PowerTec DC1080 Owner's Manual

Owner’s Manual

Model No. DC1080

17-0619

You will need this manual for safety instructions, operating procedures, and warranty.

Put it and the original sales invoice in a safe, dry place for future reference.

Visit us on the web at www.southerntechllc.com

Dust Collector

QUESTION...

1•847•780•6120

Horsepower ..................................1 HP

Voltage .................................120/240V

Hertz ......................................60 Hz

Phase .........................................1

Motor Speed ............................3450 RPM

Air Capacity .............................. 800 CFM

Max. Static Pressure ...........................5.67"

Main Inlet Size .........................4"(101.6 mm)

Impeller Type ............................Radial Fin

Impeller Size ..........................10" (254 mm)

Collection Bags

Upper bag (filter) ....................... 2.5 micron

Lower bag( collection) .......................plastic

Bag Overall Dimensions ............... 14-1/2" x 22"

Weight ..............................55 lbs (25 kgs)

NOISE DATA

a weighted sound pressure level measuring (no load)

Operators position .......................... 83dB

a weighted sound pressure level measuring (loaded) .....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85dB

TABLE OF CONTENTS

PRODUCT

SPECIFICATIONS

SAFETY RULES 1

Work Preparation

Work Area Preparation

Tool Maintenance

Tool Operation

Specific Safety Instructions

ASSEMBLY 2

Unpacking

Installation

Test

Power Source

Grounding Instructions

Extension Cords

Motor

Electrical Connections

OPERATION 7

Basic Operations

MAINTENANCE 8

General Maintenance

Cleaning

Lubrication

Machine Storage

Tool Repairs

TROUBLESHOOTING 9

PARTS ILLUSTRATION & 10

LIST

WARRANTY 12

SECTION PAGE

SAFETY RULES

1

WARNING

For your own safety, read and understand all warnings

and operating instructions before using any tool or

equipment.

WARNING

Some dust created by power sanding, sawing, grinding,

drilling and other construction activities contains chemicals

known to the State of California to cause cancer, birth

defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other

masonry products.

• Arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures vary, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area and work

with approved safety equipment. Always wear OSHA/

NIOSH approved, properly fitting face mask or respirator

when using such tools.

WARNING

Always follow proper operating procedures as defined in

this manual even if you are familiar with the use of this or

similar tools. Remember that being careless for even a

fraction of a second can result in severe personal injury.

WORK PREPARATION

• Wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets or other jewelry which

may get caught in moving parts of the tool.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States ANSI

Z87.1. Everyday glasses have only impact resistant

lenses. They are NOT safety glasses.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools

when tired, intoxicated or when taking medication that

cause drowsiness.

WORK AREA PREPARATION

• Keep work area clean. Cluttered work areas invite

accidents.

• Do not use power tools in dangerous environments. Do

not use power tools in damp or wet locations. Do not

expose power tools to rain.

• Work area should be properly lit.

• Ground all tools. Proper electrical receptacle should

1

SAFETY RULES

be available for tool. Three-prong plug should be

plugged directly into properly grounded, three-prong

receptacle. If an adapter is used to accomodate a

two-prong receptacle, the adapter lug MUST be to a

known ground.

• Extension cords should have a grounding prong and

the three wires of the extension cord should be of the

correct gauge.

• Keep visitors at a safe distance from work area.

• Keep children out of the work area. Ensure your work

shop is child-proof. Use padlocks, master switches or

remove switch keys to prevent any unintentional use of

power tools.

TOOL MAINTENANCE

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining and

adjusting procedures.

• Keep tool lubricated and clean for a safe operation.

• Remove adjusting tools. Form habit of checking to

see adjusting tools or accessories are removed before

switching tool on.

• Keep all parts in working order. Check to determine that

guard or other parts will operate properly and perform

their intended function.

• Check for damaged parts. Check for alignment of

moving parts, binding, breakage, mounting and any

other condition that may affect tool’s operation.

• A guard or any other part that is damaged should

be properly repaired or replaced. Do not perform

makeshift repairs.

