Page 1

POWERTEC

Industrial Motors

DFS-1

DFS-1

SOFTWARE RELEASE 1.0

SOFTWARE RELEASE 1.0

MICROPROCESSOR B ASED

BRUSHLESS D.C.

MOTOR CONTROLLER

INSTALLATION AND

OPERATION

INSTRUCTION MANUAL

PRODUCTION RELEASE

AUGUST, 1994

Page 2

A subsidiary of

POWERTEC Industrial Corporation

Mailing Address: P.O.Box 2650 • Rock Hill, South Carolina USA 29732 • PHONE: 803-328-1888

Shipping Addre

ss: 2606 Eden Terrace • Rock Hill, South Carolina USA 29730 • FAX: 803-328-1870

© POWERTEC Publication # DFS-1

PM080994

Page 3

Corrections to page 44 of the manual, Attachment A: Detailed Commands

Read Speed/Status (81)

Changes shown in gray

[ST2] - 7 6 5 4 3 2 1 0

Local/Remote (0,1)

Master/slave (0,1)

At Speed (1)

Fwd. Dir. Set

Fault Detected (1)

Drive Enabled (1)

Microprocessor Fault

Zero Speed

ERRA T A

[ST1] - 7 6 5 4 3 2 1 0

Bus not charged (1)

IOC (1)

Stall

Inverse Time OL (1)

Heatsink Thermal OT

Commutation Fault

Overvolt

Undervolt

DFS-01IM

PM94290

Page 4

Additional Info

DFS Software Modification For

Dynamic Braking or Output Contactor

Operation

25 October, 1994

Functional Description

A new function for Contactor Aux has been added to the digital input choices. When configured as described

in the example, 24VDC must be present at this input for the drive to run. Parameter #62, Contactor Delay, is a

number of 25ms intervals that will occur between the DFS controller acceptance of a run command and the

firing of the transistors. If the Contactor Aux input signal is low, the DFS starts the timer and closes the

Contactor Output. If the Contactor Aux input does not switch high before the timer runs out, the drive will

return to the stop condition. If the Contactor Aux input does switch high, the drive will start running when the

timer runs out.

Example Setup for Dynamic Braking

1 Set Digital Input #7 mode to Contactor Aux, polarity to Active Low .

2 Set Digital Output #4 mode to Contactor, polarity to Normally Closed.

3 Set Contactor Delay to 20 (20 x 25ms = 500ms = 1/2 second).

Run command causes the Contactor Output to close, the Contactor Relay opens, the feedback contacts close

and the drive starts to run.

Example Setup for Output Contactor

1 Set Digital Input #7 mode to Contactor Aux, polarity to Active Low .

2 Set Digital Output #4 mode to Contactor, polarity to Normally Closed.

3 Set Contactor Delay to 10 (10 x 25ms = 250ms = 1/4 second).

Run command causes the Contactor Output to close, the Contactor Relay closes, the feedback contacts close

and the drive starts to run.

The difference in the operation of the two types of contactors is that the Dynamic Braking Contactor is

normally closed whereas the Output Contactor is normally open. In both contactors, the auxilliary contacts are

normally open.

Terms Used

1 Contactor Aux - The digital input on the DFS board which is connected to the feedback contacts on the

contactor relay.

2 Contactor Output - The digital output on the DFS board which activates the solenoid on the contactor

relay.

3 Signal low - 0VDC

4 Signal high - 24VDC

Page 5

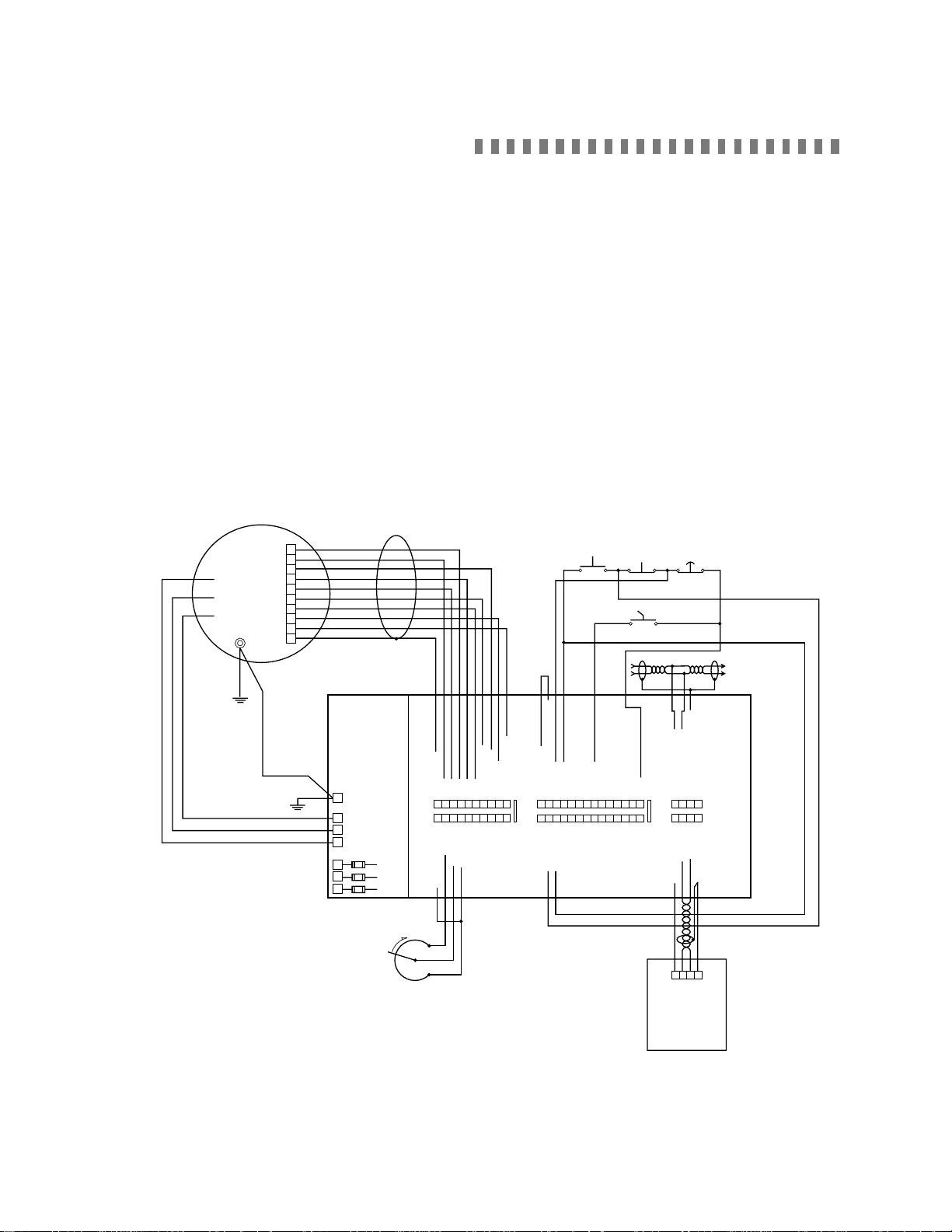

1.0 INSTALLATION

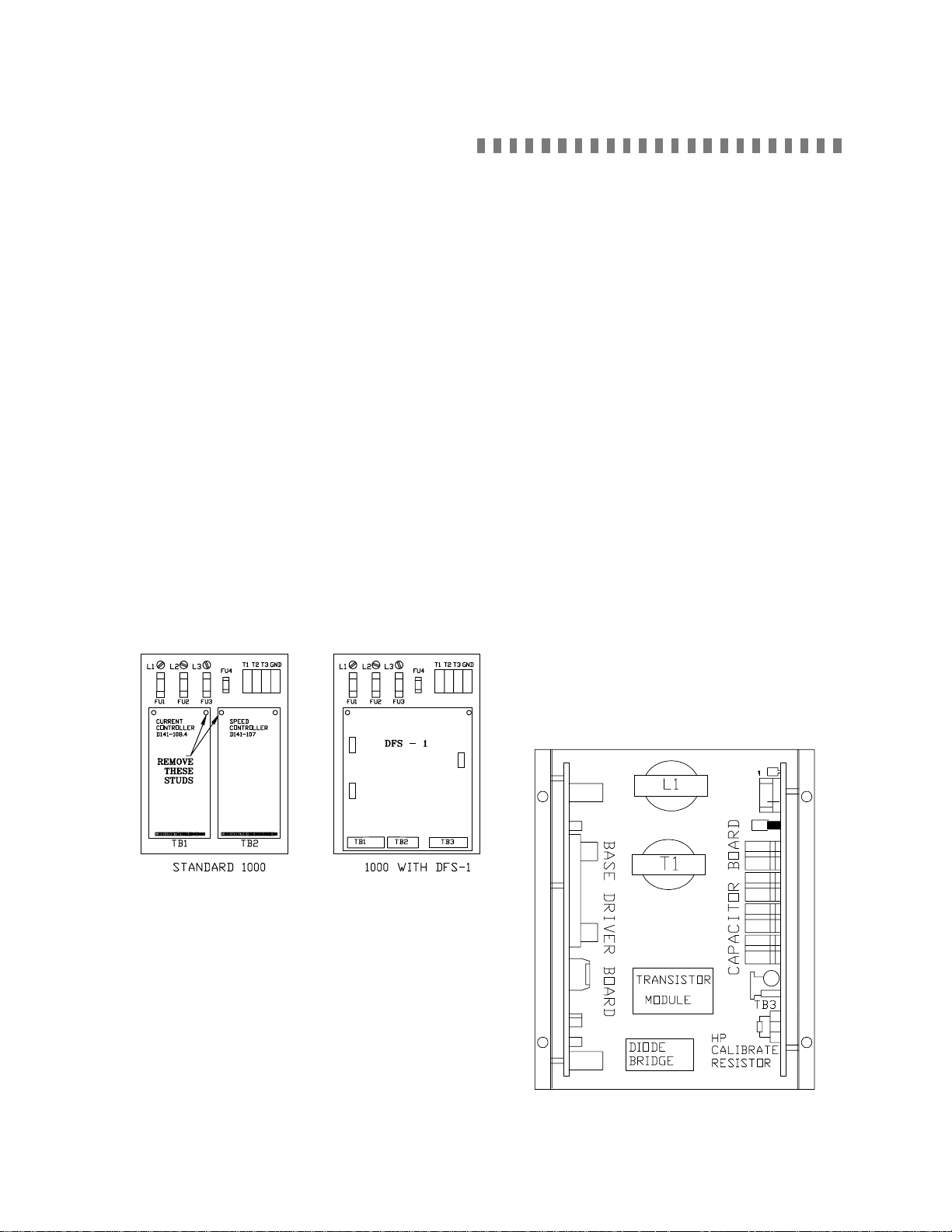

The DFS-1 printed circuit board mounts on

any POWERTEC Brushless DC motor control

except the Model 500. The Model 1000 is used here

for illustration purposes only.

