this manual on a tear out page), and an

operator password (parameter #21). The maintenance code is built into software and cannot

be changed, except by the factory. The operator password may be changed at will by anyone

with access to the parameter tables.

Before following this procedure, read section 2.0 (ORIENTATION) of this manual.

Access to the parameters is gained by the following procedure:

1. Change from REMOTE to LOCAL, if necessary (REMOTE LED should be off).

2. Change to COMMAND mode, if necessary (display will be dimmed).

3. Press the PGM/CLR button (the display will blank out).

4. Enter the security code (a dash will appear for each number entered).

It is not necessary to enter any leading zeroes. Enter 12, if that is the code. It is not

necessary to enter 00012, although that will work. The number "0" is a legitimate code. You

must press at least 1 digit to enter a code.

5. Press the ENTER (ENT) button.

If the number has been incorrectly entered, the display will return to the display mode

it was in before the PGM/CLR button was pressed. If the number is correctly entered, the

display will show a "P-nn" ('nn' is a number from 1 to 41). That number will be the parameter

currently available for review. If this is the first access since power was applied, parameter

#1 will show (a "P-01" will be displayed). If there was a previous access since the last time

power was applied, the parameter visible when setup mode was exited will be showing.

DIGIMAXDIGIMAX

If the

DIGIMAX® is running, and parameter access is denied during run mode

DIGIMAXDIGIMAX

(parameter #16 is set to "0") the display will flash "Err 15" (see page 31). Press the PGM/

CLR button again, and, if the display goes blank, press the PGM/CLR button to restore the

display. Wait until the RUN command is off before attempting to change parameters. The

parameters may be accessed as soon as the RUN input is off, even during deceleration.

If frequent access to the parameters is necessary, change parameter #16 to "1" to allow

access to the parameters while running, and change parameter #21 to "0" so that access to

the parameters may be gained very quickly by pressing the PGM/CLR button, "0", and the

ENT button..

6. Enter the desired parameters.

Moving up in the parameter tables (#1 to #2 to #3, etc.) is accomplished with the UP

button. When parameter #41 is reached, pressing the UP button will roll over to parameter

#1. Moving down in the parameters (#10 to #9 to #8, etc.) is accomplished with the DN

button. Pushing DN when parameter #1 is showing will roll over to parameter # 41.

ARAMETERSARAMETERS

ARAMETERS

ARAMETERSARAMETERS

DIGIMAXDIGIMAX

DIGIMAX® has been set up in a specific application, it is a good idea

DIGIMAXDIGIMAX

®®

®

®®

Manual

Page 13DIGIMAX

Page 22

POWERTEC

DIGIMAX ®

POWERTEC Industrial Corporation

Rock Hill, South Carolina, USA 29732

PARAMETER DESCRIPTION RANGE DEFAULT VALUE

1 Maximum Motor Speed

2 Display High EGU 0 to 99999 1750

3 Decimal Places 0to4 0

4 Base Ratio 0 to 79999

5 Feedback PPR 0 to 9999 120

6 Acceleration Time 0 to 99999 10

7 Deceleration Time 0 to 99999 10

8 Master/Slave 0to2 0

9 Preset Speed 0 to 99999 200

10 Jump UP Change 0 to 99999 10

11 Jump Down Change 0 to 99999 10

12 Up to Speed Tolerance 0to255 10

SERIAL NO:

0 to 65535

DATE:

1750

1.OOOO

13 Jump/MOP 0to1 0

14 Float/Freeze 0to1 0

15 Display Sample Rate 1to255 1

16 Setup During Run 0to1 1

17 Unit ID 1to255 1

18 Baud Rate

19 Local/Remote/Keylock 0to2 0

20 ** A to D Trim SETPOINT 0 to 99999 0

21 Operator Password 0 to 99999 0

** Parameter #20 function was used as Speed/Ratio setpoint. Change was

Table I: Parameter table for the

implemented in Software version 93166.

DIGIMAXDIGIMAX

DIGIMAX®. Default values are the values used for basic testing. Values used in a particular

DIGIMAXDIGIMAX

3, 6, 12, 24, 48 or 96

application may be entered in the VALUE column.