TOOL OPERATION

• Use the right tool for your job. Do not force your tool or

attachment to do a job for which it was not designed.

• Avoid accidental start-up. Make sure that the tool is in

the “OFF" position before plugging in.

• Never leave tool running unattended.

• Know your tool. Learn the tool’s operation, application

and specific limitations before using it.

CAUTION

Think safety! Safety is a combination of operator common

sense and alertness at all times when tool is being used.

WARNING

Do not attempt to operate tool until it is completely

assembled according to the instructions.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

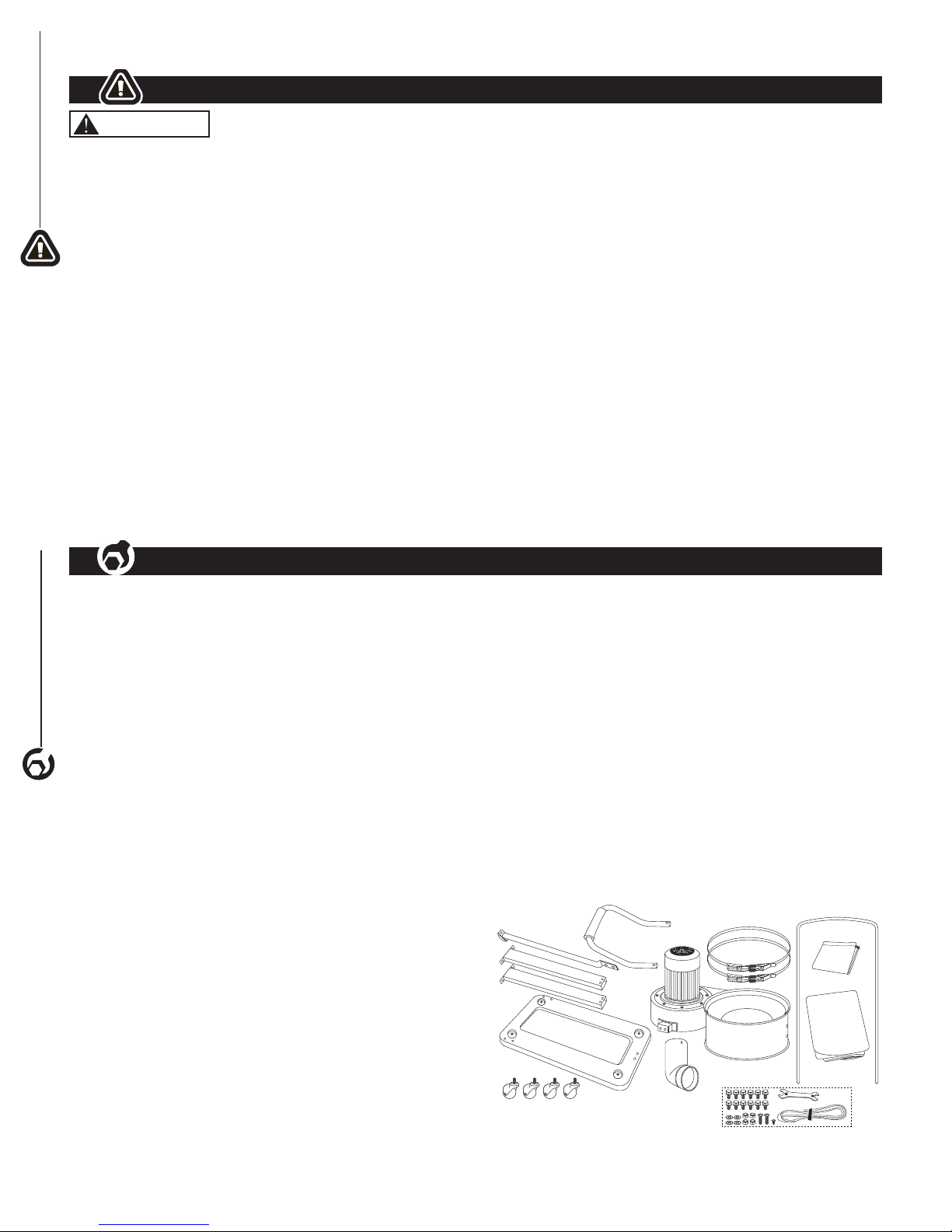

UNPACKING

Refer to Figure 1.