1.1 MOUNTING -- READ THIS ENTIRE

SECTION BEFORE STARTING!

The DFS-1 printed circuit board mounts on

the Model 1000 or Model 1000AR motor control in

place of both the Current Controller board (part

#141-108) and the Speed Controller board (part

#141-107 on the non-regenerative model 1000, part

# 147-101 on the regenerative model 1000AR).

These boards are mounted side by side on all

standard motor controls. TB1 is located on the

Current Controller (left hand board) and TB2 is on

the Speed Controller (right hand board). The first

eight connections which normally come into TB1

(the motor cable leads) will connect to the same

places on the DFS-1. The connections going into

TB2 (mainly operators and speed pot) on the

standard motor control will go to different connections on the DFS-1.

There are two flat ribbon cables which must be

connected from the DFS-1 to the other parts of the

motor control: one goes to the Base Driver Board

(part #141-105), and the other cable goes to the

Capacitor Board (part #141-106). See figure 2 for

the physical layout of the control and the location of

these boards. If the DFS-1 board is being installed

in the field, the cables should come with the new

board, since the connectors on the DFS-1 end are

different from the connectors on the Speed and

Current controller ends of the previous cables. Make

sure that you have these new cables before proceeding to install the board. If you do not have them, call

POWERTEC's service department before proceeding.

The DFS-1 board may be used as either a nonregenerative control or as a regenerative control.

This selection is made by one of its parameter

settings. The DFS-1 may be installed on a Model

1000 non-regenerative brushless DC control, but if

the unit is to be used for a regenerative application,

a bus loader of the appropriate voltage and resistors

of sufficient wattage must be added before the drive

may be used regeneratively. If a bus loader is not

installed before regenerative operation occurs, it is

likely that the control will trip out repeatedly. A

Model 1000AR will already have a bus loader and

resistors attached.

Figure 1: The DFS-1 replaces two boards.

If the board is being installed to replace the

boards on a standard control, unplug the strips on

TB1 and TB2, but do not disconnect any wires from

them yet. Unplug the 14-pin connector on P2 (at the

Base Driver Board) and the 10-pin connector on P3

(at the Capacitor Board). Remove these cables and

the Speed and Current controller boards from the

chassis and set them aside. Remove the studs at the

top right of where the Current Controller board was,

and at the top left of where the Speed Controller was

located ( the center studs - see figure 1).

Figure 2: The Model 1000 chassis

Page 1

Page 6

CONTENTS

Introduction ...............................................................................................................................1

Summary of Warranty and Disclaimer ......................................................................................2

WARNING!...............................................................................................................................2

1.0 Connections ........................................................................................................................3

POWER CONNECTIONS: ............................................................................................................. ............... 3

MOTOR ENCODER CABLE: ....................................................................................................................... 4

ANALOG INPUTS:........................................................................................................................................ 4

ANALOG OUTPUTS:................................................................................................................................... 5

FREQUENCY INPUT:................................................................................................................................... 5

FREQUENCY OUTPUT:............................................................................................................................... 6

DIGITAL INPUTS:......................................................................................................................................... 6

DIGITAL OUTPUTS:..................................................................................................................................... 7

COMMUNICATIONS:................................................................................................................................... 7

DEFAULT SETUP.......................................................................................................................................... 9

2.0 Specifications ................................................................................................................... 11

POWER SUPPLIES...................................................................................................................................... 11

ANALOG INPUTS....................................................................................................................................... 11

ANALOG OUTPUTS................................................................................................................................... 11

FREQUENCY INPUTS AND OUTPUTS...................................................................................................12

DIGITAL INPUTS........................................................................................................................................ 12

DIGITAL OUTPUTS.................................................................................................................................... 12

COMMUNICATIONS.................................................................................................................................. 13

3.0 DFS-1 Parameters.............................................................................................................15

1. UNIT ID ................................................................................................................................................ 15

2. BAUD RATE......................................................................................................................................... 15

3. LOCAL / REMOTE CONTROL ........................................................................................................... 15

4. COMMUNICATIONS PROTOCOL ..................................................................................................... 16

5. MODES OF OPERATION..................................................................................................................... 16

6. MAXIMUM MOTOR SPEED...............................................................................................................17

7. ENCODER PULSES PER REVOLUTION .......................................................................................... 17

8. MASTER RAMP UP TIME .................................................................................................................. 18

9. MASTER RAMP DOWN TIME ........................................................................................................... 18

10. SLAVE RAMP UP TIME ...................................................................................................................... 1 8

11. SLAVE RAMP DOWN TIME............................................................................................................... 18

12. MASTER PRESET SPEED ................................................................................................................... 19

13. SLAVE RATIO PRESET ....................................................................................................................... 1 9

14. ENGINEERING UNITS ........................................................................................................................ 19

15. BASE RATIO......................................................................................................................................... 19

16. MAXIMUM RATIO ..............................................................................................................................20

17. ANALOG INPUT #1 MODE SELECT................................................................................................. 20

18. ANALOG INPUT #1 SIGNAL CONDITIONING............................................................................... 21

19. ANALOG INPUT #1 LOW ENGINEERING UNITS (EGU).............................................................. 21

20. ANALOG INPUT #1 HIGH ENGINEERING UNITS (EGU) ............................................................. 22

21. ANALOG INPUT #2 MODE SELECT................................................................................................. 22

22. ANALOG INPUT #2 SIGNAL CONDITIONING............................................................................... 22

Page 7

23. ANALOG INPUT #2 LOW ENGINEERING UNITS (EGU).............................................................. 22

24. ANALOG INPUT #2 HIGH ENGINEERING UNITS (EGU) ............................................................. 22

25. ANALOG OUTPUT #1 MODE SELECT............................................................................................. 23

26. ANALOG OUTPUT #1 LOW ENGINEERING UNITS (EGU).......................................................... 23

27. ANALOG OUTPUT #1 HIGH ENGINEERING UNITS (EGU) ......................................................... 23

28. ANALOG OUTPUT #2 MODE SELECT............................................................................................. 23

29. ANALOG OUTPUT #2 LOW ENGINEERING UNITS (EGU).......................................................... 24

30. ANALOG OUTPUT #2 HIGH ENGINEERING UNITS (EGU) ......................................................... 24

31. DIGITAL INPUT #1 FUNCTION......................................................................................................... 25

32. DIGITAL INPUT #2 FUNCTION......................................................................................................... 25

33. DIGITAL INPUT #3 FUNCTION......................................................................................................... 25

34. DIGITAL INPUT #4 FUNCTION......................................................................................................... 25

35. DIGITAL INPUT #5 FUNCTION......................................................................................................... 26

36. DIGITAL INPUT #6 FUNCTION......................................................................................................... 26

37. DIGITAL INPUT #7 FUNCTION......................................................................................................... 26

38. DIGITAL OUTPUT #1 FUNCTION..................................................................................................... 26

39. DIGITAL OUTPUT #2 FUNCTION..................................................................................................... 27

40. DIGITAL OUTPUT #3 FUNCTION..................................................................................................... 27

41. DIGITAL OUTPUT #4 FUNCTION..................................................................................................... 27

42. DRIVE GAIN SETTING ....................................................................................................................... 27

43. DRIVE STABILITY SETTING............................................................................................................. 27

44. DRIVE MOTORING CURRENT LIMIT ............................................................................................. 27

45. DRIVE REGENERATIVE CURRENT LIMIT..................................................................................... 28

46. PULSE MULTIPLIER ........................................................................................................................... 28

47. MODULATION AND OPERATION MODES..................................................................................... 28

48. JUMP OR MOP OPERATION .............................................................................................................. 28

49. MASTER JUMP UP AMOUNT............................................................................................................ 29

50. MASTER JUMP DOWN AMOUNT .................................................................................................... 29

51. SLAVE JUMP UP AMOUNT................................................................................................................ 29

52. SLAVE JUMP DOWN AMOUNT ........................................................................................................ 29

53. INPUT DEBOUNCE VALUE ............................................................................................................... 30

54. FLOAT OR FREEZE ............................................................................................................................. 30

55. MINIMUM RATIO................................................................................................................................30

56. COMMUNICATIONS TURNAROUND DELAY................................................................................ 30

57. MASTER JOG SPEED .......................................................................................................................... 31

58. SLAVE JOG RATIO .............................................................................................................................. 31

59. EGU TAG SELECT ............................................................................................................................... 31

60. MASTER PRESET #2 ........................................................................................................................... 31

61. SLAVE PRESET #2...............................................................................................................................31

4.0 DFS - 1 Setup ..................................................................................................................33

4.1 BASIC SETUP OF THE DFS-1 CONTROLLER................................................................................. 34

4.2 MASTER MODE SETUP..................................................................................................................... 35

4.3 SLAVE MODE SETUP......................................................................................................................... 36

4.4 INPUTS AND OUTPUTS SETUP....................................................................................................... 37

4.5 COMMUNICATIONS SETUP.............................................................................................................38

Page 8

5.0 DFS-1 ERROR CODES ..................................................................................................39

6.0 COMMUNICATION PROTOCOL..................................................................................41

COMMAND LIST........................................................................................................................................ 42

PARAMETER LIST ..................................................................................................................................... 43

ATTACHMENT A: DETAILED COMMANDS......................................................................................... 44

ATTACHMENT B: PARAMETER DESCRIPTION.................................................................................. 50

Additional Info ................................................................................................................ ........51

Typical Output Contactor Connections ........................................................................................................ 52

Typical Dynamic Braking Connections........................................................................................................ 53

Appendix A .............................................................................................................................55

RETROFITTING THE MODEL 1000,1000A, OR 1000AR

Appendix B..............................................................................................................................57

MENU AND KEYPAD HIERARCHY

Page 9

THIS PAGE WAS INTENTIONALLY LEFT BLANK.