96

Page 14 © copyright 1992-1996 by Powertec Industrial Motors

Page 23

A quick way to move between parameters is to press the ALT key and then the number

of the parameter desired. The

A new value may be entered and changed once or several times at any time while the

parameter number is flashing. If you make a mistake, and the number is an illegal value or

outside the legal range for that parameter, an error code will flash. See page 27 for the error

codes. Press PGM/CLR to cancel the error and try again.

7. After the desired parameters are entered, press the PGM/CLR button again.

The display will return to its normal mode. If it goes blank, press the PGM/CLR button).

SETPOINT CONTROLSETPOINT CONTROL

SETPOINT CONTROL

SETPOINT CONTROLSETPOINT CONTROL

The speed or ratio entered via the keypad is called the SETPOINT. This value is stored

in non-volatile memory. If parameter #14 (see page 18) is set to 1, the SETPOINT will be

remembered after stops and even after power has been removed from the

parameter #14 is set to 0, the SETPOINT is lost when the RUN command is removed.

A new speed or ratio may be entered via the keypad while the unit is stopped or while

it is in operation. When a new speed or ratio SETPOINT is entered, the ENTER button must

be pressed to make it take effect. Speed and ratios may be entered from the comm link.

Speeds and ratios may be entered while stopped. They will be entered and registered,

but they will not show up in the COMMAND mode display until the

Speeds and ratios entered while not in RUN mode will take effect when the RUN is enabled.

If the new setpoint in MASTER mode is an illegal value , an error code will flash ("Err01).

Press PGM/CLR to cancel the error code. The legal values of the SETPOINT are determined

by parameter #2 in the MASTER mode.

If a new SETPOINT is entered during acceleration or deceleration (run is still active),

the DIGIMAX® goes to the new value, changing from acceleration to deceleration, or from

deceleration to acceleration, as necessary.

DIGIMAXDIGIMAX

DIGIMAX® will go directly to the selected parameter.

DIGIMAXDIGIMAX

DIGIMAXDIGIMAX

DIGIMAX®. If

DIGIMAXDIGIMAX

DIGIMAXDIGIMAX

DIGIMAX® is started.

DIGIMAXDIGIMAX

PARAMETER DESCRIPTIONSPARAMETER DESCRIPTIONS

PARAMETER DESCRIPTIONS

PARAMETER DESCRIPTIONSPARAMETER DESCRIPTIONS

In the following descriptions of the parameters, note that some of the parameters may

be changed while in RUN mode, and some may not, regardless of setting of parameter #16.

Where a new entry is prohibited, an error code is generated (see page 27 for the error codes).

#1 #1

MAXIMUM MOTOR SPEEDMAXIMUM MOTOR SPEED

#1

MAXIMUM MOTOR SPEED

#1 #1

MAXIMUM MOTOR SPEEDMAXIMUM MOTOR SPEED

This is the fastest speed (in RPM) at which the motor is allowed to run. It is normally

set at the base speed of the motor, or, in some applications, at the top speed of the motor

(such as 1925 RPM maximum on a 1750 motor; or at 2300 for an 1150/2300 constant power

motor). No decimal values are allowed. Valid values are 0 to 65535.

This number works with parameter #5 to prevent excessive speed of the motor.

Attempting to change this parameter while running generates an error code ("Err13").

#2 #2

SETPOINT HIGH EGUSETPOINT HIGH EGU

#2

SETPOINT HIGH EGU

#2 #2

SETPOINT HIGH EGUSETPOINT HIGH EGU

This is the value which will be displayed in the five-digit display when the motor is

running at maximum motor speed (parameter #1). The keypad number to be entered as a

SETPOINT conforms to this number in the MASTER mode.

If the calibration point of process speed to motor speed is at some point other than at

maximum motor speed, then the value which should be displayed at maximum motor speed

is proportional (i.e., if 1000 RPM = 200 FPM, then 1750/1000 means that at 1750 RPM (the

max speed) it would be 350 FPM, so enter 350 here with no decimal places or 3500 here with

one decimal place. Valid values are from 0 to 99999.

This parameter may be changed while the

(EGU STANDS FOR ENGINEERING UNITS)

DIGIMAXDIGIMAX

DIGIMAX® is in operation.

