PowerTec BD4800 Owner's Manual

Model No. BD4800

Owner’s Manual

4" x 8" Woodworking Belt Disc Sander

QUESTION...

1•877•393•7121

Visit us on the web at www.southerntechllc.com

You will need this manual for safety instructions, operating procedures, and warranty.

Put it and the original sales invoice in a safe, dry place for future reference.

11-0615

TABLE OF CONTENTS

PRODUCTION

SECTION PAGE

SAFETY RULES 1

Work Preparation

Work Area Preparation

Tool Maintenance

Tool Operation

ASSEMBLY 2

Unpackaging

Tool Needed

Mount Sander

Attach Abrasive Disc

Attach Table

Attach Dust Collection Bag

Power Source

Grounding Instructions

Extension Cords

Motor

Electrical Connections

OPERATION 5

SPECIFICATIONS

Horsepower (Peak HP).................................................. 1/3

Voltage......................................................................... 120

Amp............................................................................... 5.5

Hertz............................................................................... 60

Phase........................................................................ Single

RPM............................................................................ 3450

Belt size.................................................................. 4” x 36”

Belt speed.......................................................... 1850 FPM

Disc diameter.................................................................. 8”

Disc speed......................................................... 3000 RPM

Table dimensions.................................................. 6.5” x 9”

Table tilts................................................................ 0 to 45°

Dust port diameter........................................................ 2.5”

Base dimensions...................................................10” x 17”

Basic Sander Operations

Adjusting Belt Tracking

Adjusting Belt Assembly Position

Adjusting Table Angle

Horizontal Belt Sanding with Work Stop

Abrasive Belt Sanding

Abrasive Disc Sanding

Using Mitre Gauge

Replacing Abrasive Belt

Replacing Abrasive Disc

MAINTENANCE 8

General Maintenance

Cleaning

Lubrication

Tool Repairs

TROUBLESHOOTING 9

PARTS ILLUSTRATION & 10

LIST

WARRANTY 13

SAFETY RULES

WARNING

For your own safety, read and understand all warnings

and operating instructions before using any tool or

equipment.

WARNING

Your Powertec belt/disc sander is designed and

engineered to sand wood or wood products. Sanding of

steel or other ferrous materials is a fire hazard and could

damage your sander.

WARNING

Some dust created by power sanding, sawing, grinding,

drilling and other construction activities contains chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other

masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area and work

with approved safety equipment. Always wear OSHA/

NIOSH approved, properly fitting face mask or respirator

when using such tools.

WARNING

Always follow proper operating procedures as defined

in this manual even if you are familiar with use of this or

similar tools. Remember that being careless for even a

fraction of a second can result in severe personal injury.

WORK PREPARATION

• Wear proper apparel. Do not wear loose clothing gloves,

neckties, rings, bracelets or other jewelry which may get

caught in moving parts of the tool.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States ANSI

Z87.1. Everyday glasses have only impact resistant

lenses. They are NOT safety glasses.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools

when tired, intoxicated or when taking medications that

cause drowsiness.

WORK AREA PREPARATION

• Keep work area clean. Cluttered work areas invite ac-

cidents.

• Do not use power tools in dangerous environments. Do

not use power tools in damp or wet locations. Do not

expose power tools to rain.

• Work area should be properly lit.

1

• Proper electrical receptacle should be available for tool.

Three-prong plug should be plugged directly into properly grounded, three-prong receptacle.

• Extension cords should have a grounding prong and the

three wires of the extension cord should be of the correct gauge.

• Keep visitors at a safe distance from work area.

• Keep children out of the work area. Ensure your work

shop is child-proof. Use padlocks, master switches or

remove switch keys to prevent any unintentional use o

power tools.

TOOL MAINTENANCE

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining and adjusting

procedures.

• Keep tool lubricated and clean for a safe operation.

• Remove adjusting tools. Form habit of checking to

see adjusting tools or accessories are removed before

switching tool on.

• Keep all parts in working order. Check to determine that

guard or other parts will operate properly and perform

their intended function.

• Check for damaged parts. Check for alignment of moving parts, binding, breakage, mounting and any other

condition that may affect tool’s operation.