Page 4

DFS-1 Manual Revised 7/95

POWERTEC Ind. Corp.©

Page 10

INTRODUCTION

s the computer revolution takes greater

control of industrial processes, there is

A

the process parameters. It is becoming ever more

necessary to control the important characteristics of

motors directly from computers and microprocessorbased controllers. Such control cannot wait for

operator intervention when changes occur in milliseconds and tolerances are measured in thousandths.

are controllable by manipulating its speed, torque,

and power. POWERTEC digitally implemented,

speed, torque, and power control - the DFS-1.

digitally based, and are a natural choice for a

computer controlled environment. Now computers

and PLC's talk to the drive itself when the field-

installable DFS-1 control board replaces the Speed

and Current boards on the standard POWERTEC

Brushless DC drive.

DFS-1 is that there are no adjustment potentiometers

and no setup switches. All characteristics of the drive

are controlled by software parameters which may be

entered by the optional KDU-1 keypad or host

computer. The KDU-1 keypad can be mounted on the

DFS-1 board, in a remote location (usually the

enclosure door), or in a handheld unit. A default set

of parameters which represent the most common

operating conditions will facilitate immediate

operation and testing after installation.

networks, the DFS-1 is programmable by an optional

keypad with its two line, 16-character display. A

single computer port may be used to monitor and

control up to 32 units in an RS-485 communications

link.

a growing need for more intimate control of

All of the operational characteristics of a motor

The Brushless DC motor and its control are

One of the first things you will notice about the

Capable of operating on a single drive or in

Programmable analog inputs and analog outputs

allow many possibilities for control through external

voltages, currents, and frequencies. They may also be

used to monitor drive operation. Digital inputs and

outputs (also programmable) give control and

monitoring flexibility as well as coordination

functions.

Provision is made for plug-in options which add

input and output options and accomplish special

functions. Optional software packages may be

ordered for specific application needs.

Revised 7/95 DFS-1 Manual

POWERTEC Ind. Corp.©

Page 5

Page 11

SUMMARY OF WARRANTY AND DISCLAIMER

POWERTEC Industrial Corporation warrants the DFS-1 to be free from defects in materials and work-

manship for a period of one year from the date of shipment from the factory, or if purchased from an authorized POWERTEC distributor or Original Equipment Manufacturer, not more than 18 months from the date

of shipment from the factory. Upon written notification to the factory of a possible defect in materials or

workmanship, POWERTEC will, at its sole option, repair or replace, at the factory, such defective parts as it

deems necessary to restore the unit to its original specifications.

There is no other warranty, express or implied, including fitness of purpose for the application intended.

This warranty does not cover accidental or intentional damage; physical or electrical misuse or abuse; defective or incorrect installation; effects on other equipment or caused by other equipment; attempted use outside

of specified ranges; or any other situation outside of the control of POWERTEC Industrial Corporation.

The user is responsible for the application of the DFS-1 product and the programming thereof.

This warranty does not encompass any other claims, including, but not limited to, special, incidental, or

consequential damages.

This manual has been assembled as a guide to the use of a POWERTEC product. It represents the best

efforts to compile and present the information herein. Such errors as may appear in no way affect the above

stated warranty. If mistakes of fact are found or suspected in this manual, please notify the factory or your

distributor at once.

WARNING!

The DFS-1 contains static sensitive parts which may be damaged by careless handling of the printed

circuit board. You can avoid this type of damage by always touching the frame of the drive before you touch

the printed circuit board or any of its connections.

The DFS-1 is supplied for field installation in a protective bag. Bring the bag into contact with the

motor controller frame before removing the board from the bag.

Page 6

DFS-1 Manual Revised 7/95

POWERTEC Ind. Corp.©

Page 12

1.0 CONNECTIONS

POWER CONNECTIONS:

POWERTEC Brushless DC motor controllers

are supplied with nominal input voltages of 230, 380,

and 460VAC. Three phase input power is required.

The input is not phase sensitive. Connect the appropriate power supply to the input fuses at L1, L2, and

L3 (check nameplate for proper input voltage and

capacity).

Connect the output terminals T1, T2, and T3 to

the respective terminals on the Brushless DC motor.

It is very important that the T1 terminal on the motor

connects to T1 on the drive, T2 of the motor connects

to T2 of the drive, and T3 of the motor connects to

T3 of the drive. An earth ground wire of the same

gauge as the motor power leads or one gauge smaller

(no smaller than #14 AWG) must be run from a bolt

Orange

Motor

T1

T2

T3

1

Brown

2

Red

3

Blue

4

Yellow

5

Black

6

Green

7

Purple

8

White

9

Shield

10

in the motor junction box to the ground terminal on

the drive. A wire must then be run from the ground

terminal on the drive (next to the motor terminals) to

an earth ground at or near the power source. The

Model 1000 drive does not have the common

circuitry connected to earth ground (chassis). In

most cases this works best, but in some cases it does

not. POWERTEC recommends connecting a short

jumper wire from the drive common at any one of the

several places available on the terminal strips to a

nearby point on the drive chassis or backpanel that

will establish this ground. This is more important in

applications where multiple drives are connected

together or serial communications from a host are

used. All other POWERTEC drives have the

common grounded by mounting screws on the

regulator boards.

Run

Stop

Fwd Rev

E-Stop

RS-485

Communications

POWERTEC

Brushless

DC Drive

COMMUNICATIONS+

COMMUNICATIONS-

COMMUNICATIONS SHIELD

24V COMMON

Digital Input COMMON Cathodes

E-STOP

Digital In 1

Digital In 2

Digital In 3

Digital In 4

Digital In 5

Digital In 6

Digital In 7

FREQ REF IN+

FREQ IN-

FREQ REF SHIELD

Digital Out 4A

Digital Out 4B

FREQ REF OUT-

FREQ REF OUT+

+24V

Spacer

TB3

Spacer

SPEED OUT

Speed Out COMMON

FREQ REF COMMON

HALL SHIELD

HS1

HS3

HS2

HS4

HS5

HALL COMMON

HALL POWER

THERMAL

THERMAL POWER

-10VREF

Analog In 2-

Analog Out 1+

Spacer

1 2 3 4 5 6 7 8 9 10 11 12 13 14

A

TB2

1 2 3 4 5 6 7 8 9 10 11 12 13 14

B

+24V

Spacer

Analog Out 2+

Digital Out 1A

Analog Out COMMON

Digital Out 1B

Digital Out 2A

Digital Out 2B

Digital Out 3A

Digital Out 3B

G

T3

T2

T1

L3

L2

L1

Analog

Speed Pot

A

1 2 3 4 5 6 7 8 9 10

TB1

B

1 2 3 4 5 6 7 8 9 10

+10VDC

Analog In 1+

Analog In COMMON

Analog In 1-

Analog In 2+

1 2 3 4

A

1 2 3 4

B

DISPLAY POWER

1 2 3 4

Keypad

Display

Unit

COMMUNICATIONS COMMON

DISPLAY-

DISPLAY +

Display COMMON

DFS-1

Board

KDU Cable is

Belden # 9463

“Blue Hose” or

equivalent

Figure 3: Basic connections to the DFS-1 controlled POWERTEC Brushless DC motor control, using the factory default

settings for some of the inputs and outputs. Note that the speed pot input is the default, and that using the 4-20mA input

will require a change in the DFS-1 setup.

Revised 7/95 DFS-1 Manual

POWERTEC Ind. Corp.©

Page 7

Page 13

MOTOR ENCODER CABLE:

The motor encoder cable is connected to plug-in

terminal strip TB1:A on the DFS-1 PC board. A

shielded cable must be used for the motor encoder

cable. The recommended cable is a 9-conductor

shielded cable (Belden Cable part # 9539 or equivalent). The shield should be connected at the drive end

to the shield terminal (TB1:A1) and to terminal 10 (if

there is one) at the motor terminal strip and if not (as

on motors built prior to April 1992), the shield

should be cut off at the motor end and taped up.

The DFS-1 PC Board contains all of the func-

tions necessary to operate the Brushless DC motor

control according to the inputs connected to its

terminals and the programmed information in

memory. The DFS-1 board takes care of all speed,

torque, and control functions. It takes speed information from the encoder, environmental information and

current (load) information from the power output

circuits of the drive, and compares all that information to the input conditions and programmed parameters. It processes this information and turns the

power transistors on and off according to the needs of

the system.

The DFS-1 is delivered with an installed set of

default parameters which will allow it to operate with

a standard set of connections (as illustrated in Figure

3) of the types used with standard motor controls.

However, these standard connections will not be in

the same physical positions as they are in the

standard control, and the default setting will not

take care of any optional modes of operation.