DIGIMAXDIGIMAX

®®

®

®®

Manual

Page 15DIGIMAX

Page 24

#3 #3

DECIMAL PLACESDECIMAL PLACES

#3

DECIMAL PLACES

#3 #3

DECIMAL PLACESDECIMAL PLACES

Set the number of decimal places in the ACTUAL display (whether in MASTER or in

SLAVE mode). Enter a whole number from 0 (no decimal places at all) to 4 (decimal point

after the first digit on the left).

Ratios automatically have four decimal places in the COMMAND mode, and this

cannot be altered by the setting of this parameter.

Parameter #3 may be changed in the RUN mode. The display will immediately reflect

the new decimal location.

#4 #4

SLAVE RATIO SETTINGSLAVE RATIO SETTING

#4

SLAVE RATIO SETTING

#4 #4

SLAVE RATIO SETTINGSLAVE RATIO SETTING

In the MASTER mode, this value is ignored.

In the SLAVE mode, this parameter is the ratio of the motor pulse rate (at TB2 terminals

11 and 12) to the incoming pulse rate at TB2 terminals 13 and 14 when the SETPOINT is

1.0000. The pulse train frequencies involved are dependent on motor size, RPM's and

encoder rate (for information on setting the base ratio, see page 34).

Attempting to change this parameter while running generates an error code (Err13).

#5 #5

FEEDBACK PPRFEEDBACK PPR

#5

FEEDBACK PPR

#5 #5

FEEDBACK PPRFEEDBACK PPR

This pulse train (in pulses per revolution) is a product of the encoder pulses per

revolution (in one feedback channel) times the pulse multiplier of the EPROM on the Current

Controller Board (part # 141-108) of the motor control.

Parameter #5 may not be changed in the RUN mode.

The standard multiplier for the 141-108 Current Controller EPROM (part no. 141-300)

is four. This gives 120 PPR output from the control for 30 PPR encoders, and 240 PPR output

from the control with the 60 PPR encoders. Other multiplier values of 2 or 1 are used mostly

on high speed motors (above 3600 RPM) and/or with encoders rated at 600 PPR or more.

The Model 500 has a selectable feedback rate via switches on the logic board. With the

Model 500, check switches S1-1 and S1-2.

If there is a doubt as to either the encoder PPR or the EPROM multiplier, check the

motor for a special (external) encoder, then follow this procedure :

If there is no special encoder, make sure that the default parameters are installed in

the first eight parameters of the

them later), set a speed of 60 (sixty) into the SETPOINT and start the control. A standard

EPROM and a 30 PPR encoder will cause the motor to turn one revolution every second.

A standard EPROM and a 60 PPR encoder will cause the motor to turn once every 2

seconds. An EPROM multiplier of 2 will result in motor speeds twice as fast and an EPROM

multiplier of 1 in motor speeds four times as fast.

If there is an external encoder on the motor, put the number of PPR (or "lines") from

the encoder nameplate into parameter #5. With the default values in the rest of the first eight

parameters in the

on. A standard EPROM (with a multiplier of 4) will cause the motor to turn at a rate of one

revolution per second (or 60 RPM). An EPROM with a multiplier of 2 will cause a speed of

2 revolutions per second (120 RPM). An EPROM with a multiplier of 1 will result in a speed

of 4 revolutions per second (240 RPM).

DIGIMAXDIGIMAX

DIGIMAX® , set a speed value of 15 into the SETPOINT and turn the motor

DIGIMAXDIGIMAX

DIGIMAXDIGIMAX

DIGIMAX® (record the current parameters for restoring

DIGIMAXDIGIMAX

#6 #6

ACCELERATION TIMEACCELERATION TIME

#6

ACCELERATION TIME

#6 #6

ACCELERATION TIMEACCELERATION TIME

For MASTER mode, enter the acceleration time (in tenths of seconds) from zero speed

to full speed (as determined by parameter #1). Valid values are from 0.0 to 999.9 seconds.

It will take one half (1/2) of this time to go from zero speed to half speed or from half speed

to full speed. Other proportional changes in speed take like proportions of time. This

parameter also sets the increase rate of the Motor Operated Potentiometer mode.