Check for shipping damage. Check immediately whether all

parts and accessories are included. If anything is missing or

broken, contact your retailer or call 847-780-6120.

• Carefully remove all contents from shipping carton. The

shipping carton contains:

ITEM DESCRIPTION QUANTITY

A Collector Body/Motor 1

B Base 1

C Casters 4

D Supports (rectangular) 2

E Support (round) 1

F Handle 1

G Filter Bag 1

H Collection Bag 1

I Upper Bag Support 1

J Elbow 1

K Quick Release Bag Clamp 2

ASSEMBLY

2

2

2

SAFETY RULES

SPECIFIC SAFETY INSTRUCTIONS

2

WARNING

Read and understand the instruction manual before

operating the dust collector. Basic precautions listed

below should always be followed when using your dust

collector to reduce the risk of injury, electrical shock

or fire.

• This dust collector is designed to collect sawdust only.

• Never attempt to use this dust collector to collect water

or any other liquids.

• Never try to use this dust collector to collect large

wood pieces.

• Never attempt to use this dust collector to collect metal

materials such as screws, nails or other metal parts.

• Never attempt to use this dust collector to collect

flammable or combustible dust/gas. DO NOT use near

any flammable or combustible liquids.

• Never attempt to use this dust collector to collect

anything that is burning or smoking.

• DO NOT use outdoors or on wet surfaces.

• Turn machine off, disconnect power cord and ensure all

moving parts have stopped completely before servicing

or changing/emptying the bags.

• Always wear approved eye protection and respirator

when emptying collection/filter bags.

• Ensure the machine is turned off before unplugging the

dust collector.

• Unplug dust collector when not in use.

• Grasp the plug not the cord to unplug the dust collector.

• Never pull the dust collector by the power cord.

• ALWAYS ensure collection/filter bags are secured

in place.

• Do not place your hand or tools near the open inlet

while operating. Serious personal injury or damage to

the machine can happen.

• Always connect dust collector to the matched

power source.

IMPORTANT : Always consider safety first as it applies

to your individual working conditions, the environment in

every shop is different.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

L Hardware Bag Contains

5/16" nuts (caster) 4

5/16-18" washer (caster)

4

Hex head screws 5/16" x 1/2"

(supports) 12

Phillips head screws 5/16" x

1/2" (handle) 2

Flange screw 10-24-3/8"

(Elbow) 1

12-10 mm Wrench 1

Foam Strip 1

Owner's Manual (not shown)