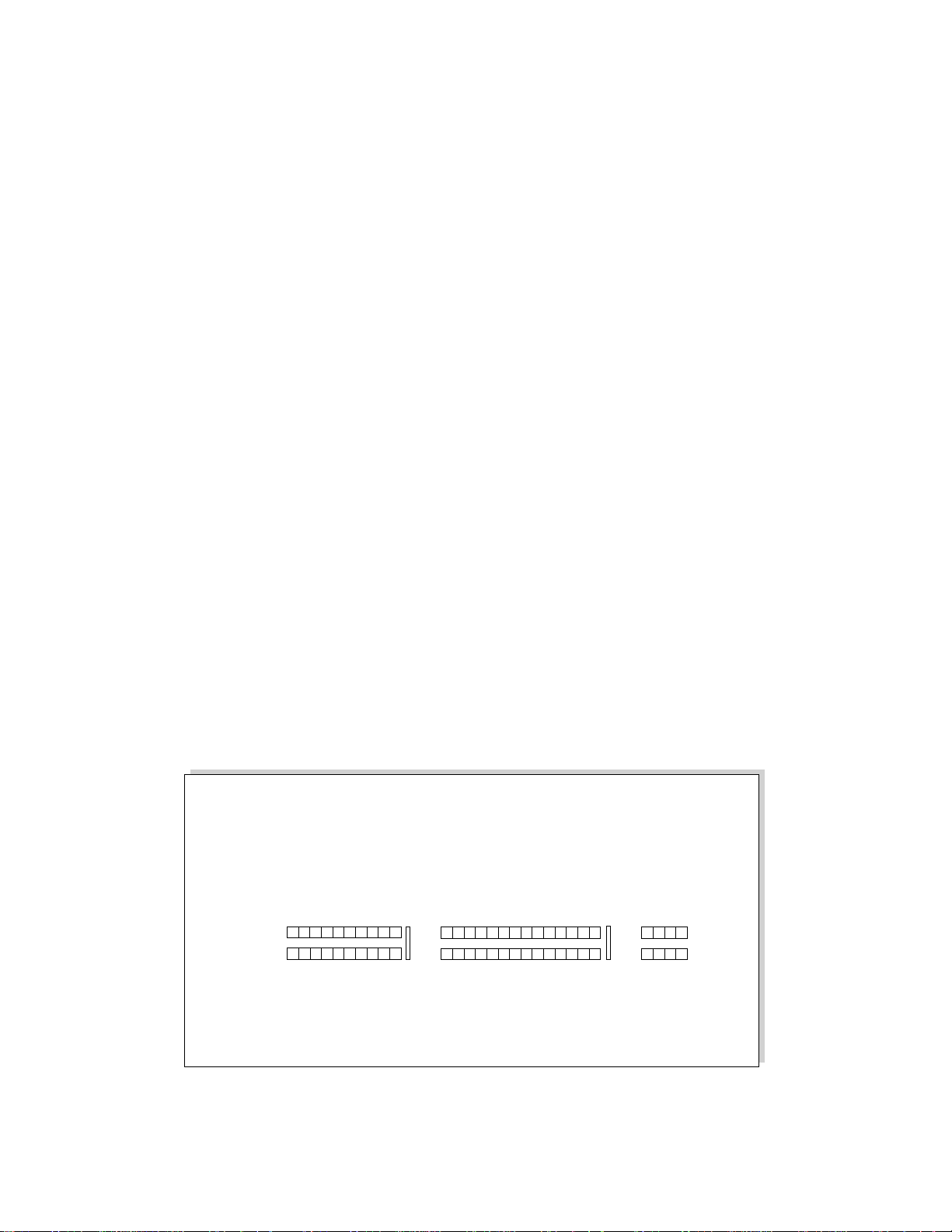

There are three plug-in terminal strips on the

bottom of the DFS-1 PC board labelled in sections

from left to right: TB1, TB2, and TB3. Though the

three sections look like two rows of strips, there is a

small separator between each of the sections. Each

of the sections has an upper row (A) and a lower row

(B). The B row is closest to the PC board. The

terminals are numbered consecutively from left to

right on each level.

ANALOG INPUTS:

There are two analog input ports to the DFS-1 on

TB1:B. When used as a voltage input, both of the

analog inputs are a differential type of input with a

minimum input impedance of 200 Kohms. When

using one of the analog inputs for a voltage input, the

input common at terminal 1 on TB1:B should be used

for shields.

When using an analog input as a milliamp input,

the (-) side of the input (terminal 4 for Analog Input

#1 or terminal 6 for Analog Input #2) should be

connected to the common of the milliamp current

source. The milliamp source should be connected to

the (+) input (terminal 3 for Analog Input #1 or

terminal 5 for Analog Input #2).

COMMUNICATIONS+

COMMUNICATIONS-

COMMUNICATIONS SHIELD

1 2 3 4

1 2 3 4

DISPLAY-

DISPLAY +

DISPLAY POWER

COMMUNICATIONS COMMON

Display COMMON

HALL SHIELD

HS1

HS3

HS2

A

1 2 3 4 5 6 7 8 9 10

TB1

B

1 2 3 4 5 6 7 8 9 10

+10VDC

Analog In 1+

Analog In COMMON

HS4

HS5

HALL COMMON

-10VREF

Analog In 1-

Analog In 2-

Analog In 2+

HALL POWER

THERMAL

THERMAL POWER

Spacer

TB2

Spacer

Analog Out 1+

Analog Out 2+

Analog Out COMMON

COMMON

Digital Input COMMON Cathodes

E-STOP

Digital In 1

Digital In 2

Digital In 3

Digital In 4

Digital In 5

Digital In 6

Digital In 7

1 2 3 4 5 6 7 8 9 10 11 12 13 14

A

1 2 3 4 5 6 7 8 9 10 11 12 13 14

B

+24V

Digital Out 1A

Digital Out 1B

Digital Out 2A

Digital Out 2B

Digital Out 3A

Digital Out 3B

Digital Out 4A

Digital Out 4B

FREQ REF OUT+

FREQ REF IN+

FREQ IN-

FREQ REF SHIELD

+24V

Spacer

TB3

Spacer

SPEED OUT

FREQ REF OUT-

Digital out COMMON

Speed Out COMMON

A

B

Figure 4: Assignments of the DFS-1 terminals. There are default assignments, but any of the analog and digital inputs

and outputs (except the motor connections, power supplies, commons, emergency stop input, and frequency input) may be

changed by setup.

Page 8

DFS-1 Manual Revised 7/95

POWERTEC Ind. Corp.©

Page 14

The default speed reference input is Analog

Input #1, located on TB1:B. The default input is for

a 0 to +10VDC for zero to full speed of the motor.

Terminal 3 is the positive side of the input and

terminal 4 is the negative side. If the speed signal

being used is externally supplied, the differential

input will have a noise cancelling effect. Terminal 1

on TB1:B is a common for shields.

Reference sources of +10VDC and -10VDC are

supplied on the terminal strips at TB2:B2 and

TB2:B7, respectively. The default speed pot connections should be made as illustrated in figure 3. Notice

that the (-) side of the differential input (terminal 4)

is connected by a jumper to common (terminal 1),

because the DFS-1 reference source is being used. If

an external reference source is to be used, no jumper

is necessary.

IN THE DEFAULT SETUP, ONLY ANALOG

INPUT #1 IS ACTIVE. WHILE THE OTHER

ANALOG INPUT HAS A DEFAULT SETUP, IT IS

NOT ACTIVE UNTIL THE USER CHANGES THE

SETUP TO MAKE IT ACTIVE.

The microprocessor will look ONLY to Analog

Input #1 for speed information until it is told to do

otherwise in the setup program.

The other analog input to the DFS-1 is at TB1:B

(lower level) terminals 5 (+) and 6 (-). Both of the

inputs may be programmed for one of six inputs as

shown in the table below.

4. Comm set (value is set via Communications)

5. Commanded speed

Analog Output #1 default is a -10 to +10VDC

signal representing motor speed. The outputs are on

TB1:B terminals 8 (+) and 10 (-). The opposite

polarity is available by a parameter change. See the

description for parameters #26 and #27.

The default for Analog Output #2, terminals 9

(+) and 10 (-), is -10 to +10VDC representing motor

load, 0% to 150% load. The opposite polarity is

available by changing a parameter.

The maximum output current for the analog

outputs is 20 milliamps.

FREQUENCY INPUT:

There is only one frequency input on the DFS-1.

This input is used by the drive as the reference to

follow when the drive is in the SLAVE Mode of

operation. This input cannot be reassigned.

If the DFS-1 is in the MASTER mode, it will

ignore the frequency input.

The Frequency input is located at TB2:A

terminals 11(+) and 12 (-). This input is a differential

line receiver type intended to interface directly with

another DFS-1, a BCDMAX or CRM-1. There may

be multiple slaves connected to a single Master by

Input Signal Level (+) input term (-) input term jumper terms input impedance

-10 to +10 VDC 3 or 5 4 or 6 none ** 200 Kohms

0 to +10 VDC 3 or 5 4 or 6 none ** 200 Kohms

0 to +5 VDC 3 or 5 4 or 6 none ** 200 Kohms

1 to +5 VDC 3 or 5 4 or 6 none ** 200 Kohms

0 to 20 mADC 3 or 5 1 4 or 6 to 1 250 ohms

4 to 20 mADC 3 or 5 1 4 or 6 to 1 250 ohms

TB1:B TB1:B

** if the DFS-1 supplies are used, jumper 4 or 6 to 1 to establish the reference common.

ANALOG OUTPUTS:

daisy-chaining the frequency reference line. The last

slave on the line should have the jumper at JP1 on the

There are two analog outputs on TB1:B. Each of

the outputs may be programmed in several ways:

1. Disabled

2. Actual speed (value is proportional to motor

speed)

3. Load output (value is proportional to motor

load)

Revised 7/95 DFS-1 Manual

POWERTEC Ind. Corp.©

two rightmost pins. This inserts a terminating

resistor at the end of the line to help eliminate

electrical noise from the system. All others should

be on the two leftmost pins.

Contact POWERTEC’ s Application Engineering

Department before trying to use another type of

frequency on this input.

Page 9

Page 15

FREQUENCY OUTPUT:

DIGITAL INPUTS:

There are two outputs available to supply a

frequency for external use.

The first is located at TB2:B terminal 10 (+) and

11 (-). This is an output which is intended to provide

a reference frequency input for another DFS-1,

BCDMAX or CRM-1. This output is not compatible

with the DIGIMAX. It will provide a signal of +/-

1.5V minimum when connected to another DFS-1's

reference frequency input. This output on a unit

configured as a master, operates at 16 times the

frequency of the motor speed output reference. There

is a 120 ohm termination resistor built into the output

for transmission line termination.