In SLAVE mode, this time affects the time it takes for the ratio to change from one value

Page 16 © copyright 1992-1996 by Powertec Industrial Motors

Page 25

to another. When the DIGIMAX® is in the SLAVE mode, the ratio SETPOINT must be

entered the first time after power-up, and accelerate to that value. On subsequent restarts,

the ratio will be effective immediately when the RUN is closed. If it is changed while in

operation, the time it takes to change will be proportional to the percentage of the full range

times the parameter #6 value.

This parameter may be changed while in the RUN mode.

#7 #7

DECELERATION TIMEDECELERATION TIME

#7

DECELERATION TIME

#7 #7

DECELERATION TIMEDECELERATION TIME

For the MASTER mode, enter the desired length of deceleration time (enter in tenths

of seconds) from full speed (as determined by parameter #1) to zero speed. Valid values

are from 0.0 to 999.9 seconds. It will take 1/2 this time to go from full speed to half speed

or from half speed to zero speed. This parameter also sets the rate of decrease in the Motor

Operated Potentiometer mode.

In SLAVE mode, this time affects the time it takes for the ratio to change from one ratio

to another. If the ratio is changed while in operation, the time it takes to change will be

proportional to the percentage of the full range times the parameter #6 value.

This parameter may be changed while the unit is in the RUN mode.

#8 #8

MASTER/SLAVEMASTER/SLAVE

#8

MASTER/SLAVE

#8 #8

MASTER/SLAVEMASTER/SLAVE

Valid values are 0, 1, or 2. See page 32 for more information.

Enter 0 for MASTER mode. In MASTER mode, the DIGIMAX® generates a train of

pulsesbased on the SETPOINT and parameter #5, limited by parameter #1. The frequency,

during ramping periods, is also modified by parameters #6 and #7. The display value is

controlled by parameters #2 and #3. Control from the keypad is ranged by parameter #2.

Enter 1 for SLAVE mode, where direct ratios are entered as SETPOINTs. A reference

frequency must be supplied to TB2 terminals 13(-) and 14(+). The ratio to be entered as a

setpoint is SLAVE/MASTER. The frequency which is generated is determined as a multiple

of the input frequency by parameter #4 and the SETPOINT, and limited by parameter #1.

When the ratio is changed the ramping is controlled by parameters #6 and #7. The ratio will

ramp to a new value, either accelerating or decelerating at the appropriate rate.

Enter 2 for the INVERSE SLAVE mode. This is the same as the SLAVE mode, but

inverse ratios may be entered (i.e.,MASTER/SLAVE instead of SLAVE/MASTER) , as is the

case very often when the lead (or master) motor is after the slave motor in the process. This

makes it unnecessary for the machine operator to calculate ratios of less than 1.0000.

This parameter may not be changed during the RUN mode.

#9 #9

PRESET SPEEDPRESET SPEED

#9

PRESET SPEED

#9 #9

PRESET SPEEDPRESET SPEED

In the MASTER mode, enter the speed here as you would a SETPOINT. This is the

SETPOINT for the PRESET speed mode. Valid values are from 0 to 99999, but the value

may not exceed parameter #4 (an error code is generated).

In the SLAVE mode, this value is a preset ratio.

This parameter may be changed while running.

#10 #10

#10

#10 #10

JUMP UP CHANGEJUMP UP CHANGE

JUMP UP CHANGE

JUMP UP CHANGEJUMP UP CHANGE

This parameter is an absolute number. Exactly as entered, it will affect the value shown

in the display. Valid values are from 0 to 99999.

Being an absolute value, if the number is 10, the value of the speed or ratio command

will increased by this amount when the UP button is pushed or the UP input is activated. A

speed of 1000 will change to 1010, and a ratio of .4000 will become .4010.

This value is used for the JUMP UP mode and the first step in the MOP UP mode. See

parameter #13 for the explanations of these modes.

This parameter may be changed while running.

®®

®

®®

Manual

Page 17DIGIMAX

Page 26

#11 #11

JUMP DOWN CHANGEJUMP DOWN CHANGE

#11

JUMP DOWN CHANGE

#11 #11

JUMP DOWN CHANGEJUMP DOWN CHANGE

This parameter is the same as #10 (Jump UP Change), but in the downward direction.