• A guard or any other part that is damaged should be

properly repaired or replaced. Do not perform makeshift

repairs.

TOOL OPERATION

• Use the right tool for your job. Do not force your

tool or attachment to do a job for which it was not

designed.

• Disconnect tool when changing sanding sheets/belts.

• Avoid accidental start-up. Make sure that the tool is in

the “OFF” position before plugging in.

• Do not force tool. It will work most efficiently at the rate

for which it was designed. Keep hands away from moving parts and sanding surfaces.

• Never leave tool running unattended. Turn the power off

and do not leave tool until it comes to a complete stop.

• Do not overreach. Keep proper footing and balance.

• Never stand on tool. Serious injury could occur if tool is

tipped or if sanding surface is unintentionally contacted.

• Know your tool. Learn the tool’s operation, application

and specific limitations before using it.

• Use recommended accessories. Use of improper accessories may cause risk of injury to persons.

• Handle workpiece correctly. Protect hands from possible

injury.

• Turn tool off if it jams. The motor may jam if too much

pressure is applied on the sanding surface.

• Support workpiece with mitre gauge, belt platen or worktable.

• Maintain 1/16" (1.5 mm) maximum clearance between

table and sanding belt or disc.

SAFETY RULES

1

CAUTION

Think safety! Safety is a combination of operator common

SAFETY RULES

sense and alertness at all times when tool is being used.

WARNING

Do not attempt to operate tool until it is completely

assembled according to the instructions.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