When operating the DFS as a slave, the output

frequency is internally divided by 16 in addition to

being multiplied by the set ratio from the slave. As a

consequence, the frequency output from a DFS slave

cannot be used as the reference to another DFS slave

without some way of first multiplying this frequency

by 16. POWERTEC’s Cascade Ratio Multiplier

option board (4001-153430-XXX) can be used for

this purpose. Contact the factory for any frequency

following application which requires a reference

source other than a master DFS.

The other frequency output is at TB2:B13. This

is a 24VDC peak square wave referenced to the DFS-

1 common (TB2:B14). This signal is at the motor

speed output reference frequency and may be used

to interface with a DIGIMAX or a BLDC motor

control. This output sources a maximum of 10mA

and can sink 30mA.

There are eight digital control inputs on TB2:A

as well as a +24VDC supply (TB2-A14) and common (TB2-A1). The eight inputs are optical isolator

input diodes with a common cathode connection at

TB2-A2. When the +24VDC, DFS-1 supply is used

to power the inputs, TB2:A2 must be jumpered to

the 24VDC common terminal on TB2:A1.

The functions of all inputs are programmable

except Emergency Stop (TB2-A3). All digital inputs

are electrically isolated from the DFS-1 power

supplies and common when an external power supply

is used to power the digital inputs (such as from a

PLC).

The default parameter setup is for a set of

standard motor controller input connections on

TB2:A terminal strip (see figure 3 on page 3).

Five of the inputs are set up for standard pushbutton operation of the DFS-1. They are:

Run 4 (+)

Preset 5 (+)

UP (increase) 6 (+)

DOWN (decrease) 7 (+)

Reverse 8 (+)

All of these inputs are referred to TB2-A2. Note

that TB2-A2 (the common cathode connection) must

be jumpered to common (TB2:A1) in the basic

connections.

Each of these inputs will take a +24VDC input

(no more than 30VDC, not less than 18VDC). If an

external source of +24VDC is used, TB2-A2 on the

upper level must be connected to the negative side of

the external source.

Mode of Operation: differential

Number of receivers: 32 maximum

Maximum Cable Length: 4000 feet

Maximum Frequency: 10 Megahertz

Common Mode Voltage: +12V, -7V

maximum

Driver Output: +/-1.5V minimum

Driver Load: 60 ohm minimum

Driver Short Circuit: 1 50 mA to ground

Driver Output Resistance: 120 ohms (ON)

Receiver Input Resistance: 12 Kohms

Receiver Sensitivity: +/-200 mA

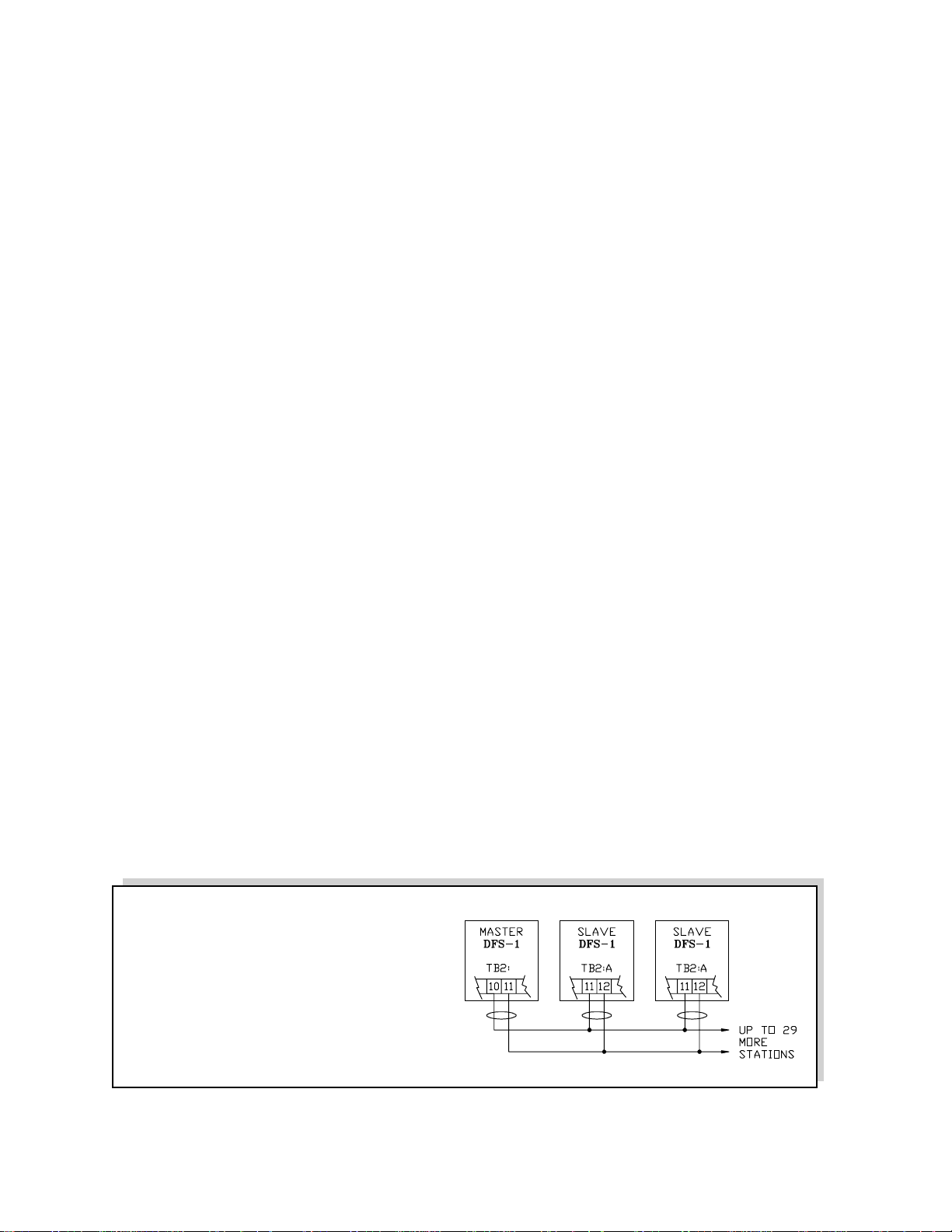

Figure 5: Slaving DFS-1 units with the Reference Frequency Output.

Page 10

B

DFS-1 Manual Revised 7/95

POWERTEC Ind. Corp.©

Page 16

The programmable inputs (TB2-A4 through

TB2-A10) may be programmed for jog, thread, or

other preset speeds. The inputs may also be used to

change torque levels, trim values, or ramp rates. Any

value which can be affected by a parameter can be

changed by a digital input.

DIGITAL OUTPUTS:

Digital outputs are located on TB2:B. The four

outputs are normally open relay contacts. The

contacts are rated at 120VAC at 1 amp, resistive.

The default setup assigns the outputs as follows:

Digital Out #1 Run

Digital Out #2 No Fault

Digital Out #3 At Speed

Digital Out #4 Reverse

These assignments may be changed by parameters.

All of the digital outputs are programmable and

may be configured as Normally Open or Normally

Closed. If more than one contact is required for a

certain function, an external relay may be used, or

more than one output may be programmed for the

same function.

COMMUNICA TIONS:

The standard communications for the DFS-1 is

the EIA standard RS-485 communications format

over a single twisted pair cable into TB3:A terminals

1 and 2. Terminal 3 is for the shield. DO NOT

CONNECT TERMINAL 3 TO GROUND! Maximum allowable distance for twisted pair operation is

4000 meters (about 12,000 feet). Maximum nodes

without repeaters is 32. Maximum communications

rate is 38.4 kilobaud. The last unit on the comm line

should have a jumper at JP2 on the rightmost 2 pins.

All other units should have the jumper on the

leftmost two pins.

There is an RS-485 local programming input at

TB3:B for an optional keypad display unit.

RS485 Communications Connections:

Most host or converter devices (including the

RS232/485 converter made by POWERTEC) include

1.2 Kohm pull up resistors which insure rx-tx- is

pulled down to ground and rx/tx+ is pulled up to +5V

when the line is inactive (tristated). This ensures the

high impedance (floating) line does not change state

due to noise when the line is not being driven. No

matter how many units are connected in the network,

only one such set of pull ups should be installed.

NOTE: The Allen Bradley RS485 connections

on their coprocessor module for the Series 5 PLCs do

not provide these pull ups and must be installed or

noise will prevent proper communications.

1.2K ohm

tx/rx+

tx/rx-

1.2K ohm

Revised 7/95 DFS-1 Manual

POWERTEC Ind. Corp.©

TB1A-8

TB3A-1

TB3A-2

TB3A-4

Page 11

Page 17

THIS PAGE WAS INTENTIONALLY LEFT BLANK.

Page 12

DFS-1 Manual Revised 7/95

POWERTEC Ind. Corp.©

Page 18

The concept behind the DFS-1 calls for fully

programmable inputs and outputs. The ability to

change analog and digital inputs and outputs at will

lends a whole new meaning to the word "flexibility".

POWERTEC has established a set of "default"

parameters which will leave the setup of the DFS-1

in a way that will operate a motor in the basic

configuration (see figure 3 on page 3 and figure 4 on

page 4). There are two good reasons for doing this:

1. This default setup allows the user to connect

and operate a motor using common, everyday

connections without having to program the DFS-1

prior to its initial use.

2. The default setup provides a baseline to

which the user can return if it appears that something

is wrong with either the user's setup or the motor

control. There is a command which allows the "reset"

of the setup to the default configuration.

DEFAULT SETUP

Revised 7/95 DFS-1 Manual

POWERTEC Ind. Corp.©

Page 13

Page 19

THIS PAGE WAS INTENTIONALLY LEFT BLANK.

Page 14

DFS-1 Manual Revised 7/95

POWERTEC Ind. Corp.©

Page 20

2.0 SPECIFICATIONS

POWER SUPPLIES

+24VDC • Available at TB2:A14, and TB2:B1.