This number is subtracted from the displayed number. It may be changed while running.

#12 #12

UP-TO-SPEED TOLERANCEUP-TO-SPEED TOLERANCE

#12

UP-TO-SPEED TOLERANCE

#12 #12

UP-TO-SPEED TOLERANCEUP-TO-SPEED TOLERANCE

In the MASTER mode, enter a number between 0 and 255 to set how close the actual

speed must be to the SETPOINT to turn on the Up-to-Speed circuit (both the front panel LED

and the output at TB2 terminal 15). This number is an absolute value. For example, if this

parameter has a value of 5 and the commanded speed is 1500, the speed must be between

1495 and 1505 RPM. The AT SPEED source is set in parameter #40 (see page 22).

The Up-to-Speed LED is always ON in SLAVE mode and the AT SPEED output does

not change while in the SLAVE mode except when it is slewing to a new ratio.

This parameter may be changed while in the RUN mode.

#13 #13

#13

#13 #13

#14 #14

#14

#14 #14

JUMP / M.O.P.JUMP / M.O.P.

JUMP / M.O.P.

JUMP / M.O.P.JUMP / M.O.P.

Enter a 0 for JUMP mode, or a 1 for MOP mode. Any other number will generate an

error code in the display. This number may be changed while running. See page 31.

In JUMP mode, the UP button or the TB2 terminal 9 input will add the AMOUNT of the

value in parameter #10 to the current speed or ratio. If the current speed is 1100 and 50 is

stored in parameter #10, the speed will increase to 1150 as long as the UP button or UP input

is active. When the button is released, the speed returns to its previous value. This temporary

operation is the same for ratios and for the DN button or the DN input at TB2 terminal 10.

In MOP mode, the closure of the UP button or input will increase the SETPOINT (speed

or ratio) as soon as the closure takes place by the AMOUNT in parameter #10. If the button

or input is released in less than half a second (0.5 sec), the SETPOINT will stay at the new

value. If the contact stays closed for more than 0.5 second, then the SETPOINT will continue

to increase at the rate set by the Acceleration Time (parameter #6). The increase will

continue until the circuit opens, at which point the speed or ratio will remain at the new value.

In MOP mode, the closure of the DN button or input will decrease the SETPOINT by

the AMOUNT in parameter #11 immediately, and, after 0.5 second continue to decrease the

SETPOINT at a rate determined by the Deceleration Time (parameter #7). If the circuit is

opened before 0.5 second elapses, the decrease is by the amount in parameter #11 only.

FLOAT / FREEZEFLOAT / FREEZE

FLOAT / FREEZE

FLOAT / FREEZEFLOAT / FREEZE

Valid values are 0 or 1. This parameter may be changed while running.

If this parameter is set to 0, the SETPOINT is lost when the DIGIMAX® is stopped. If

this parameter is set to 1, the SETPOINT value is stored in non-volatile memory and is

retained while the motor is stopped. (This parameter used to be tied to the MOP function,

but no longer.)

If power is turned off, the SETPOINT is lost if this parameter is set to 0.If this parameter

is set to 1, the SETPOINT will be remembered after power is restored.

#15 #15

DISPLAY SAMPLE RATEDISPLAY SAMPLE RATE

#15

DISPLAY SAMPLE RATE

#15 #15

DISPLAY SAMPLE RATEDISPLAY SAMPLE RATE

The valid values for this parameter are 1 to 255. It may be changed while running.

A setting of 1 is a 1 second update period. Higher numbers also reflect the number of

seconds. The higher the number entered, the longer the period before the display changes.

#16 #16

#16

#16 #16

Page 18 © copyright 1992-1996 by Powertec Industrial Motors

SETUP DURING RUNSETUP DURING RUN

SETUP DURING RUN

SETUP DURING RUNSETUP DURING RUN

If the value in this parameter is 0, and the operator presses the PGM/CLR button, an

error code flashes in the display. The error code is "Err15". The PGM/CLR button should

be pressed again to clear the error code and the COM/ACT key to restore the display.

A 1 enables changes while in RUN.