2

2

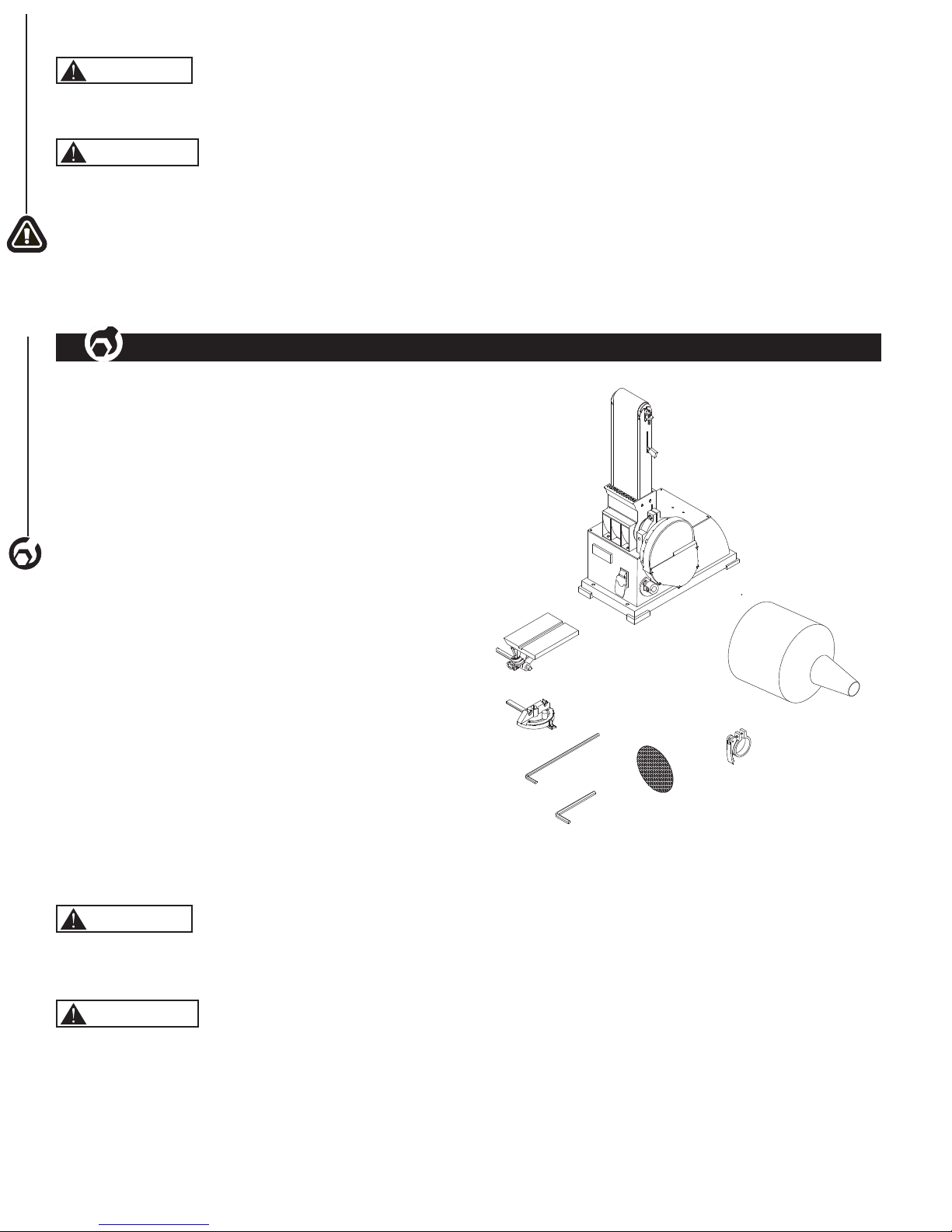

UNPACKING

ASSEMBLY

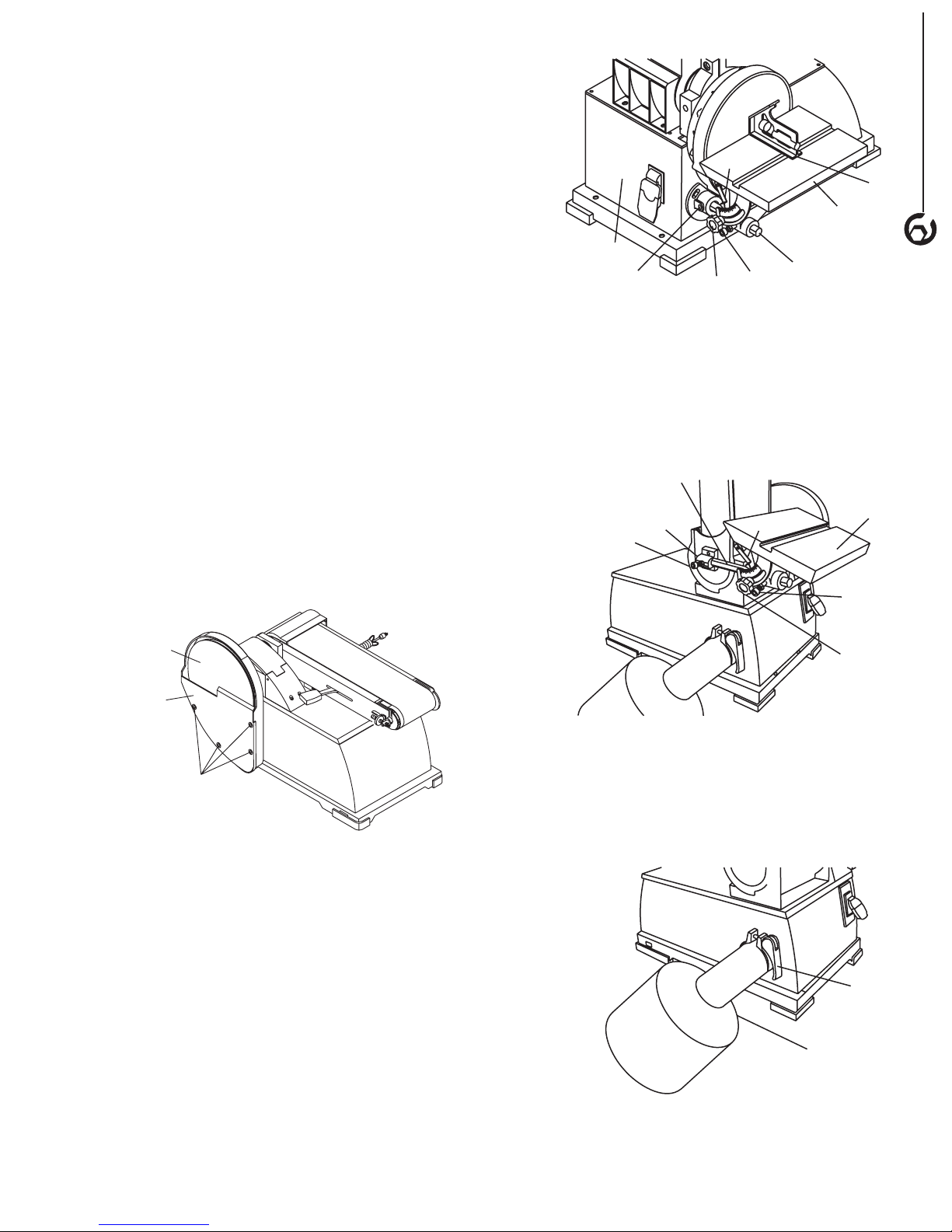

Refer to Figure 1.

Check for shipping damage. Check immediately whether

all parts and accessories are included. If anything is

missing, or broken, contact your retailer or call

1-877-393-7121.

The sander comes assembled as one unit. Additional

parts which need to be fastened to sander, should be

located and accounted for before assembling.

2

ITEM DESCRIPTION QUANTITY

A Sander 1

B Dust Collection Bag 1

C Bag Clamp 1

D Mitre Gauge Assembly 1

E Table Assembly 1

F Disc 1

G Wrench (4 mm) 1

H Wrench (6 mm) 1

ASSEMBLY

Figure 1

A

E

B

D

G

F

H

C

Refer to Figures 2 - 5.

CAUTION

Do not attempt assembly if parts are missing.

Call the Customer service line to obtain replacement

parts.

WARNING

Do not operate sander until completely assembled. Do not

operate this tool until you have completely read

and understood this manual.

TOOLS NEEDED

While assembling or adjusting your belt and disc sander,

you will need the following tools (not included):

• 10mm Wrench

• 5 and 6mm Hex Wrenches

• Combination Square

• Phillips Screwdriver

Figure 3

ASSEMBLY

8

6

MOUNT SANDER

1. Choose a suitable location to mount the sander. The

sander must be installed in a place with ample lighting

and correct power supply. To install sander:

2. The sander must be bolted to a firm, level surface.

3. Make sure there is plenty of room for moving the

workpiece. There must be enough room that neither

operators nor bystanders will have to stand in line with

the wood while using the tool. Allow room so that the