• The combination is fused at 250 milliamps

(mA). The fuse is self-healing.

• The opening of the fuse alerts the microprocessor.

• These supplies should only be used for

push-buttons, relays, PLC outputs, etc.

which interface directly with the DFS-1.

They should not be used as general purpose supplies.

+10VDC • Reference supply available at TB1:B2.

This output is rated at 100mA. This output is current limited and thermally protected.

-10VDC • Reference supply available at TB1:B7.

This output is rated at 100mA, current

limited and thermally protected.

+5VDC • Supply for motor encoder available at

TB1:A9. This supply is fused at 100mA

with a self-healing fuse. When the fuse

opens, it alerts the microprocessor.

5.0 Each of the two inputs may be set up one of

six ways:

1. -10 to +10 VDC

2. 0 to +10 VDC

3. 0 to 5 VDC

4. 1 to 5 VDC

5. 0 to 20 mADC

6. 4 to 20 mADC

6.0 Setup is by parameter selection (#18 for

Analog Input #1 and parameter #22 for Analog

Input #2).

7.0 Voltage inputs are a differential input connection.

8.0 Input impedance of each input in voltage input

mode is 200 Kilohms minimum.

9.0 Input impedance in milliamp input mode is

250 ohms.

Factory default setups are included so that the

DFS-1 does not have to be programmed prior to its

initial use. Factory defaults are only one of the many

ways the DFS-1 can be set up.

Default setups are as follows:

INPUT SETUP FUNCTION

1. 0 to +10VDC Speed Reference Input

2. -10 to +10VDC General Purpose Input

THIS SUPPLY IS FOR THE MOTOR ENCODER

ONLY!

ANALOG INPUTS

1.0 There are two analog inputs on TB1:B. (see

section 1.2, page 4)

2.0 Each input may be set up in one of several

modes.

3.0 Pre-programmed modes are:

3.1 General purpose Input

3.2 Speed Reference Input

3.3 Trim (dancer or load cell) Input

3.4 External Motoring Torque Limit

3.5 External Regenerative Torque Limit

3.6 Horsepower Mode

4.0 The mode of the input is set by parameter (#17

for Analog Input #1 and parameter #21 for

Analog Input #2).

Revised 7/95 DFS-1 Manual

POWERTEC Ind. Corp.©

ANALOG OUTPUTS

1.0 There are two analog outputs on TB1:B.

2.0 The analog outputs may be programmed for

3.0 Output impedance is less than 100 ohms.

4.0 Maximum output voltage is +/- 10VDC.

5.0 Maximum current is 25mADC.

one of five modes:

2.1 Disabled

2.2 Motor Speed Output -10 to +10VDC

= 0 to 100% (Actual Motor Speed)

Default - Analog Output #1

2.3 Motor Load Output -10 to +10VDC

= 0 to 150%

Default - Analog Output #2

2.4 Set by Communications Link

2.5 Commanded Motor Speed

Page 15

Page 21

FREQUENCY INPUTS AND

OUTPUTS

There is one frequency input and there are two

frequency outputs available.

INPUT

#1 REFERENCE FREQUENCY INPUT

TB2:A Terminals 11 (+) and 12 (-).

• This is a line receiver type input which must be

driven by a differential line driver output.

• This frequency input requires a frequency 16

times the feedback from the motor.

• The feedback from the motor is normally 120

PPR for 4 pole motors and 240 PPR for 8 pole

motors.

• Normal input is 56 Kilohertz for 0 to full speed

for a 1750 RPM motor with a 120ppr encoder.

• Terminal 13 is for the shield. Do not ground

terminal 13 directly. It is internally terminated.

OUTPUTS

#1 REFERENCE FREQUENCY OUTPUT

TB2:B Terminals 10 (+) and 11 (-),

• This is a differential line driver output which

must be used with a differential line driver input.

• This frequency output is 16 times the reference

frequency to the motor.

• This output may drive up to 32 receivers.

• Connect the shield to terminal 12. This will

ground the shield internally.

#2 MOTOR SPEED FREQUENCY OUTPUT

TB2:B Terminals 13 (+) and 14 (common),

• This output is a +24VDC peak square wave at

the motor feedback pulse rate, which is 2 times

RPM for 4 pole motors and 4 times RPM for 8

pole motors.

The reference frequency input and output are

capable of receiving and sending at up to 1 Megahertz.

Motor Speed output emits frequencies up to 100

Kilohertz.

DIGITAL INPUTS

The eight digital inputs of the DFS-1 are

optically coupled requiring +24VDC (+/-6VDC) at

about 5mA each. These inputs are isolated from the

common of the board.

All inputs are programmable as to function,

EXCEPT the EMERGENCY STOP input. Inputs #1

through #7 may be assigned as general purpose

inputs.

The defaults are as follows:

TB2:A terminal 3(+) Emergency Stop

(Cannot be reassigned)

DI 1. TB2:A4(+) Run

DI 2. TB2:A5(+) Preset Speed

DI 3. TB2:A6(+) Up (Increase)

DI 4. TB2:A7(+) Down (Decrease)

DI 5. TB2:A8(+) Reverse

DI 6. TB2:A9(+) Frequency Mode

DI 7. TB2:A10(+) Local/Remote

Inputs #1 through #7 may also be programmed

for inverted input, i.e., active when input is low.

DIGITAL OUTPUTS

There are four dry contact outputs from the

DFS-1. All of these outputs are on TB2:B. All

outputs are programmable as to function, and all

outputs may be set up as either normally open or

normally closed.

Each relay output has a single, isolated, contact

output which may be programmed as normally open

or normally closed, with the contact rated at 1 Amp,

125VAC resistive.

The default assignments are as follows:

DO 1. TB2:B terminals 2 and 3 Run relay contact

Closed while running

DO 2. TB2:B terminals 4 and 5 No fault relay

Closed while no faults

DO 3. TB2:B terminals 6 and 7 At Speed relay

Closed when at speed

DO 4. TB2:B terminals 8 and 9 Remote Mode

Closed when in Remote

Page 16

DFS-1 Manual Revised 7/95

POWERTEC Ind. Corp.©

Page 22

COMMUNICA TIONS

Standard: RS-485

Data Rates: 300, 600, 1200, 2400, 4800, 9600,

19.2K, and 38.4K baud

Addresses: 1 to 255

Protocols: POWERTEC Binary protocol

Distance: 4000 meters (about 12,000 feet)

maximum with twisted pair shielded

cable

Nodes: 32 maximum

Revised 7/95 DFS-1 Manual

POWERTEC Ind. Corp.©

Page 17

Page 23

THIS PAGE WAS INTENTIONALLY LEFT BLANK.

Page 18

DFS-1 Manual Revised 7/95

POWERTEC Ind. Corp.©

Page 24

3.0 DFS-1 PARAMETERS

DFS-1 parameters are stored as DOUBLE

WORD values (32 bits), regardless of the actual size

of the data. This method is used to simplify the entire

system at a cost of a little extra data storage.

A double word consists of four BYTES (8 bits).

Each byte is a hexadecimal (base 16) value which

ranges from 00h (0 decimal) to FFh (255 decimal).

The largest number used in the DFS-1 parameters is

99,999 decimal, which, in hexadecimal notation is

0001 869Fh.

In many cases, information other than numbers

is passed and stored in the parameters. The left byte

is the most significant and the last byte is the least

significant. The arrangement of the bytes for this

purpose is: VL4 VL3 VL2 VL1 where VL4 is the

Most Significant Bit (MSB) and VL1 is the Least

Significant Bit (LSB). Each parameter breaks down

the bytes accordingly.

All four bytes are required in communications. A

number which must be either 0 or 1 must be passed

as either 0000 0000h or 0000 0001h.

1. UNIT ID

USE PARAMETER #1 TO IDENTIFY THE ADDRESS OF THE UNIT ON A NETWORK.

RANGE OF VALUES: 0000 0001h to 0000 00FFh

1 to 255 (decimal)

Default Value: 0000 0001h 1 (decimal)

The Unit ID number is installed in parameter #1.

This serves as an address on the external communications link. Two DFS-1 units cannot have the same

address while installed on the same communications

link.

There are 254 possible addresses if the default

value of 1 is not used as an address. Since the default

value is 1, there could be a problem if a new unit is

installed without changing the #1 parameter.

2 . BAUD RA TE

USE PARAMETER #2 TO SET THE COMMUNICATIONS SPEED OF THE NETWORK.

RANGE OF VALUES: 0000 0000h to 0000 0007h

0 to 7 (decimal)

Default Value: 0000 0002h 2 (decimal)

This establishes the rate at which data is exchanged in the communications link. Every DFS-1 in

the communications link must have the same baud

rate set up in parameter #2. The parameter selects

from among eight industry standard baud rates:

NUMBER BAUD RATE

0000 0000h 38.4 Kilobaud (38,400 baud)

. . . . 01 19.2 Kilobaud (19,200 baud)

. . . . 02 9,600 baud

. . . . 03 4,800 baud

. . . . 04 2,400 baud

. . . . 05 1,200 baud

. . . . 06 600 baud

. . . . 07 300 baud

3 . LOCAL / REMOTE CONTROL

USE PARAMETER #3 TO SET UP WHICH

FUNCTIONS ARE CONTROLLED REMOTELY.

RANGE OF VALUES: 0000 0000h to 0000 007Fh

0 to 127 (decimal)

Default Value: 0000 0000h 0 (decimal)

Parameter #3 is first broken down into bytes, and

then VL1 is further broken down into bits.

When broken down into bits, 00h = 0000 0000b,

and 7Fh = 0111 1111b.

VL4 is always 00h.

VL3 is always 00h.

VL2 is always 00h.

VL1 is broken down into eight bits, which are

numbered from right to left: 7654 3210h.