The number can be changed from 1 to 0 while running, but obviously not from 0 to 1.

Page 27

NOTE: SERIAL COMMUNICATIONS REQUIRES SOME EXPERTISE IN THE USE OF COMPUTERS AND/OR PROCESS CONTROLS. THE

COMMUNICATIONS

TION. THE OPERATION OF THE

THE

RS-232 SPECIFICATION (A SINGLE PORT TO SINGLE PORT SYSTEM) TO THE RS-422 SYSTEM (A MULTI-PORT INDUSTRIAL

STANDARD

#17 #17

#17

#17 #17

PROTOCOLS IN THE

DIGIMAXDIGIMAX

DIGIMAX® FROM A PERSONAL COMPUTER'S RS-232 PORT REQUIRES A DEVICE TO CHANGE FROM

DIGIMAXDIGIMAX

). THESE DEVICES ARE AVAILABLE AS EXTRA COST OPTIONS FROM POWERTEC.

UNIT I.D. UNIT I.D.

UNIT I.D.

UNIT I.D. UNIT I.D.

When using the Binary protocol (see parameter#27), valid values are from 1 to 255.

When using one of the Allen Bradley protoccols, valid values are from 0 to 254. No unit

may have a value of 255, since that is the address used for general broadcast functions.

Each unit on an RS-422 link must have a unique I.D. The default I.D. number is 1.

Using 1 as one of the unit I.D. numbers may cause an addressing conflict if a unit

returns to its default values, so it may be advisable to start the addresses number 2.

Entering an illegal address causes an error code 08. Press PGM/CLR to clear it.

This parameter may be changed while running, but consider the consequences on the

communications system.

DIGIMAXDIGIMAX

DIGIMAX® CONFORM TO THE ANSII STANDARD RS-422 COMMUNICATIONS SPECIFICA-

DIGIMAXDIGIMAX

#18 #18

#18

#18 #18

#19 #19

#19

#19 #19

#20 #20

#20

#20 #20

#21 #21

#21

#21 #21

BAUD RATEBAUD RATE

BAUD RATE

BAUD RATEBAUD RATE

Set the Baud Rate for serial communications. Valid values are 3 (for 300 baud), 6 (for

600), 12 (for 1200), 24 (for 2400), 48 (for 4800) and 96 (for 9600).

After setting the baud rate, the serial communications of the host must be set to 8 data

bits, NO parity, and 1 stop bit (8-N-1). These settings in the

Entering an incorrect baud rate generates error code 10. Press PGM/CLR to clear it.

LOCAL / REMOTE / KEYLOCKLOCAL / REMOTE / KEYLOCK

LOCAL / REMOTE / KEYLOCK

LOCAL / REMOTE / KEYLOCKLOCAL / REMOTE / KEYLOCK

Enter 0 for LOCAL (keypad) operation.

Enter 1 for REMOTE. The front panel LED will stay lit until LOCAL control is restored.

Enter 2 for KEYLOCK, which is LOCAL/REMOTE controlled through the parameters.

Any other number will generate error code 09. Press PGM/CLR to clear the error code.

TO RETURN TO LOCAL ONCE THE

PRESS THE KEY SEQUENCE [ALT] [CODE] [UP] [ENT] TO RESTORE LOCAL CON-

TROL. The code may be either the operator or the maintenance access code.

This parameter may be changed while running.

A TO D TRIM SETPOINTA TO D TRIM SETPOINT

A TO D TRIM SETPOINT

A TO D TRIM SETPOINTA TO D TRIM SETPOINT

This parameter sets the gain of the A to D input (TB2 terminals 17+ and 15-) when the

input is used as an analog trim input. When the analog input is 5 VDC, the trim is zero. The

voltage difference above or below 5 VDC (0 VDC min, 10 VDC max) is multiplied by 1/5th

of the number in parameter # 20 and added or subtracted to the SETPOINT.

Parameter #26 must be set to 1 to enable the AtoD input as a trim input.

OPERATOR PASSWORDOPERATOR PASSWORD

OPERATOR PASSWORD

OPERATOR PASSWORDOPERATOR PASSWORD

This is the code given to the operator for access to the parameters. It may be any

number from 0 to 99999. The number may be from one to five digits, and leading zeroes do

not need to be entered. This parameter may be changed while the unit is running.