Figure 1

A

G

H

B

D

E

C

J

L

K

I

F

ASSEMBLY

3

ASSEMBLY

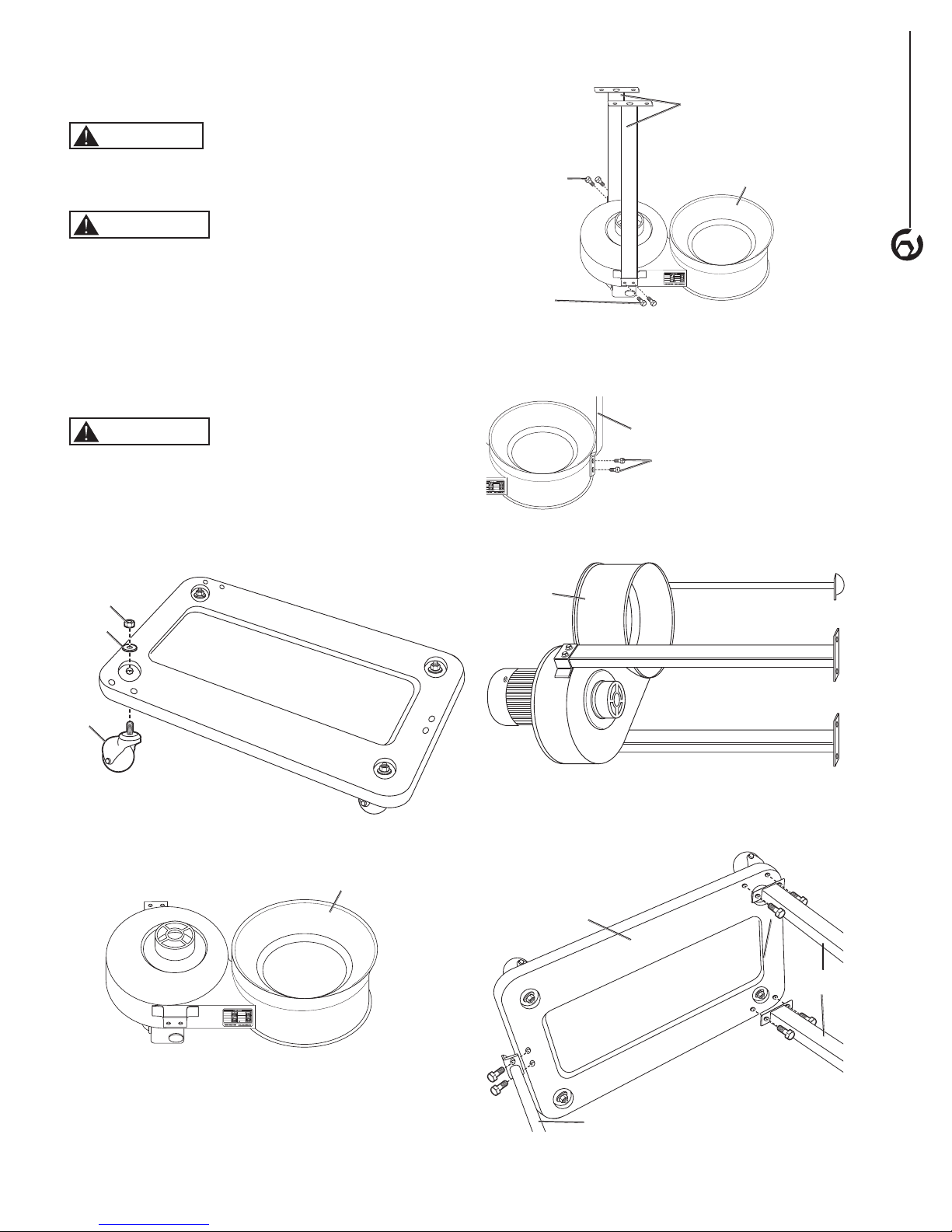

INSTALLATION

Refer to Figures 2 - 14

CAUTION

Do not attempt assembly if parts are missing.

Call the Customer service line to obtain replacement parts.

WARNING

Do not operate dust collector until completely assembled.

Do not operate this tool until you have completely read

and understood this manual.

NOTE: After unit is assembled dispose of all packaging

material in an environmentally safe way.

Tools required for assembly:

• 10-12 mm Wrench

• Phillips Screwdriver

WARNING

Ensure the dust collector is unplugged before

assembling.

1. Place the four casters through the bottom of the base

plate. Secure with the 5/16-18 washers and 5/16"

nuts, use the 12 mm wrench to tighten hardware.

Figure 2

Caster

Nut

Washer

2. Lay the collection body upside down on a

protective surface as shown.

Figure 3

Collection Body

3. Attach the two rectangular supports to the collection

body using the 5/16 x 1/2" hex head screws, use the

12 mm wrench to tighten hardware.

Figure 4

Collection

Body

Rectangular

Supports

5/16 X 1/2" Hex

Head Screws

5/16 X 1/2" Hex

Head Screws

4. Attach the round support to collection body with the

5/16 x 1/2" hex head screws, use the 12 mm wrench

to tighten hardware.

Figure 5

Round

Support

5/16 X 1/2" Hex

Head Screws

5. Lay the collection body assembly on its side.

Figure 6

Collection

Body

6. Use 5/16 x 1/2" hex head screws to attach the

collection body assembly to the base assembly as

shown. Use the 12 mm wrench to tighten hardware.

Round

Support

Base

Assembly

Rectangular

Supports

Figure 7

Loading...

Loading...