Functions are assigned as follows:

Bit Position Function

7 NOT USED

6 Master/Slave (not presently functional)

5 Frequency Mode

4 Reverse

3 Down

2Up

1 Preset

0 Run

A zero in a bit position means that function may

be controlled from an input terminal assigned to it. A

one in a bit position means that the function may

only be controlled via a communications link, such as

the operator’s station connection or the external RS485 communications link.

For instance, if VL1 is given a value of 01 (0000

Revised 7/95 DFS-1 Manual

POWERTEC Ind. Corp.©

Page 19

Page 25

0001b) , the Run FUNCTION cannot be controlled

from the terminal strip, but can only be controlled

through the external communications link or the local

comm link (keypad display unit).

If VL1 has a value of 73 (0111 0011b), all

functions except UP and DOWN are controlled

remotely.

NOTE: Parameter #3 ONLY determines

whether a FUNCTION is controlled locally or

remotely. This parameter has nothing to do with the

assignment of functions to terminals.

Any input function can be assigned to any input

terminal with the exception of the Emergency Stop

input. The Emergency stop function is hard-wired on

the DFS-1 board and cannot be changed by either

programming or parameters.

If the RUN function is assigned to an input

terminal, and this parameter is set to remote the RUN

function control, the terminal will be IGNORED.

4. COMMUNICATIONS

PROTOCOL

5 . MODES OF OPERA TION

USE PARAMETER #5 TO SET UP MASTER/

SLAVE AND TORQUE LIMITING MODES.

RANGE OF VALUES: 0000 0000h to 0003 0002h

no decimal significance

Default Value: 0000 0000h no decimal

significance

This parameter is a dual purpose command used

to set operational modes of the DFS-1:

VL2 VL1 sets the basic operation of the board.

There are three modes of basic operation used to

determine where the speed and/or torque commands

originate:

0000h MASTER mode (the board generates its

own speed/torque based on its parameters)

0001h SLAVE mode (the board follows an

external signal in direct proportion)

0002h INVERSE Slave mode (board follows

an external signal in inverse

proportion)

USE PARAMETER #4 TO IDENTIFY THE NETWORK COMMUNICATIONS LANGUAGE.

RANGE OF VALUES: 0000 0000h to 0000 0001h

0 to 1 (decimal)

Default Value: 0000 0000h 0 (decimal)

At the present time, the only communications

protocol available is Powertec’ s Binary protocol.

This parameter has been included with the intent of

providing alternative protocols at some time in the

future.

The DFS-1 board in MASTER mode generates

its own speed and torque commands.

In SLAVE mode the board follows a reference

frequency at TB2:A terminals 11(+) and 12(-), which

should be nominally 16 times the desired speed of the

motor. This signal is available from another DFS-1

board or from a BCDMAX board. It may also come

from another source which has a compatible line

driver output. (See the description for frequency

input elsewhere in this manual).

In INVERSE slave mode, the board follows the

external frequency in a proportion of 1/RATIO.

Instead of setting a direct ratio of 0.5000, a ratio of

2.0000 may be entered for half speed. This is useful

in cases requiring draw settings where the slave is

physically located before the master, which is set for

line speed.

VL4 VL3 contains information on modified

operational modes in which the torque in the motor is

limited below the current limit level (current limits

are always set by parameters 44 and 45). These

optional modes are defined as follows:

Page 20

DFS-1 Manual Revised 7/95

POWERTEC Ind. Corp.©

Page 26

0000h Normal current limits (motor current

not limited at a lower level)

0001h Motoring torque setpoint (motoring

current to be limited at a lower level)

0002h Regenerative torque setpoint (regenera-

tive current to be limited at a lower

level)

0003h Horsepower setpoint (the product of

motor current and motor speed is

limited)

0004h through 000Fh available for future use

When in the normal mode, the current in the

motor is not controlled below current limit.

If one of the modified operational modes is

chosen, the torque/horsepower setpoint is selectable

in one of three places:

1. Analog Input #1 (must be set up in

parameter #17)

2. Analog Input #2 (must be set up in

parameter #21)

3. The Set Application Mode (8F)

Command via communications

If one of these three setpoints is not present, the

setpoint defaults to the appropriate current limit

level.

6. MAXIMUM MOTOR SPEED

USE PARAMETER #6 TO SET THE ABSOLUTE

MAXIMUM MOTOR SPEED.

RANGE OF VALUES: 0000 0001h to 0000 2710h

1 TO 10,000 (decimal)

Default Value: 0000 06D6h 1750 (decimal)

The maximum motor speed parameter is set

directly in Revolutions Per Minute (RPM) once the

Encoder Pulses Per Revolution (PPR) is set in

parameter # 7. If the incorrect PPR is set in parameter #7, the maximum motor speed will not be correct

and the motor may overspeed or not be able to go fast

enough.

The maximum motor speed is normally the

number given on the nameplate of the motor. This

number may be set higher than the motor nameplate

in some situations because the Brushless DC motor is

capable of some overspeed with light loads.

This parameter may be set to a value which is

lower than the motor’s base speed in cases where it is

not desired to use the full speed of the motor.

7 . ENCODER PULSES PER

REVOLUTION

USE PARAMETER #7 TO ESTABLISH THE

PULSE FEEDBACK RATE FROM THE MOTOR.

RANGE OF VALUES: 0000 0001h to 0000 4E20h

1 TO 20,000 (decimal)

Default Value: 0000 0078h 120 (decimal)

This parameter tells the DFS-1 the resolution of

the encoder in Pulses Per Revolution (PPR). This is

normally four times (4X) the rate of one channel of

the motor’s encoder.

Motors from the 42 frame through the 259T

frame have a 30 PPR, two channel, quadrature

internal encoder. For these motors using the internal

encoders the parameter should be set to 120 PPR.

Motors from 287TZ through 5010ATZ have an

internal 60 PPR, two channel, quadrature encoder.

The parameter for these motors using the internal

encoders should be set to 240 PPR.

External encoders may have almost any PPR

rate, and they must have two channels in quadrature

(the channels have the same pulse rate, but they are

90° out of phase with each other). The pulse rate will

be on the ENCODER nameplate.

Encoders with higher pulse rates are normally

used to obtain lower speeds and/or finer resolution of

motor shaft position. The most common external

encoder on POWERTEC motors is a 600 PPR, two

channel, quadrature optical encoder. For this encoder

the PPR in this parameter will be 2400.

For other encoders, multiply the pulse rate for

one channel (the usual number given on the nameplate) by four and enter that number in this parameter.

This parameter may not be changed while

running. Attempting to change this parameter while

running will result in the effect being delayed until

the next time a setpoint command is given or until

the control is stopped. Changing this number will

drastically affect the calibration of the system.

(Also see Parameter 46)

Revised 7/95 DFS-1 Manual

POWERTEC Ind. Corp.©

Page 21

Page 27

8. MASTER RAMP UP TIME

10. SLA VE RAMP UP TIME

USE PARAMETER #8 TO SET THE TIME TO

RAMP FROM ZERO TO FULL SPEED.

RANGE OF VALUES: 0000 0001h to 0003 E418h

1 TO 255,000 (decimal)

Default Value: 0000 2710h 10,000 (decimal)

This is the acceleration time from zero speed to

full speed in the MASTER mode. The time may be

set from 1 millisecond (.001 sec.) to 255 seconds.

The default is 10 seconds (10,000 mSec).

The acceleration rate is calculated from zero to

maximum motor speed (parameter 6). This rate is

used when the speed command in MASTER mode is

changed from a lower speed (including 0) to a higher

speed.

If the change in speed is from zero speed to full

speed, the full amount of time will be used. If the

change is from 25% speed to 75% speed, it will take

1/2 of the time set in this parameter to reach the new

speed. If the change is from 80% speed to 90%

speed, it will take 1/10th the time in this parameter.

The acceleration rate does not affect the JUMP

UP change in speed.

9 . MASTER RAMP DOWN TIME

USE PARAMETER #9 TO SET THE TIME TO

RAMP FROM FULL TO ZERO SPEED.

RANGE OF VALUES: 0000 0001h to 0003 E418h

1 TO 255,000 (decimal)

Default Value: 0000 2710h 10,000 (decimal)

This is the deceleration rate in the MASTER

mode. The rate may be set from 1 millisecond (.001

sec.) to 255 seconds. The default is 10 seconds.

The rate is calculated from maximum speed

(parameter 6) to zero speed. This rate is used

whenever the speed command in the MASTER mode

is changed from a higher speed to a lower speed

(including 0).

If the change in speed is from full speed to zero

speed, the full amount of time will be used. If the

change is from 75% speed to 25% speed, it will take

1/2 of the time set in this parameter to reach the new

speed. If the change is from 80% speed to 90%

speed, it will take 1/10th the time in this parameter.

The deceleration rate does not affect the JUMP

DOWN change in speed.

USE PARAMETER #10 TO SET THE UP RAMP

TIME WHEN THE RATIO IS CHANGED.

RANGE OF VALUES: 0000 0001h to 0003 E418h

1 TO 255,000 (decimal)

Default Value: 0000 2710h 10,000 (decimal)

This is the acceleration rate in the SLAVE mode.

The rate may be set from 1 millisecond (.001 sec.) to

255 seconds. The default is 10 seconds (10,000

mSec).

This parameter sets a rate determined by the

amount of time it takes to change from a ratio of

0.0000 to a ratio of 1.0000. This rate is used whenever the ratio setpoint in the SLAVE or INVERSE

SLAVE mode is changed from a lower ratio (including 0) to a higher ratio.

This rate does not affect the rate at which the

DFS-1 responds to changes in the reference frequency, nor does it affect the ratio when the drive is

started as a slave if parameter #54 is set to Freeze.

This rate does not affect the Slave JUMP UP

time.

11. SLAVE RAMP DOWN TIME

USE PARAMETER #11 TO SET THE down RAMP

TIME WHEN THE RATIO IS CHANGED.

RANGE OF VALUES: 0000 0001h to 0003 E418h

1 TO 255,000 (decimal)

Default Value: 0000 2710h 10,000 (decimal)

This is the deceleration rate in the SLAVE mode.