belt assembly can be positioned horizontally.

4. Sander can be installed on a workbench or tool stand

using bolts, lock washers and hex nuts (not supplied).

ATTACH ABRASIVE DISC (Fig. 2)

1. Remove disc cover (1) by loosening and removing five

screws (2).

2. Peel protective paper from the back of the abrasive disc(3)

3. Center the abrasive disc onto the aluminum disc and

press on firmly and evenly.

4. Replace disc cover.

Figure 2

3

4

2

3

7

1

5

To use the table with the belt (Fig 4)

1. Insert support rod (1) into bracket (2). Secure with bolt

(3) on flat surface of rod.

2. Position table assembly (4) on rod. Make sure gap

table and belt is 1/16"

(1.5 mm)

or less. Secure with bolt (5)

between

3. Using a combination square, set the table perpendicular

to the belt and secure in position with knob (6).

If necessary, set pointer (7) at 0.

Figure 4

1

2

3

7

5

6

3

4

1

2

ATTACH TABLE

The included table is used with both the disc and belt.

To use the table with the disc: (Fig. 3)

1. Insert support rod (1) into base (2). Secure with bolt (3)

on flat surface of rod.

2. Position table assembly (4) on rod. Make sure gap

between table and disc is 1/16"

with bolt (5).

3. Using a combination square (6), set the table

perpendicular to the disc, and secure in position with

knob (7).

If necessary, set pointer (8) at 0.

(1.5 mm)

or less. Secure

ATTACH DUST COLLECTION BAG (Fig. 5)

1. Place clamp (1) over bag sleeve (2).

2. Slide sleeve with clamp over the dust port.

3. Secure in position by tightening clamp handle. Do

not force handle. Rotate the handle to increase the

clamp size.

Figure 5

1

2

Loading...

Loading...