DIGIMAXDIGIMAX

DIGIMAX® cannot be altered.

DIGIMAXDIGIMAX

DIGIMAXDIGIMAX

DIGIMAX® IS IN KEYLOCK, YOU MUST

DIGIMAXDIGIMAX

#22 #22

#22

#22 #22

A TO D LOW ENGINEERING UNITSA TO D LOW ENGINEERING UNITS

A TO D LOW ENGINEERING UNITS

A TO D LOW ENGINEERING UNITSA TO D LOW ENGINEERING UNITS

The input at terminals 15 (-) and 17 (+) on TB2 may range from 0 to +10 VDC. This

parameter sets, in engineering units, what the effect of the 0 VDC level will be.

This parameter may be changed while the unit is running.

®®

®

®®

Manual

Page 19DIGIMAX

Page 28

DIGIMAX ®

PARAMETER DESCRIPTION RANGE DEFAULT VALUE

22 A to D low Engr Units 0....999 0

23 A to D high Engr Units 0....999 100

Parameter table (continued)

24 A to D Display mode 0 0

25 A to D Sample Rate 1to255 1

26 A to D Trim Enable 0to1 0

27 Communications Protocol 0,2,3 0

28 D to A Source 0,1,2,3 0

29 D to A low Engr Units 0....99999 0

30 D to A high Engr Units 0....99999 10000

31 Maximum Ratio 0....79999 79999

32 Preset Input Mode 0,1,2 0

33 Reverse Input Mode 0,1,2,3 0

34 Up Input Mode 0,1 0

35 Down Input Mode 0,1 0

36 Installed Option Enable 0,1 0

37 Command Ratio Setpoint 0....79999 0

38 Minimum Command Ratio 0....79999 0

39 Debounce Value 0....255 8

SET TO "0"

40 AT SPEED Source 0to1 0

41 Comm Turn-Around Time 0to255 1

Table 1A: Additional parameters for the DIGIMAX® .

#23 #23

#23

#23 #23

#24 #24

#24

#24 #24

#25 #25

#25

#25 #25

#26 #26

#26

#26 #26

Page 20 © copyright 1992-1996 by Powertec Industrial Motors

A TO D HIGH ENGINEERING UNITSA TO D HIGH ENGINEERING UNITS

A TO D HIGH ENGINEERING UNITS

A TO D HIGH ENGINEERING UNITSA TO D HIGH ENGINEERING UNITS

The input at terminals 15 (-) and 17 (+) on TB2 may range from 0 to +10 VDC. This

parameter sets, in engineering units, what the effect of the 10 VDC level will be.

This parameter may be changed while the unit is running.

A TO D DISPLAY MODEA TO D DISPLAY MODE

A TO D DISPLAY MODE

A TO D DISPLAY MODEA TO D DISPLAY MODE

This parameter must be set to "0". It has not been implemented in software.

A TO D SAMPLE RATEA TO D SAMPLE RATE

A TO D SAMPLE RATE

A TO D SAMPLE RATEA TO D SAMPLE RATE

This is the rate at which the voltage information on terminals 15 and 17 of TB2 is

updated. Valid values are 1 to 255. Each increment is 50 ms; a setting of 100 is 5 seconds.

A TO D TRIM ENABLEA TO D TRIM ENABLE

A TO D TRIM ENABLE

A TO D TRIM ENABLEA TO D TRIM ENABLE

When this parameter is set to 0, the analog input (TB2 terminals 15 and 17) is read

normally, as set up in parameters #22, #23, and #24. See page 7.

Page 29

If this parameter is set to 1, the analog input becomes a trim input for speed or ratio.

Five volts input is no effect. Voltages greater than five volts add to the setpoint; less than five

volts subtracts from the setpoint.

If it is set to 2, zero input is zero effect. Increasing voltage adds to the SETPOINT.

If set to 3, zero input is zero effect. Increasing voltage subtracts from the SETPOINT.

Parameter #20 determines the amount (or gain) of the trim. The trimming is done at the

sample rate (parameter #25). See page 7.

#27 #27

#27

#27 #27