The rate may be set from 1 millisecond (.001 sec.) to

255 seconds. The default is 10 seconds (10,000

mSec).

This parameter sets a rate determined by the

amount of time it takes to change from a ratio of

1.0000 to a ratio of 0.0000. This rate is used whenever the ratio setpoint in the SLAVE or INVERSE

SLAVE mode is changed from a higher ratio to a

lower ratio (including 0).

This rate does not affect the rate at which the

DFS - 1 responds to changes in the reference

frequency, nor does it affect the ratio when the drive

is stopped as a slave if parameter #54 is set to Freeze.

This rate does not affect the slave JUMP time.

Page 22

DFS-1 Manual Revised 7/95

POWERTEC Ind. Corp.©

Page 28

12. MASTER PRESET SPEED

USE PARAMETER #12 TO SET A PRESET SPEED

WHICH CAN BE TOGGLED IN AND OUT.

RANGE OF VALUES: 0000 0000h to 0000 2710h

0 TO 10,000 (decimal)

Default Value: 0000 00C8h 100 (decimal)

The MASTER preset speed is the speed to which

the motor will go when a PRESET input is activated

on one of the Digital inputs (any of the seven digital

inputs may be programmed as a PRESET input)

when the DFS-1 is in the MASTER mode. If more

than one input is programmed as a PRESET input,

they must both be present to activate the PRESET

Speed function (the inputs are logically ANDed).

13. SLA VE RA TIO PRESET

USE PARAMETER #13 TO SET A PRESET RATIO

WHICH CAN BE TOGGLED IN AND OUT.

RANGE OF VALUES: 0000 0000h to 0001 869Fh

0 TO 99,999 (decimal)

Default Value: 0000 2710h 10,000 (decimal)

The SLAVE preset ratio is the ratio to which the

motor will go when a PRESET input is activated on

one of the Digital inputs (any of the seven digital

inputs may be programmed as a PRESET input)

when the DFS-1 is in the SLAVE mode. If more than

one input is programmed as a PRESET input, they

must both be present to activate the PRESET Speed

function (the inputs are logically ANDed).

Note: For all ratio setpoints, 4 decimal places

are implied. Therefore, the maximum ratio setpoint

is 9.999.

tionship between motor speed and EGU is defined in

parameter #14, which sets the value of EGU’s at full

motor speed. This parameter is used to determine the

relationship between units of commanded speed and

RPM. The number entered in this parameter is

equivalent to the number in parameter #6. This

allows the user to enter speed commands in engineering units (such as Feet Per Minute, Yards Per Minute,

etc).

Speed commands entered by commands #82 and

#84 are entered in terms of this parameter. If the

value of this parameter is the same as the value of

parameter #6, then there is a 1:1 relationship between

the Engineering Units and the RPM (i.e., enter 1750

(06D6h) as a speed command for 1750 RPM).

However, if this parameter is set to 1000

(03E8h) and #6 is set to 1750, then the relationship is

1:1.75. Entering 1000 (03E8h) as a command results

in 1750 RPM, but entering 500 (01F4h) results in

875 RPM.

15. BASE RATIO

USE PARAMETER #15 TO SET THE “GEAR

RATIO” OF THE MOTOR IN A SLAVE SYSTEM.

RANGE OF VALUES: 0000 0001h to 0001 869Fh

1 TO 99,999 (decimal)

Default Value: 0000 2710h 10,000 (decimal)

This is the “gearing” ratio which corrects for the

mechanics of the system and also for differences in

motor speeds. The output frequency at TB2:B

terminals 10 (+) and 11(-) is determined by the

settings of the maximum motor speed (parameter #6)

and the encoder PPR (parameter #7). The output

frequency will be:

1 4. ENGINEERING UNITS

x Encoder PPR x 16 / 60

USE PARAMETER #14 TO SET THE ENGINEERING UNITS AT MAXIMUM MOTOR SPEED.

RANGE OF VALUES: 0000 0001h to 0001 869Fh

1 TO 99,999 (decimal)

Default Value: 0000 06D6h 1750 (decimal)

Engineering Units (EGU) define the relationship

between motor speed or torque and process reference

points. It allows setting and reading of parameters in

terms other than speed and torque. The basic rela-

Revised 7/95 DFS-1 Manual

POWERTEC Ind. Corp.©

puts out a reference frequency of 56 Kilohertz. This

frequency varies with the commanded speed. When

this frequency is used as a reference, it is first

multiplied by the base ratio, and then by the SETPOINT. These steps change the frequency to the

proper level.

system to be able to enter a SETPOINT of 1.0000 on

Output Reference Frequency = Motor max RPM

A 1750 RPM motor with a 120 PPR encoder

For example, it is generally useful in a slave

Page 23

Page 29

the slave unit to match the line speed, motor speed,

or section (master). Many times, however, the

gearing between the slave motor and the surface of a

roll is not the same as the master, or the diameter of

the rolls vary from section to section, or motors of

different RPM’s may have to be tracked. The BASE

RATIO is a correction factor which allows the

SETPOINT to be adjusted.

The following are other examples of how the

Base Ratio parameter is used: if a standard 2500

RPM motor is to follow a standard 1750 RPM motor,

and both motors must attain their full speed at the

same time, and a setpoint of 1.0000 is desired, enter

1.4826 (2500/1750) into parameter #15 to make the

follower motor go 48.26% faster when the setpoint is

1.0000.

If the surface speed of a lead roll is 100 FPM at

1750 RPM (4-pole motor, 120 PPR encoder), and the

surface speed of the follower roll is 100FPM at 1550

RPM (4-pole motor, 120 PPR encoder), enter 0.8857

in parameter #15 to make the follower roll go

88.57% of the speed of the lead when the setpoint is

set to 1.0000.

If the lead motor is a 100 HP, 1750 RPM (8-pole,

240PPR), and the follower is a 5 HP, 3000 RPM (4pole, 120 PPR) motor, the reference output frequency

of the lead is 1750 x 240 *16 / 60 = 112 kHz. The

follower motor needs a frequency of 3000 x 120 *

16 / 60 = 96 kHz to operate at a 1.0000 setpoint.

Therefore the maximum 112 kHz must be reduced to

a maximum of 96 kHz by setting the base ratio to

0.8571.

If the SETPOINT needs to be something other

than 1.0000, make a proportional adjustment in the

base ratio. If the desired SETPOINT is 2.0000, use a

base ratio of 1/2 of the value necessary for a 1.0000

setpoint.

16 . MAXIMUM RATIO

USE PARAMETER #16 TO SET THE HIGHEST

ALLOWABLE RATIO IN A SLAVE SYSTEM.

RANGE OF VALUES: 0000 0001h to 0001 869Fh

1 TO 99,999 (decimal)

Default Value: 0001 869Fh 99,999 (decimal)

Set the maximum ratio in the system if it is to

be lower than the default, which is the absolute

maximum.

Note: For all ratio setpoints, 4 decimal places

are implied. Therefore, the maximum ratio setpoint

is 9.999.

17. ANALOG INPUT #1 MODE

SELECT

USE PARAMETER #17 TO SELECT THE PURPOSE OF A SIGNAL AT ANALOG INPUT #1.

RANGE OF VALUES: 0000 0000h to 0000 001Fh

0 TO 32 (decimal)

Default Value: 0000 0001h 1 (decimal)

Analog Input #1 is a general purpose input

which may be programmed for one of several modes

of operation. The mode affects how the signal is used

for setting or changing of the motor’s speed and/or

torque.

The following modes are provided for:

0000 0000h General Purpose Input - can be

read via the COMM port

0000 0001h Speed Reference input - Sets the

speed of the motor (see below)

0000 0002h Trim Input - may be used for

dancer or other transducer input

(not yet implemented)

0000 0003h External Torque Limit, Motoring -

Used in conjunction with parameter #5

0000 0004h External Torque Limit, Regenera-

tive - Used in conjunction with

parameter #5

0000 0005h External Horsepower Limit - Used

in conjunction with parameter #5

0000 0006h to 0000 001Fh Undefined -

Reserved for future use

If an undefined mode (...06h through ...1Fh) is

selected, Analog Input #1 will be inoperative.

The type of input is selected by parameter #18.

Each type of input has a lowest value and a highest

value.

The effective range of the input is set by parameters #19 and #20. Parameter #19 sets the low

threshold level and parameter #20 sets the highest

effective level. These two levels are set in EGU (see

parameter #14).

As a general purpose input ( ... 00h) Analog

input #1 may be used by the program to sense any

analog signal representing an external parameter for

use by the program.

Page 24

DFS-1 Manual Revised 7/95

POWERTEC Ind. Corp.©

Page 30

As a Speed Reference input ( ...01h), Analog

input #1 sets the speed of the controlled motor

directly if the DFS-1 is set up in Master Mode

(parameter #5 - VL2 VL1).

If the DFS-1 is in SLAVE mode, Analog Input

#1, when set to ...01h will act as a Ratio SETPOINT.

The External Torque Limits are used to set limits

on the motor current which are below the current

limit level. When parameter #5 VL4 VL3 is set to 00

01h, or 00 02h, Analog Input #1 may be set to ...03h

or ...04h respectively to supply the torque limiting

reference.

The External Horsepower Limit sets the maximum horsepower produced by the drive. Horsepower

is the PRODUCT of speed and torque. When motor

speed is low, motor current is high, and when speed

is high, current is low. The drive increases speed until

sufficient load is developed and the product of load

and speed equals the setpoint. After that is achieved,

increasing load reduces speed, and decreasing load

increases speed.

18 . ANALOG INPUT #1 SIGNAL

CONDITIONING

USE PARAMETER #17 TO SELECT THE FORM

OF THE SIGNAL AT ANALOG INPUT #1.

RANGE OF VALUES: 0000 0000h to 0000 001Fh

0 TO 32 (decimal)

Default Value: 0000 0001h 1 (decimal)

Six types of signals will be accepted by Analog

Input #1. Parameter #18 selects the form of signal to

be processed.

The six types of signals are:

0000 0000h -10VDC to +10VDC